Patents

Literature

35results about How to "Easily imparted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

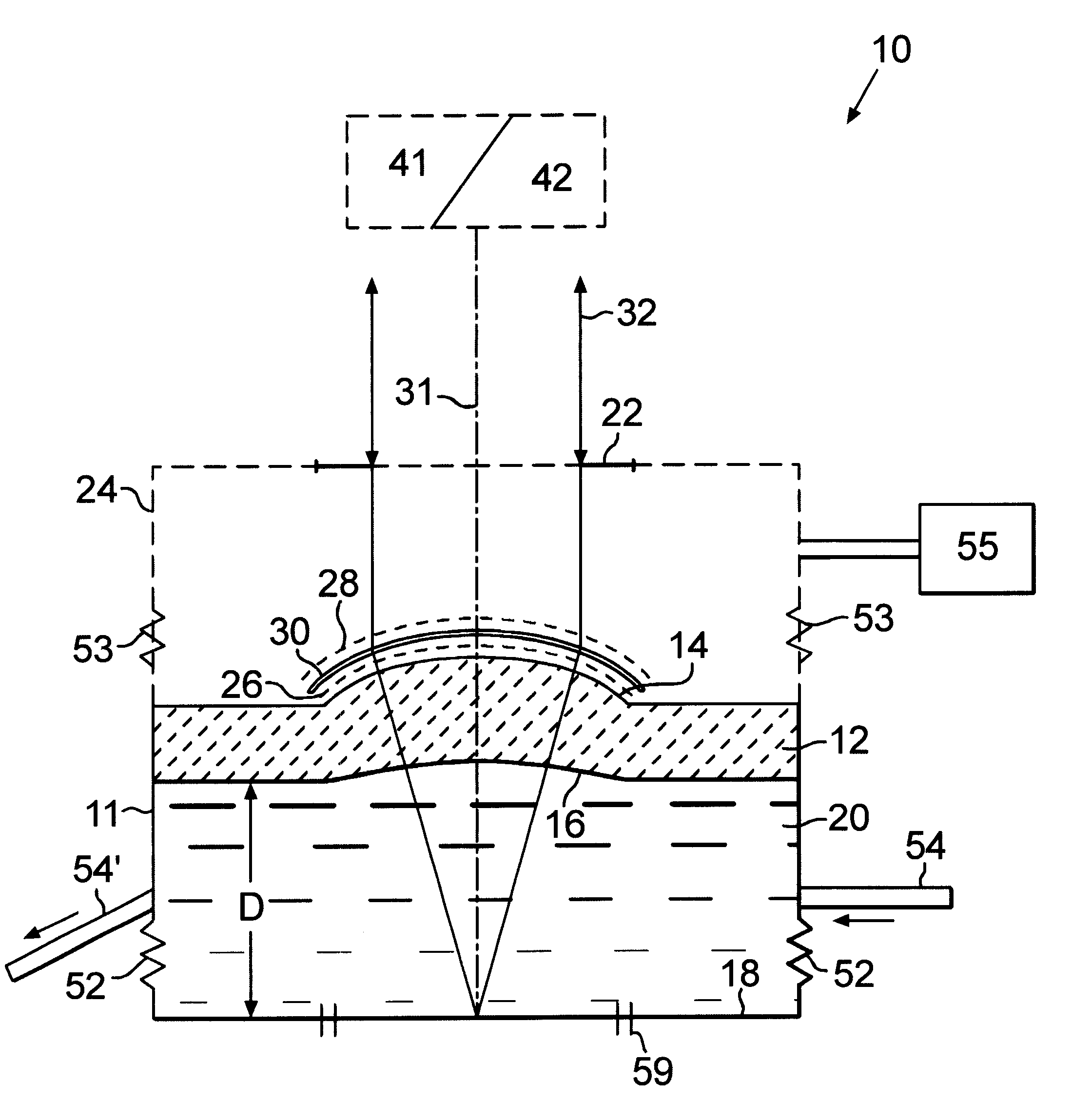

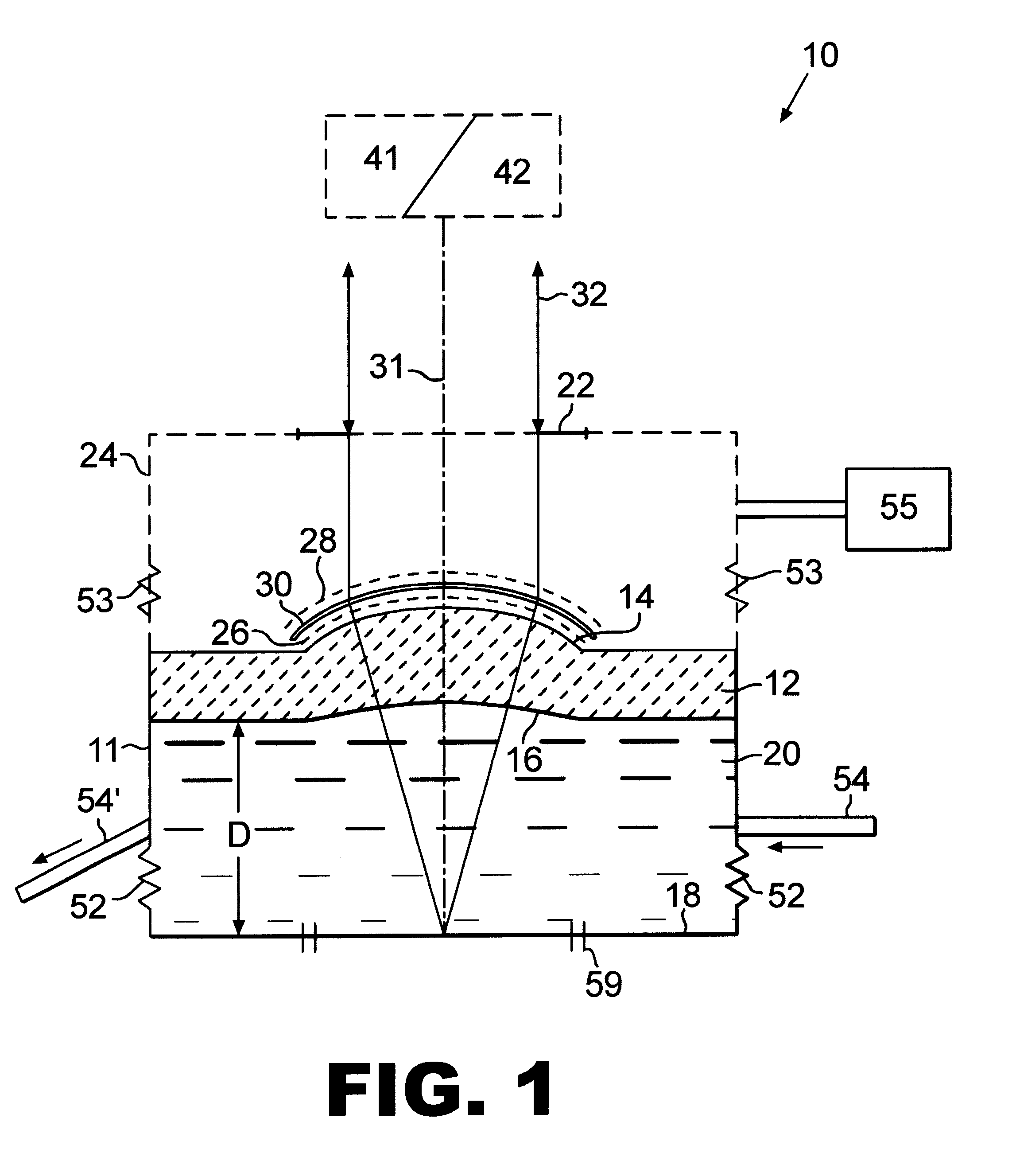

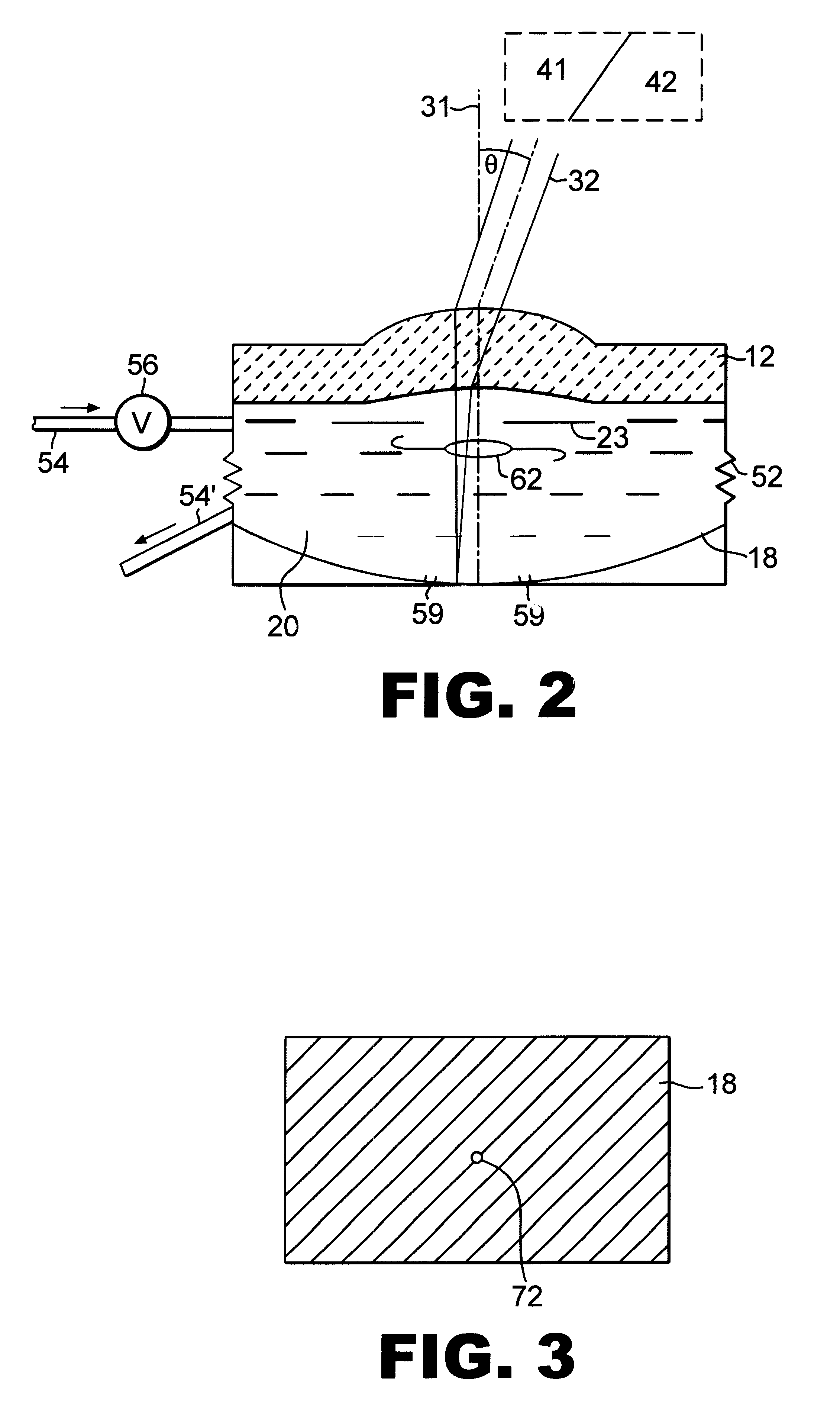

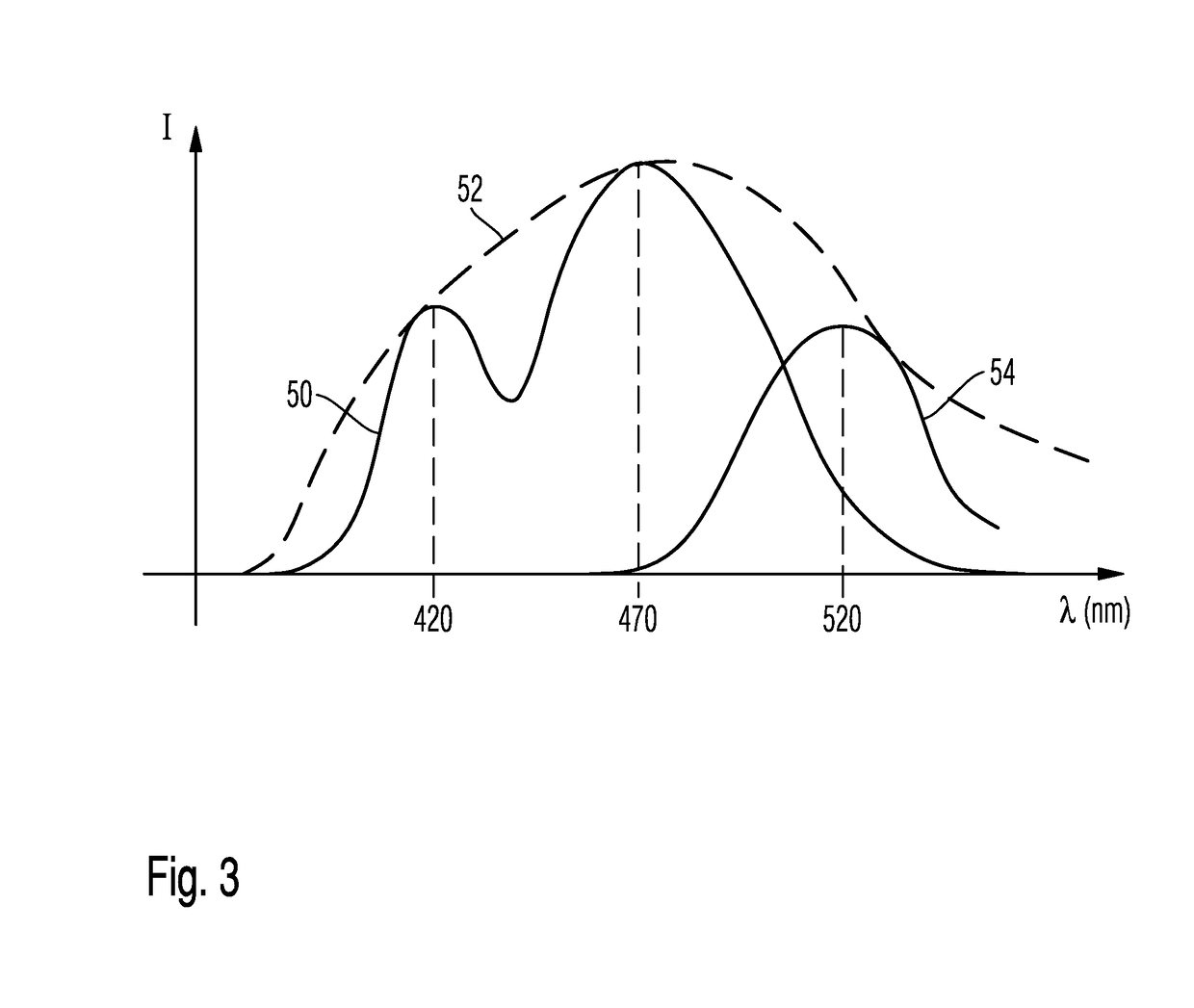

Lens-eye model and method for predicting in-vivo lens performance

InactiveUS6626535B2Easily impartedRate of evaporationSpectales/gogglesPhase-affecting property measurementsModel systemEngineering

An eye model system for remotely predicting the in-vivo performance of a vision altering optic includes a representative cornea, a dispersion medium, and a retinal surface. The corneal surfaces provide anatomical shape, optical power, and higher order aberration content. The dispersion medium mimics chromatic dispersion in an actual eye. The retinal surface is moveable to provide selected defocus. A humidity and temperature enclosure may be provided. Model eye elements can be tilted or decentered to simulate actual conditions. An associated method for remotely measuring the performance of a vision altering optic to predict its performance in-vivo includes making topography, wavefront, interferometry, PSF, MTF, or other optical and / or physical measurements of the model eye system with and without the optic in combination.

