Patents

Literature

73 results about "Line printer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A line printer prints one entire line of text before advancing to another line. Most early line printers were impact printers. Line printers are mostly associated with unit record equipment and the early days of digital computing, but the technology is still in use. Print speeds of 600 lines-per-minute (approximately 10 pages per minute) were achieved in the 1950s, later increasing to as much as 1200 lpm. Line printers print a complete line at a time and have speeds in the range of 150 to 2500 lines per minute.

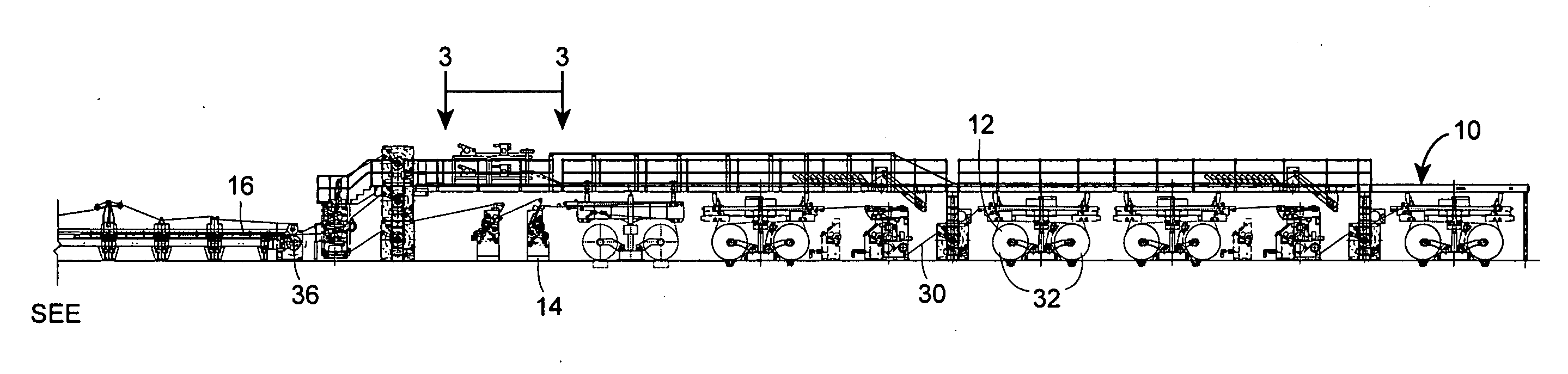

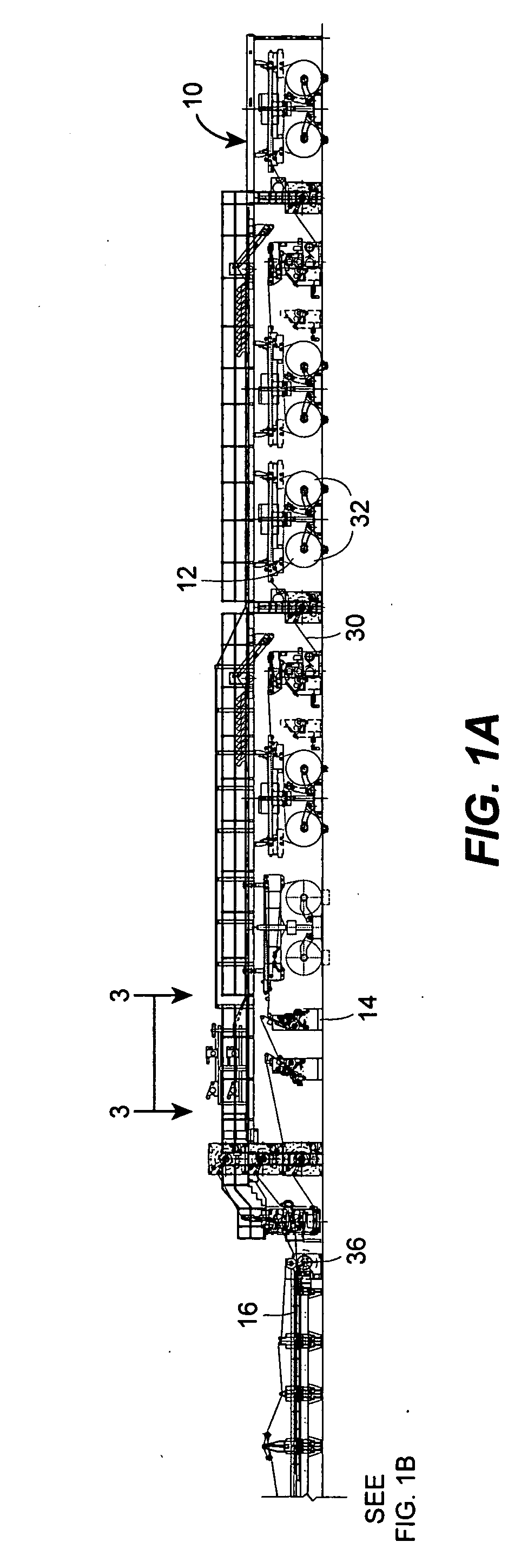

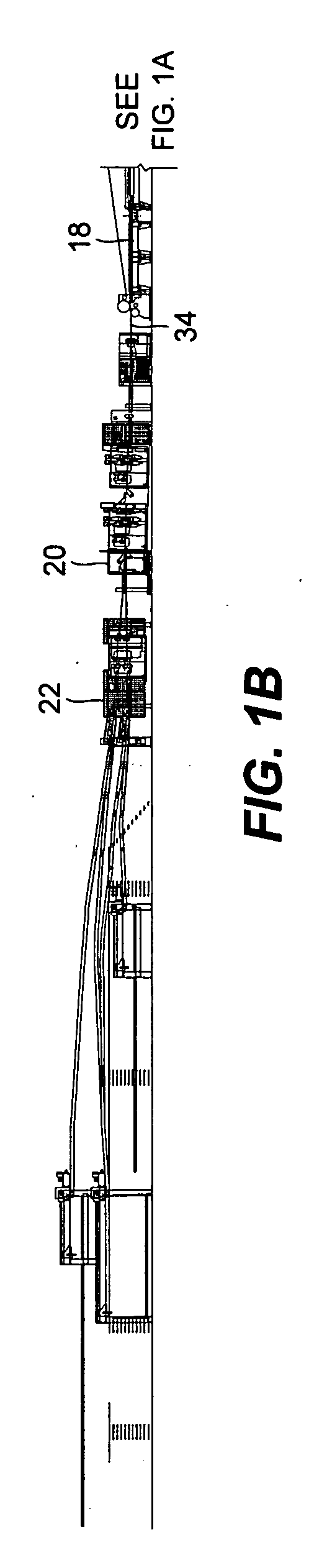

Manufacturing line for making corrugated cardboard

A manufacturing line for making corrugated paper has both a conventional feed stock location where stock is fed to the line and a gluing station where the stock is connected to the corrugated medium. The line includes multiple in-line printers that are positioned between the feed stock location and the gluing station. One printer can be used to print a first color or coating on a first portion of the stock, and another printer can be used to print a second color on a second portion of the stock. A center trim pickup can be used to divide the paper stock between the two portions.

Owner:CORRUGATED SUPPLIES CORP

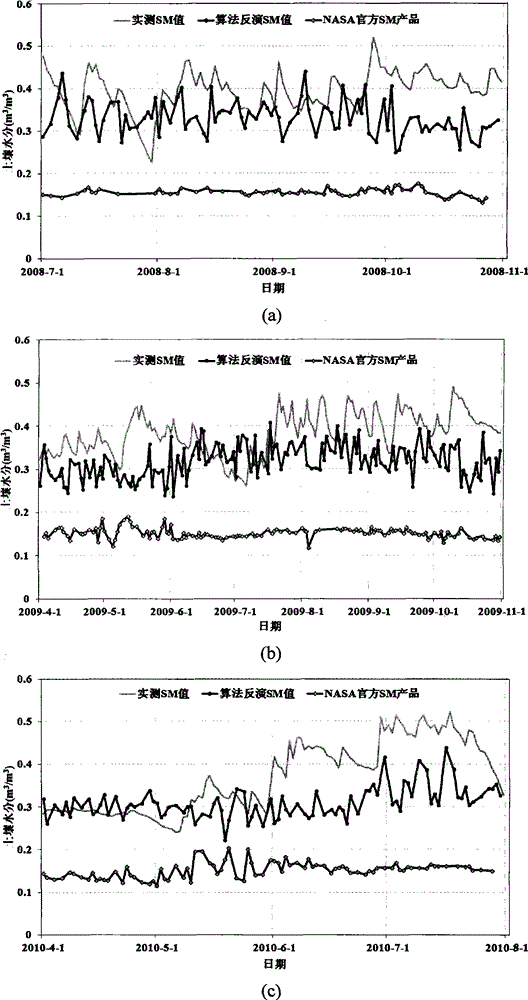

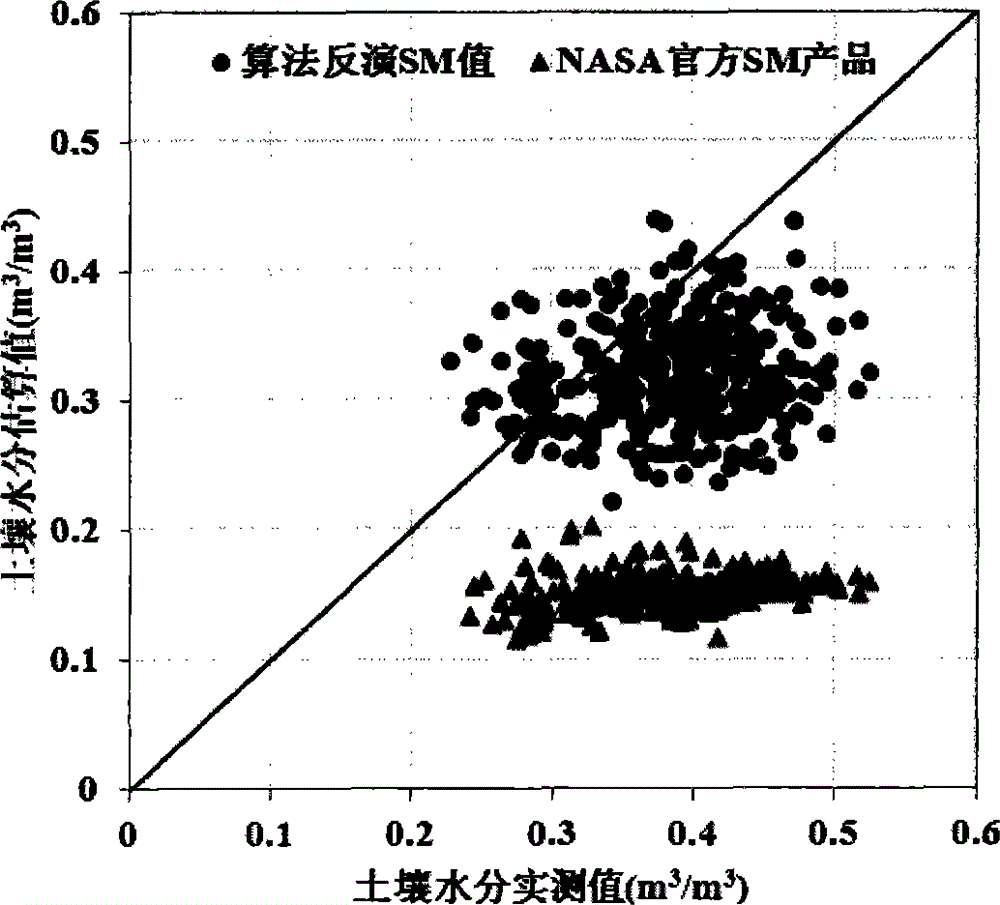

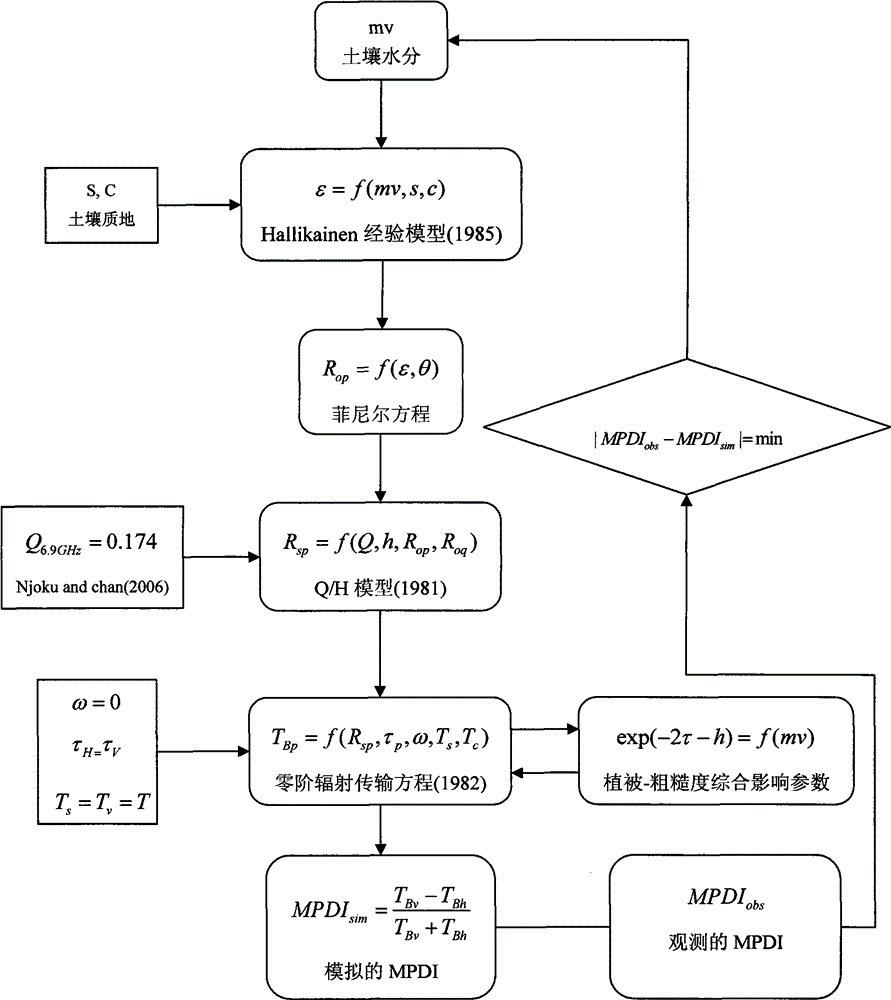

Soil moisture inversion method of mono-frequency microwave radiometer

InactiveCN103149220ANo region dependenciesMoisture content investigation using microwavesLine printerMicrowave radiometer

The invention provides a soil moisture inversion method of a mono-frequency microwave radiometer and belongs to the field of microwave remote sensing. The soil moisture inversion method of the mono-frequency microwave radiometer is neither a multi-parameter simultaneous inversion method, nor an experience regression method, but uses the minimum auxiliary data, and the soil moisture is obtained by the single-parameter inversion method. According to the soil moisture inversion method of the mono-frequency microwave radiometer, the problems existing in the multi-parameter inversion of multiple solutions and huge calculation amount are solved, and the inversion error due to the fact that roughness is set to be a definite value in line printer remover (LPRM) algorithm is also avoided. Meanwhile compared with a science clubs of America (SCA) algorithm which excessively dependent on auxiliary data, the auxiliary data used by the soil moisture inversion method of the mono-frequency microwave radiometer are only soil texture data which are globally and freely shared, and the business application difficulty of the soil moisture inversion is greatly reduced.

Owner:CENT FOR EARTH OBSERVATION & DIGITAL EARTH CHINESE ACADEMY OF SCI

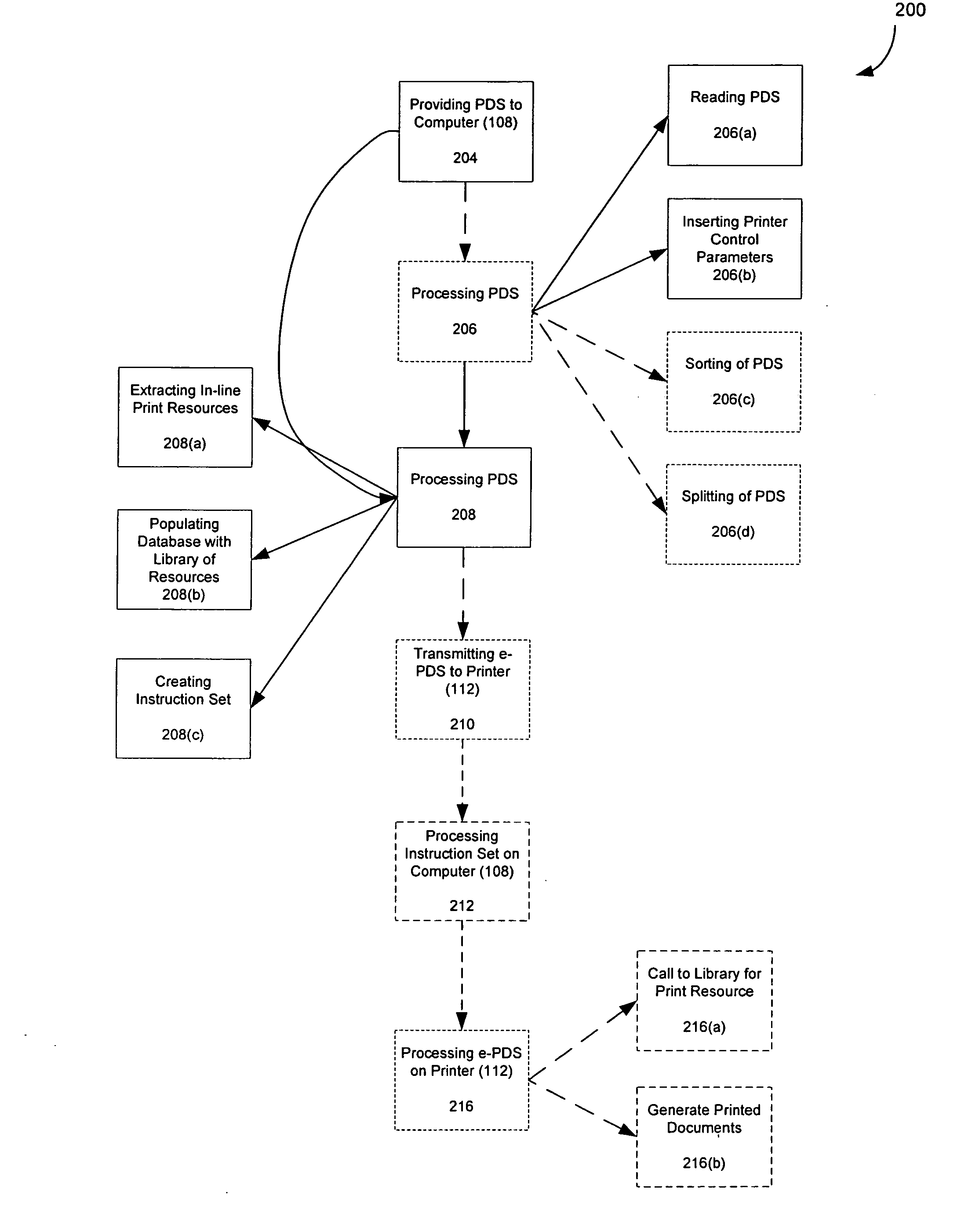

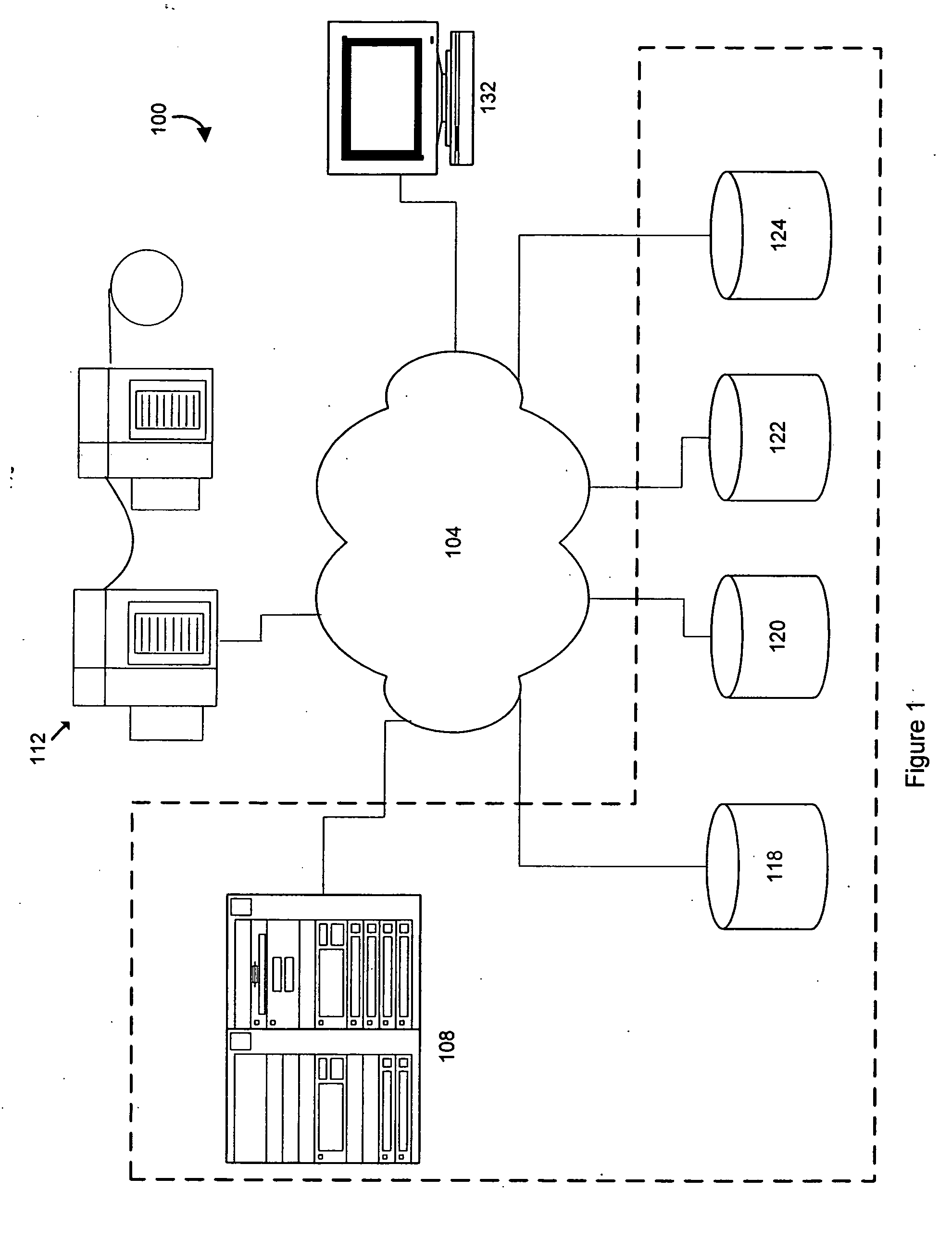

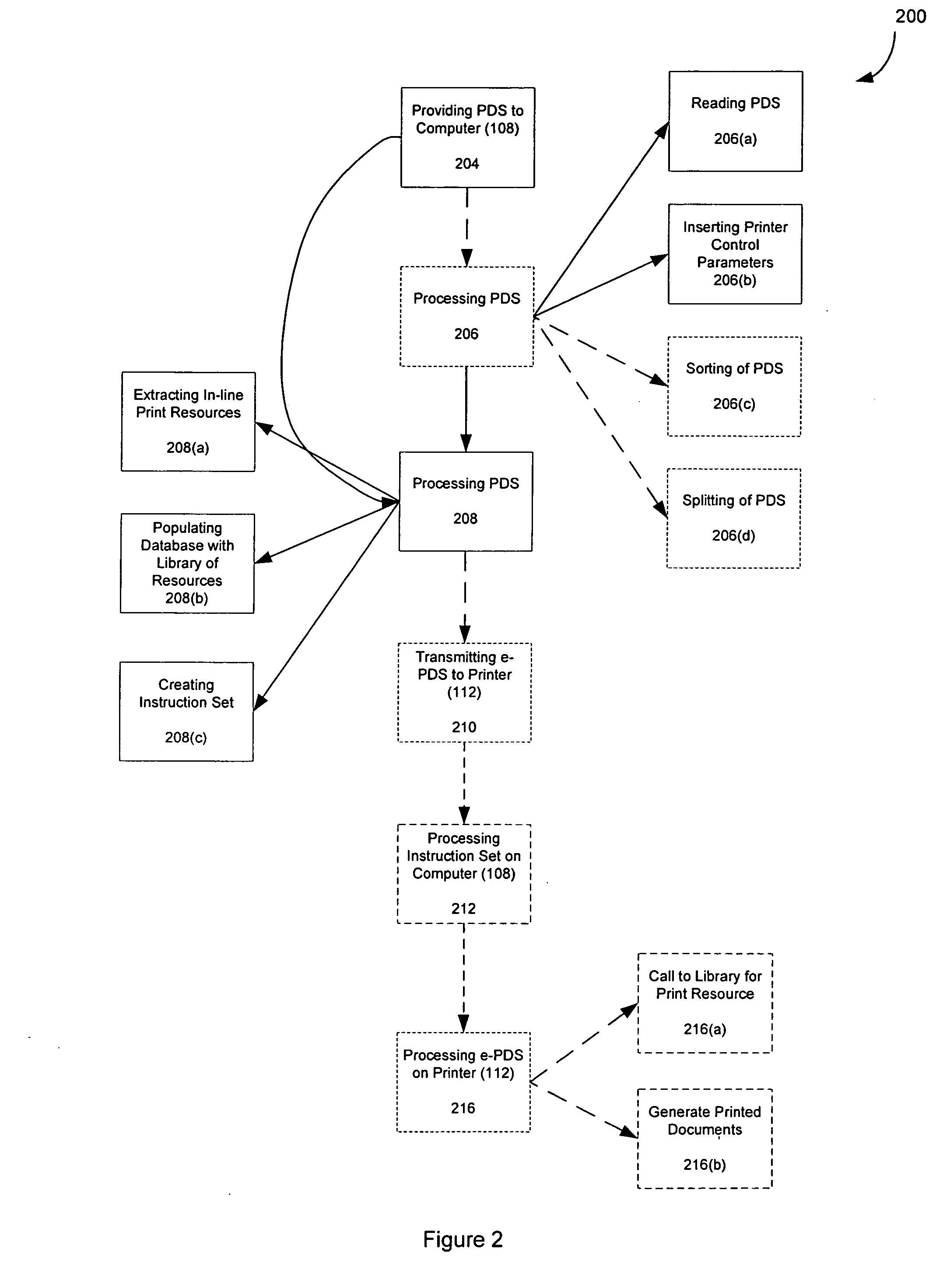

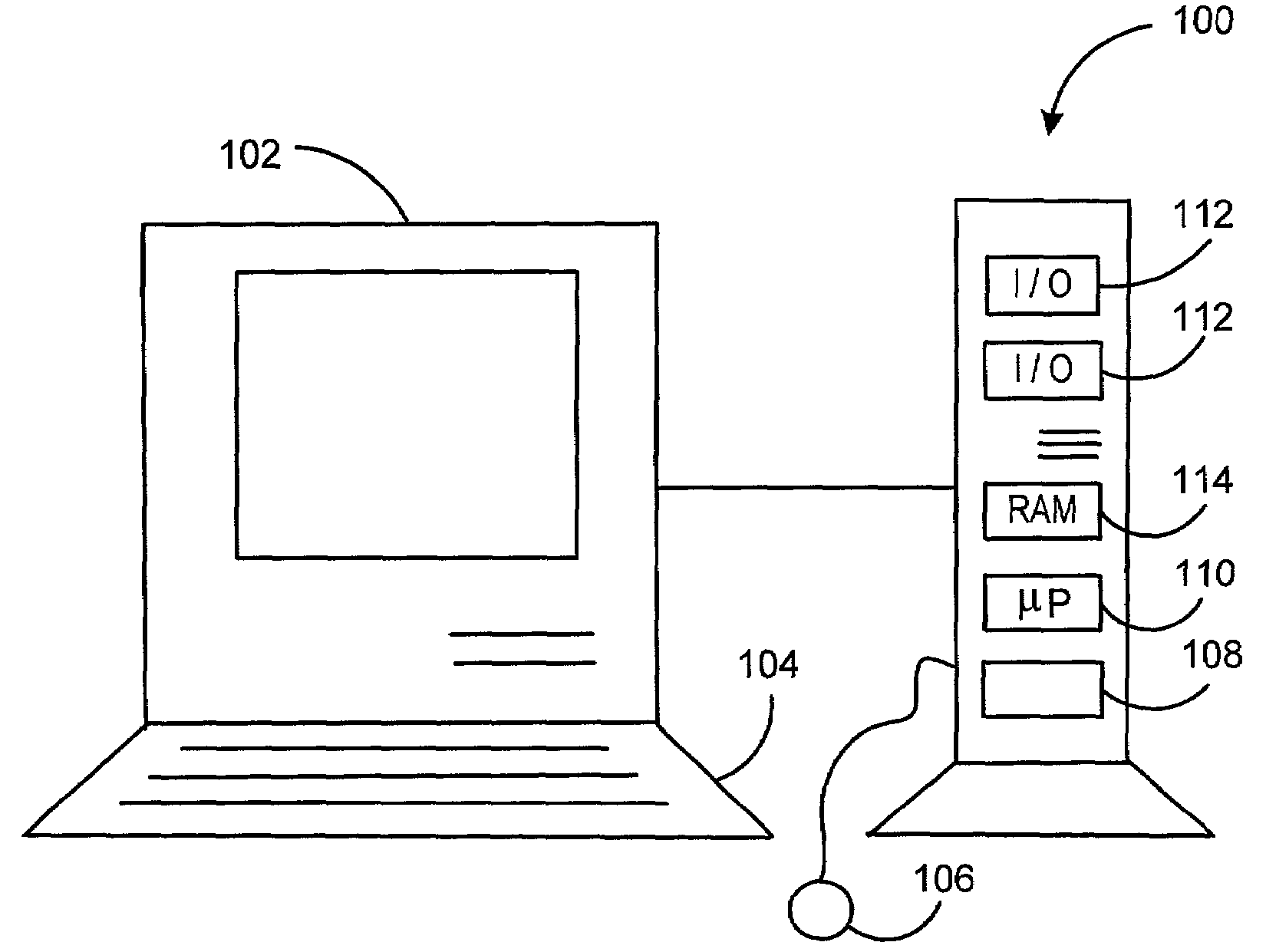

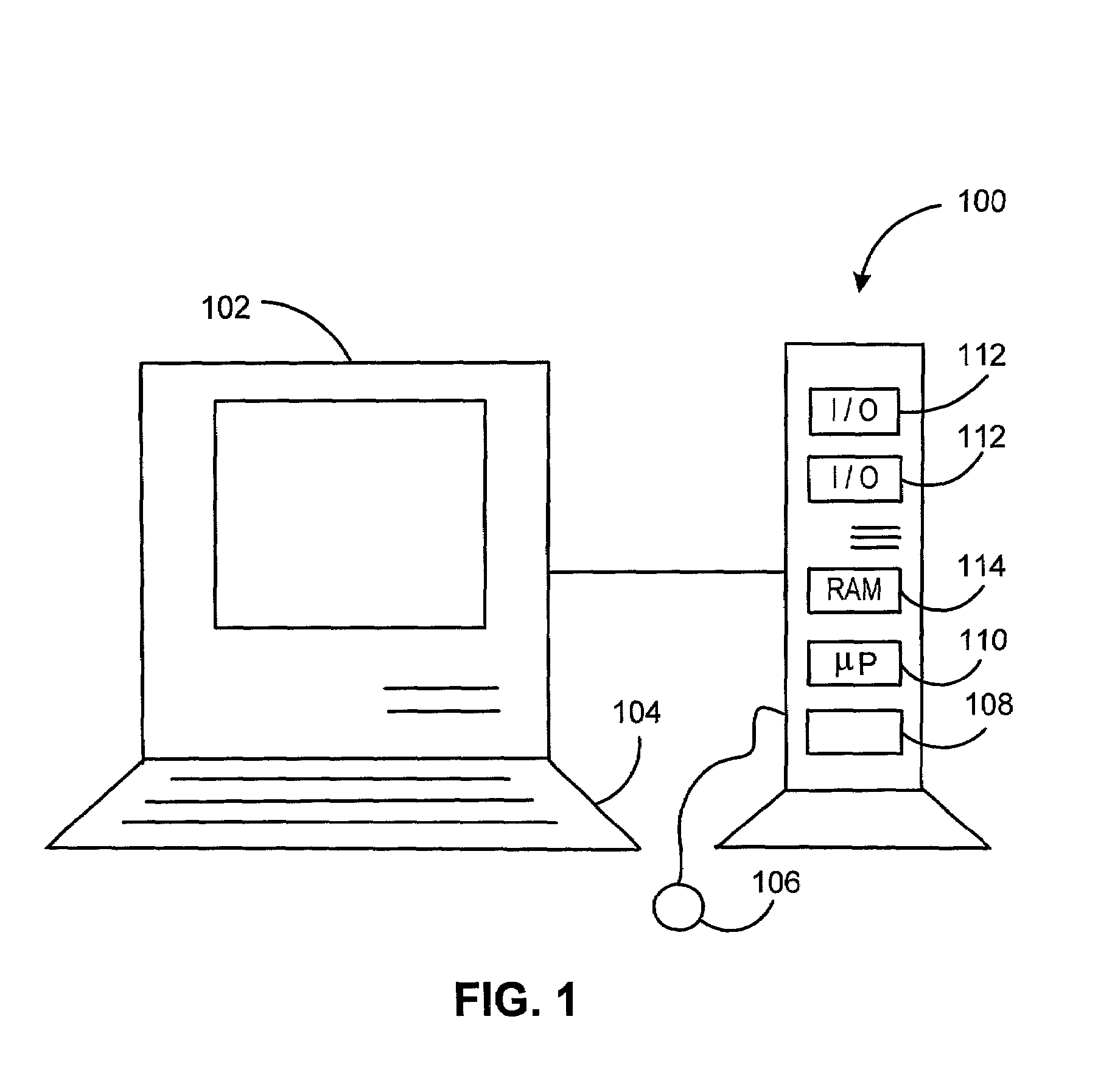

System and method for improved printing efficiency

InactiveUS20060256357A1Improve efficiencyHigh operating requirementsDigital computer detailsVisual presentationData streamLine printer

In accordance with the present invention, the efficiency of printing systems are improved by manipulating the print data stream (PDS), e.g., an AFP data stream (AFPDS) prior to communication to the printer. The methods generally involve manipulating a PDS prior to communication to a printer to provide a modified PDS which is more efficiently process by a printer. The PDS may be manipulated in a variety of ways, including combinations of in-line printer resource extraction, data parsing, insertion of printer control parameters, etc. In various embodiments, in-line printer resources may be extracted from the data stream and placed in a database for later access, or alternatively may be processed by software or algorithms to generate a modified resource which is reintroduced to the data stream.

