Hydrophobic associative cationic xanthan gum preparation method

A technology of hydrophobic association and cationic yellow, applied in the directions of botanical equipment and methods, chemical instruments and methods, drilling compositions, etc., can solve the problem of inability to reduce viscosity with heavy oil, achieve safe use and improve biological stability The effect of stability and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

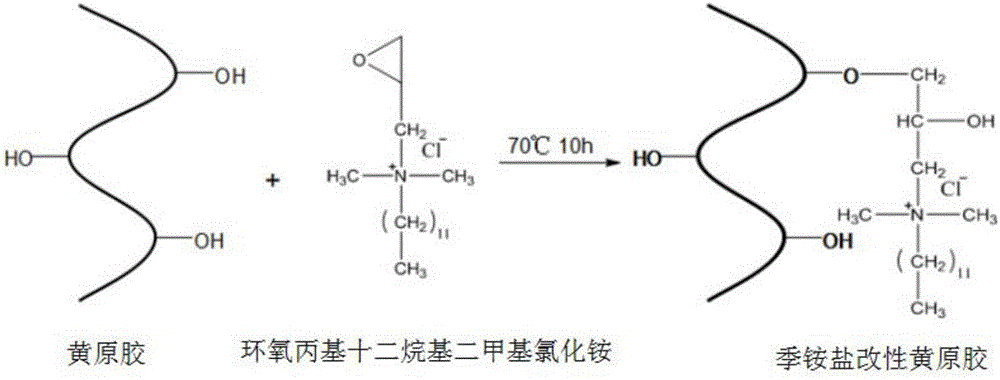

Method used

Image

Examples

Embodiment 1

[0039] The preparation of quaternary ammonium salt containing long alkyl chain—glycidyl dodecyl dimethyl ammonium chloride is as follows:

[0040] (1) Dissolve 13.558 mL of dimethyl dodecyl tertiary amine in 40 mL of acetone, and place it in a 100 mL single-necked round bottom flask containing magnets.

[0041] (2) Put the round-bottomed flask in (1) into a thermostatic oil bath at 45°C and start stirring.

[0042] (3) Dissolve 4.703 mL of epichlorohydrin in 10 mL of acetone to prepare an acetone solution of epichlorohydrin, and place it in a constant pressure dropping funnel.

[0043] (4) Slowly drip the acetone solution of epichlorohydrin in (3) constant pressure dropping funnel into (1) round bottom flask.

[0044] (5) In step (4), the system was reacted at 45°C for 28 hours.

[0045] (6) After the reaction is completed, the reaction system in step (4) is cooled to room temperature, and left overnight, white crystals are precipitated.

[0046] (7) The reaction system in (4) is suction ...