Owner:BAUSCH & LOMB INC

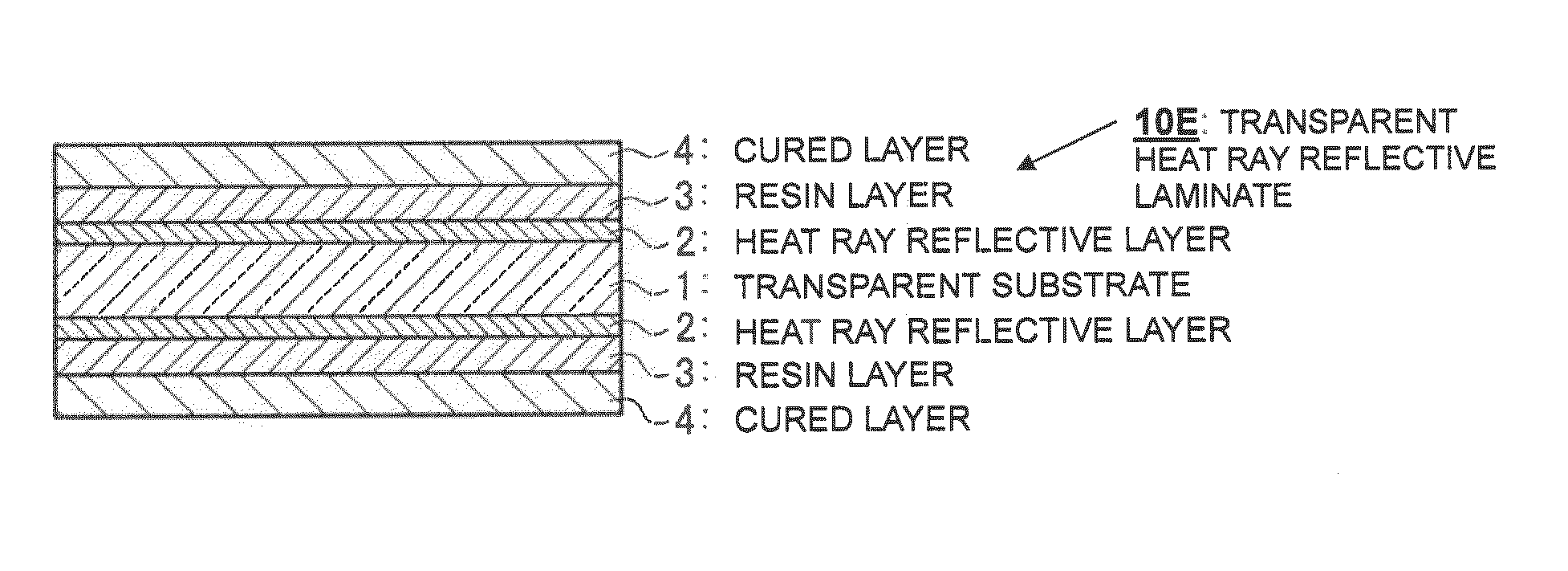

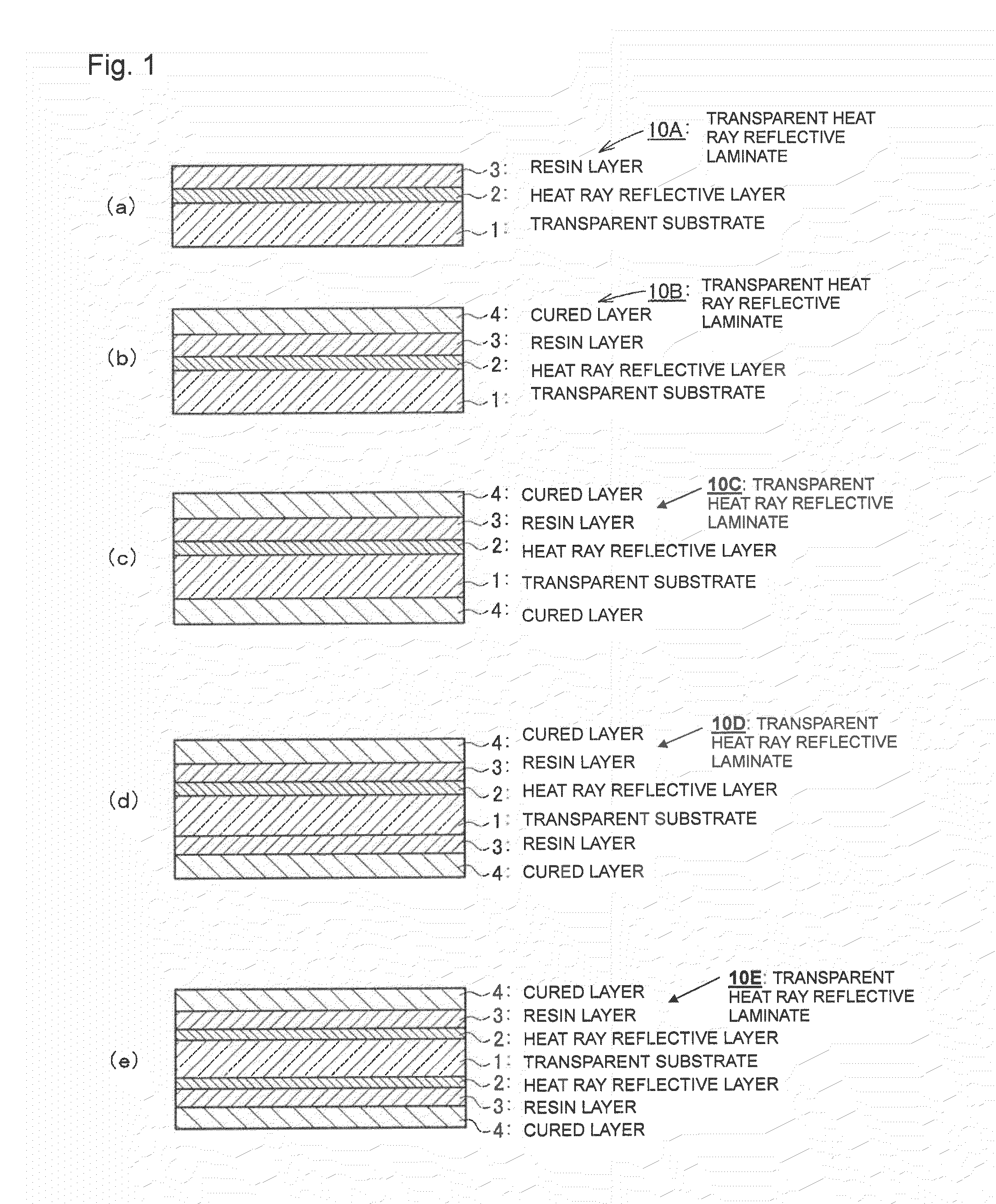

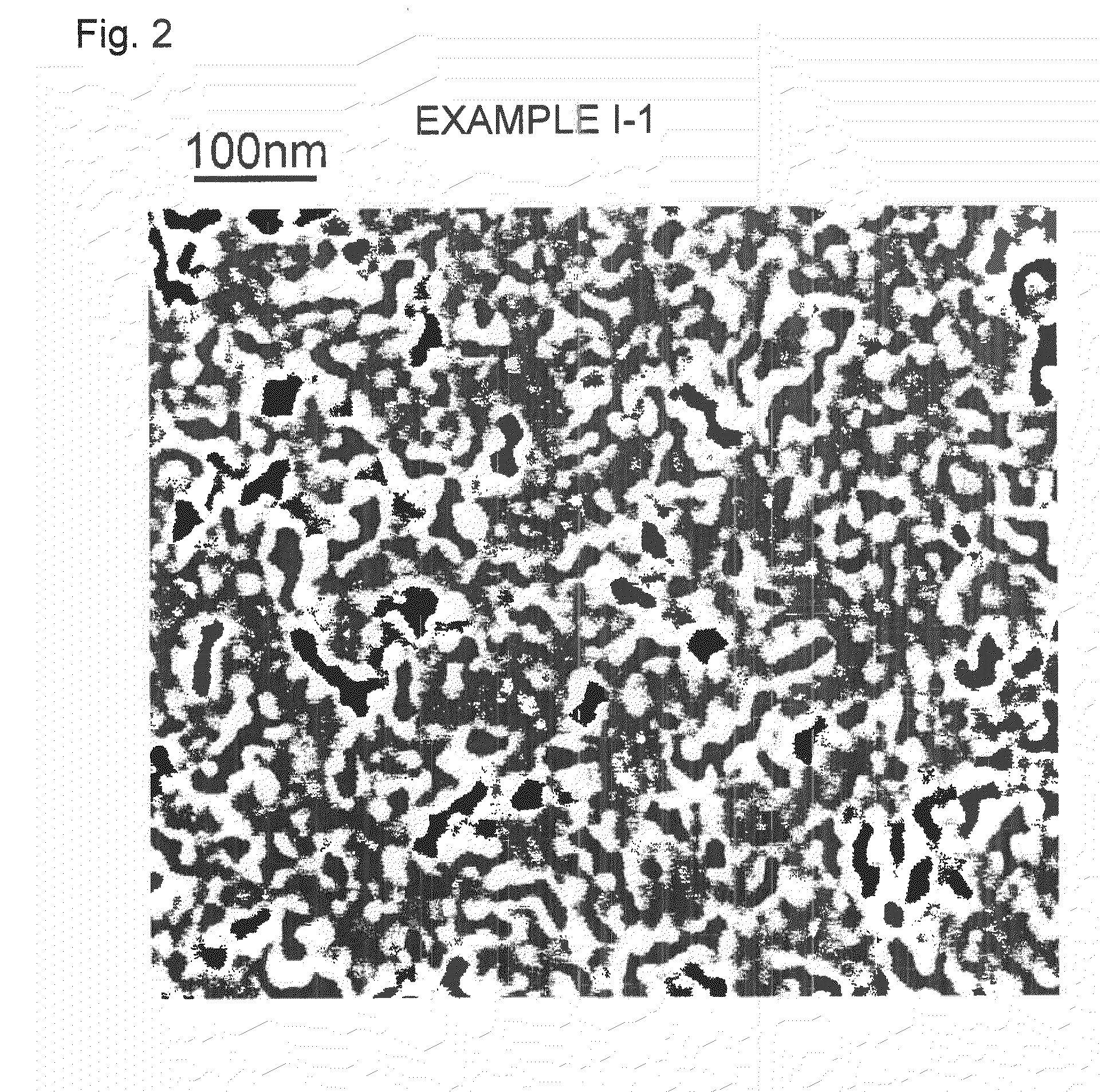

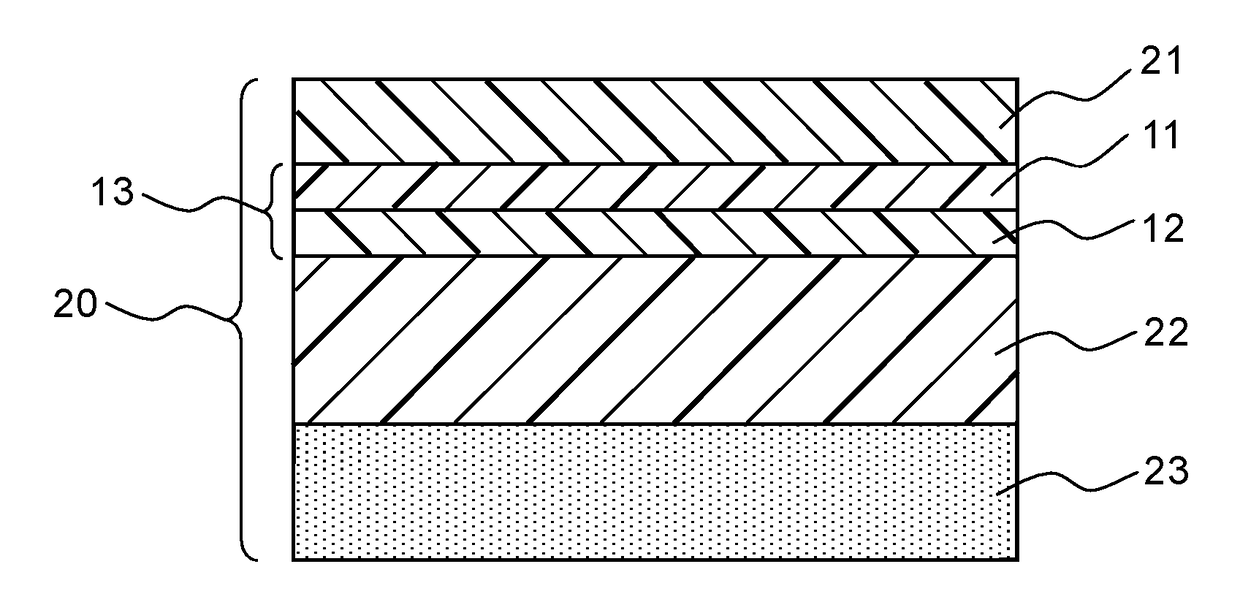

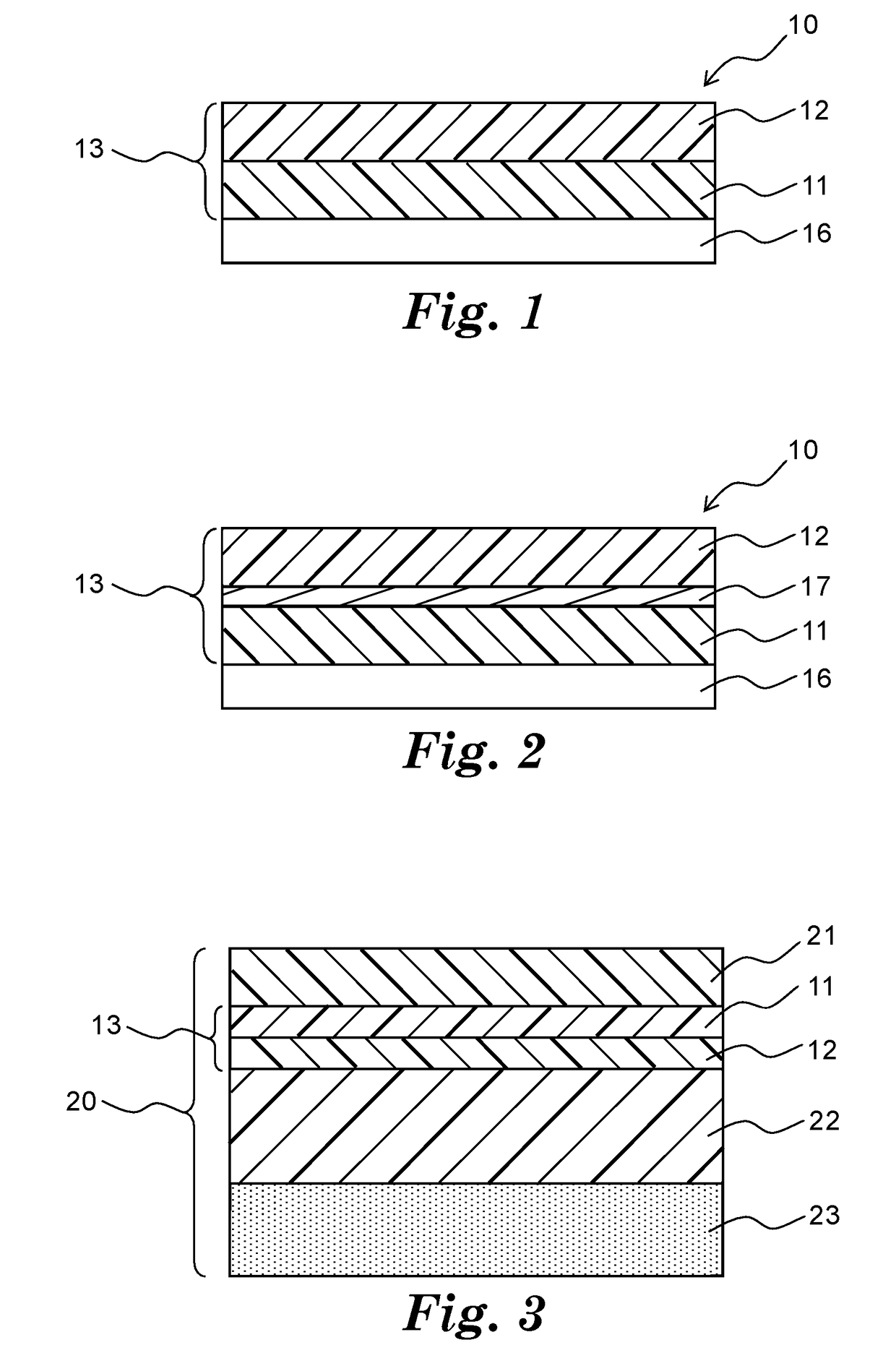

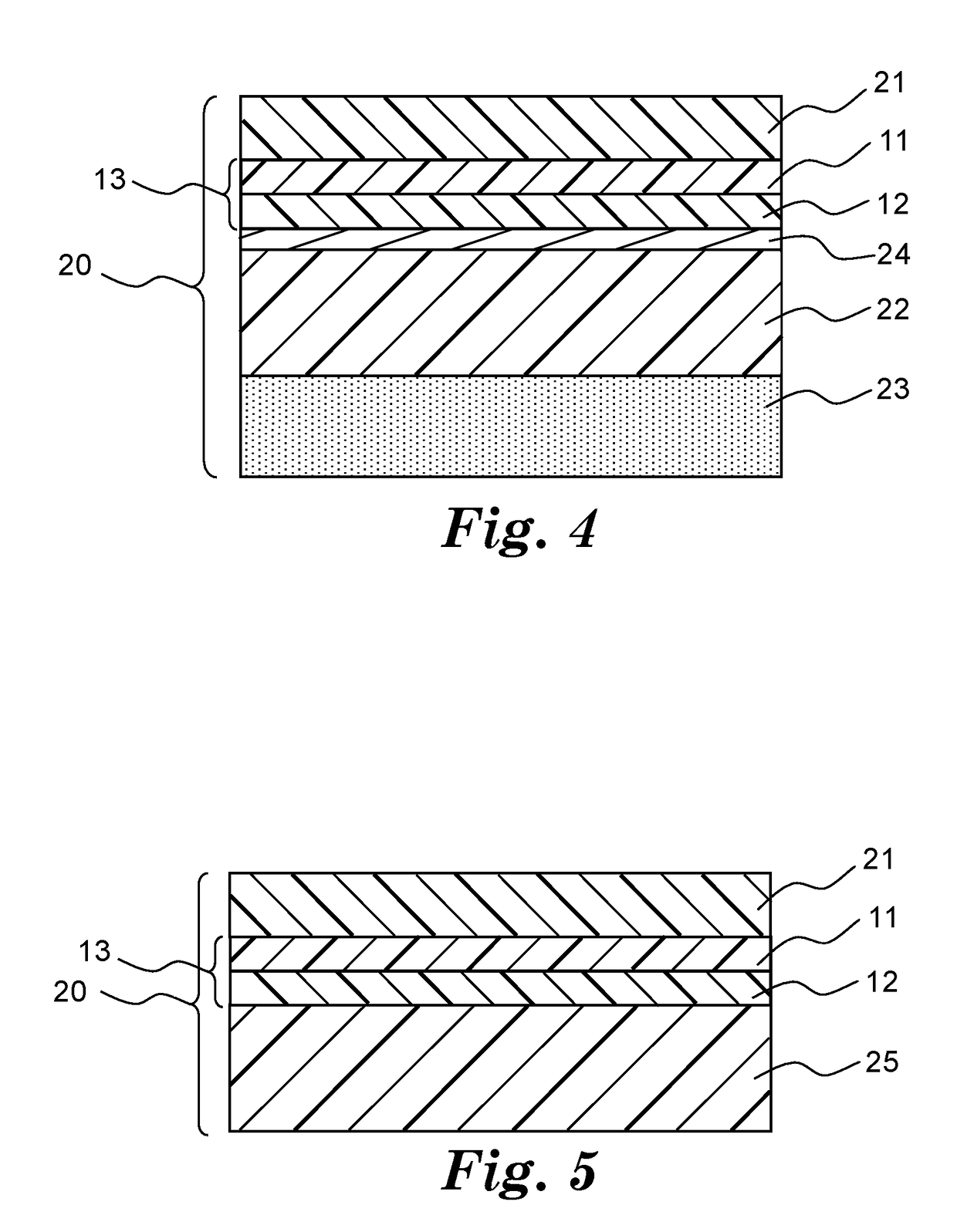

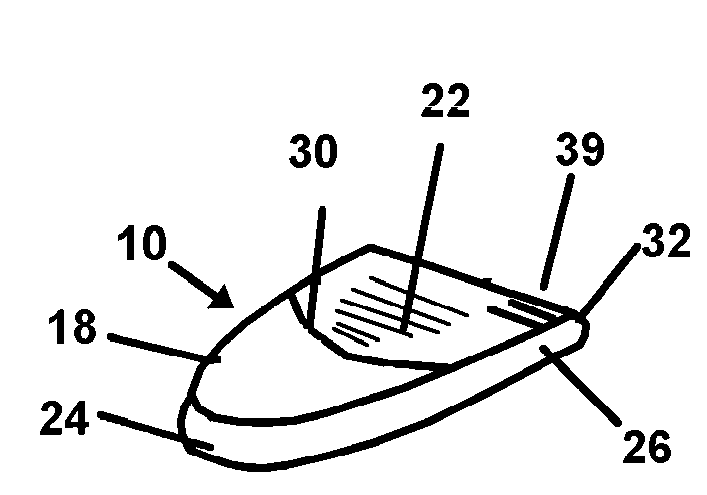

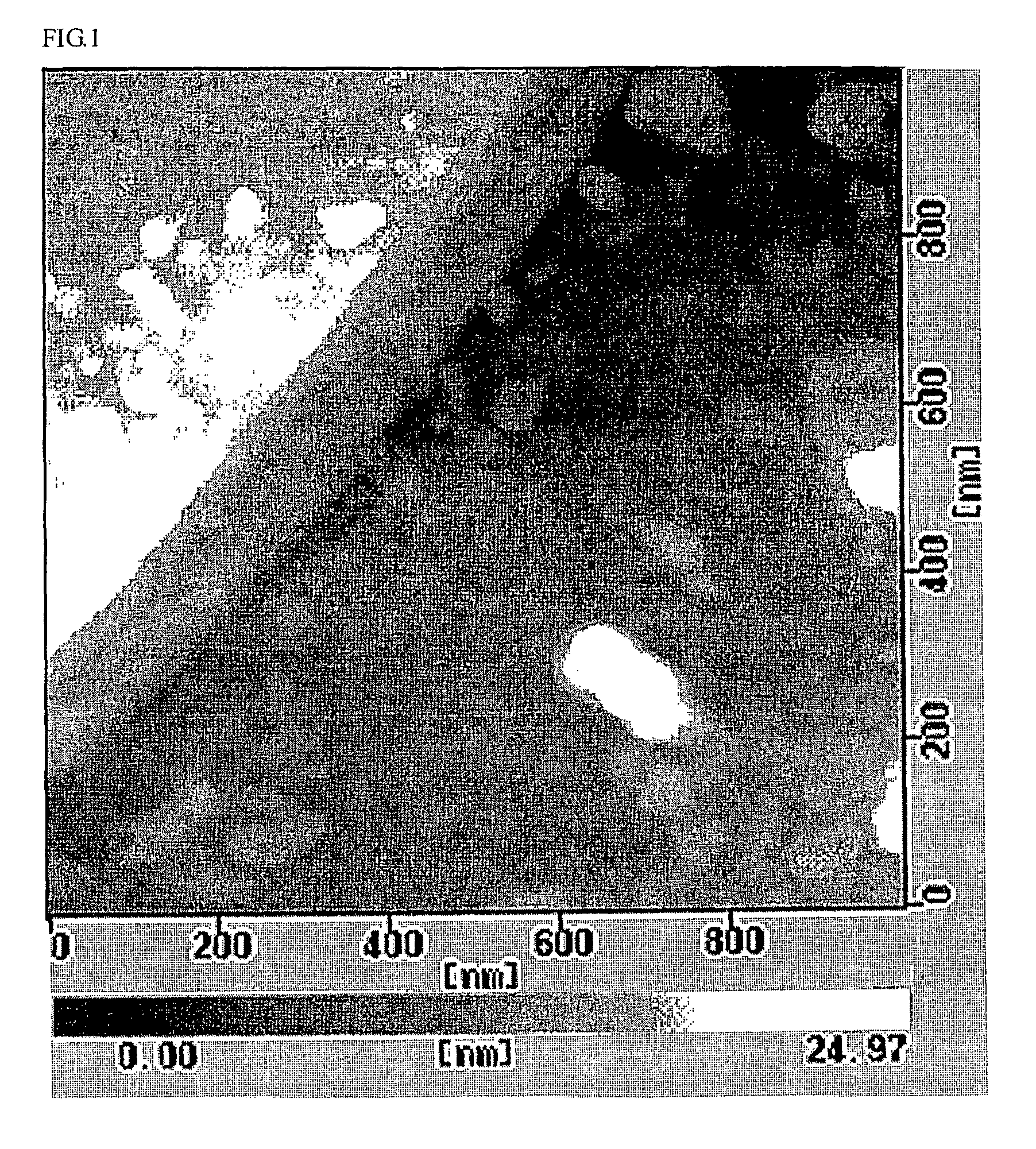

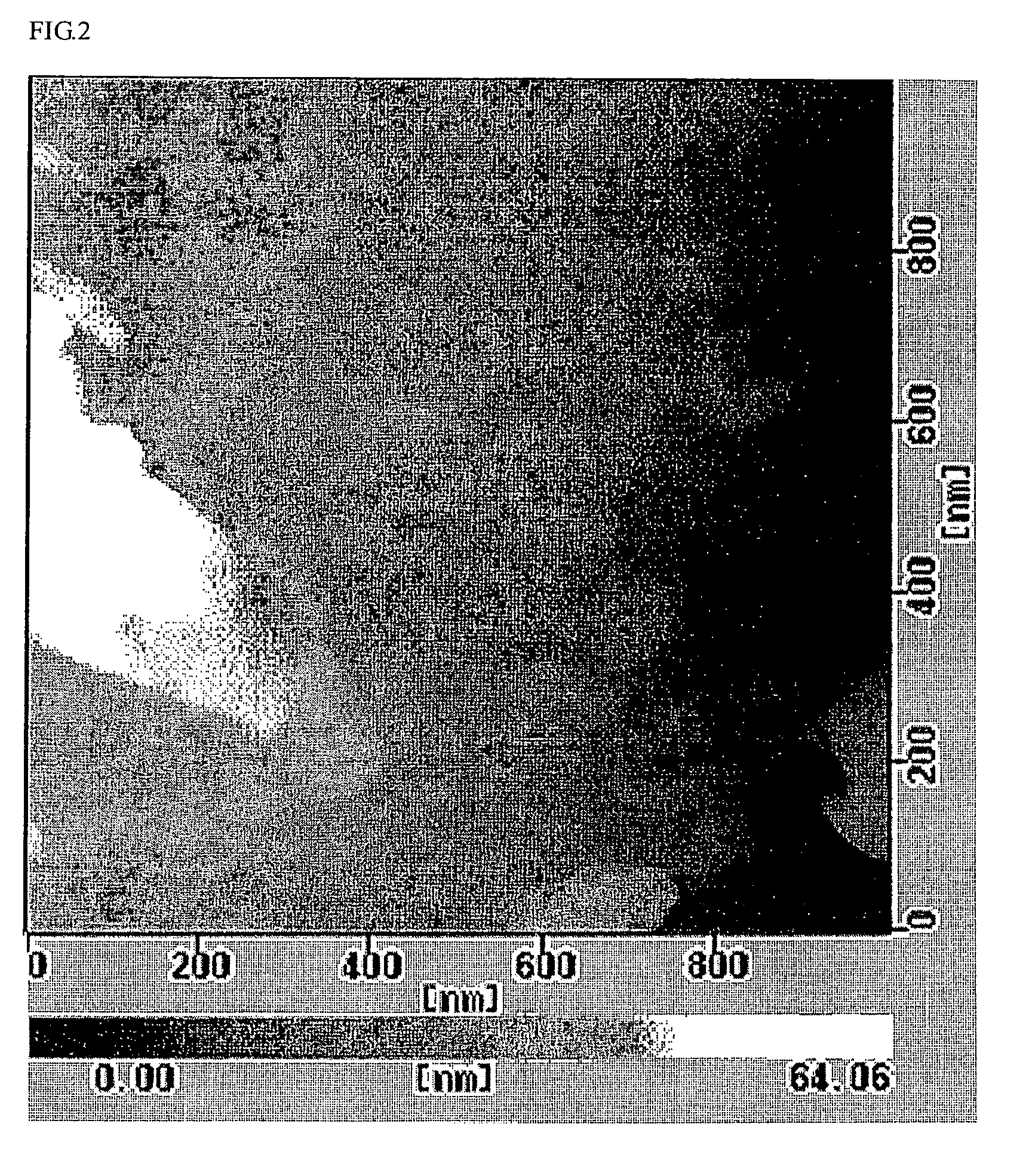

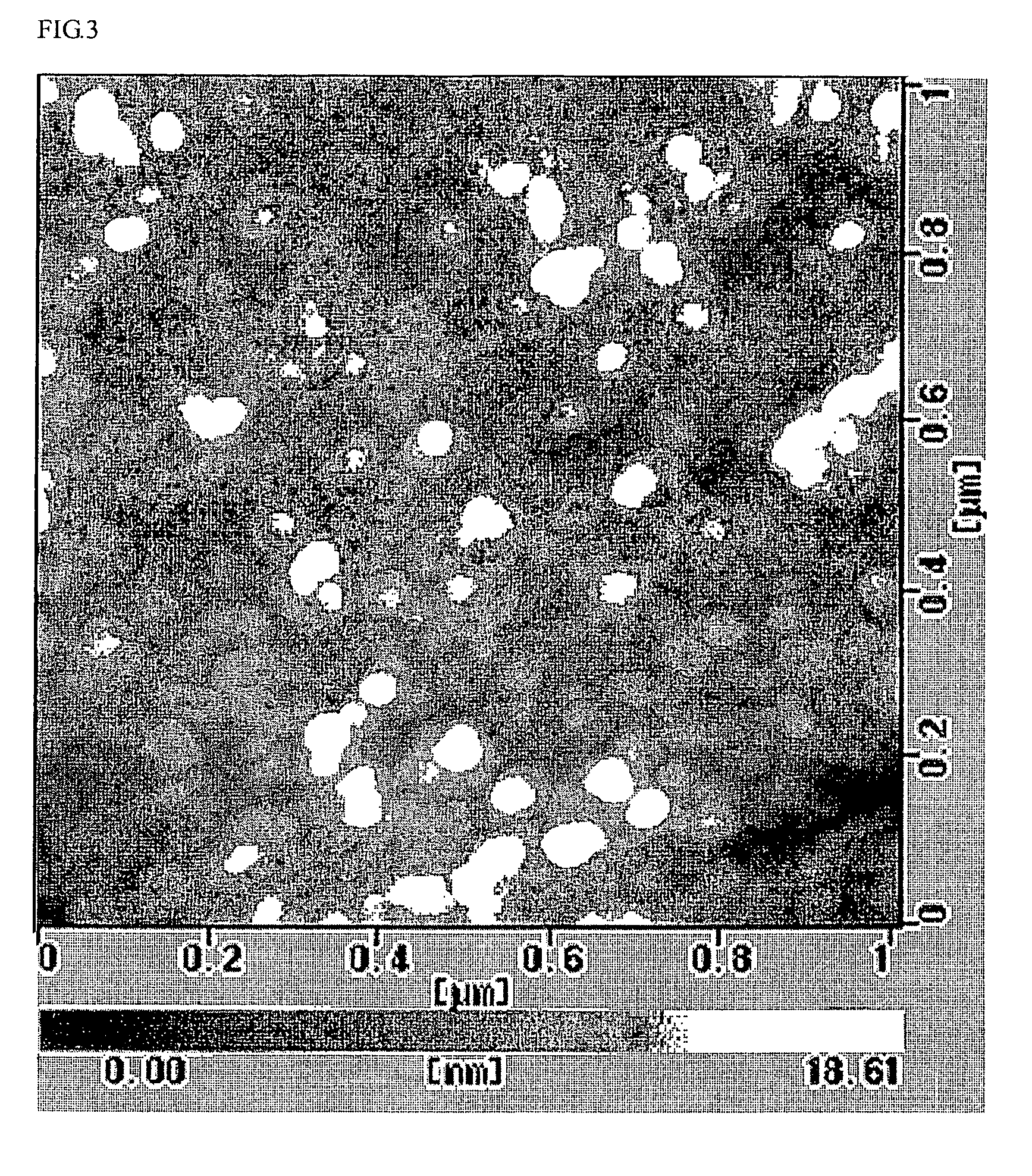

Heat ray reflective film and laminate thereof, and coating fluid for forming heat ray reflective layer

InactiveUS20110261443A1High heat ray reflectivityHigh environmental durabilityMaterial nanotechnologyMirrorsMetalLight reflection

Disclosed is a heat ray reflective film having a single layer structure, which has high heat ray reflectivity, can relatively control visible light absorption and visible light reflection and has excellent heat stability. Also disclosed is a heat ray reflective laminate which has high environmental durability and is suitable as a window material for buildings or automobiles.A heat ray reflective laminate which is a laminate comprising a transparent substrate and a heat ray reflective layer and which has a solar reflectance of at least 15% as measured from the side containing the heat ray reflective layer, wherein the heat ray reflective layer comprises a binder resin containing a hydrophilic group other than an N-pyrrolidonyl group, and a metal, and the heat ray reflective layer has a layer thickness of at most 100 nm.

Owner:MITSUBISHI CHEM CORP

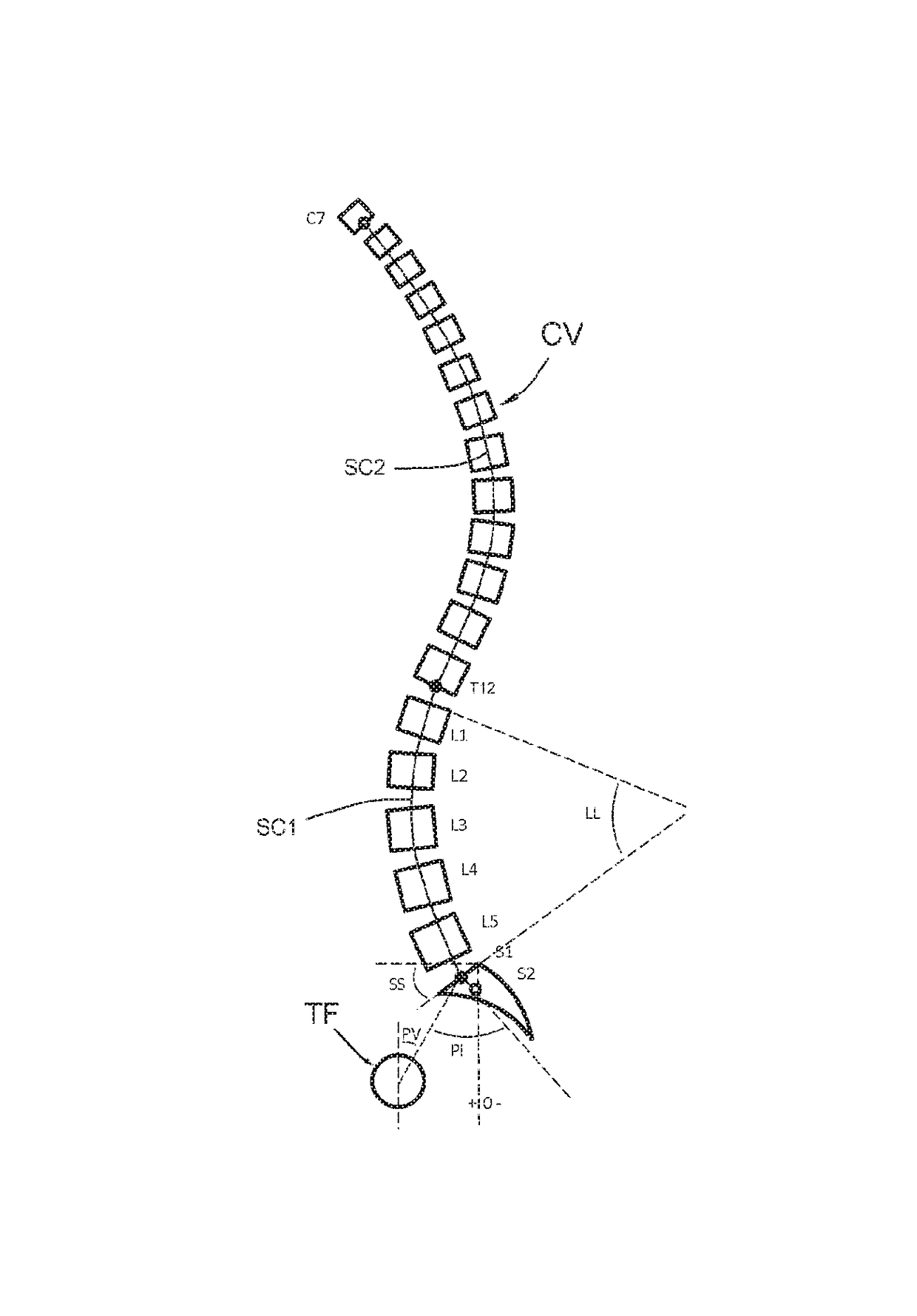

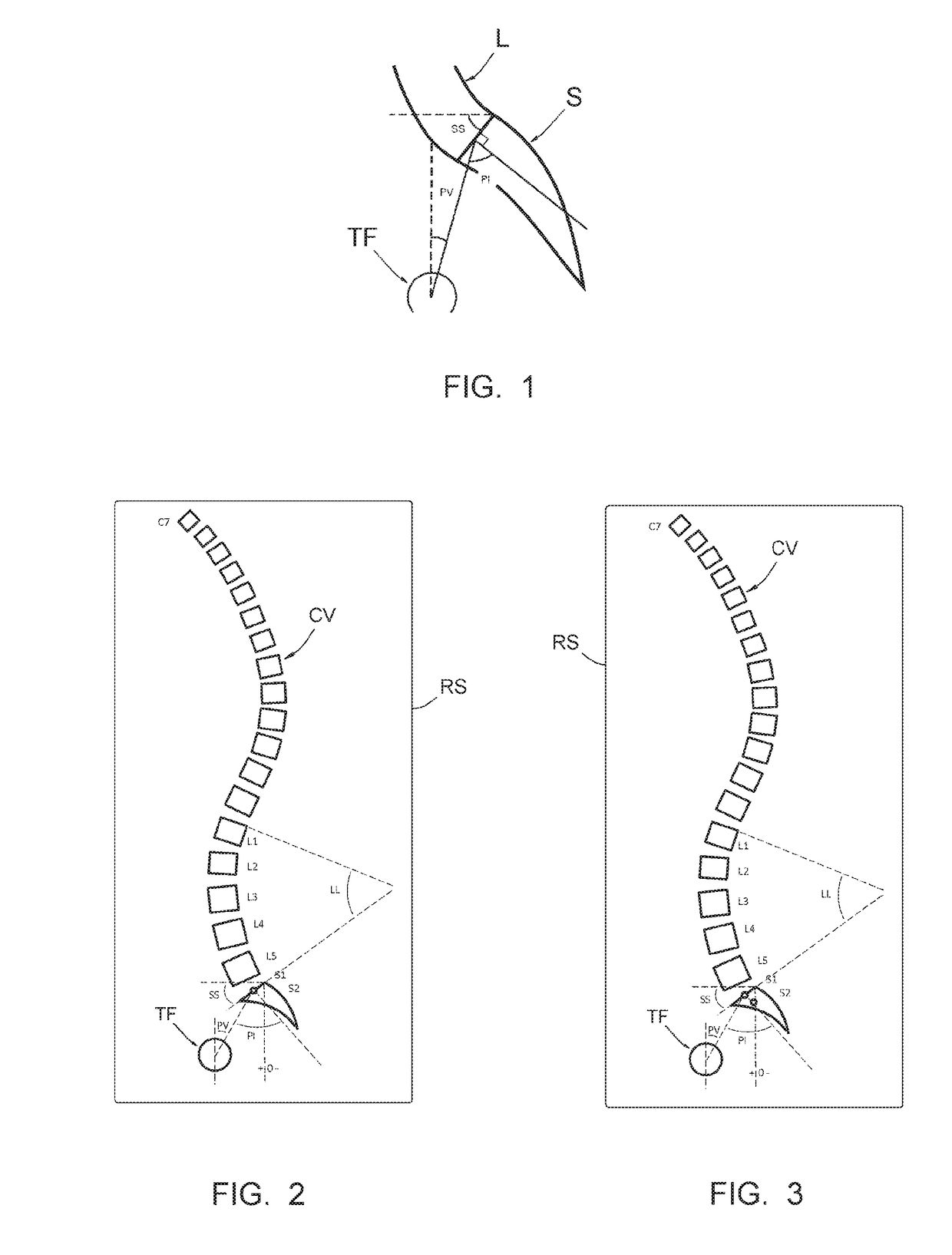

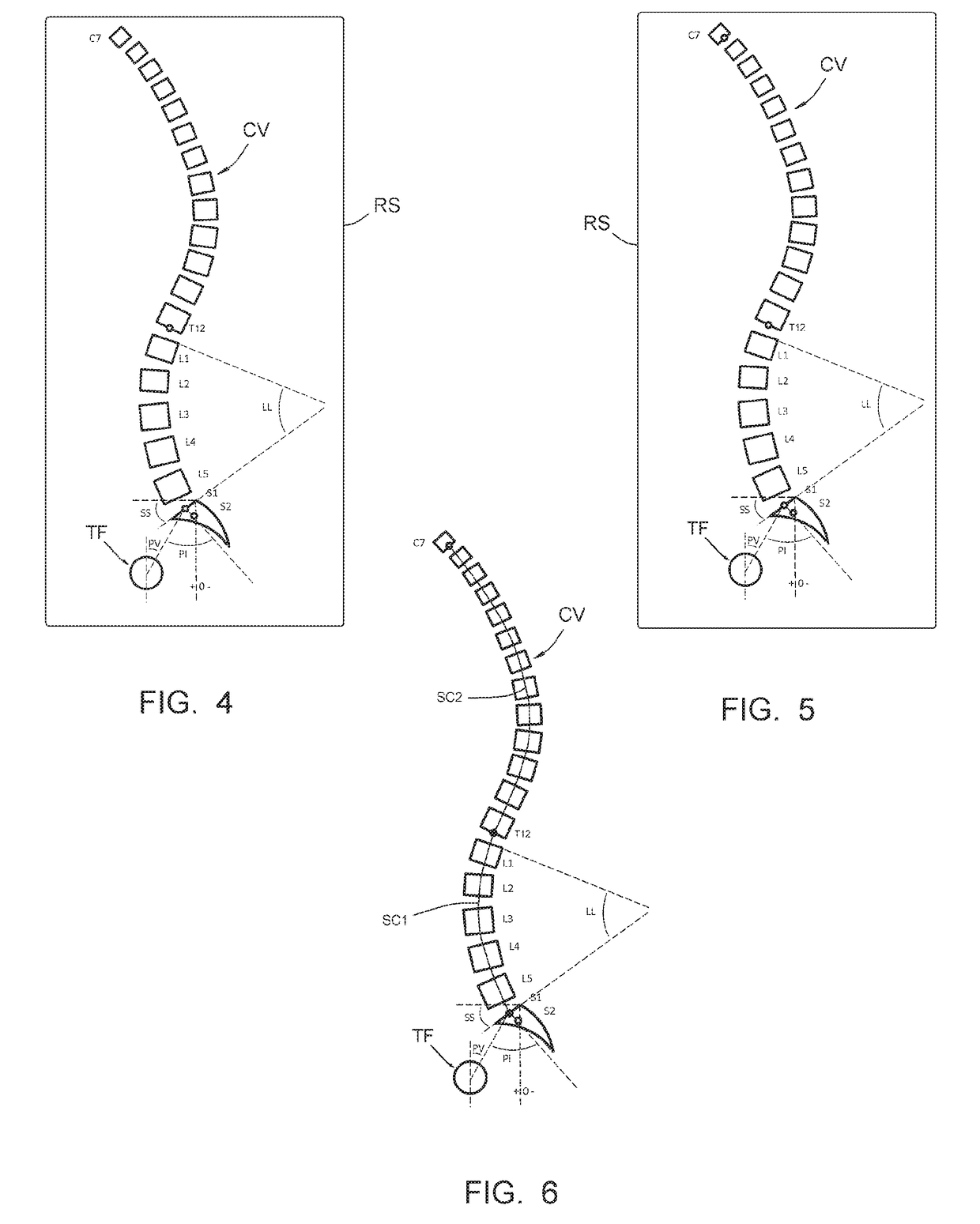

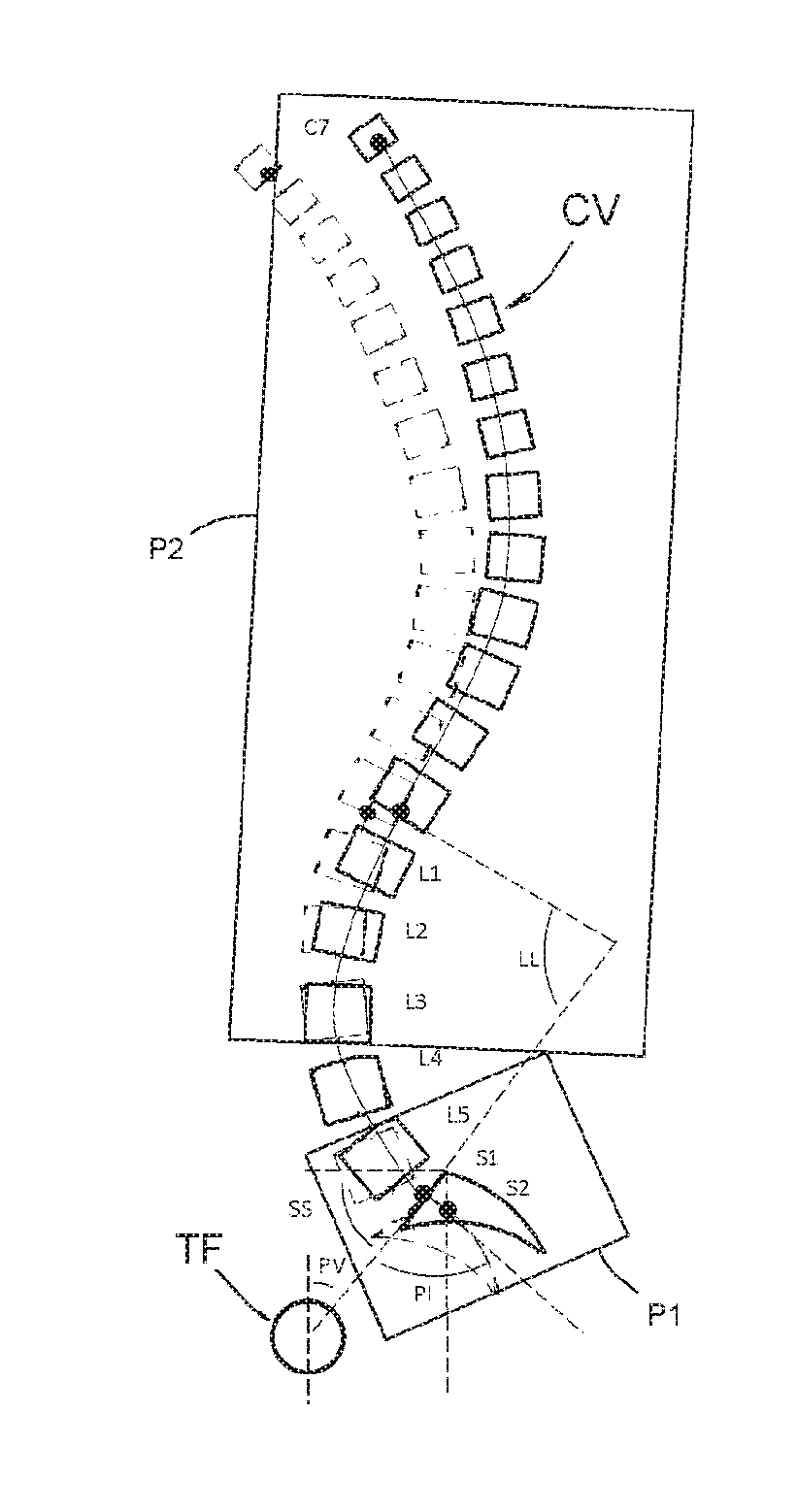

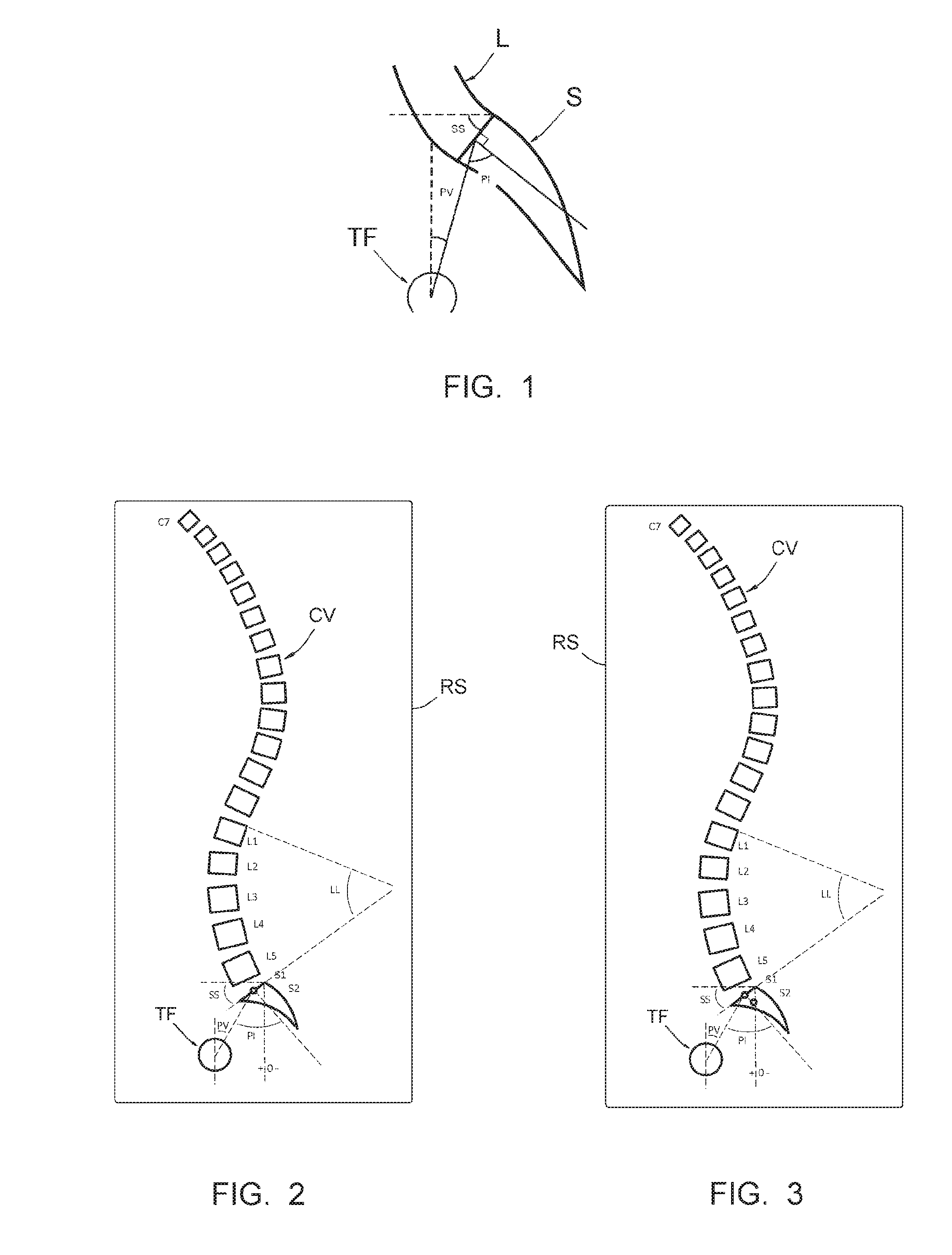

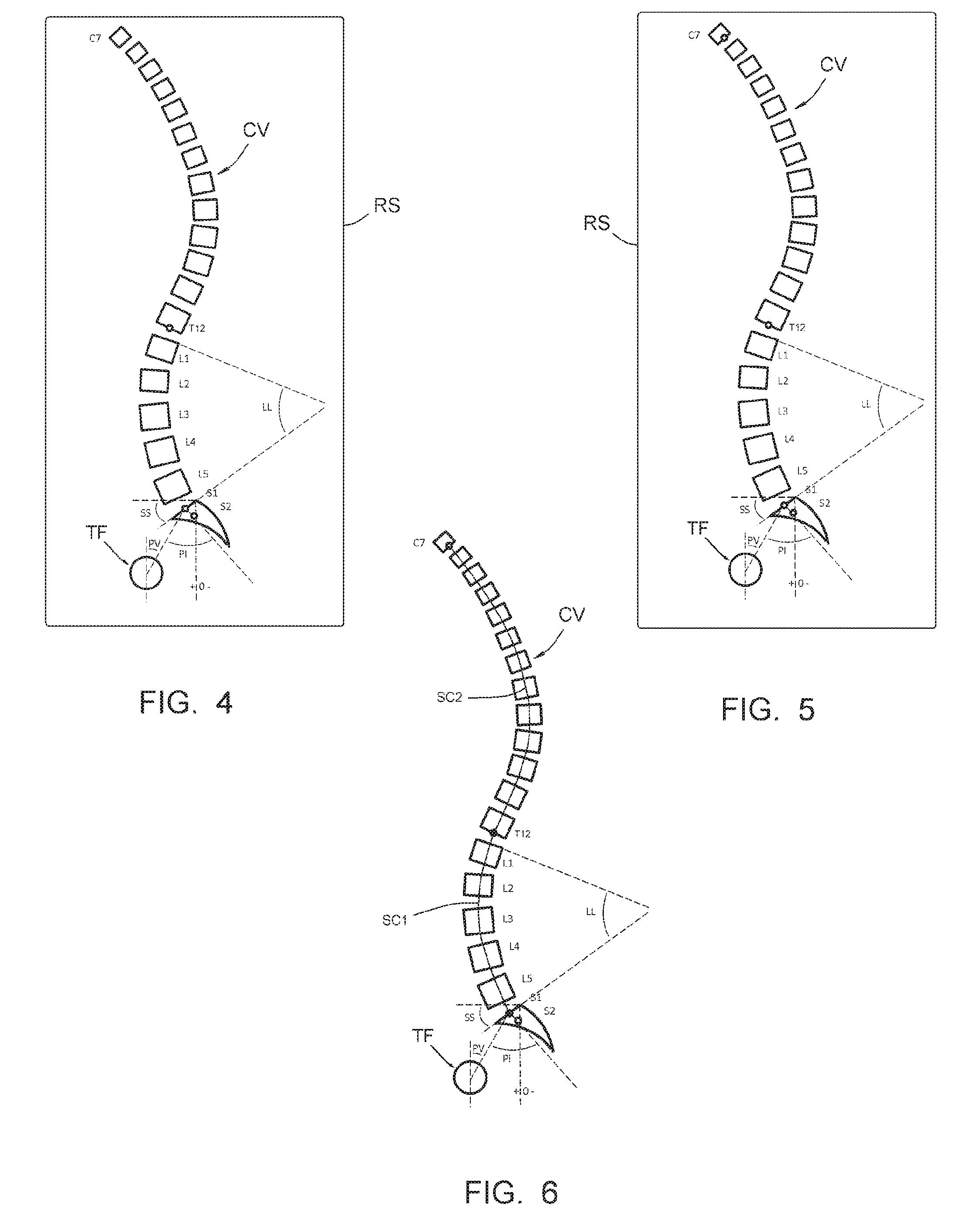

Method making it possible to produce the ideal curvature of a rod of vertebral osteosynthesis material designed to support a patient vertebral column

ActiveUS9693831B2Impart the appropriate curvature to a straight rod easilyEasily impartedImage enhancementImage analysisSpinal columnMedicine

According to the invention, the process includes the steps of: a) taking a sagittal preoperative x-ray of the vertebral column of the patient to be treated, extending from the cervical vertebrae to the femoral heads; b) on that x-ray, identifying points on S1, S2, T12 et C7; c) depicting, on the said x-ray, curved segments beginning at the center of the plate of S1 et going to the center of the plate of C7; e) identifying, on that x-ray, the correction(s) to be made to the vertebral column, including the identification of posterior osteotomies to make; f) pivoting portions of said x-ray relative to other portions of that x-ray, according to osteotomies to be made; g) performing, on said x-ray, a displacement of the sagittal curvature segment extending over the vertebral segment to be corrected; h) from a straight vertebral rod (TV), producing the curvature of that rod according to the shape of said sagittal curvature segment in said displacement position.

