Inkjet line printer

An inkjet printer, line type technology, used in printing devices, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Next, an inkjet line printer to which the present invention is applied will be described with reference to the drawings.

[0019] (overall composition)

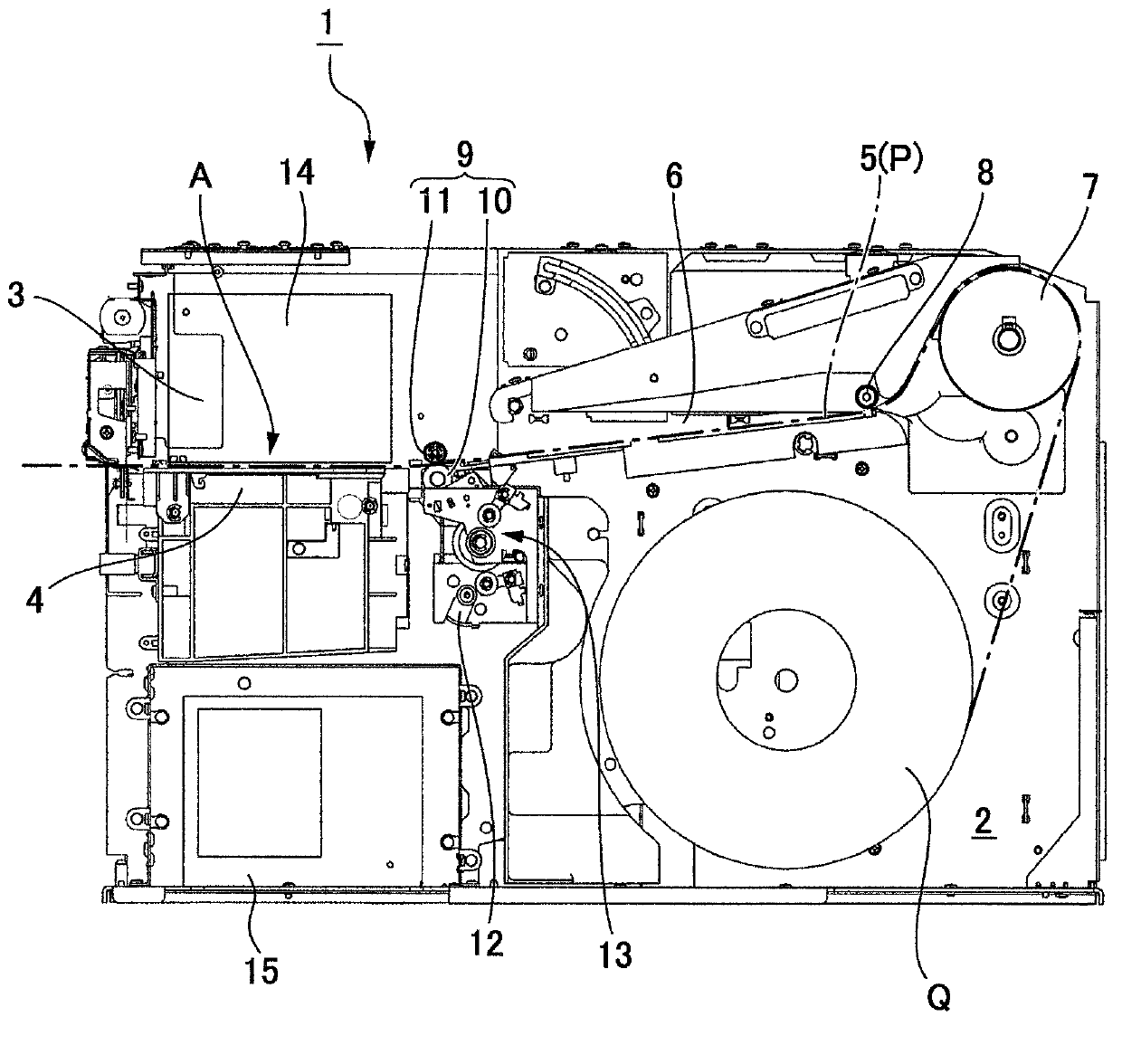

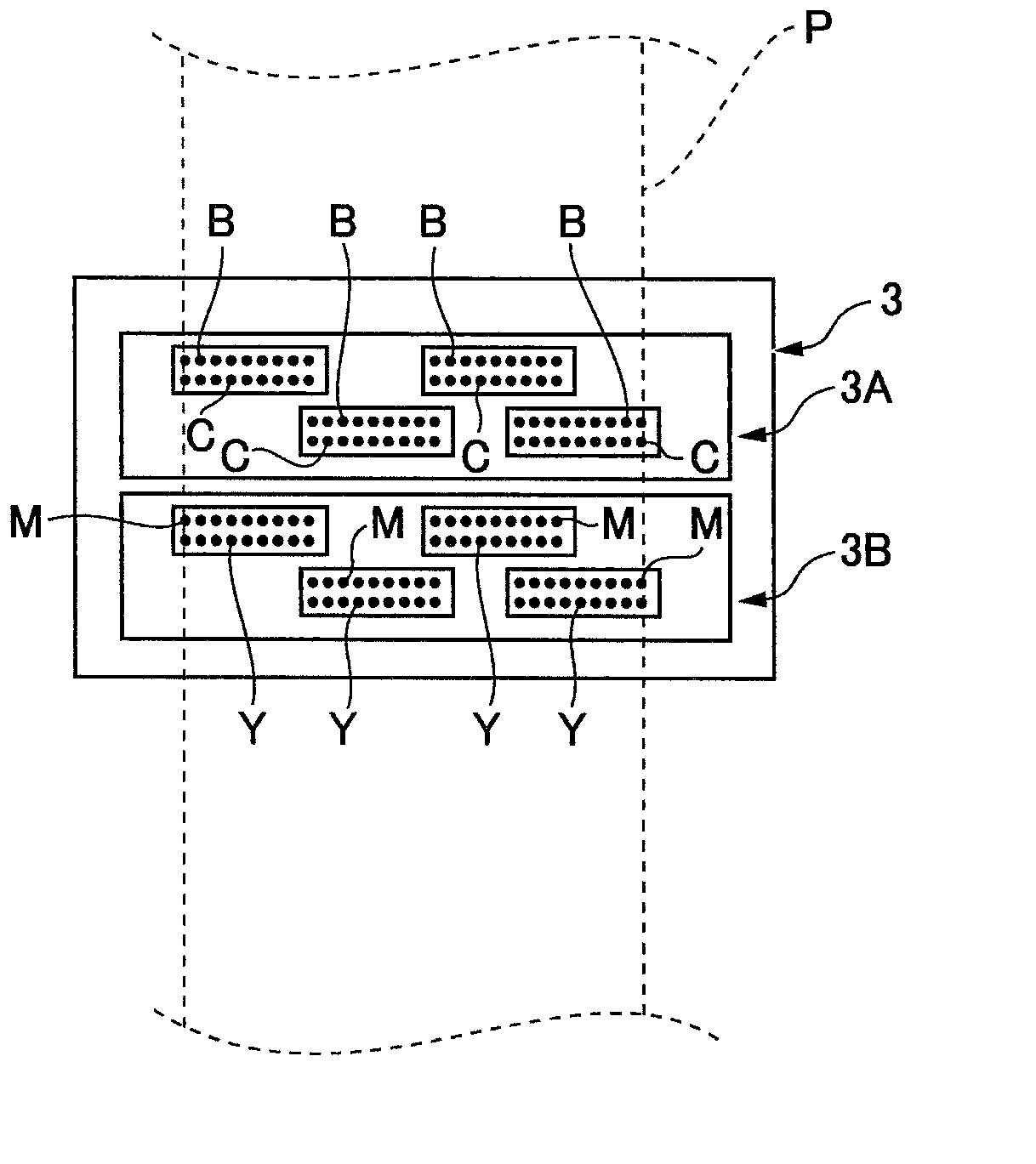

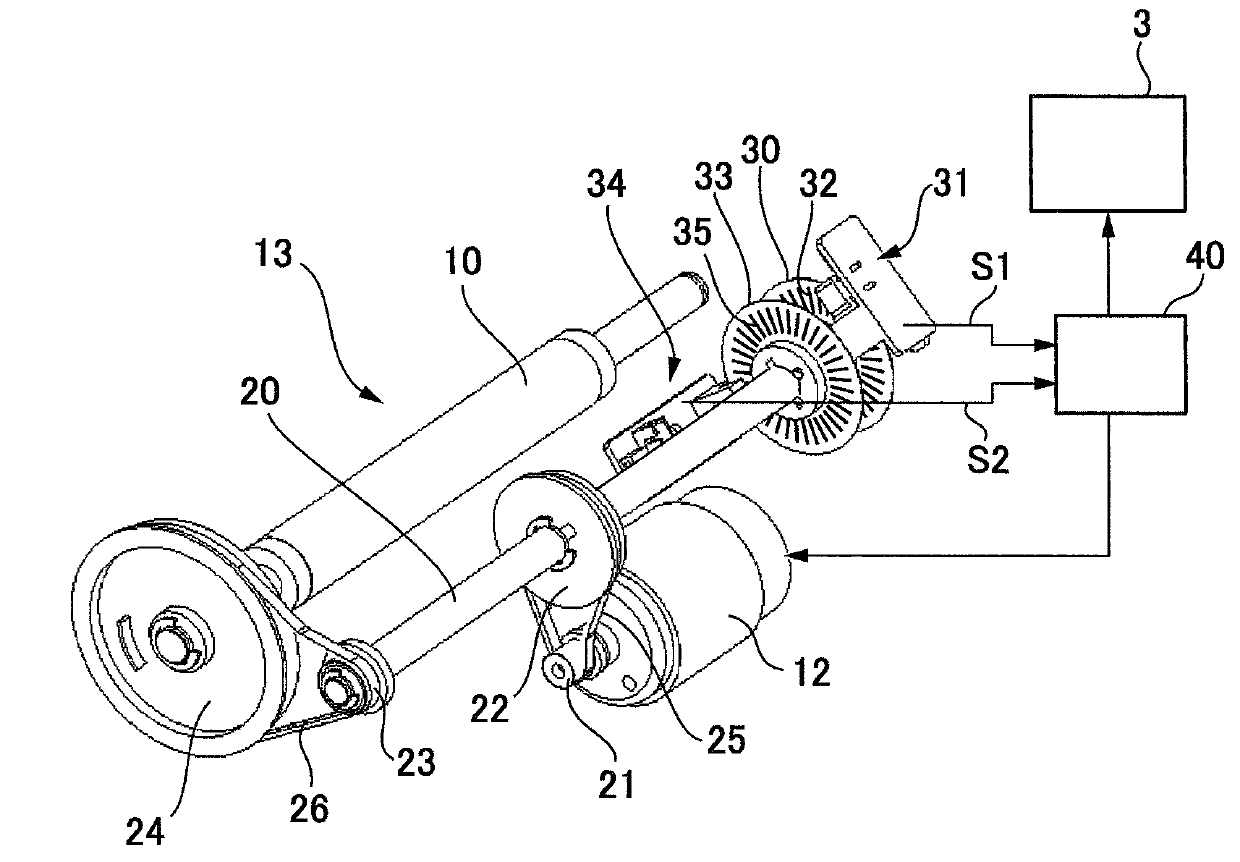

[0020] figure 1 It is a schematic longitudinal sectional view showing the overall configuration of the line inkjet printer according to the embodiment of the present invention. The line inkjet printer 1 is a printer that prints on rectangular recording paper P using multiple color inks. A roll paper loading part 2 is provided at the rear side of the line inkjet printer 1, and the recording paper P derived from the roll paper Q loaded here is drawn along the path for specifying the printing position A performed by the inkjet head 3. It is conveyed via the conveyance path 5 on the surface of the platen 4 .

[0021] A paper guide 6 for preventing the recording paper P from skewing is disposed above the roll paper loading unit 2, and a lead-out roller 7 for leading the recording paper P from the roll paper Q is disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com