Owner:FIRST DATA

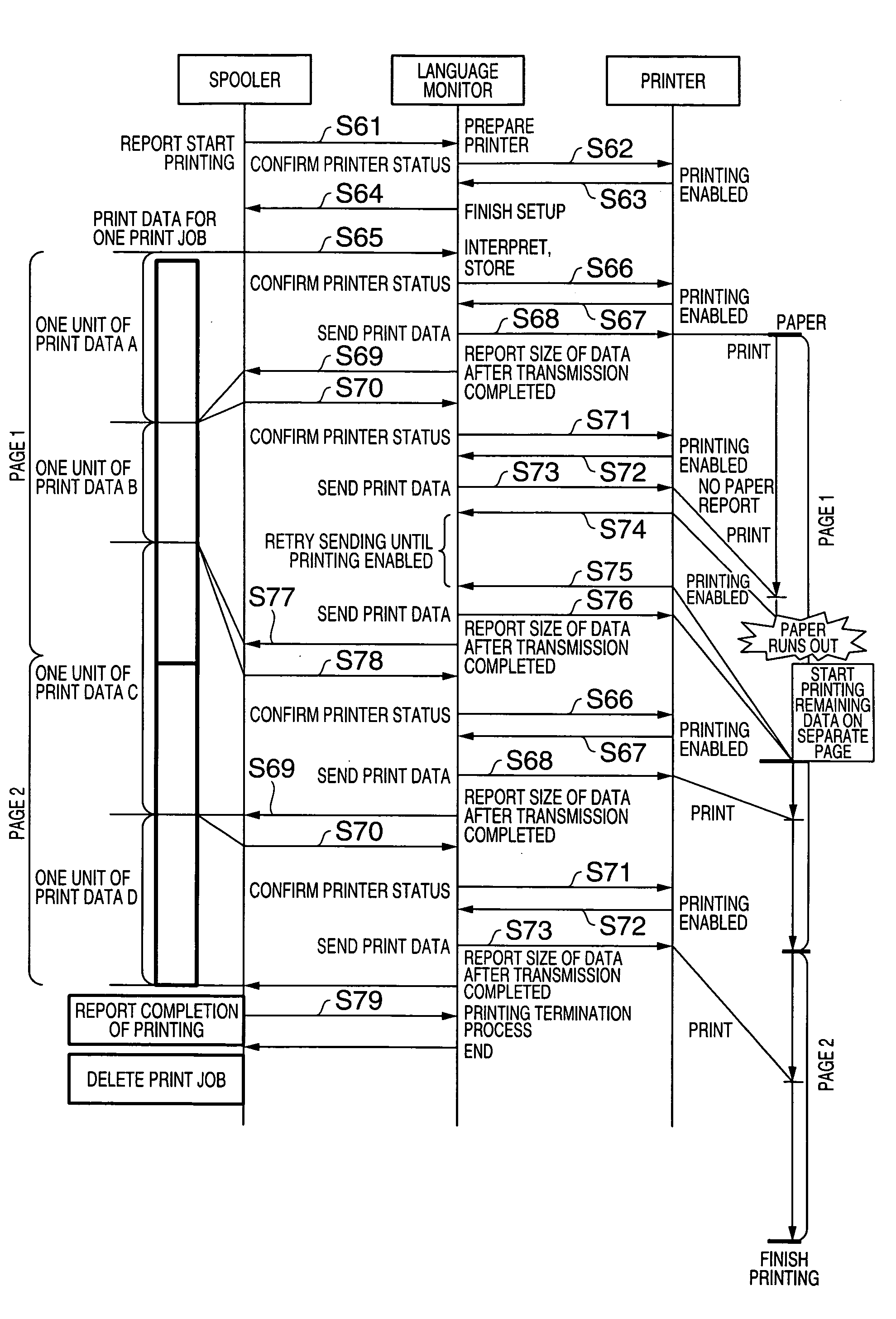

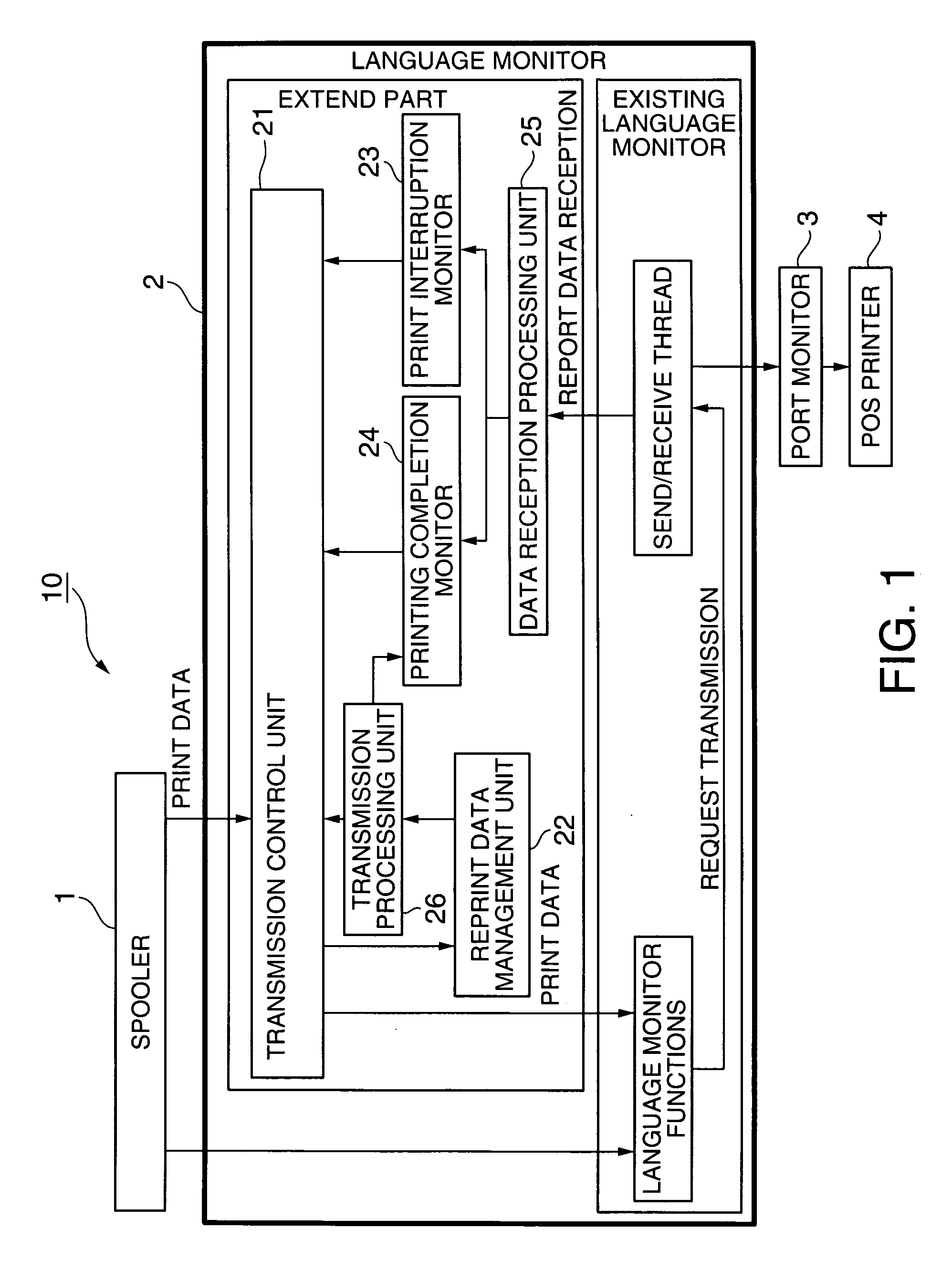

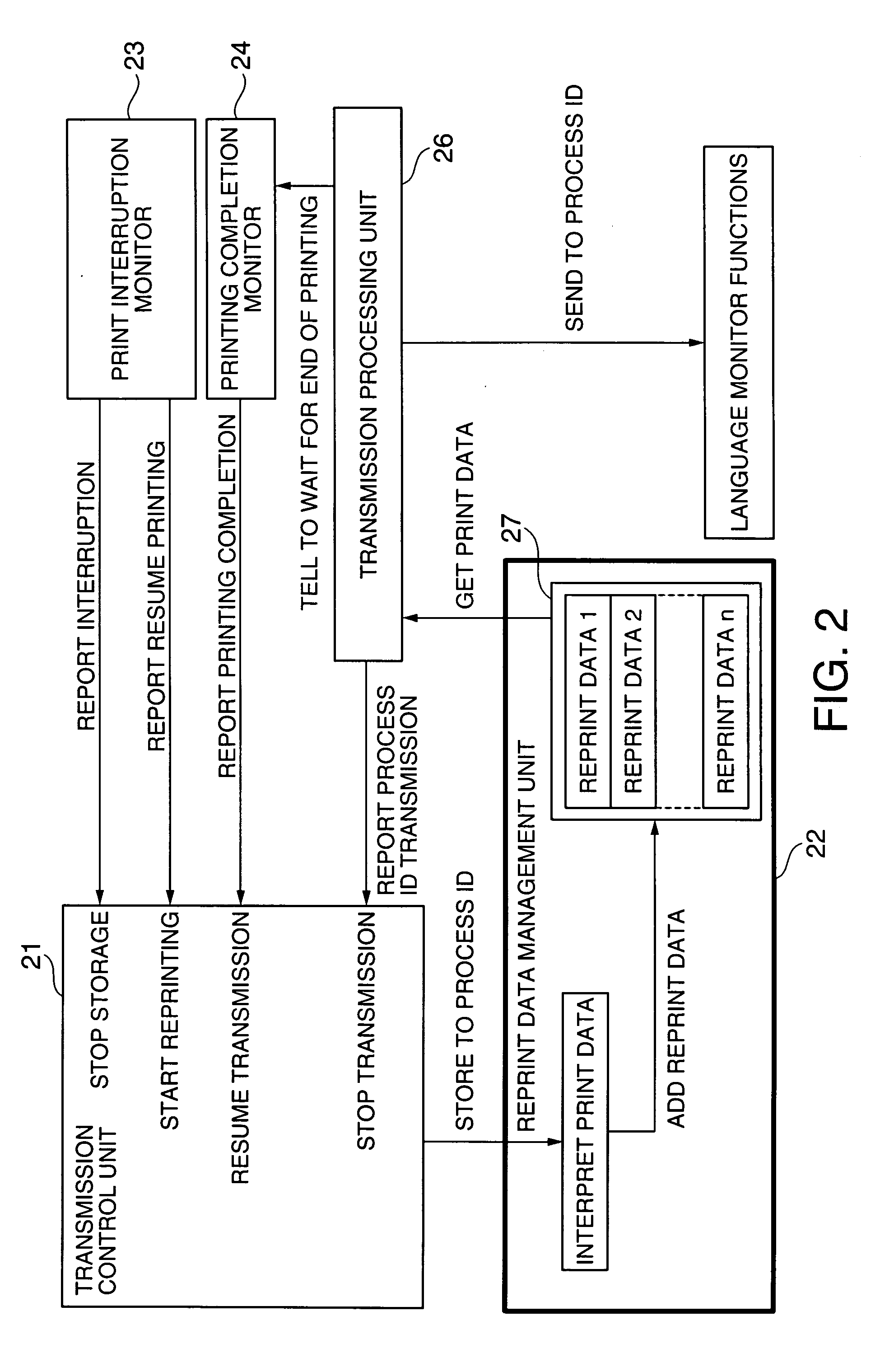

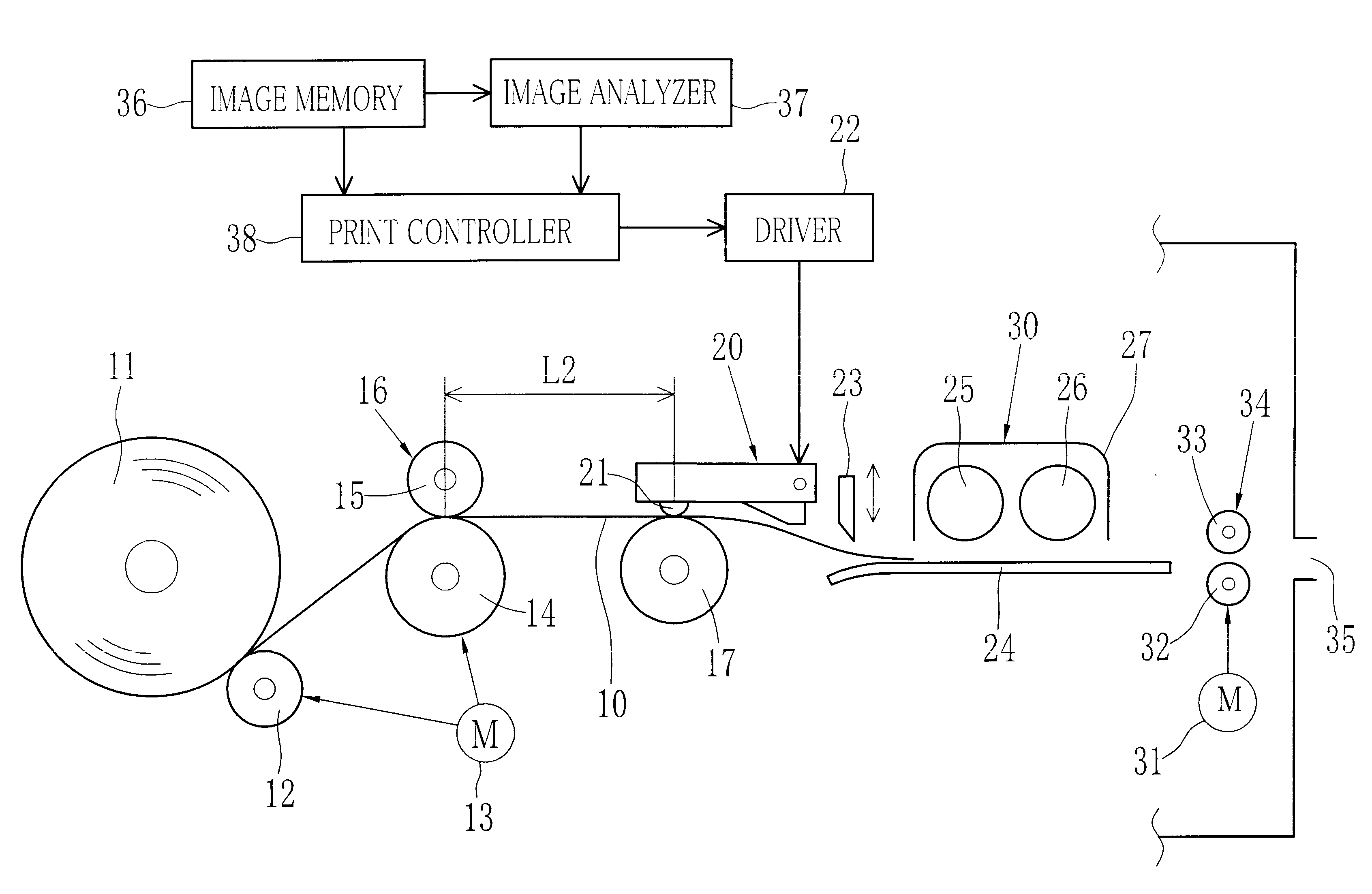

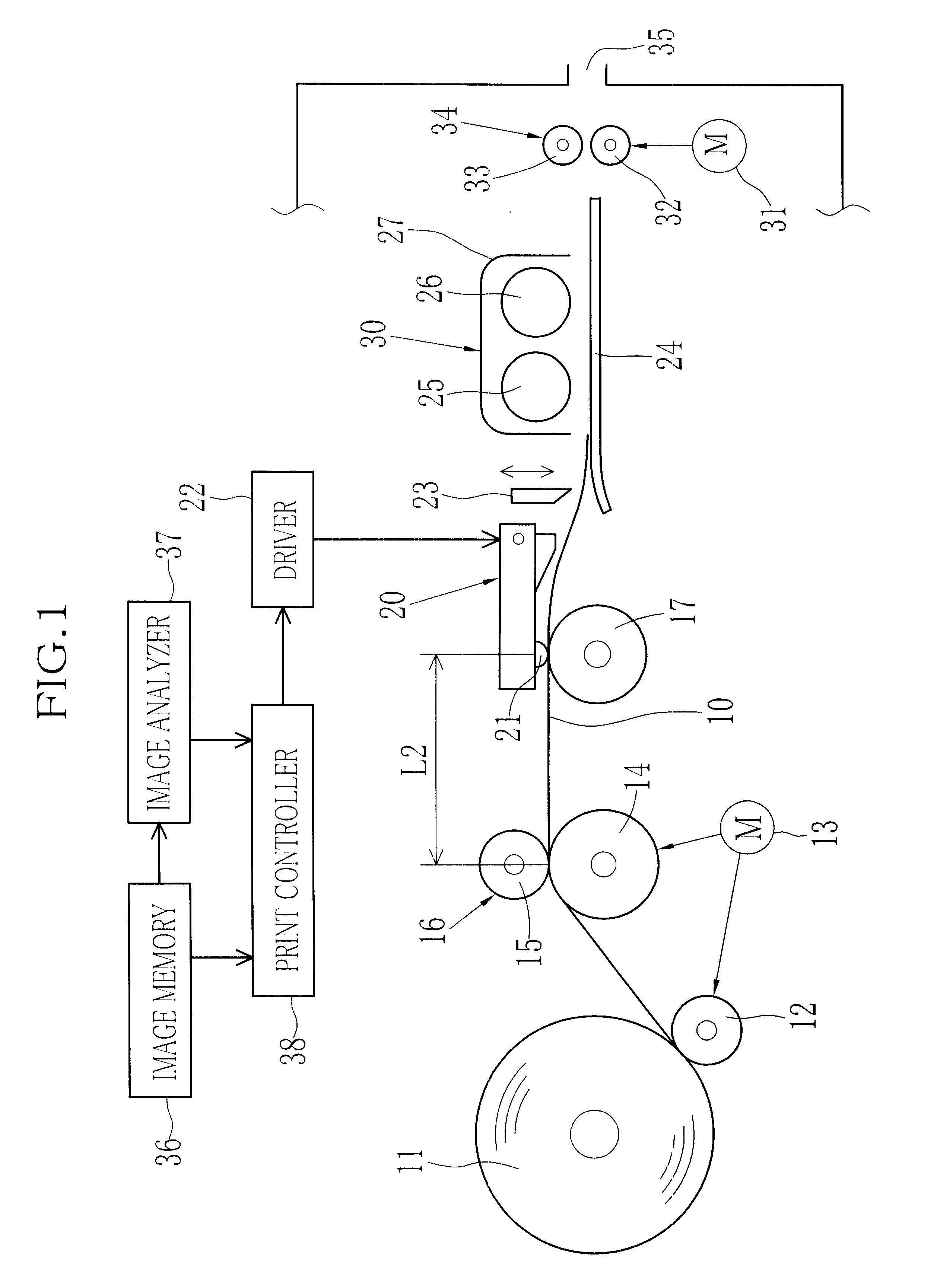

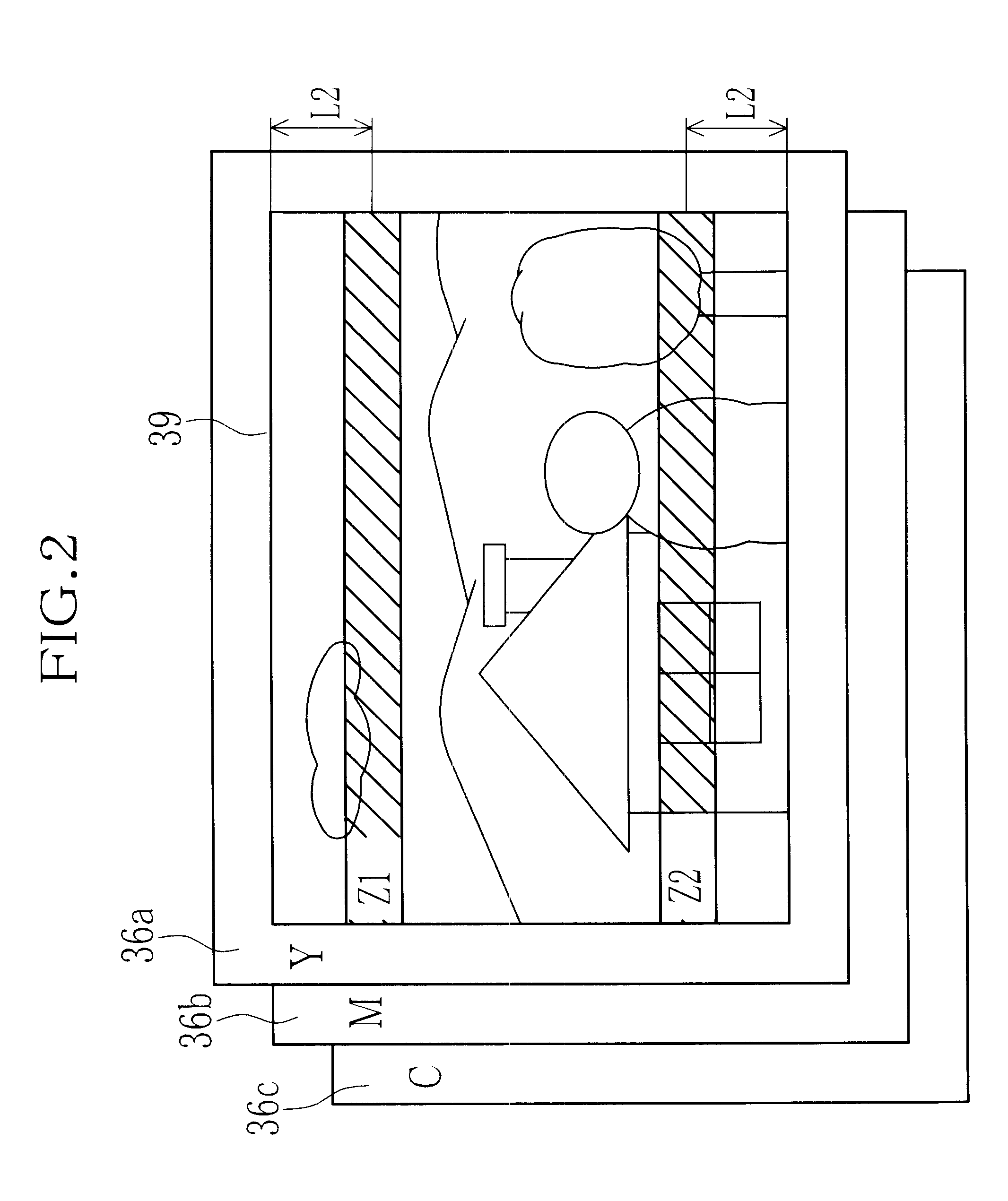

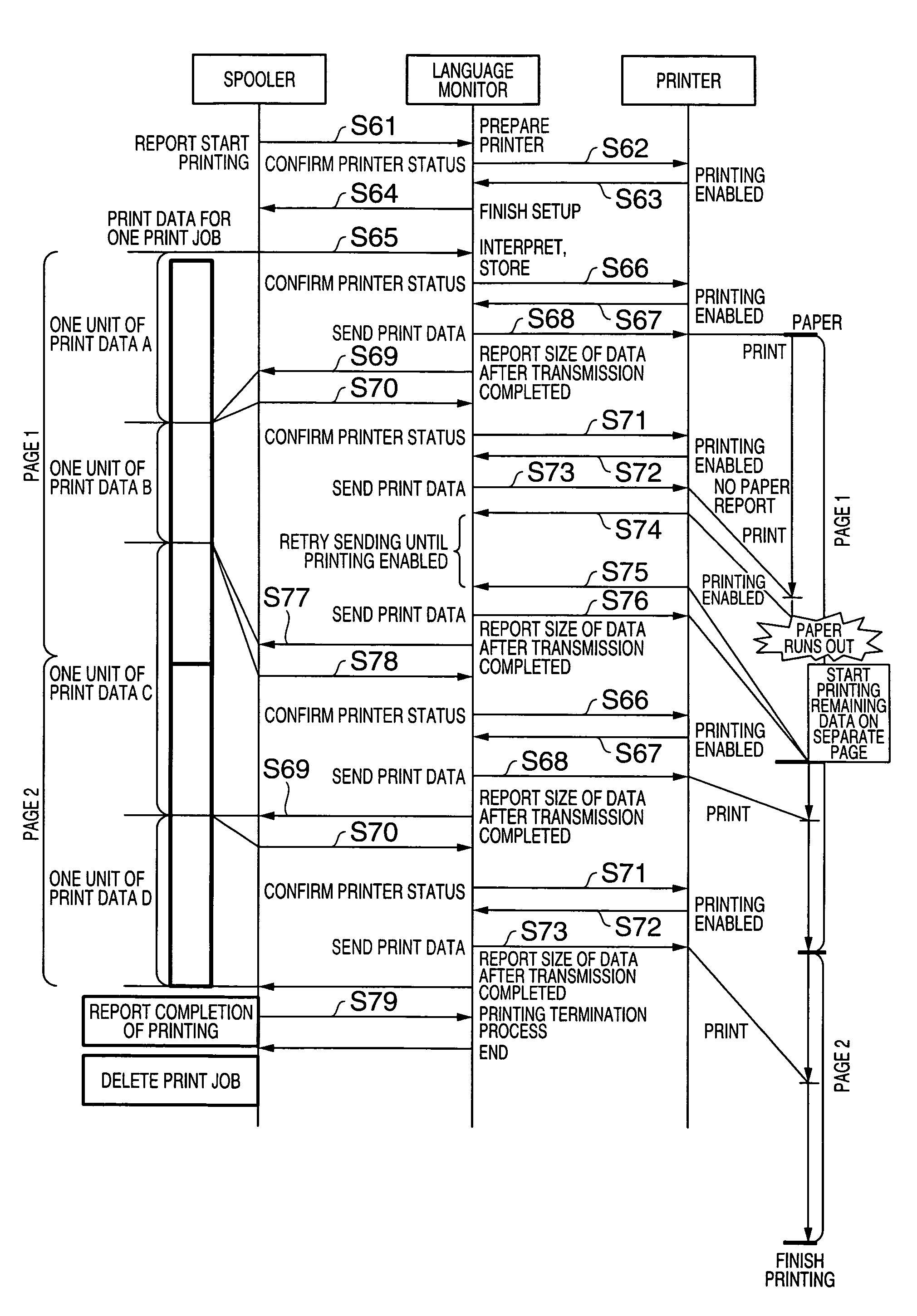

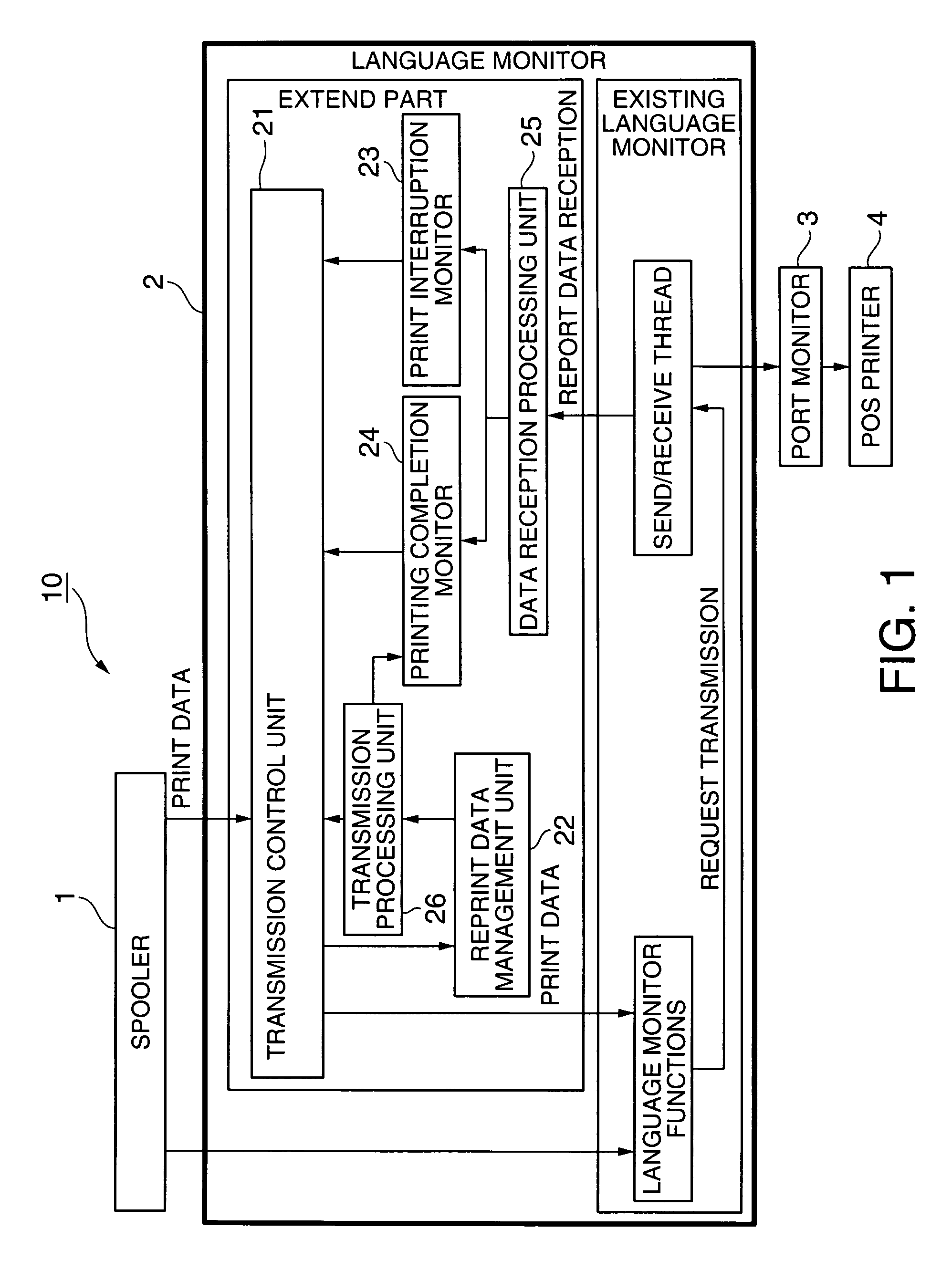

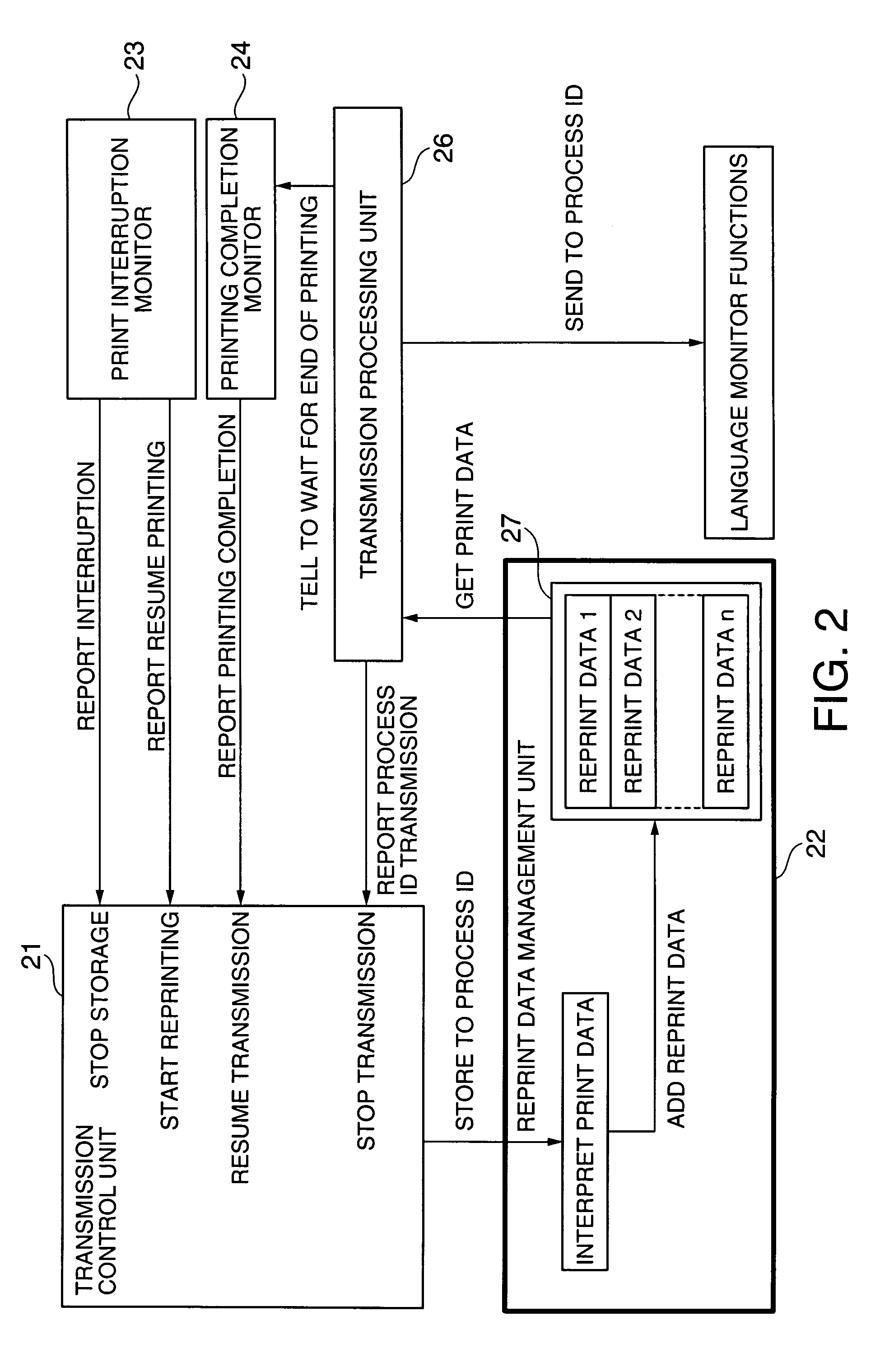

Printing control device and printing control method

ActiveUS20080144100A1Inhibit outputDigitally marking record carriersMultiple digital computer combinationsLine printerManagement unit

A printing system and a printing control method for a printing system that enables automatically resumption of printing after recovering from a printing interrupt event without adding any changes to the conventional page printer, serial printer, line printer, or other type of printer and without needing to monitor which page is being printed when a printing interrupt event occurs. A reprint data management unit temporarily stores one page of print data to which page end information is added. A printing completion monitor monitors reception of a completion report that is sent by the printer when the printer reads the page end information. When the printing completion monitor detects the completion report, the reprint data management unit deletes the stored page of print data. A print interruption monitor detects if a printing interrupt event occurs during printing. If the print interruption monitor detects an interrupt and the cause of the interrupt is then corrected, the reprint data management unit sends the stored page of print data to the POS printer from the beginning again.

Owner:SEIKO EPSON CORP

Thermal line printer and printing method therefor

InactiveUS6533477B2Character printing data arrangement from carrierError detection/correctionLine printerThermal deformation