Owner:MEDICREA INT SA

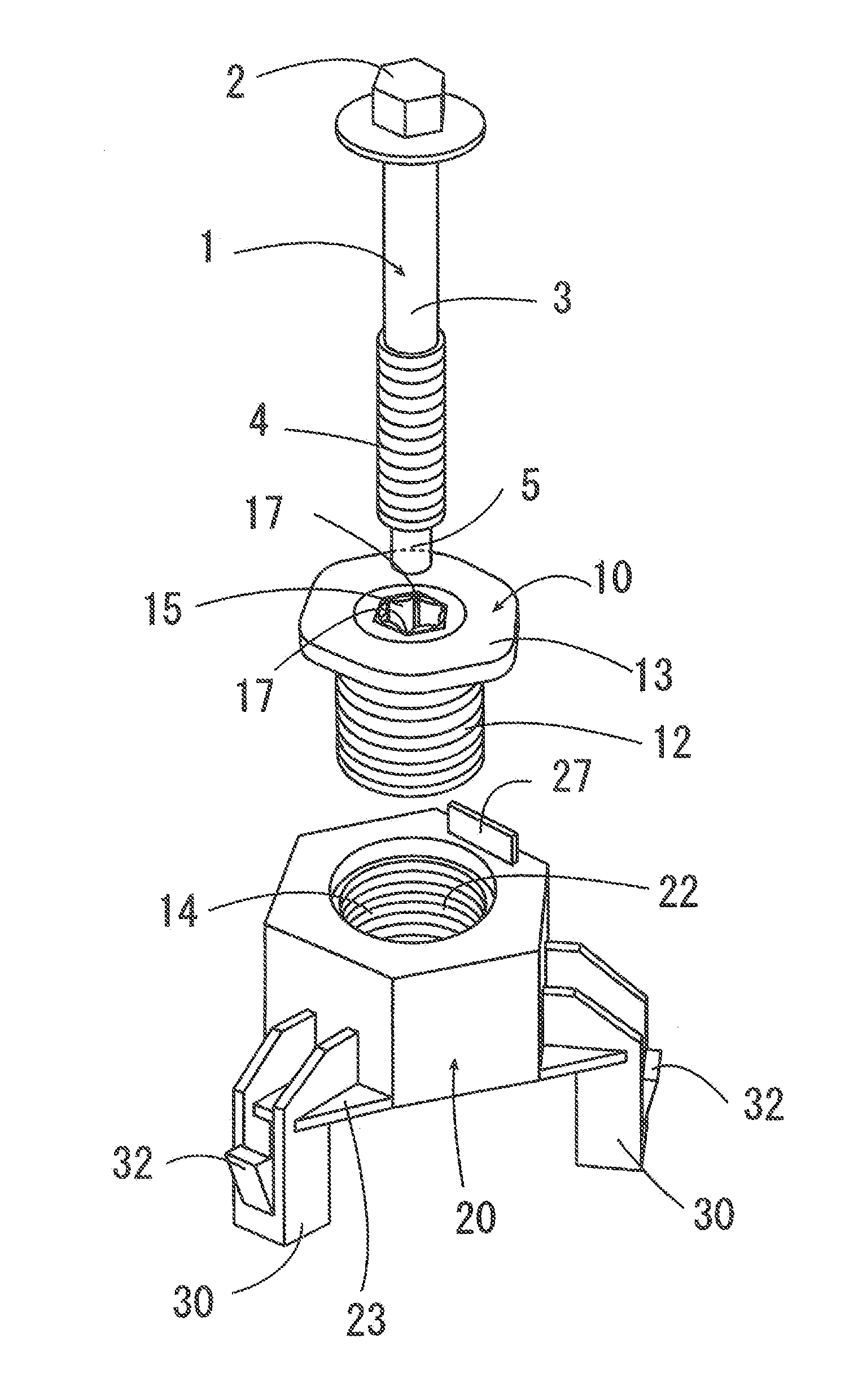

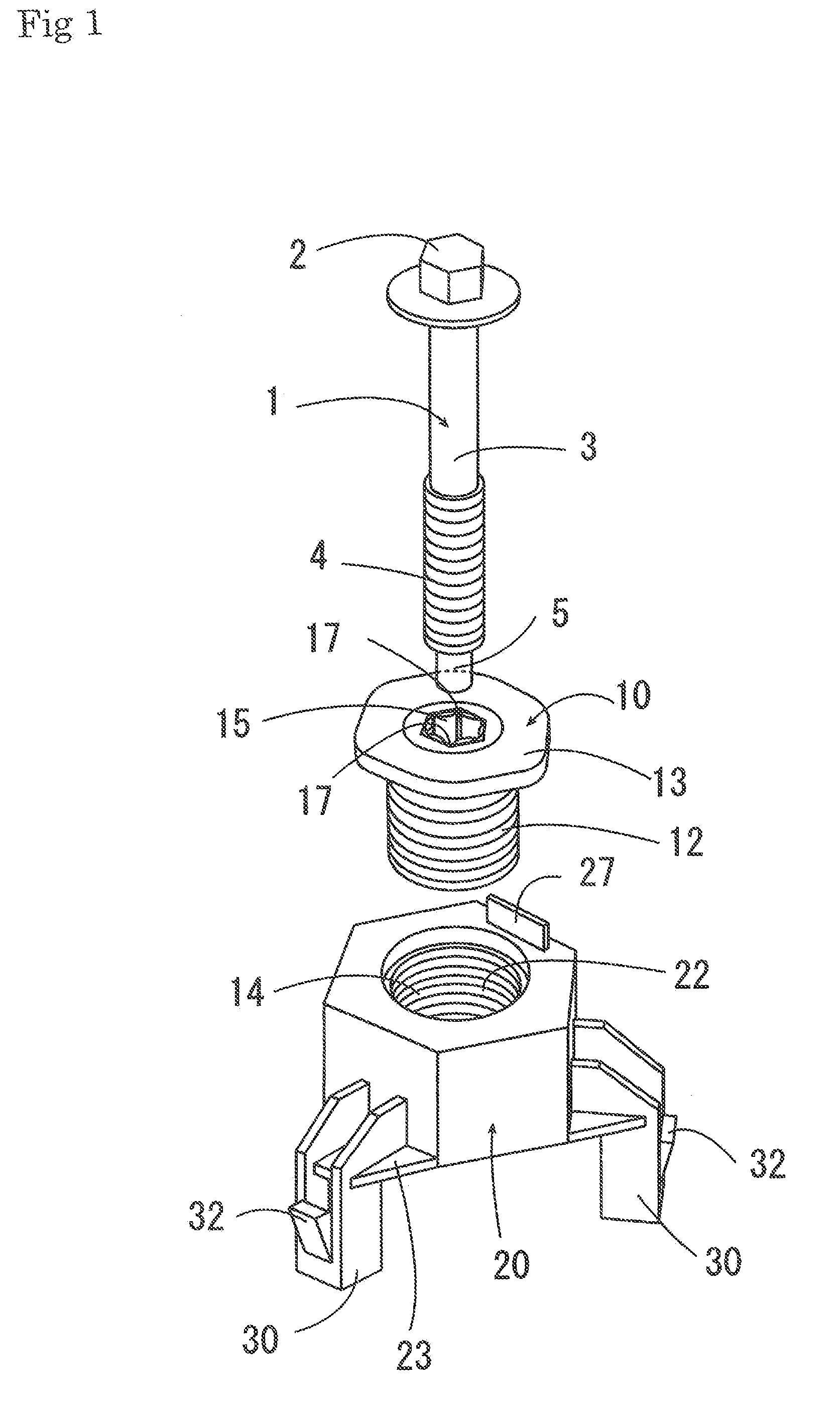

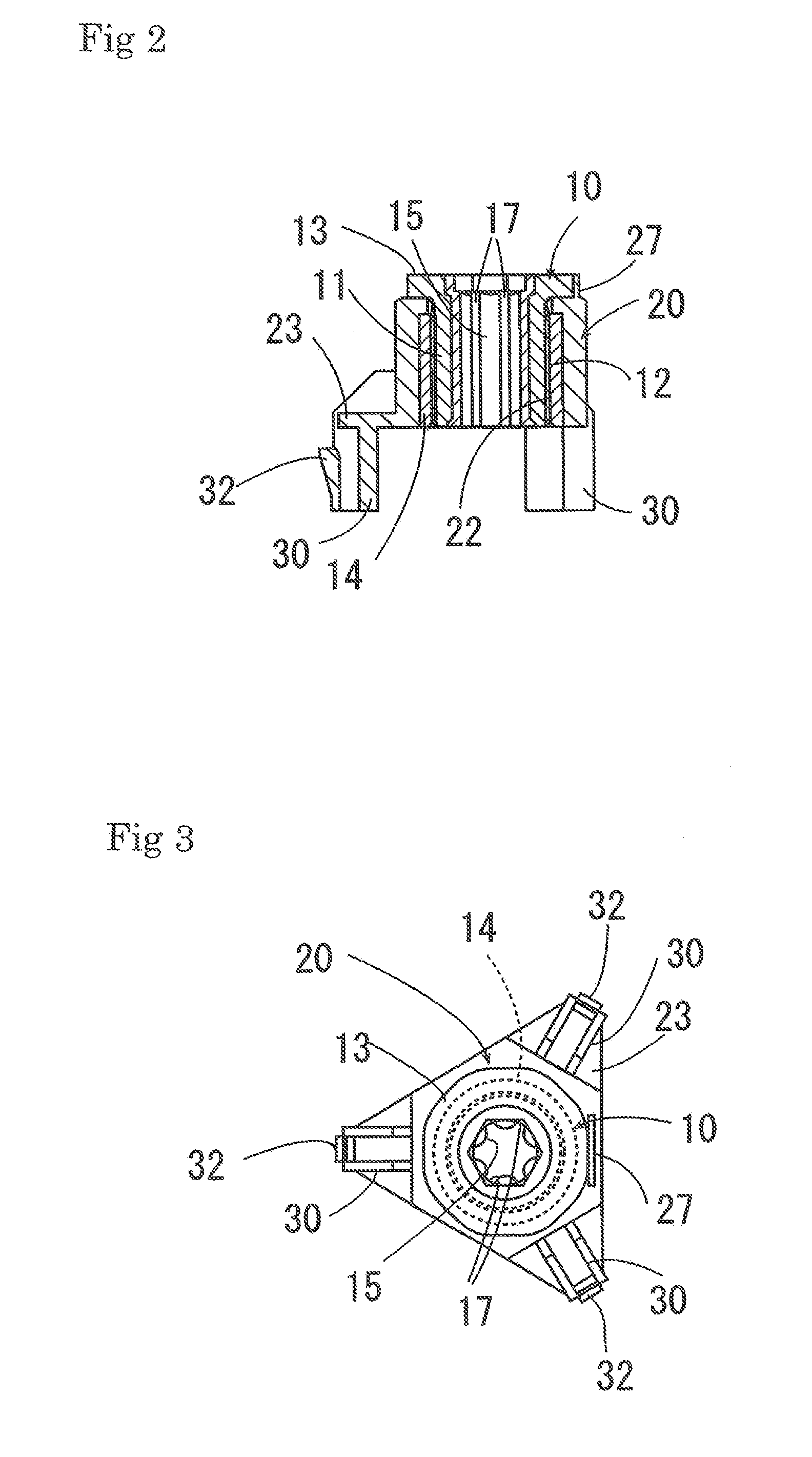

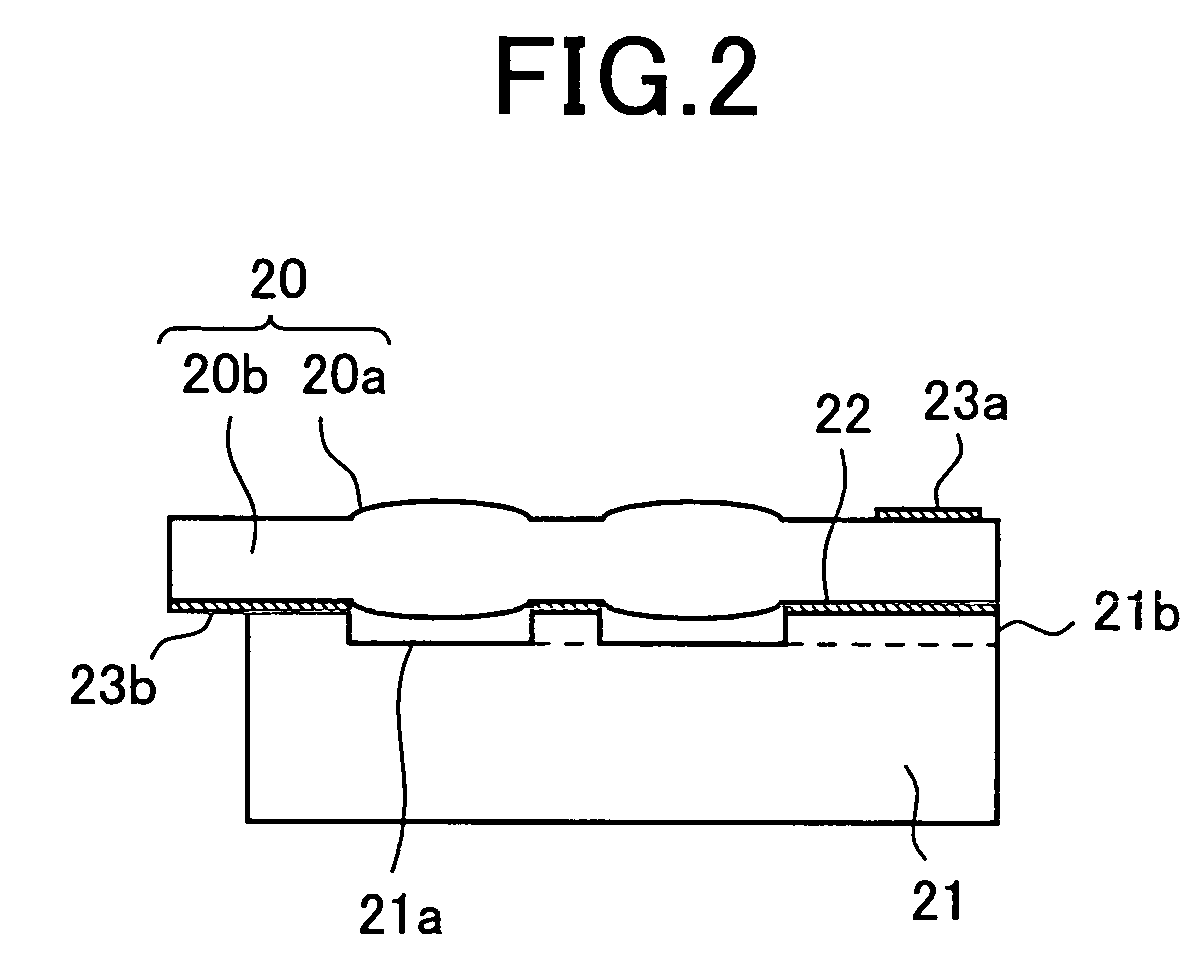

Fastening device

InactiveUS20090067921A1Low costEasily impartedCouplings for rigid shaftsSheet joiningEngineeringMechanical engineering

A fastening device, including: a sleeve 20 fixed to a first member 40; a bolt 1; and a movable spacer 10 that is engaged with a male screw portion 4 of the bolt 1 to be detachable upon receiving a transmission torque exceeding a predetermined value, and moves to a position coming into contact with a second member 50 distanced from the first member as a result of rotating while mating with the reversal screw portion 22 of the sleeve 20 upon receiving the rotational torque from the bolt 1. On the inner peripheral surface of the movable spacer 10, an elastic body layer 15 which elastically deforms when engaged with the male screw portion 4 of the bolt 1 to exhibit a torque transmitting function and a pitch deviation absorbing function is formed.

Owner:AOYAMA SEISAKUSHO CO LTD

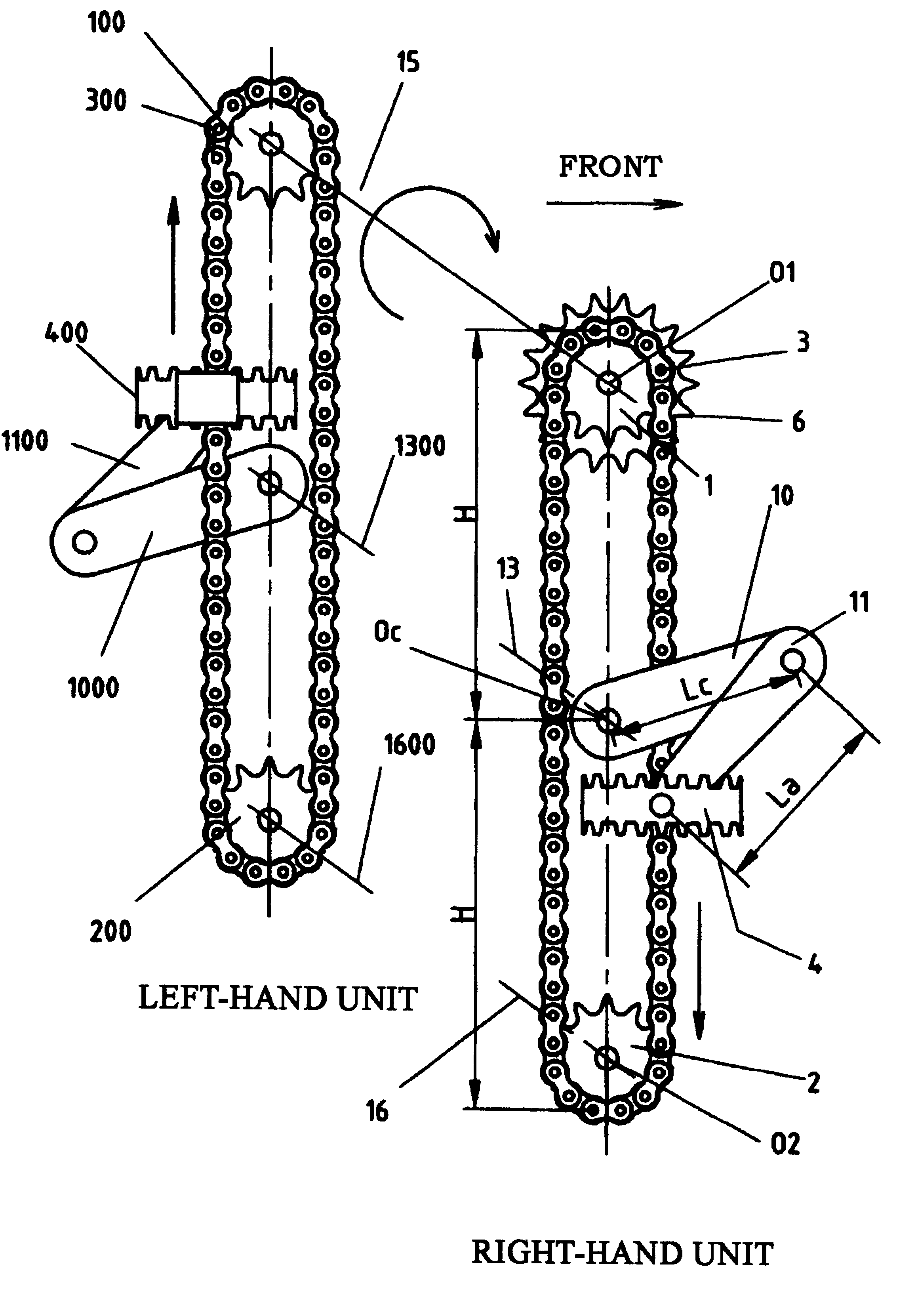

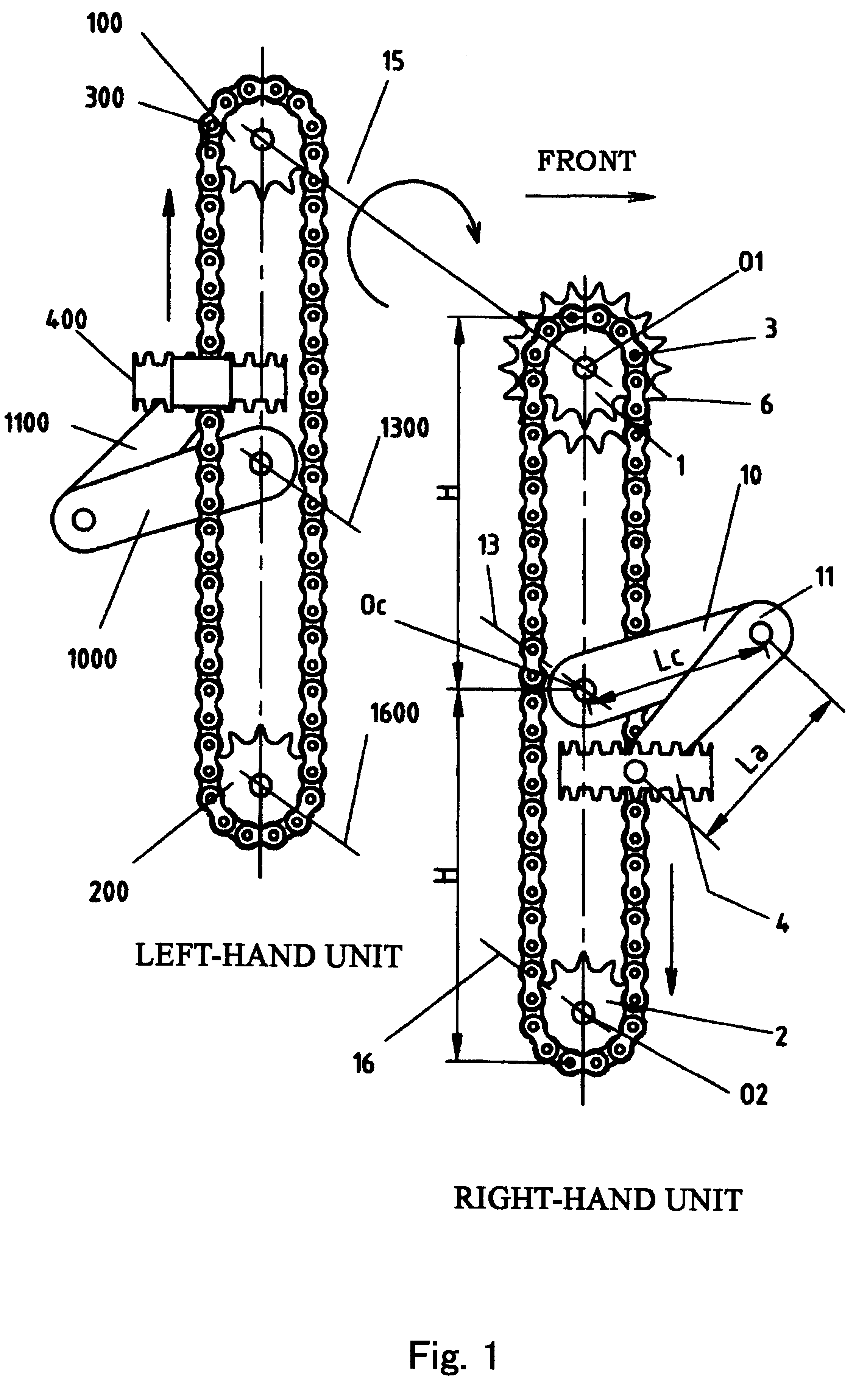

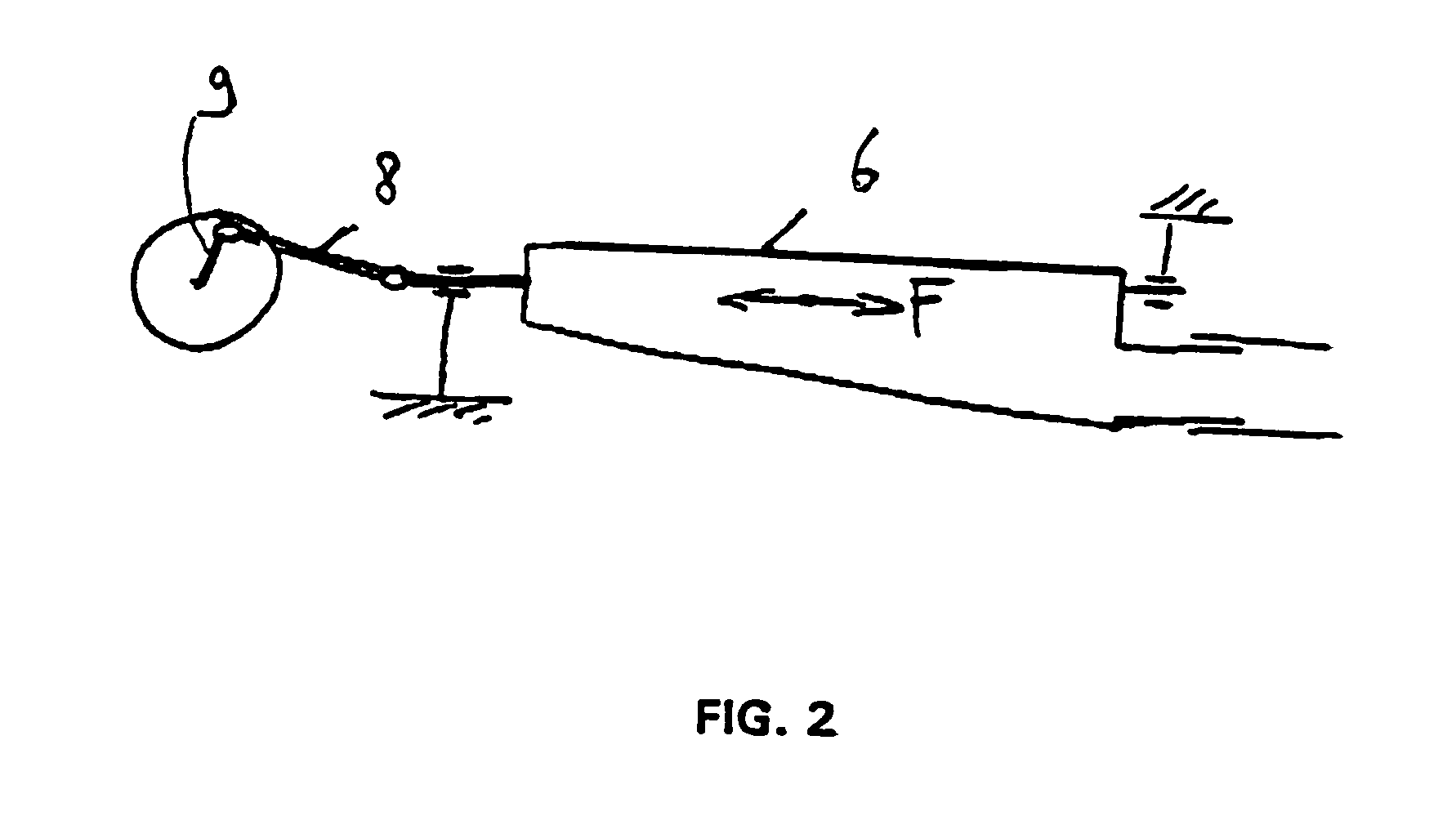

Human-powered driving mechanism

A human powered drive units each including a pair of a rotatable member having a sprocket and a supporting member having a sprocket, which are arranged up and down, and including a chain extended around the rotatable member and the supporting member, are disposed at left and right sides, respectively. The left and right rotatable members 1, 100 are fixed on a driving shaft 15. A chain ring 6 on which the load is applied is mounted on the driving shaft between upper rotatable member 1 and rotatable member 100. In each of the units, constraining means including a free crank (10 for the right-hand unit, and 1000 for the left-hand unit) and arm (11 for the right-hand unit, and 1100 for the left-hand unit), is provided so as to maintain perpendicularity of a shaft of the pedal relative to the plane in which the chain moves. By the rider kicking the pedal along the closed orbit including a linear orbit portion, the force transmitted to the pedal from the foot of the rider is efficiently converted to a rotational force in a longer period of time, thus increasing the power input.

Owner:ODA NORIYUKI

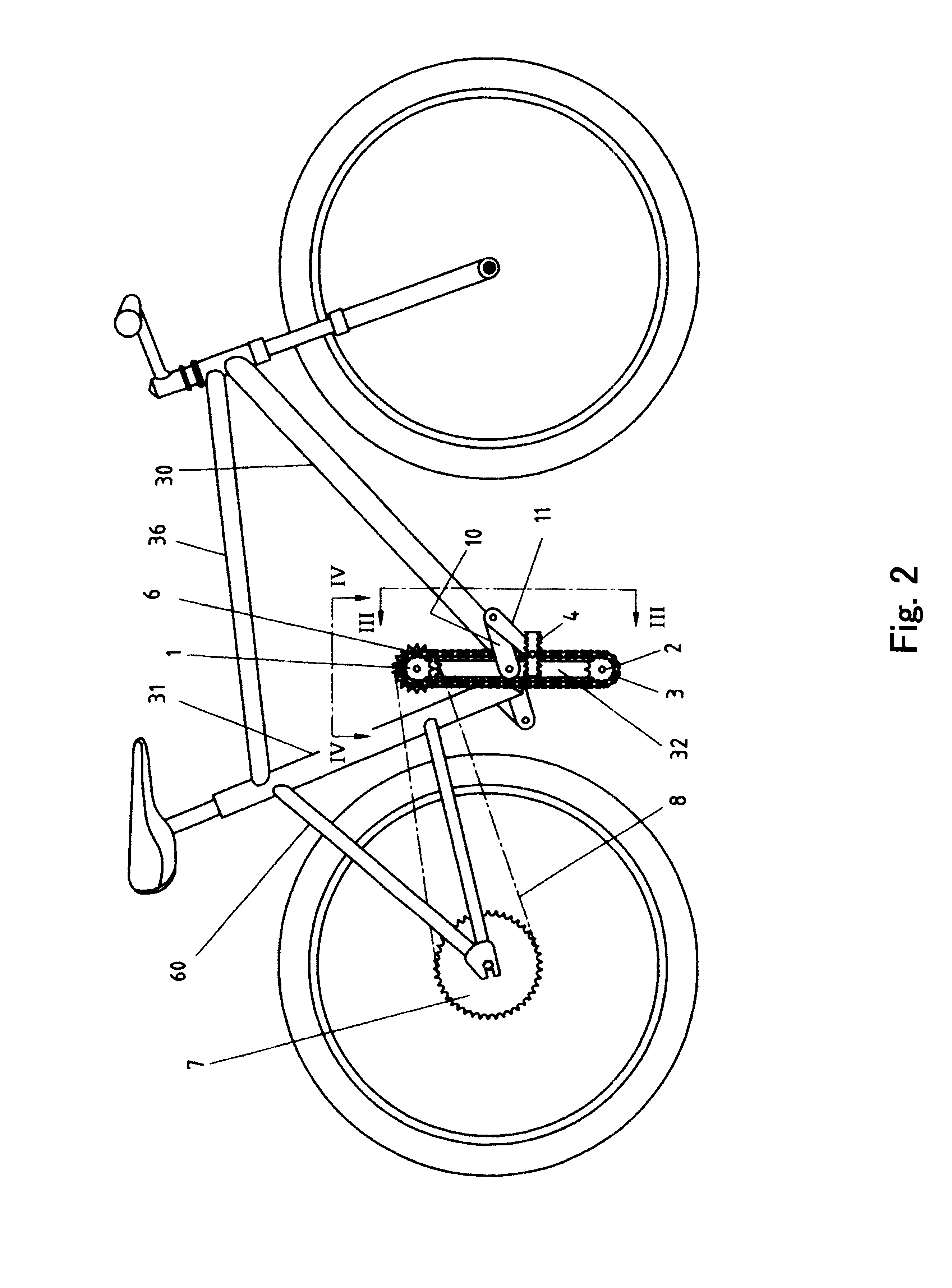

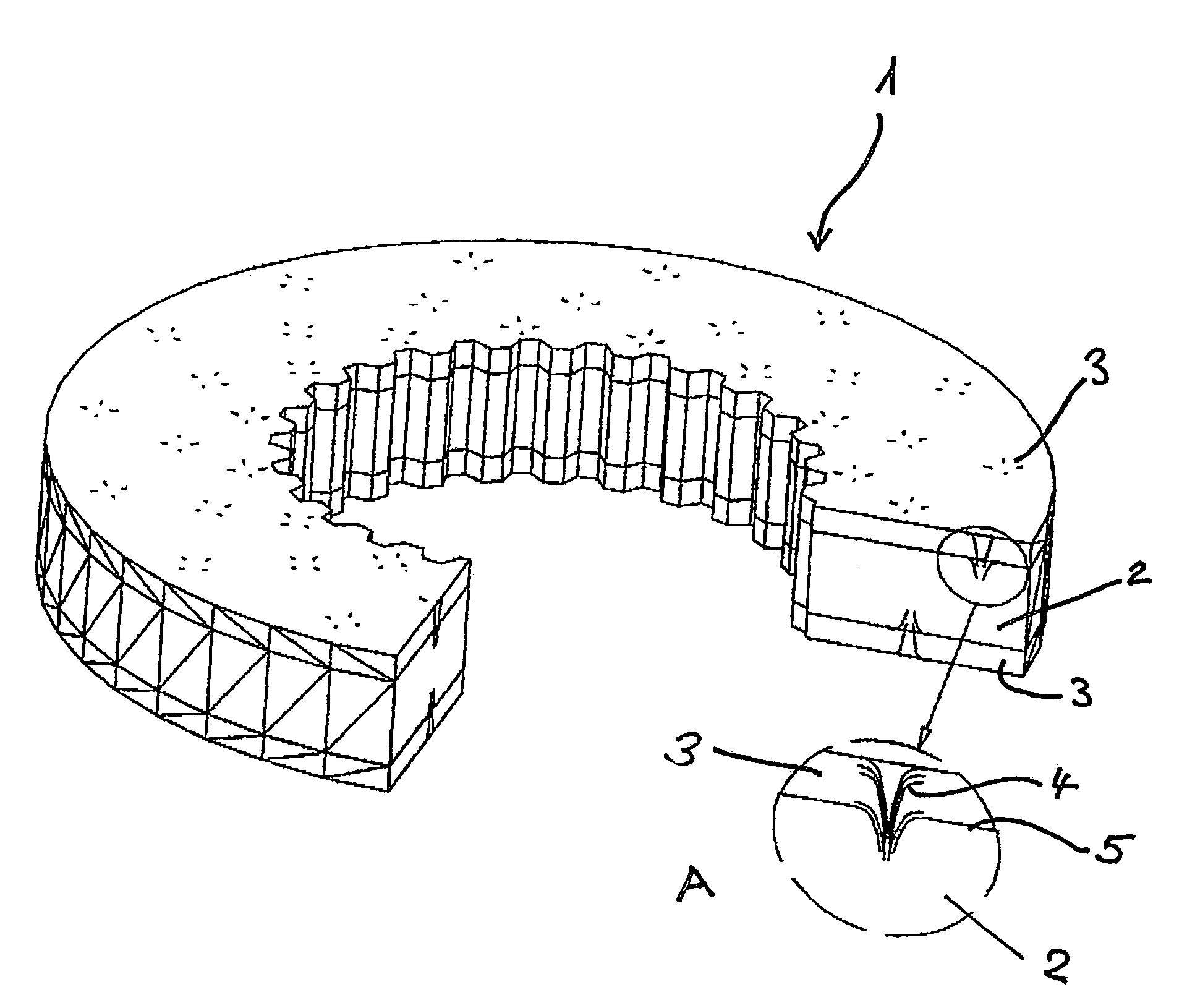

One-piece friction body with a support and a friction pad disposed thereon and method of its manufacture

InactiveUS7370738B2Improve strength propertiesIncreased shear strengthOther chemical processesBraking membersFiberBiomedical engineering

