Patents

Literature

34results about How to "Avoid print failures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

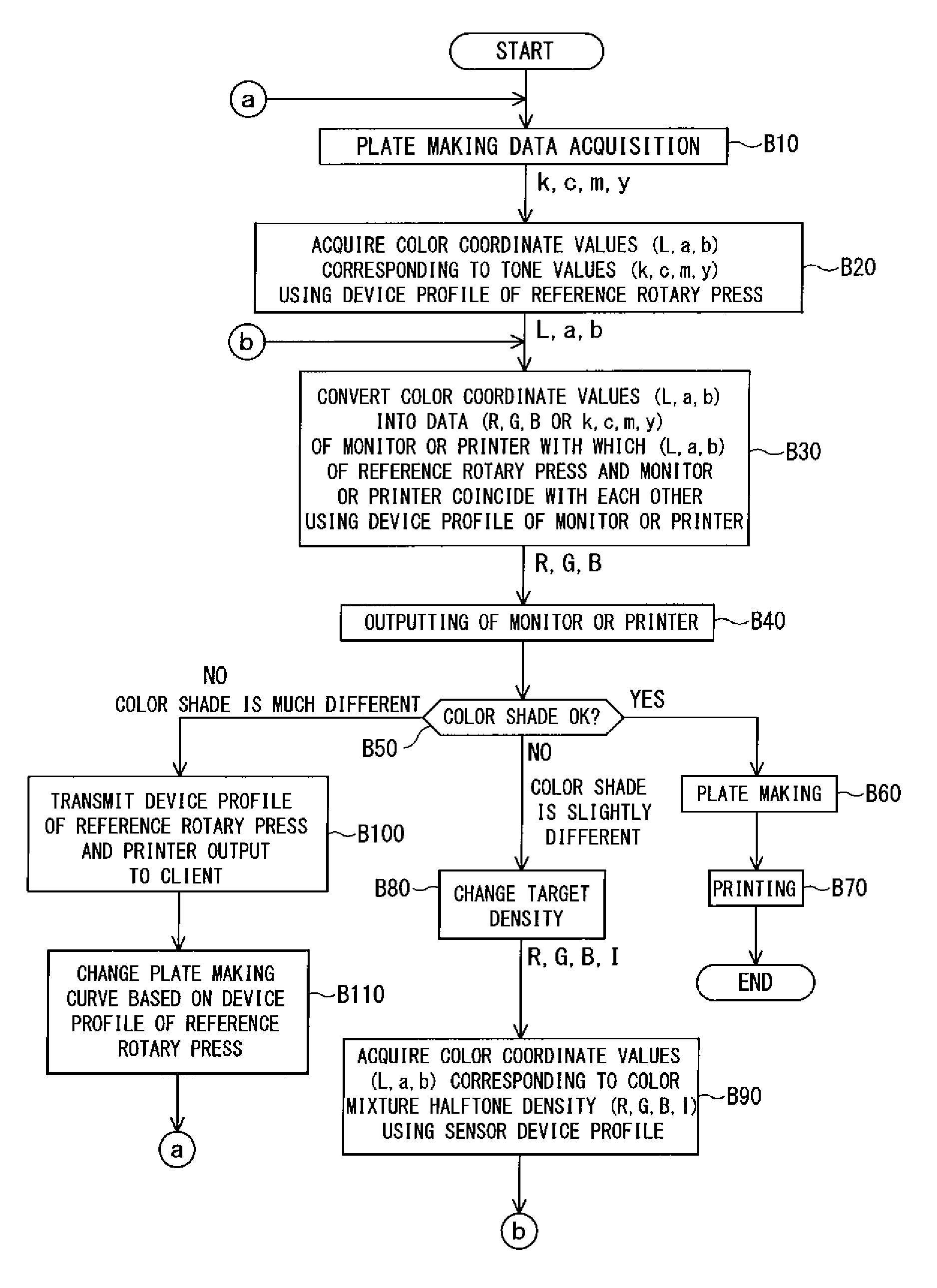

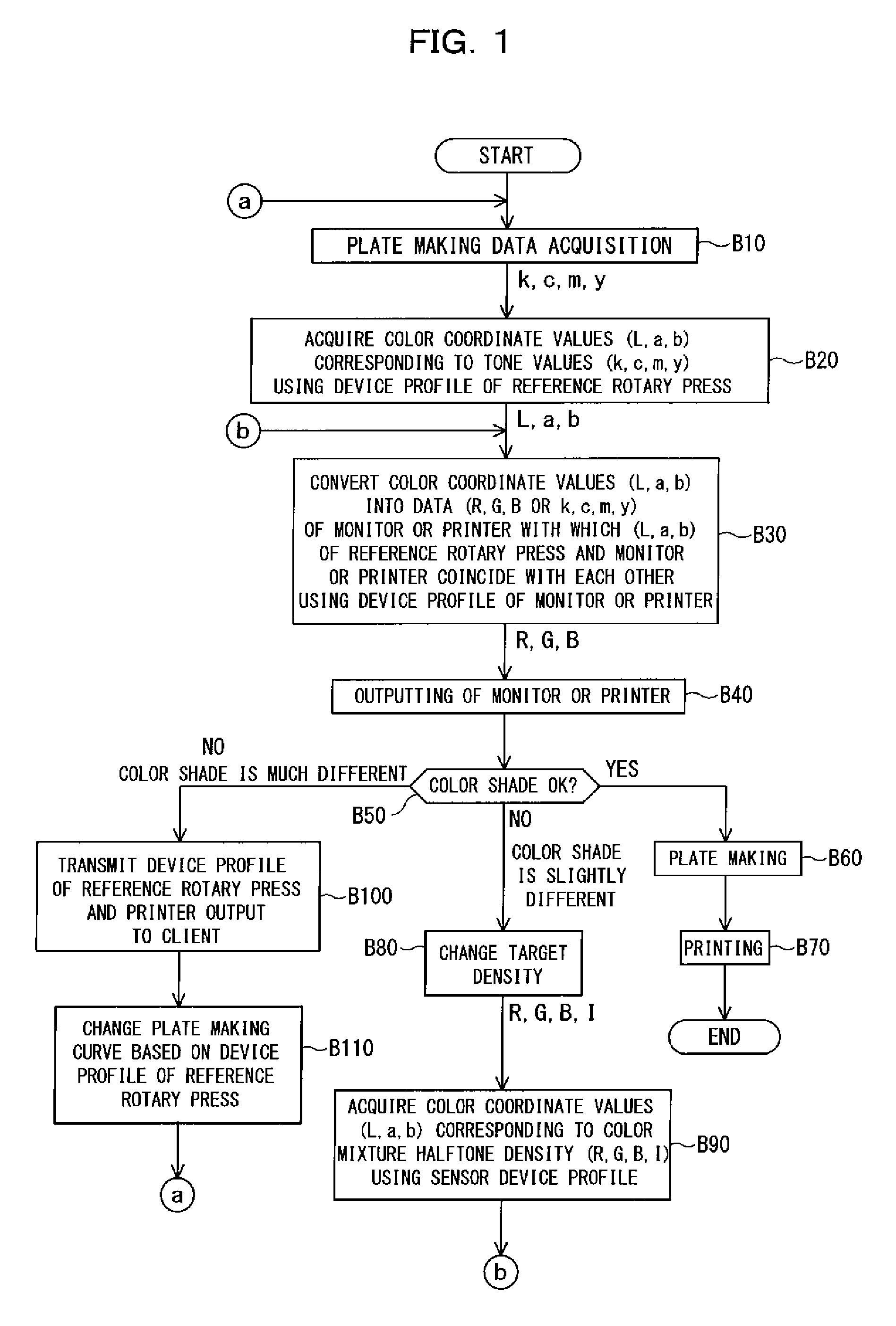

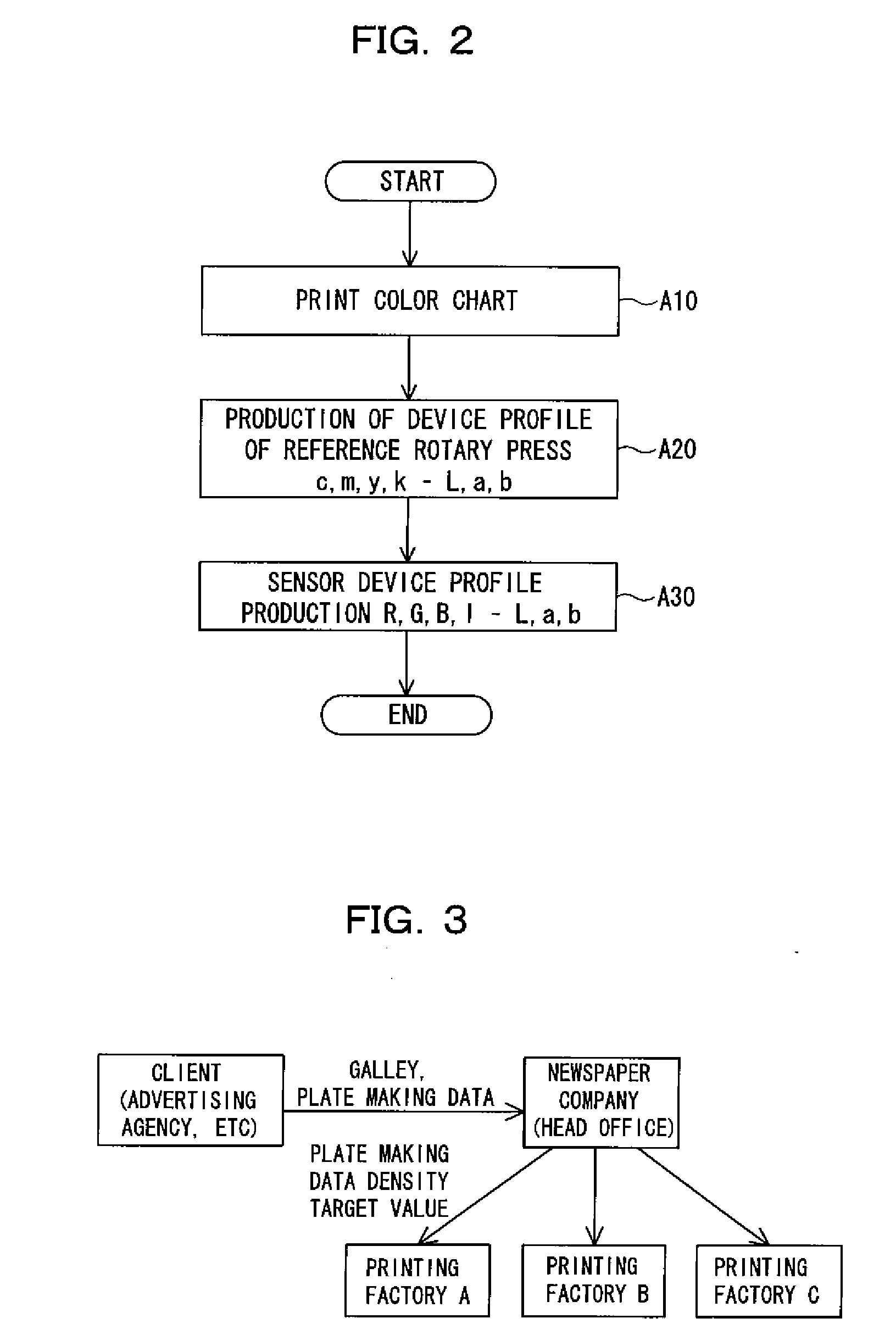

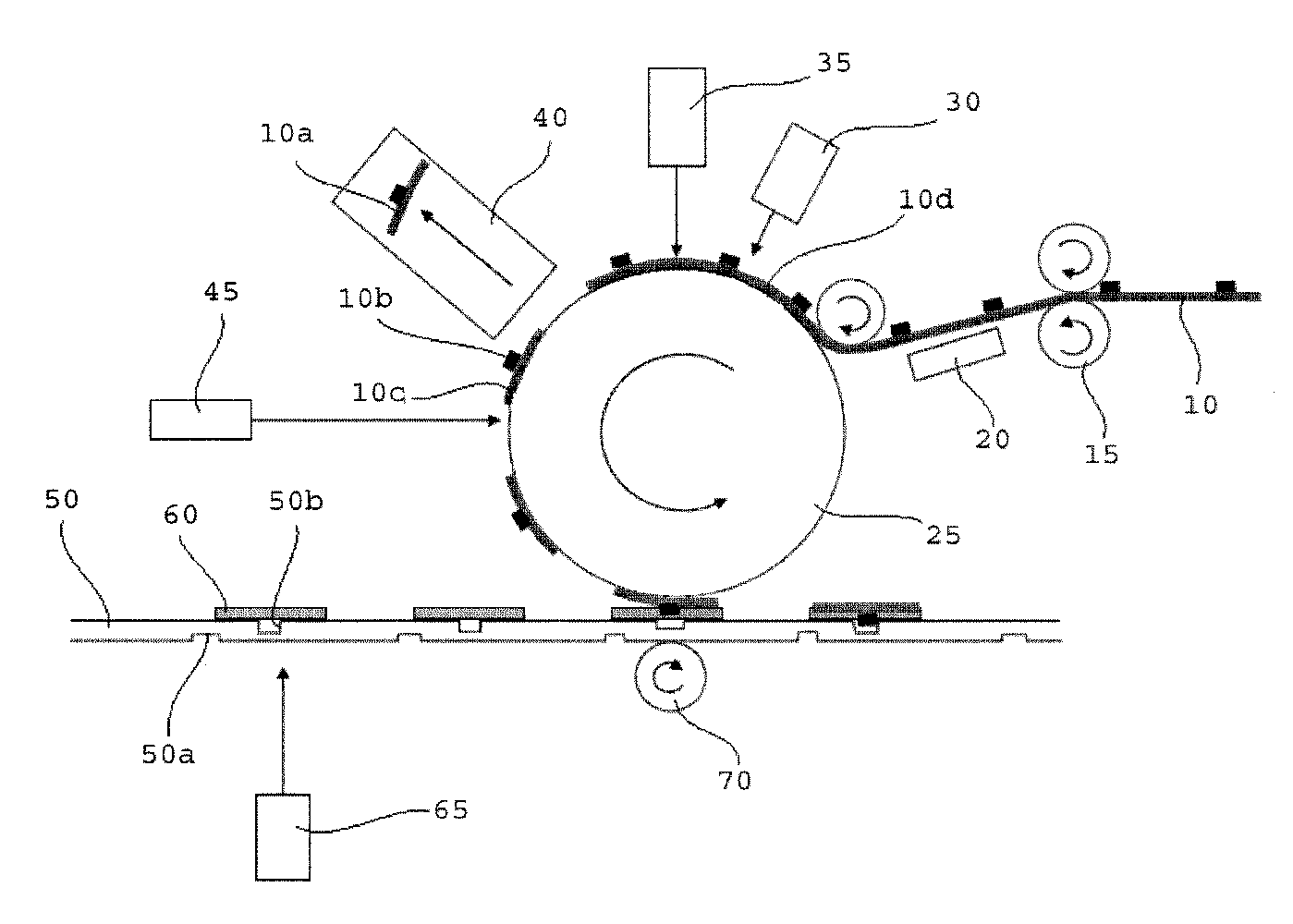

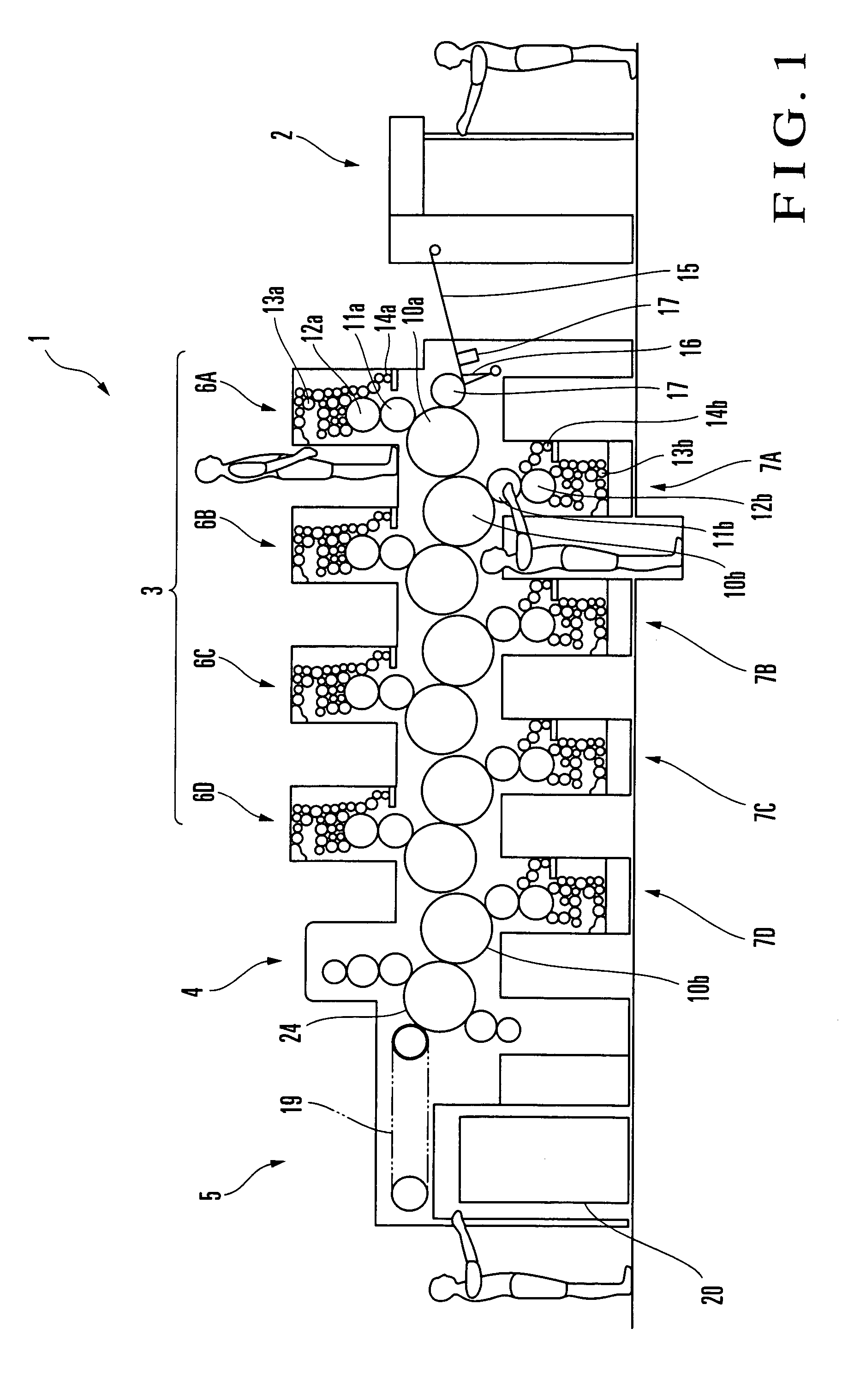