Owner:FUJIFILM HLDG CORP +1

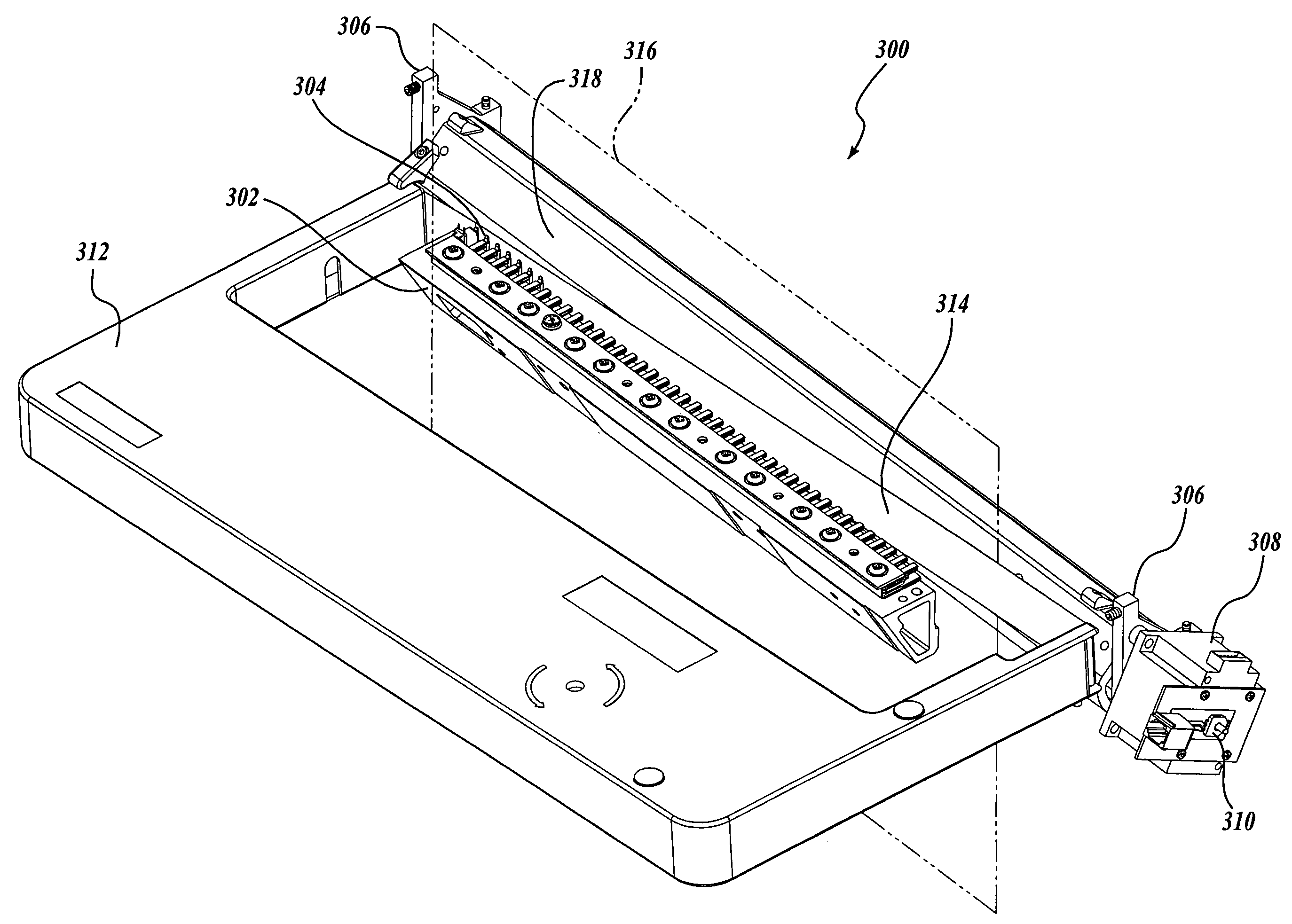

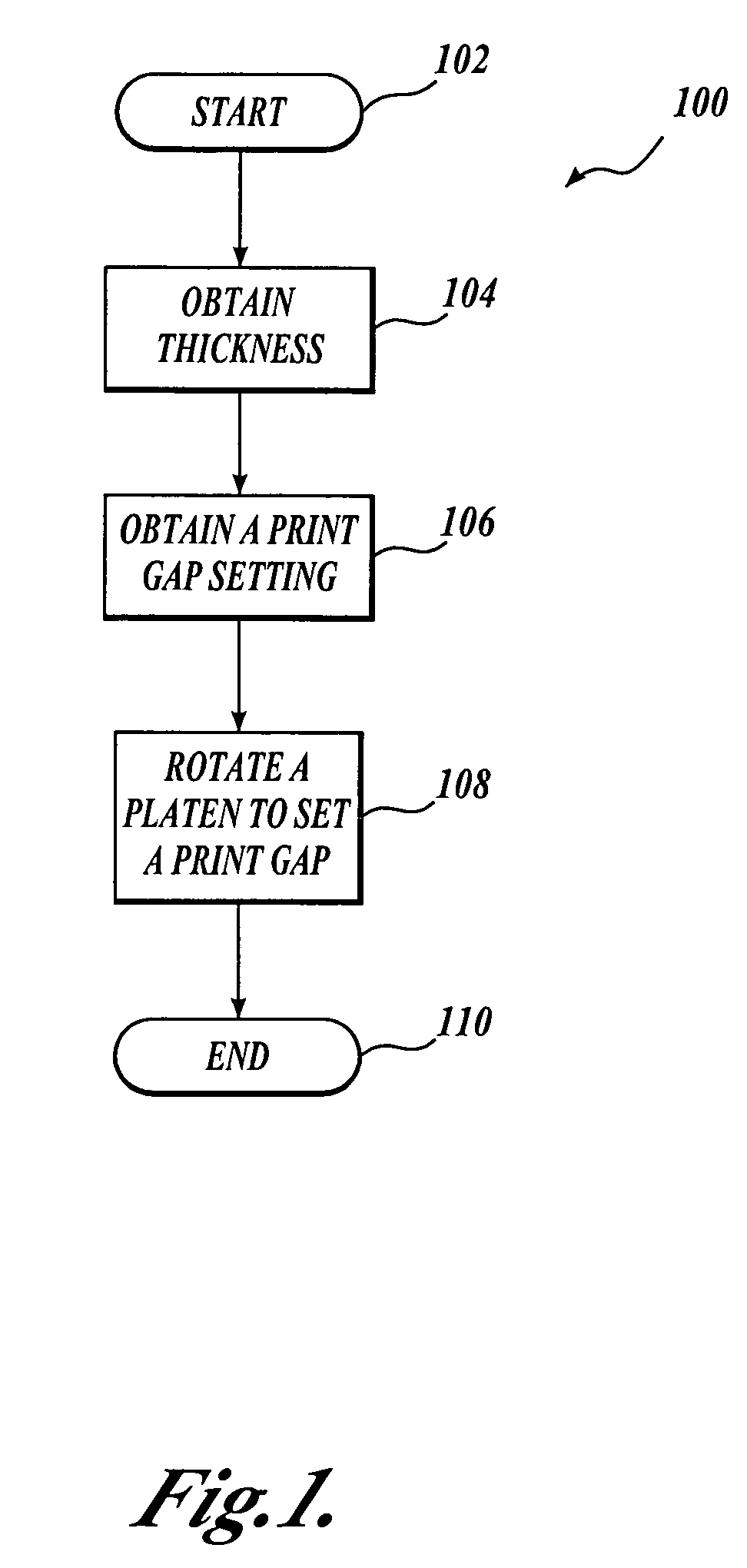

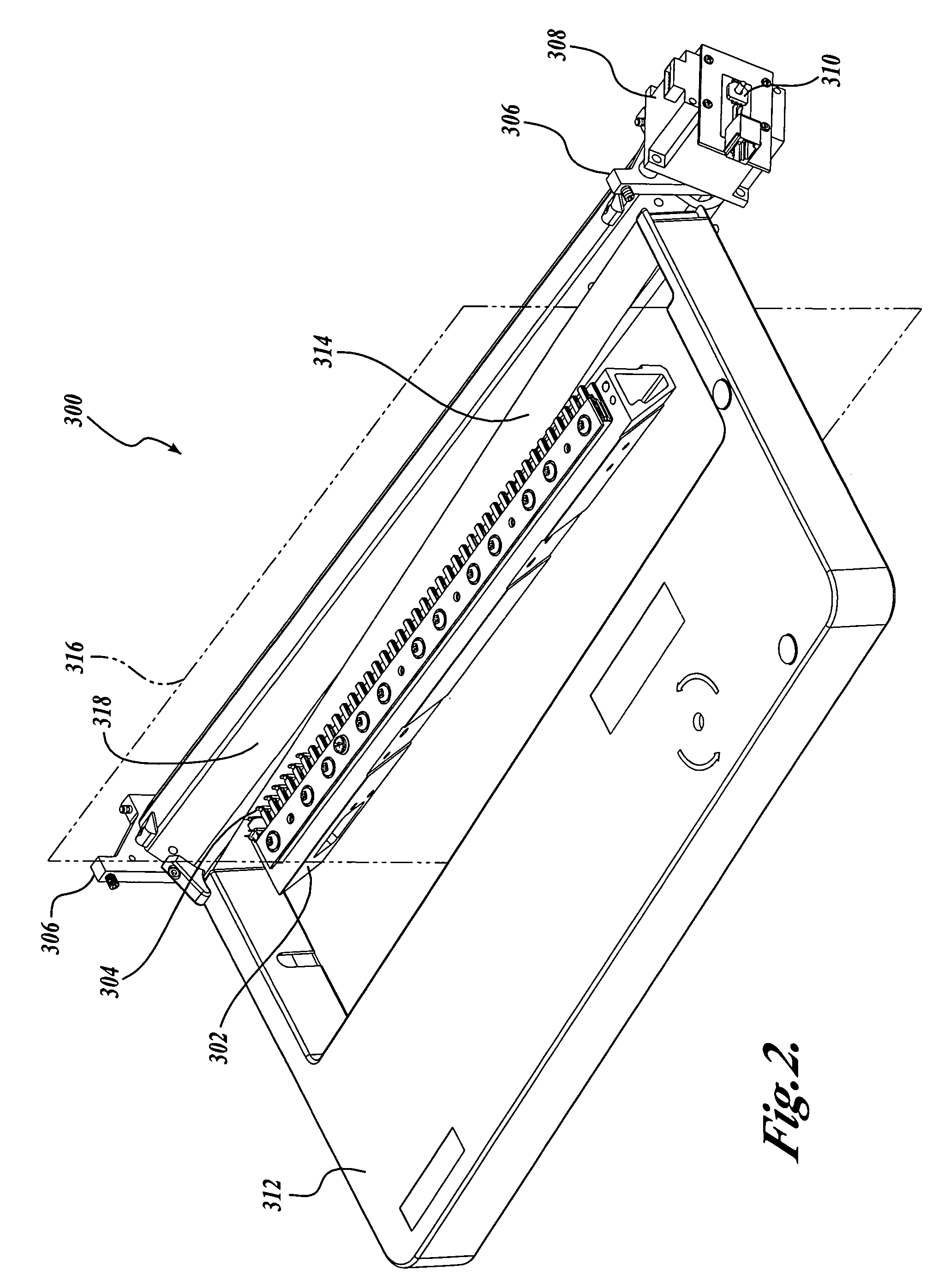

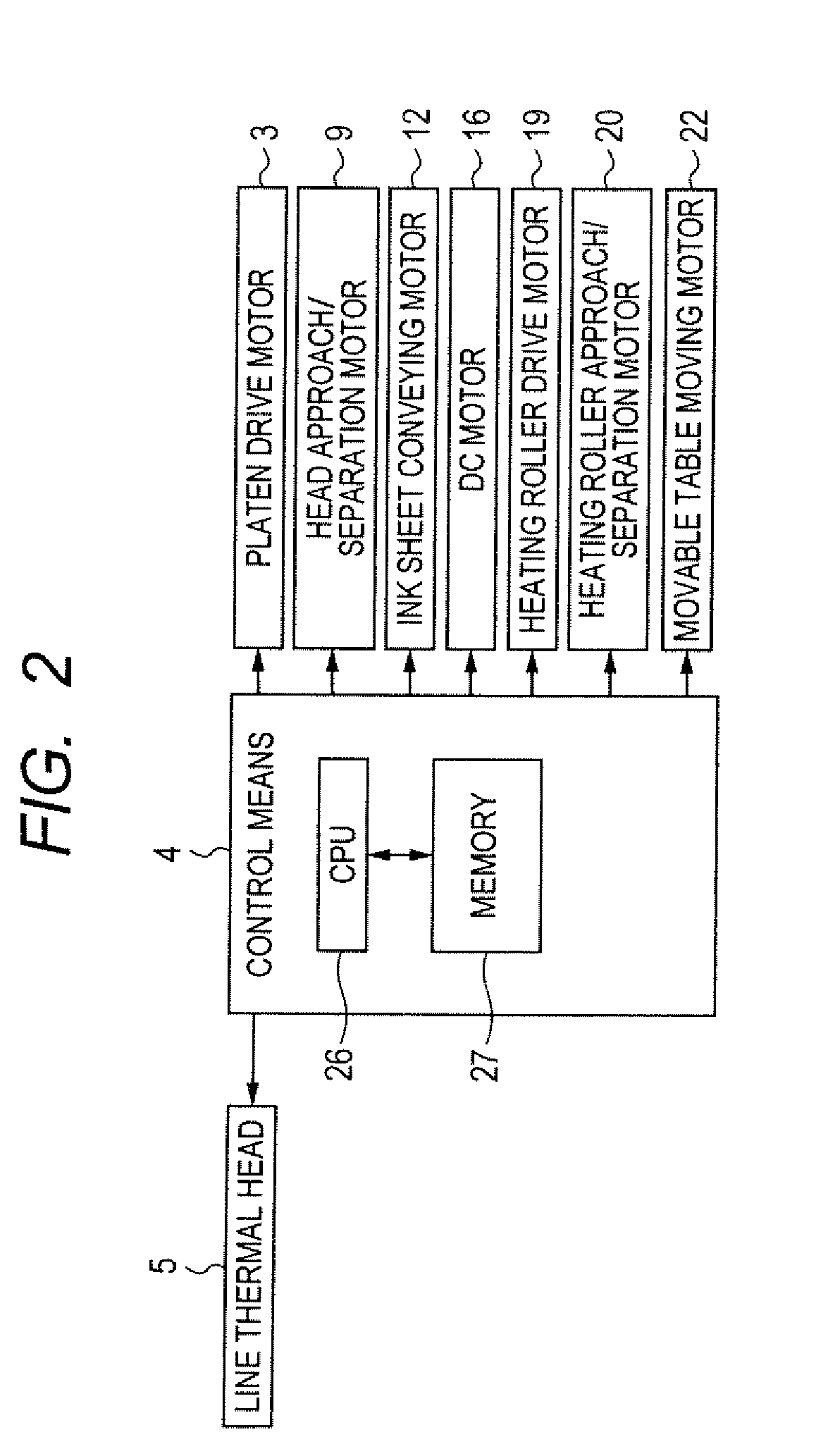

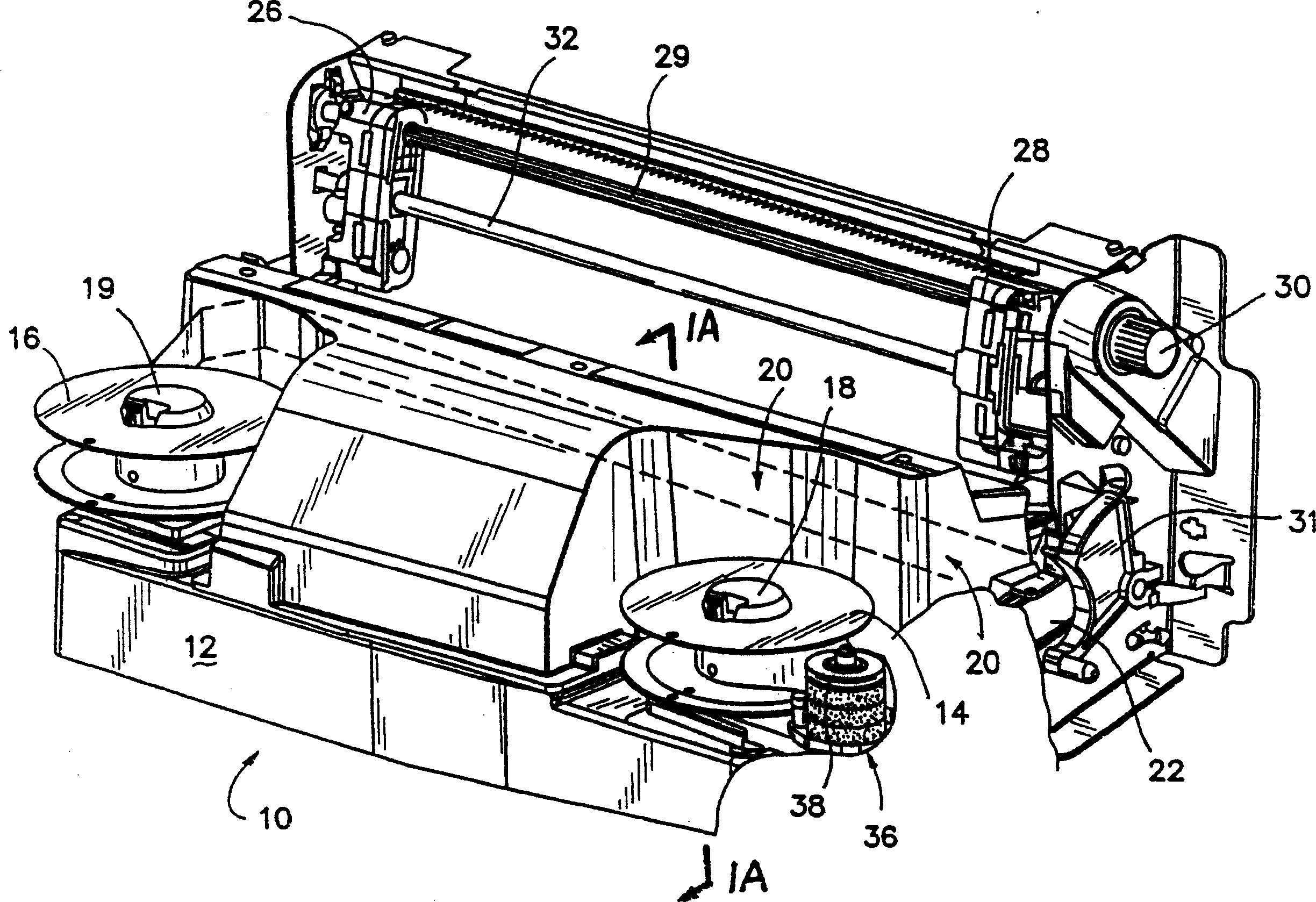

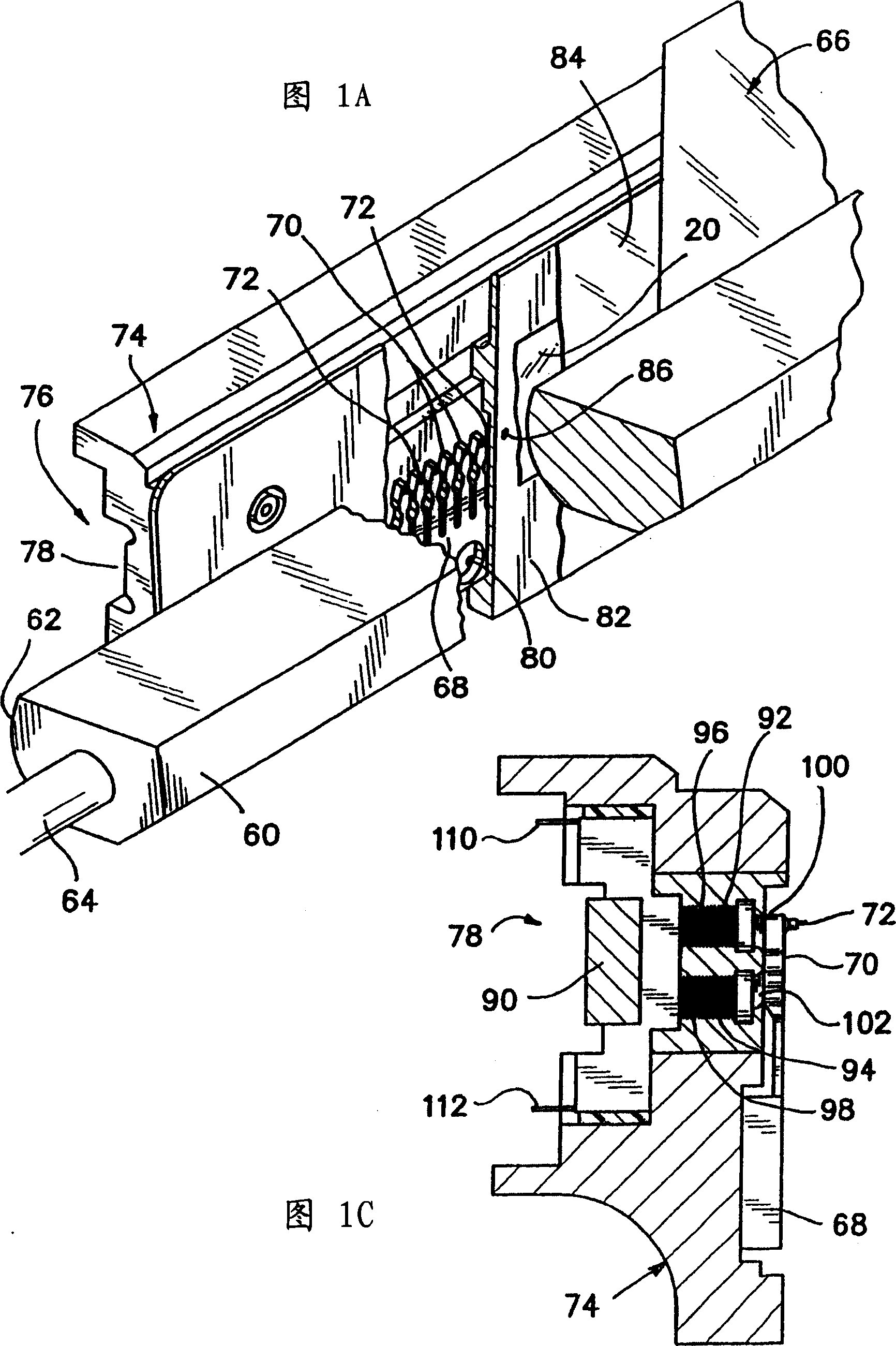

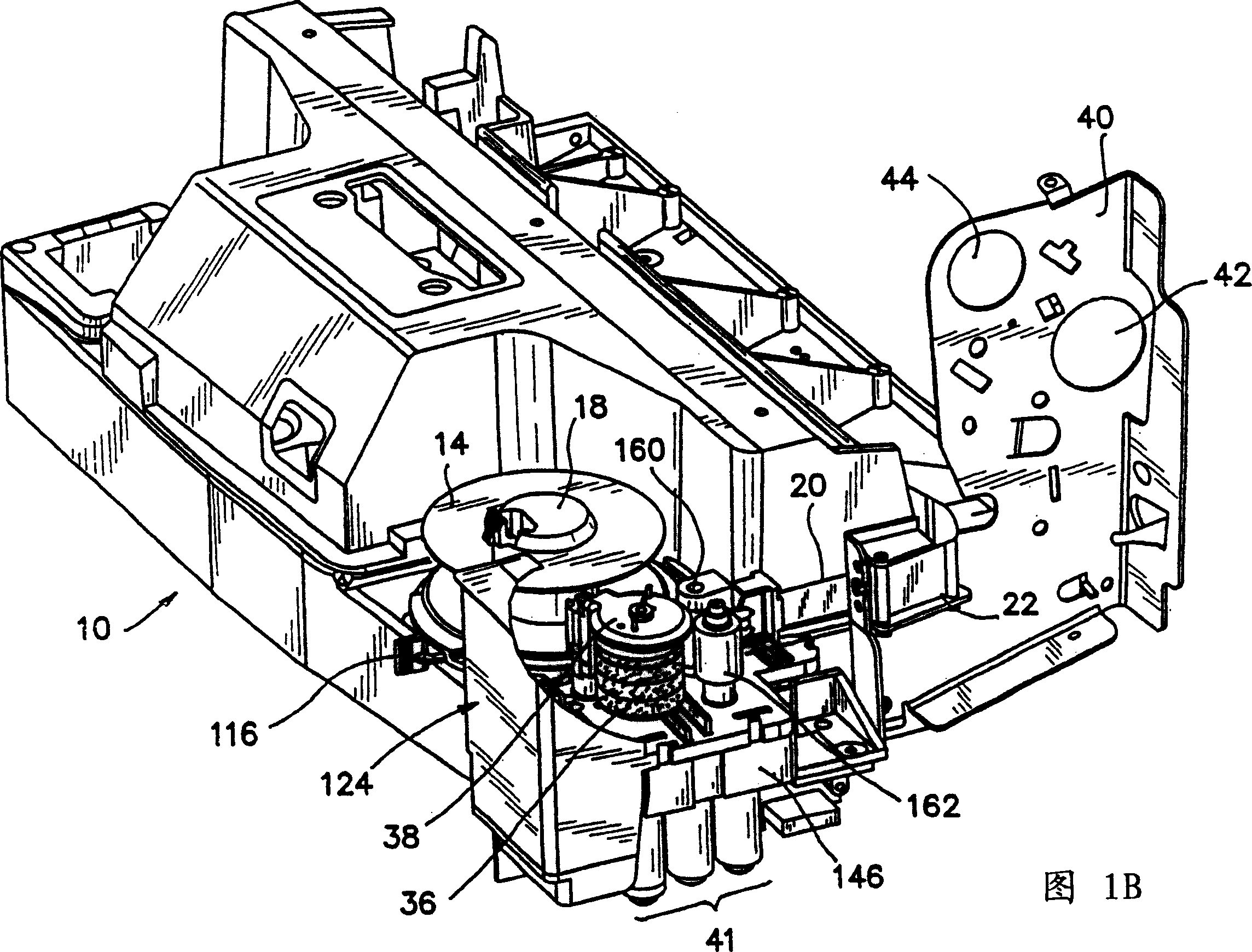

Line printer having a motorized platen that automatically adjusts to accommodate print forms of varying thickness

InactiveUS7290949B1Improve printing qualityRealize automatic adjustmentPower drive mechanismsOther printing apparatusLine printerEngineering

Methods for setting the print gap in a printer are disclosed. The printer has an eccentric platen wherein rotation of the platen changes the print gap distance. A driver controls the eccentric platen rotation, and a sensor may be used to determine the position of the motor and platen. The configuration of an eccentric platen and a driver having a position sensor enables measuring the thickness of a form at one or more locations to create a representative thickness profile of the form, which may be saved to the printer's computer memory and repeated when printing similar forms in the future, thus obviating the need to measure the thickness of every individual form.

Owner:PRINTRONIX INCORPORATED

Printing control device and printing control method

ActiveUS8441666B2Inhibit outputDigitally marking record carriersMultiple digital computer combinationsManagement unitLine printer

A printing system and a printing control method for a printing system that enables automatically resumption of printing after recovering from a printing interrupt event without adding any changes to the conventional page printer, serial printer, line printer, or other type of printer and without needing to monitor which page is being printed when a printing interrupt event occurs. A reprint data management unit temporarily stores one page of print data to which page end information is added. A printing completion monitor monitors reception of a completion report that is sent by the printer when the printer reads the page end information. When the printing completion monitor detects the completion report, the reprint data management unit deletes the stored page of print data. A print interruption monitor detects if a printing interrupt event occurs during printing. If the print interruption monitor detects an interrupt and the cause of the interrupt is then corrected, the reprint data management unit sends the stored page of print data to the POS printer from the beginning again.

Owner:SEIKO EPSON CORP

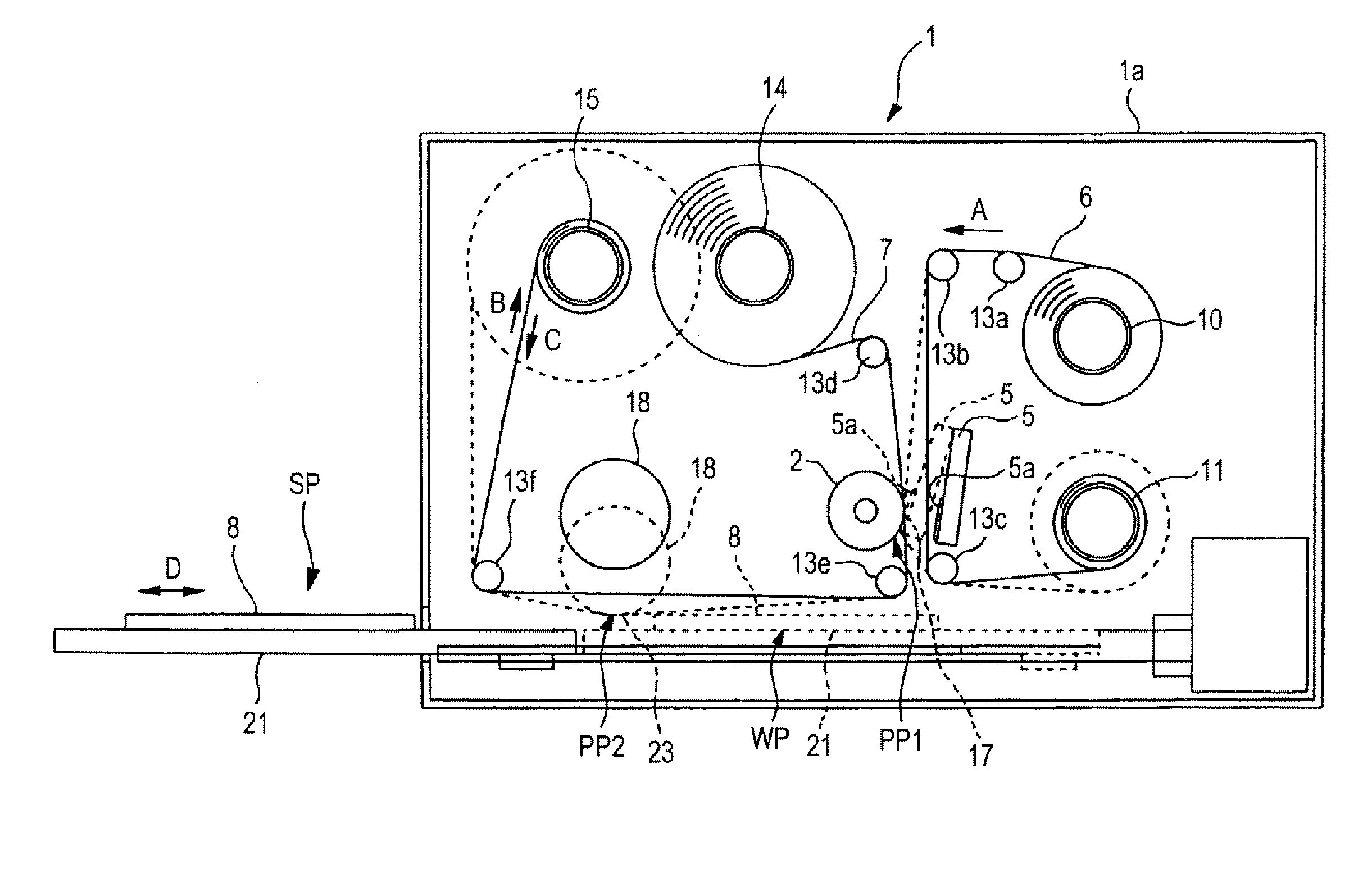

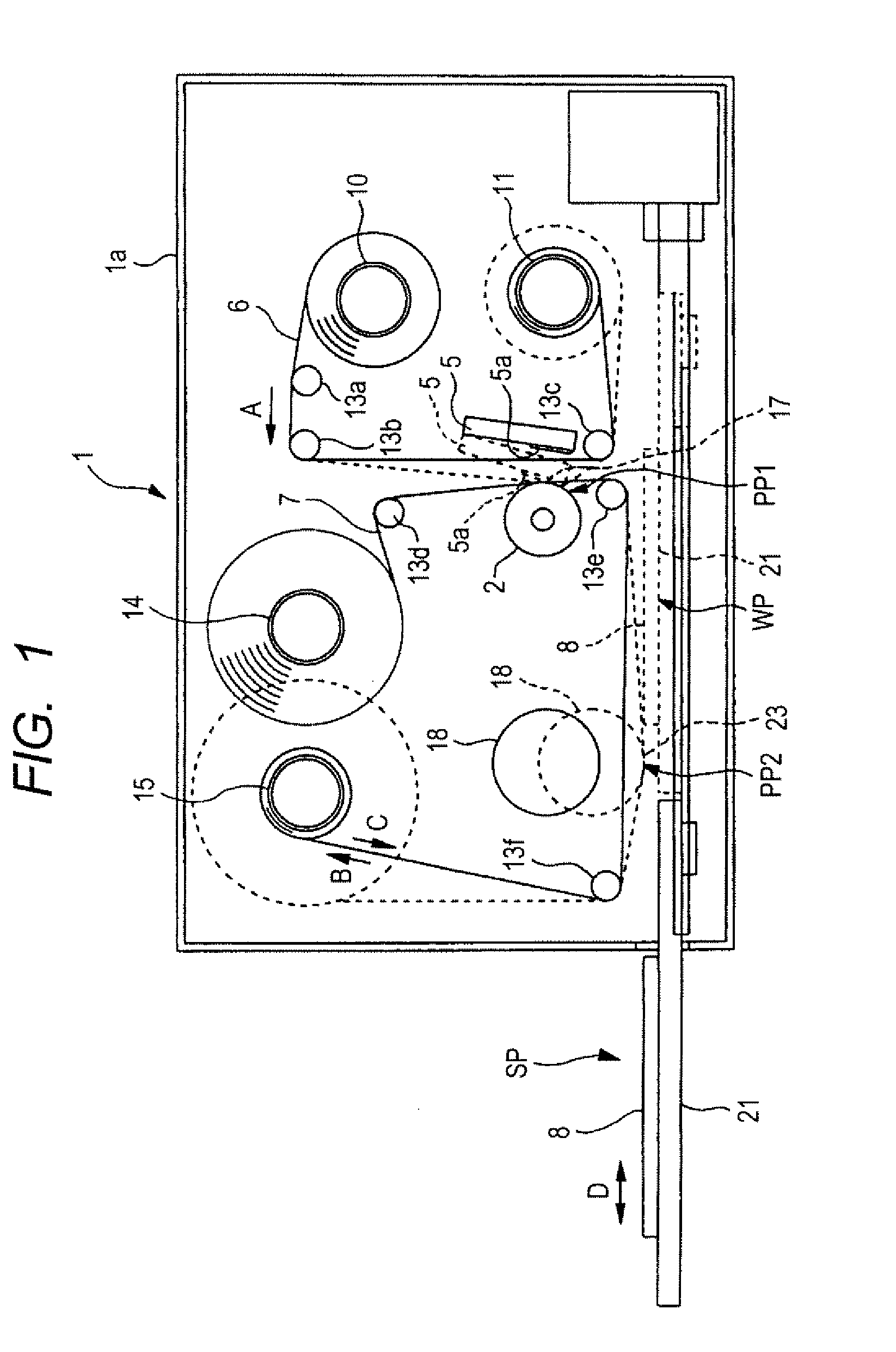

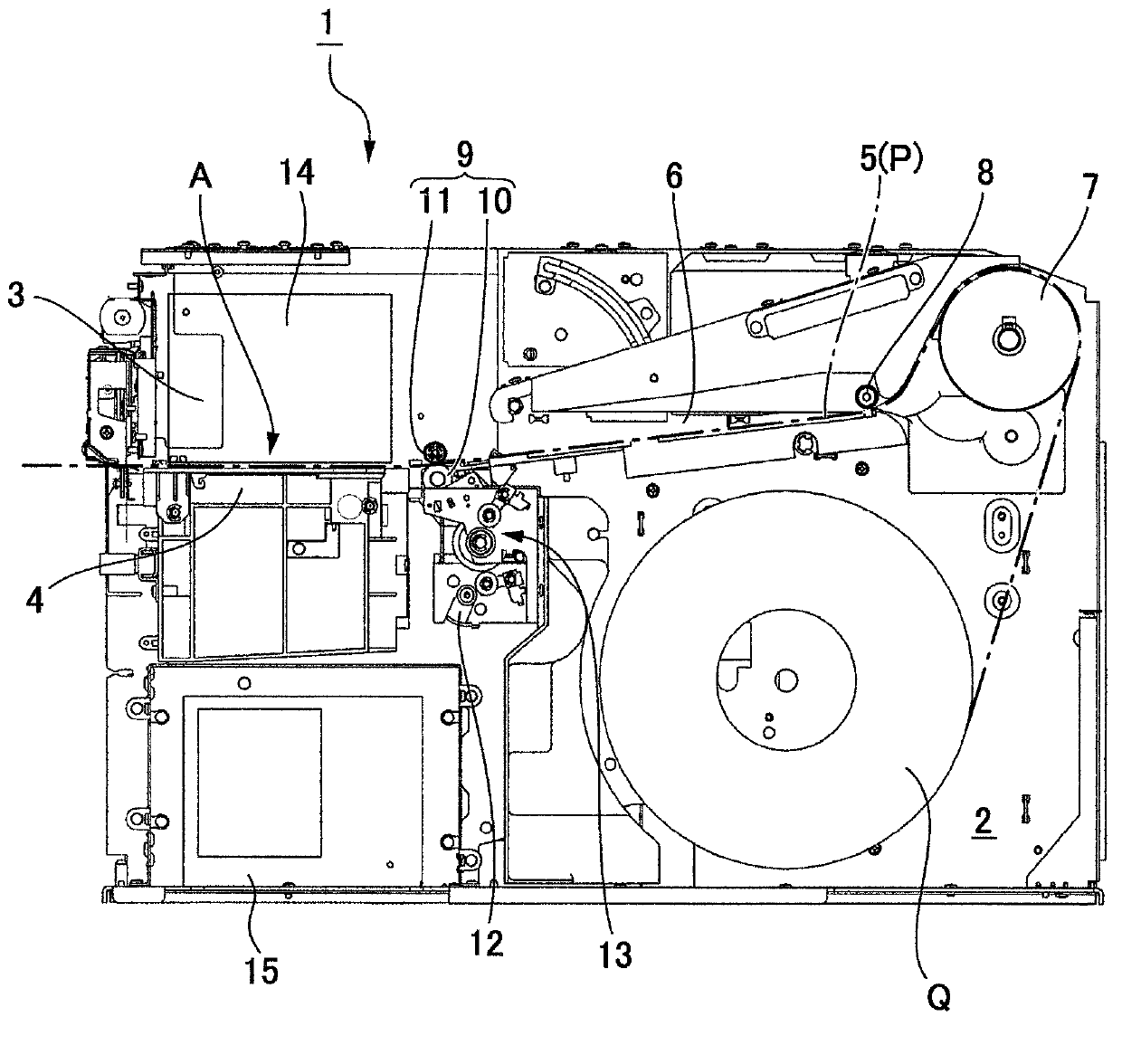

Thermal transfer printer that is capable of maintaining intermediate transfer sheet tension constant

InactiveUS20020167582A1ConstantSimple structureRecording apparatusAutomatic control devicesLine printerComputer printing

The thermal transfer line printer is provided with tension roller position detection means having tension rollers, rotatable tension roller support frames that support the tension rollers rotatably and press the tension rollers toward an intermediate sheet, and a detector and a sensor for detecting a position of the tension rollers and is provided with a controller for controlling operation of an intermediate transfer sheet feeding motor that moves at least the intermediate transfer sheet, and the controller controls the intermediate transfer sheet feeding motor so as to position the detectors in a detection range of the sensors when the intermediate transfer sheet is moved.

Owner:ALPS ALPINE CO LTD

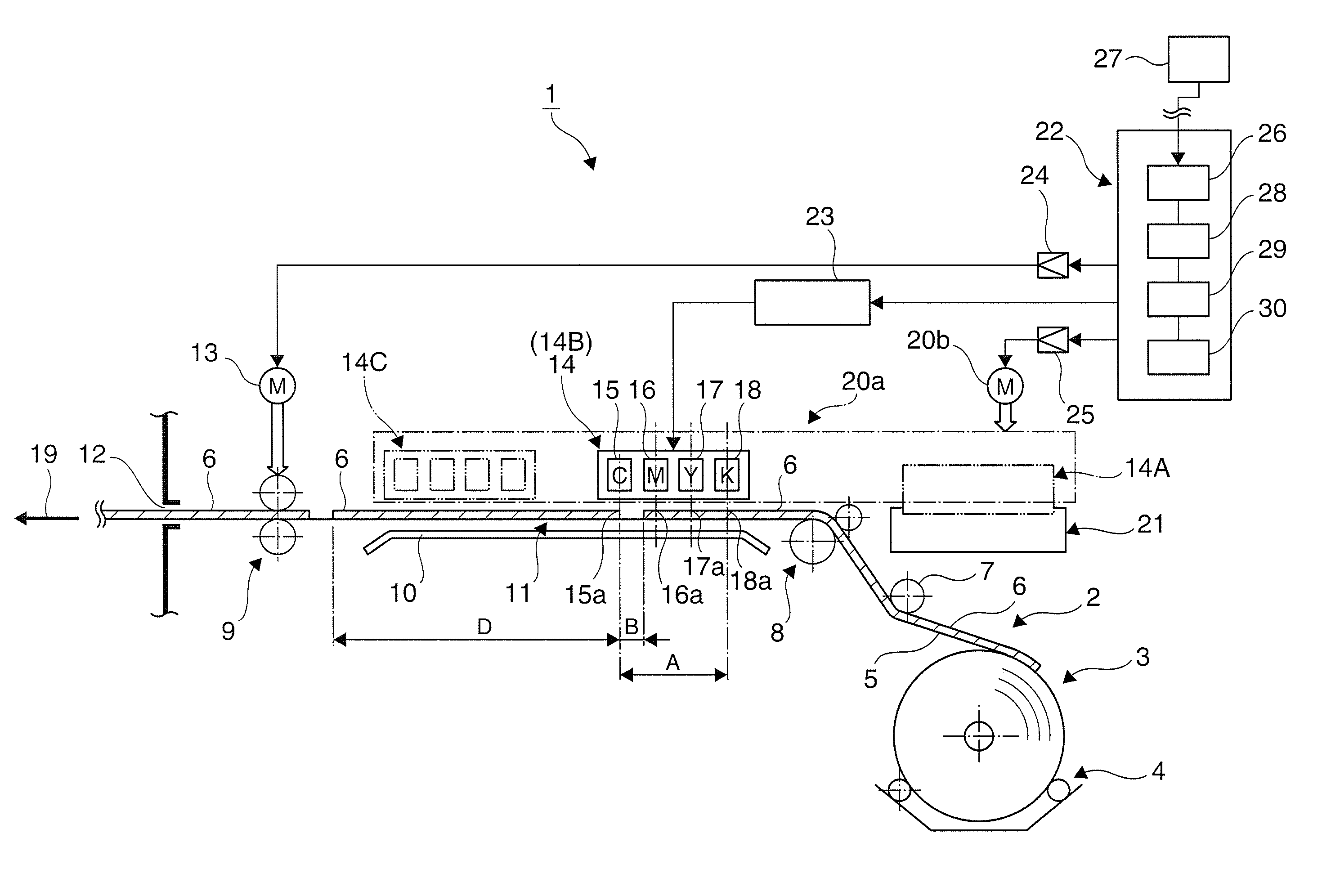

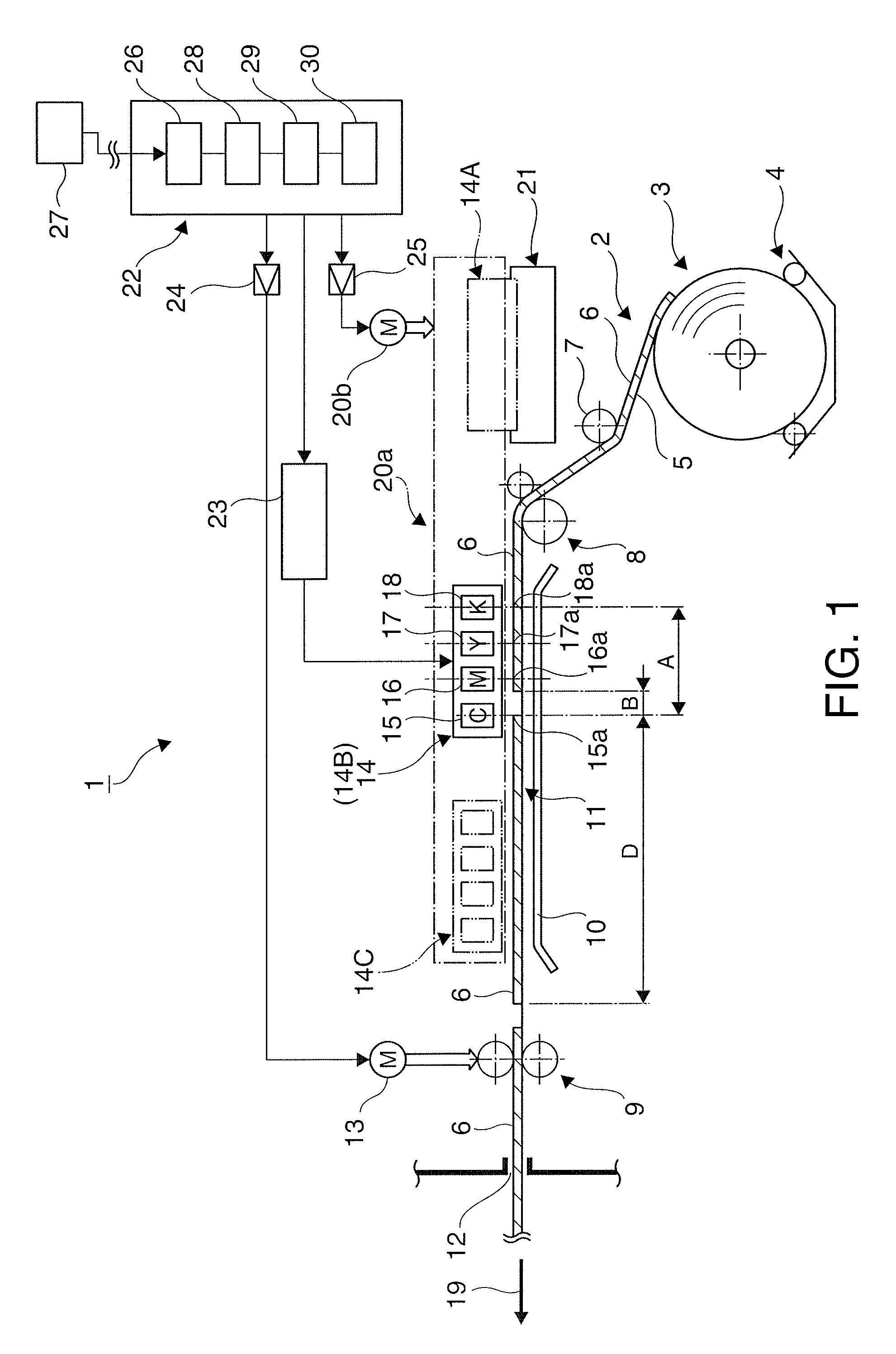

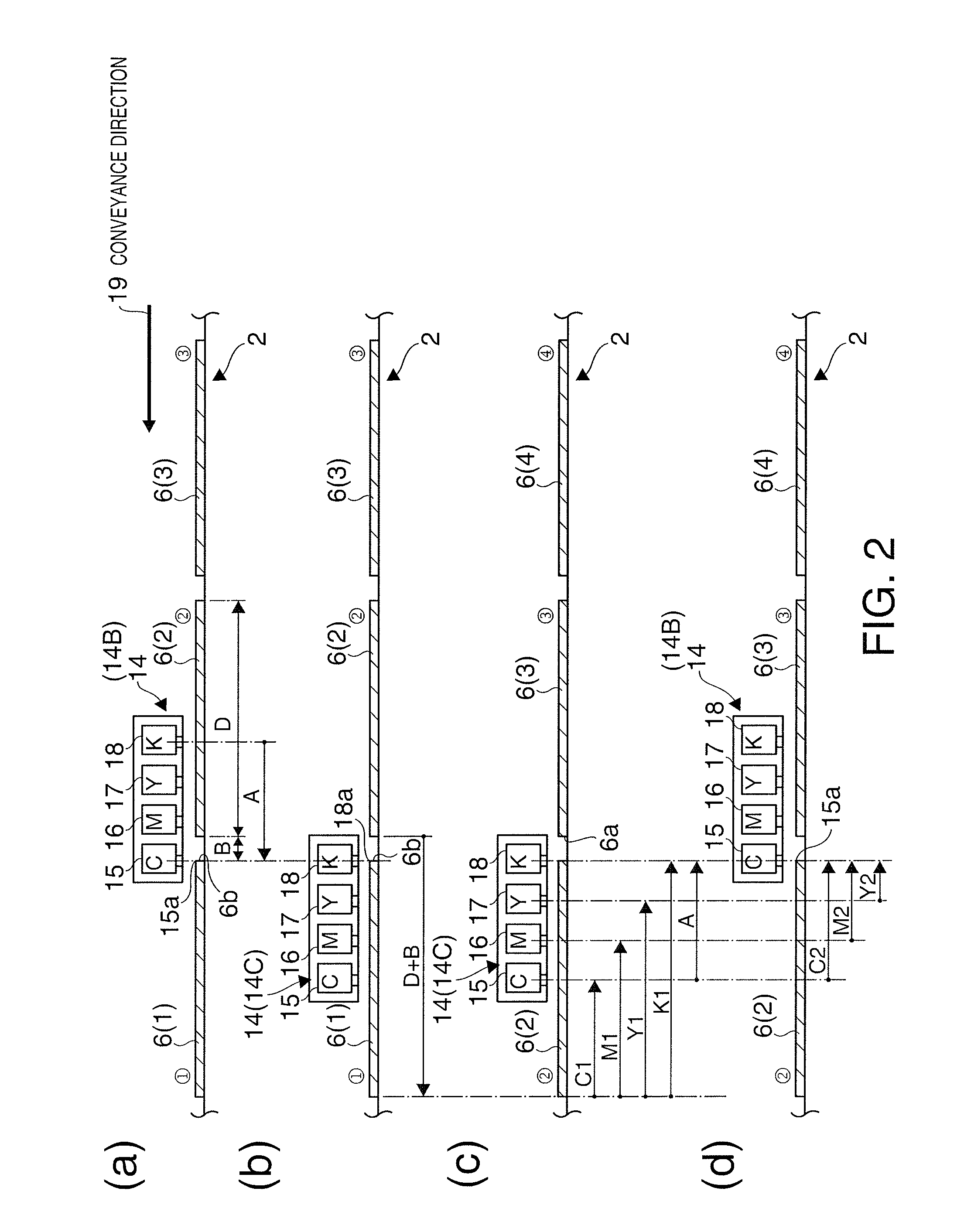

Paper printing method for a line printer, and a line printer

InactiveUS20120236075A1Low costMade small and moreSpacing mechanismsTypewritersLine printerElectrical and Electronics engineering

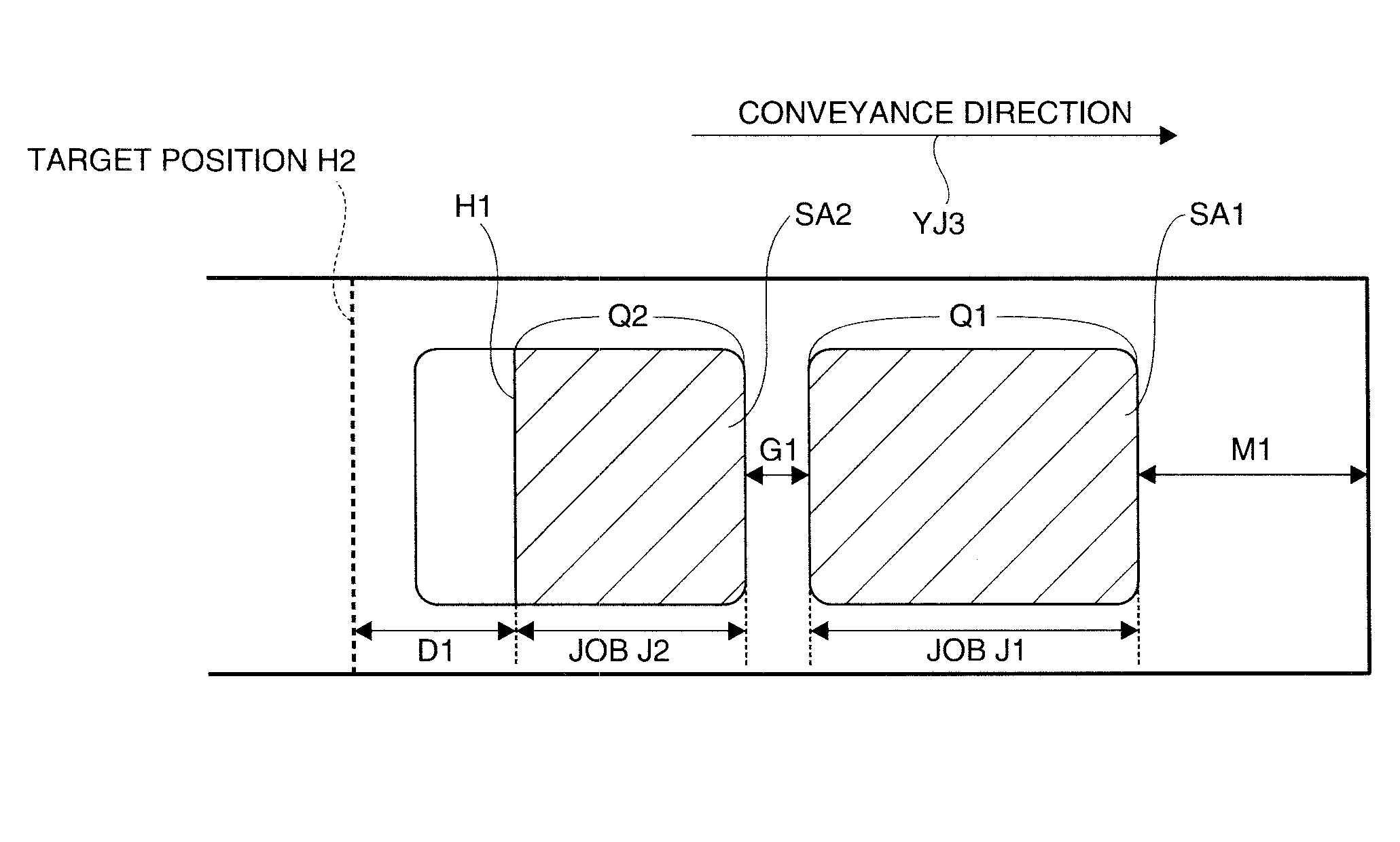

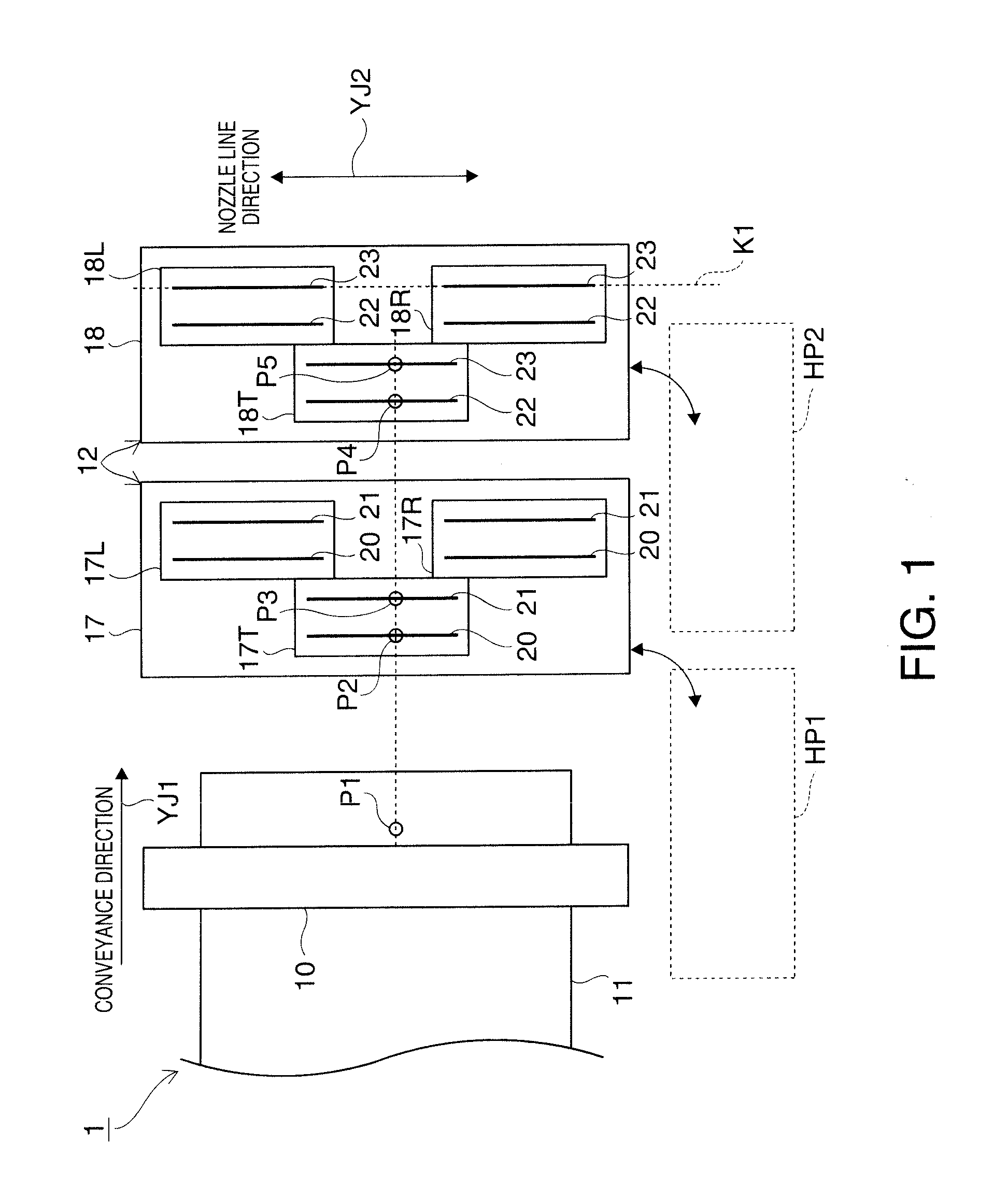

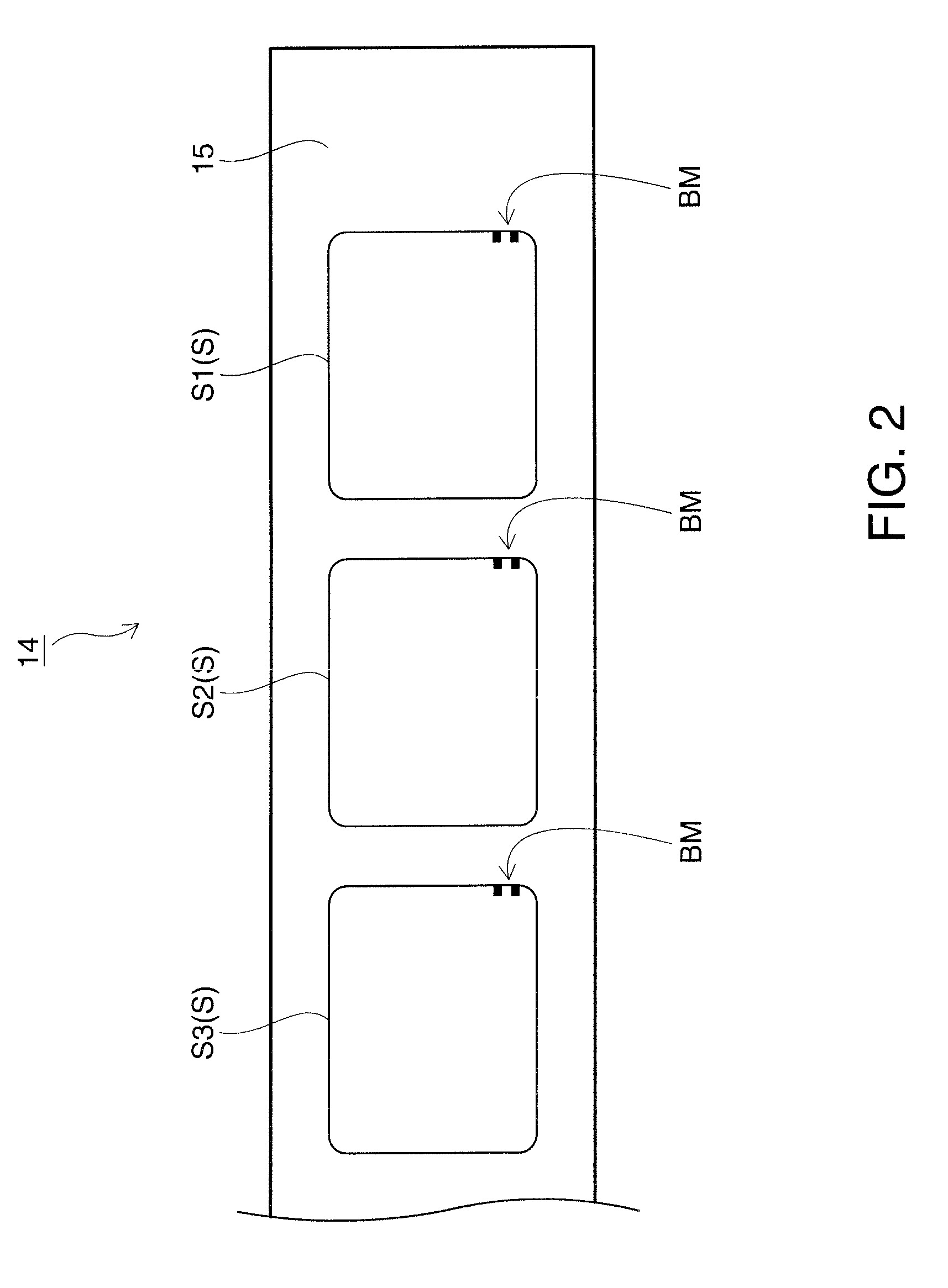

A paper printing method for a line printer that can print a next print job with a specific margin without reversing paper. To print on label paper using a head unit having a plurality of line printheads disposed at a specific interval along the conveyance direction of the label paper, a printhead moving step advances a head unit at a first position after printing ends to a second position, and a printing step prints a label while moving the head unit in the reverse of the conveyance direction. At the second position, the printing position of the last line inkjet head of the head unit is on the forward side of the start printing position of a label on the label paper.