Owner:REX IND PROD GRAF VON REX

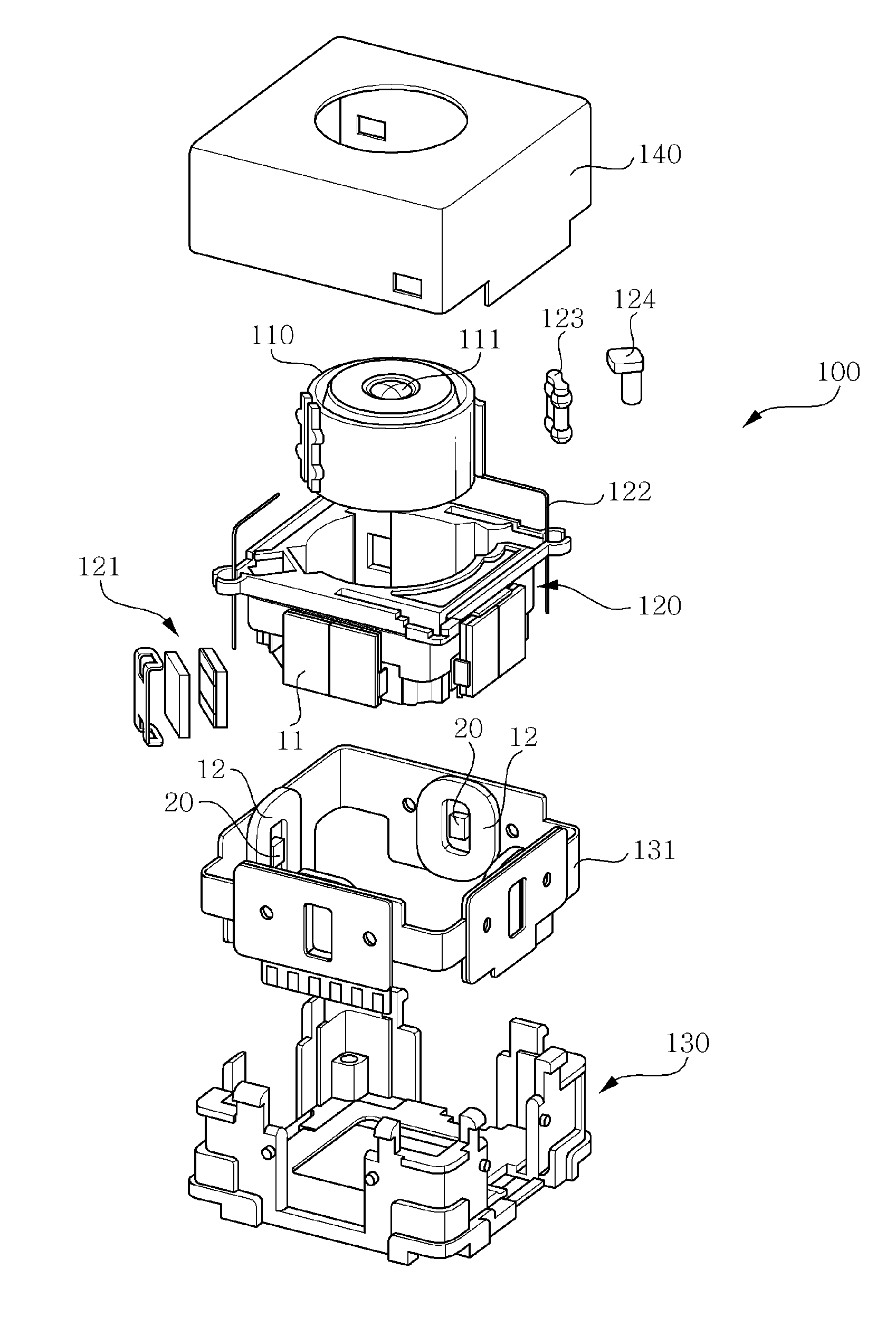

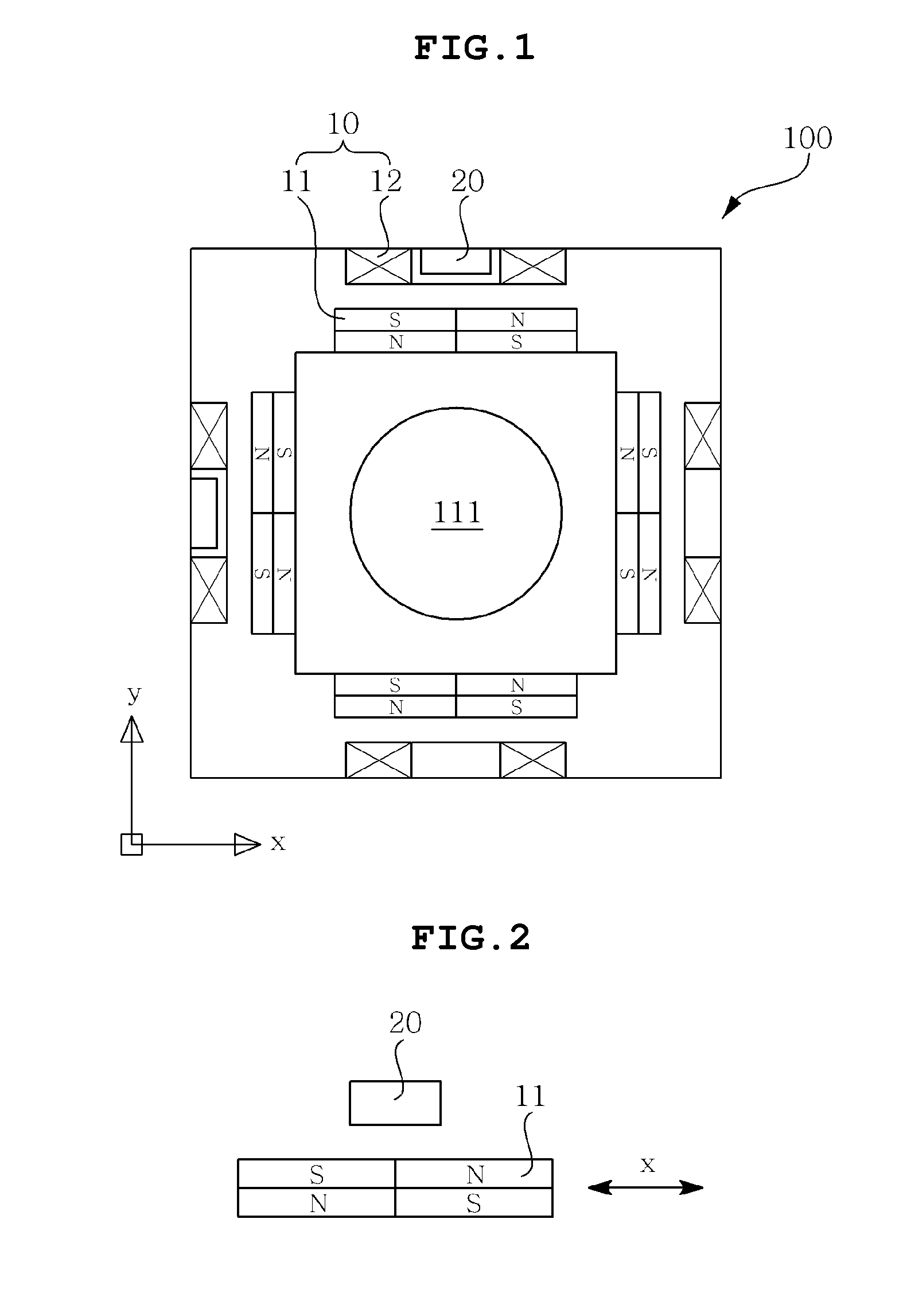

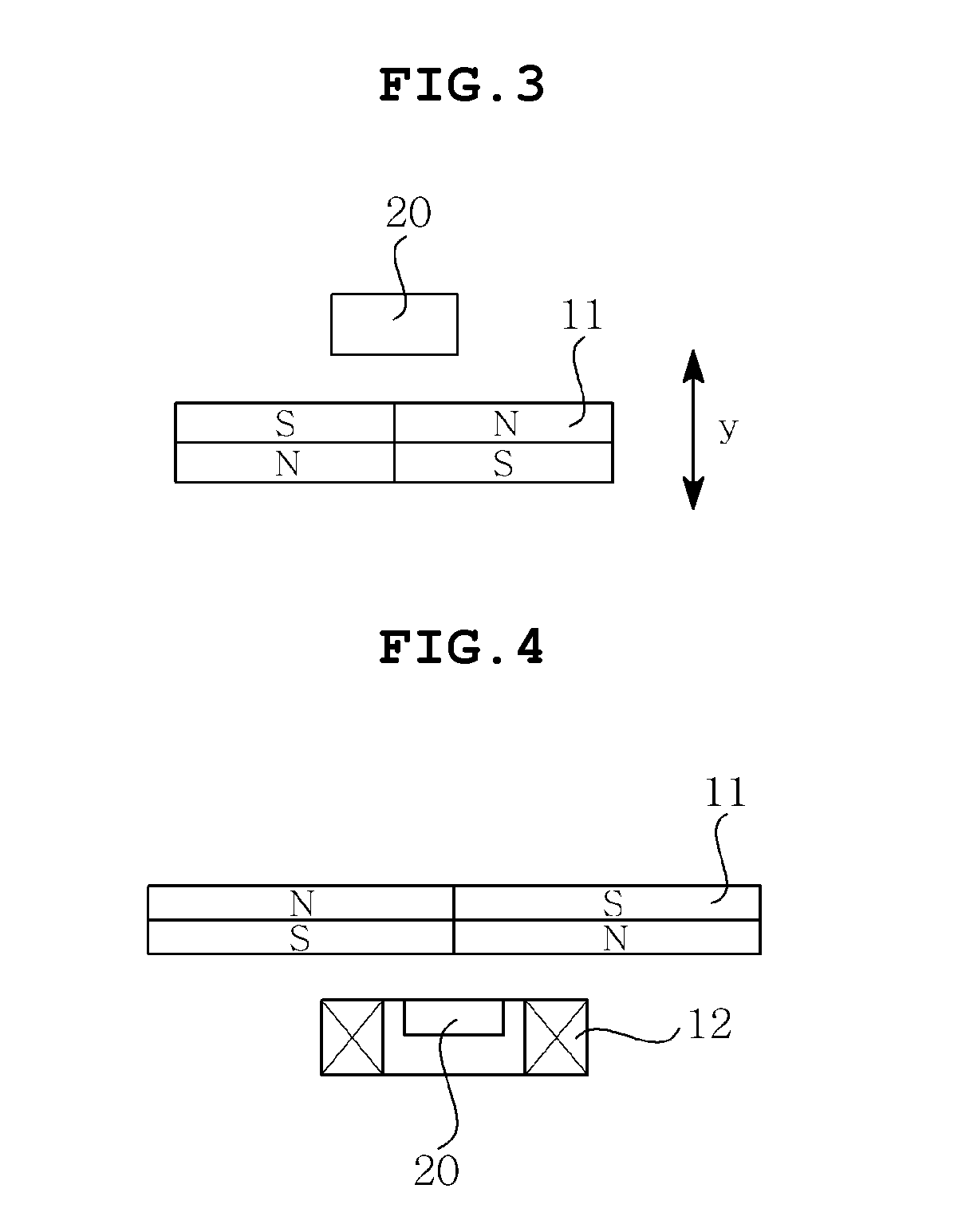

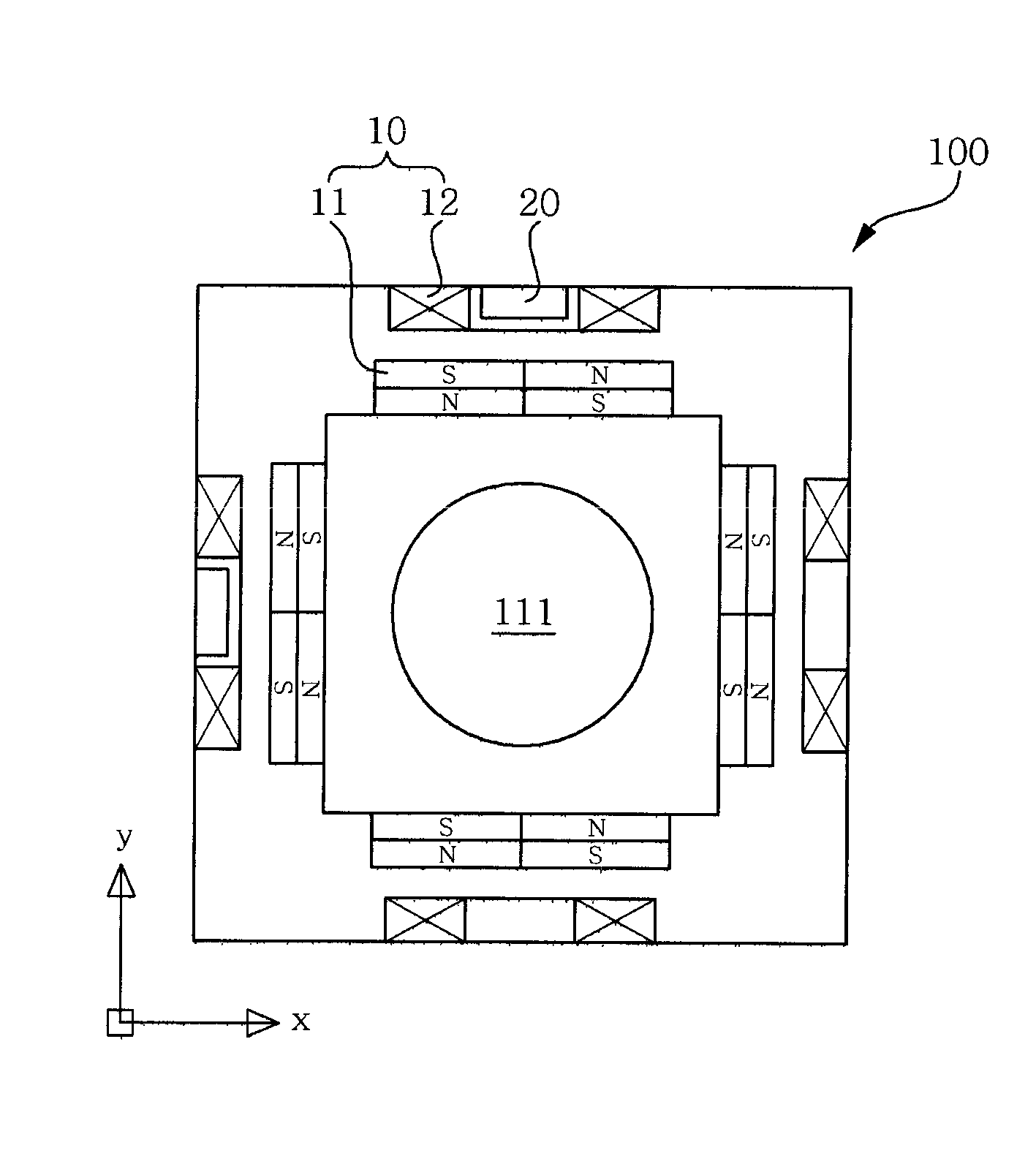

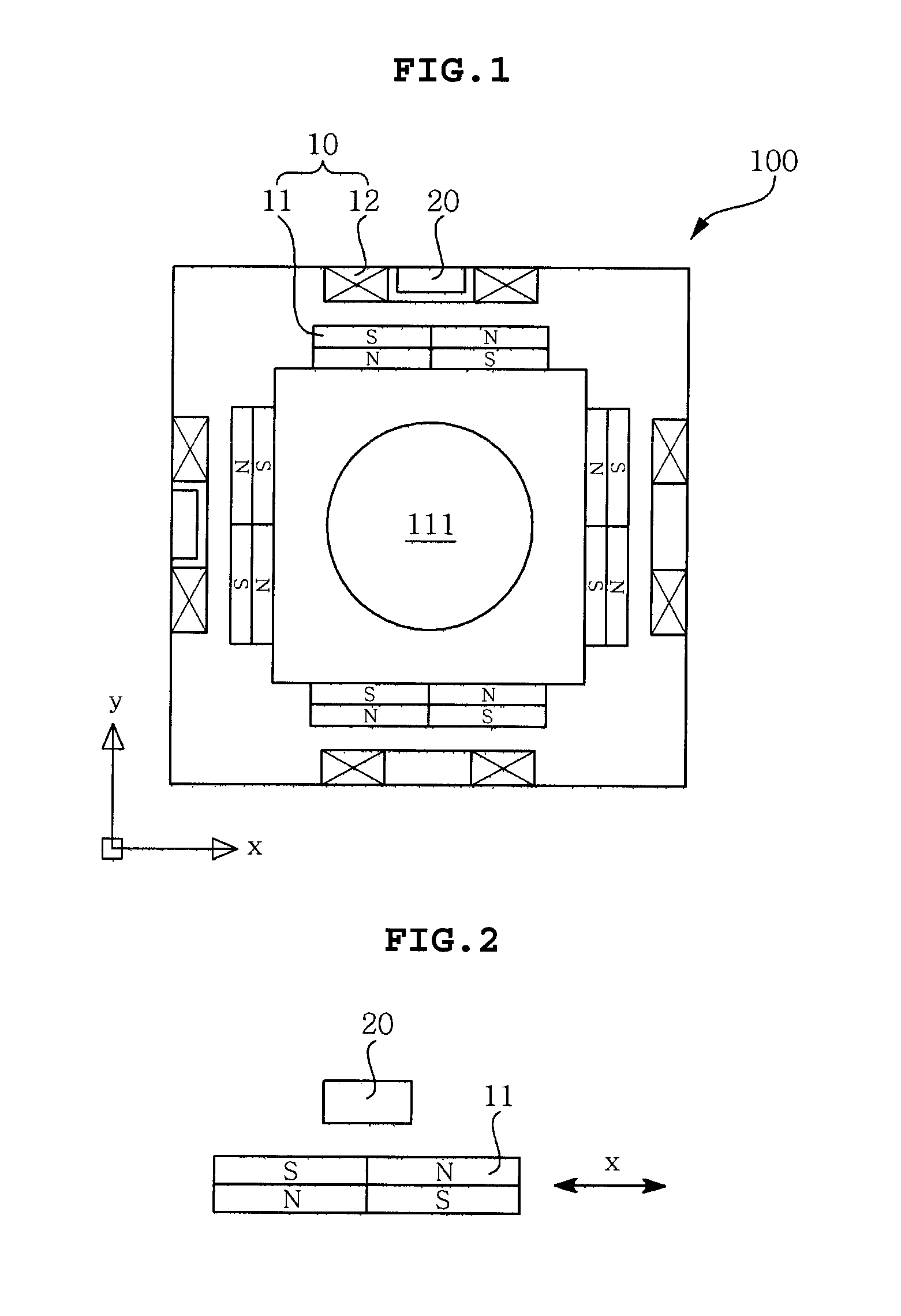

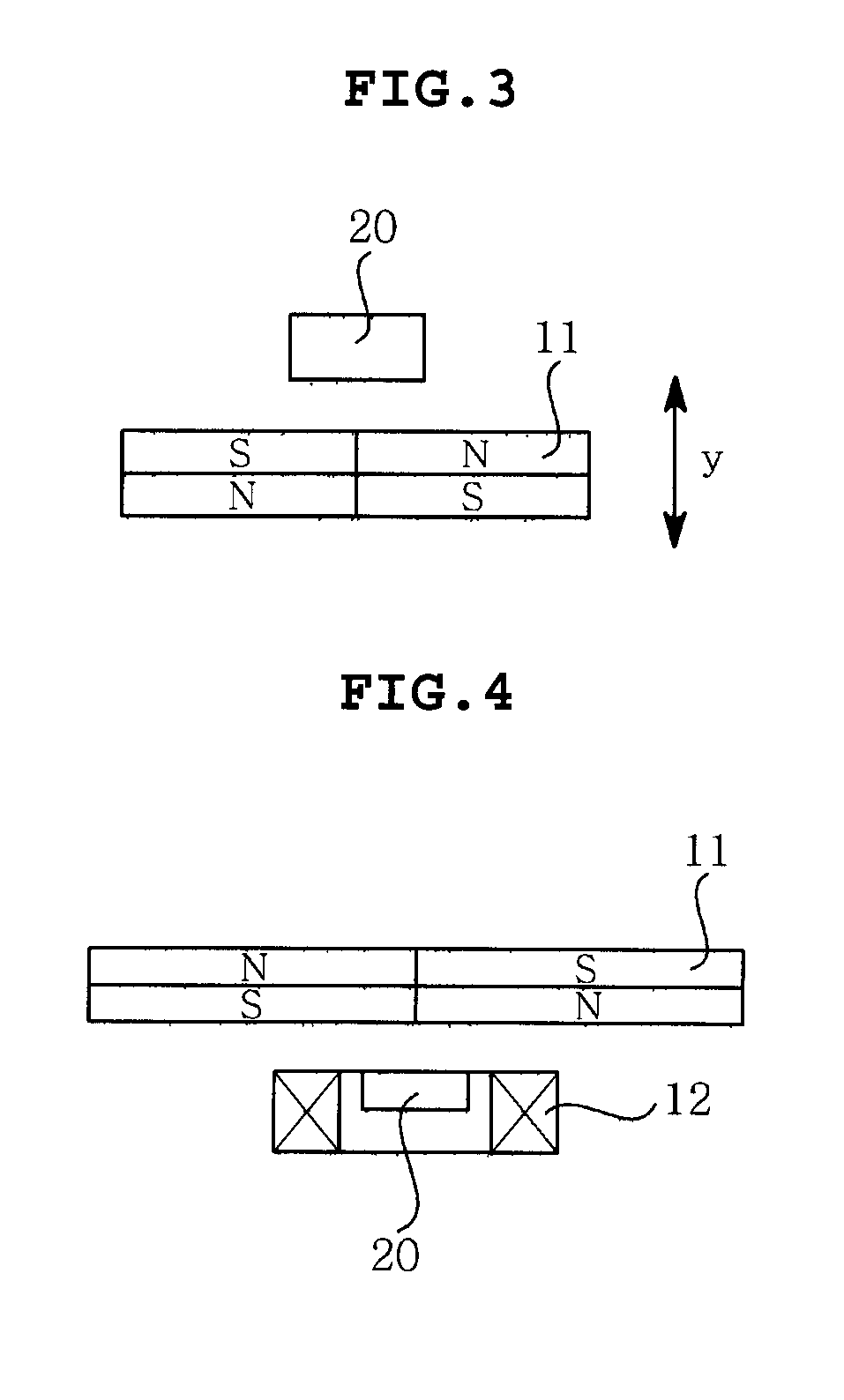

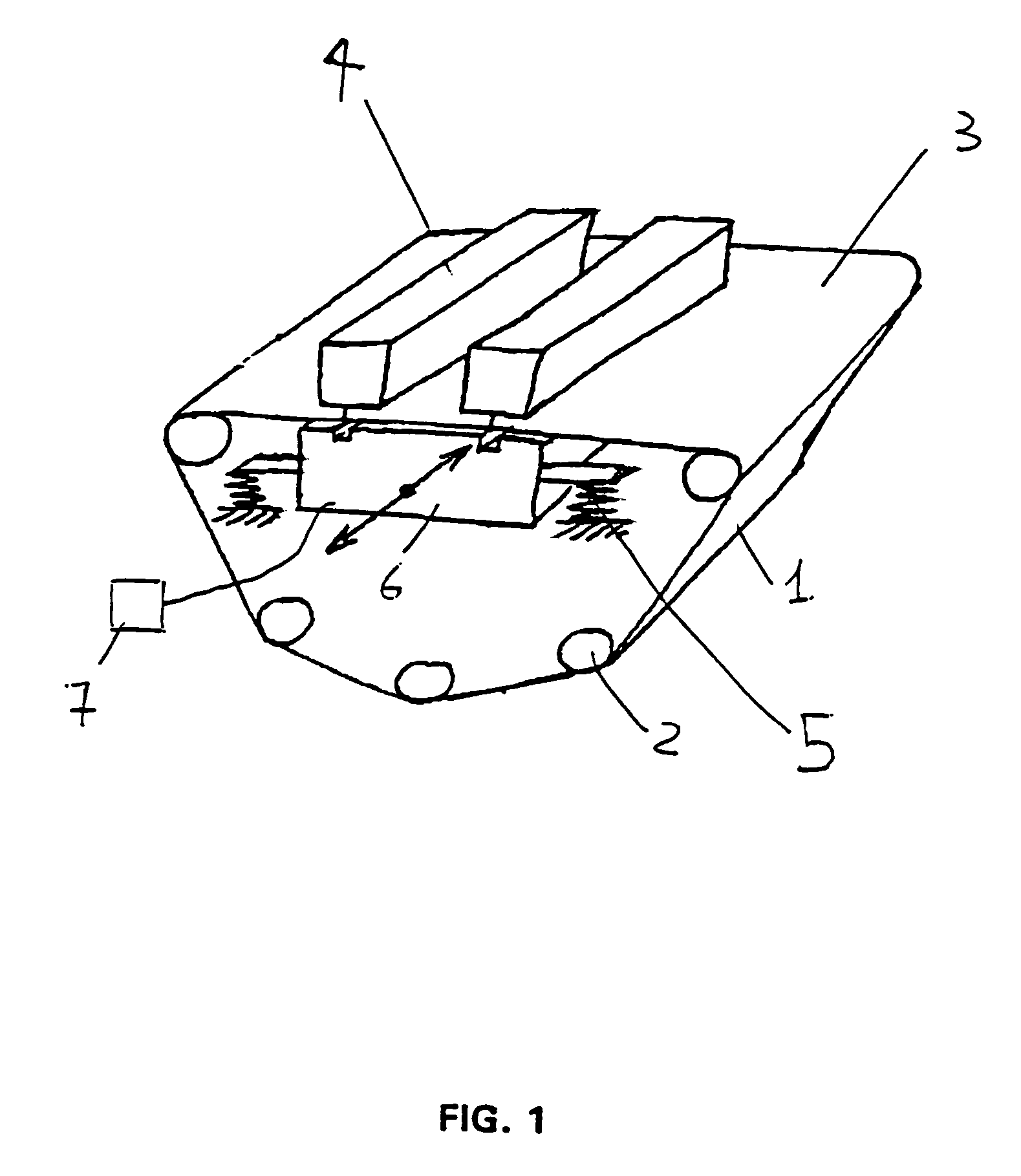

Optical image stabilizer detecting x direction displacement and y direction displacement of lens group

ActiveUS20160004091A1Thin profileConvenient ArrangementProjector focusing arrangementPermanent magnetsMagnetOptical image

An optical image stabilizer, in which a magnet and a coil are arranges such that they oppose each other. The Hall sensor is arranged such that one face thereof is opposed to one face of the magnet. The Hall sensor can easily detect the location of a group of lenses by generating a corresponding signal in response to a variation in magnetic force following a variation in the gap between magnets depending on the direction in which a group of lenses is driven, and simultaneously, in response to a variation in magnetic force that occurs when the group of lenses is displaced in the direction that intersects the direction of the gap.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Optical glass and lens using the same

The present invention has an object to provide an optical glass having excellent devitrification properties during high temperature forming and press moldability and capable of reducing weight and size of an optical system. The present invention relates to an optical glass comprising, in mass % on oxide basis; B2O3: 10 to 25%, SiO2: 0.5 to 12%, La2O3: 17 to 38%, Gd2O3: 5 to 25%, ZnO: 8 to 20%, Li2O: 0.5 to 3%, Ta2O5: 5 to 15% and WO3: 3 to 15, wherein (SiO2+B2O3) / (ZnO+Li2O) value which is a mass ratio of the total content of SiO2 and B2O3 to the total content of ZnO and Li2O is from 1.35 to 1.90.

Owner:ASAHI GLASS CO LTD

Optical image stablilizer detecting X direction displacement and Y direction displacement of lens group

ActiveUS9134587B2Thin profileConvenient ArrangementProjector focusing arrangementCamera focusing arrangementMagnetic tension forceMagnet

An optical image stabilizer, in which a magnet and a coil are arranged such that they oppose each other. The Hall sensor is arranged such that one face thereof is opposed to one face of the magnet. The Hall sensor can easily detect the location of a group of lenses by generating a corresponding signal in response to a variation in magnetic force following a variation in the gap between magnets depending on the direction in which a group of lenses is driven, and simultaneously, in response to a variation in magnetic force that occurs when the group of lenses is displaced in the direction that intersects the direction of the gap.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

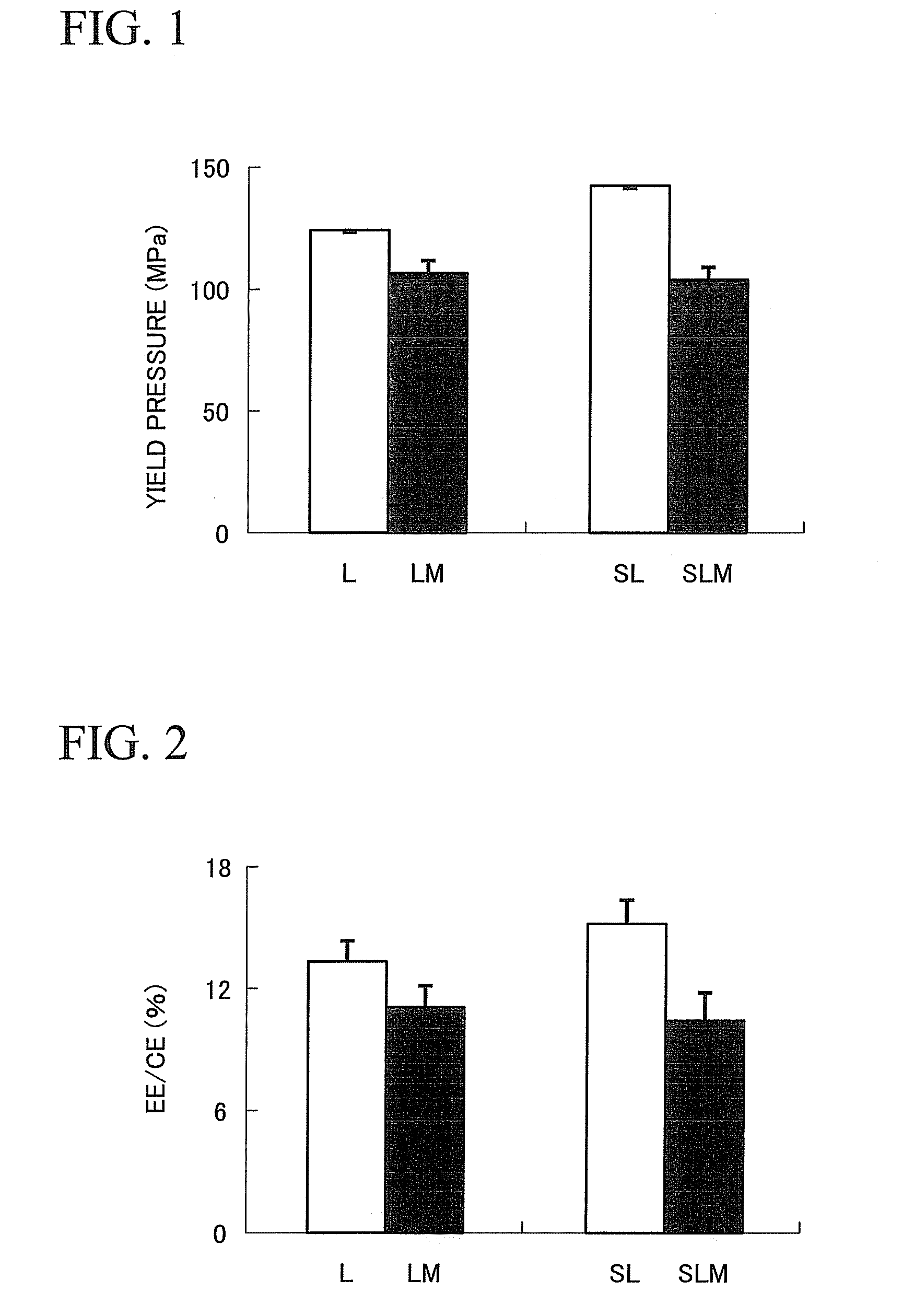

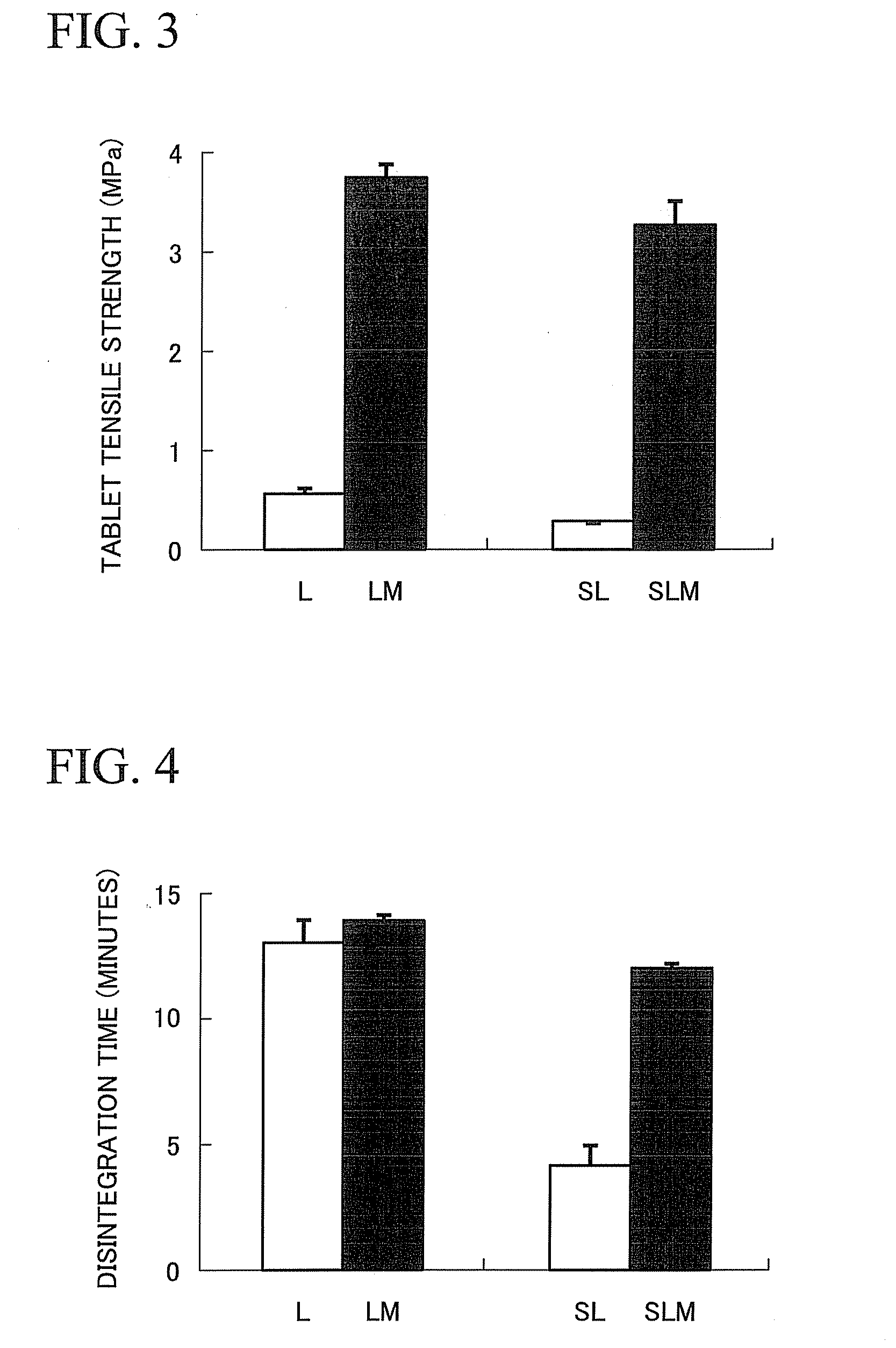

Hydroxyalkylcellulose microparticles

ActiveUS20120232167A1High strengthImprove suppression propertiesBiocidePill deliveryShock waveVolume average

Provided is a method of producing hydroxyalkylcellulose microparticles, the method including generating a pulse shock wave, and supplying a hydroxyalkylcellulose aqueous solution to the pulse shock wave generation region, thereby crushing and drying the hydroxyalkylcellulose aqueous solution. According to the production method, hydroxyalkylcellulose microparticles having a volume-average particle size of at least 0.1 μm but less than 15 μm are obtained. By mixing the hydroxyalkylcellulose microparticles with a principal agent and subjecting the resulting mixture to a tablet compression, a solid preparation having excellent tensile strength and disintegration properties can be obtained.

Owner:NIPPON SODA CO LTD +1

Method making it possible to produce the ideal curvature of a rod of vertebral osteosynthesis material designed to support a patient vertebral column

ActiveUS20160235479A1Easily impartedImpart the appropriate curvature to a straight rod easilyImage enhancementImage analysisBiomedical engineeringMaterial Design

According to the invention, the process includes the steps of : a) taking a sagittal preoperative x-ray of the vertebral column of the patient to be treated, extending from the cervical vertebrae to the femoral heads; b) on that x-ray, identifying points on S1, S2, T12 et C7 ; c) depicting, on the said x-ray, curved segments beginning at the center of the plate of S1 et going to the center of the plate of C7 ; e) identifying, on that x-ray, the correction(s) to be made to the vertebral column, including the identification of posterior osteotomies to make; f) pivoting portions of said x-ray relative to other portions of that x-ray, according to osteotomies to be made; g) performing, on said x-ray, a displacement of the sagittal curvature segment extending over the vertebral segment to be corrected; h) from a straight vertebral rod (TV), producing the curvature of that rod according to the shape of said sagittal curvature segment in said displacement position.

Owner:MEDICREA INT SA

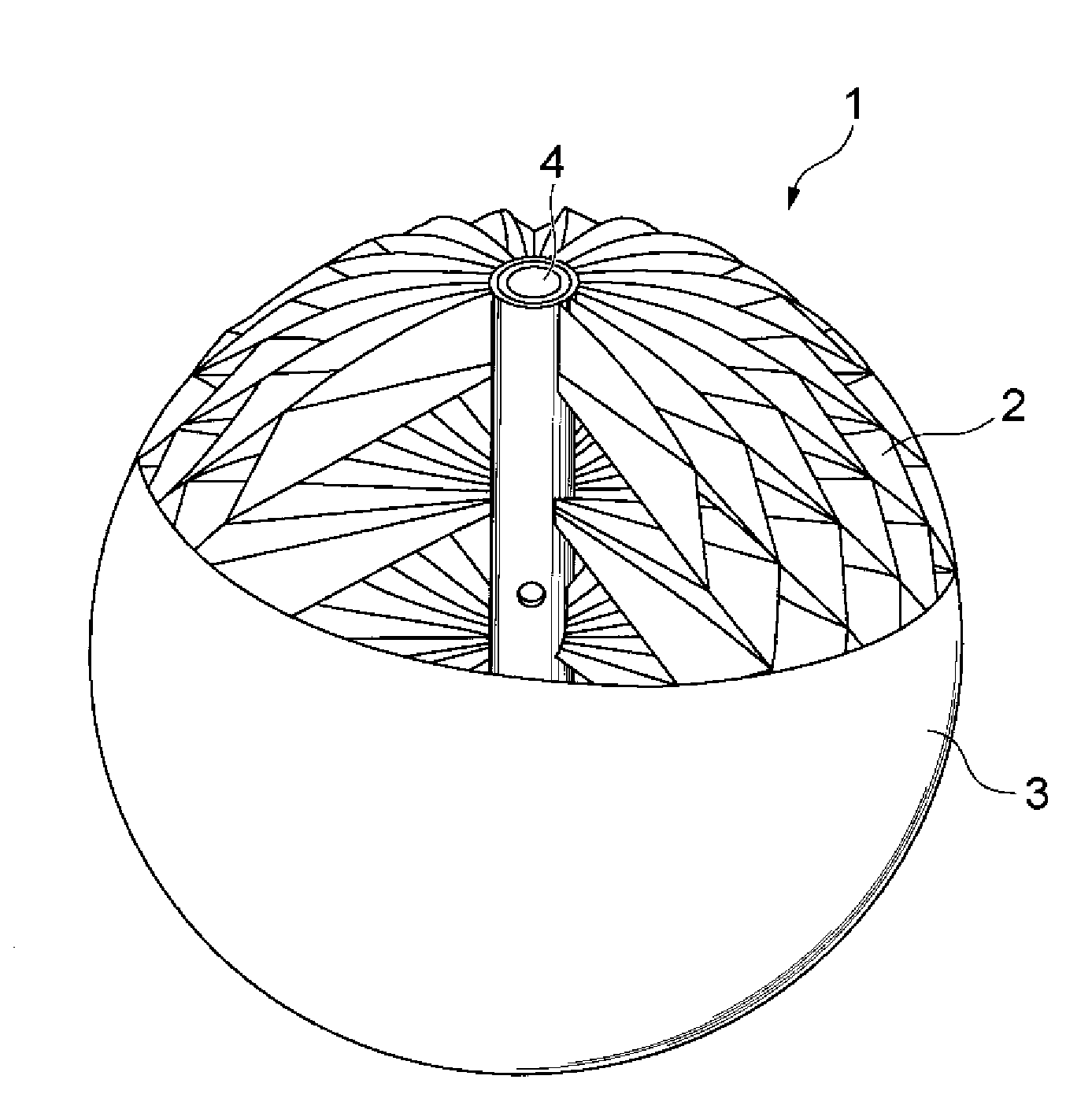

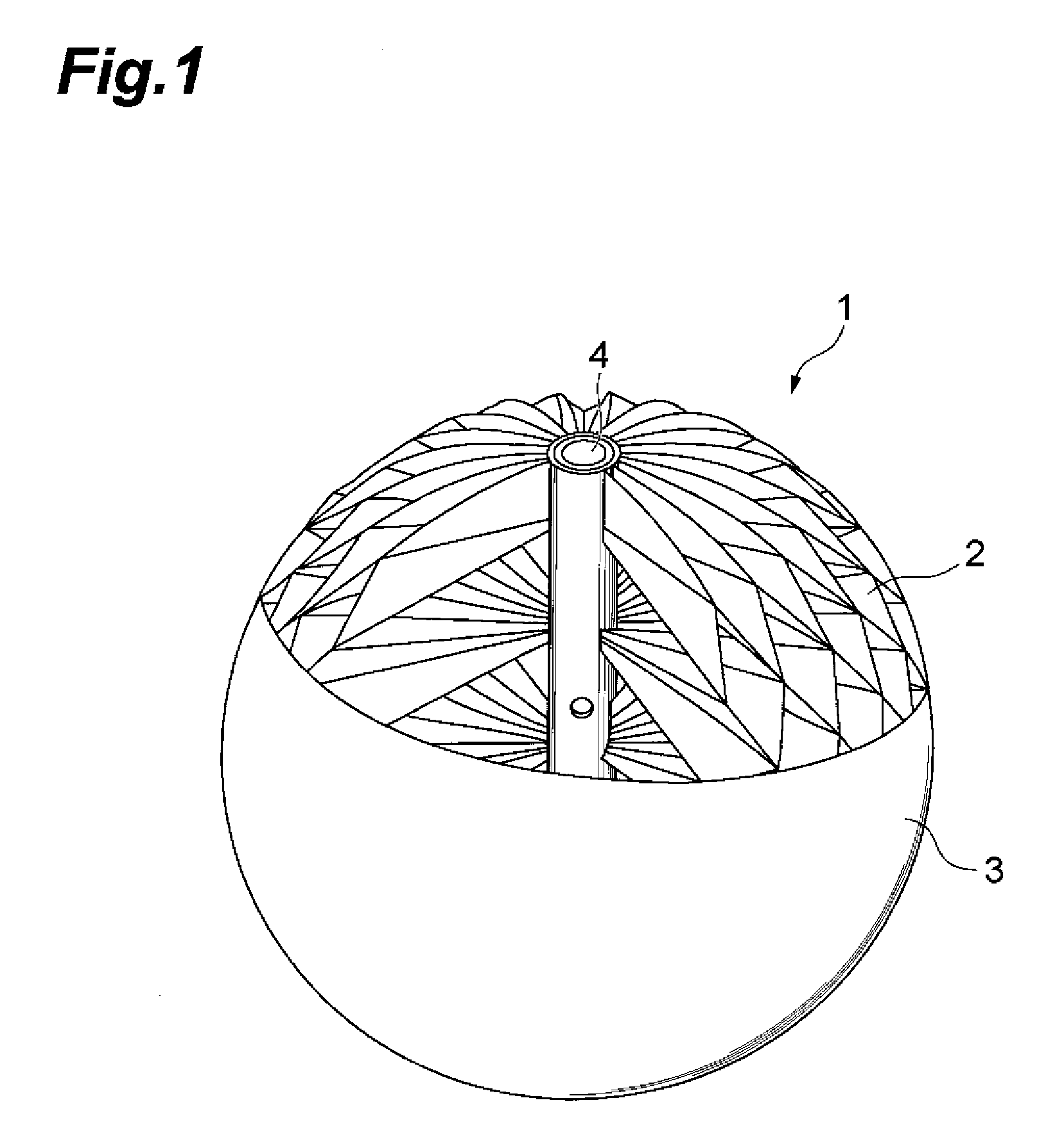

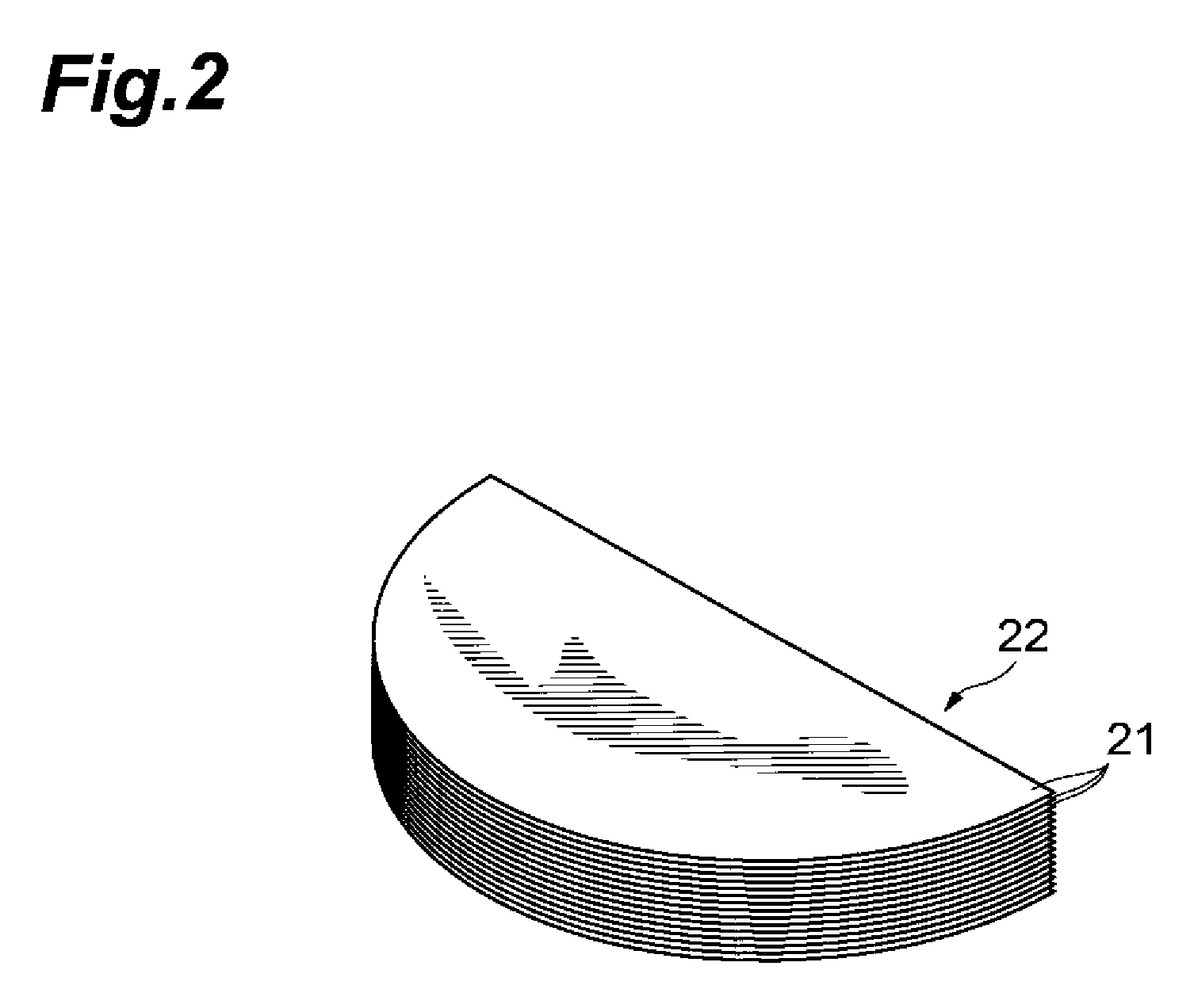

Method for producing resin structure

InactiveUS7695662B2Easy to shapeEasily impartedPaper/cardboard articlesWood working apparatusInternal pressureHoneycomb

A macrocell structure 20 having a honeycomb form is preheated to cure to a cure depth falling within a range where a flexibility of prepregs in the macrocell structure remains. Subsequently, prepregs 31, 32 are arranged along a side wall of the preheated macrocell structure 20, so as to make a preliminary structure 40. Then, the preliminary structure 40 is heated while the inside of the prepregs 31, 32 in the preliminary structure 40 is vacuumed. Thereafter, the preliminary structure 40 is heated while imparting an internal pressure thereto within a mold 5, so as to be cured, whereby a resin structure 1 is produced.