Embodiment 2

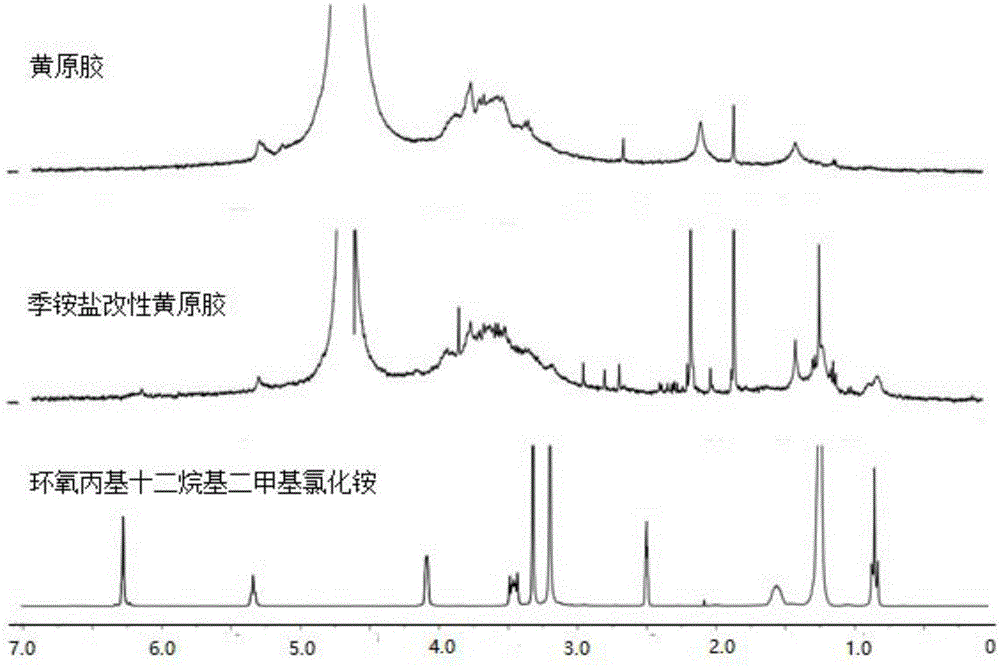

[0051] The preparation of hydrophobically associating cationic xanthan gum is as follows:

[0052] (1) Add 10 mL of 1% NaOH to 100 mL of distilled water to form an alkaline reaction environment.

[0053] (2) Weigh 0.5 g of xanthan gum and add it to the system in step (1), adjust the oil bath temperature to 45° C., stir and dissolve for 2 hours.

[0054] (3) Weigh 0.15 g of epoxypropyl dodecyl dimethyl ammonium chloride, dissolve it in 15 mL of distilled water, and place it in a constant pressure dropping funnel.

[0055] (4) The oil bath is heated to 70° C., and the aqueous solution of glycidyl dodecyl dimethyl ammonium chloride in the constant pressure dropping funnel is slowly added dropwise to the system in step (2).

[0056] (5) In step (4), the system was reacted at 70°C for 7 hours.

[0057] (6) After the reaction is completed, the reaction system in step (4) is cooled to room temperature. Then the system in (4) was neutralized with 0.1 mol / L HCl.

[0058] (7) Using anhydrous aceto...

Embodiment 3

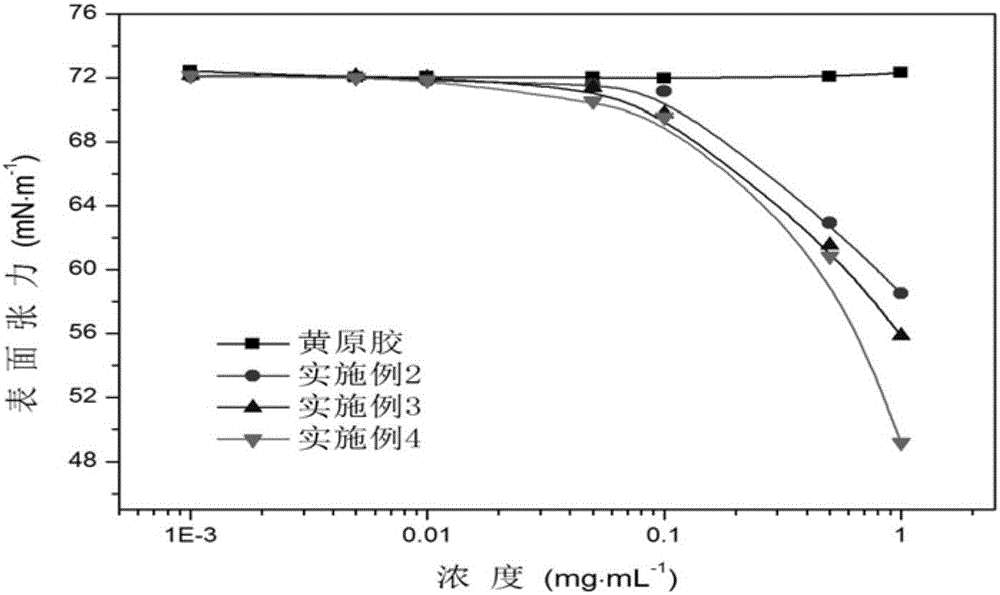

[0064] The preparation of hydrophobically associating cationic xanthan gum is as described in Example 2, except that the amount of glycidyl dimethyl ammonium chloride in step (3) is 0.3 g.

[0065] Obtained 0.445 g of hydrophobically associated cationic xanthan gum, and measured its apparent weight average molecular weight M w,app =(2.054±0.971)×10 6 g / moL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com