Owner:SEIKO EPSON CORP

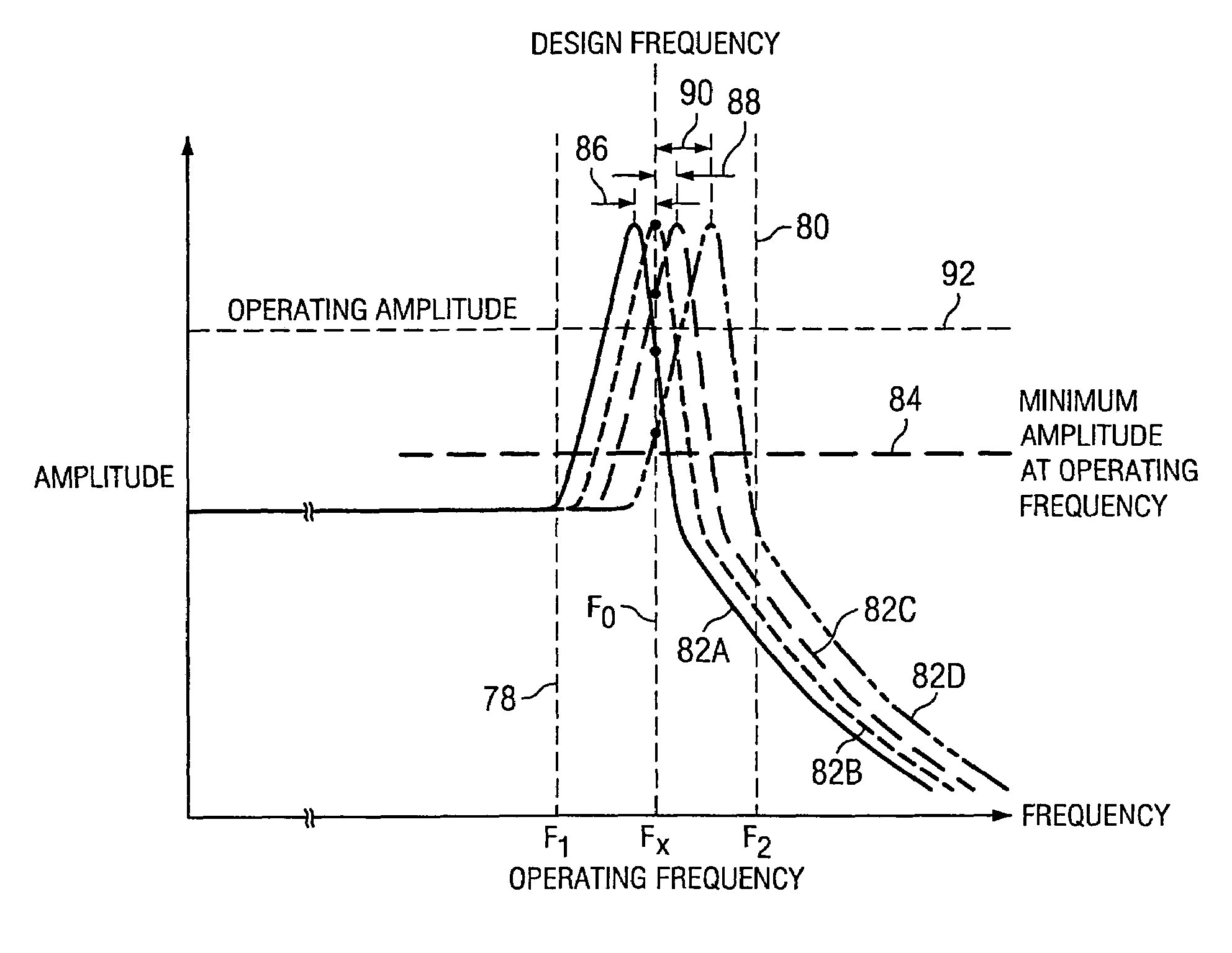

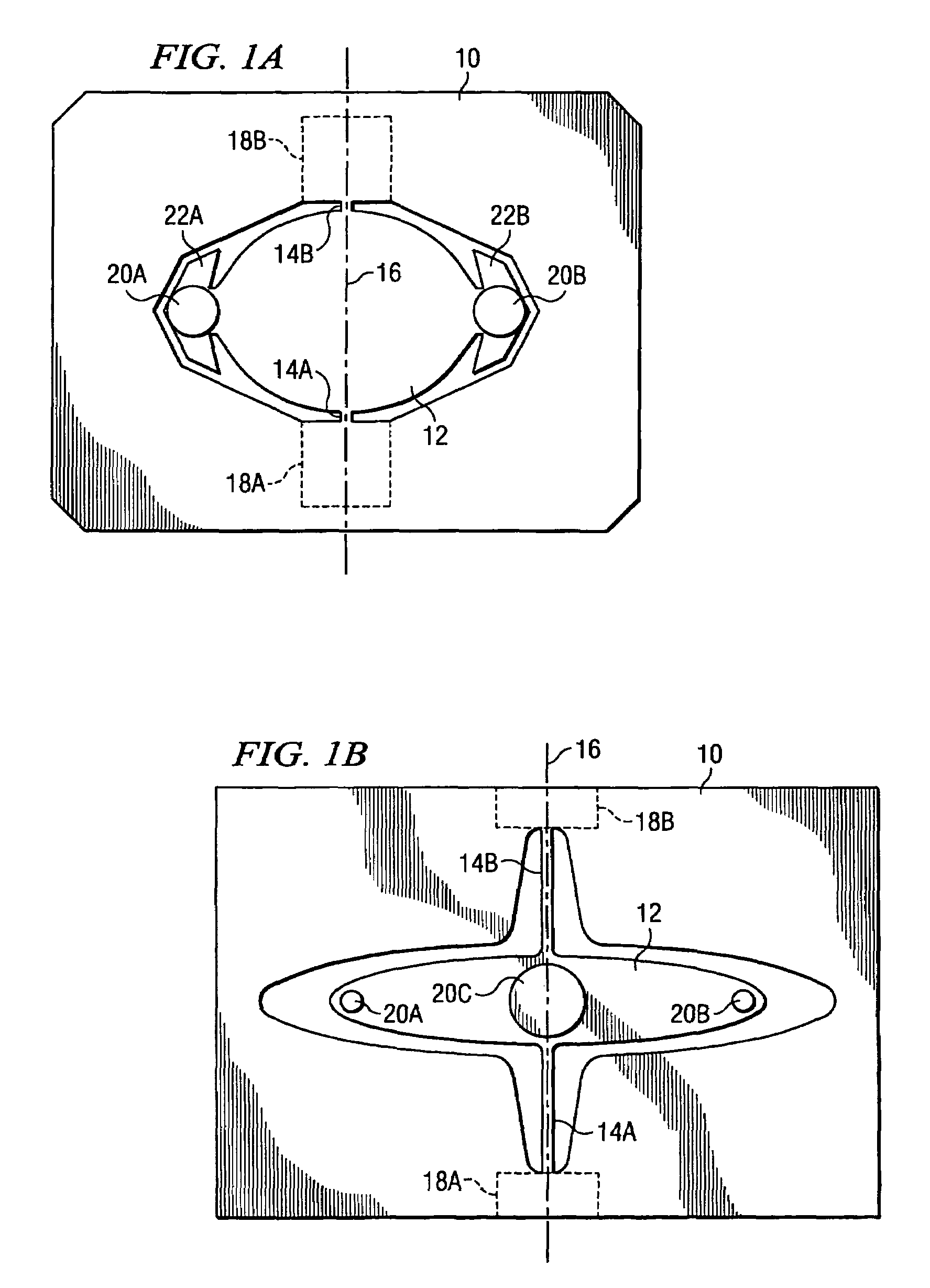

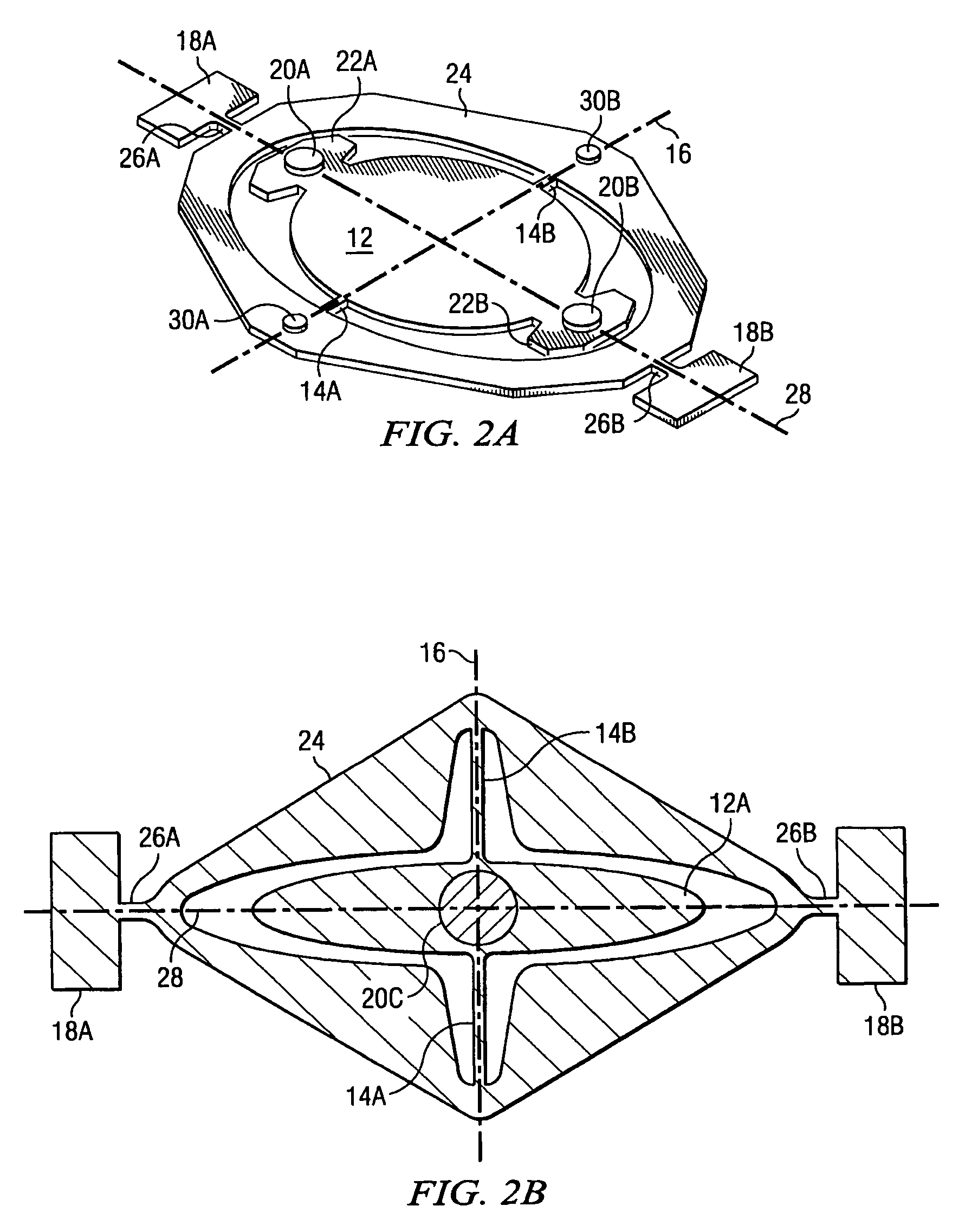

Serial printing with multiple torsional hinged MEMS mirrors

System and method for operating four resonant torsional hinged mirrors such as torsional hinged MEMS devices at the same oscillating frequency suitable for use in a color printer requiring four serially arranged line printers.

Owner:TEXAS INSTR INC

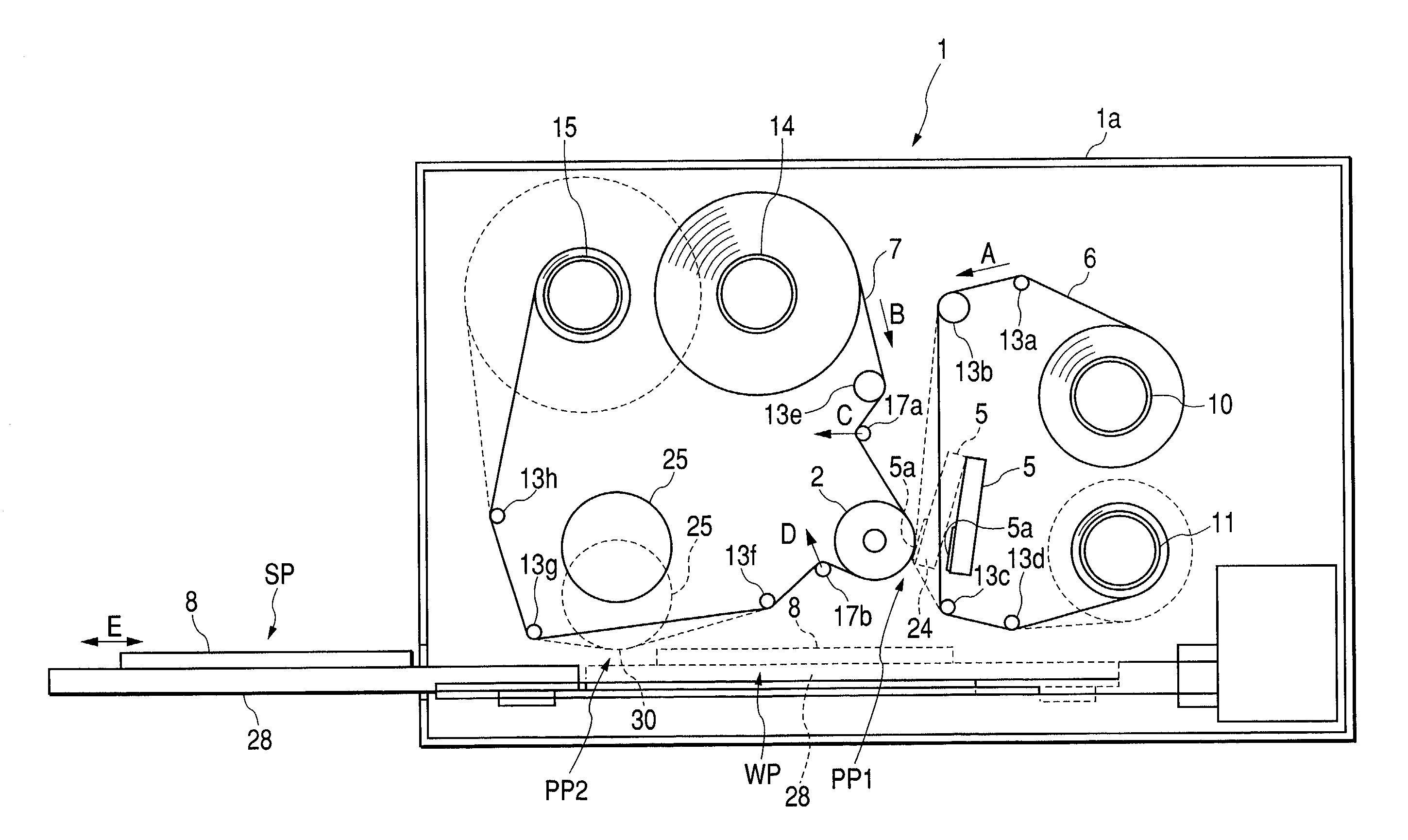

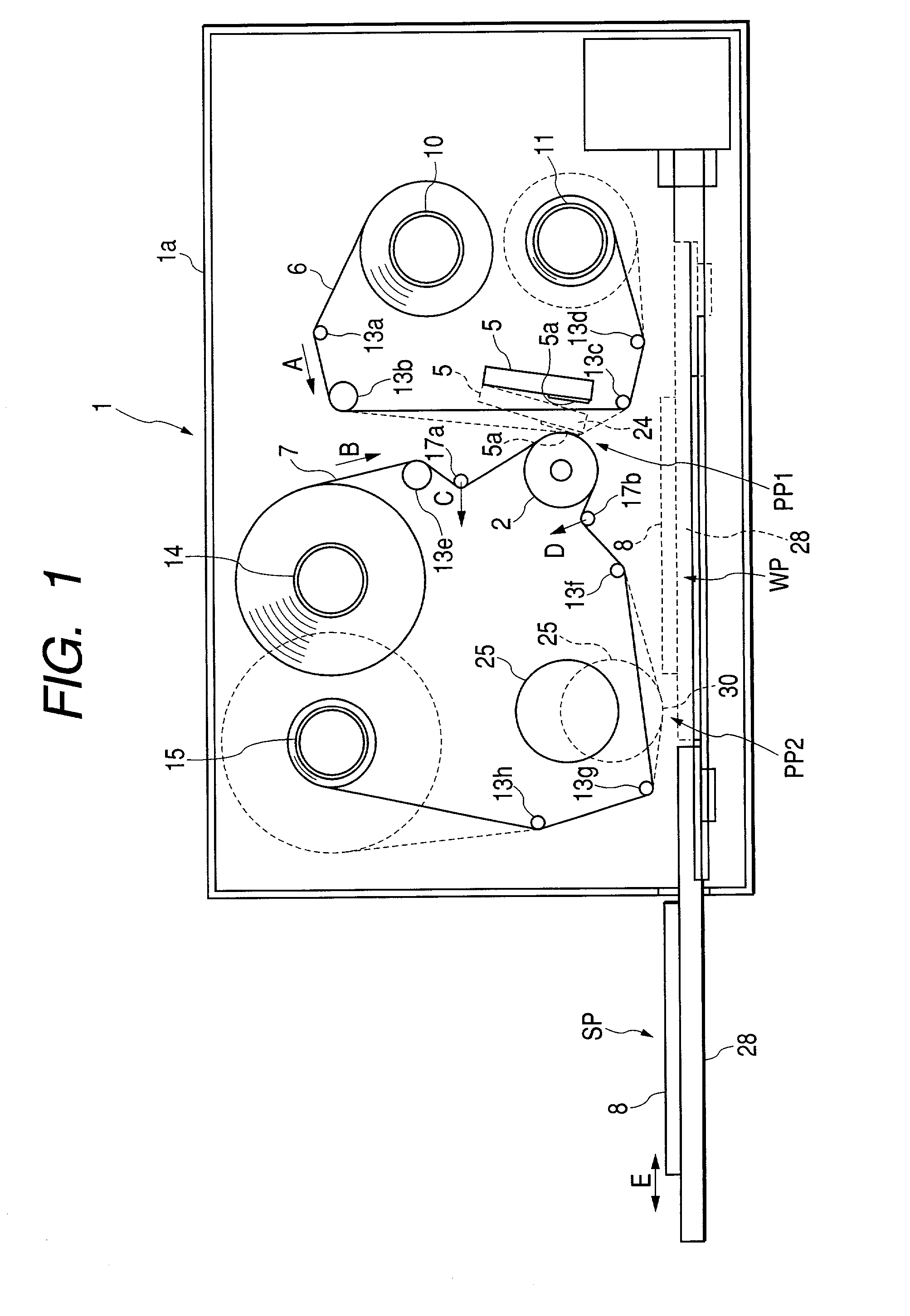

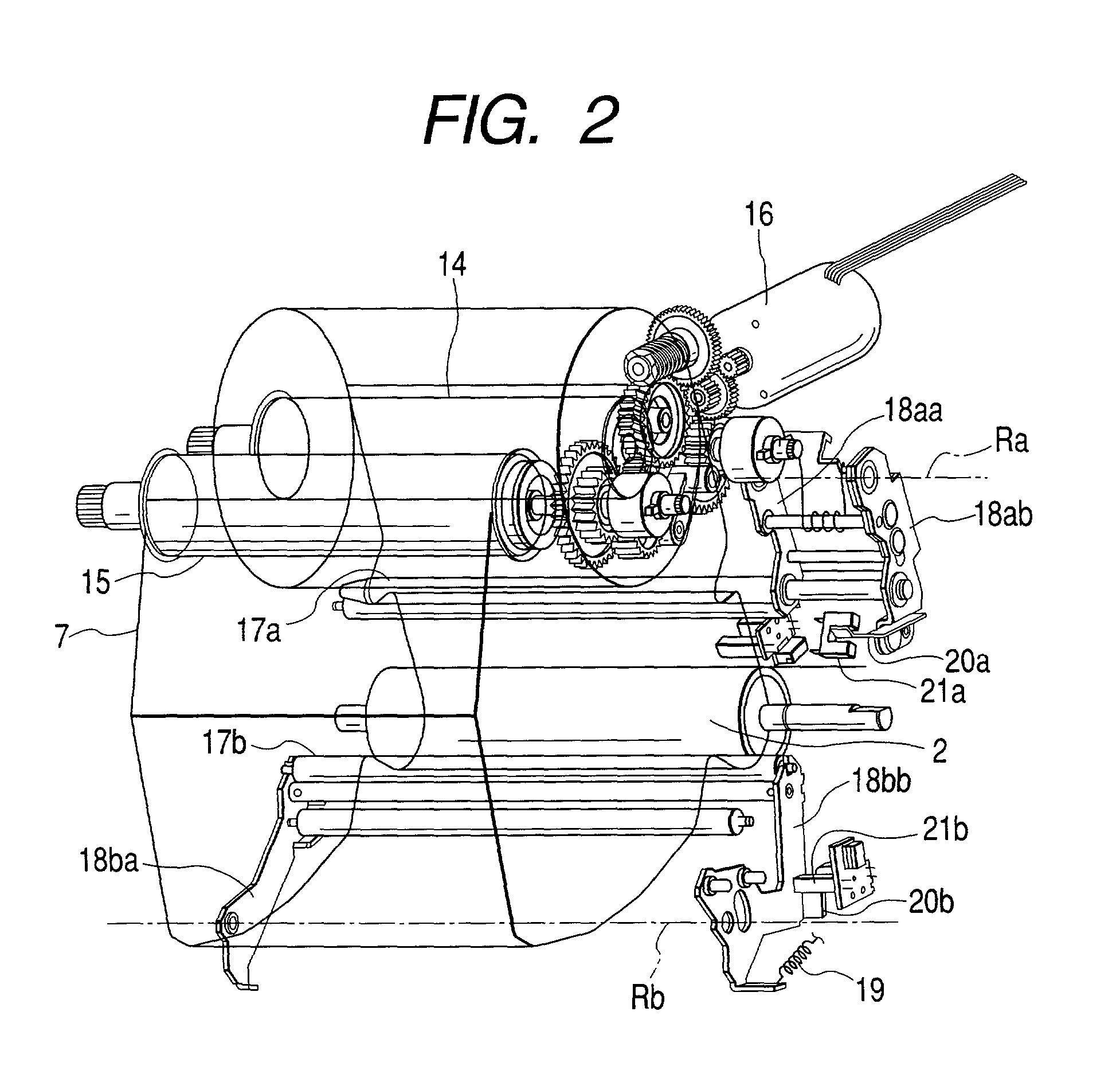

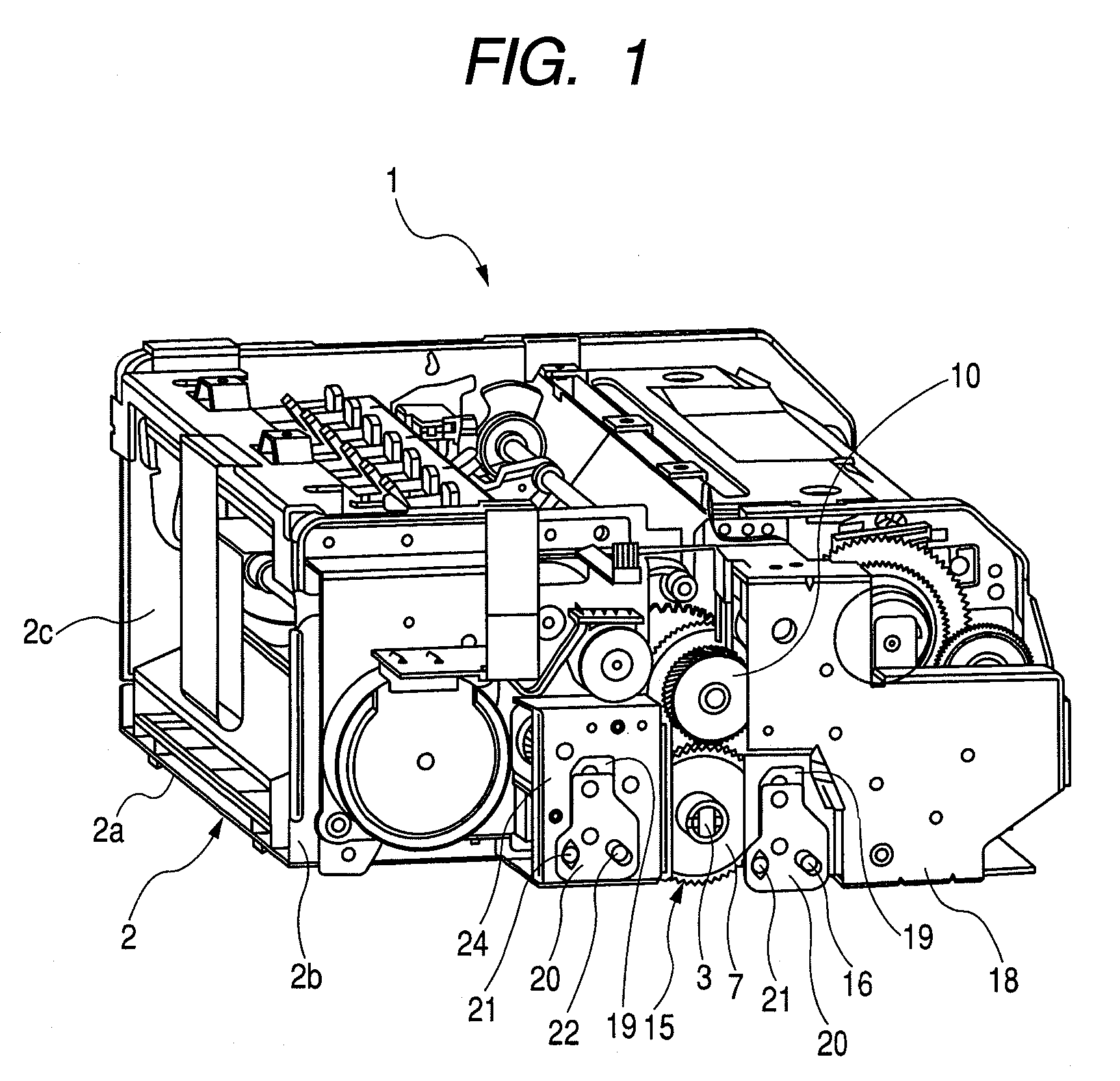

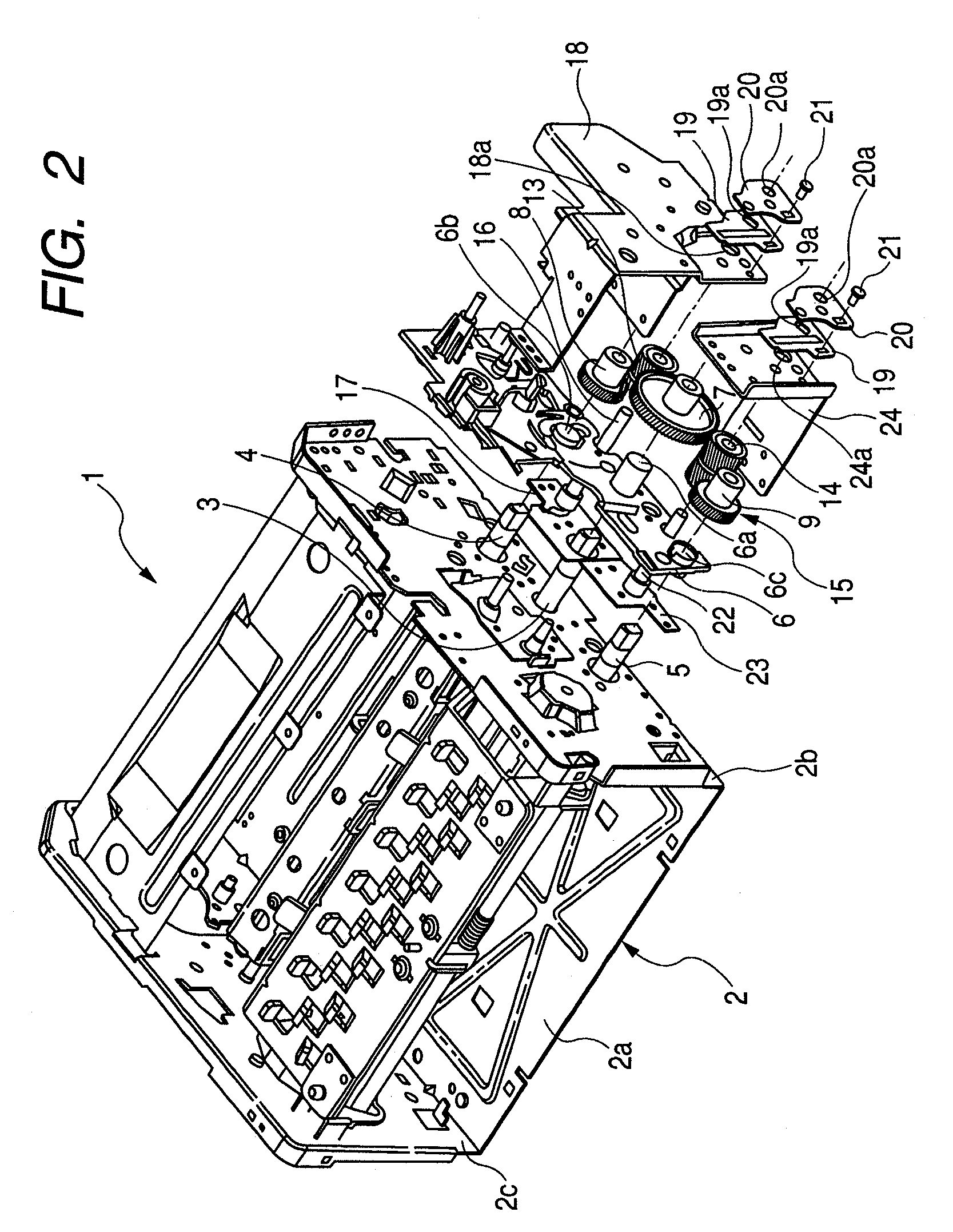

Thermal transfer line printer

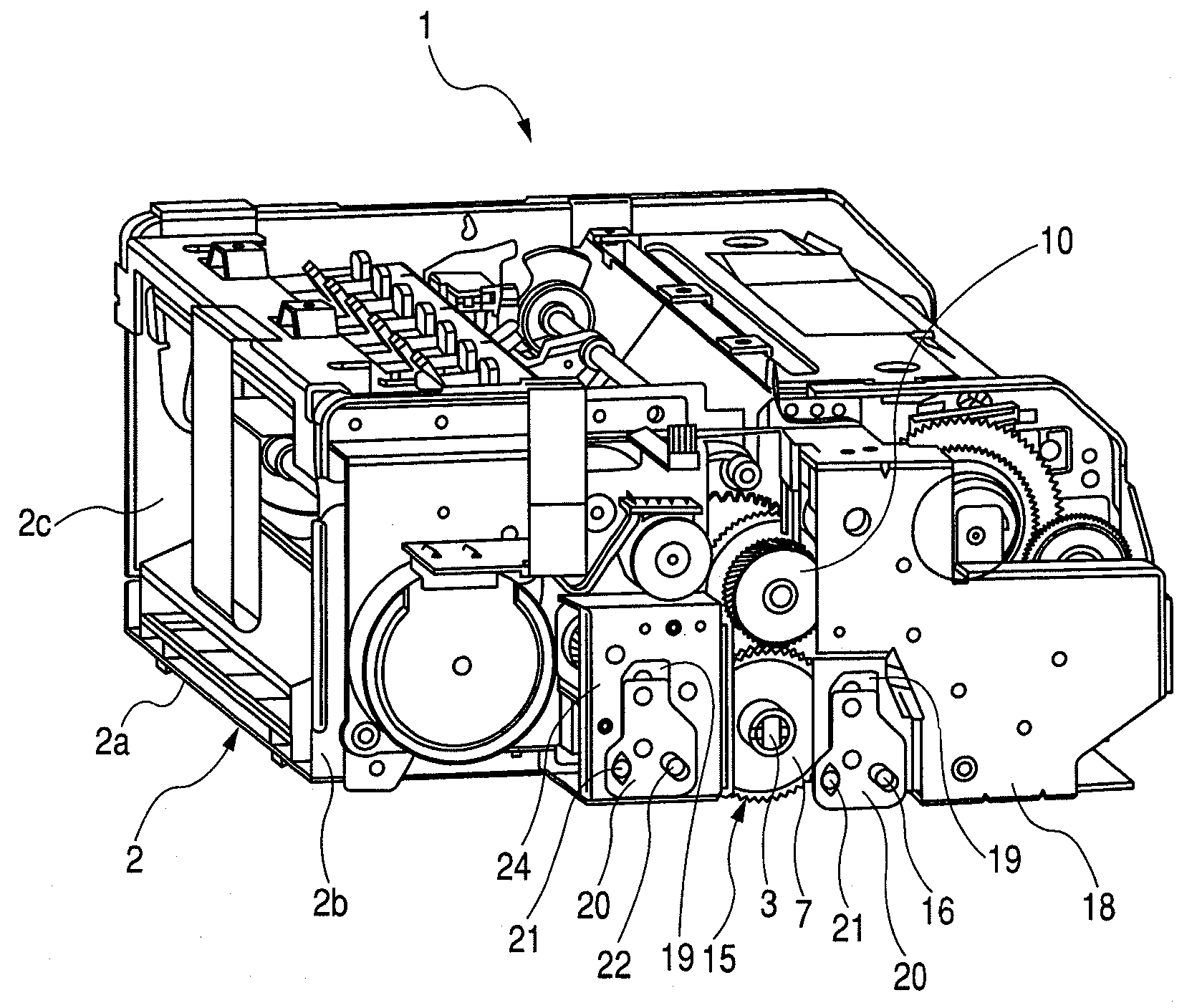

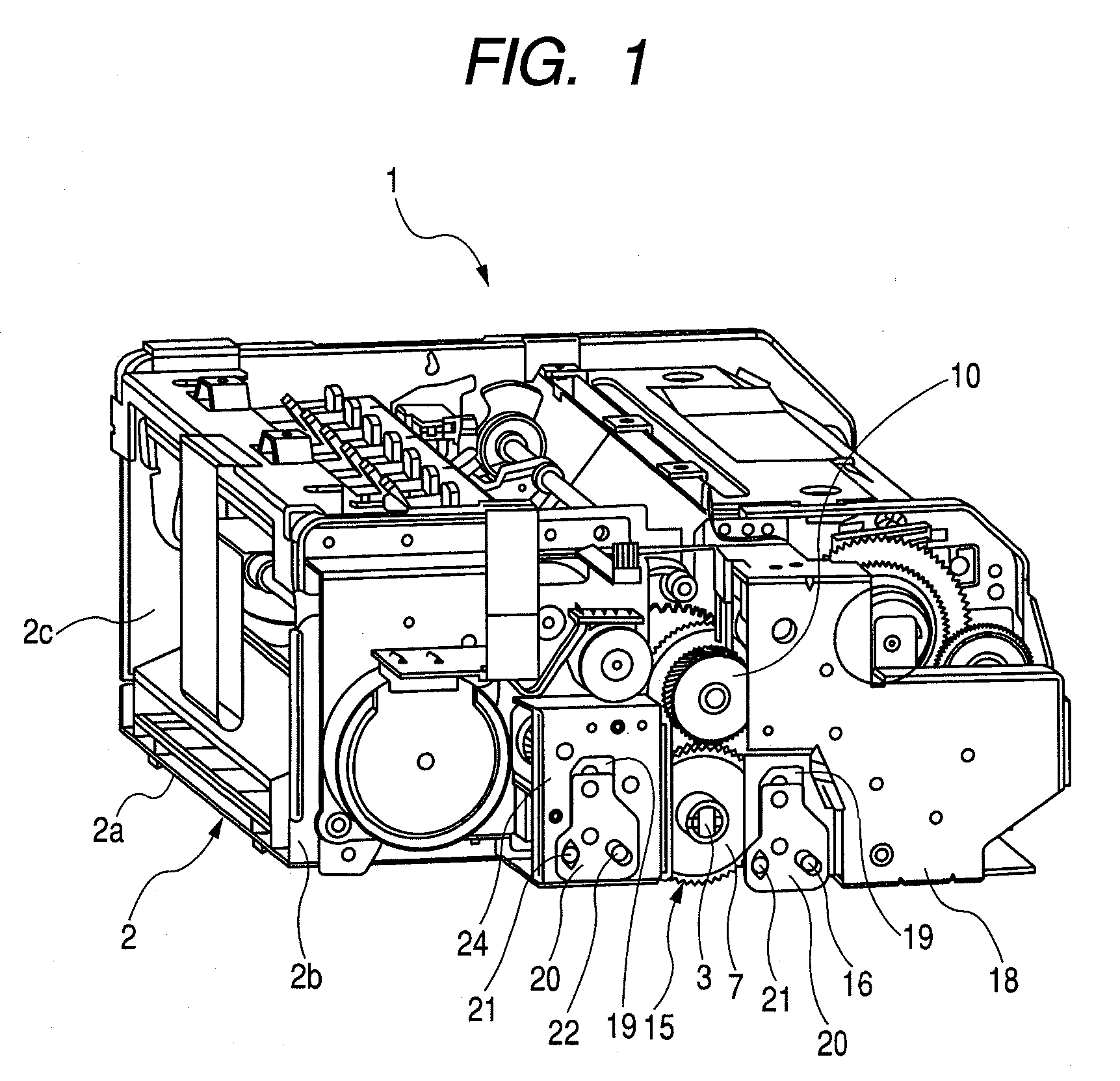

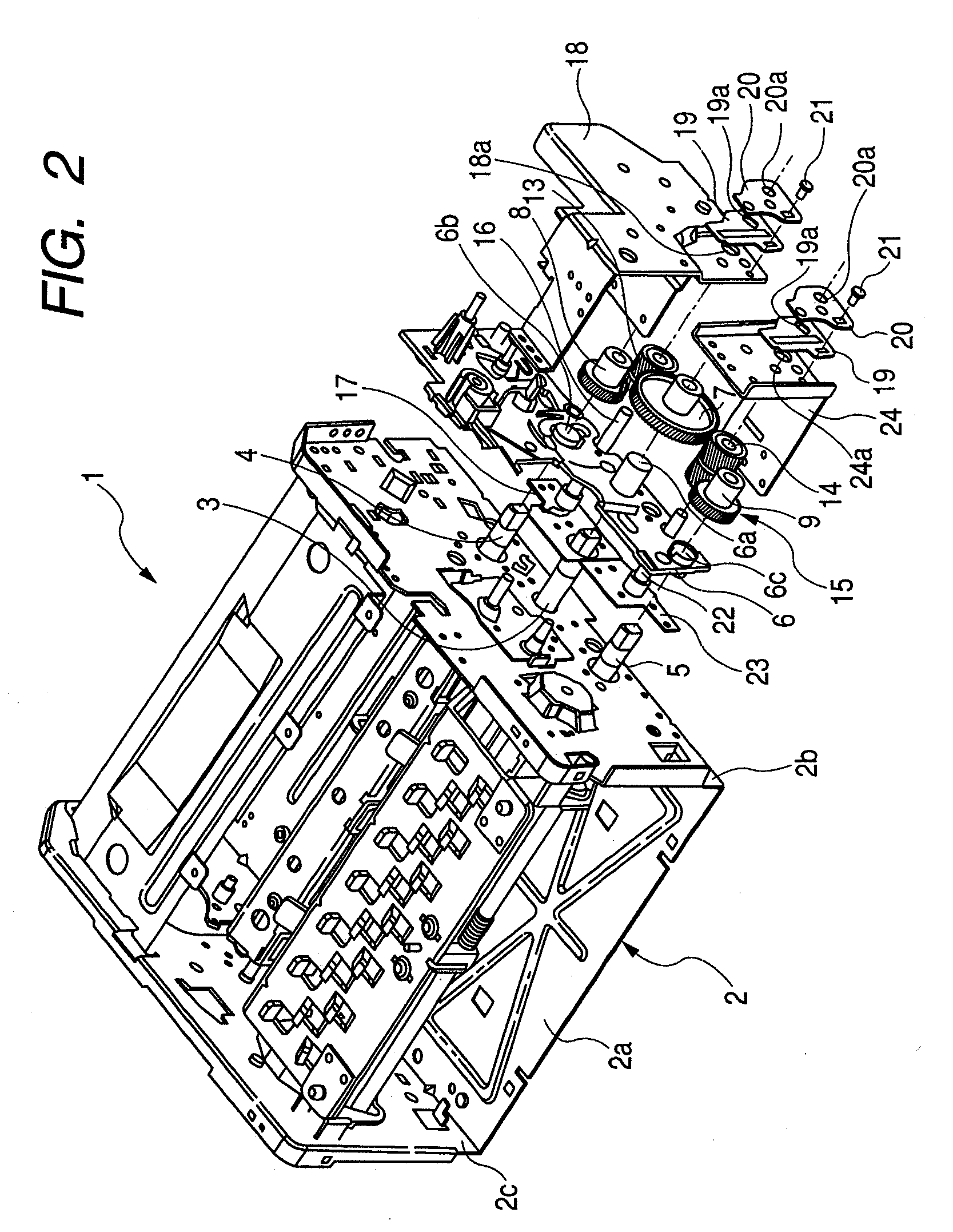

ActiveUS20080100687A1Easily and reliably controlTotal number of gears between a driving member and a driven member can be reducedRecording apparatusPrinting mechanismsLine printerGear wheel