Owner:TOYOTA JIDOSHA KK

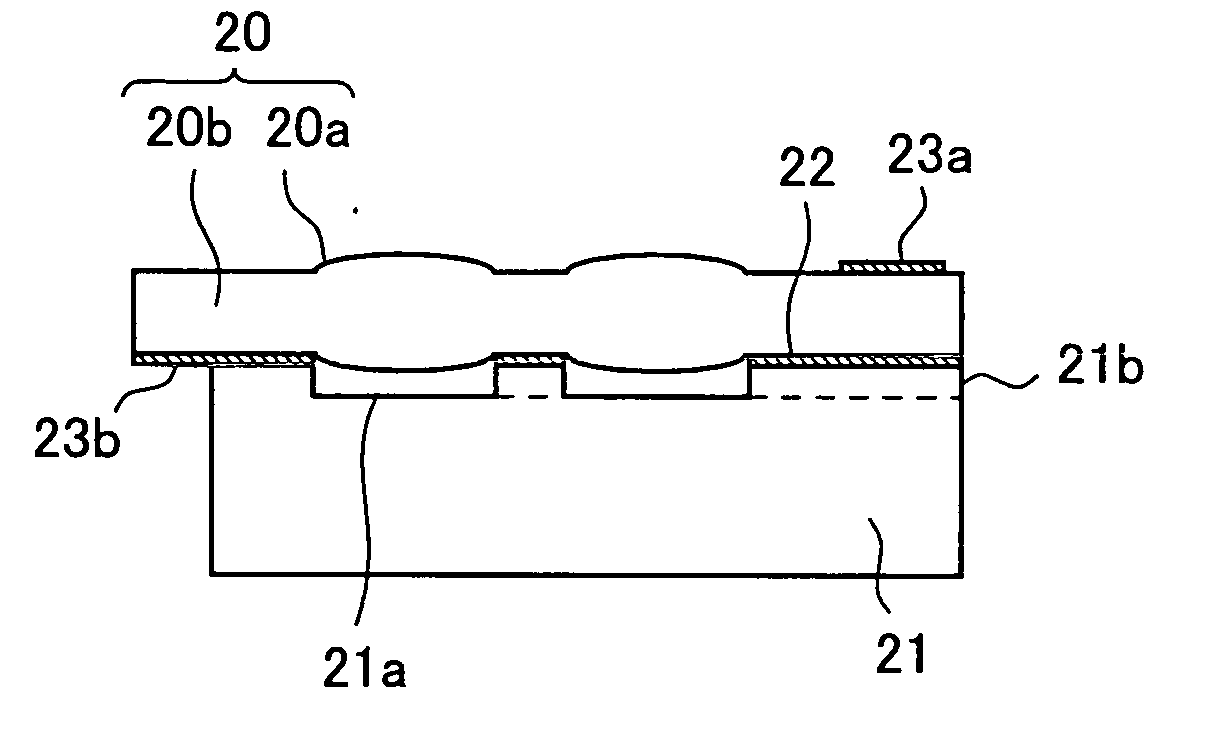

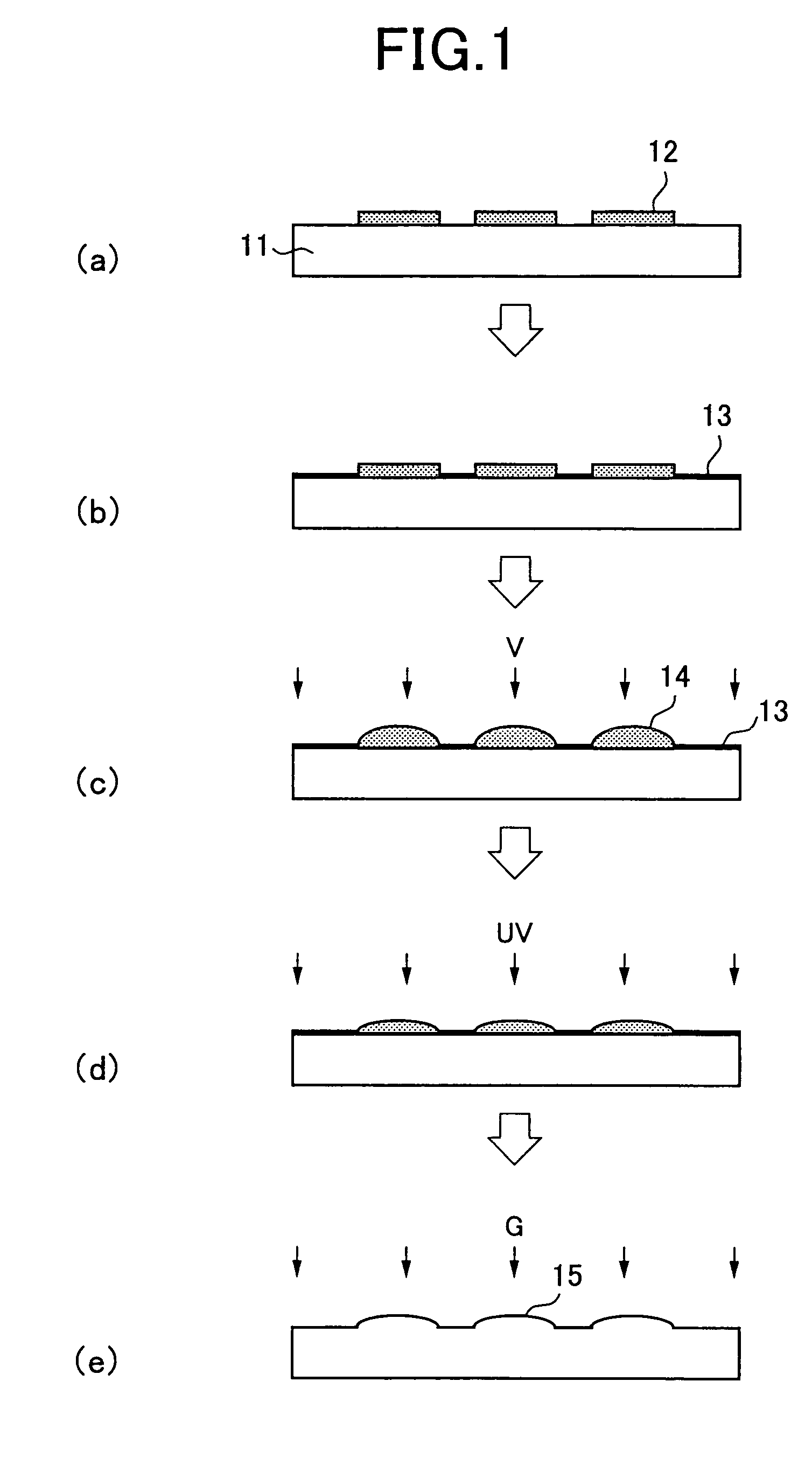

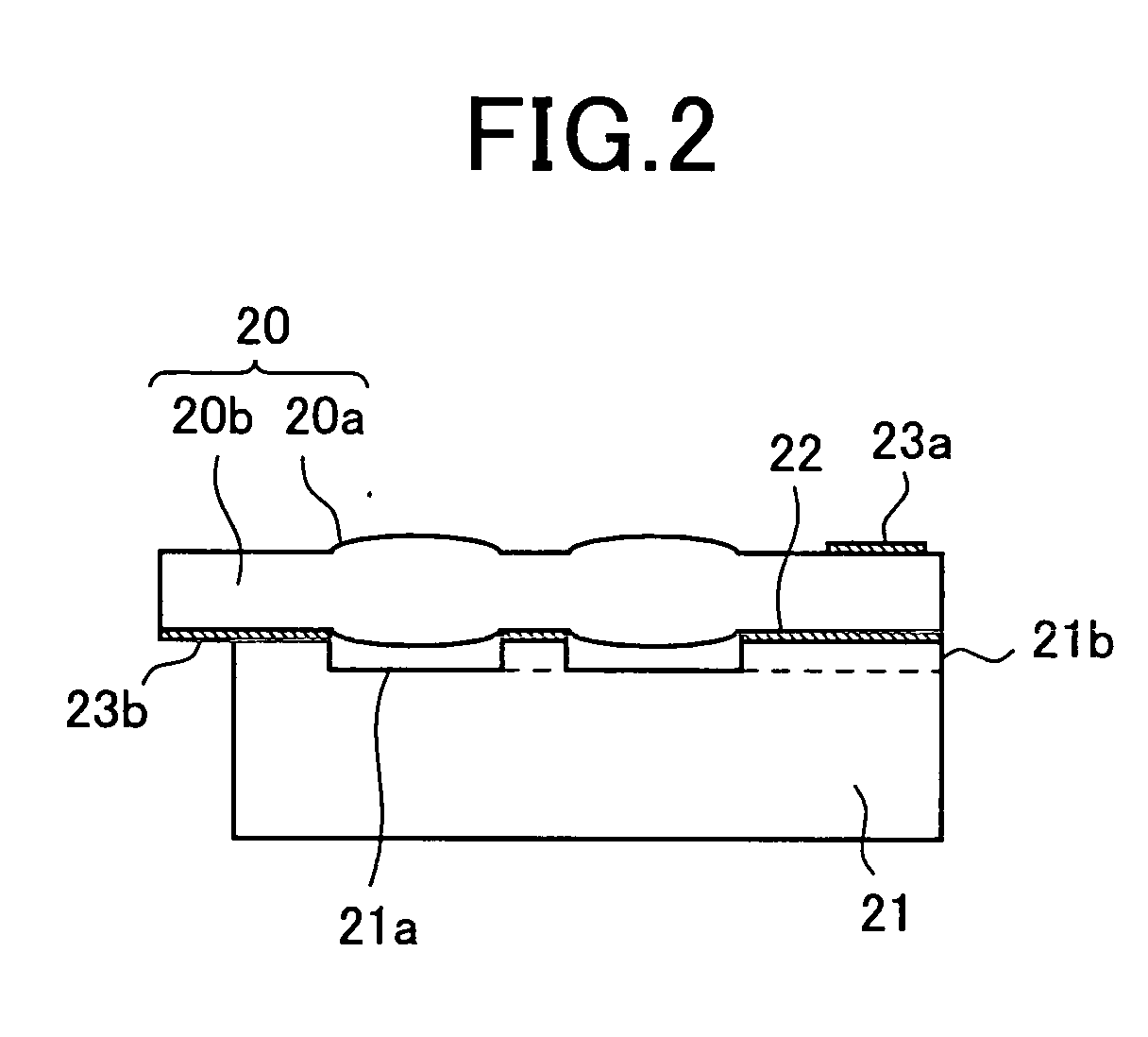

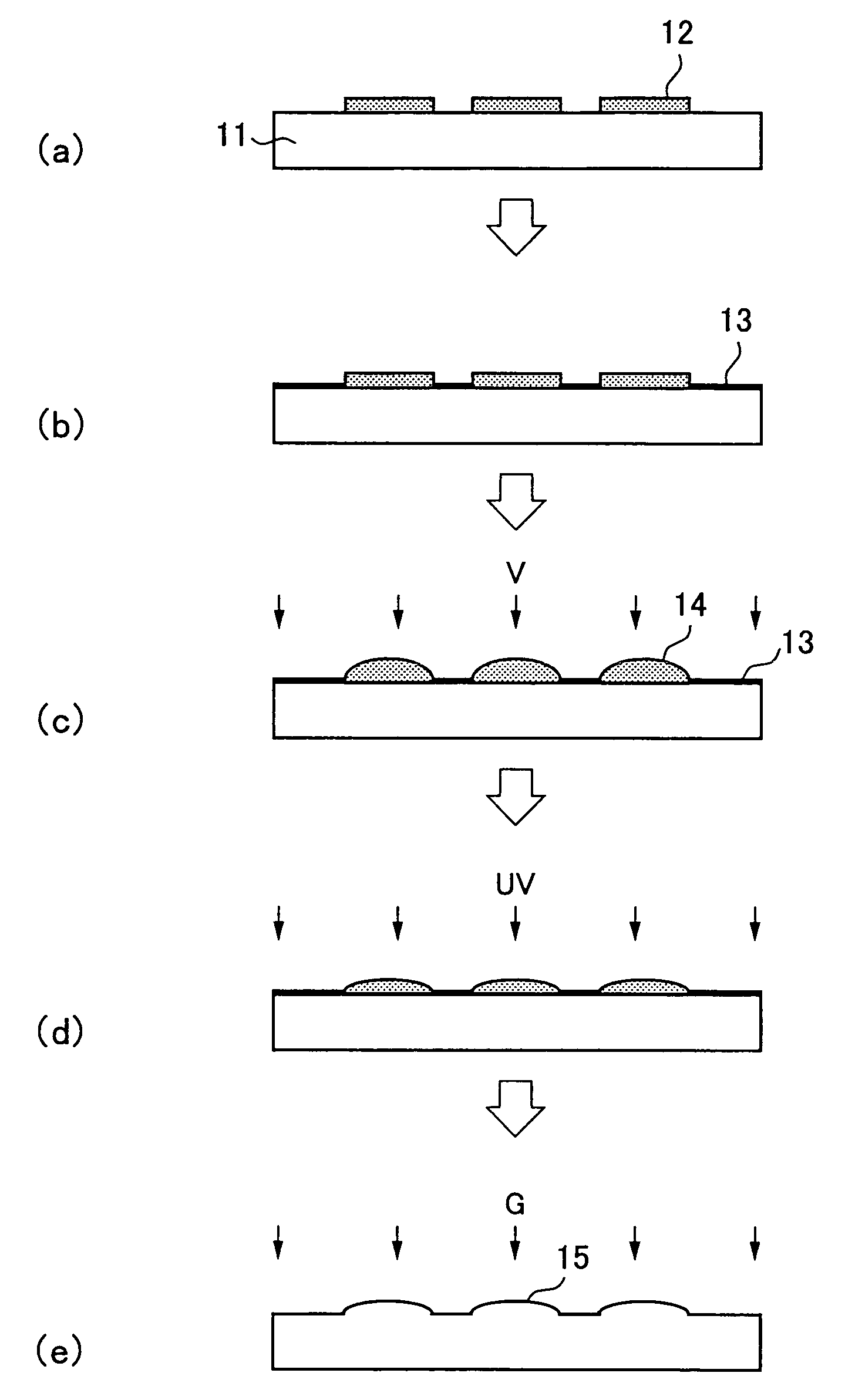

Method for fabricating piezoelectric element

InactiveUS20070130739A1Effective controlEasily impartedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesSolvent vaporSpurious oscillations

A masking agent is applied as a patterned film 12 to a surface of piezoelectric material 11 to be processed, fluidized by contact with a solvent vapor V and dressed to a domed mask 14 by its surface tension. When the piezoelectric material is dry etched together with the domed mask 14, its surface is processed to a convex profile corresponding to thickness distribution of the domed mask 14. Distribution and shape of the domed mask 14 is controlled by treating the piezoelectric material 11 with an oil repellant 13 so as to limit reflow of the masking agent to a specified region(s). The processed piezoelectric material has a surface profile with a big mass at its center suitable for principal oscillation without spurious oscillation.

Owner:JAPAN SCI & TECH CORP

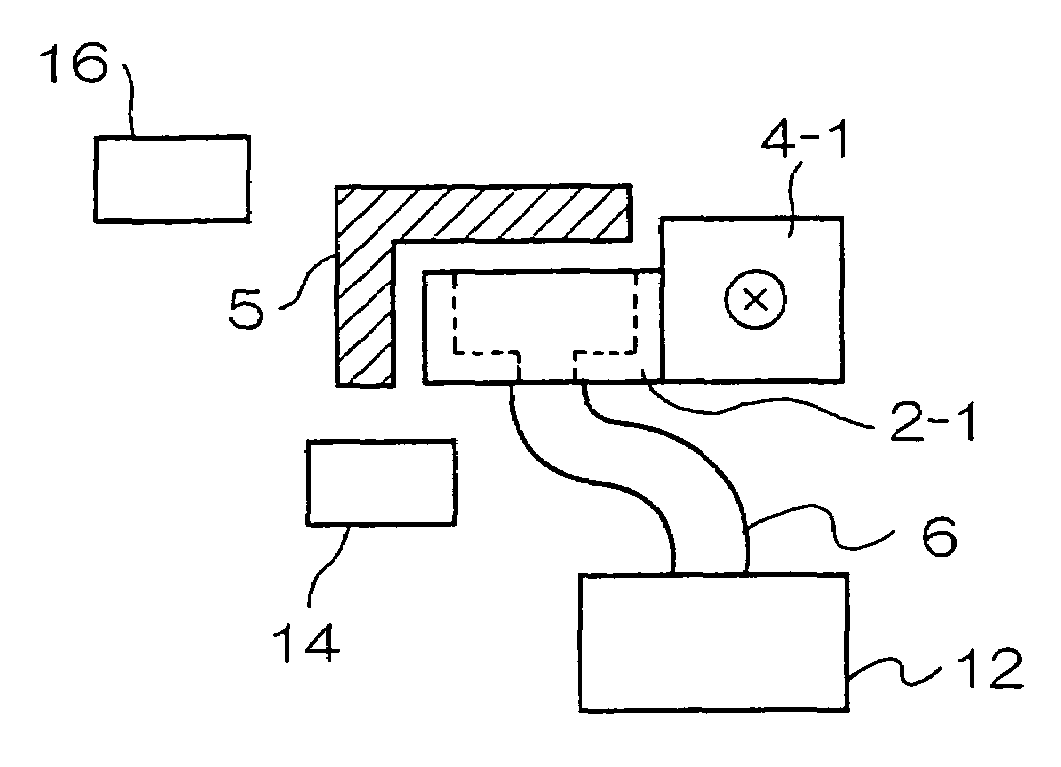

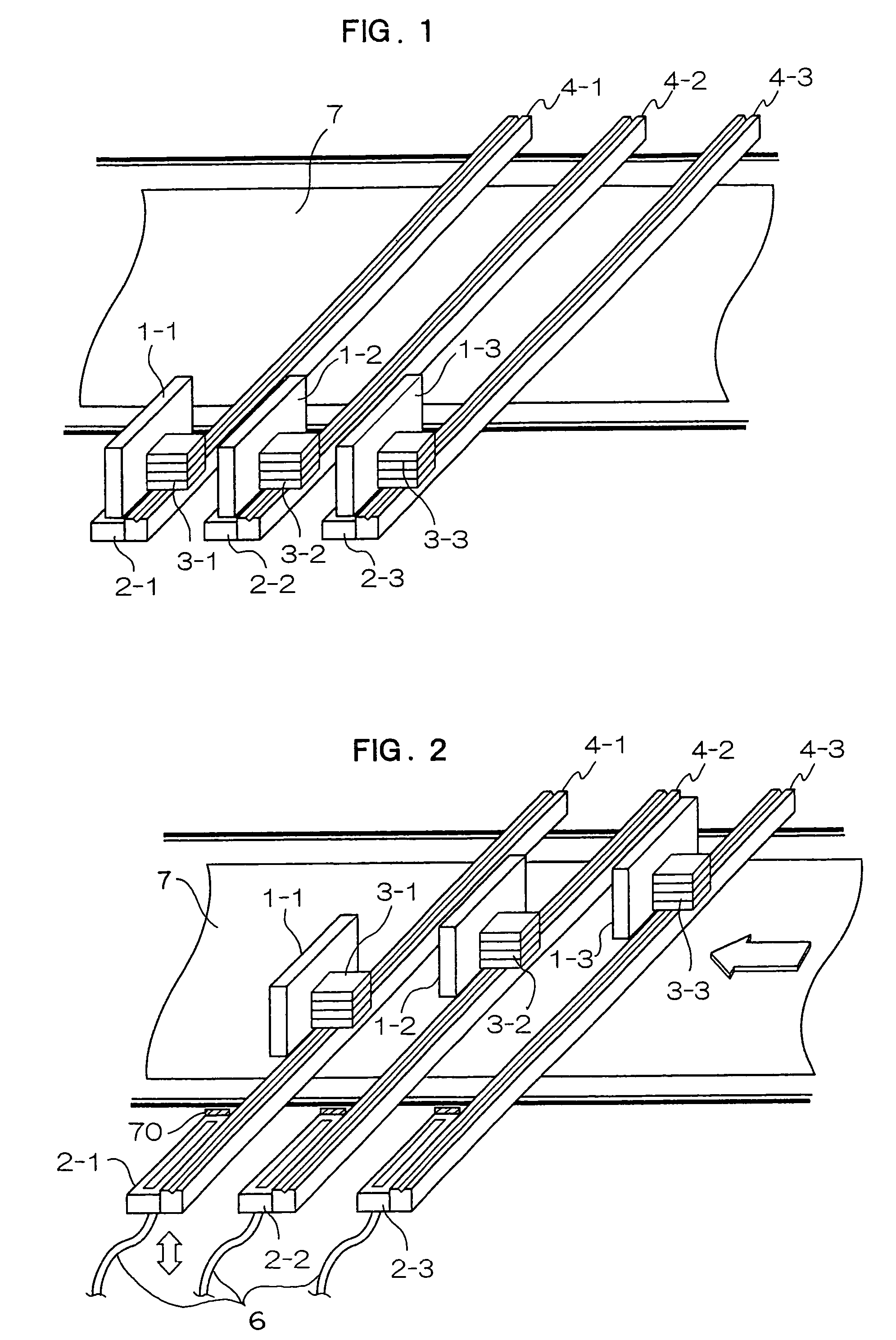

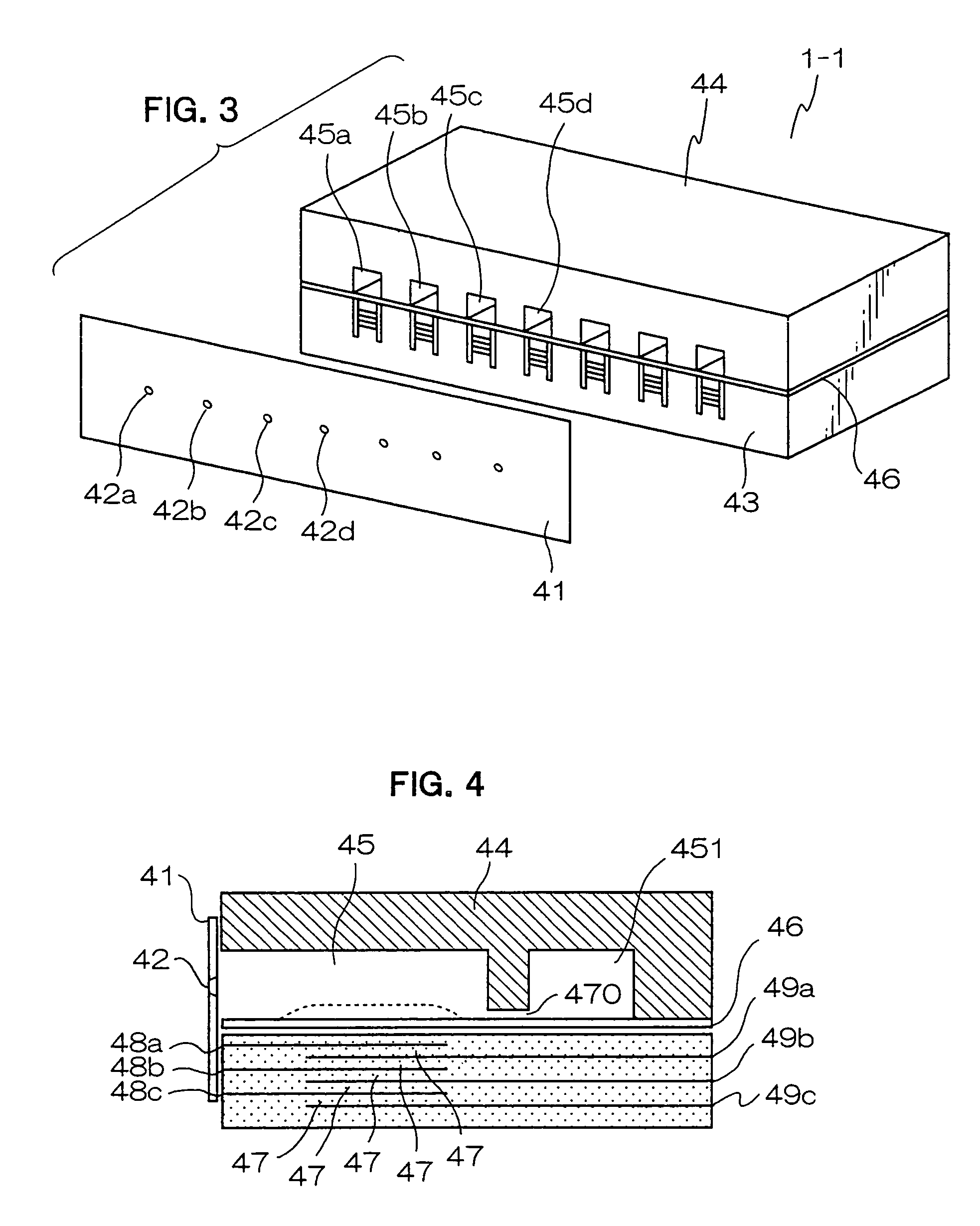

Ink-jet line printer and image forming apparatus using the same

An ink-jet line printer (30) is constituted by multiple ink-jet heads (1-1 to 1-3). Actuators (3-1 to 3-3) are arranged so as to be moved between a home position and a print position, and backup mechanisms (2-1 to 2-3) are arranged at home positions. In this ink-jet line printer, the ink-jet heads can be protected and recovered by backup mechanisms, thus making high-speed continuous printing possible. Even though the backup mechanisms are incorporated, a compact apparatus can still be achieved.

Owner:FUJIFILM BUSINESS INNOVATION CORP

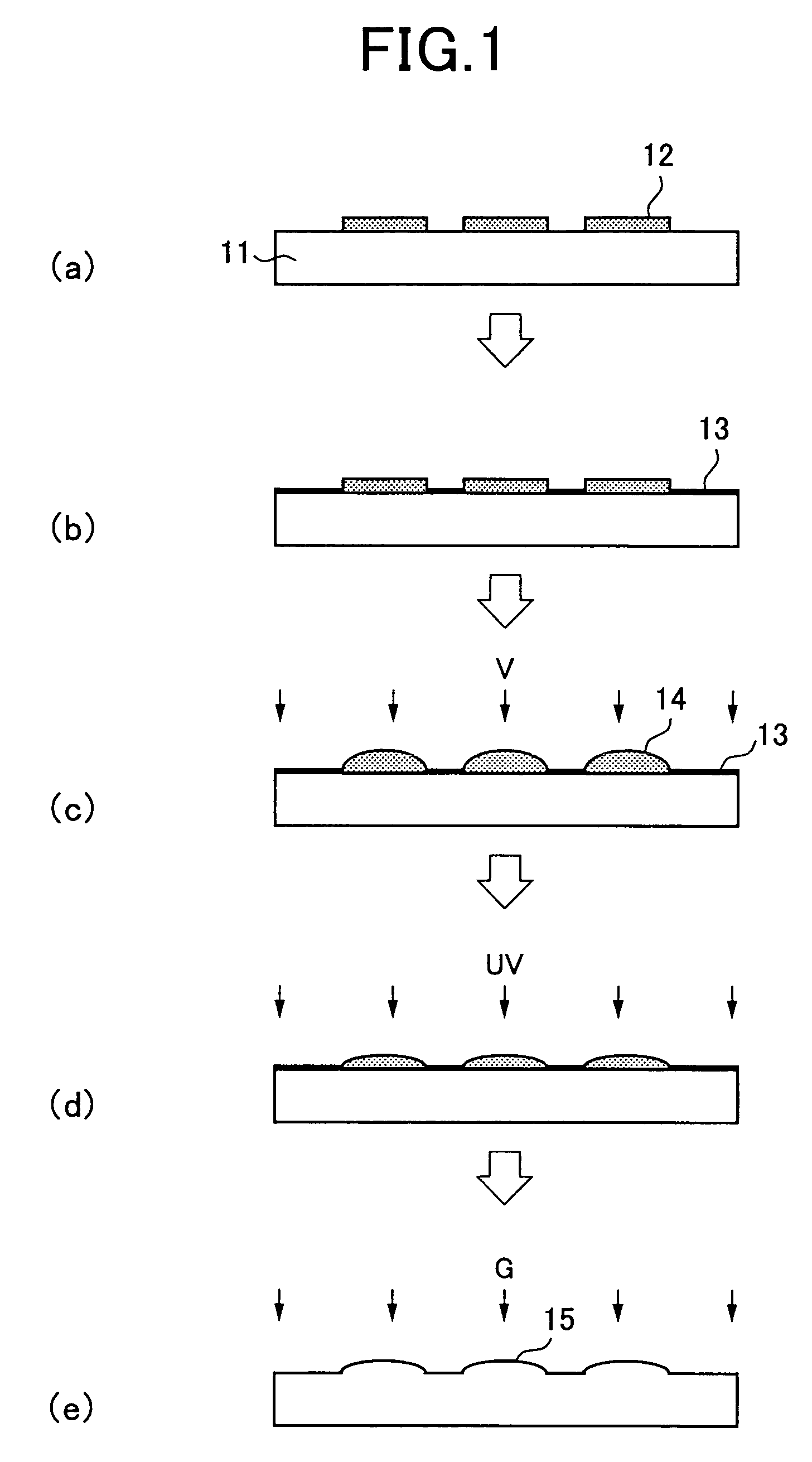

Method for fabricating piezoelectric element

InactiveUS7770273B2Effective controlEasily impartedPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksInert gas dilutionSolvent

A piezoelectric element is manufactured by applying a masking agent to a surface of a piezoelectric material to form a film of the masking agent on the surface of the piezoelectric material. The film of the masking agent is patterned into a masking pattern. Oil repellent is selectively applied to surface portions of the substrate which are not covered with the patterned film. The patterned film is held in contact with a vapor of a solvent for the masking agent, diluted with an inert gas, to fluidize the film to a domed shape on the surface of the piezoelectric material. The diluted vapor is formed by bubbling the solvent with the inert gas. The dome-shaped film is then cured and the piezoelectric material is dry etched together with the cured film to process the piezoelectric material into a three-dimensional convex profile corresponding to the thickness distribution of the domed shape.

