Wide-line printer and cleaning method

A printer, wide-line technology, applied in printing and other directions, can solve problems such as conversion use, wide-line printers cannot print normally, and different types of ink are not allowed, so as to avoid precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] Wide Line Printer Embodiment

[0026] In the present invention, a cleaning device is newly installed on the existing ink supply system. Therefore, other structures of this embodiment are the same as those of the existing wide-line printer, so only the cleaning device and related structures of this embodiment will be described in detail.

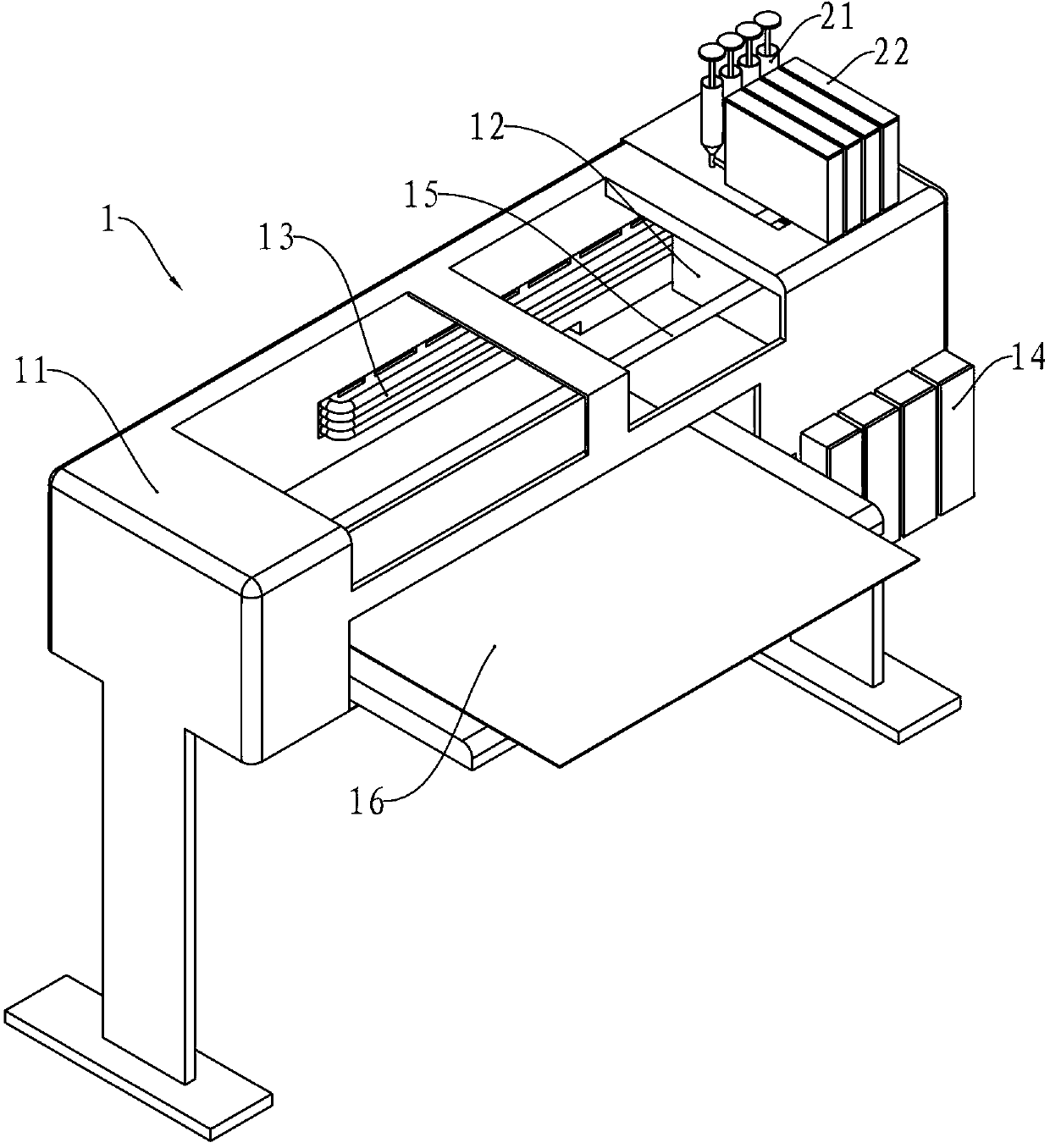

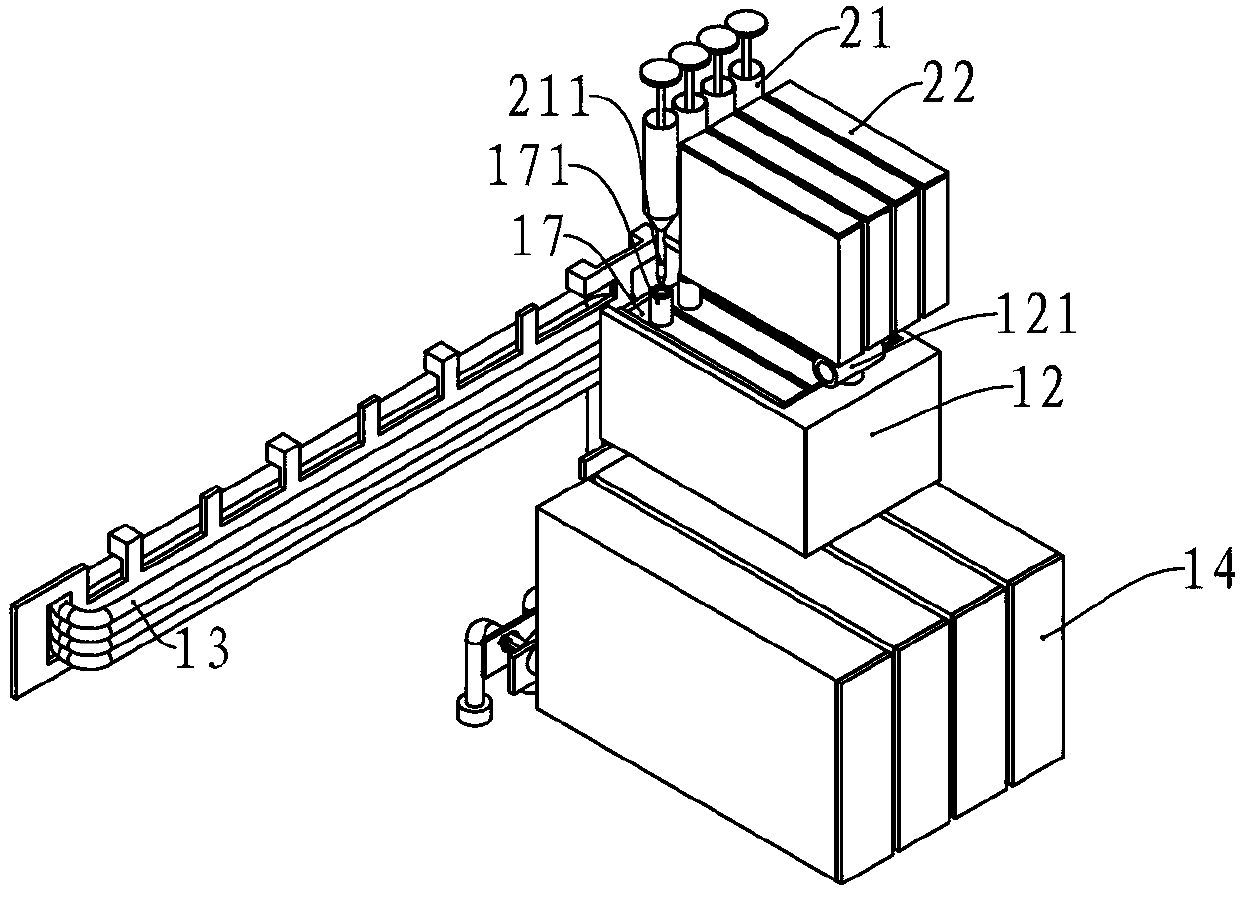

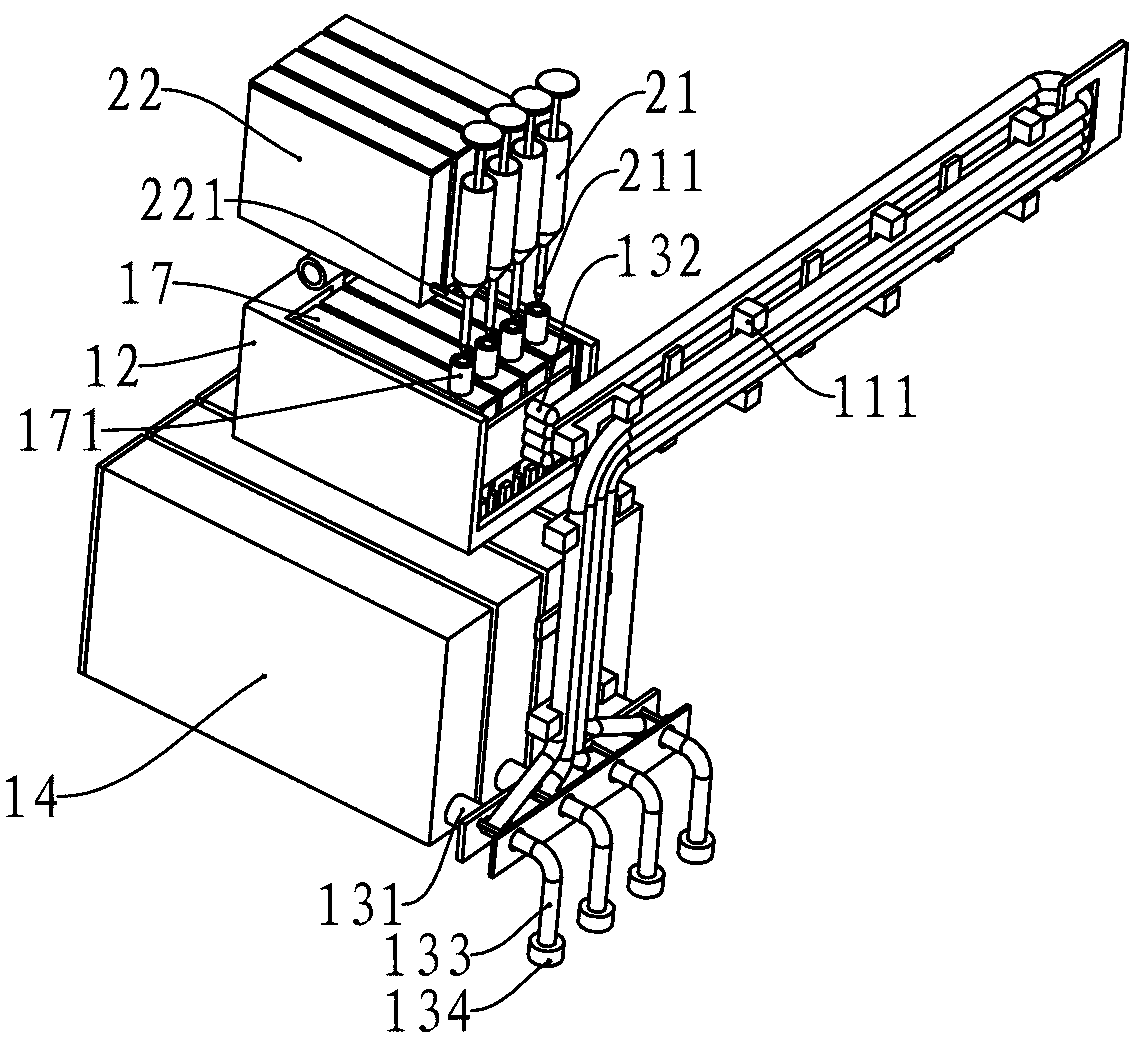

[0027] Such as figure 1 As shown, the wide-line printer 1 has a printer main body 11, and the printer main body is provided with a printing word car 12, a printing head, an ink supply system composed of a main ink box, an ink delivery pipe 13 and an auxiliary ink box 14, etc., and the main ink box is installed on the printing word. Inside the car 12. The ink delivery pipe 13 is used to communicate with the main ink tank and the auxiliary ink tank 14, so as to deliver the ink in the auxiliary ink tank 14 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com