Owner:ALPS ALPINE CO LTD

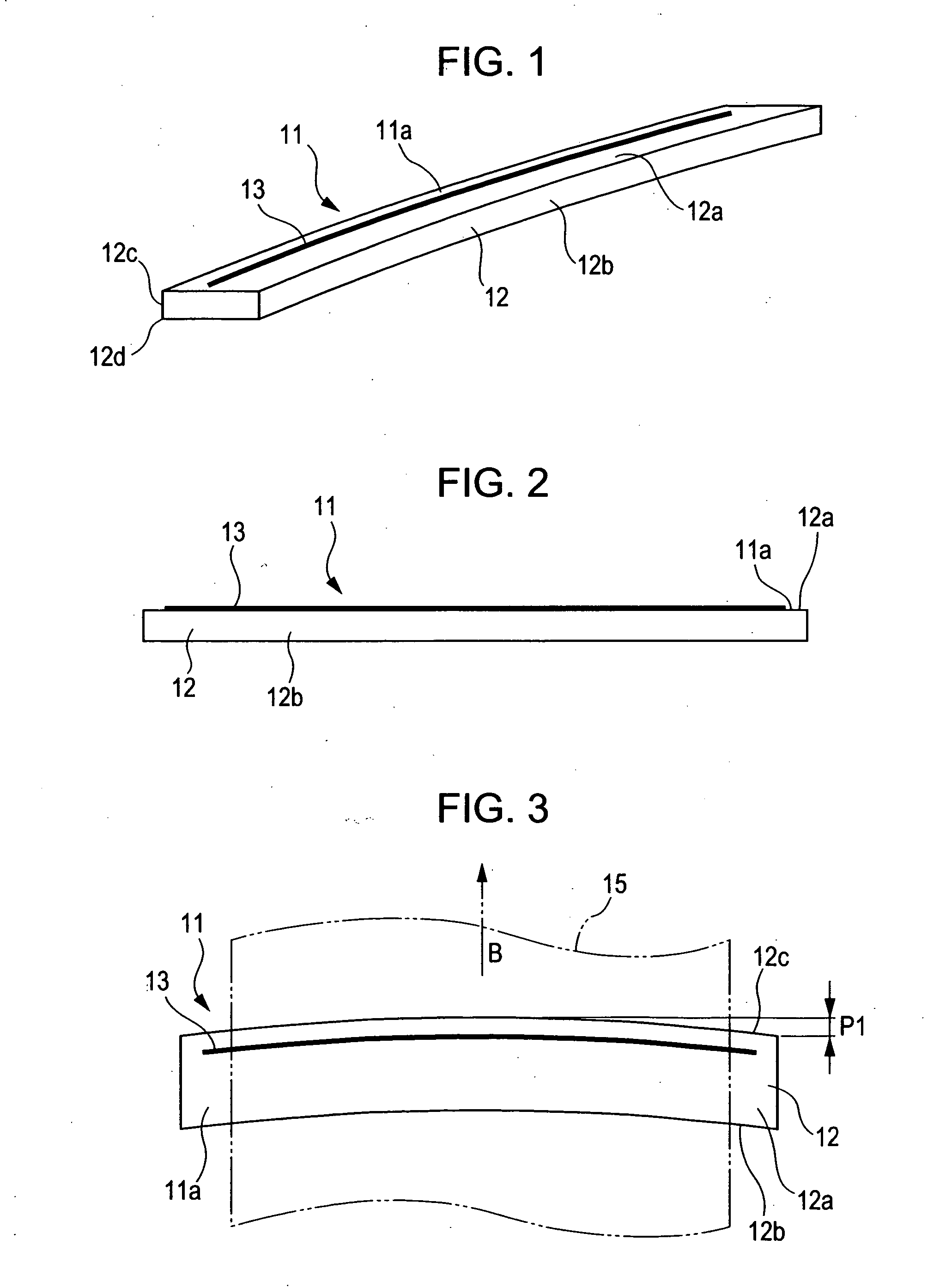

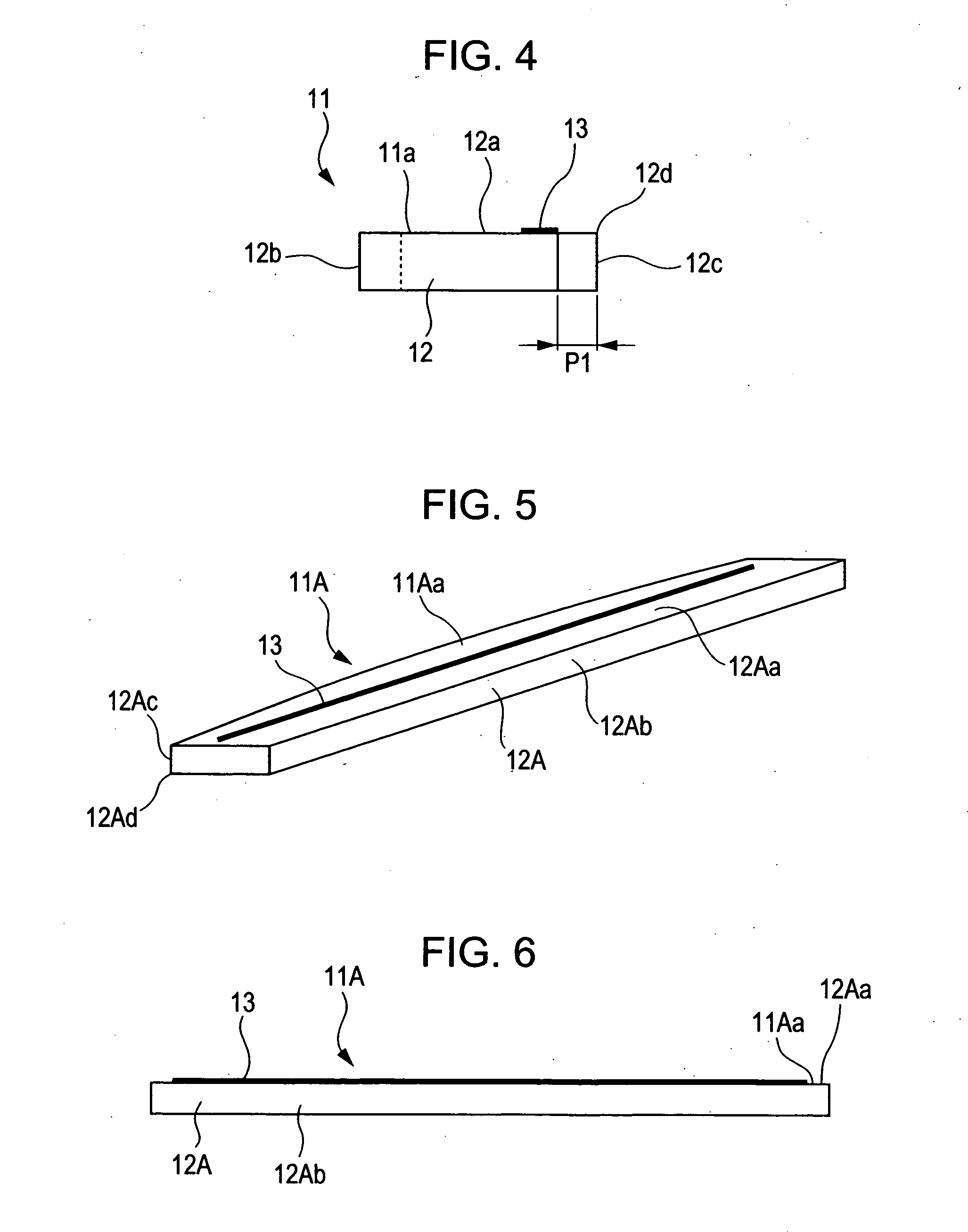

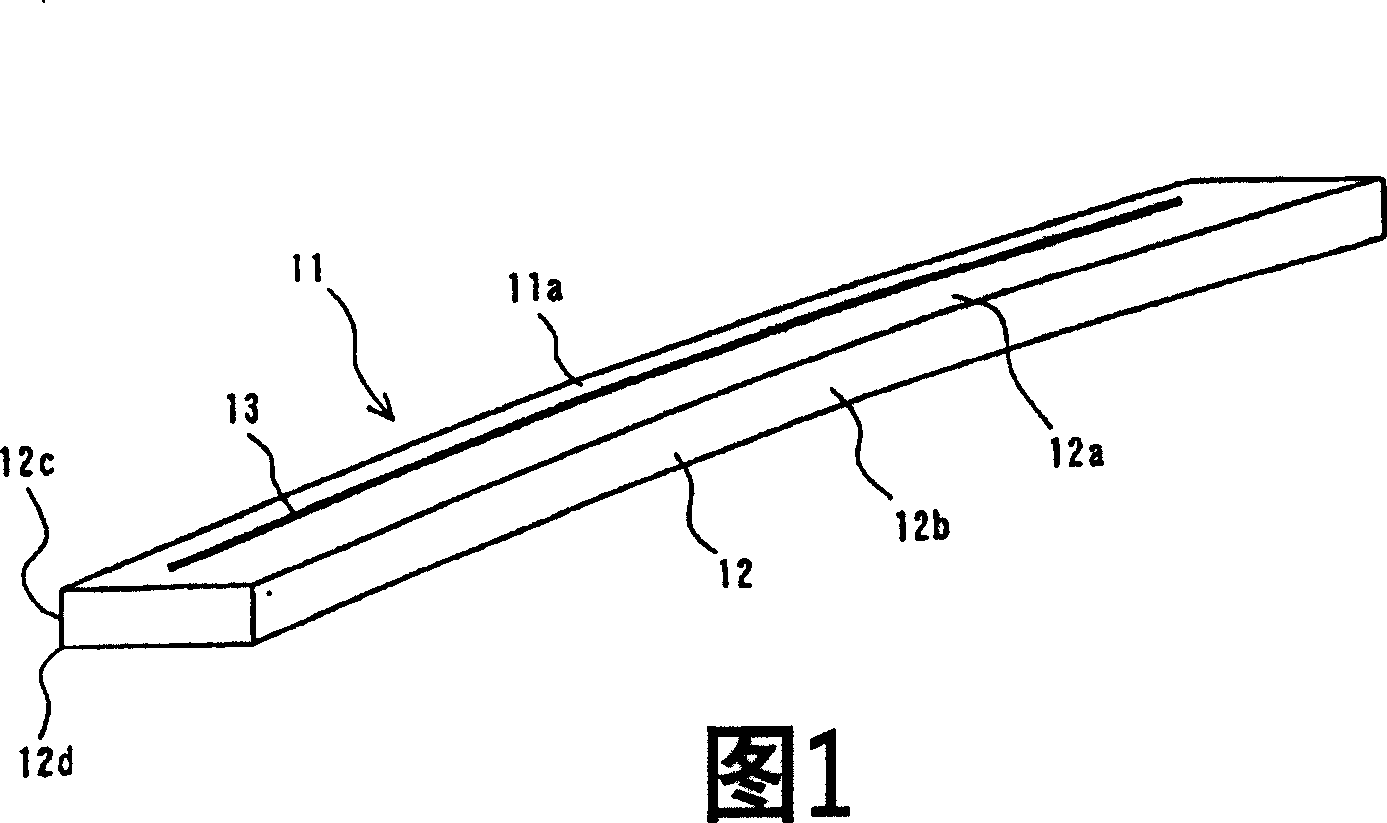

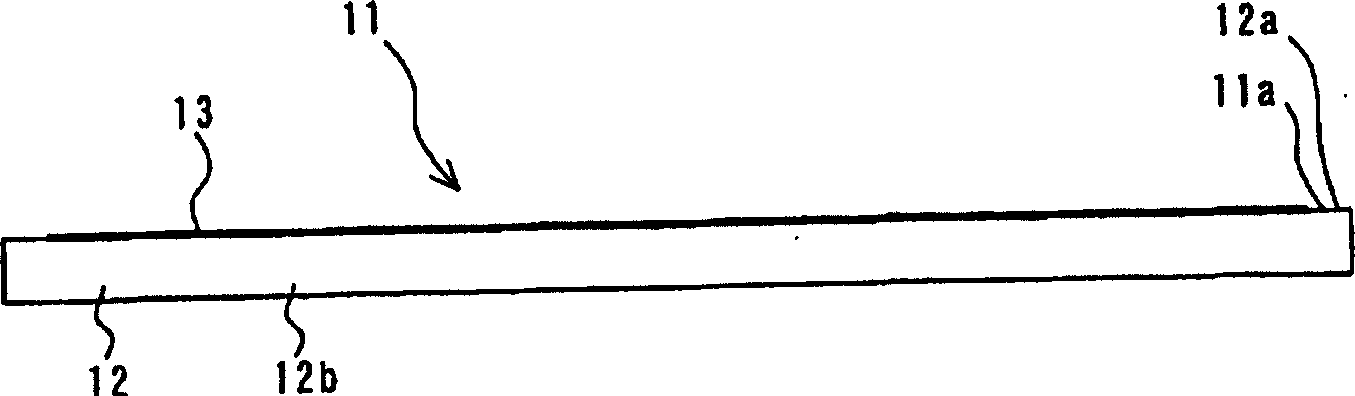

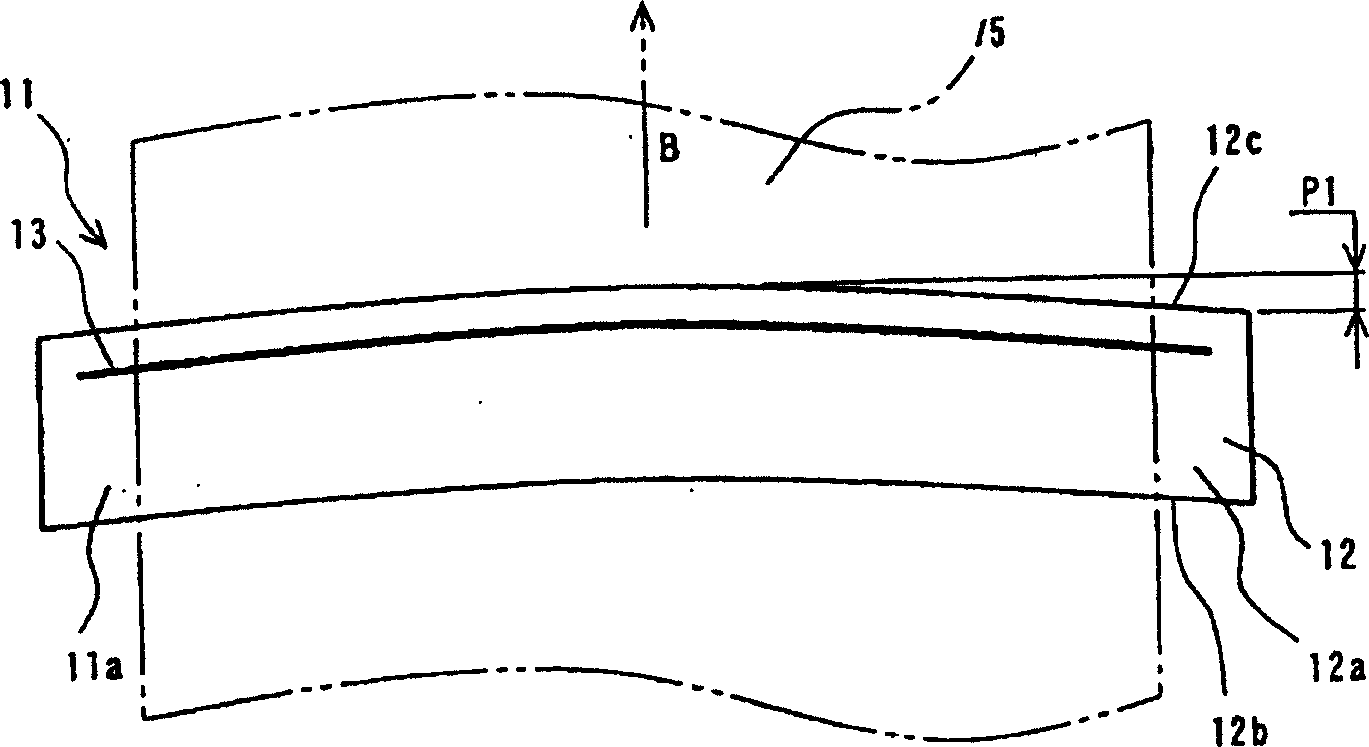

Line thermal head and thermal-transfer line printer

InactiveUS20050162504A1Improve driving stabilityGreat advantageRecording apparatusInking apparatusLine printerCurve shape

In order to improve the traveling stability of an ink ribbon, a thermal head having a structure in which an edge of one surface of a substrate, lying downstream with respect to the traveling direction of an ink ribbon, is formed so as to have a curved shape projecting most downstream with respect to the traveling direction of the ink ribbon at the widthwise central portion of the ink ribbon or a thermal-transfer line printer having a structure in which a separation member separating the ink ribbon from a paper sheet and a tension-exerting section are independently formed from each other is provided.

Owner:ALPS ALPINE CO LTD

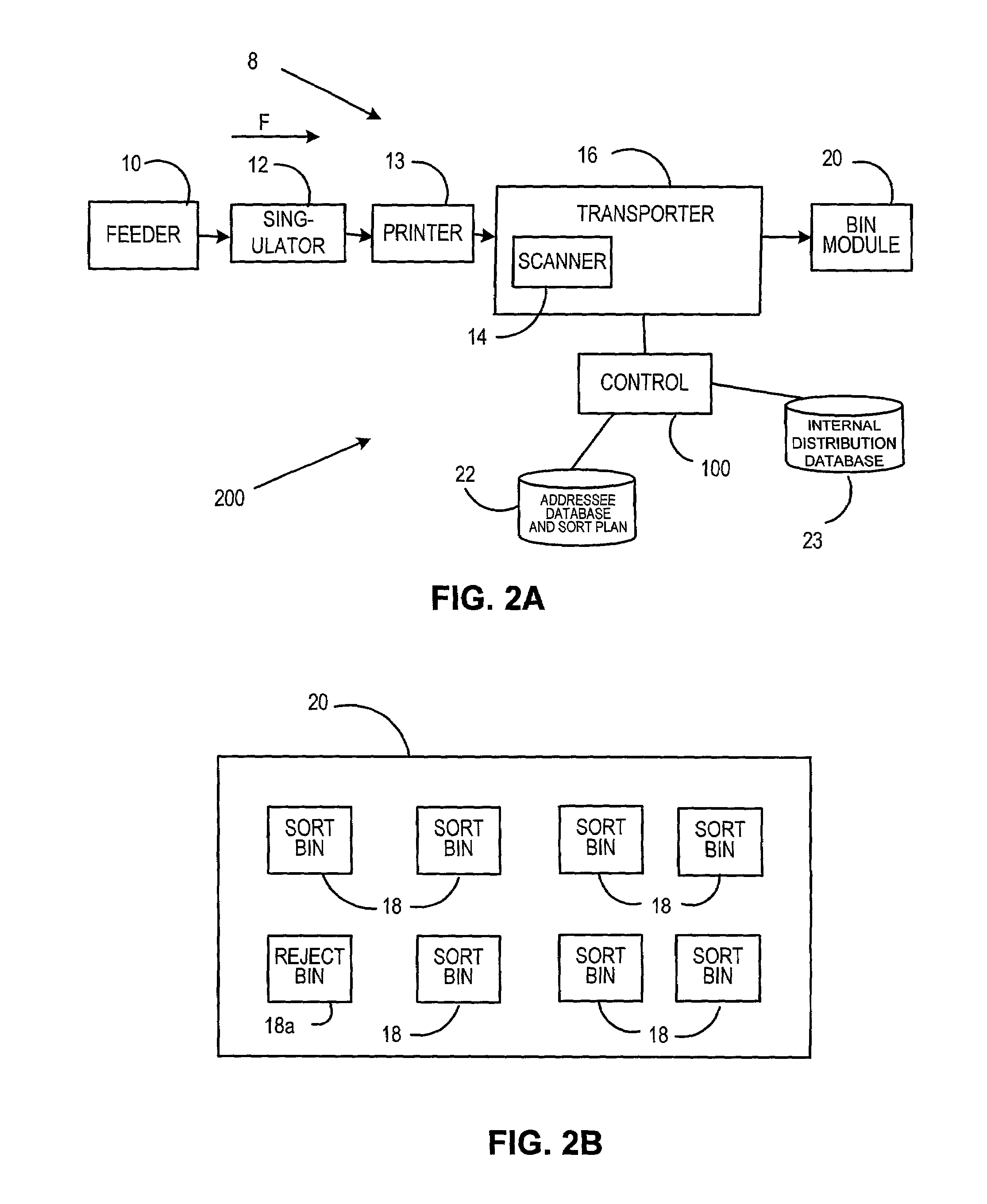

Method of addressing and sorting an interoffice distribution using an incoming mail sorting apparatus

ActiveUS6988021B2Simple preparation processObvious advantagesDigital data processing detailsSeparation devicesLine printerControl system

The present invention is directed, in a general aspect, system including a mail sorting apparatus which generally comprises a feeder, a line scan camera, an in-line printer, a control system which may be the microprocessor based personal computer system, at least one addressee database and sort plan, a mailpiece transporter, a bin module with compartments or sort bins for receiving mailpieces. This invention overcomes the disadvantages of the prior art by enabling a mail sorting apparatus to address sort internal mailings (business to employee mail). The foregoing is accomplished by addressing and sorting employee mailpieces in one process by using information from one or more databases of the mail sorting apparatus, including the addressee database and sort plan, and an in-line printer for printing employee and / or delivery information on the employee mailpiece. Thus, the method of the present invention provides a less costly, simplified way to prepare internal mailings.

Owner:DMT SOLUTIONS GLOBAL CORP

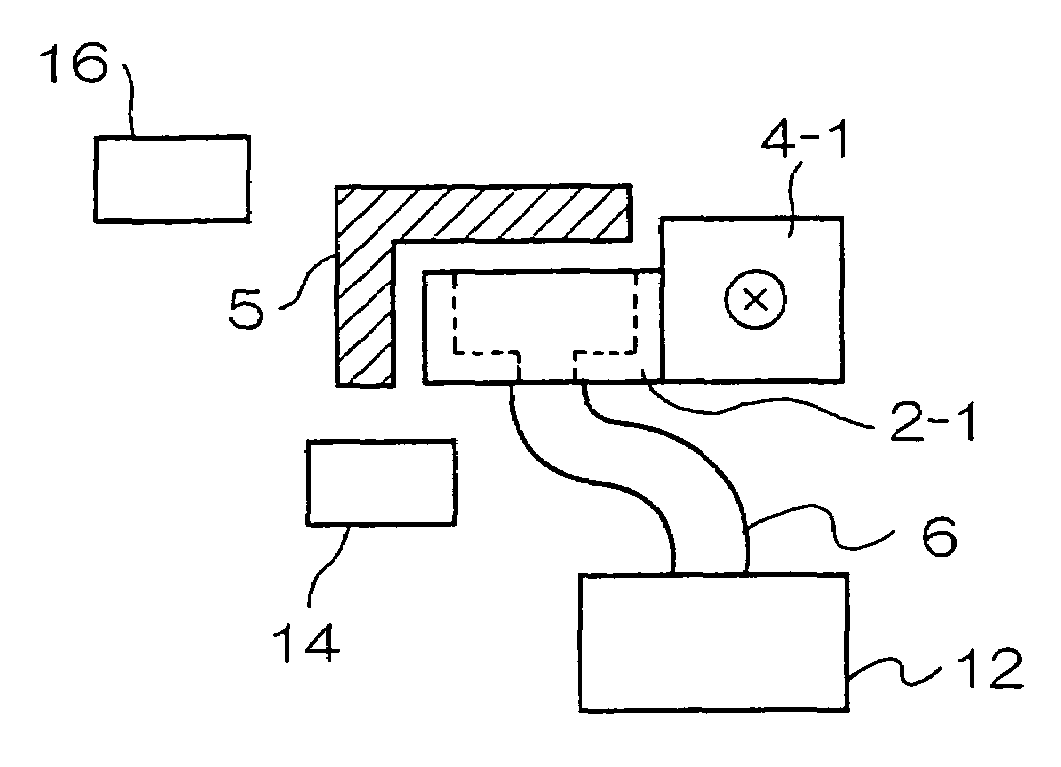

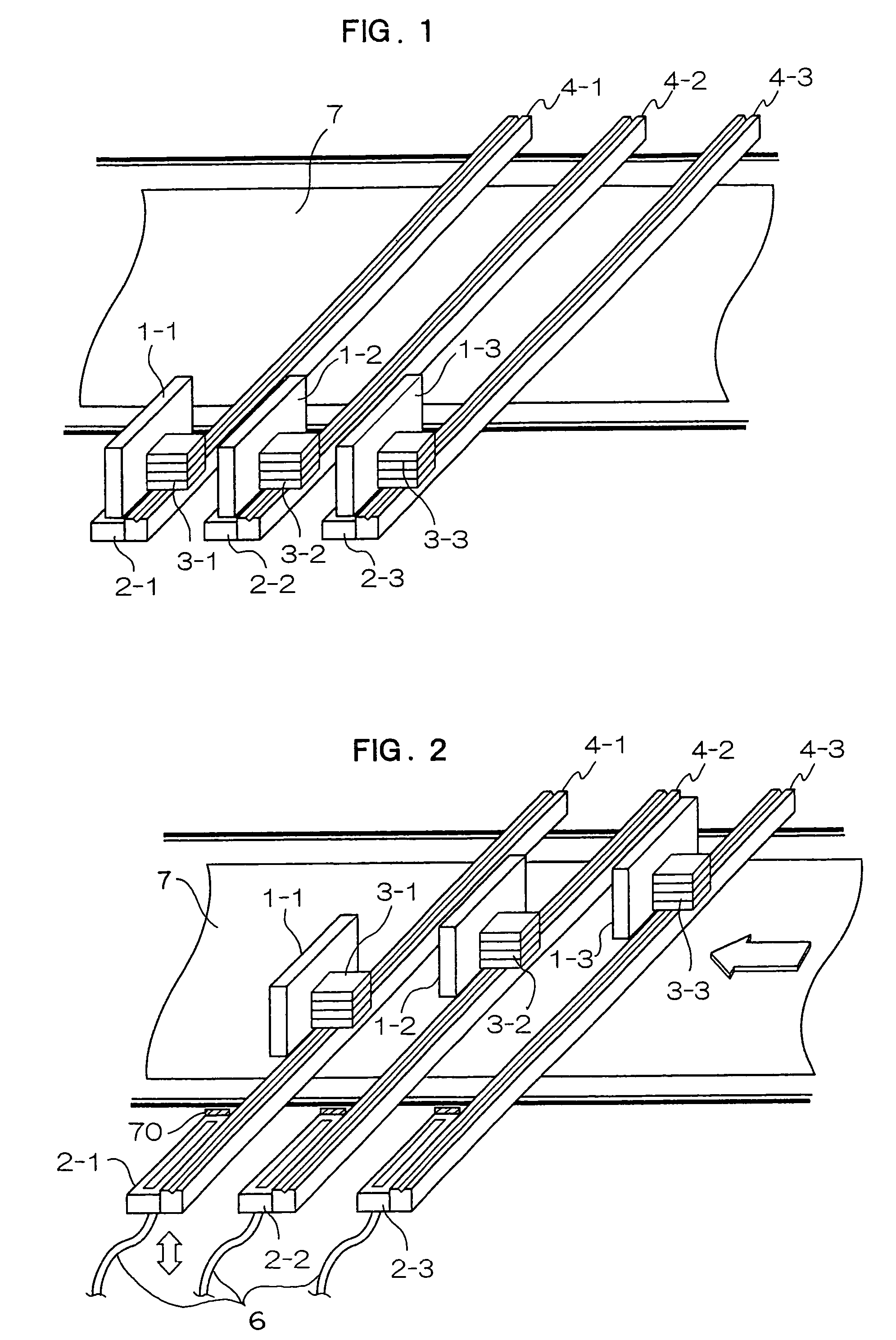

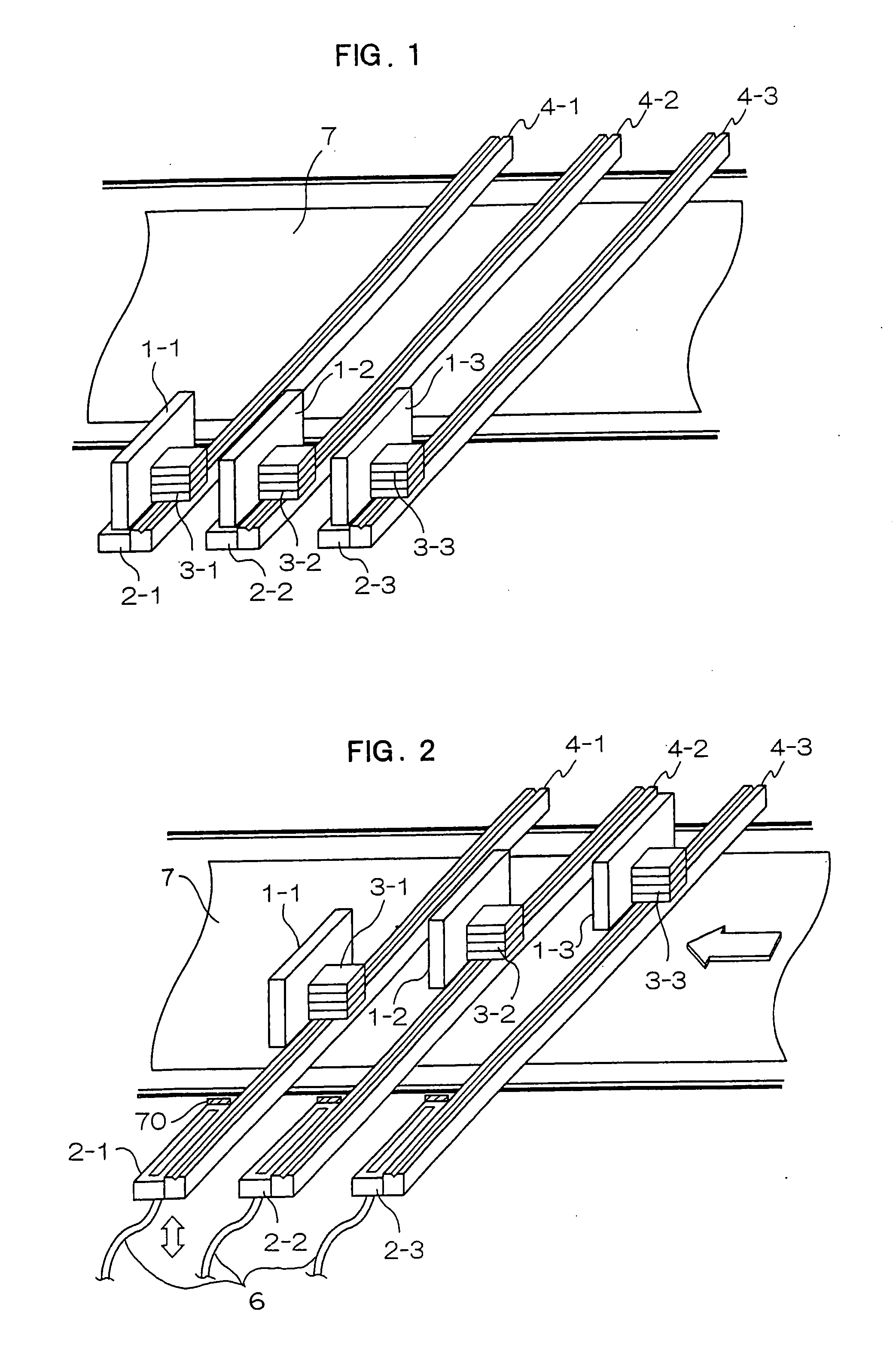

Ink-jet line printer and image forming apparatus using the same

An ink-jet line printer (30) is constituted by multiple ink-jet heads (1-1 to 1-3). Actuators (3-1 to 3-3) are arranged so as to be moved between a home position and a print position, and backup mechanisms (2-1 to 2-3) are arranged at home positions. In this ink-jet line printer, the ink-jet heads can be protected and recovered by backup mechanisms, thus making high-speed continuous printing possible. Even though the backup mechanisms are incorporated, a compact apparatus can still be achieved.

Owner:FUJIFILM BUSINESS INNOVATION CORP

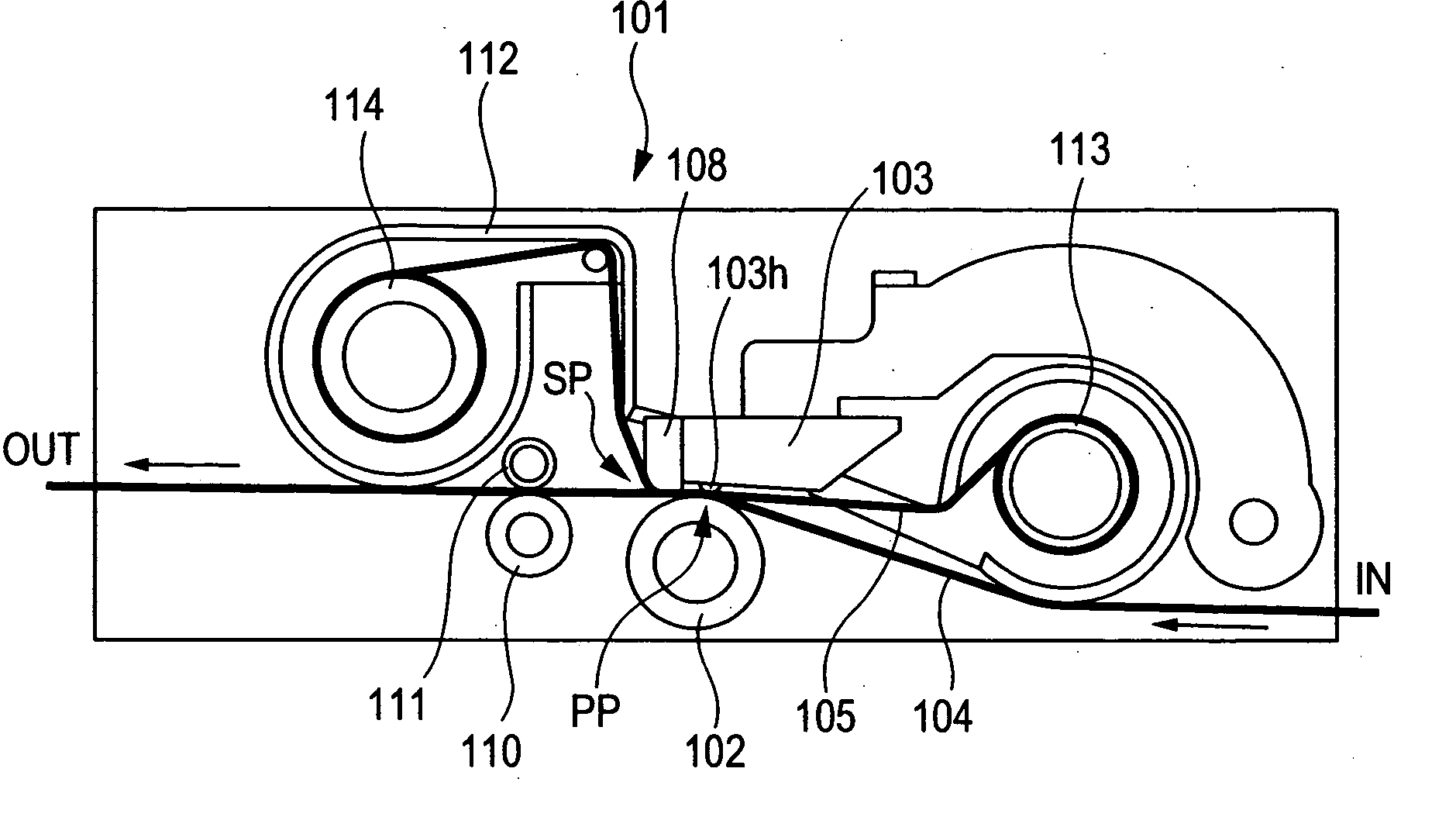

Intermediate transfer medium conveying device and thermal transfer line printer using the same

ActiveUS20110180648A1Good effectAppropriately conveyedRecording apparatusInk ribbonsLine printerConductor Coil

An intermediate transfer medium conveying device conveys an intermediate transfer medium by a drive force of one DC motor, in a normal feed direction where the intermediate transfer medium is wound on a winding reel and in a reverse feed direction where the intermediate transfer medium is wound on a feeding reel. The intermediate transfer medium conveying device includes a winding shaft that drives the winding reel during normal feed where the intermediate transfer medium is conveyed in the normal feed direction, a feeding shaft driving the feeding reel during reverse feed where the intermediate transfer medium is conveyed in the reverse feed direction, transmission means for normal feed that transmits a drive force of the DC motor to the winding shaft during the normal feed, and transmission means for reverse feed that transmits a drive force of the DC motor to the feeding shaft during the reverse feed.