Owner:JAPAN SCI & TECH CORP

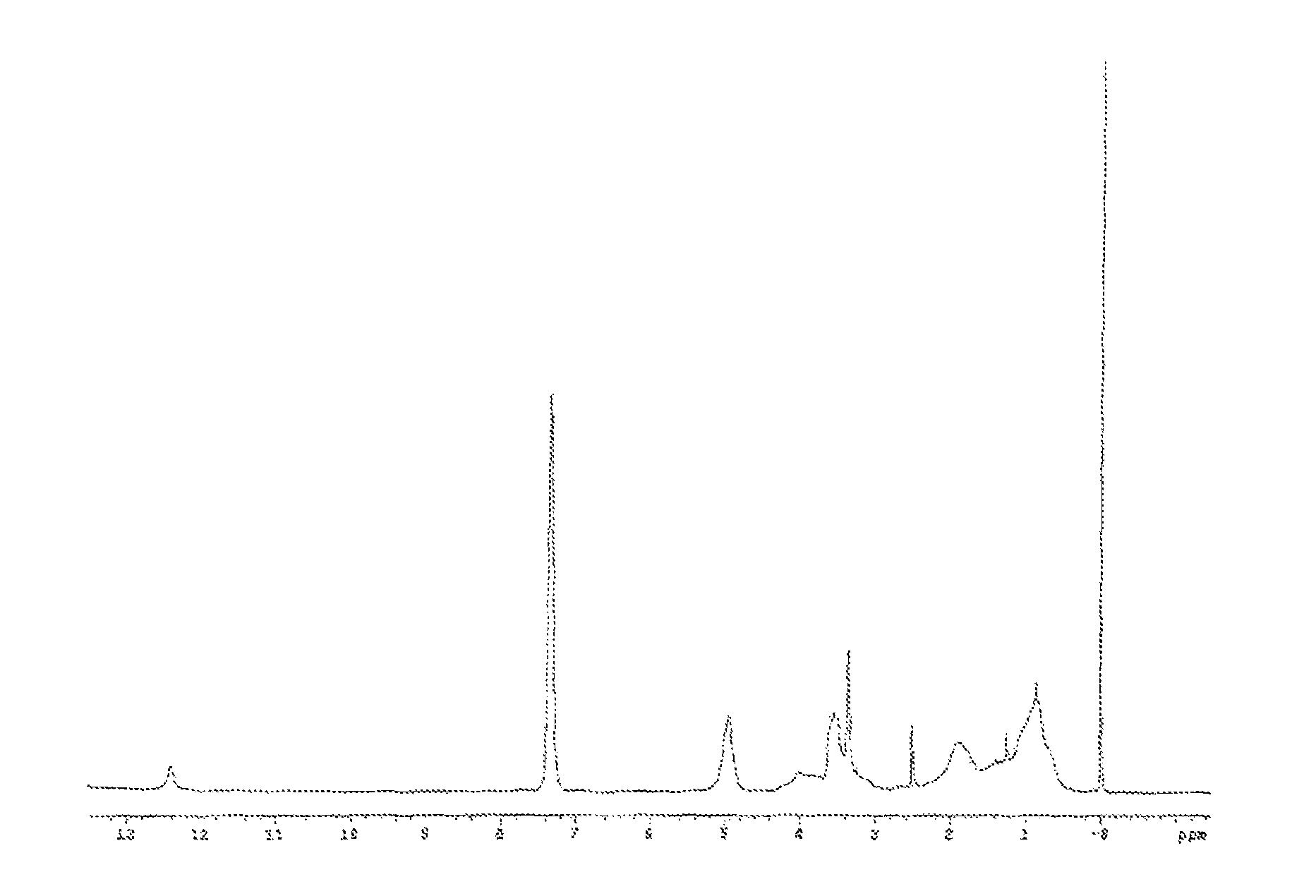

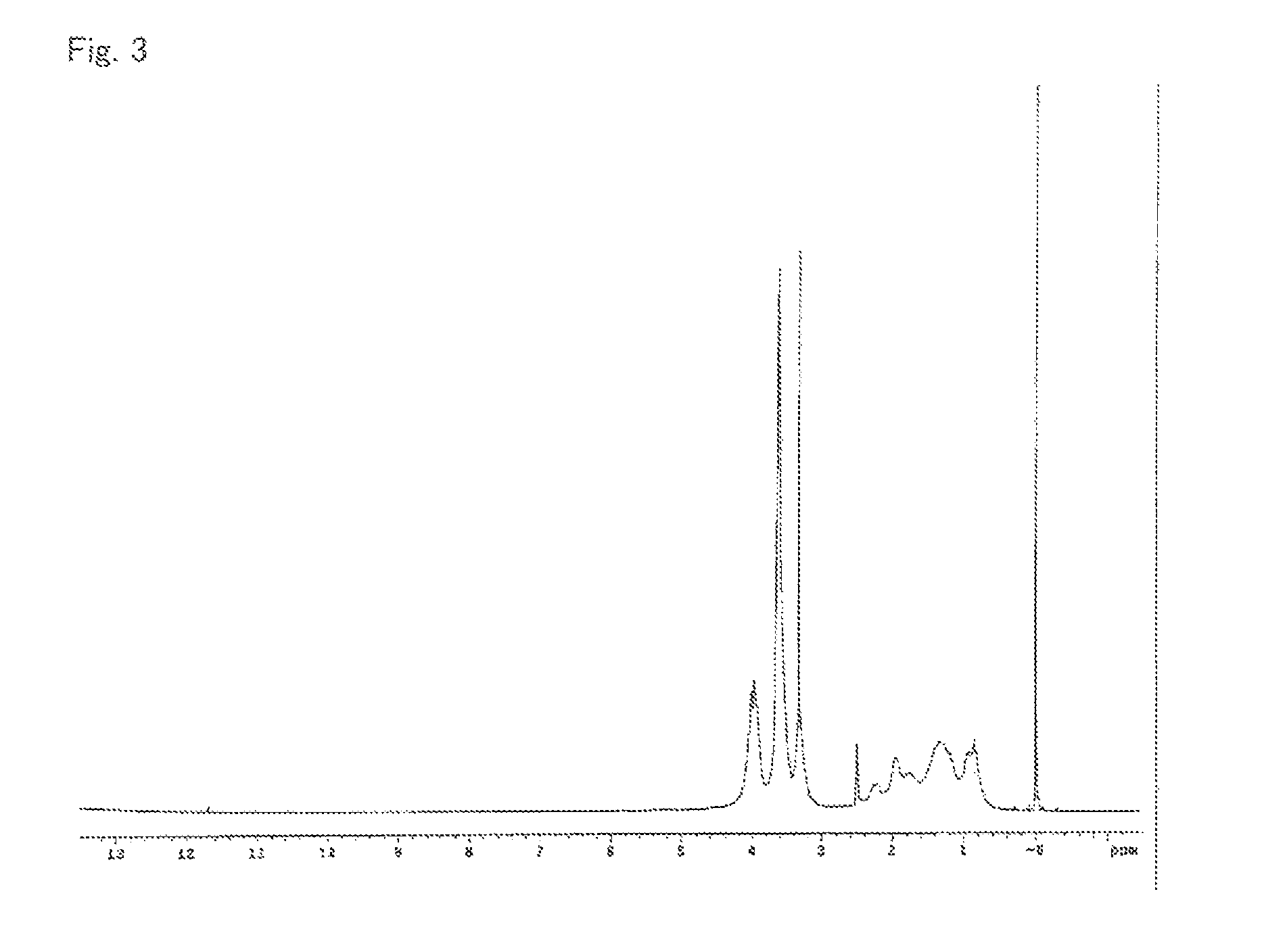

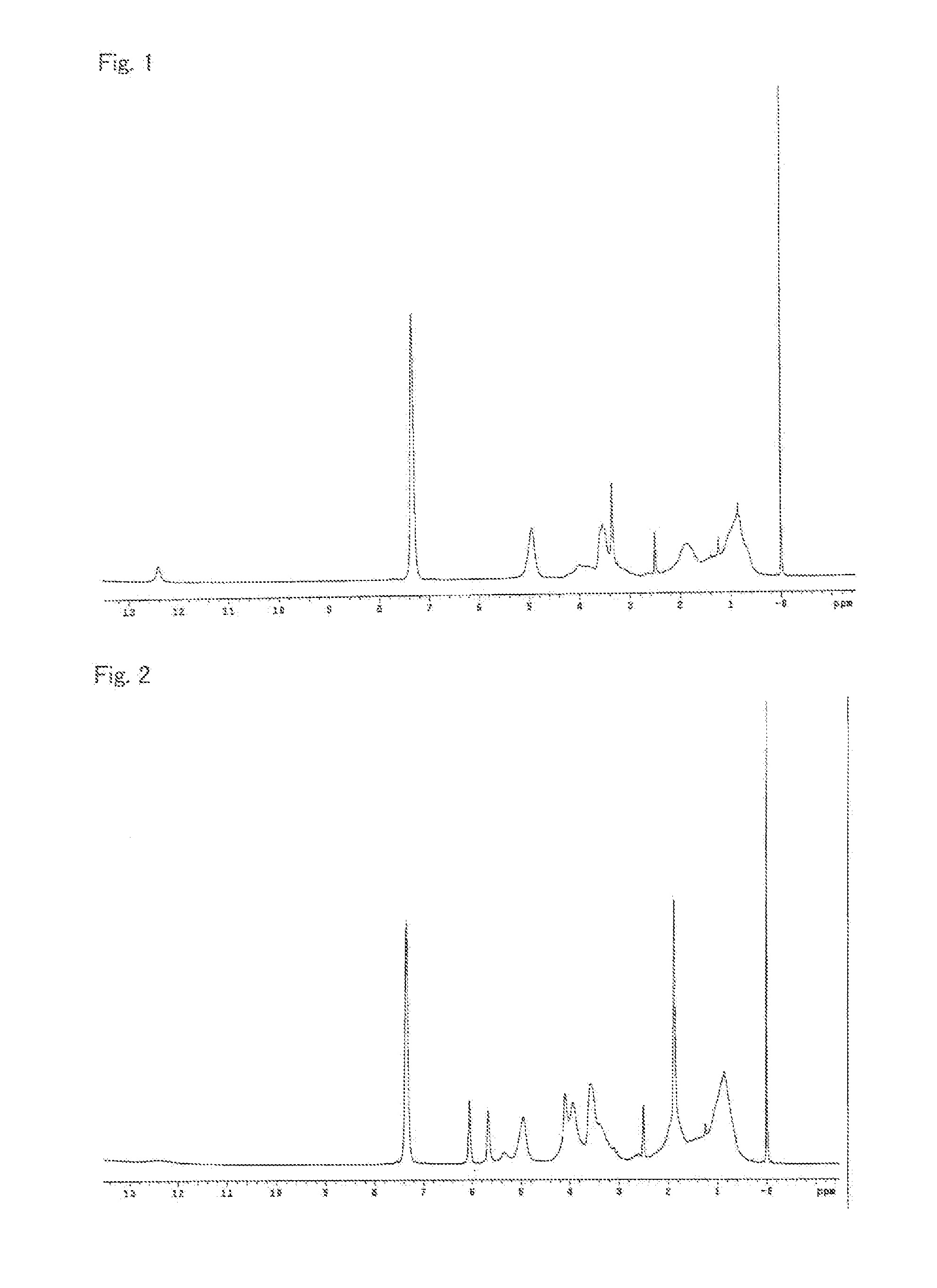

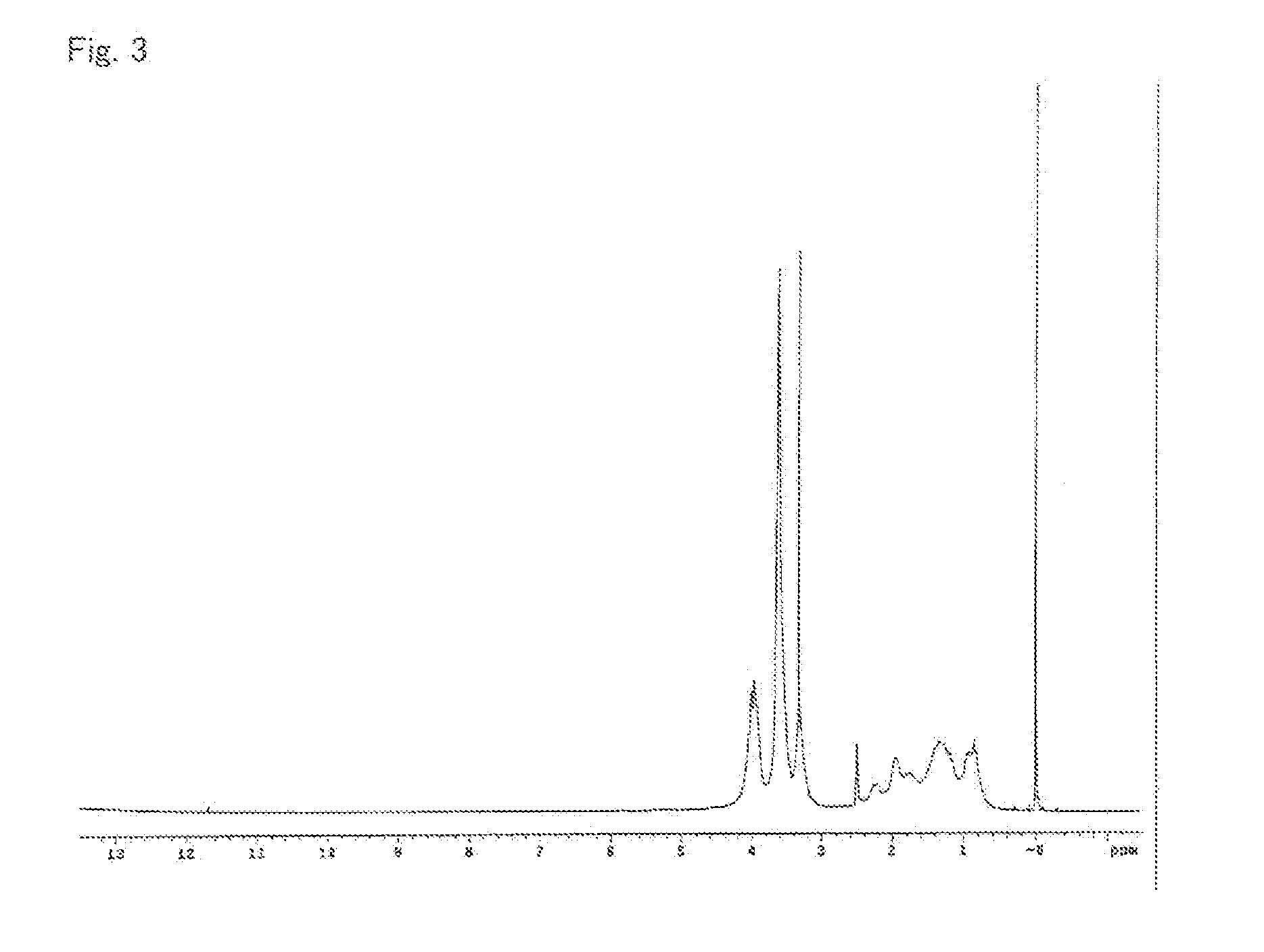

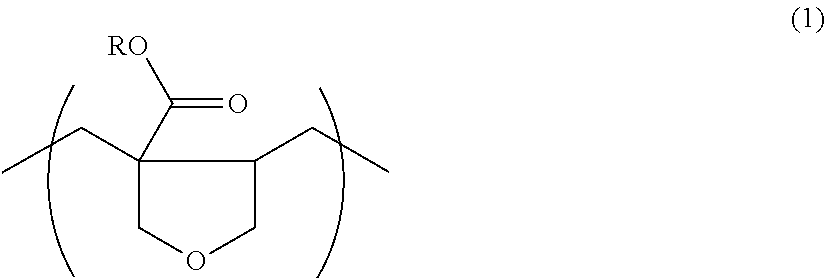

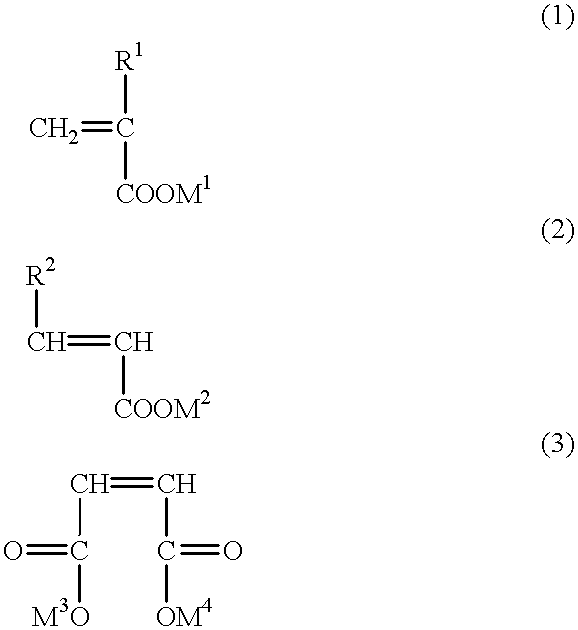

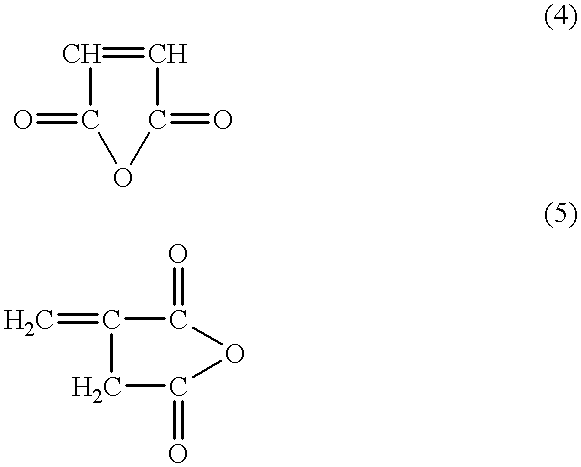

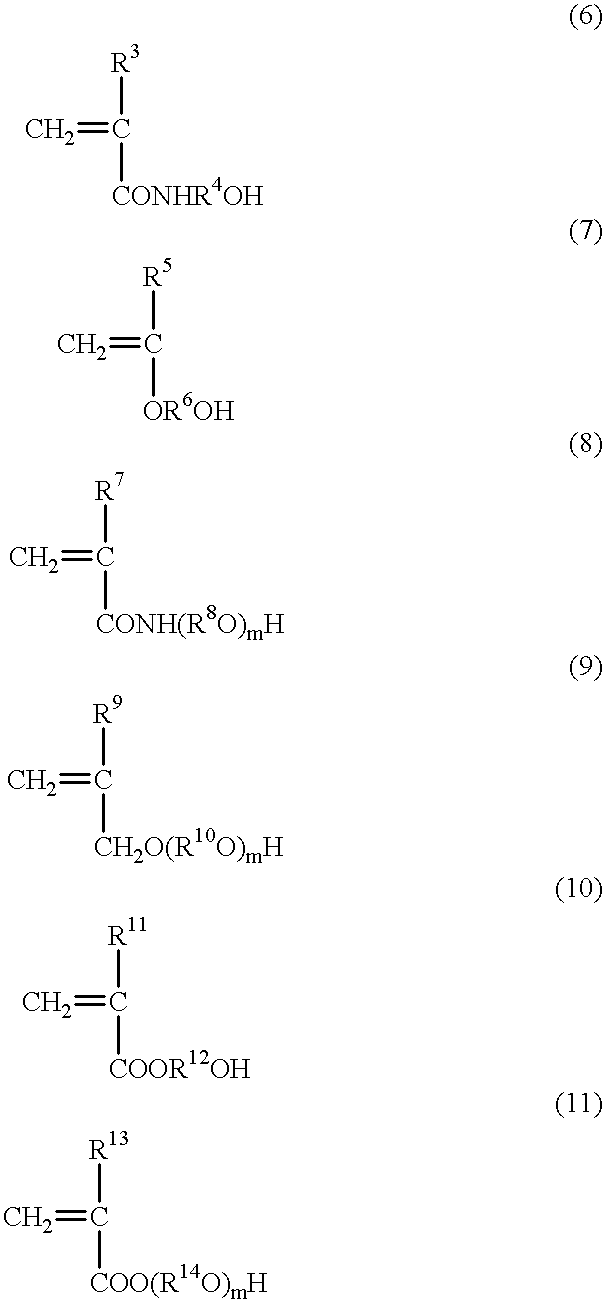

alpha-Allyloxymethylacrylic acid-based copolymer, resin compositions, and use thereof

ActiveUS8497332B2Improve heat resistanceImprove curing effectOrganic dyesEster polymer adhesivesHydrogen atomOrganic group

The present invention provides: resins which can be used for various applications such as radical curable resin compositions, colorant-dispersed compositions, and photosensitive resin compositions; resin compositions; and means for producing the resins. Specifically, the present invention provides an α-allyloxymethylacrylic copolymer having in its main chain a structural unit represented by formula (1):wherein R is a hydrogen atom or a C1-C30 organic group.

Owner:NIPPON SHOKUBAI CO LTD

Alpha-allyloxymethylacrylic acid-based copolymer, resin compositions, and use thereof

ActiveUS20110263805A1Increased durabilityGood dispersionOrganic dyesEster polymer adhesivesHydrogen atomOrganic group

The present invention provides: resins which can be used for various applications such as radical curable resin compositions, colorant-dispersed compositions, and photosensitive resin compositions; resin compositions; and means for producing the resins. Specifically, the present invention provides an α-allyloxymethylacrylic copolymer having in its main chain a structural unit represented by formula (1):wherein R is a hydrogen atom or a C1-C30 organic group.

Owner:NIPPON SHOKUBAI CO LTD

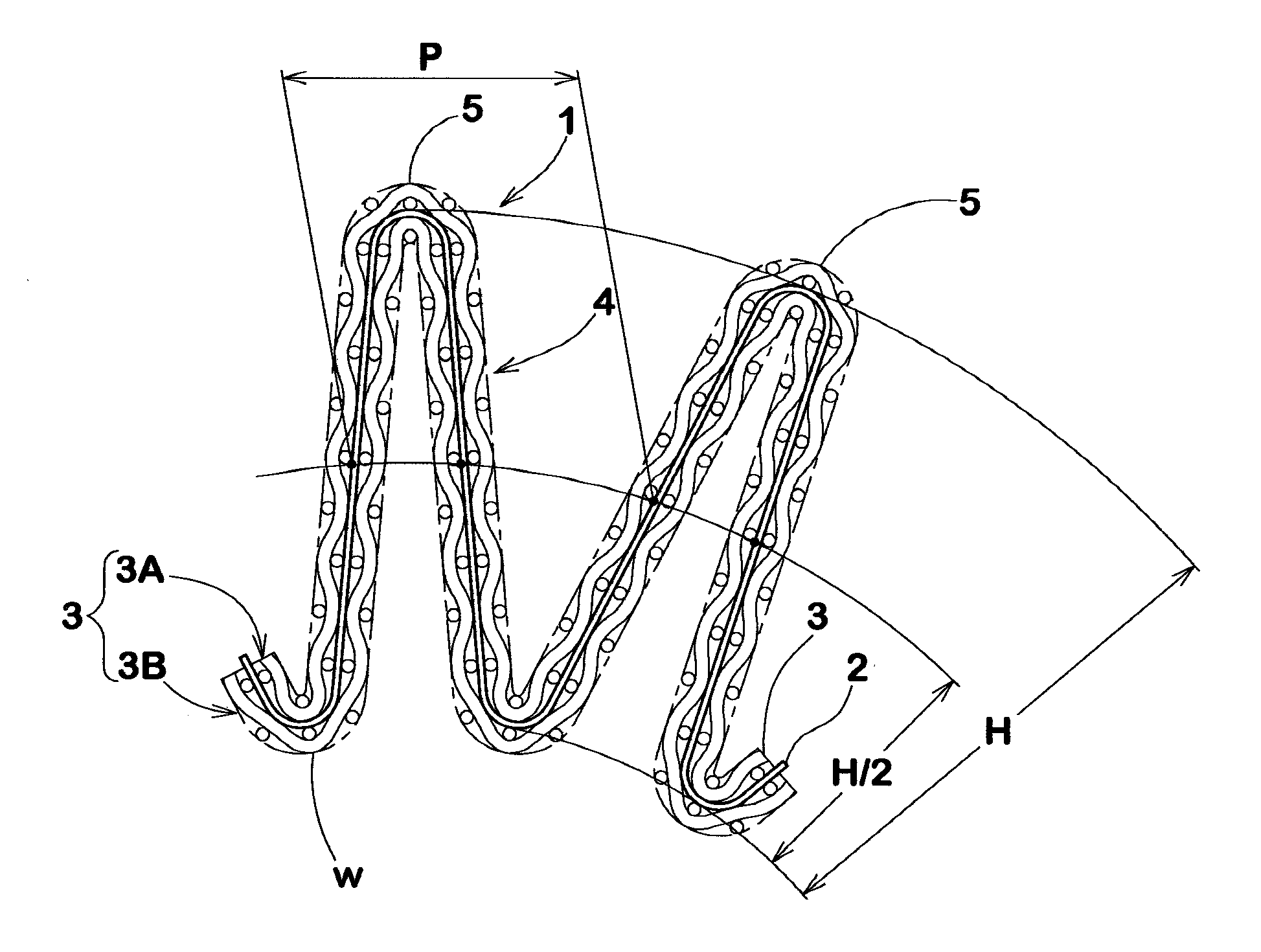

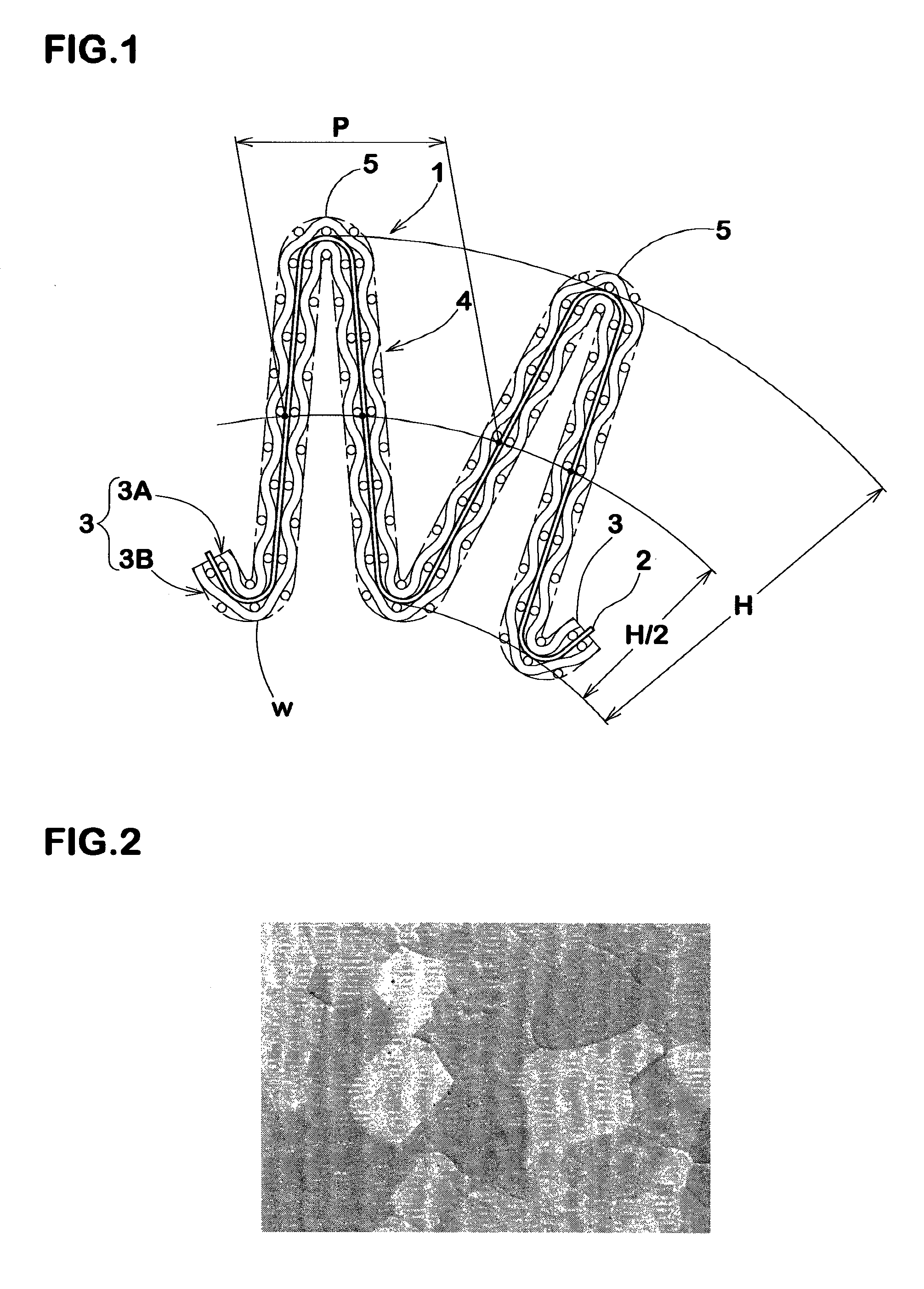

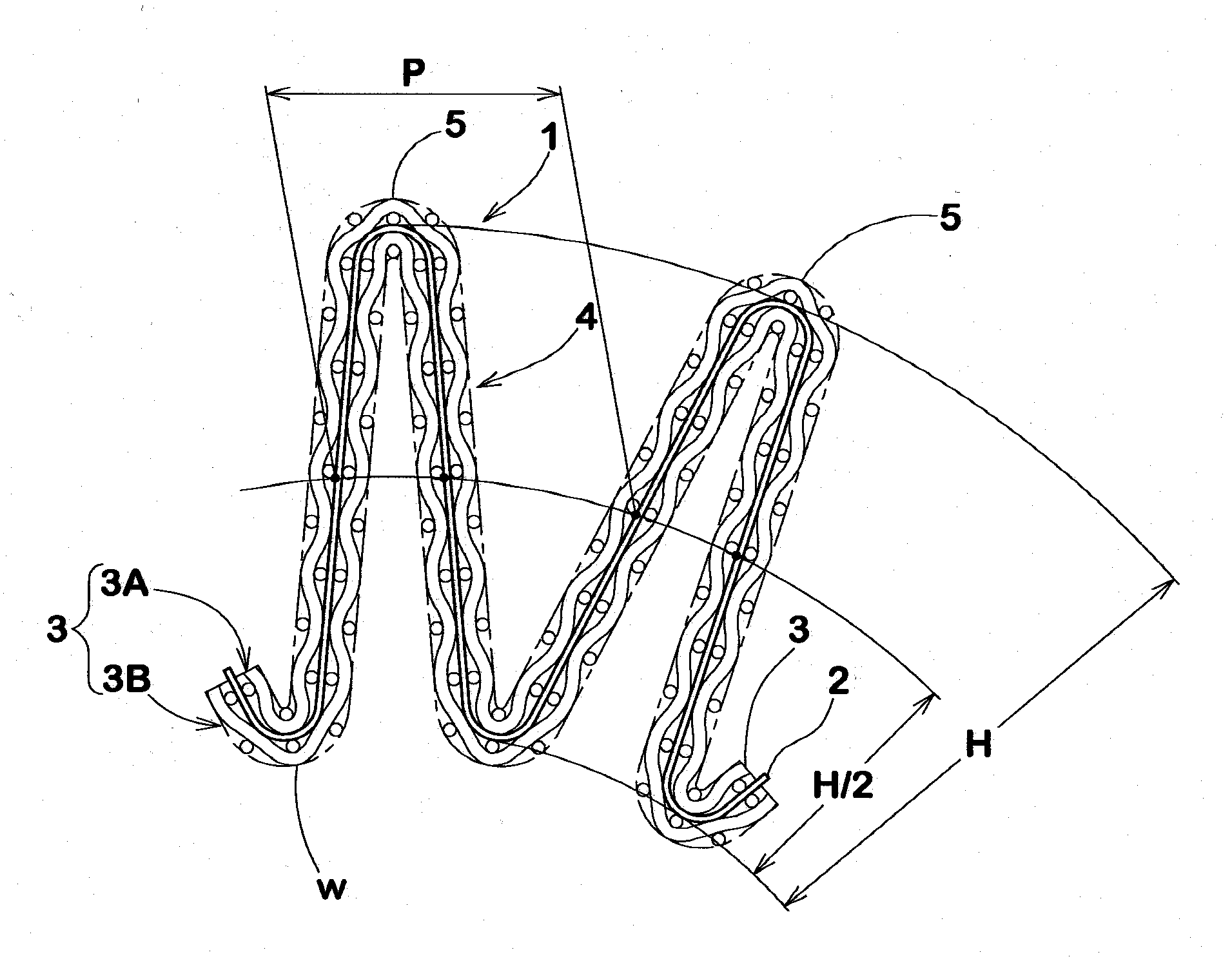

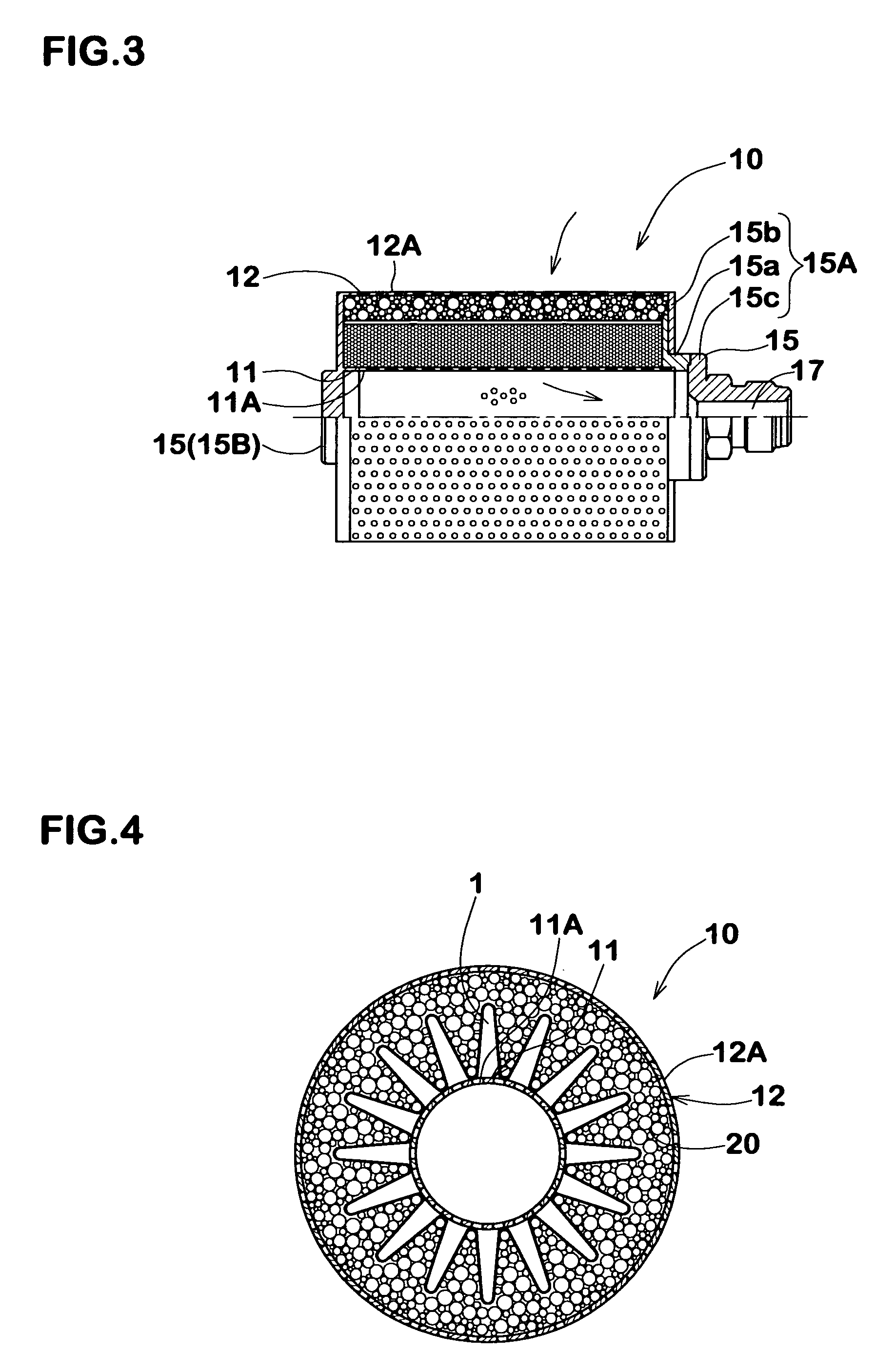

Composite membrane material for hydrogen separation and element for hydrogen separation using the same

ActiveUS8226751B2Effectively utilize it for hydrogen separationDifficult to shapeSemi-permeable membranesMembranesHydrogenMetal

A composite membrane material characterized by comprising a hydrogen-permeable membrane which is selectively permeable to hydrogen and is formed by rolling to a thickness of 30 μm or less which is difficult for the membrane by itself to retain its shape, and a shape-retention mesh which is disposed on at least one side of the hydrogen-permeable membrane and is composed of a wire of a high-melting metal which does not cause thermal diffusion into the hydrogen-permeable membrane, wherein the hydrogen-permeable membrane and the shape-retention mesh are superposed and subjected to a pleat processing in a non-bonded state so that they are separable and the hydrogen-permeable membrane has a surface area increased at least 3 times per unit area. This material is used to constitute a hydrogen separation element.

