Constant density printer system

A technology of printers and printing ribbons, applied in printing and other directions, to achieve the effects of eliminating diffusion effects, reducing ink consumption, and avoiding column effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

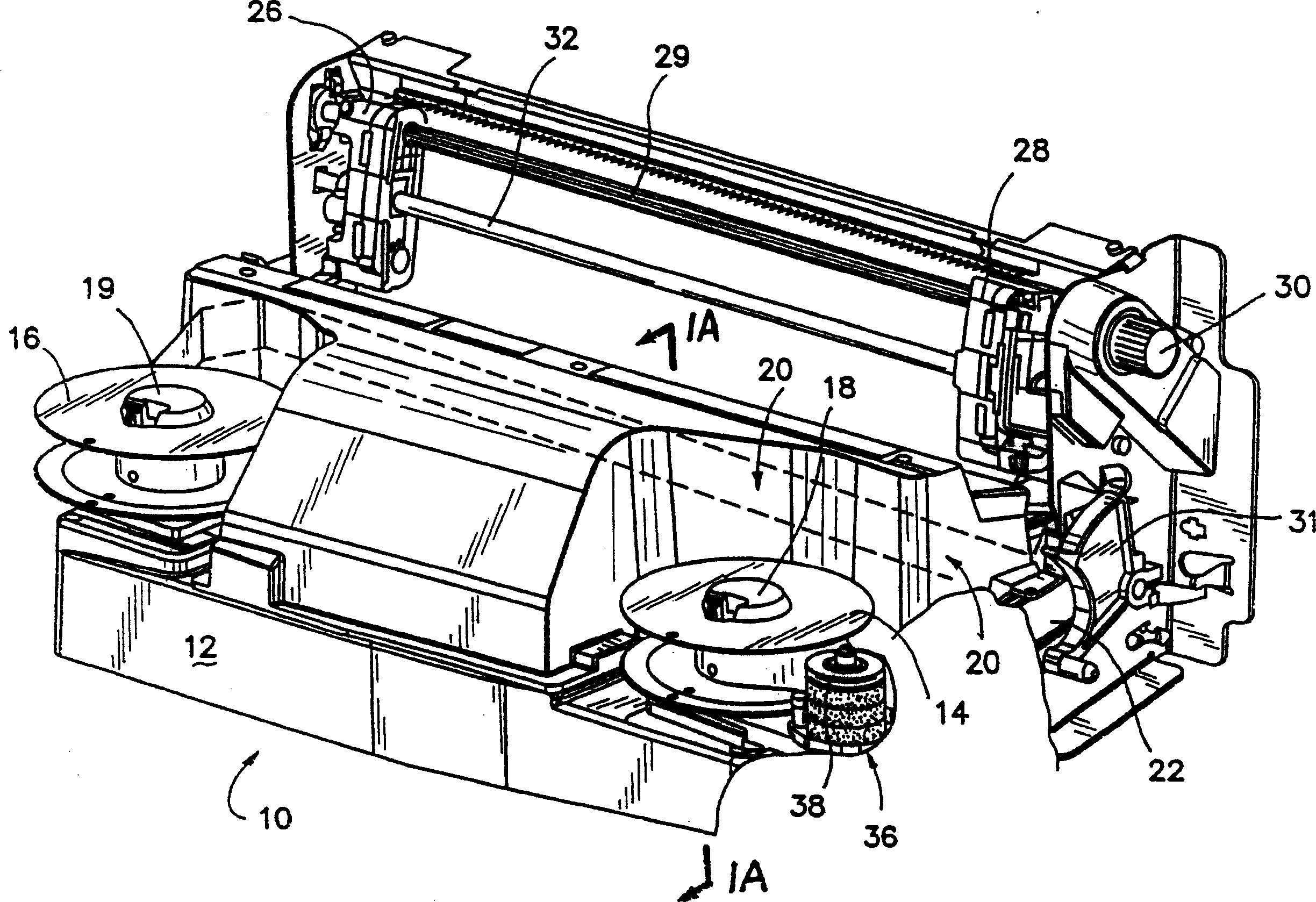

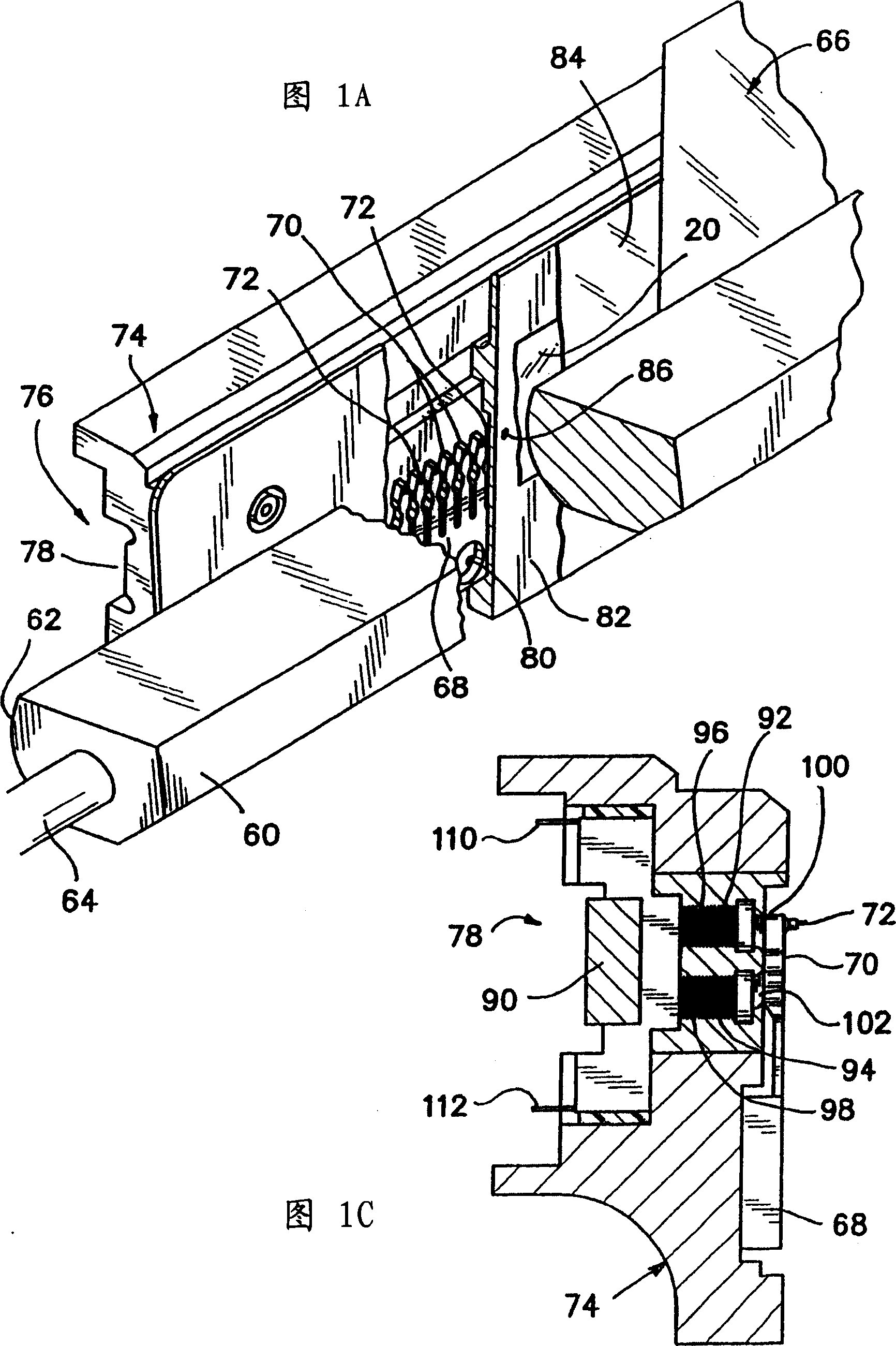

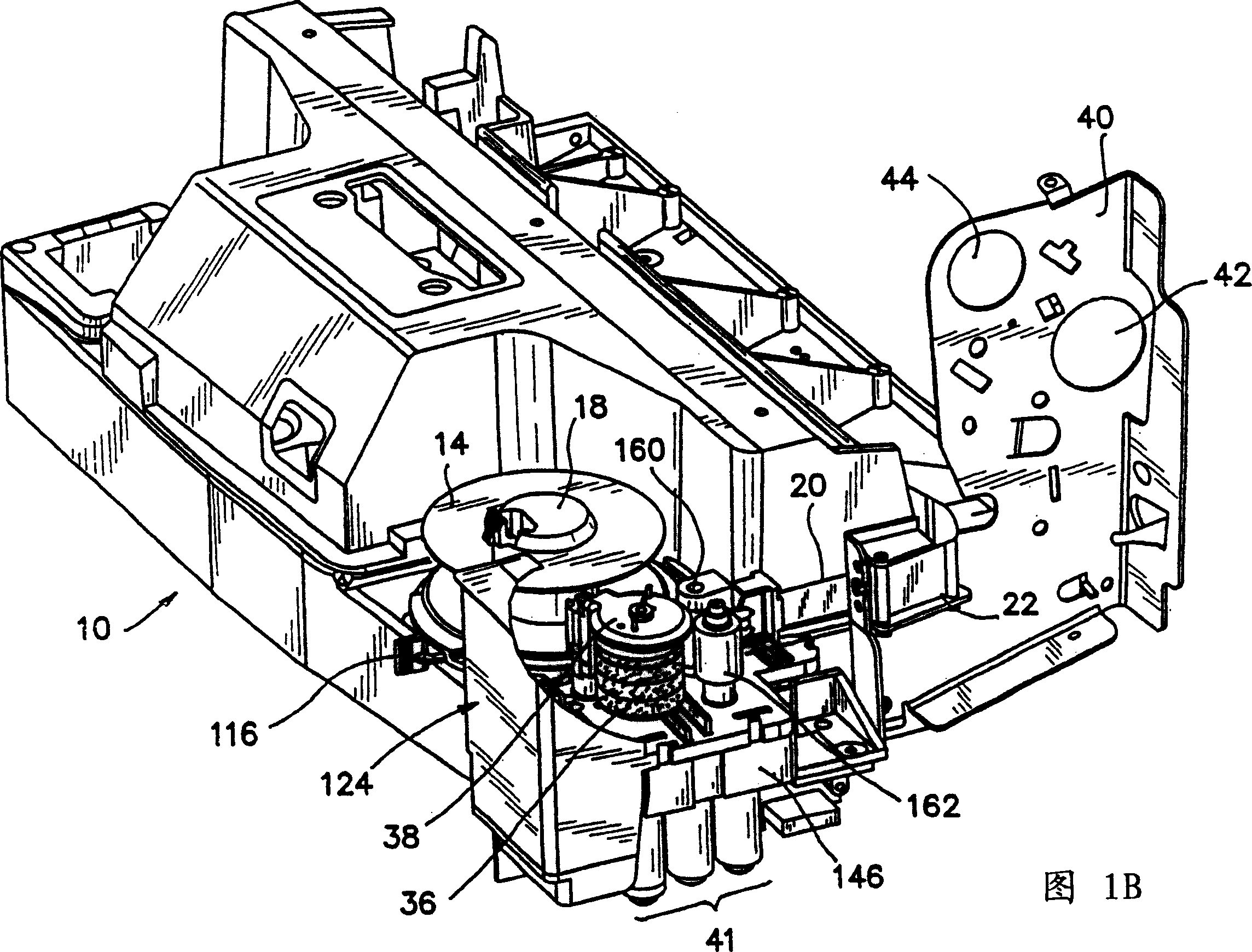

[0064] figure 1 A perspective view of the present invention as an impact line printer 10 is shown. The impact line printer 10 can be installed on a stand, a base, or can be independent in a casing. In this particular instance, the line printer 10 is shown in a configuration with operative elements and without accompanying support material or devices.

[0065] Line matrix printer 10 has a base 12 on which are mounted a pair of ribbon spools 14 and 16 . Ribbon spools 14 and 16 are mounted on hubs or spindles 18 and 19 . Hubs 18 and 19 have resiliently biased catches that tend to secure ribbon spools thereto for drive.

[0066] Ribbon spools 14 and 16 have the path of ribbon 20 shown in phantom. The ribbon 20 traverses at a slight angle in order to allow the ribbon to pass and be struck at different parts thereof as it passes over the hammer set as will be described below.

[0067] A ribbon 20 indicated by a dotted line passing through the inside of the line printer 10 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com