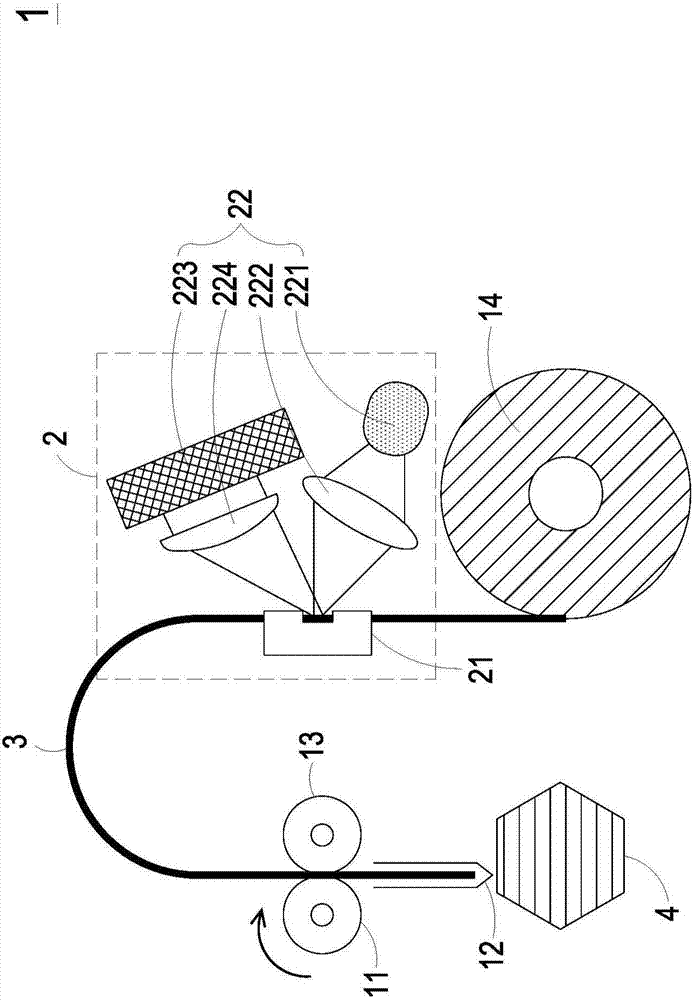

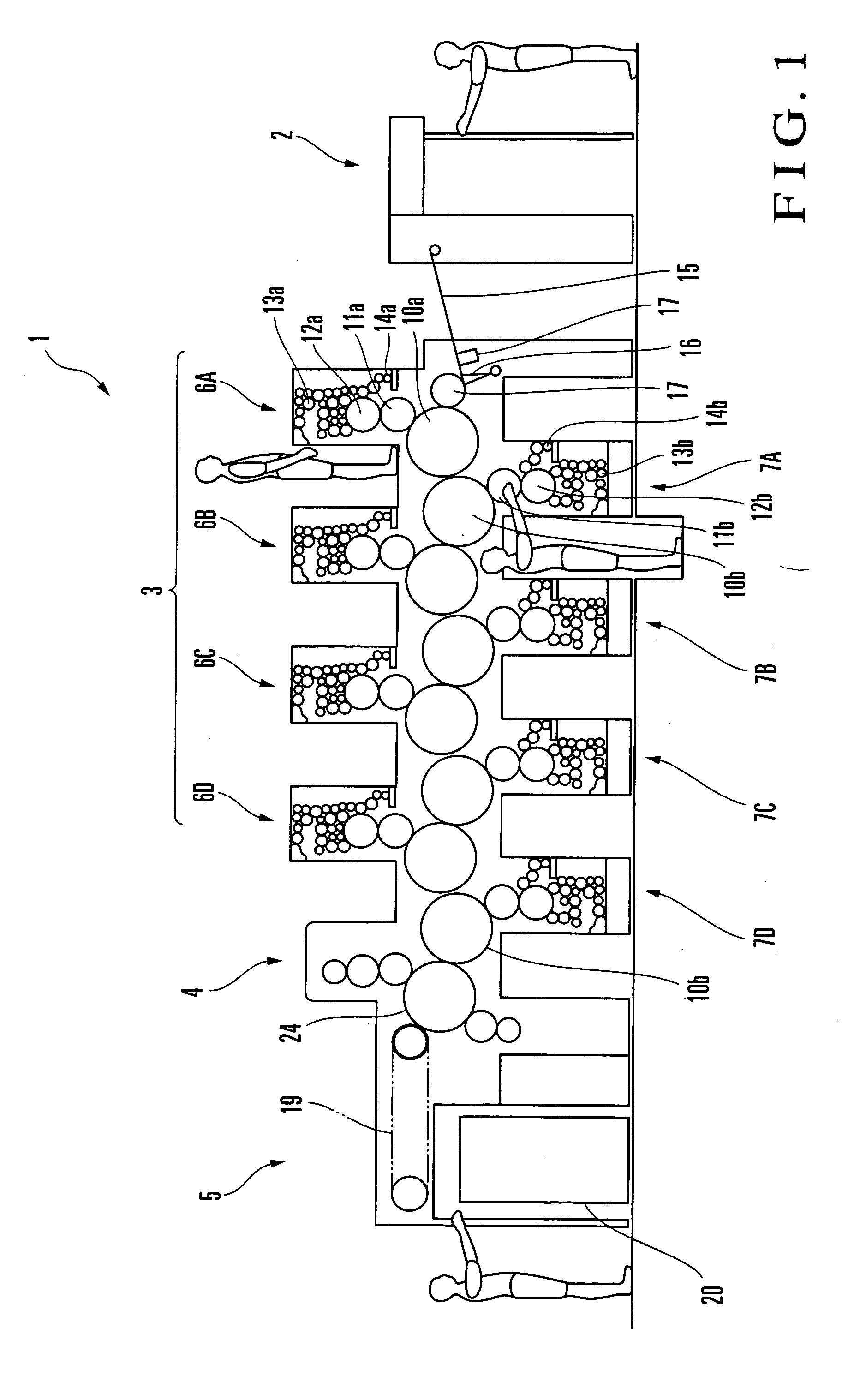

Pre-printing confirmation method and apparatus of picture color tone for printing press, plate making method, and picture color tone controlling method and apparatus for printing press

InactiveUS20090027705A1InhibitionAvoid print failuresDigitally marking record carriersColor measuring devicesPaper sheetEngineering

The invention relates to picture color tone control for a printing press, and it is an object of the invention to make it possible to confirm a color shade before printing is performed thereby to prevent failure in printing and suppress incidence of paper loss. A device profile of a printing press to be used for printing is acquired, and a device profile of a simulation printing tool is acquired and plate making data is acquired. Then, the device profile of the printing press is used to convert tone value data k, c, m, y of the plate making data into color coordinates (L*a*b*), and color coordinates (L*a*b*) obtained by conversion using the device profile of the simulation printing too are outputted with densities according to densities R, G, B from the simulation printing tool. Then, it is decided whether or not the color shade of the output is within a permissible range. Plate making and picture color tone control of the printing press are performed based on a result of the decision.