Owner:NIPPON SEISEN CO LTD

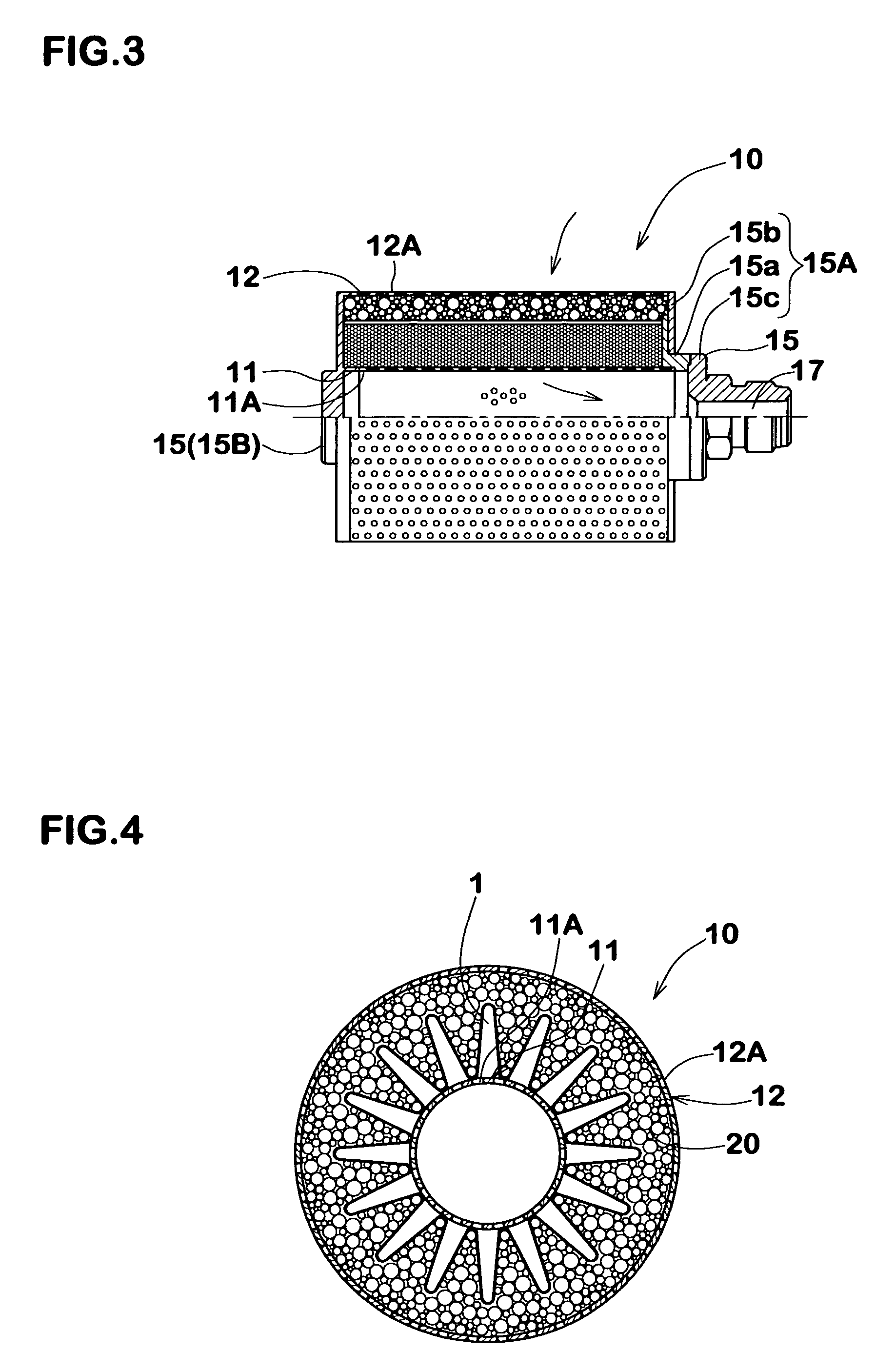

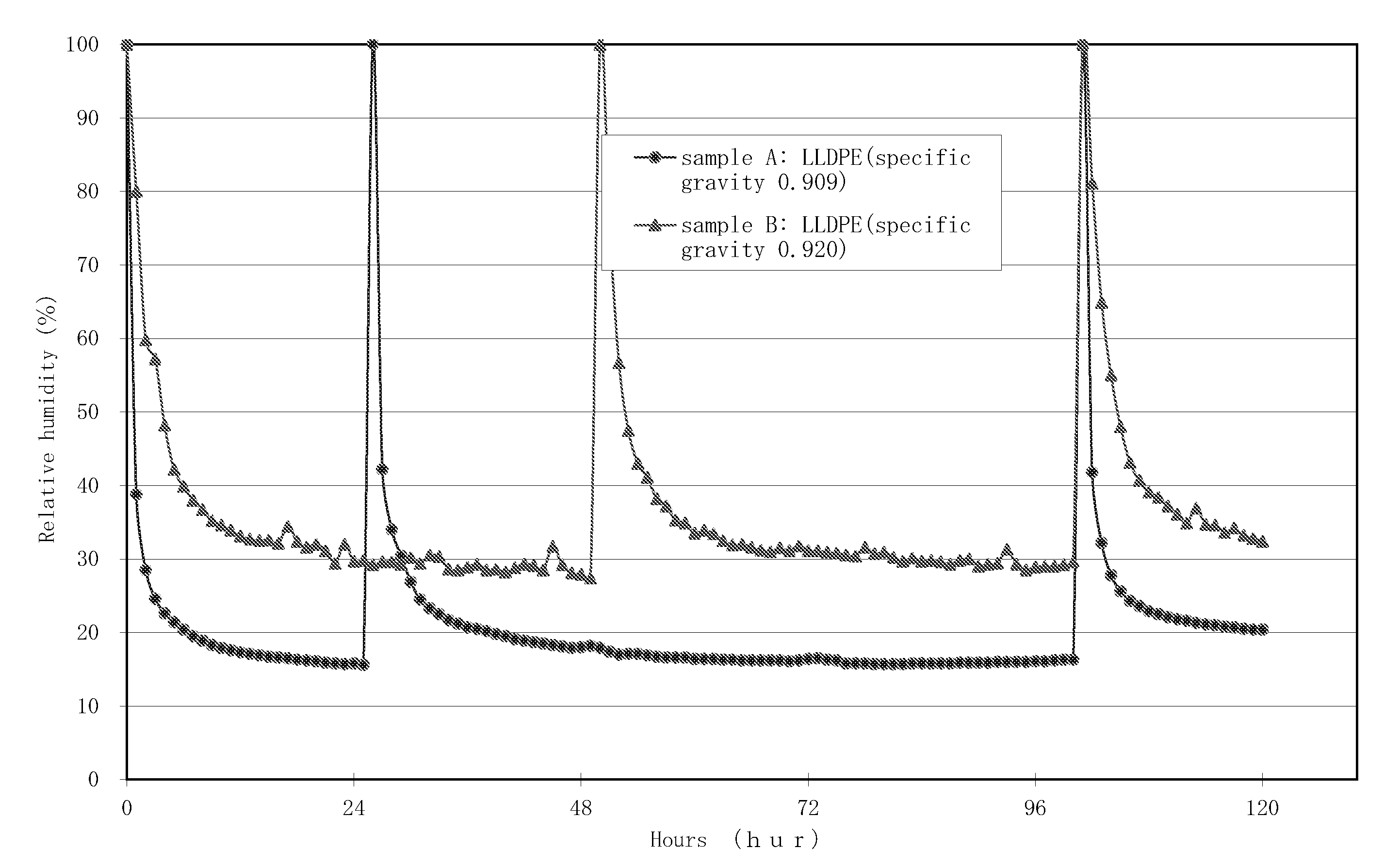

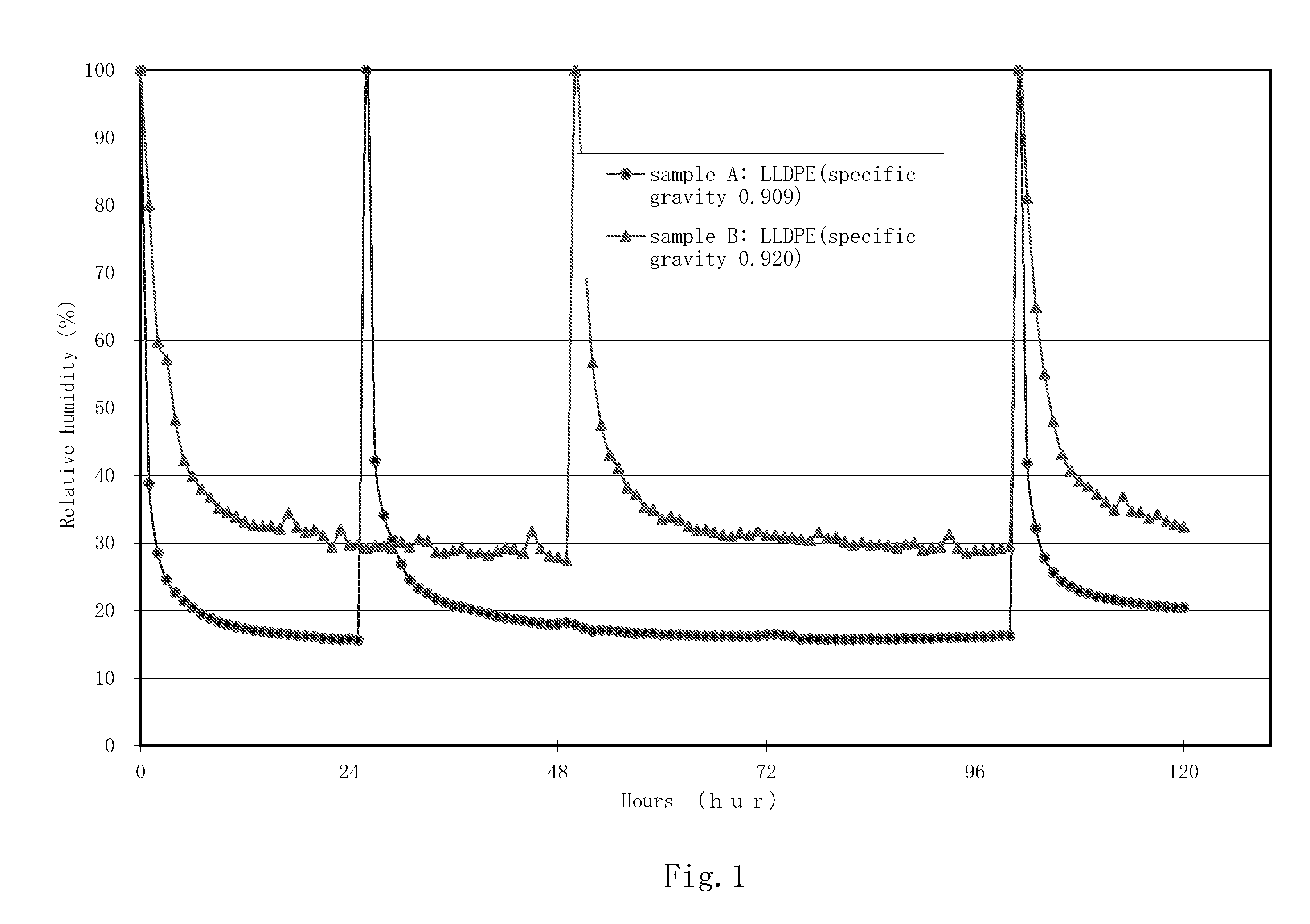

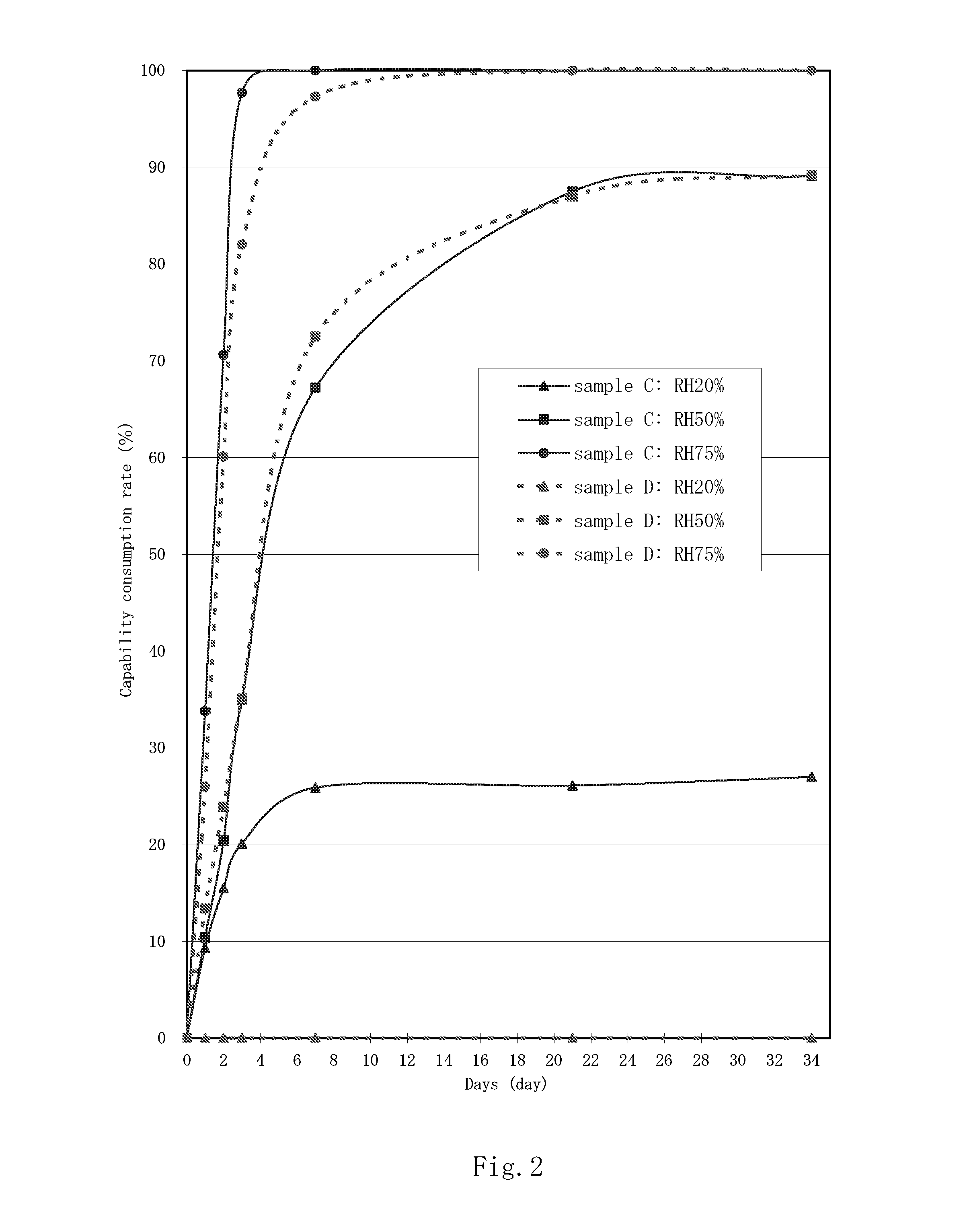

Moisture absorbent composition, moisture absorbent molding, and method for controlling equilibrium humidity, method for controlling time of maintaining equilibrium humidity

ActiveUS20080058205A1Well formedEasily impartedOther chemical processesSynthetic resin layered productsMoistureChemistry

A moisture absorbent composition is provided with a thermoplastic resin; and a moisture absorbent kneaded into the thermoplastic resin, having a secondary particle size of substantially 1 to 40 μm, wherein equilibrium humidity is controlled by selecting the specific gravity of the thermoplastic resin. A method for controlling equilibrium humidity in a moisture absorbent composition obtained by kneading a moisture absorbent into a thermoplastic resin is provided, which includes kneading the moisture absorbent such that a secondary particle size of the moisture absorbent is substantially 1 to 40 μm; and controlling equilibrium humidity by selecting specific gravity of the thermoplastic resin.

Owner:SASAKI CHEM +1

Composite membrane material for hydrogen separation and element for hydrogen separation using the same

ActiveUS20100018397A1Effectively utilize it for hydrogen separationDifficult to shapeSemi-permeable membranesMembranesHydrogenMembrane configuration

A composite membrane material characterized by comprising a hydrogen-permeable membrane which is selectively permeable to hydrogen and is formed by rolling to a thickness of 30 μm or less which is difficult for the membrane by itself to retain its shape, and a shape-retention mesh which is disposed on at least one side of the hydrogen-permeable membrane and is composed of a wire of a high-melting metal which does not cause thermal diffusion into the hydrogen-permeable membrane, wherein the hydrogen-permeable membrane and the shape-retention mesh are superposed and subjected to a pleat processing in a non-bonded state so that they are separable and the hydrogen-permeable membrane has a surface area increased at least 3 times per unit area. This material is used to constitute a hydrogen separation element.

Owner:NIPPON SEISEN CO LTD

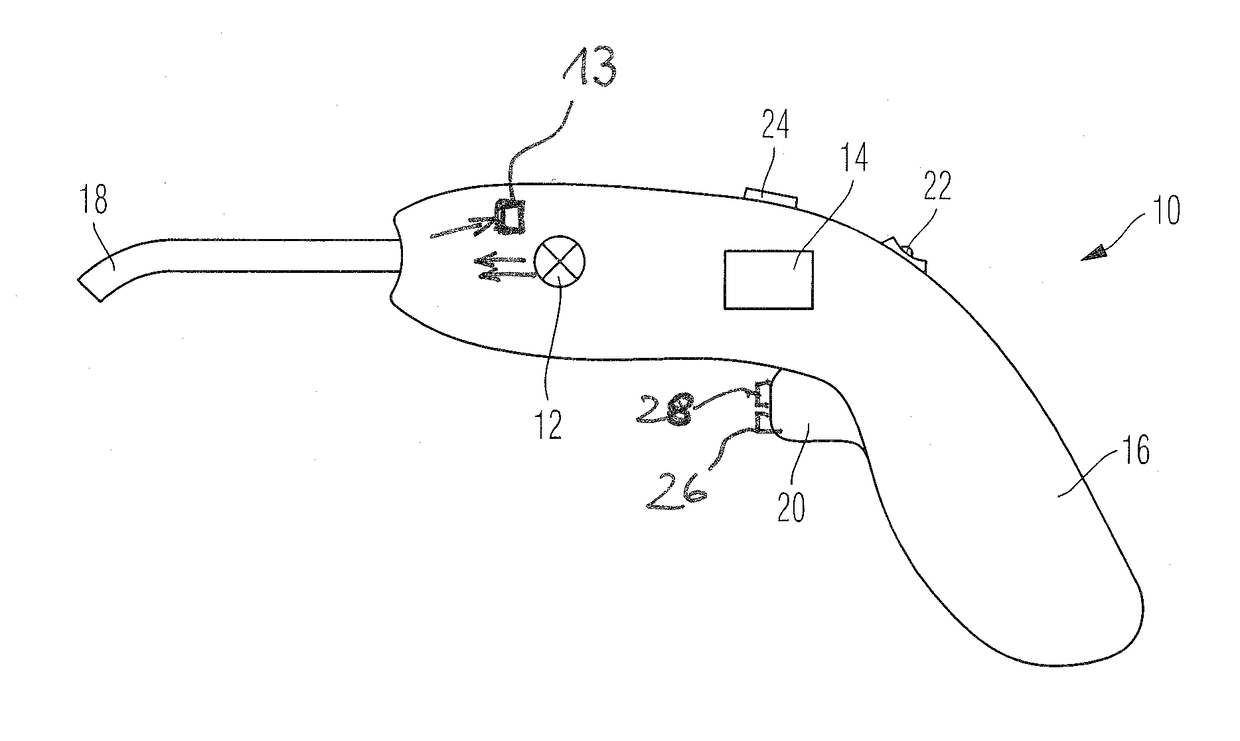

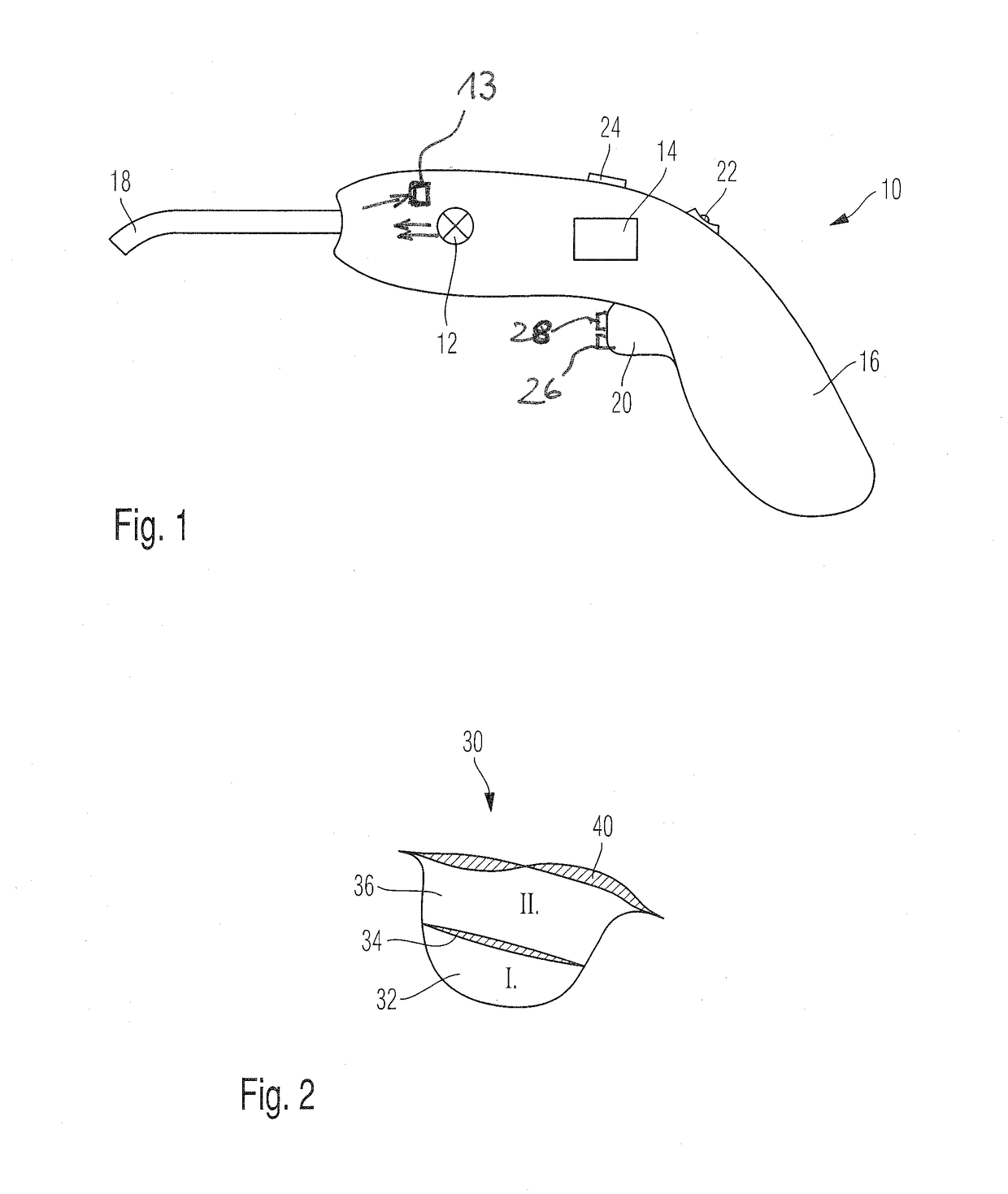

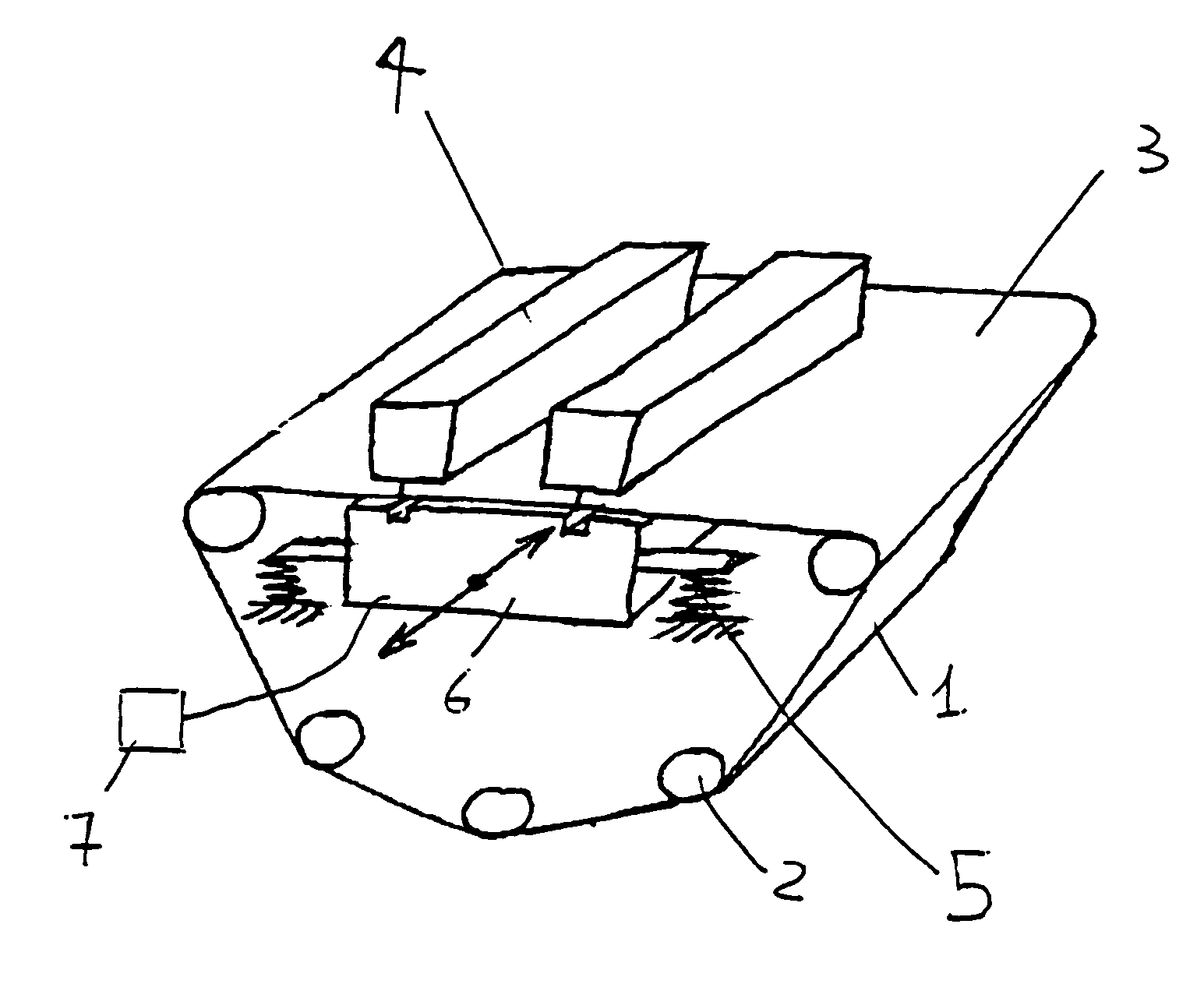

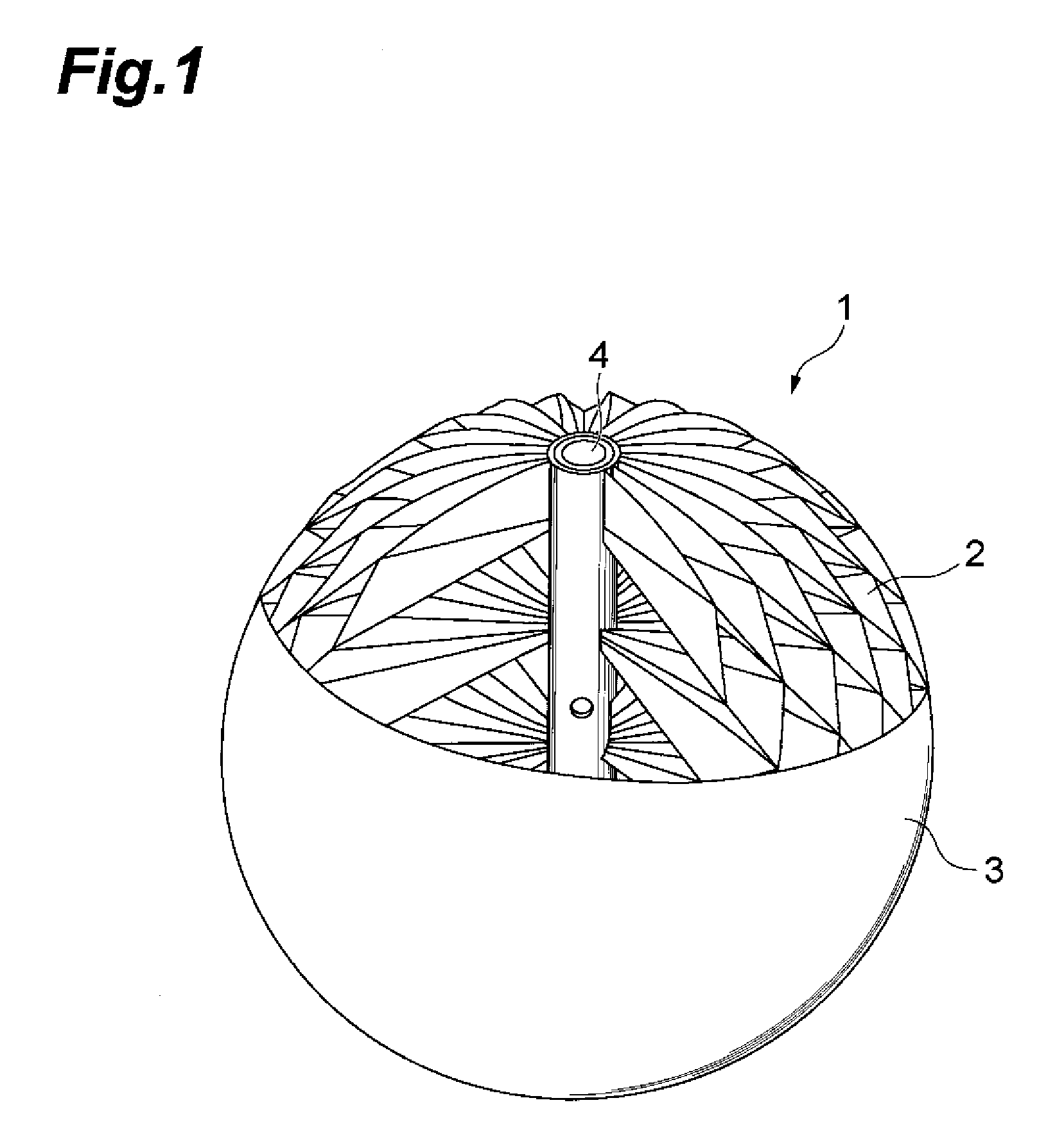

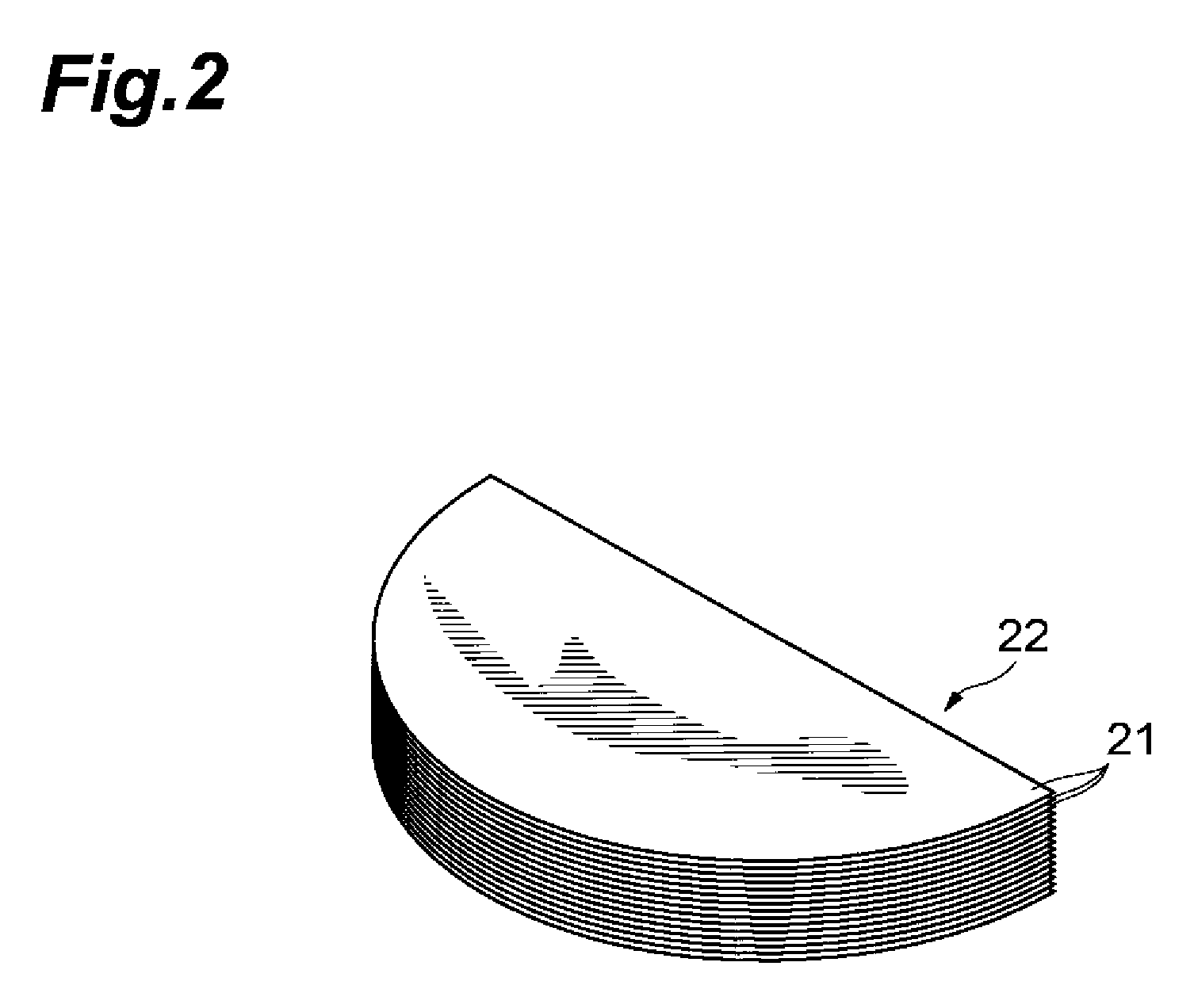

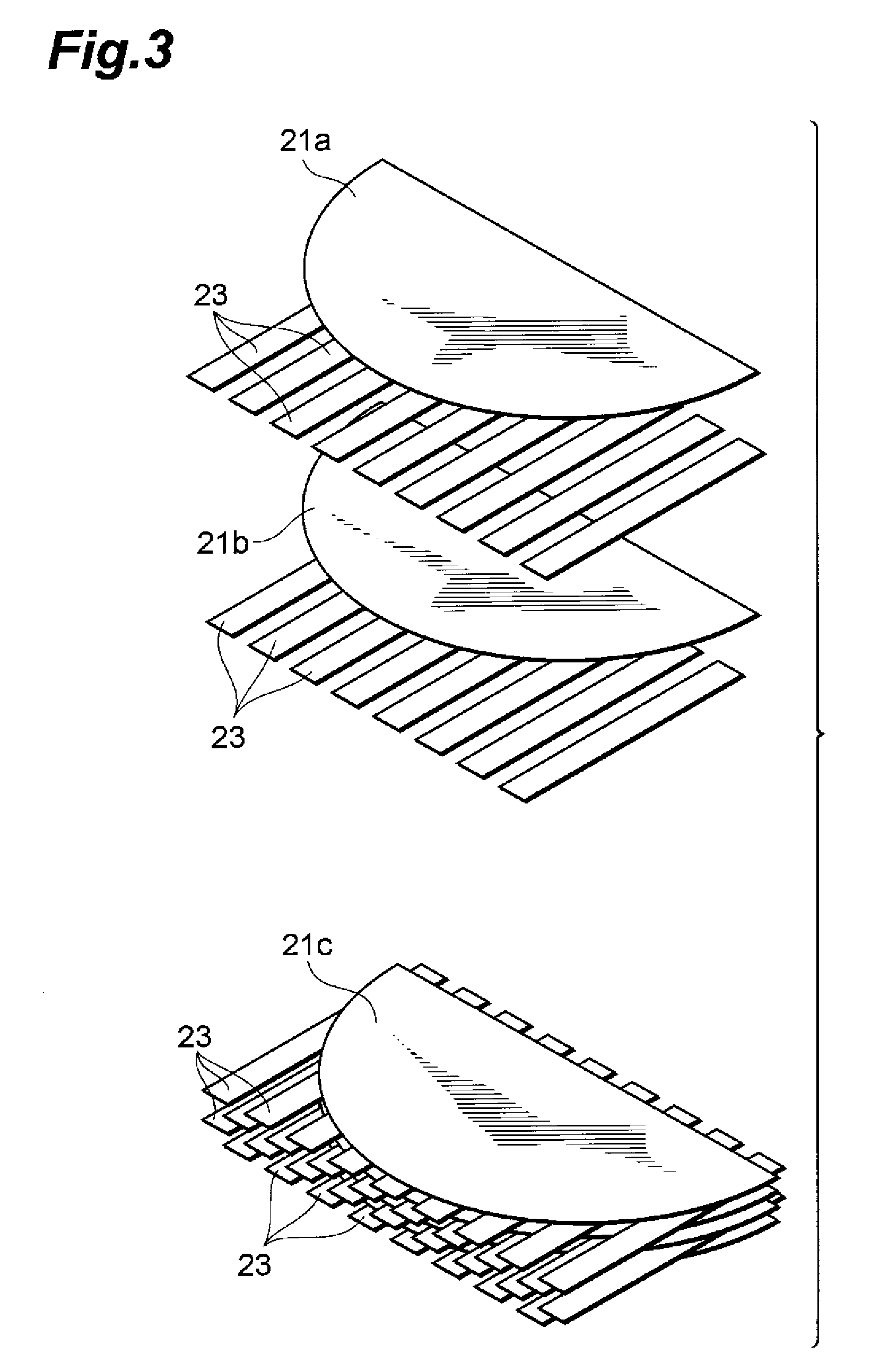

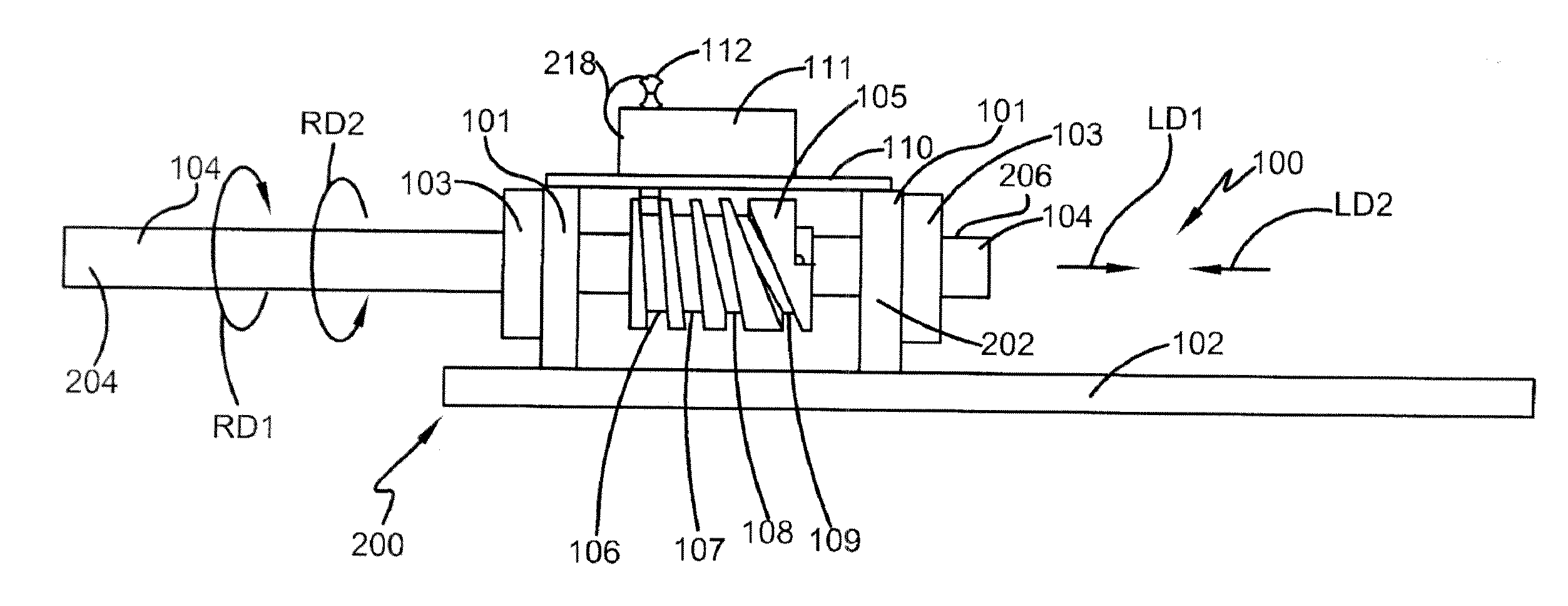

Light curing device for dental restoration materials and method of curing dental restoration materials

ActiveUS20180296310A1Reduce dosageEasy to controlBoring toolsDental prostheticsRepair materialEngineering

The invention is directed to a light curing device, in particular for dental restoration materials, having a light source and a control device for the light curing device, which control device is capable of switching on the light source at different levels of power. The light curing device includes an actuation element which can be used to switch on the light curing device upon actuation by the user at a reduced dosage of light for pre-curing the dental restoration material. The control device in particular signalizes the reduced dosage.