Owner:ALPS ALPINE CO LTD

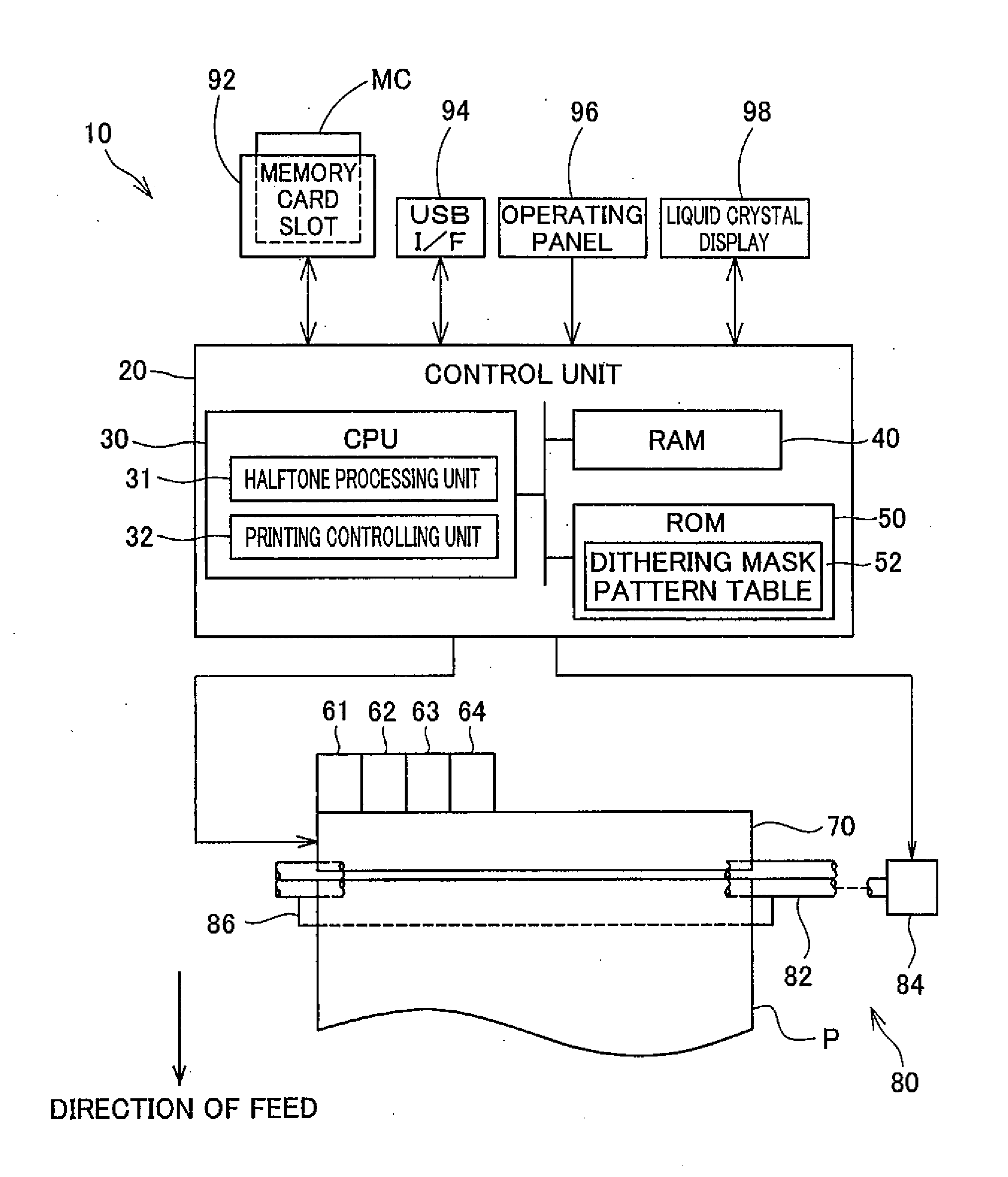

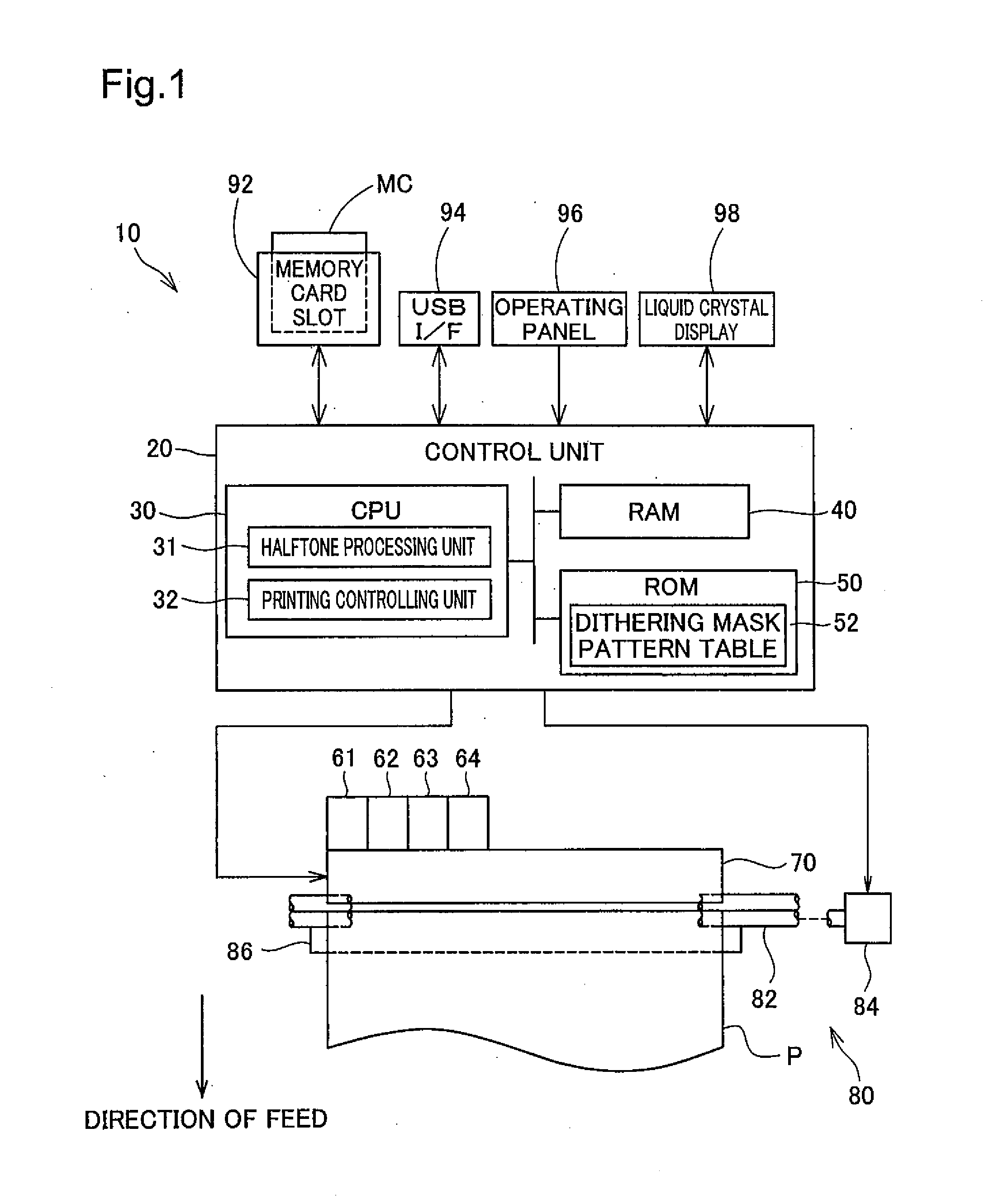

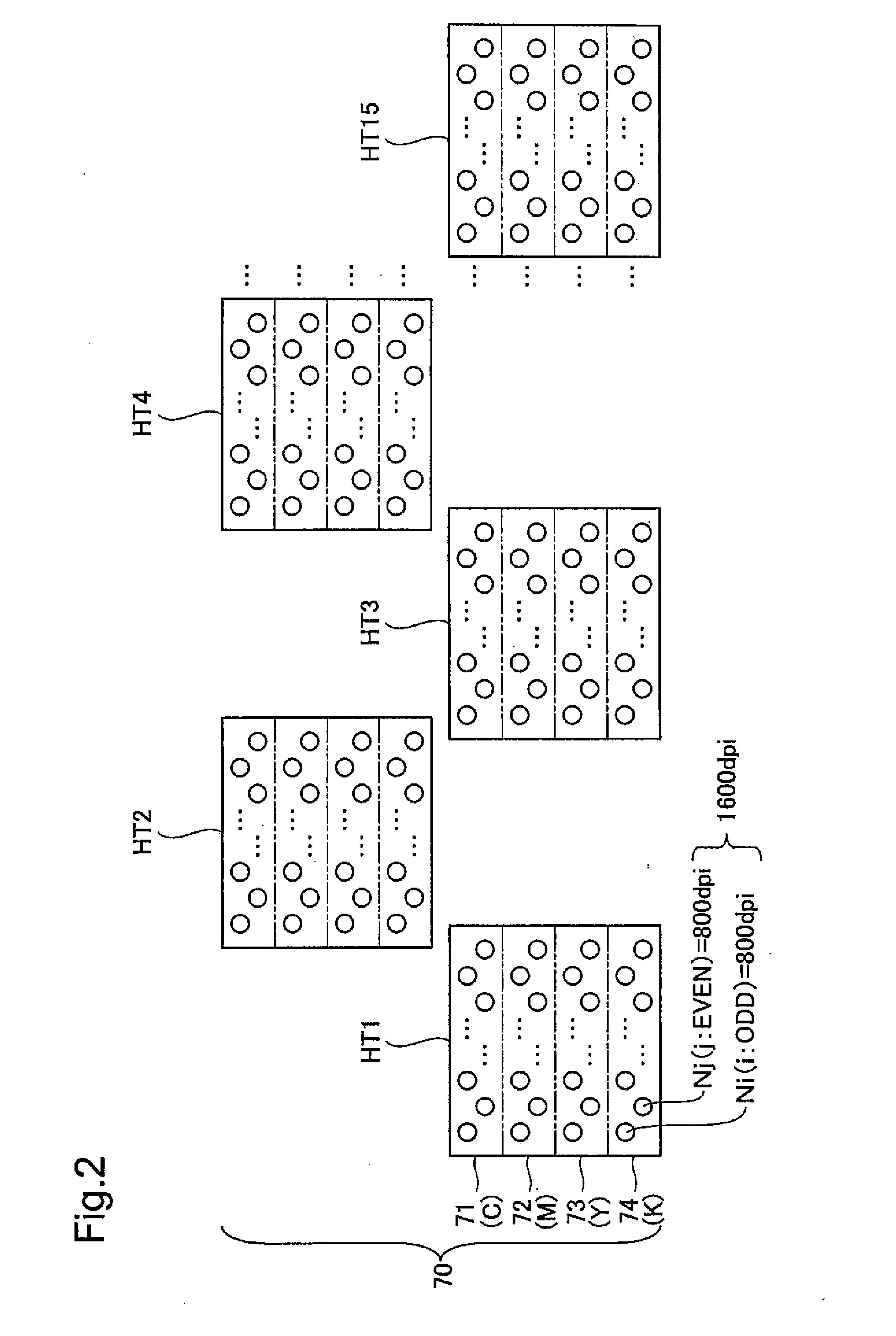

Line Printer

ActiveUS20090015871A1Improve printing qualityQuality improvementVisual presentationOther printing apparatusLine printerImaging quality

A plurality of types of positional shift postulated patterns are postulated wherein the positional shift of print head tips in a printer are postulated to have positional shift directions and distances. For each of the postulated positional shift postulated patterns, a base dithering mask is generated considering the ability to produce excellent dot dispersion characteristics when this postulated positional shift has occurred. Additionally, optimal dithering masks are generated through multiply combining the sets of threshold values that comprise the base dithering masks. Doing so enables the suppression of degradation of printed image quality, even when there are positional shifts between the print heads, in a half toning process for printing using a printer that is provided with a plurality of print heads that are arranged in a line across a printing range.

Owner:SEIKO EPSON CORP

Line thermal head and thermal-transfer line printer

In order to improve the traveling stability of an ink ribbon, a thermal head having a structure in which an edge of one surface of a substrate, lying downstream with respect to the traveling direction of an ink ribbon, is formed so as to have a curved shape projecting most downstream with respect to the traveling direction of the ink ribbon at the widthwise central portion of the ink ribbon or a thermal-transfer line printer having a structure in which a separation member separating the ink ribbon from a paper sheet and a tension-exerting section are independently formed from each other is provided.

Owner:ALPS ALPINE CO LTD

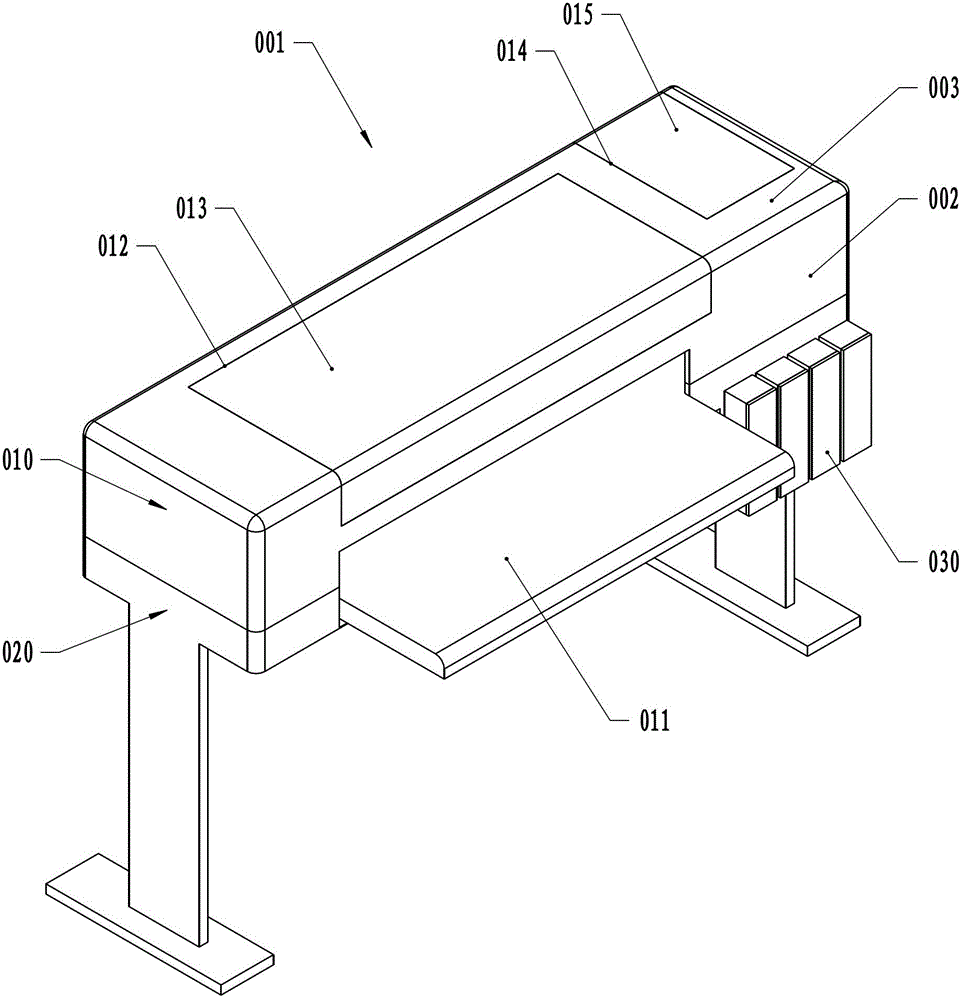

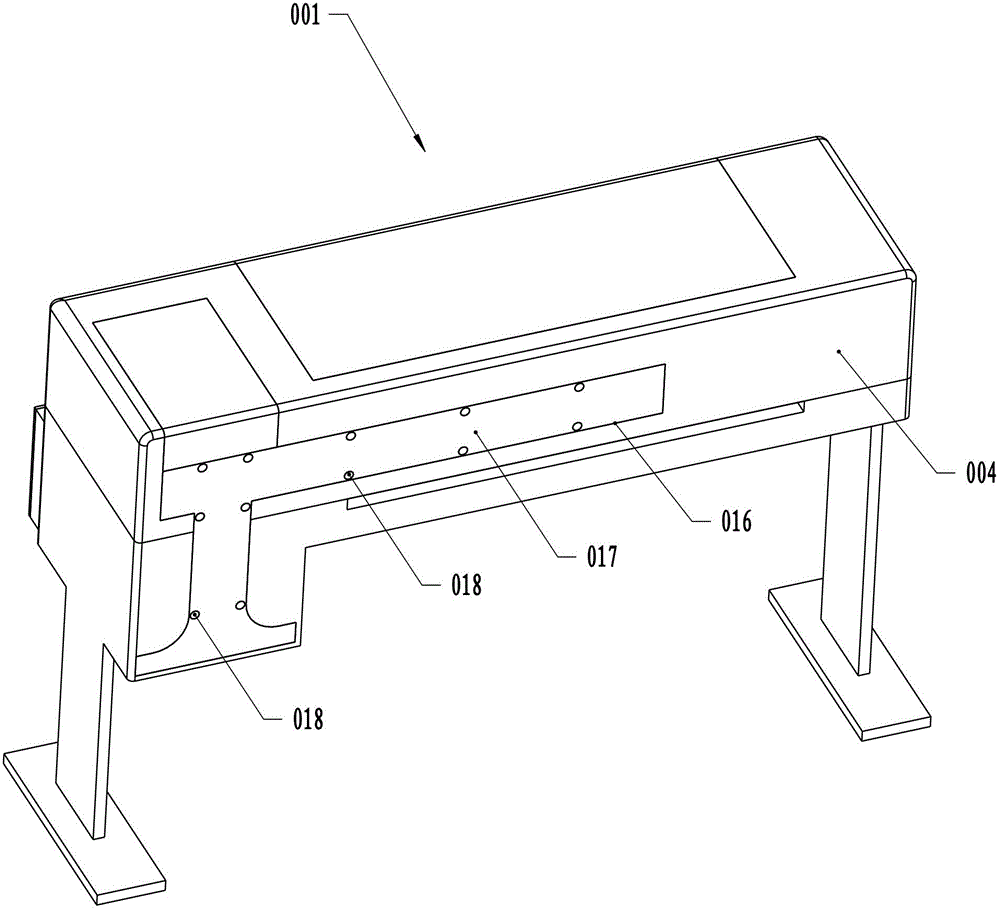

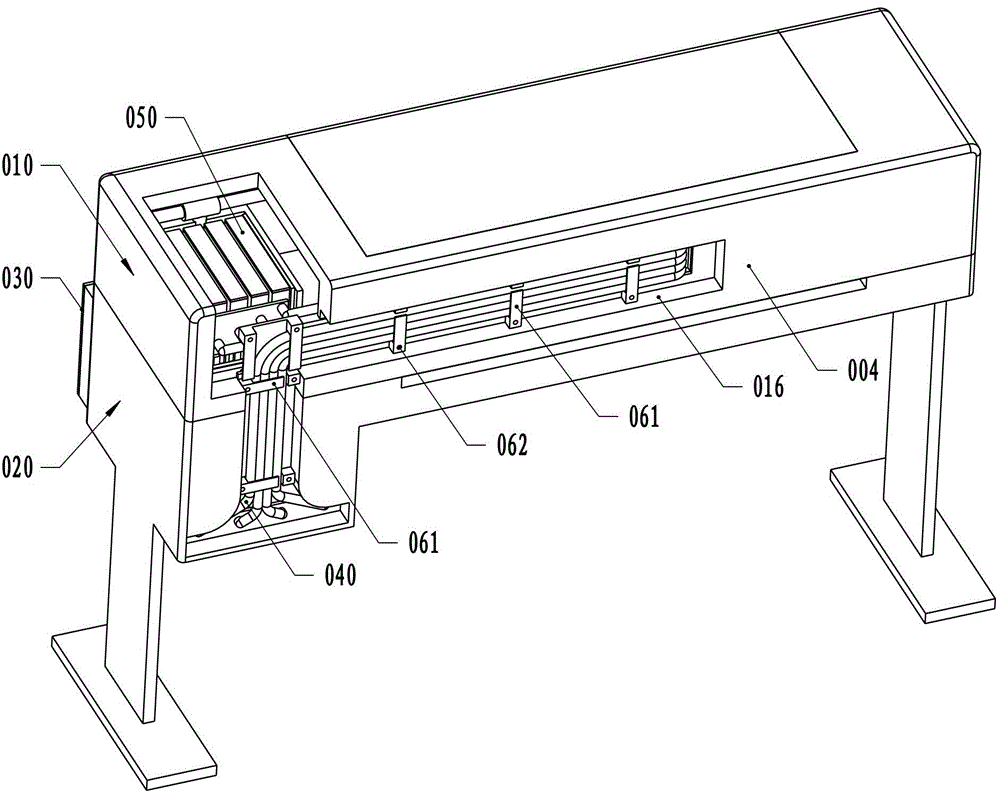

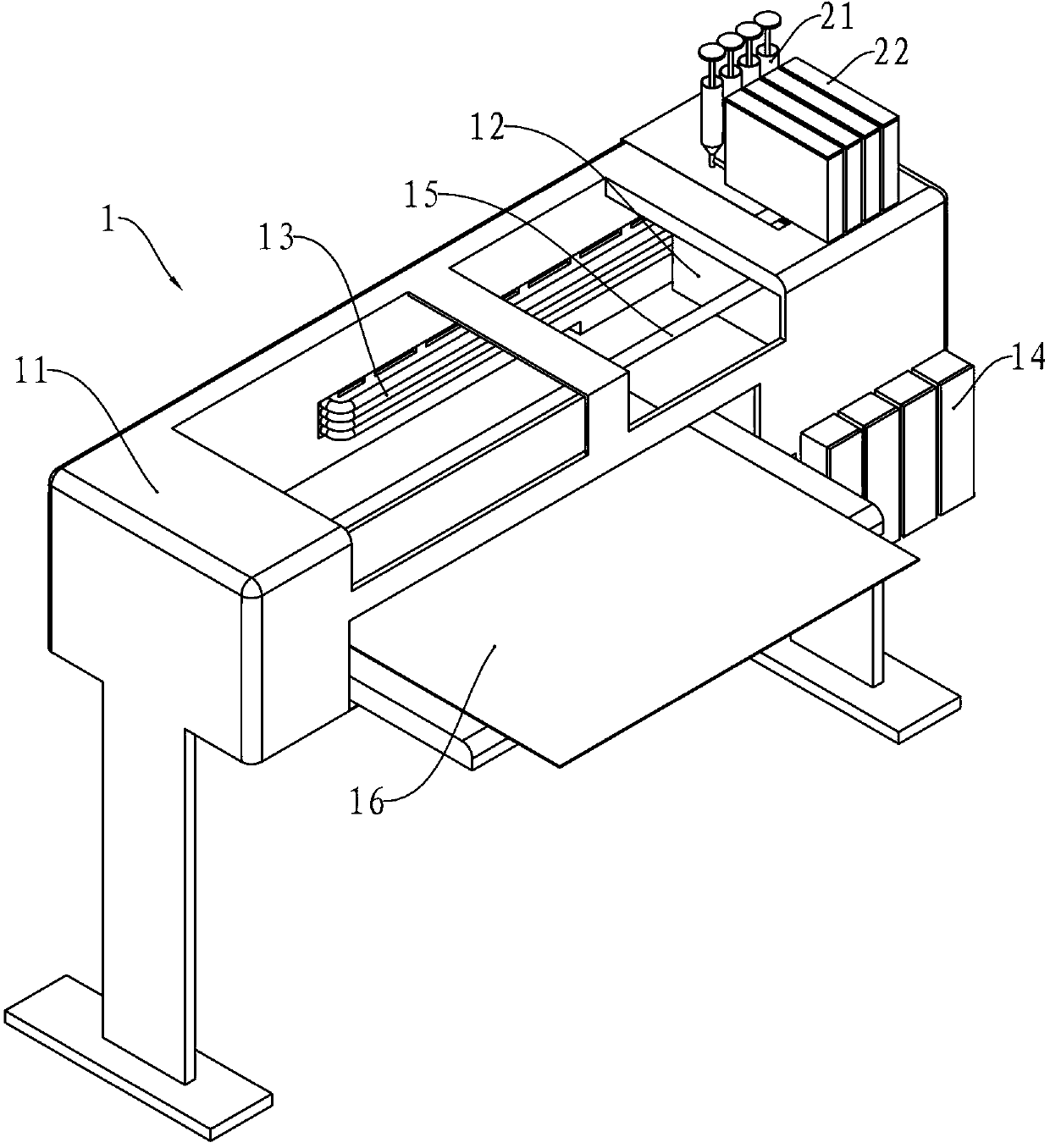

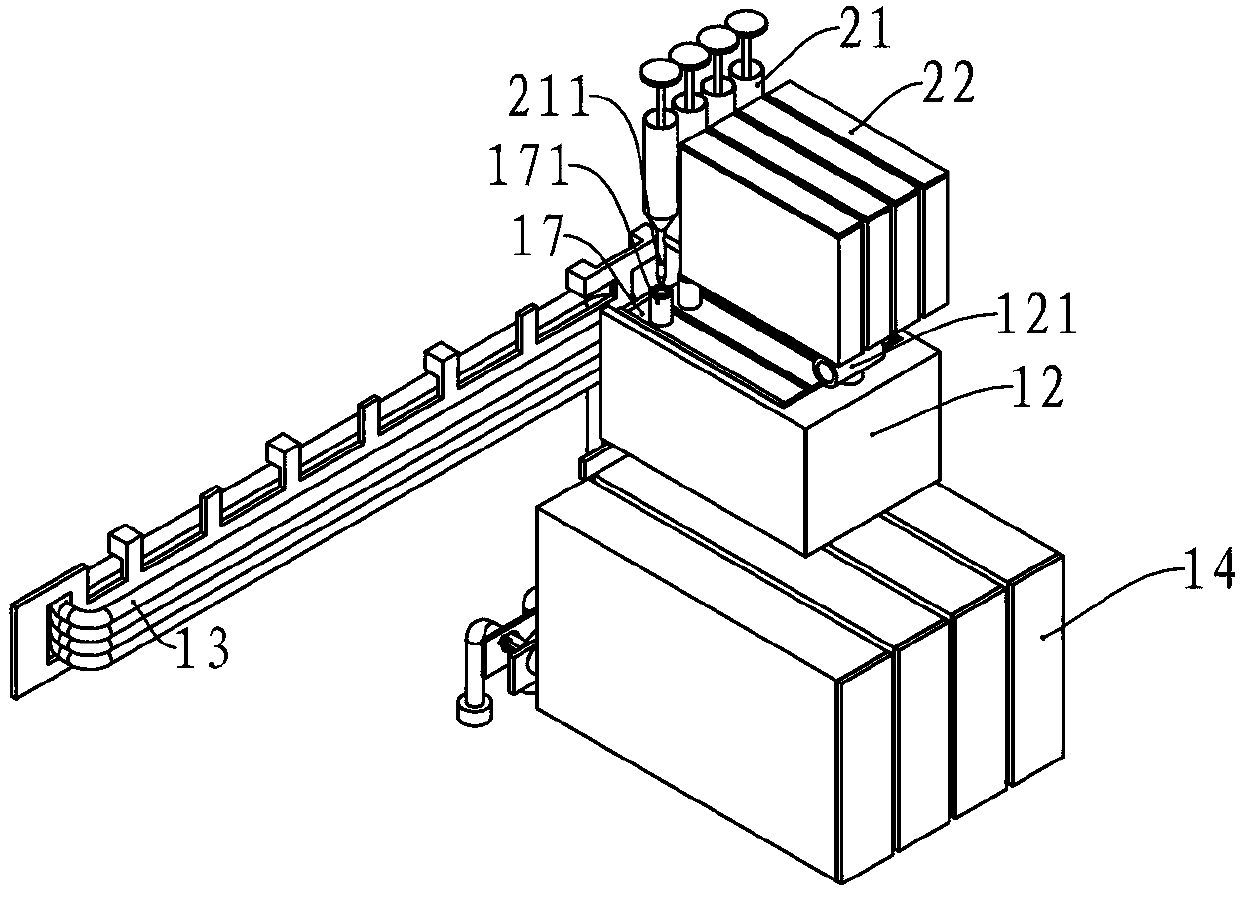

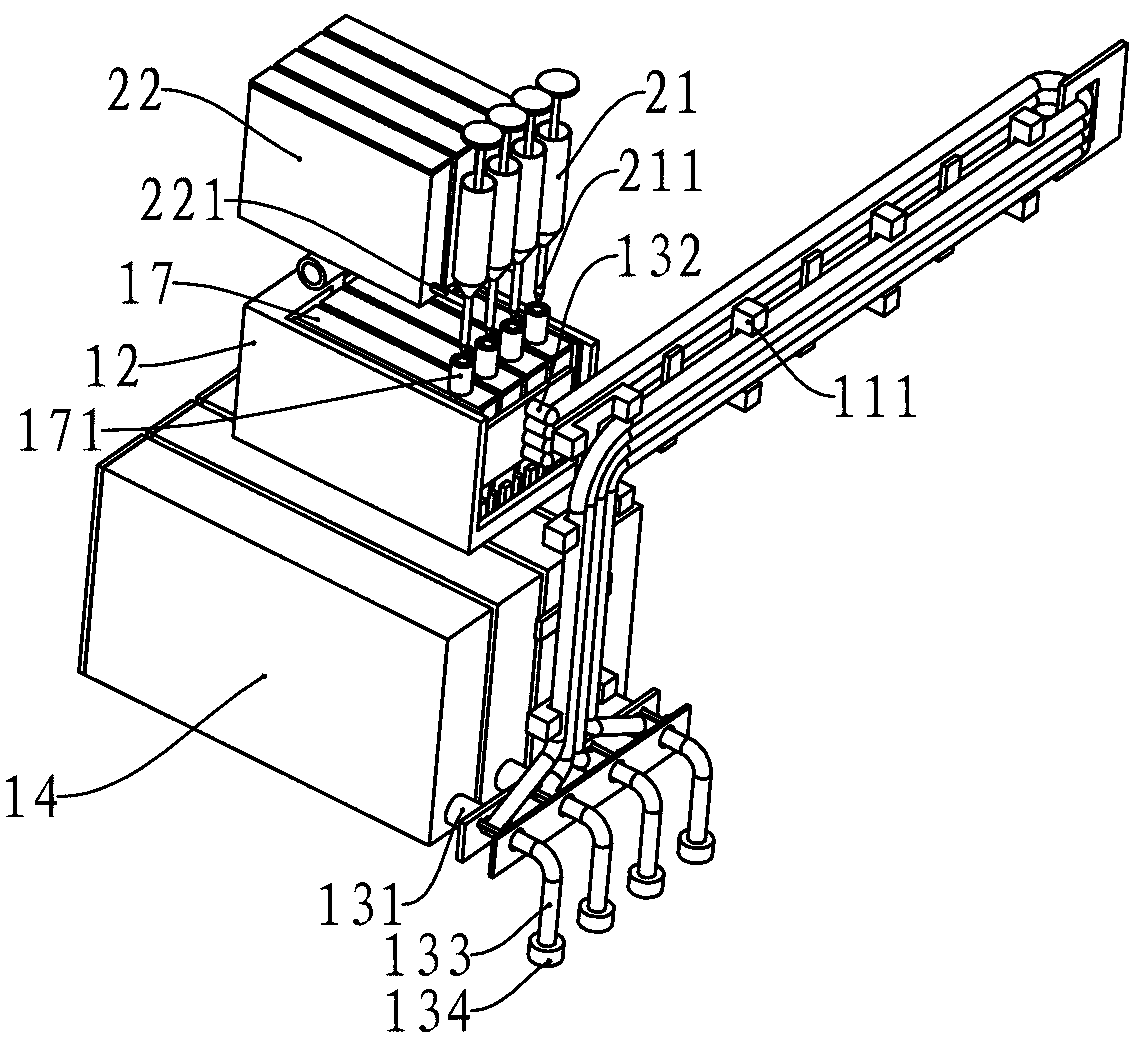

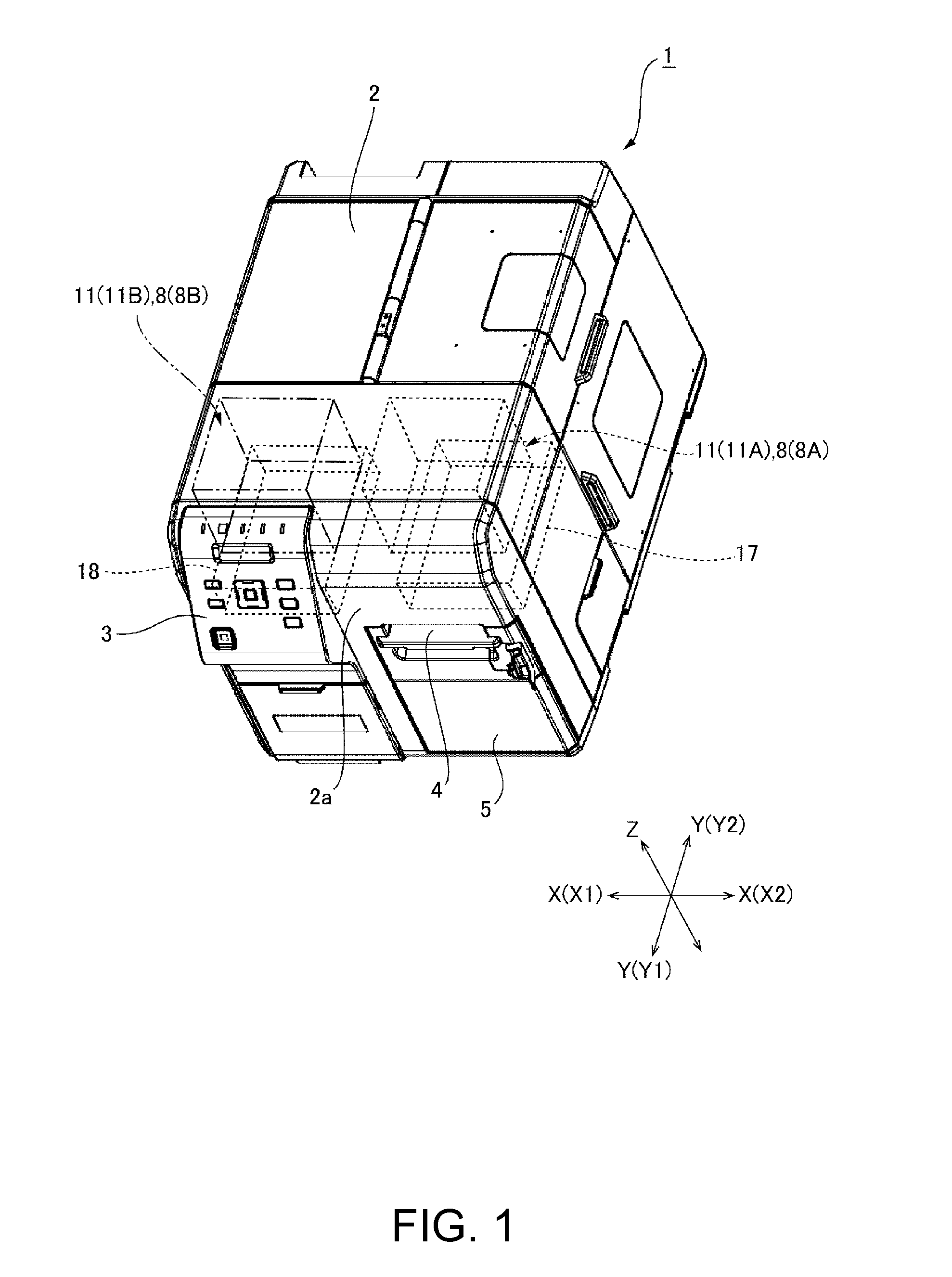

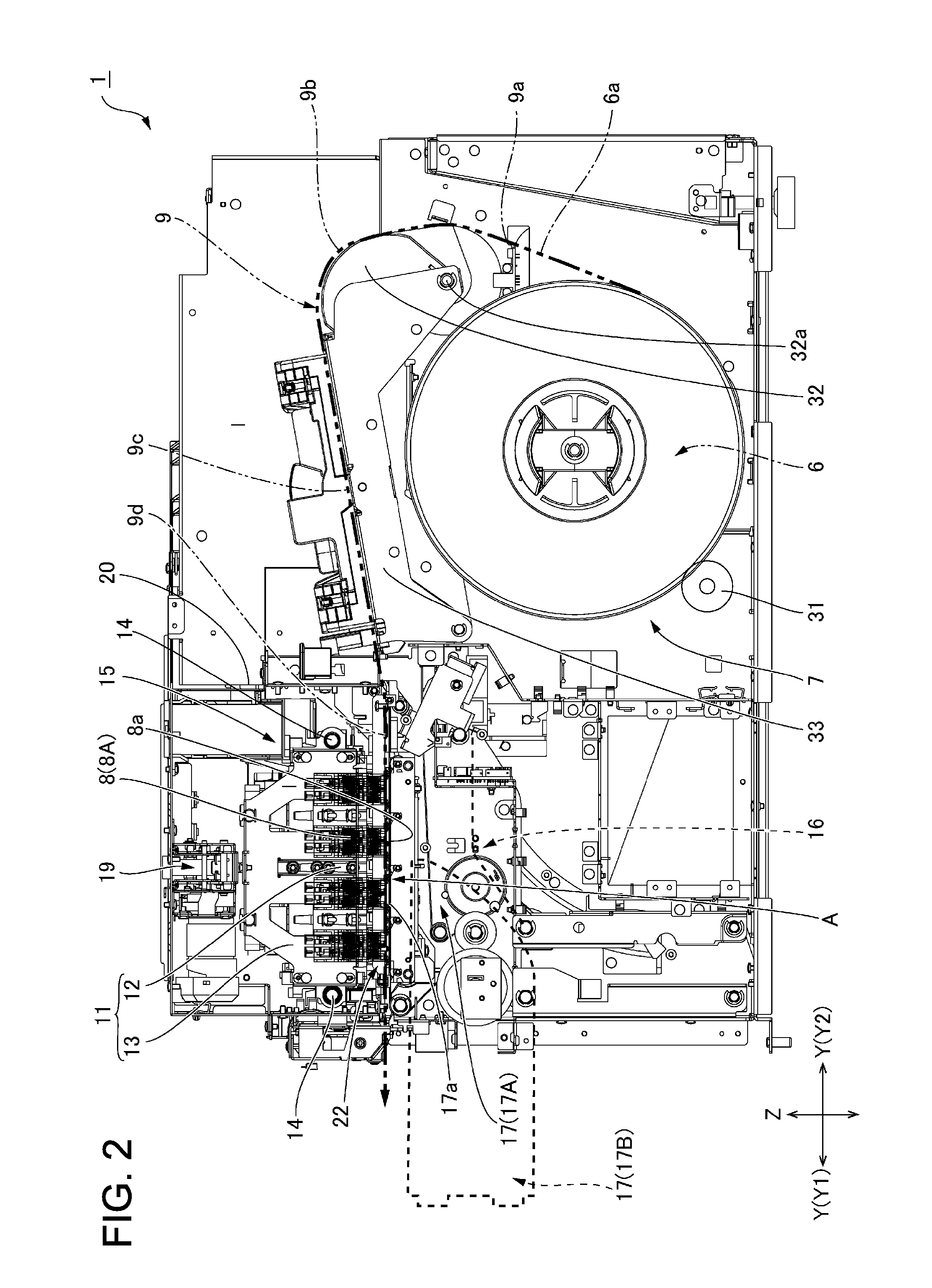

Wide-line printer and ink supply system replacement method thereof

ActiveCN103144439AAvoid it happening againReduce wasteOther printing apparatusLine printerEngineering

The invention relates to a wide-line printer and an ink supply system replacement method thereof. The wide-line printer comprises a shell, a carriage unit arranged in the shell, a printing head detachably arranged on the carriage unit, main ink boxes which are detachably arranged on the carriage unit and are communicated with the printing head, auxiliary ink boxes detachably arranged in the shell, ink conveying tubes which are detachably arranged in the shell and are communicated with the main ink boxes and the auxiliary ink boxes, an opening used for assembling and disassembling the ink conveying tube, and a baffle used for detachably covering the opening, wherein the opening is formed in the wall of the shell nearest a fixed section, and is positioned at a part corresponding to the fixed section, and each ink conveying tube comprises a swing section close to each main ink box and the fixed section close to each auxiliary ink box. When the ink supply system is replaced, the main ink boxes and the auxiliary ink boxes are replaced, the printing head is replaced or rinsed, the baffle is disassembled, and the ink conveying tubes are replaced through the opening, and then the baffle is assembled. The scheme not only is favorable for replacing the ink conveying tubes, but also can avoid the situation that different types of inks are mixed in the ink conveying tubes and the main ink boxes to generate a precipitate difficult to remove is avoided.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