Owner:MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

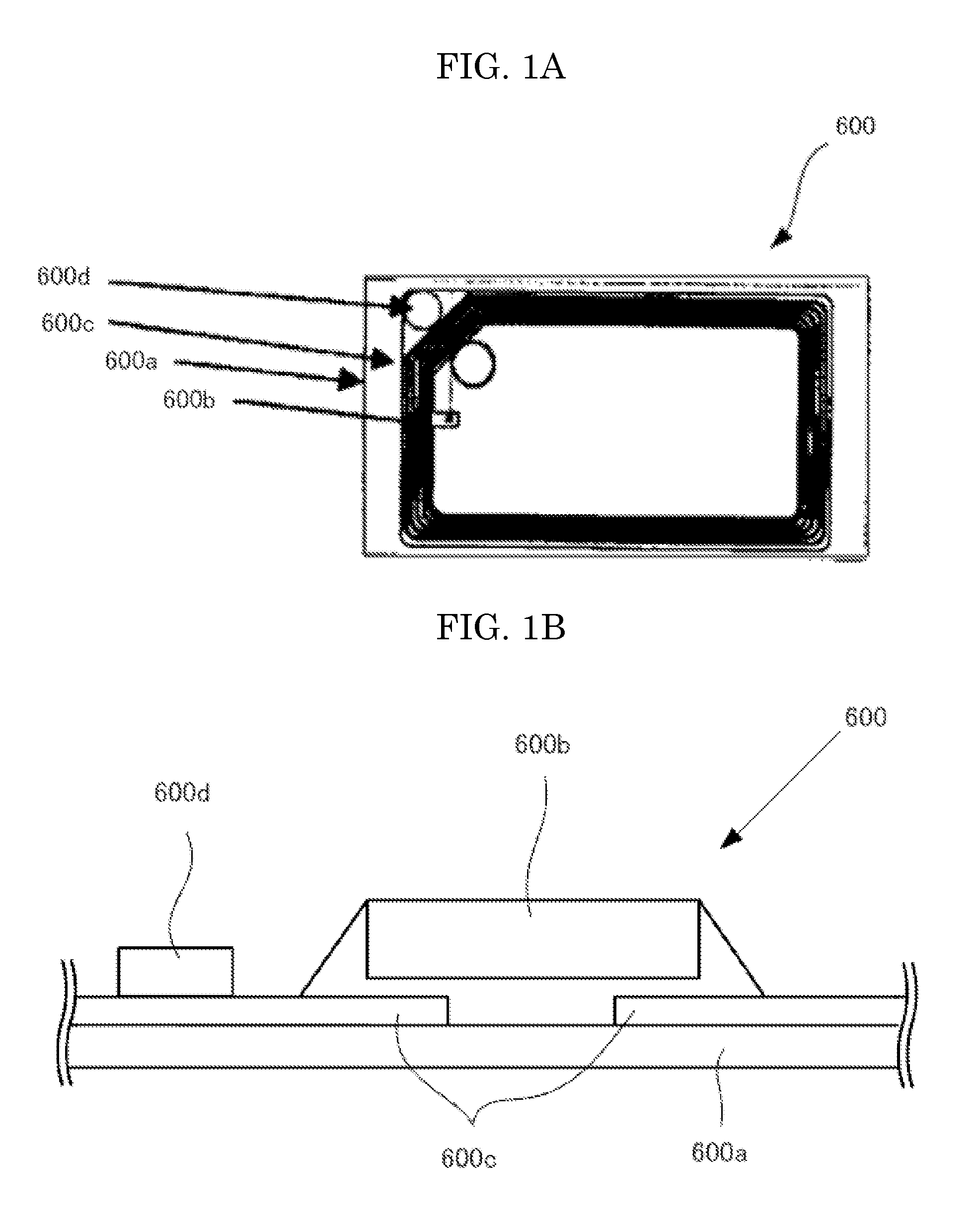

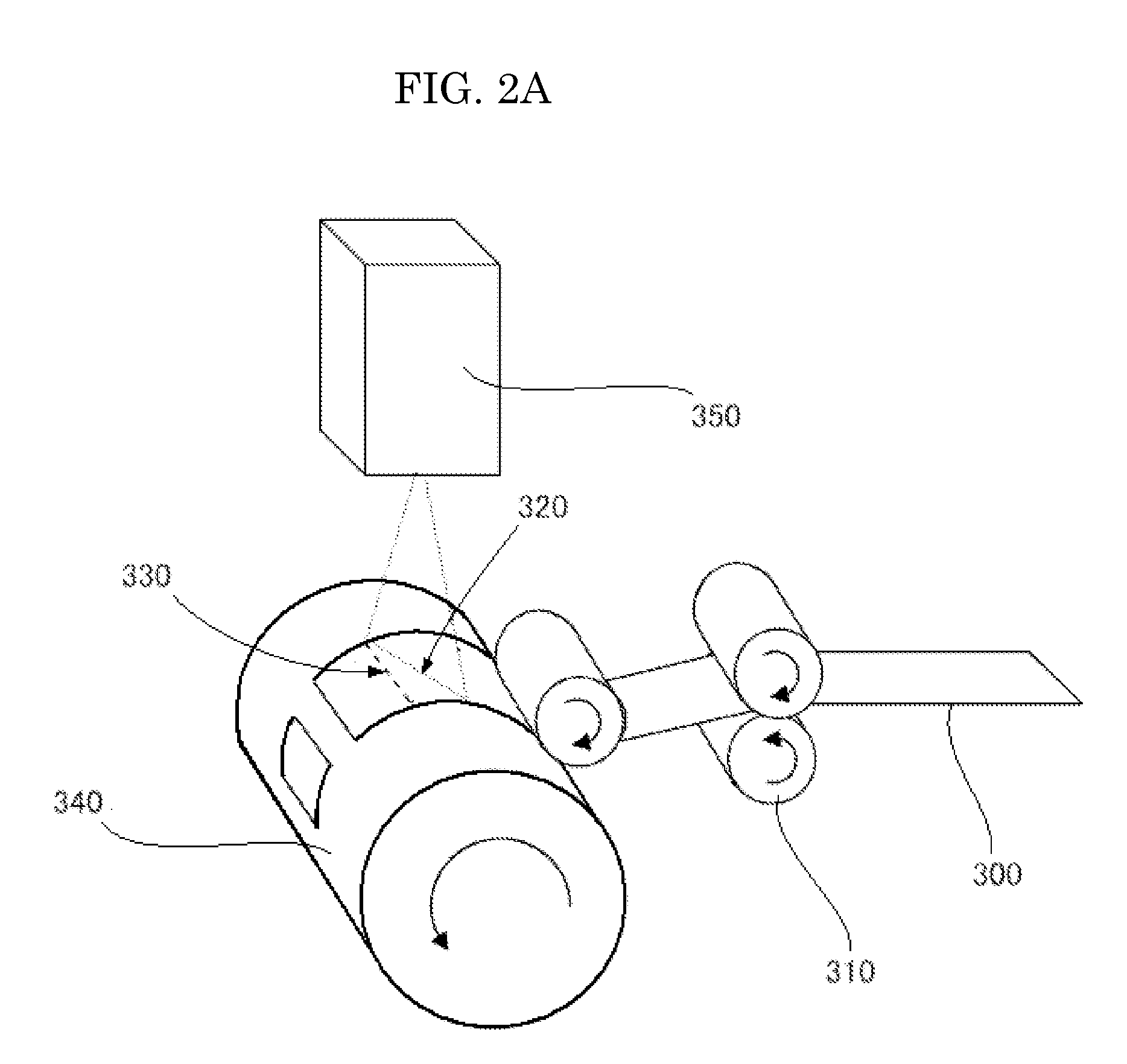

