Line thermal head and thermal-transfer line printer

A technology of thermal head and printer, which is applied in printing and other directions, can solve the problems of reduced printing quality, high noise, and high wrinkle of ink ribbon 105, and achieve the effects of improving movement stability, improving printing quality, and uniform peeling distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, the present invention will be described by means of embodiments shown in the drawings.

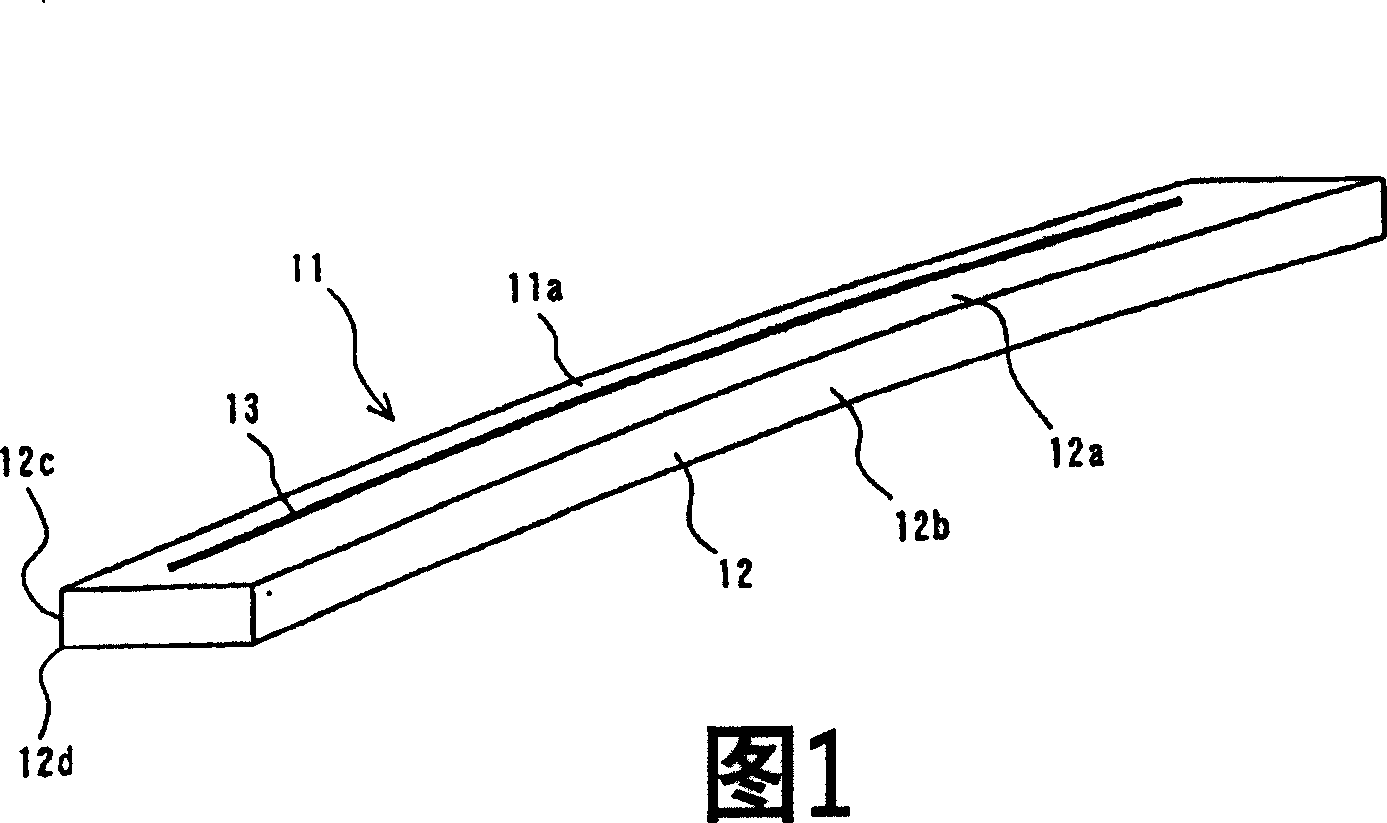

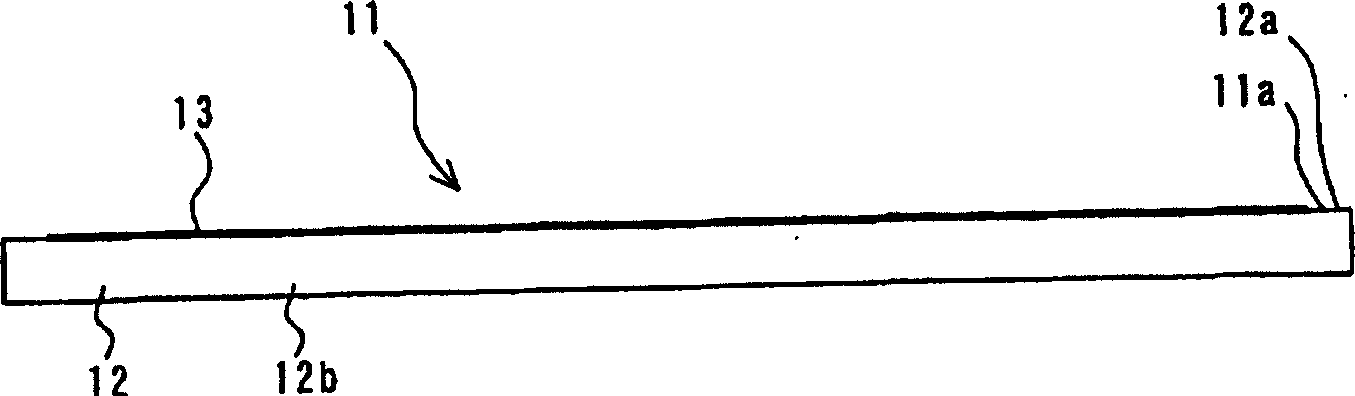

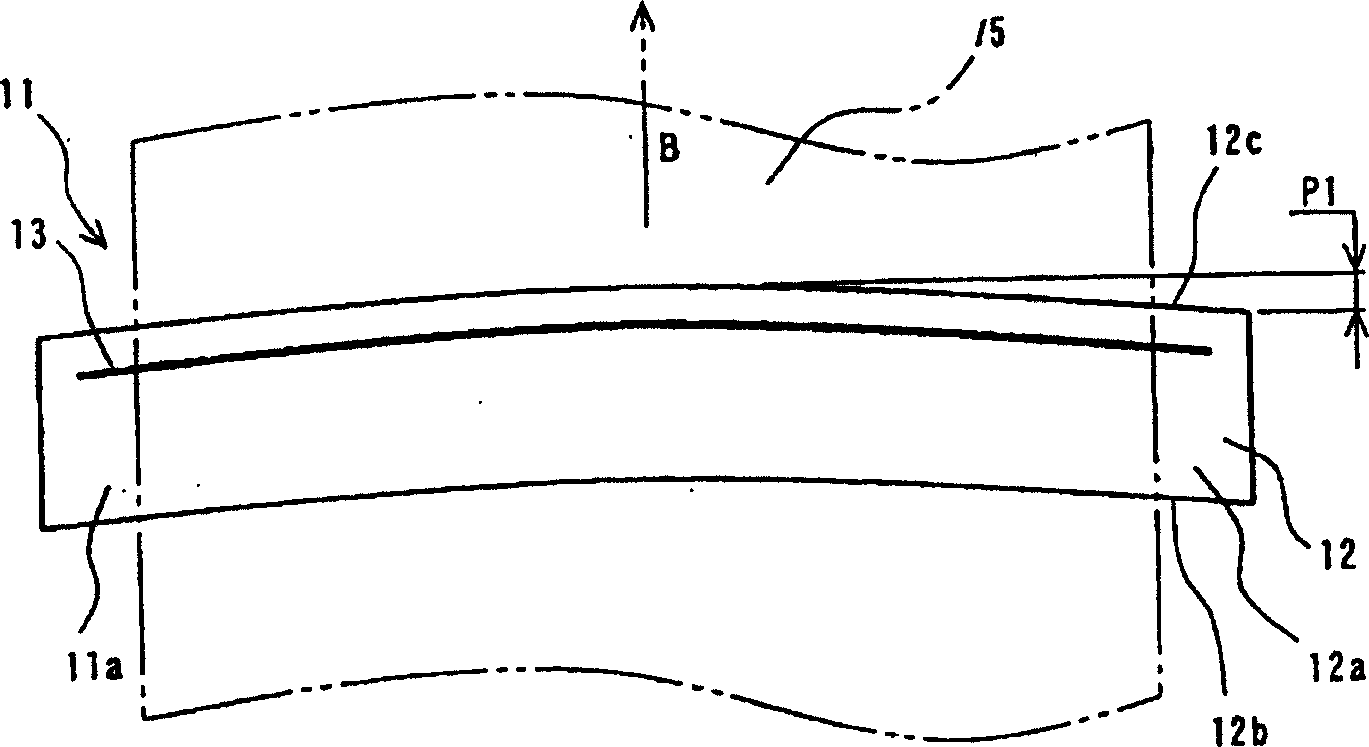

[0052] Figure 1 to Figure 4 It is a schematic diagram of the main part of the first embodiment of the line thermal head involved in the present invention, and Fig. 1 is a perspective view, figure 2 is the front view of Figure 1, image 3 Yes figure 2 floor plan, Figure 4 Yes figure 2 right side view of .

[0053] Figure 1 to Figure 4 As shown, the line thermal head 11 of this embodiment has a substrate 12 substantially formed in a flat plate shape and a image 3 A plurality of heat generating elements 13 of the ink of the ink ribbon 15 shown in phantom lines. Then, a plurality of heating elements 13 are arranged on the upper surface 12 a of the substrate 12 , and the upper surface 12 a of the substrate 12 on which the plurality of heating elements 13 are arranged becomes the printing surface 11 a of the line thermal head 11 .

[0054] The above substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com