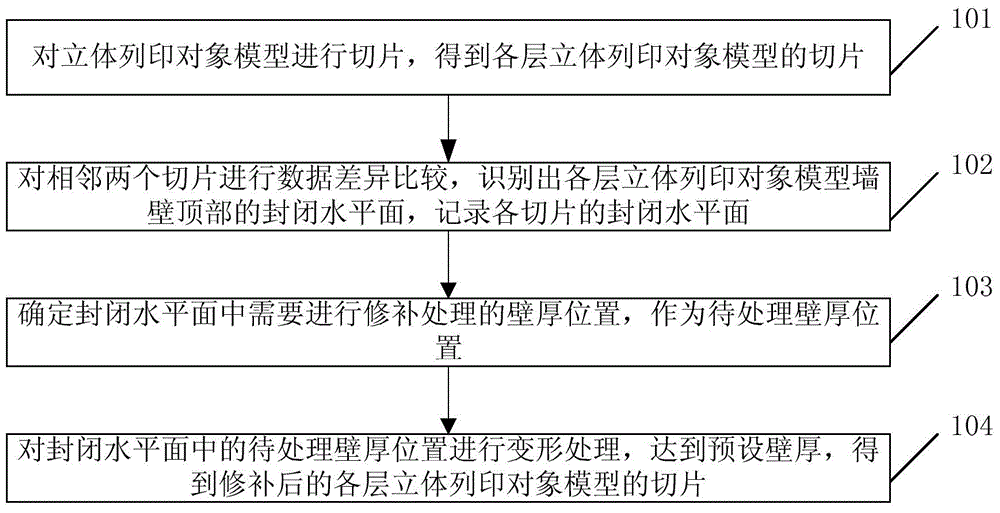

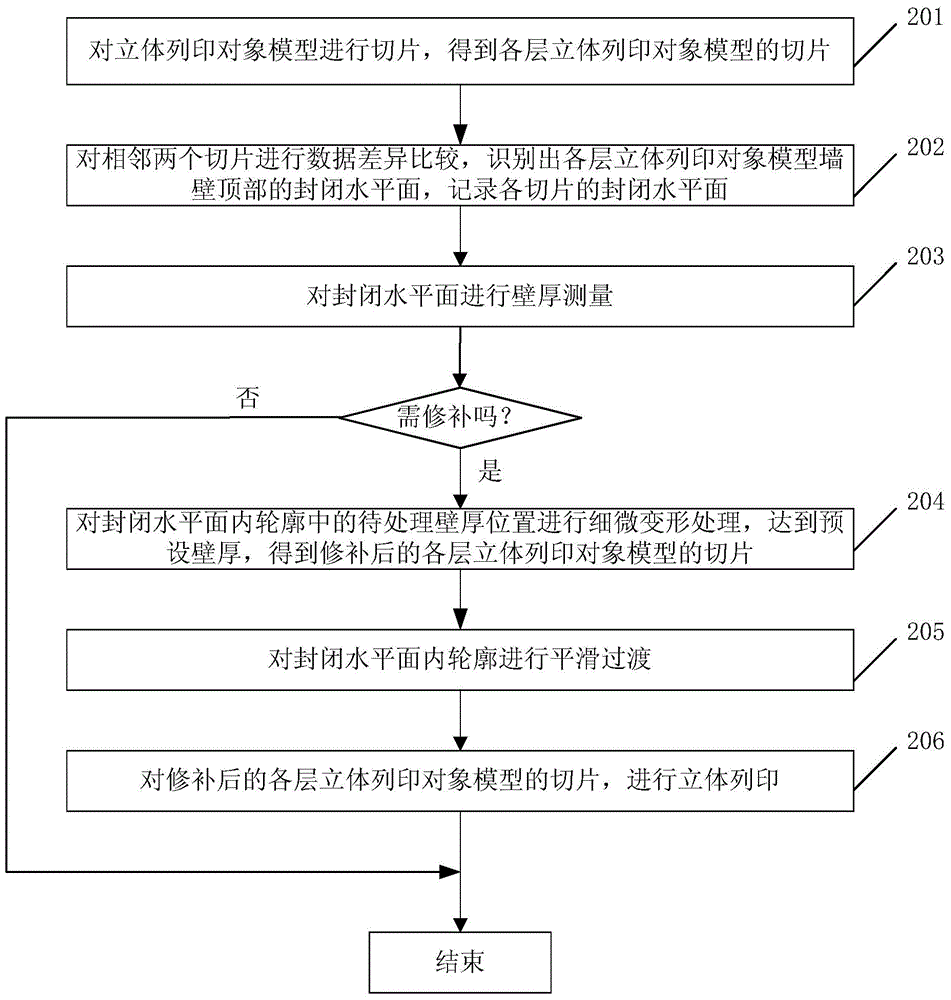

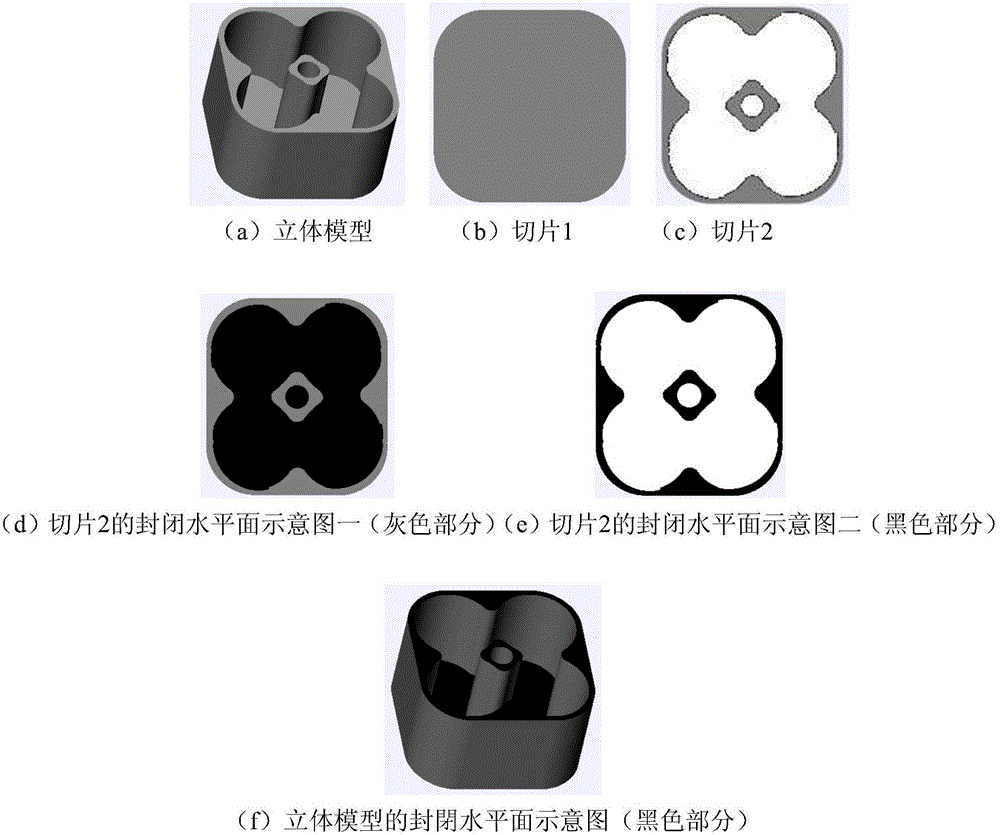

Line printing method and system of three-dimensional line printer

The invention discloses a line printing method and system of a three-dimensional line printer, wherein the method comprises the steps of conducting slicing to a three-dimensional line printing object model, and obtaining slices of the three-dimensional line printing object model of each layer; conducting data difference comparison between two adjacent slices, recognizing closed horizontal plane of the top of a wall of each layer of the three-dimensional line printing object model, and recording the closed horizontal planes of each slice; determining the positions of wall thickness needed repairing treatment in the closed horizontal plane, and treating the positions as the positions of the wall thickness to be treated; conducting deformation treatment to the positions of the wall thickness to be treated, reaching the preset wall thickness, and obtaining the repaired slices of each layer of the three-dimensional line printing object model. By means of the method and system, the forming quality of external horizontal planes of a three-dimensional line printing piece can be improved.

Owner:INVENTECSHANGHAI TECH +2

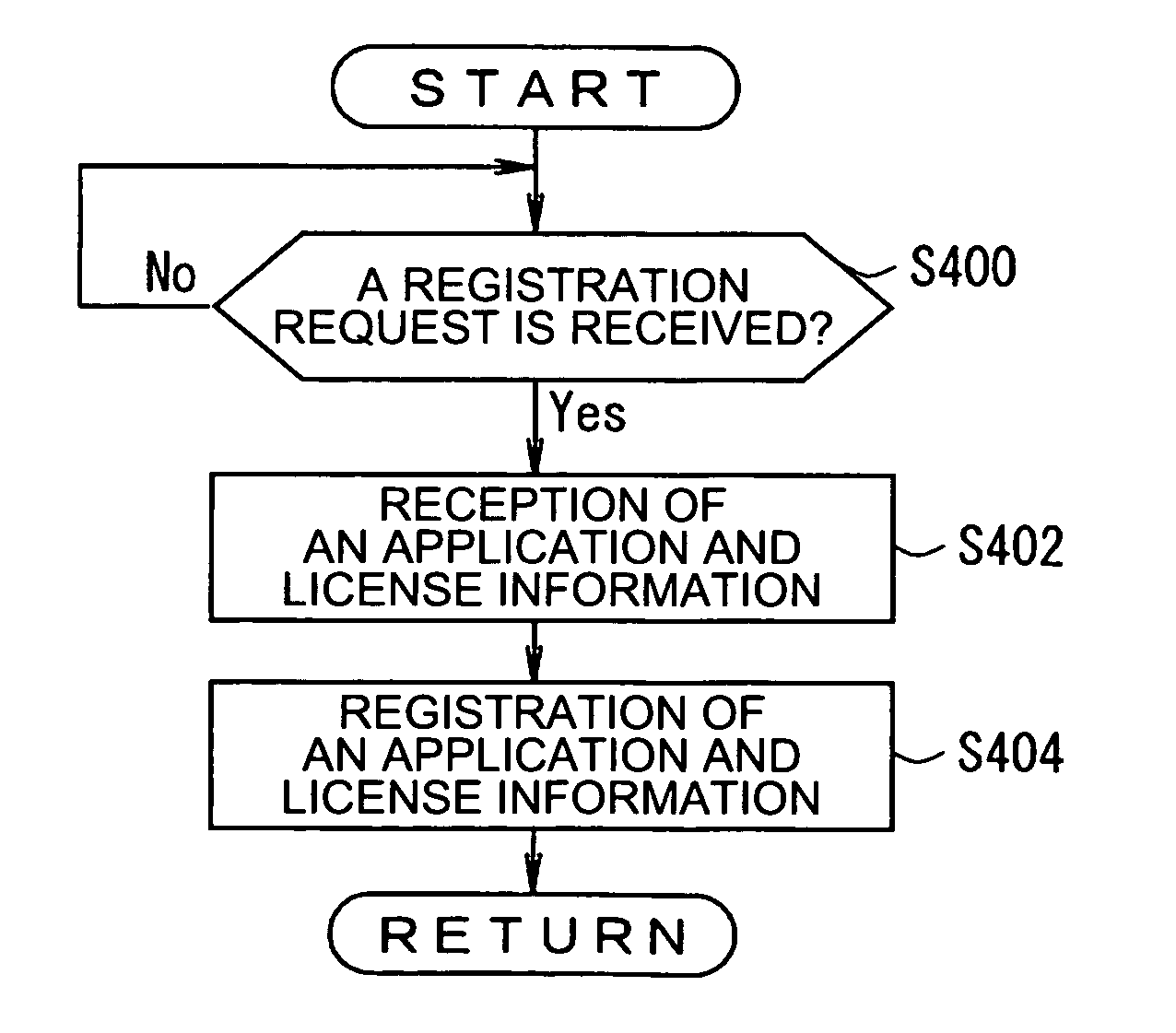

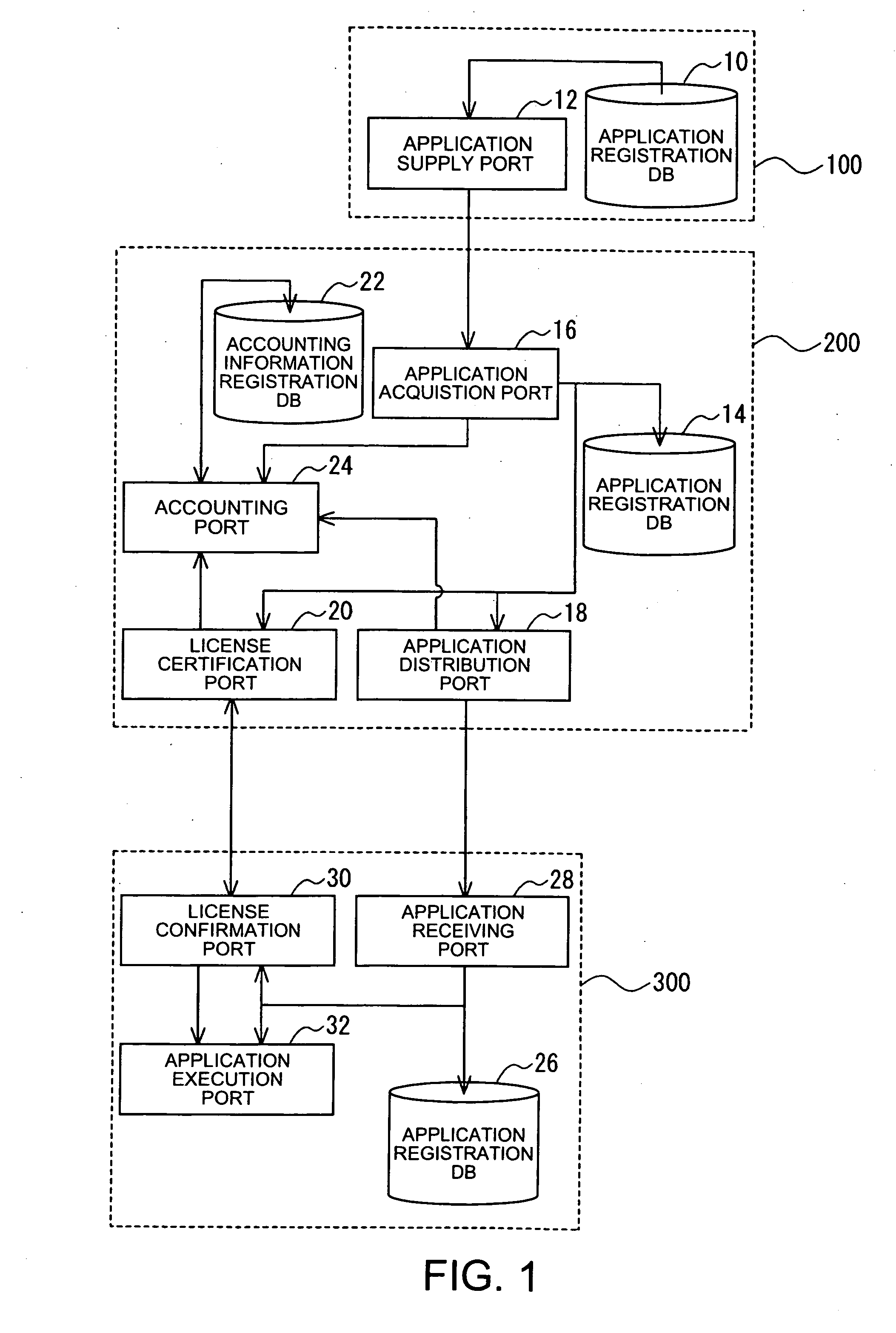

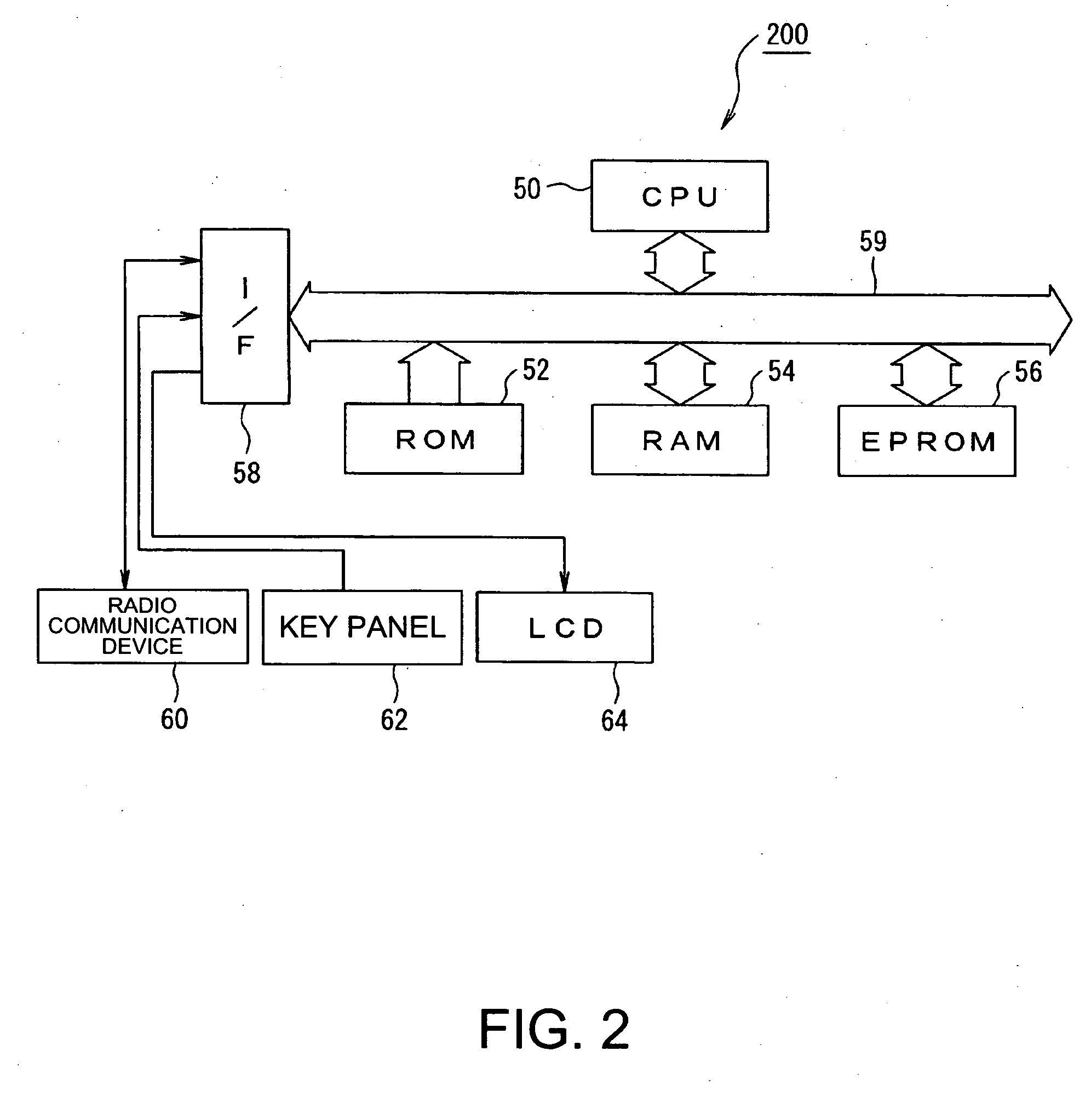

Application management system, device with application execution function, portable terminal with application management function, device program, program and memory medium for portable terminal and application management method

InactiveUS20050240766A1Accurate accountingLimit executionDigital data processing detailsUser identity/authority verificationLine printerExecution unit

An application management system having a portable terminal that manages whether an application can be executed by another device such as an off-line printer. The portable terminal includes an application memory unit that stores the application as well as correlates and stores license information for certifying the eligibility for use of the application; an application distribution unit that distributes the application and license information to the device; and a license certification unit that certifies the eligibility for use of the application. The device includes an application receiving unit that receives the application and the license information; a license confirmation unit that requests confirmation about the eligibility for use of the application; and an application execution unit that executes the application based on the result received from the license certification unit.

Owner:SEIKO EPSON CORP

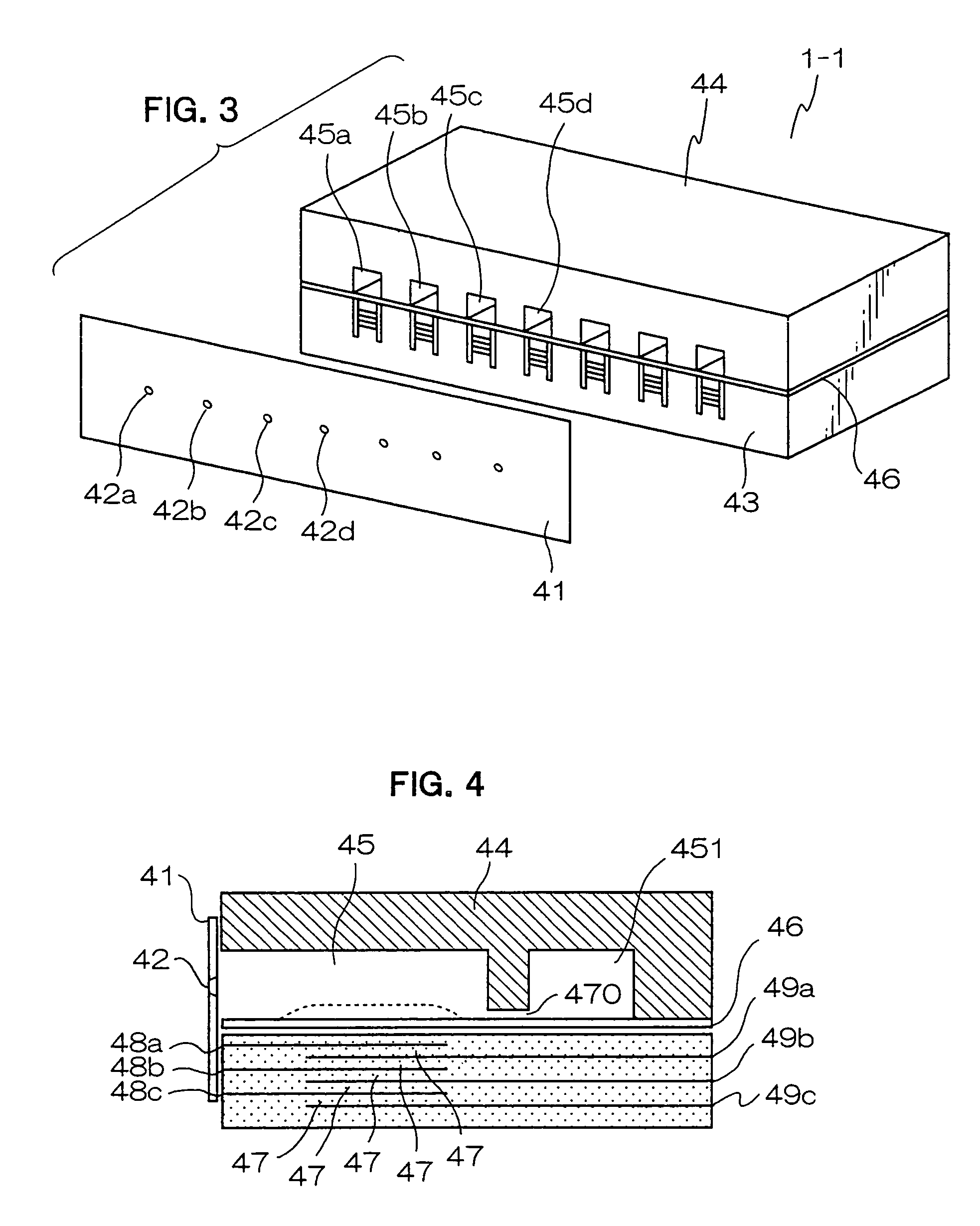

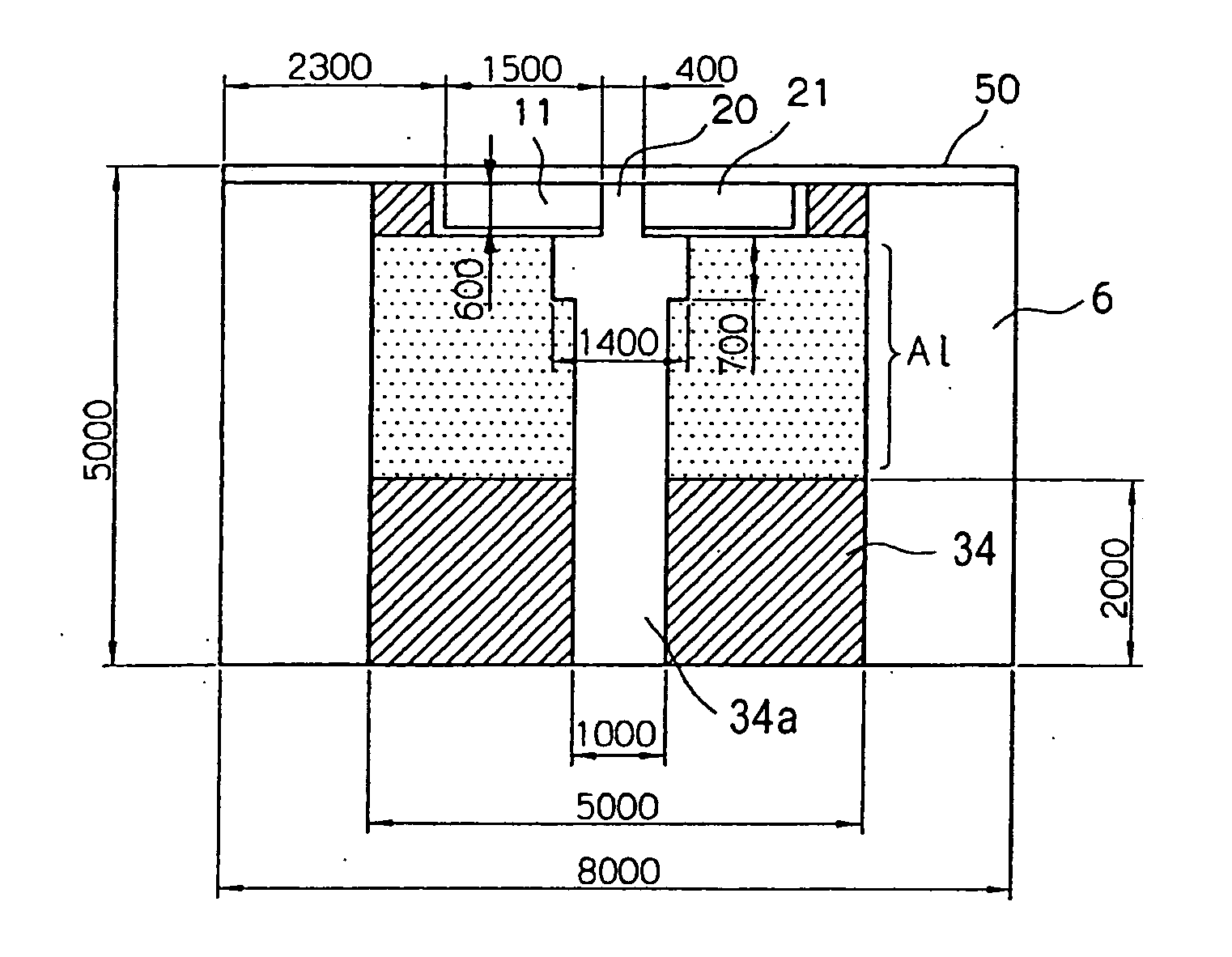

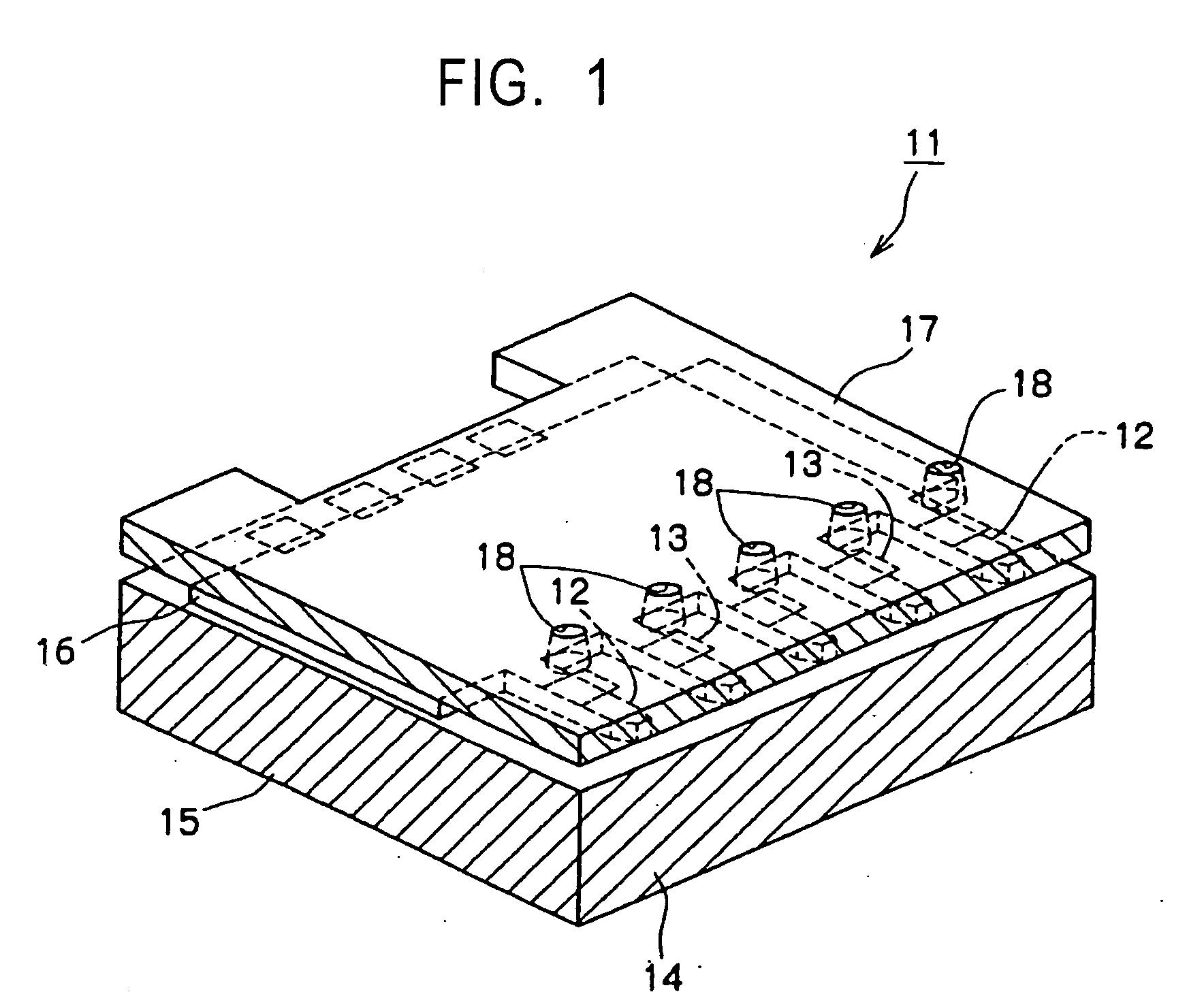

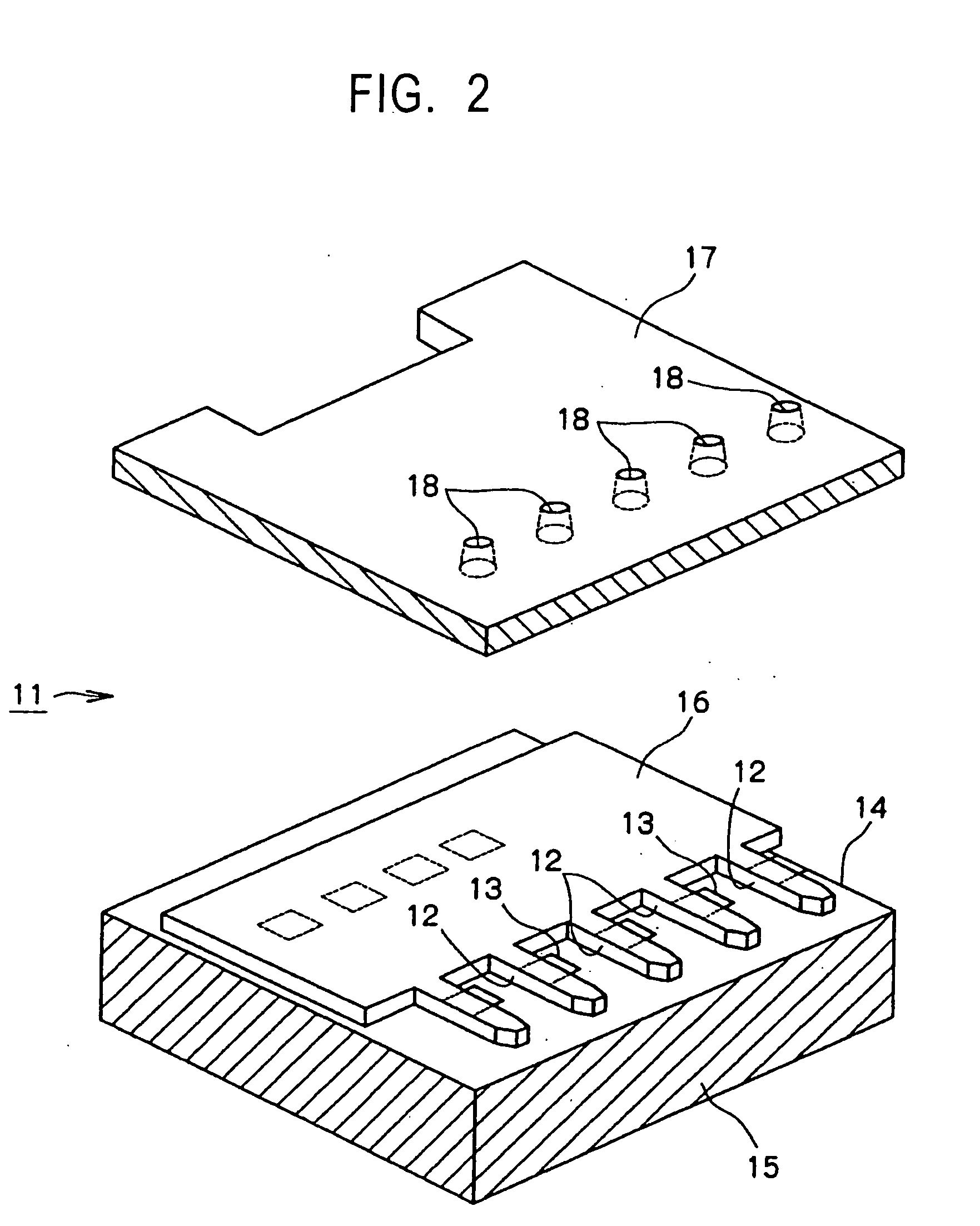

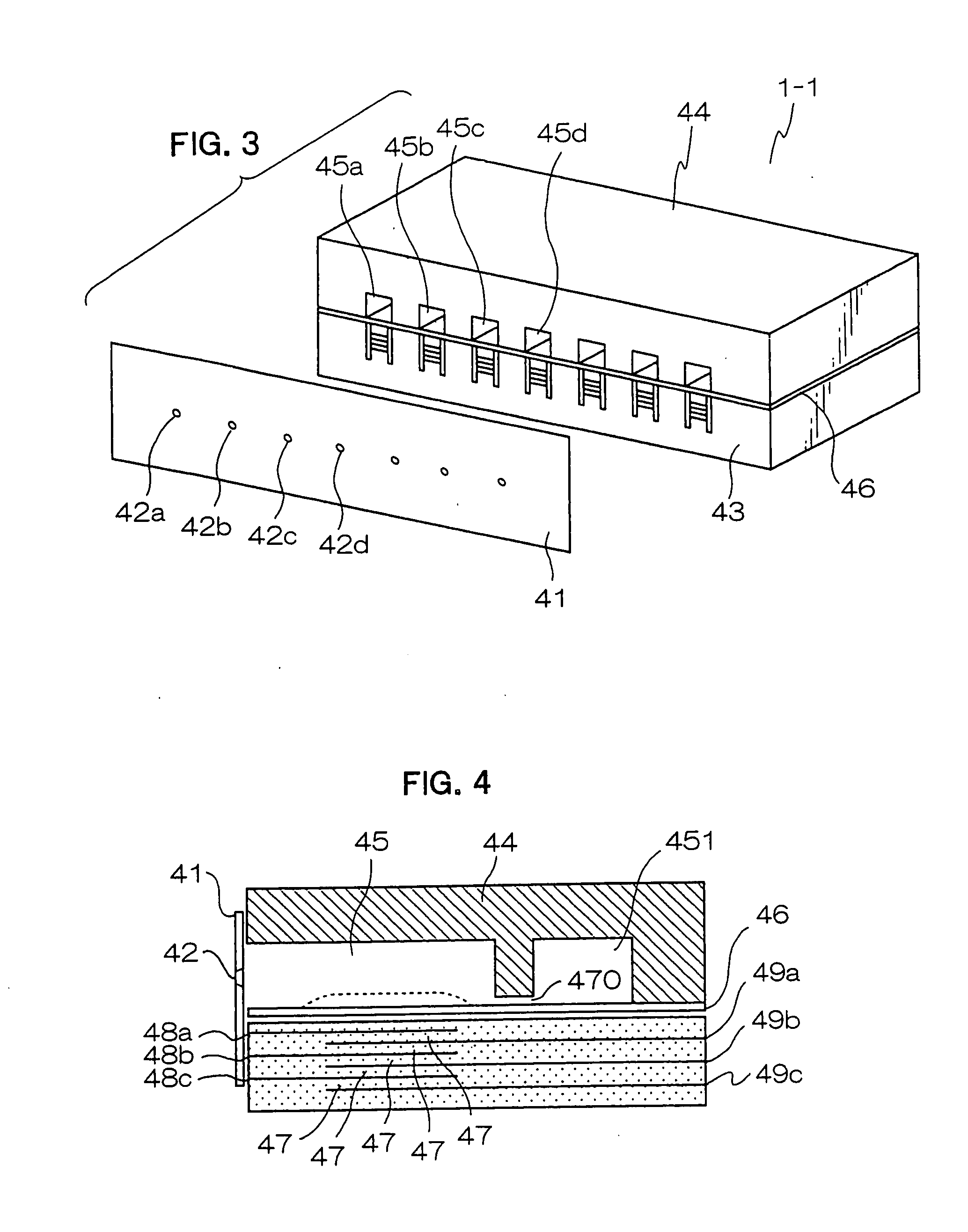

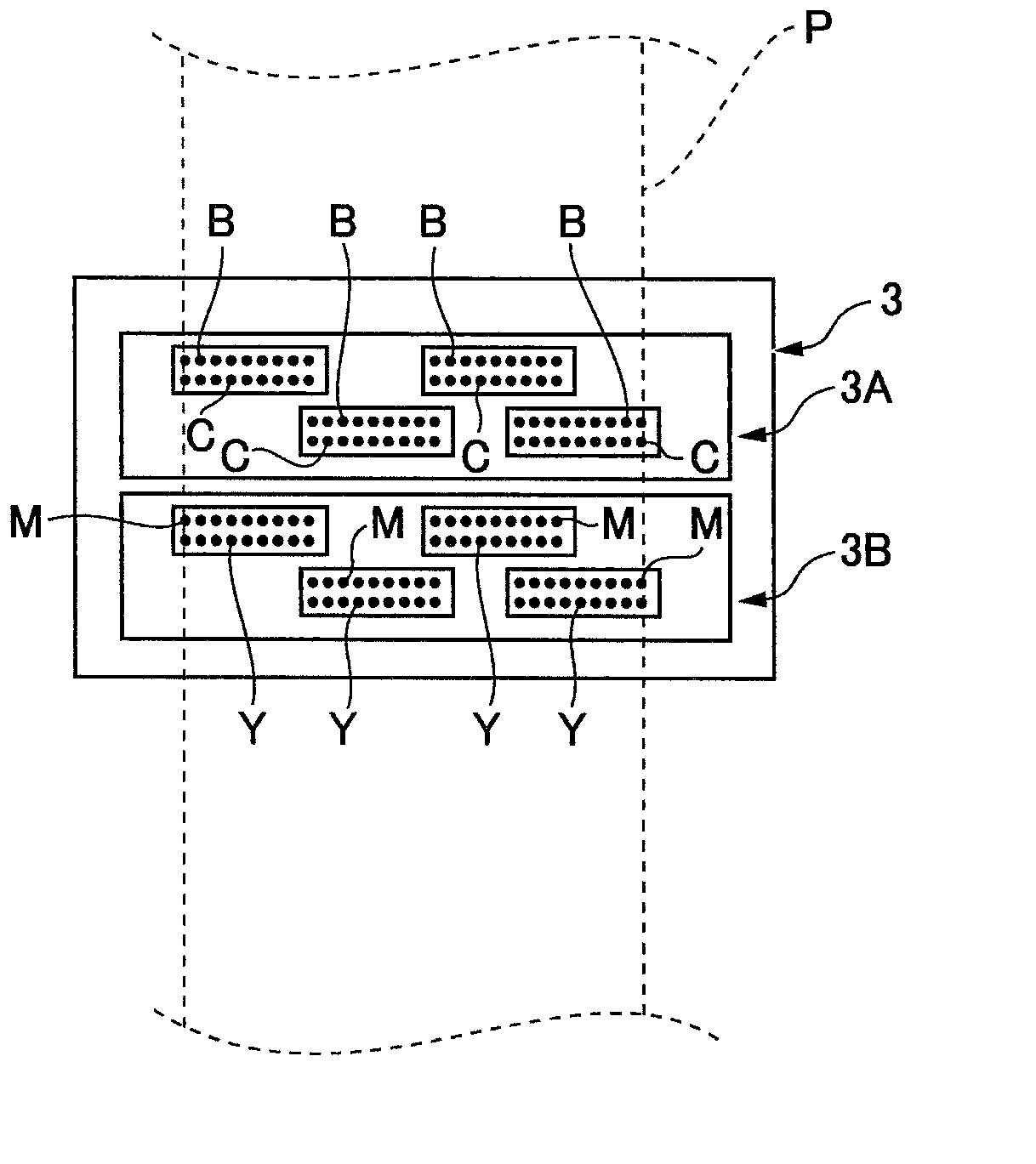

Print head

InactiveUS20050212853A1Increasing processing accuracy and attachment accuracyEfficiently dissipated without making the structure complexInking apparatusLine printerEngineering

A print head for a line printer in which errors between print head chips and another component are reduced and ink leakage is prevented, and in which heat generated in print head chips is efficiently dissipated without making the structure of the print head complex or increasing the size of the print head. A plurality of print head chips (11) are arranged along an ink path (20) and are disposed on both sides of the ink path in a zigzag pattern. Dummy chips (21) which do not eject ink are disposed at regions between the print head chips (11) arranged along the ink path (20). In addition, an ink-path member (23) is provided, at least a part of the ink-path member (23) which includes portions adhered to the print head chips (11) being composed of a material having a high thermal conductivity, so that the ink-path member (23) also serves as heat-dissipating means which dissipates heat generated in the print head chips (11).