Owner:IVOCLAR VIVADENT AG

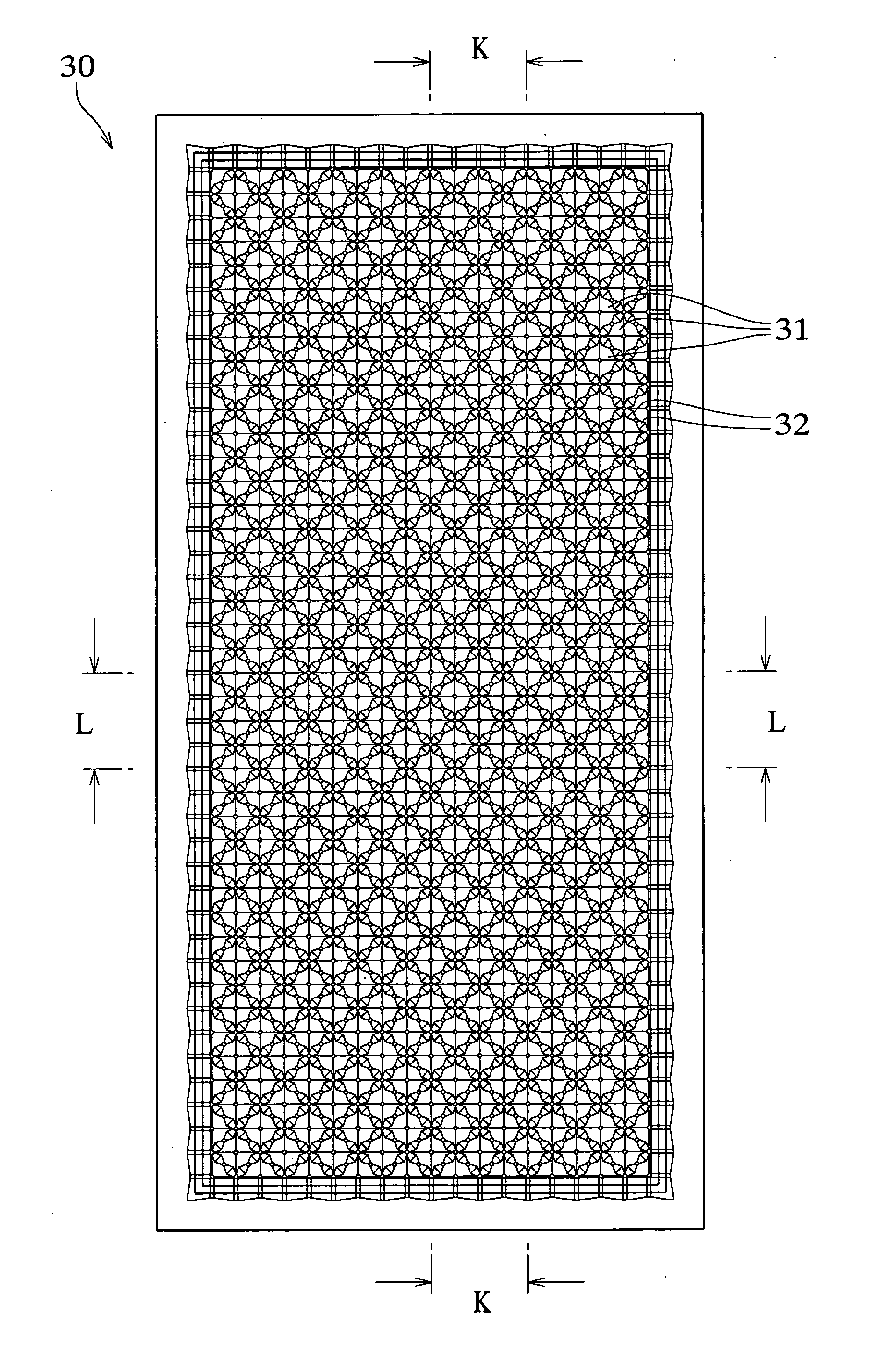

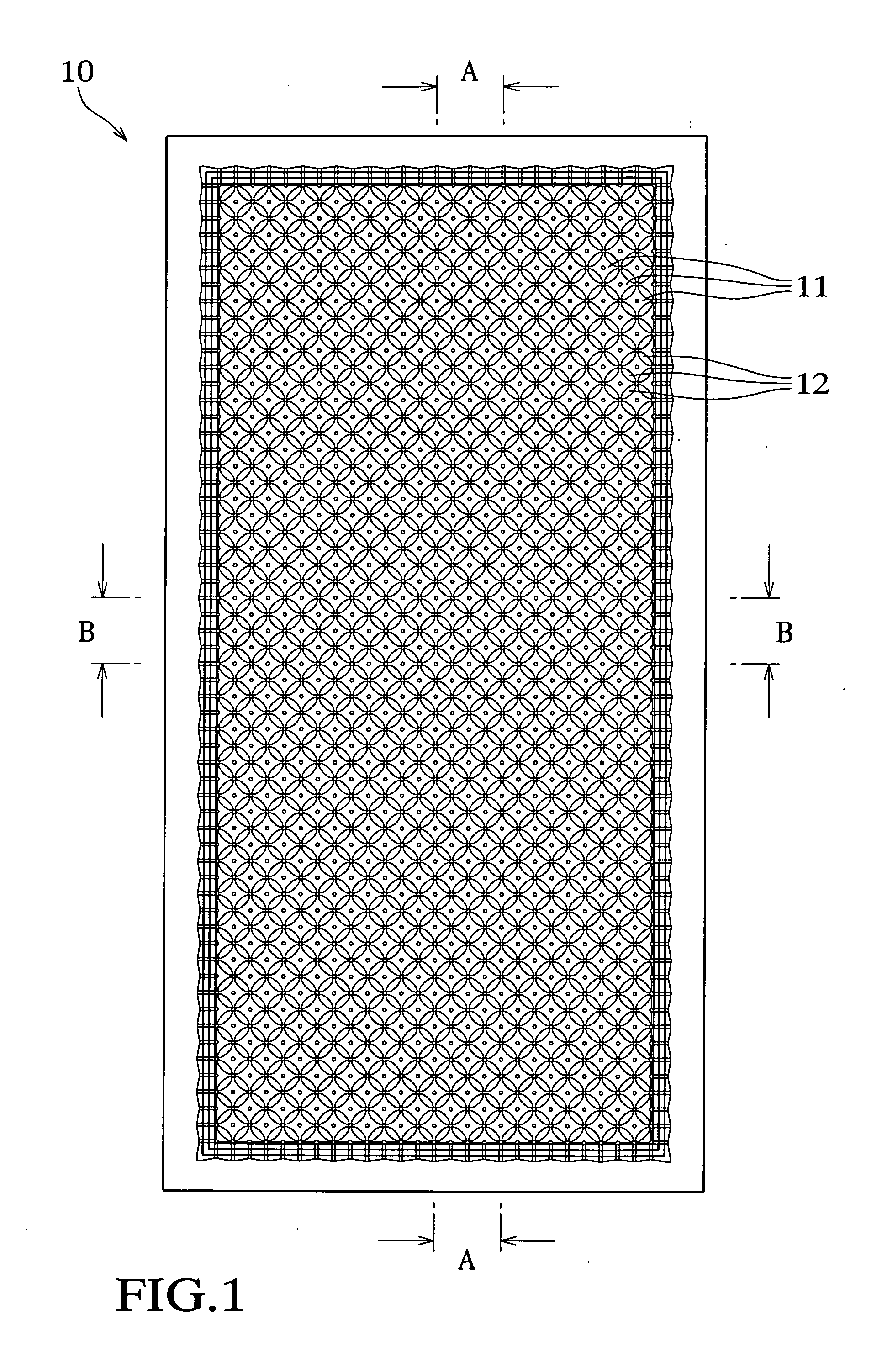

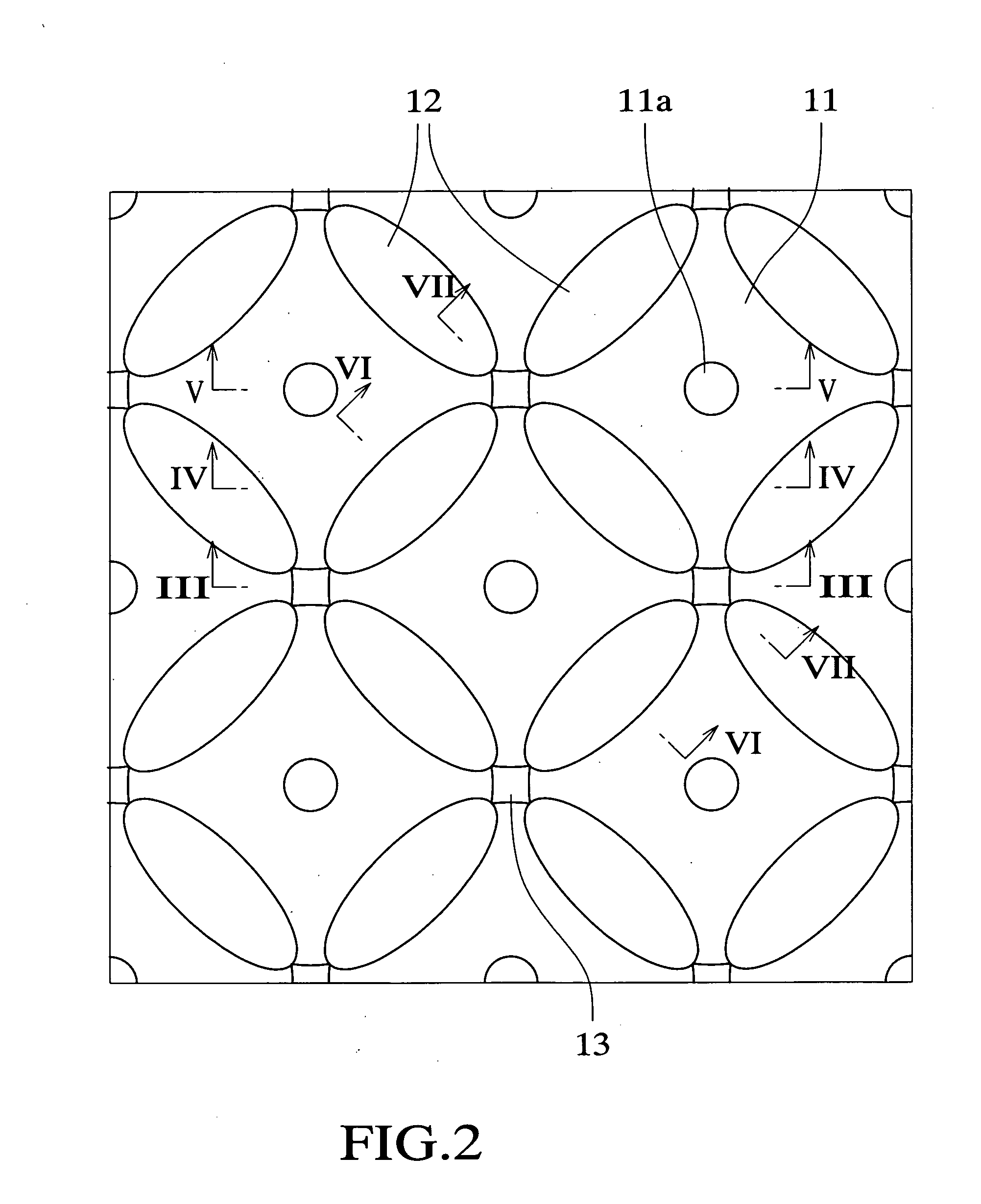

Installation for producing non-woven textile webs with jet fluids leaving no visible mark

InactiveUS7178210B2Prevent movementEasily impartedPattern makingDrying machines with progressive movementsISI markVacuum chamber

The invention concerns an installation for producing non-woven textile webs comprising a conveyor on one side of which the non-woven textile web passes between an injector and a vacuum chamber driven in an oscillating motion. The resulting web bears no mark.

Owner:RIETER PERFOJET

Heat exchange plate

InactiveUS20060162915A1Uniform heat exchangeIncrease freedomLaminated elementsStationary plate conduit assembliesShortest distanceEngineering

A heat exchange plate includes main protrusions, intermediate protrusions and non-protruded portions. The main protrusions having a truncated cone or pyramid shape are placed in positions based on a pattern on the plate. The intermediate protrusion is placed between two main protrusions that are adjacent to each other at a shortest distance so that the main protrusion is connected to two other main protrusions through two intermediate protrusions. The intermediate protrusion is defined by a flat portion extending to opposing surfaces of the two main protrusions. The intermediate protrusion has a peak portion placed in a lower position than a top of the main protrusion. The non-protruded portion is placed between adjacent intermediate protrusions. The non-protruded portion is placed in a lowest position relative to a protruding direction of the main and intermediate protrusions so as to provide a recess surrounded by the main and intermediate protrusions.

Owner:XENESYS

Design transfer sheet, and decorative film, and method for producing same

ActiveUS20170326906A1Reduce yieldEasily impartedFilm/foil adhesivesDecorative surface effectsSurface layerEngineering

A design transfer sheet of one embodiment of the present disclosure contains a release layer and a design transfer layer releasably mounted on the release layer, and the design transfer layer contains a thermally adherable first surface layer and a thermally adherable second surface layer in that order from the release layer side.

Owner:3M INNOVATIVE PROPERTIES CO

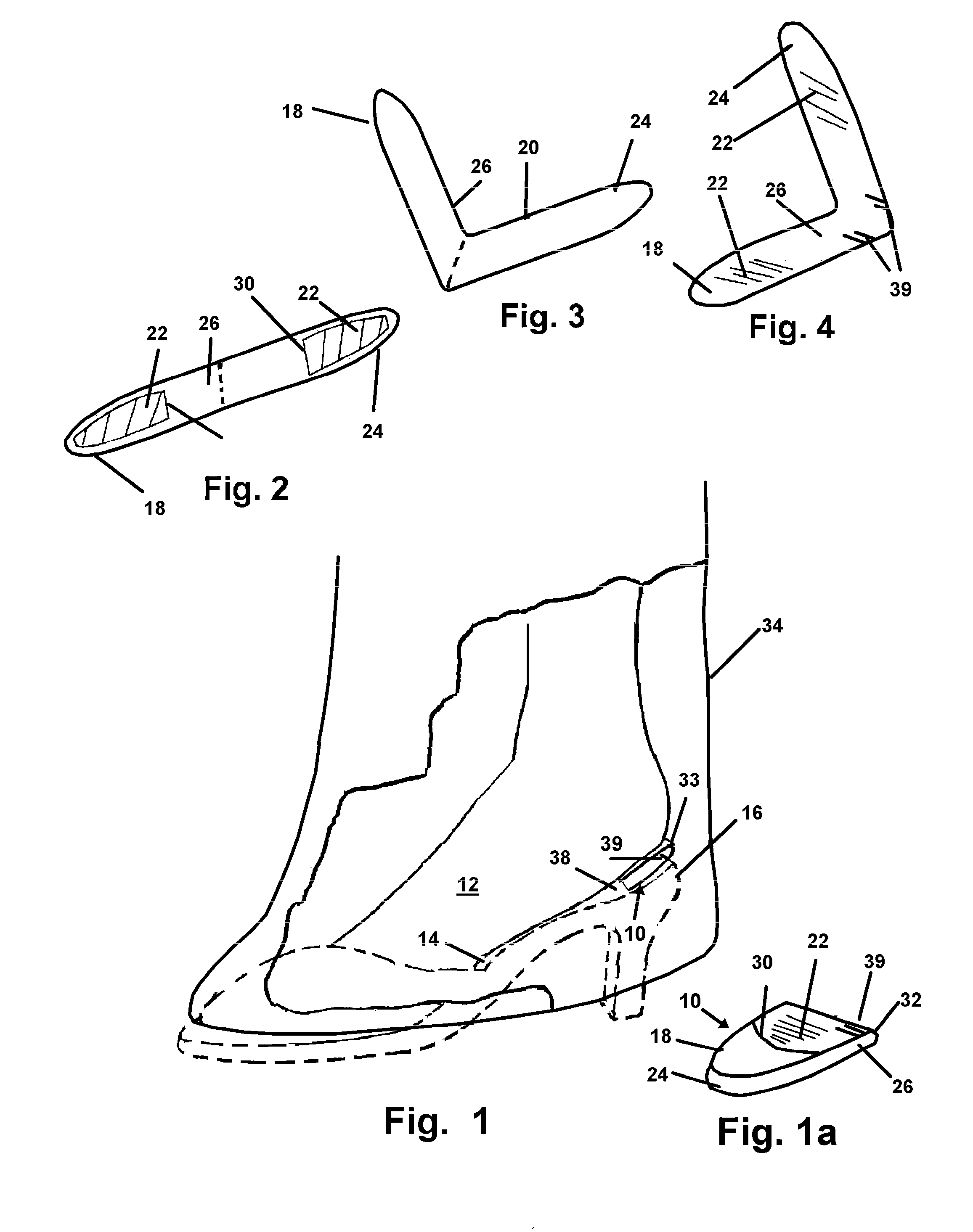

Barrier for Open Heeled Footwear

A clothing protector providing a projecting barrier to prevent clothing from becoming positioned between a heel of a foot and footwear being worn by a user. The protector has a planar body having an as-used position folded and within the gap between the heel of the foot and the footwear. Adhesive engages the body to both the heel of the foot and the top surface of the footwear. So engaged, a middle portion of the protector provides a barrier to clothing such as pants or a long dress from entering the gap when the user walks.

Owner:MASTERS MARCHITA R

Fiber product-treating agents

InactiveUS6660044B2Easily impartedReliable configurationOrganic detergent compounding agentsWrinkle resistant fibresFiberChemistry

The present invention provides a fiber product-treating agent which can impart an excellent wrinkle-resistant effect and an excellent durable press effect to the fiber product capable of being heated and being hardly effected with not only during wearing but also after washing. That is, the present invention provides the treating agent for imparting the durable press configuration on a fiber product by a heating treatment with e.g. an iron, which comprises a specific amount of (i) two or more compounds forming mutually a crosslinked structure by heating and / or (ii) a compound forming a self-crosslinked structure by heating, and water, wherein the content of a nonvolatile matter is 0.01 to 30%.

Owner:KAO CORP

Method for producing resin structure

InactiveUS20090115089A1Easy to shapeEasily impartedPaper/cardboard articlesWood working apparatusInternal pressureHoneycomb

A macrocell structure 20 having a honeycomb form is preheated to cure to a cure depth falling within a range where a flexibility of prepregs in the macrocell structure remains. Subsequently, prepregs 31, 32 are arranged along a side wall of the preheated macrocell structure 20, so as to make a preliminary structure 40. Then, the preliminary structure 40 is heated while the inside of the prepregs 31, 32 in the preliminary structure 40 is vacuumed. Thereafter, the preliminary structure 40 is heated while imparting an internal pressure thereto within a mold 5, so as to be cured, whereby a resin structure 1 is produced.

Owner:TOYOTA JIDOSHA KK

Power transfer device

InactiveUS20130145872A1Easily impartedEasy to adaptToothed gearingsEngineeringStructural engineering

A power transfer device may include a support assembly, a bearing assembly, and an axle that has at least one groove that is angled in a predetermined manner. A guide pin may be received within the groove. Rotation of the axle may then cause a linear input to be received by an output component attached to the end of the axle.

Owner:FELTENBERGER BRUCE D

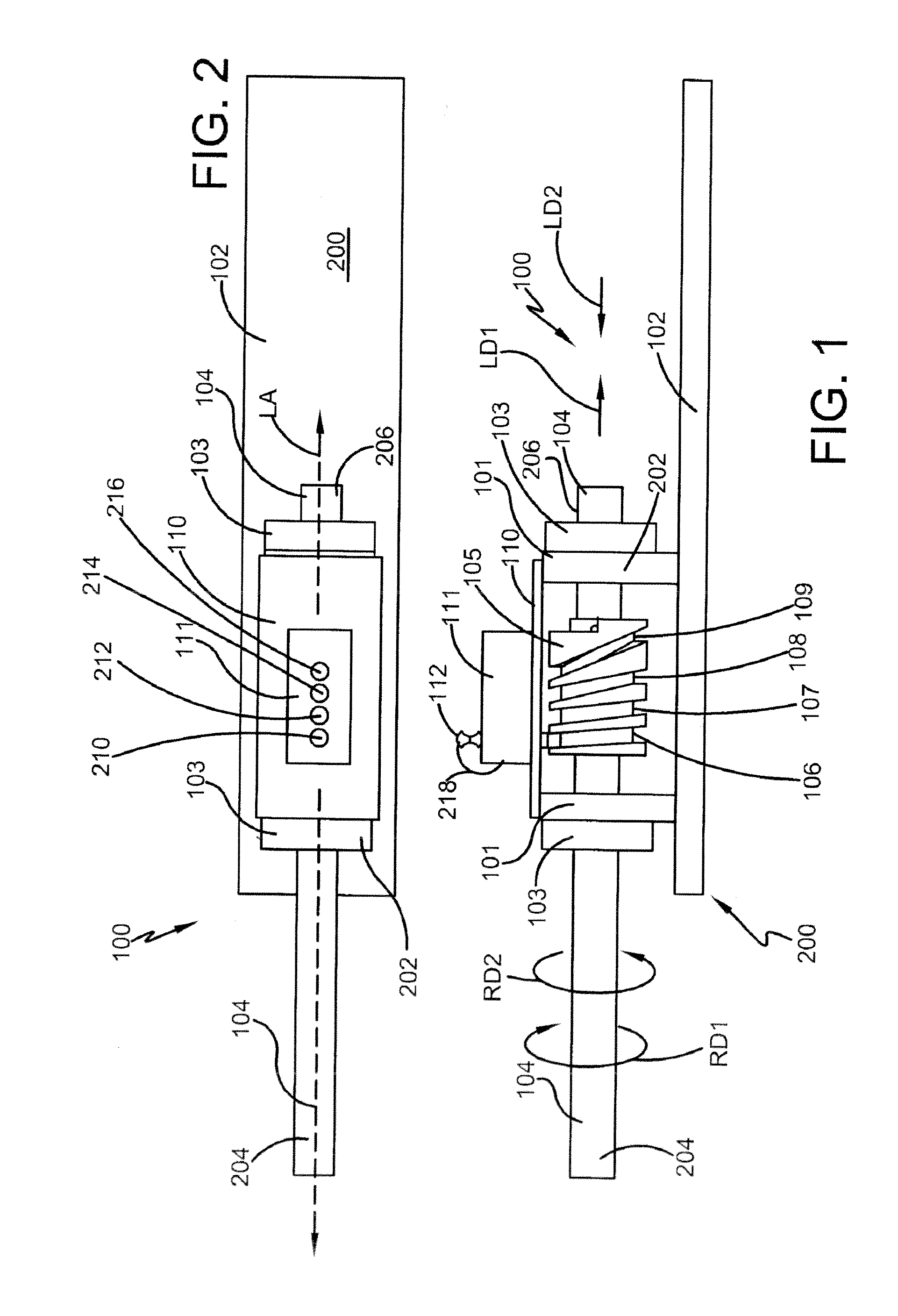

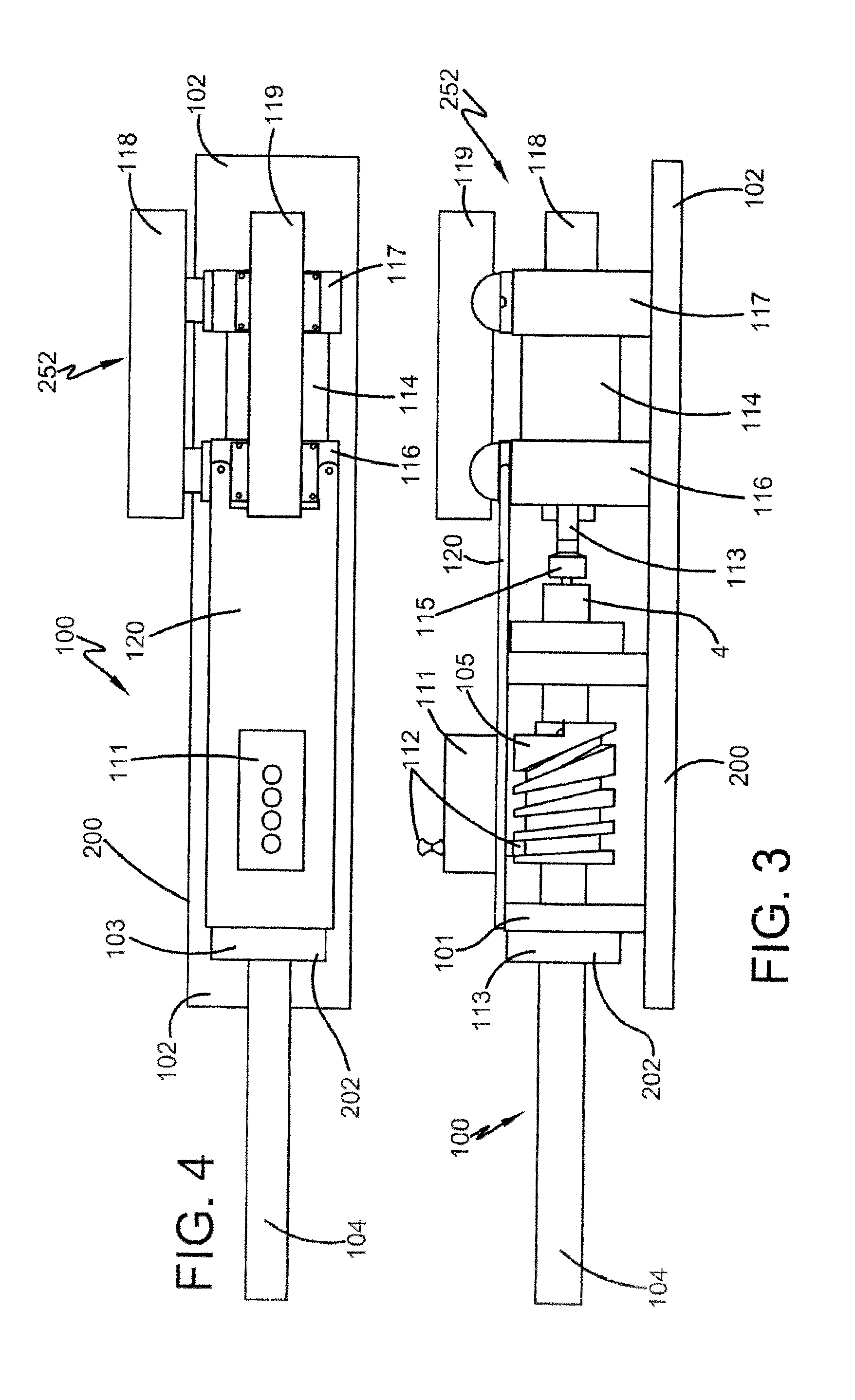

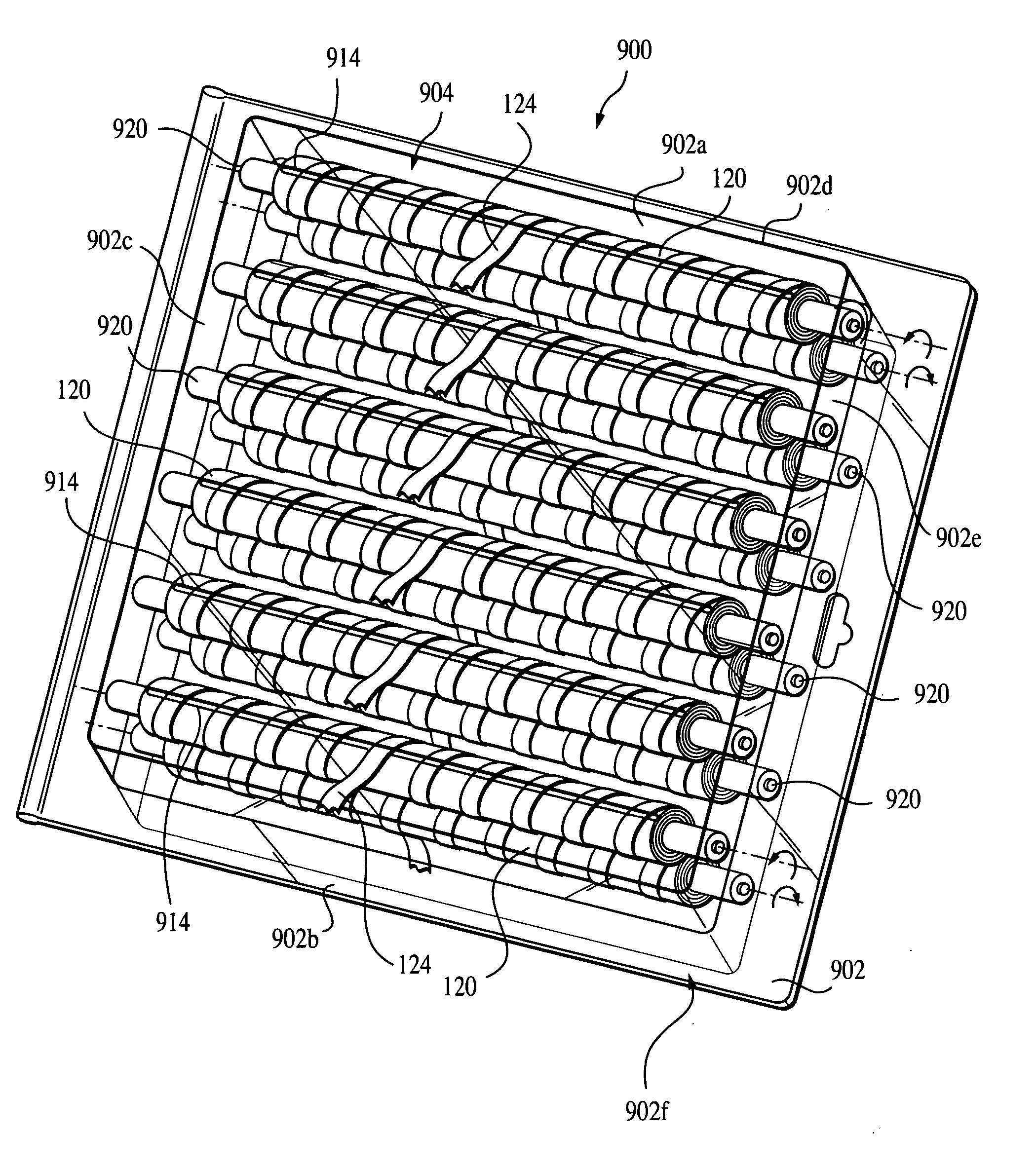

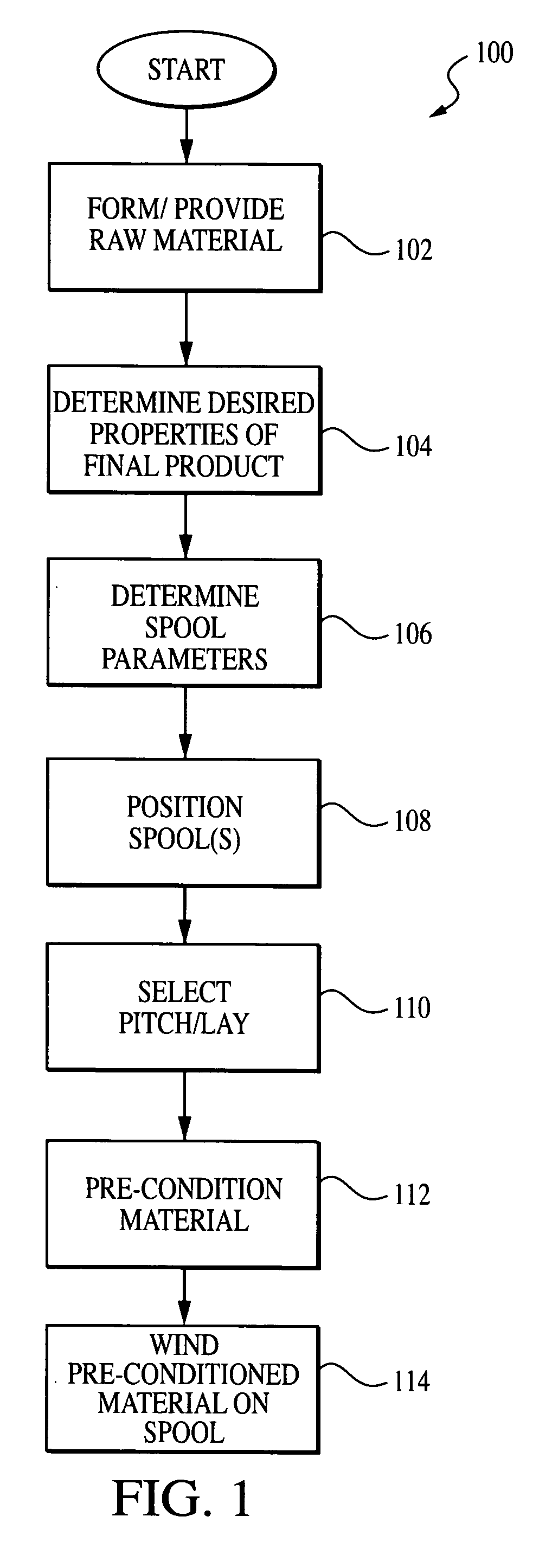

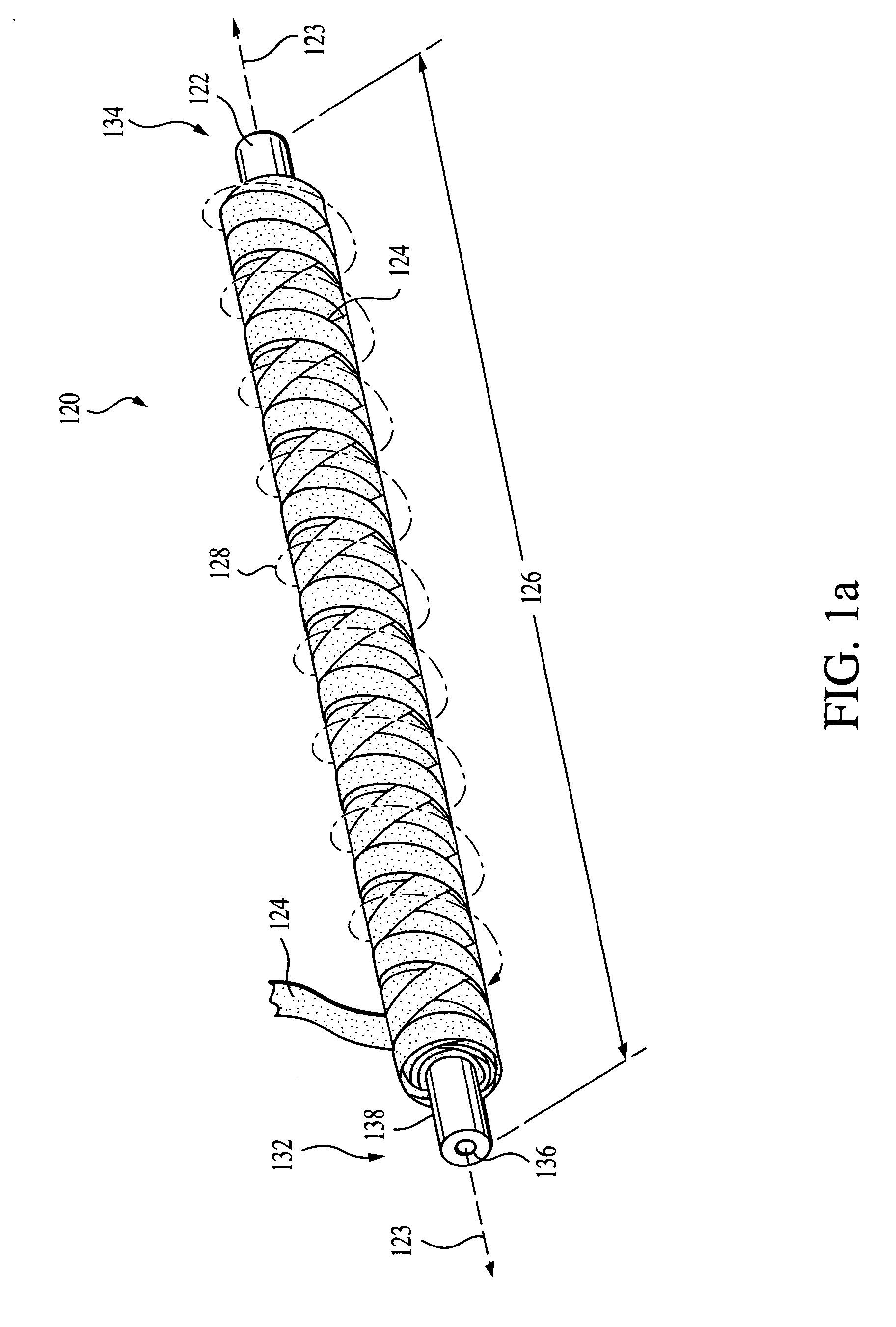

Method and apparatus for winding spooled materials

InactiveUS20070063094A1Maintaining the curl and twist of the ribbonIncrease temperatureContainers for annular articlesOrnamental textile articlesBiomedical engineeringHelix

A method and apparatus for winding conditioned material onto a spool so as to maintain its desirable properties. In one embodiment, decorative ribbon is conditioned using a curling device and wound onto an elongated spool having a predetermined radius in an alternating, helical lay pattern so as to maintain the curl of the ribbon, and permit easy removal and storage thereof. In a second embodiment, two or more different types or colors of ribbon are wound either concentrically or in juxtaposed orientation onto the same spool. An apparatus for winding one or more of the aforementioned spools is also disclosed. A multi-spool dispenser for the curled ribbon is further described.

Owner:DATO KIM J +1

Water-swellable clay mineral laminated powder, dye/water-swellable clay mineral complex and composition comprising the same

ActiveUS7897178B2High charge densityEasily impartedPigmenting treatmentCosmetic preparationsClay mineralsLightfastness

The water-swellable clay mineral laminated powder of the present invention is characterized in that a layer of ionic molecule having two or more ionic functional group is laminated on the surface of a base powder particle, and a layer of water-swellable clay mineral is laminated thereon, and the layers are sequentially laminated so that the surface charge or the ionic charge of each layer is alternately positive and negative. The water-swellable clay mineral laminated powder of the present invention can impart new functionalities to the base powder easily, as a result of that the water-swellable clay mineral is stably laminated on the surface of the base powder.And the dye / water-swellable clay mineral complex of the present invention is characterized in that polybase and / or nonionic hydrophilic polymer and dye are complexed to water-swellable clay mineral. The dye / water-swellable clay mineral complex of the present invention is excellent for various resistance characteristics of the dye such as dissolution resistance, lightfastness, and chlorine resistance. In addition, the dye / water-swellable clay mineral complex is very useful as a water-type coloring agent since it has excellent coloring abilities, clearness, and dye fastness in water.

Owner:SHISEIDO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com