Typewriter letter hammer group with magnetic shunt

A technology of magnetic shunt and hammer printing, applied in hammer printing mechanism, printing device, printing, etc., can solve the problem of increasing the starting speed of impact energy, and achieve the effect of large pull-down force or holding force, and large impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

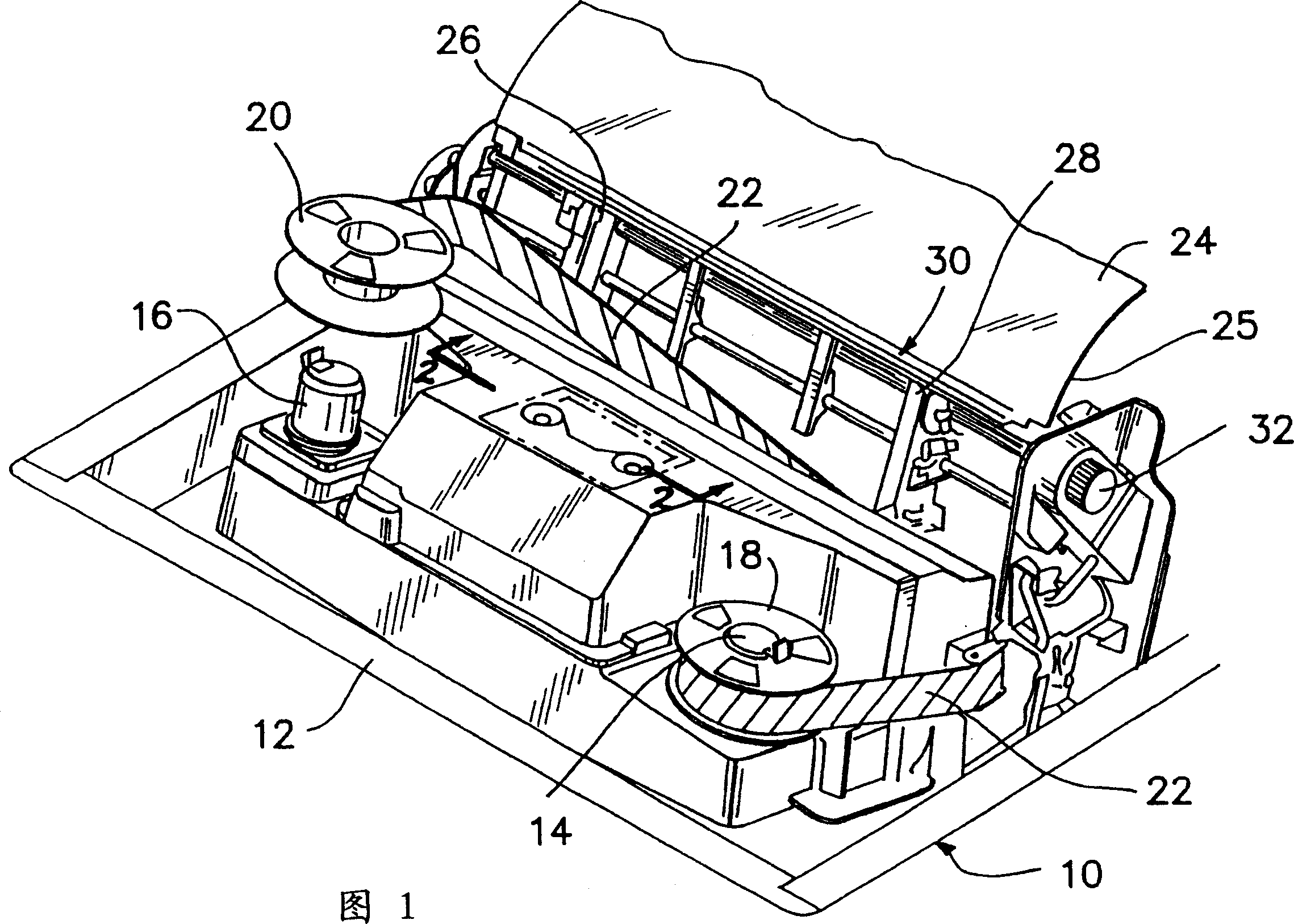

[0024] Referring to Figure 1 in more detail, a perspective view of a line matrix printer is illustrated. The line printer can be mounted on a base, substrate or combined with a housing. In this particular illustration, the line matrix printer 10 has a base 12 . The base 12 mounts various elements of the line printer including hubs 14 and 16 . Axles 14 and 16 are used to mount spools 18 and 20 . Spools 18 and 20 are a supply ribbon spool and a take-up spool, respectively.

[0025] Wrapped around spools 18 and 20 is a print ribbon 22 for printing on media 24 .

[0026] The medium 24 covers the support plate 25 . Such media may be fan-folded, barcode labels, combined plastic and paper labels and formats, paper media for images, and other such media. Depending on the thickness of the media 24, the high impact printing developed in the present invention can improve multi-form and multi-layer printing through improved impact. Also, depending on the speed required to print on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com