Owner:SONY CORP

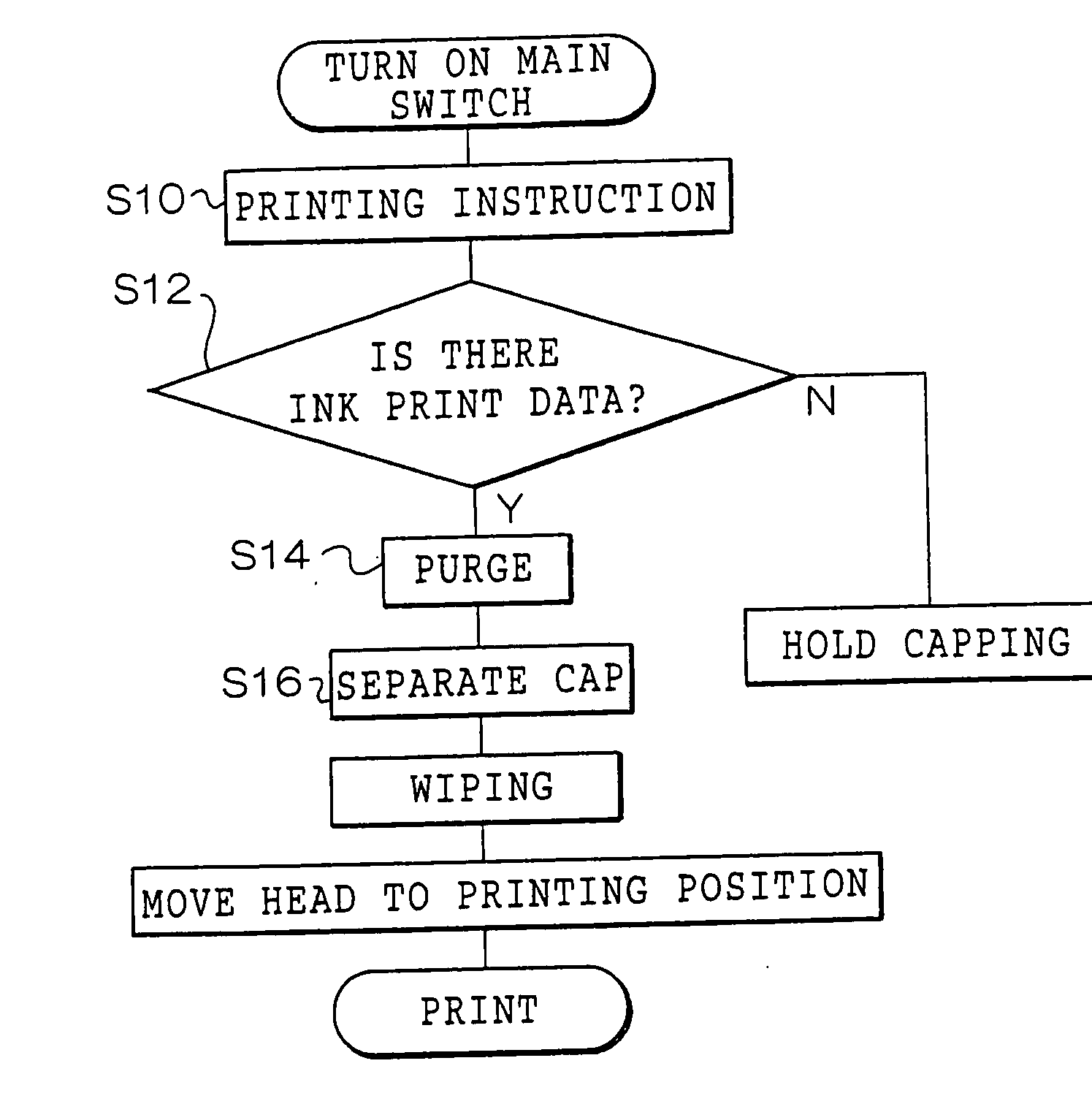

Ink-jet line printer and image forming apparatus using the same

An ink-jet line printer (30) is constituted by multiple ink-jet heads (1-1 to 1-3). Actuators (3-1 to 3-3) are arranged so as to be moved between a home position and a print position, and backup mechanisms (2-1 to 2-3) are arranged at home positions. In this ink-jet line printer, the ink-jet heads can be protected and recovered by backup mechanisms, thus making high-speed continuous printing possible. Even though the backup mechanisms are incorporated, a compact apparatus can still be achieved.

Owner:FUJIFILM BUSINESS INNOVATION CORP

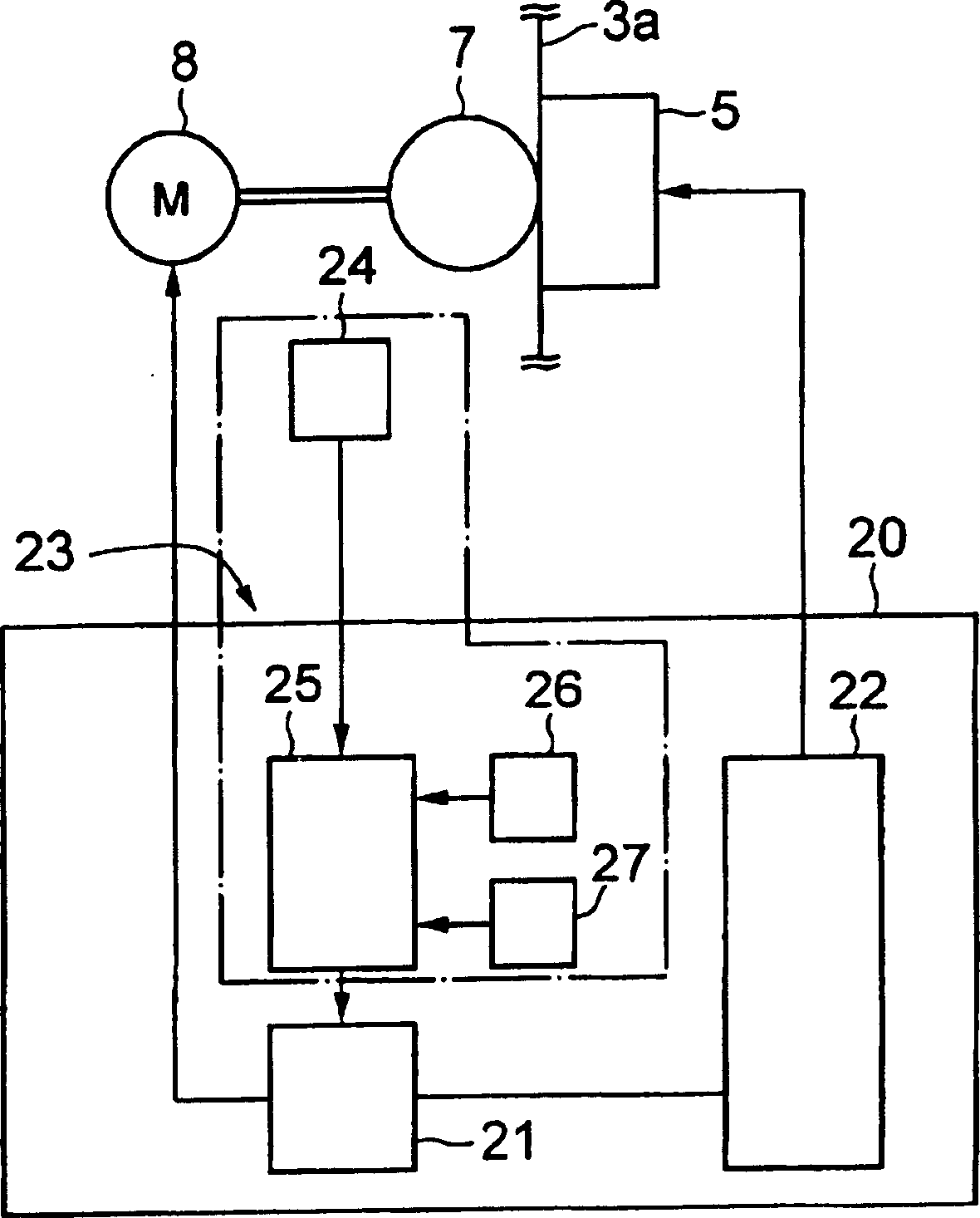

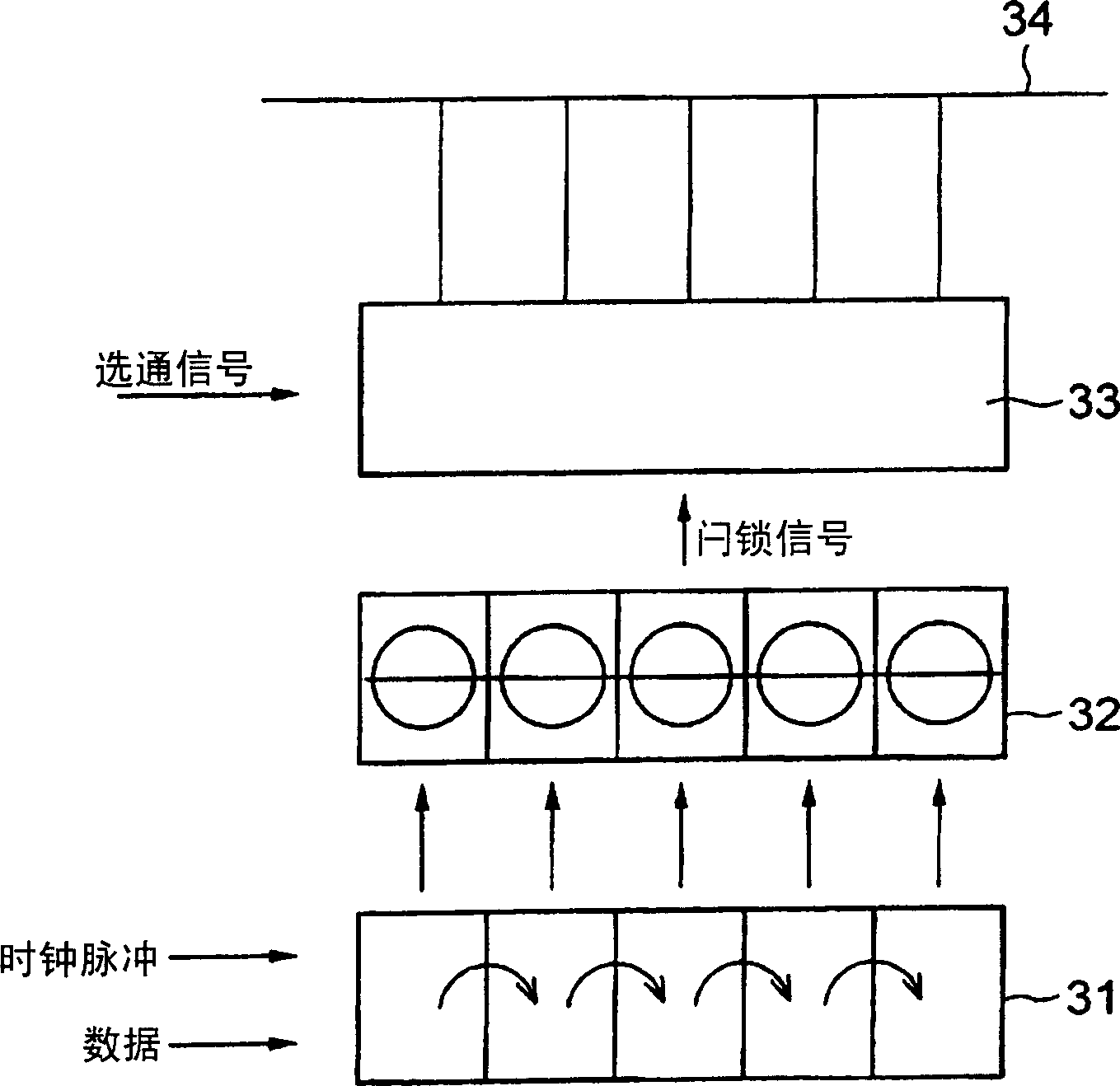

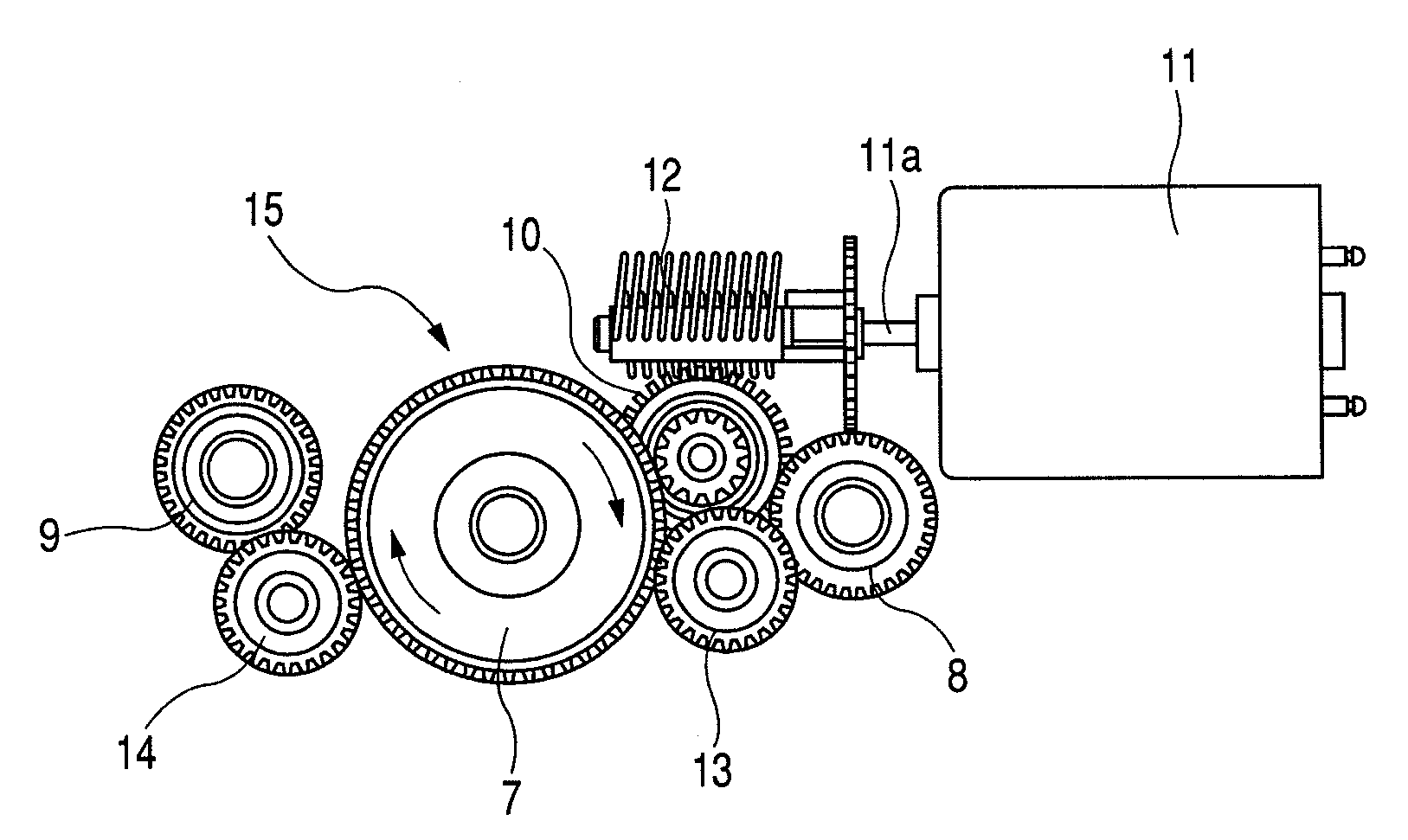

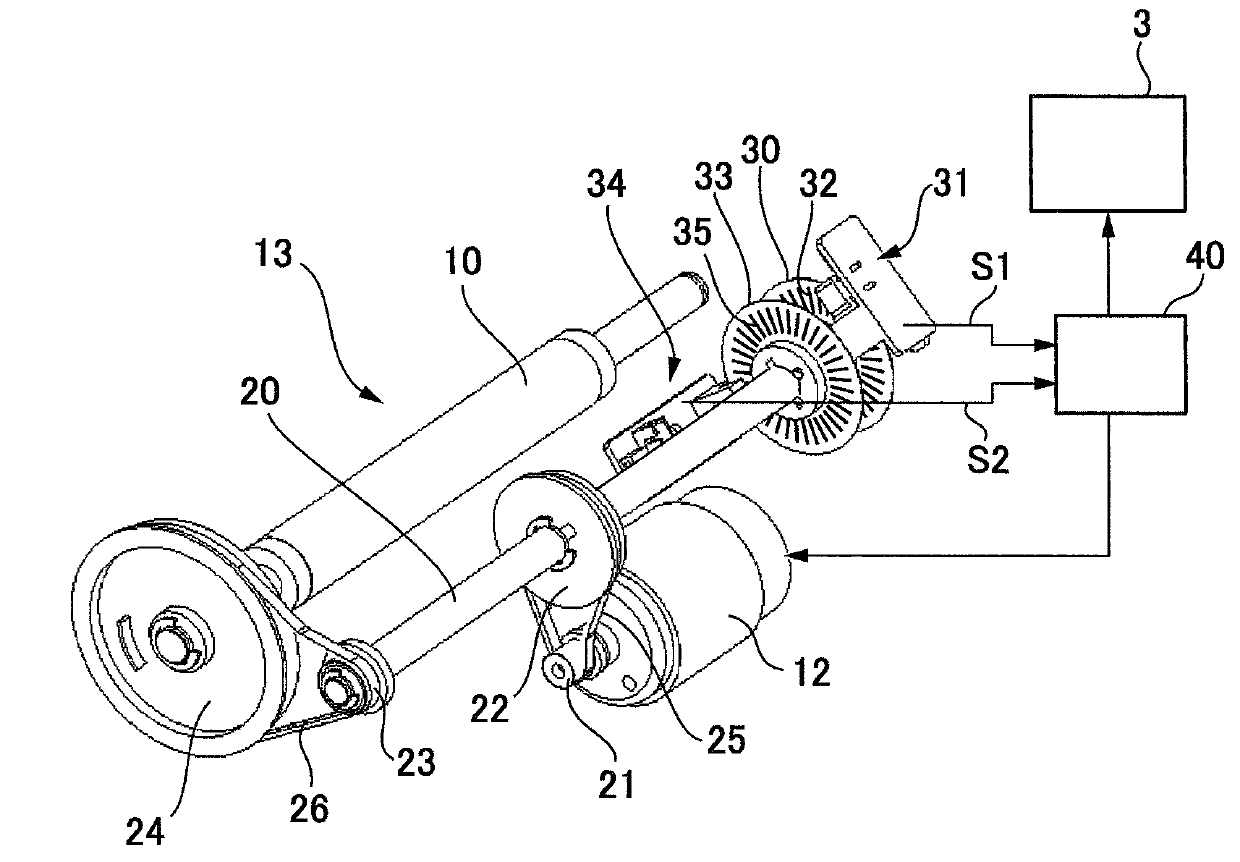

Lineprinter and its controlling method

To provide a thermal printer in which printing is carried out at a constant line interval while employing a DC motor as the power source for feeding a recording sheet.The printer comprises a sheet feed control section 25 including a unit 6 for feeding a recording sheet 3a using a DC motor 8 as a power source, a print head 5 for printing on the recording sheet 3a being fed, and a section 23 for detecting the feeding amount of the recording sheet 3a and controlling the DC motor 8, and a print control section 24 for controlling the print head 5. Feeding amount b of sheet is detected after stopping power supply to the DC motor 8 before feeding of the recording sheet 3a is stopped. Subsequent printing is started after starting power supply to the DC motor 8 and feeding the sheet by an amount (a) determined by subtracting the sheet feeding amount b from a specified interline sheet feed amount c thus performing printing at a constant line interval. (C)2005,JPO&NCIPI.

Owner:SEIKO EPSON CORP

Constant density printer system

An ink density closed loop control system for an ink ribbon of an impact line printer having a reservoir roller fluidly connected to a pump and ink supply. A transfer roller can contact the reservoir roller for imparting ink to the ink ribbon. A sensor senses the relative amount of ink on the print ribbon and an electrical drive responsive to the sensor drives the pump for a flow of ink to the one or more channels. The sensor can sense ink on different segments of the ribbon and, with two or more channels in the reservoir roller can distribute ink to two or more segments of the reservoir roller depending upon the ink sensed at a particular segment of the ribbon. A further enhancement of the invention provides a multi-viscosity ink to compensate for changes in ambient temperature conditions.

Owner:PRINTRONIX INCORPORATED

Thermal transfer line printer

ActiveUS7439994B2Easily and reliably controlTotal number of gears between a driving member and a driven member can be reducedPrinting mechanismsRecording apparatusLine printerGear wheel

Owner:ALPS ALPINE CO LTD

Wide-line printer and cleaning method

The invention provides a wide-line printer capable of using different types of ink in a transforming mode and a wide-line printer cleaning method. The wide-line printer comprises a printing head, a printing word cart, an ink supply system composed of a main ink box, an auxiliary ink box and an ink delivering tube and a cleaning device. The main ink box is installed in the printing word cart, and an ink outlet of the main ink box is detachably connected with the printing head. The ink leading-in end of the ink delivering tube is detachably connected with an ink outlet of the auxiliary ink box, and the ink output end is connected with an ink inlet of the main ink box. The cleaning device capable of being connected with the main ink box is used for cleaning the main ink box and the ink delivering tube. The cleaning method comprises the steps of a, disconnecting the printing head and the ink outlet of the main ink box and sealing the ink outlet of the main ink box; b, dismantling the ink outlet of the auxiliary ink box from the ink leading-in end; c, connecting the cleaning device and the main ink box; d, using the cleaning device to clean the main ink box and the ink delivering tube; and e, enabling the printing head and the ink outlet of the main ink box to be connected.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

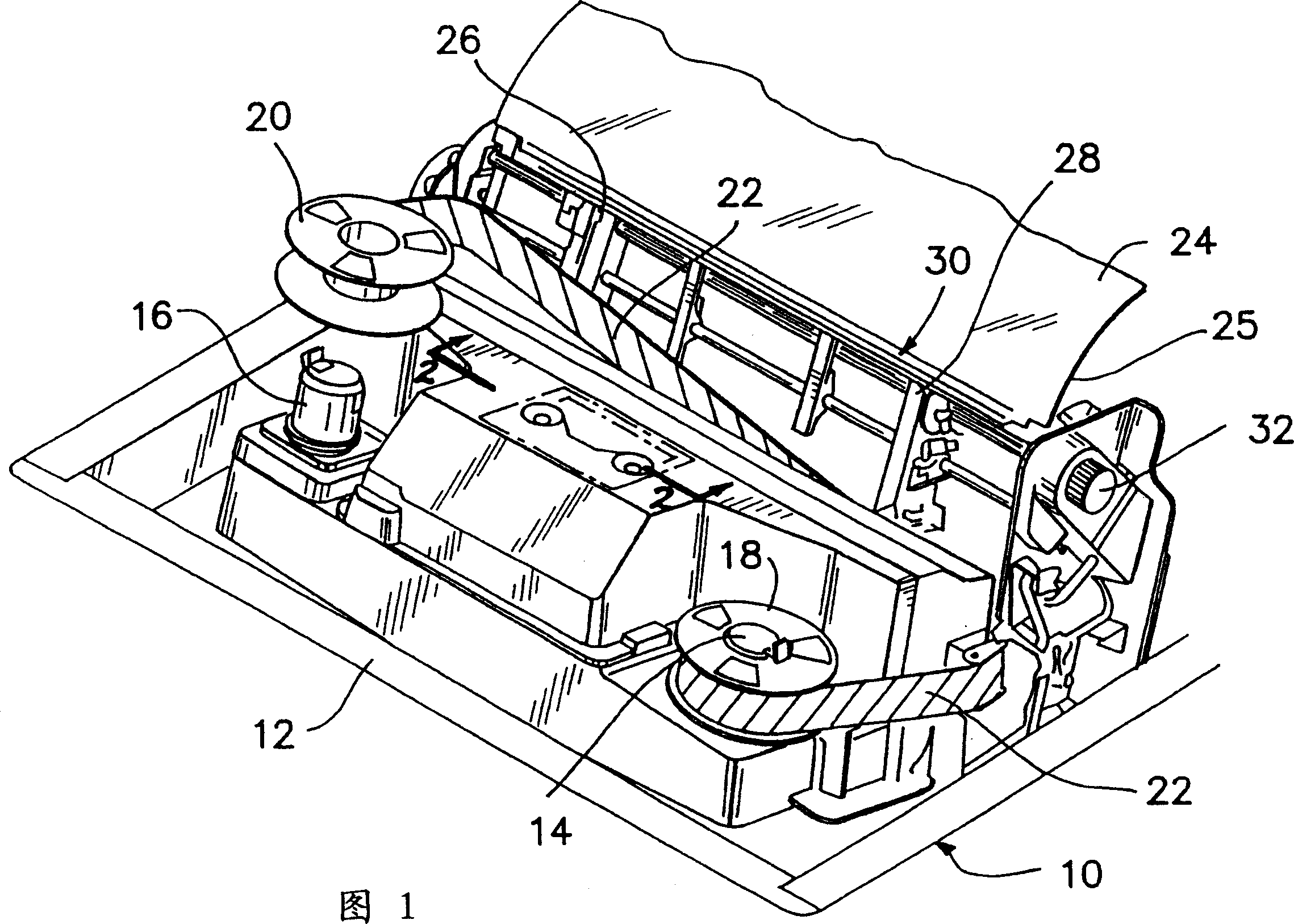

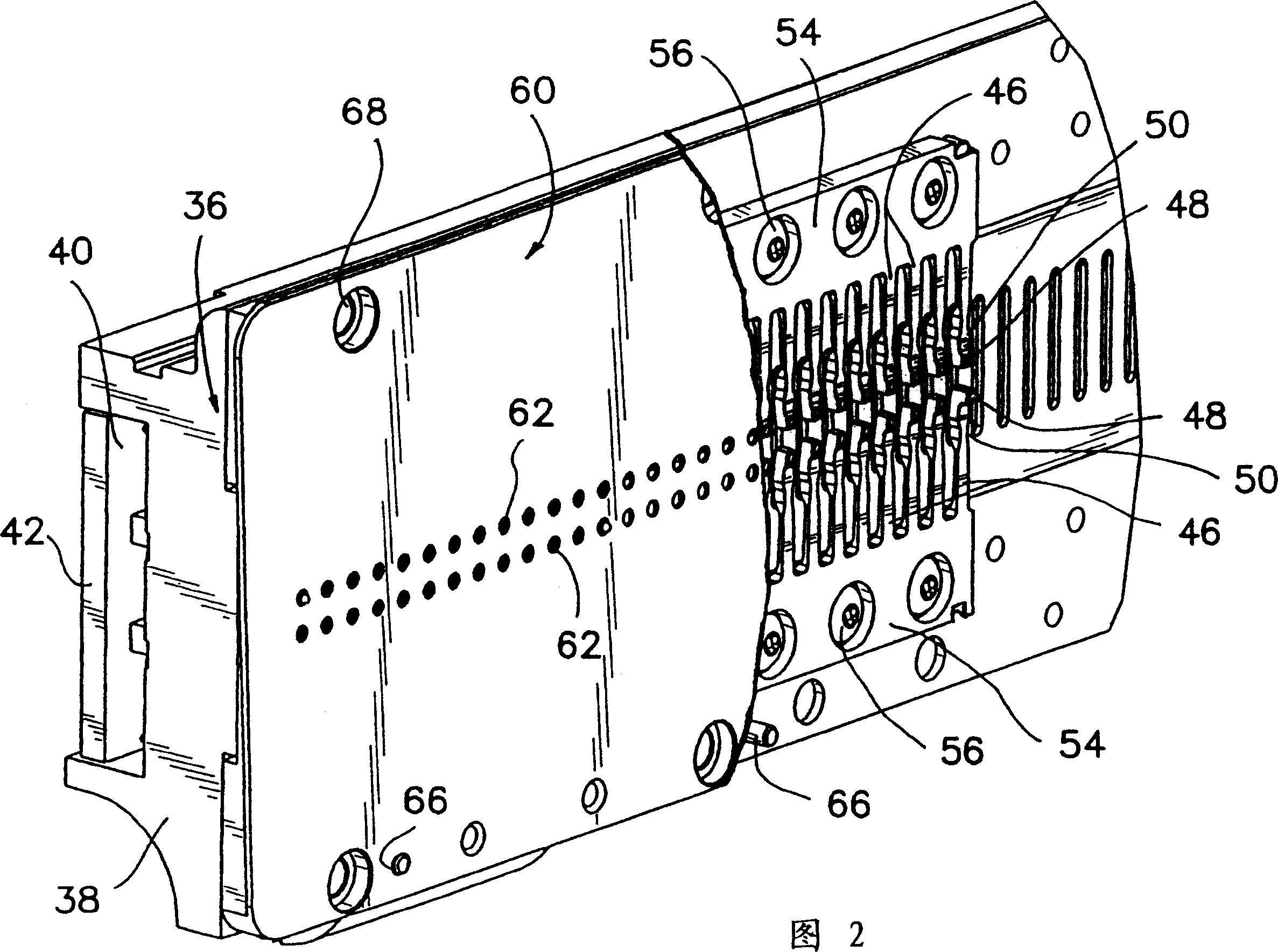

Typewriter letter hammer group with magnetic shunt

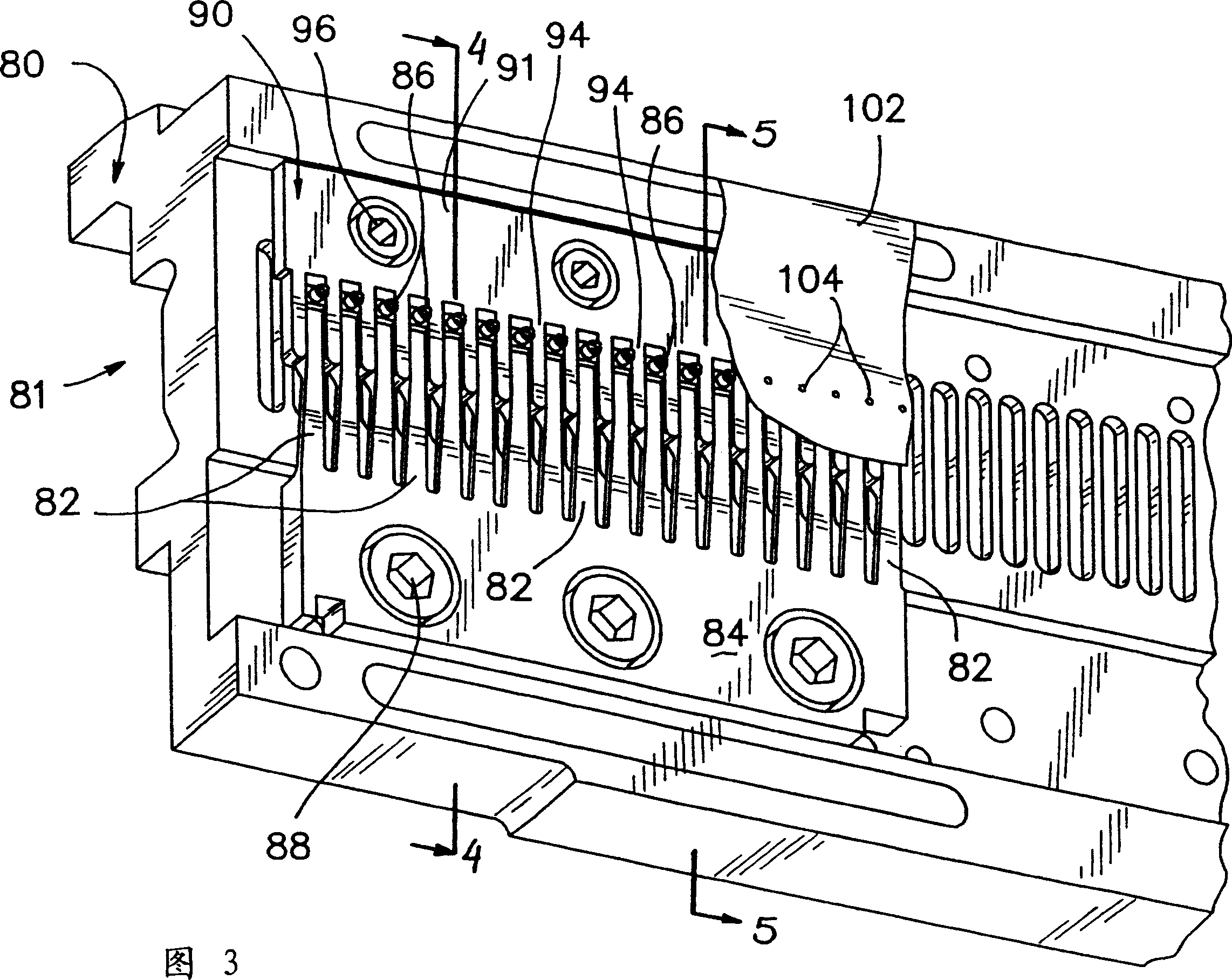

ActiveCN1526562ALight in massRaise the natural frequencyHammer-impression mechanismOther printing apparatusLine printerPole piece

An impact line printer comprising a print ribbon wound on a pair of spools for traversal in two directions across a plurality of print hammers having tips for impacting the print ribbon to print on a media. A permanent magnet having two pole pieces having pole piece ends in adjacent relationship to the print hammers retains the print hammers until a coil in associated relationship with each pole piece releases the magnetic retention of the hammers. A magnetically permeable extension is longitudinally adjacent each hammer which acts as a magnetic shunt to permit more rapid printing rates and higher impacts. The extensions conduct and shunt magnetic flux from the hammers through the longitudinally adjacent extensions.

Owner:PRINTRONIX LLC

Inkjet line printer

InactiveCN102991125ASquirting correctlySmall diameterOther printing apparatusLine printerControl signal

An inkjet line printer (1) has a first encoder (31) for detecting the media conveyance distance of the paper feed roller (10), and a second encoder (34) for generating a signal to control the ink ejection timing. The encoder scales (32, 35) of the first encoder (31) and second encoder (34) are disposed to the intermediate roller (20) of a speed reducing mechanism (13) that transfers drive power from the paper feed motor (12) to the paper feed roller (10). Because the second encoder (34) outputs a pulse signal with a predetermined number of pulses in the time the recording paper is conveyed a specific distance by the paper feed roller (10), the signal from the second encoder (34) can be used as a signal to control the timing of ink ejection from the inkjet head (3).

Owner:SEIKO EPSON CORP

Recording device, method of controlling a recording device, and recording medium

InactiveUS20120236341A1Efficient executionVisual presentation using printersComputer hardwareRelevant information

Processes related to jobs received from a control device can be executed efficiently. An inkjet line printer 1 has a printer-side control unit 27 that, when receiving jobs, gets job-related information related to the received jobs from a host computer 25, and based on the acquired job-related information determines the sequence of processes related to executing the received jobs.

Owner:SEIKO EPSON CORP

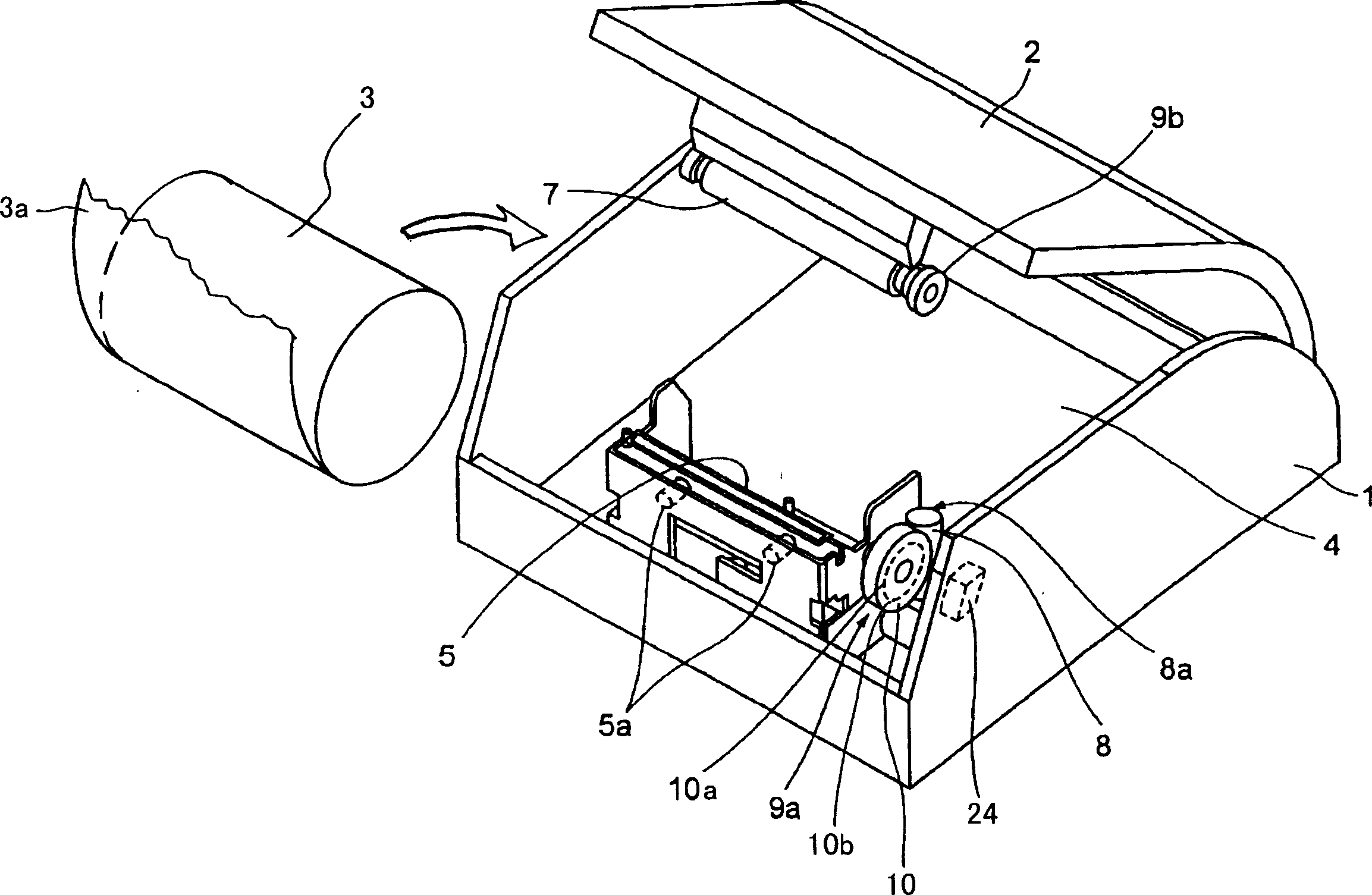

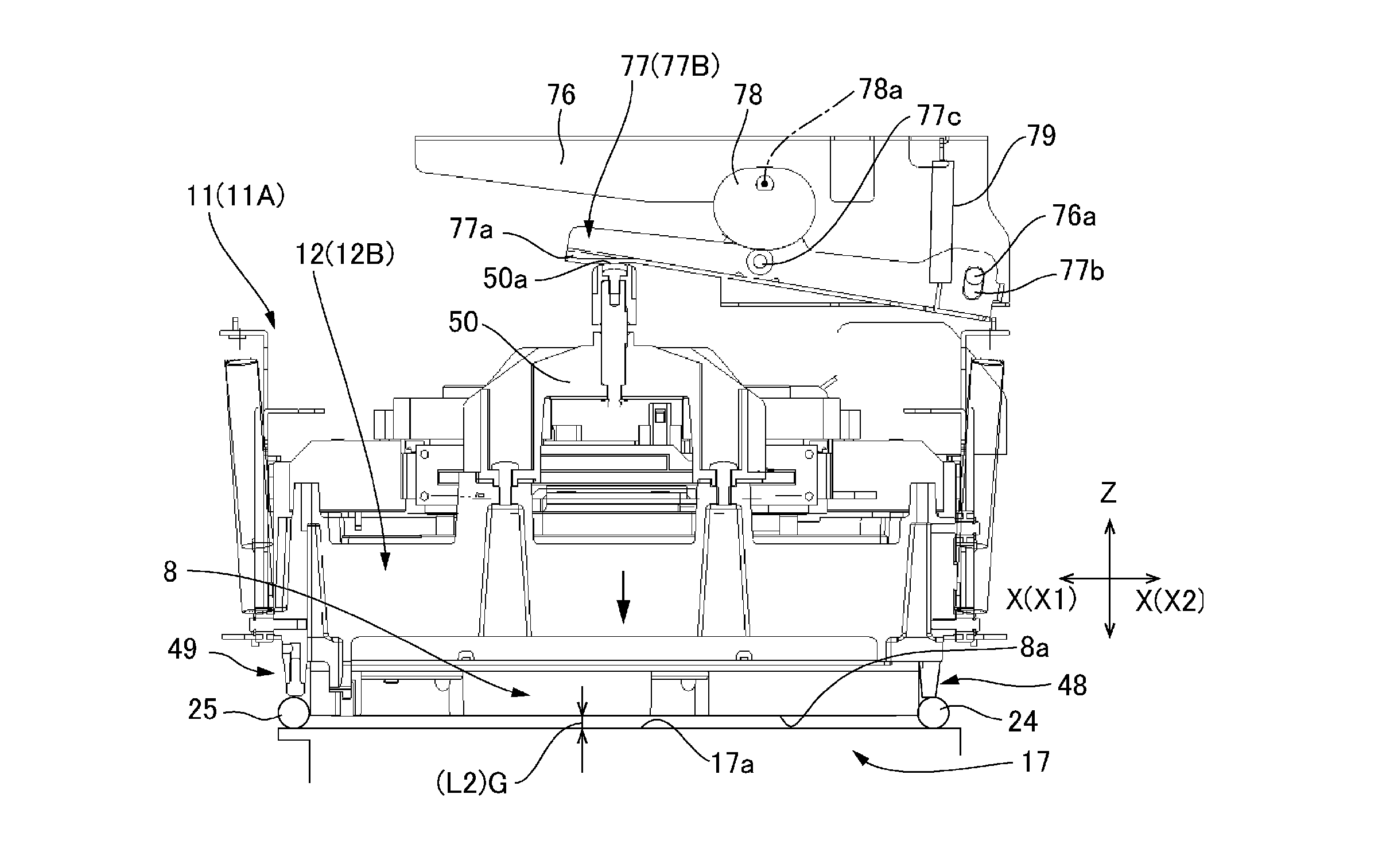

Line printer and printhead moving method of a line printer

The carriage of a line printer has a head unit that supports a printhead, and a carriage frame that supports the head unit movably up and down. When moving the carriage from a standby position to an opposing position, the carriage is moved while the head unit is held at a up position where the gap to the platen unit is a first distance. The head unit is then lowered at the standby position from the up position to a down position where the platen gap is a second distance that is shorter than the first distance.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com