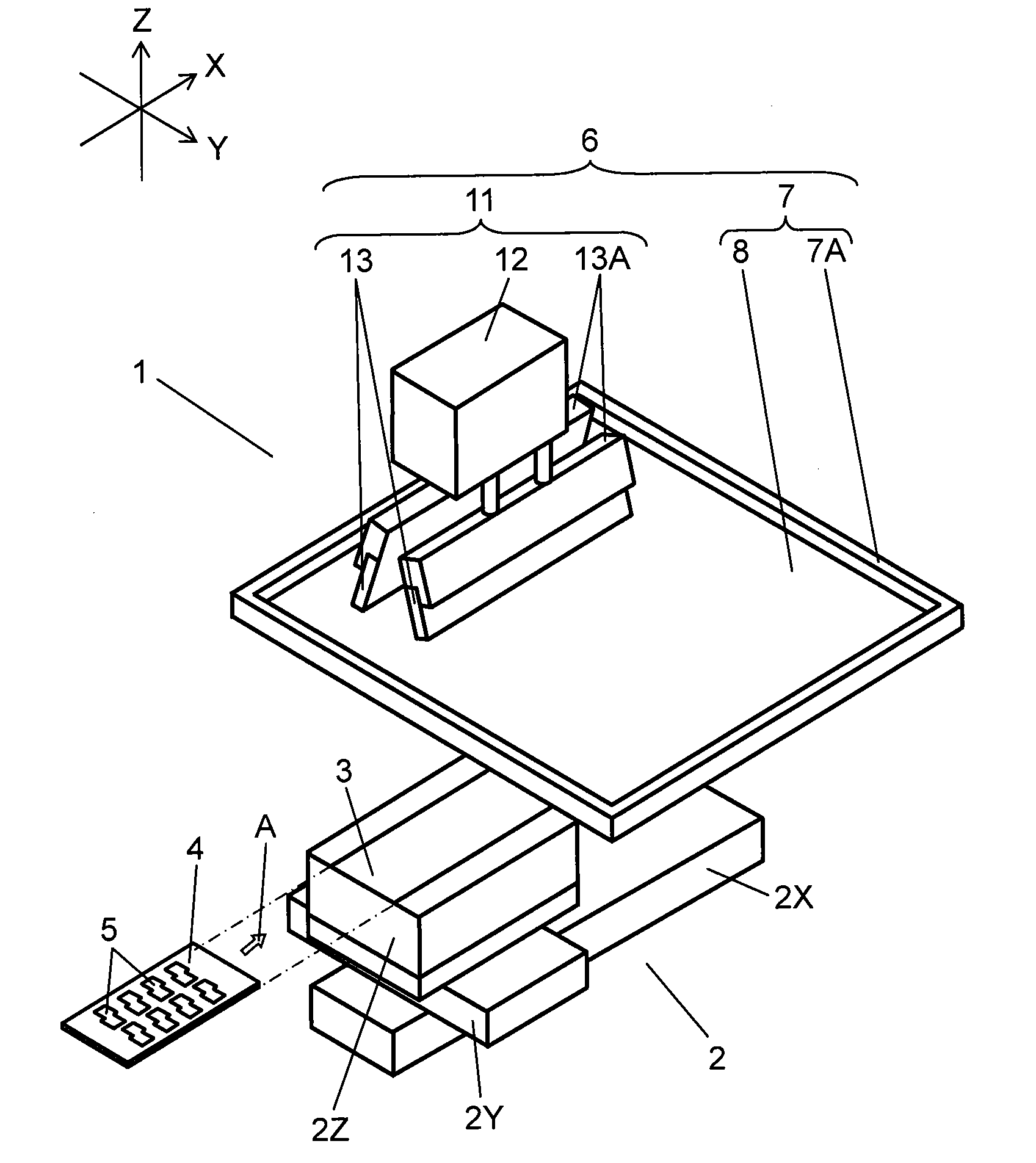

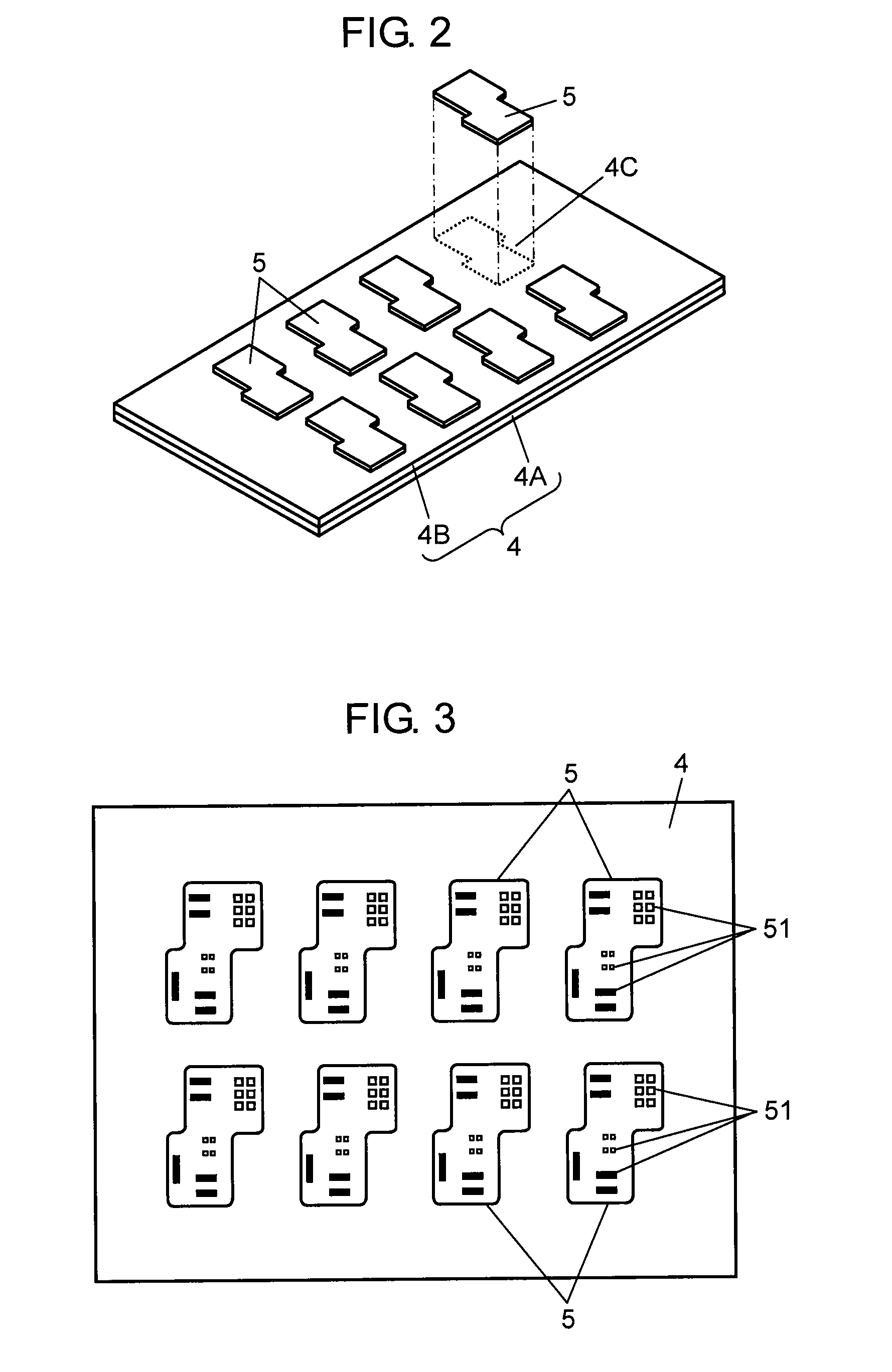

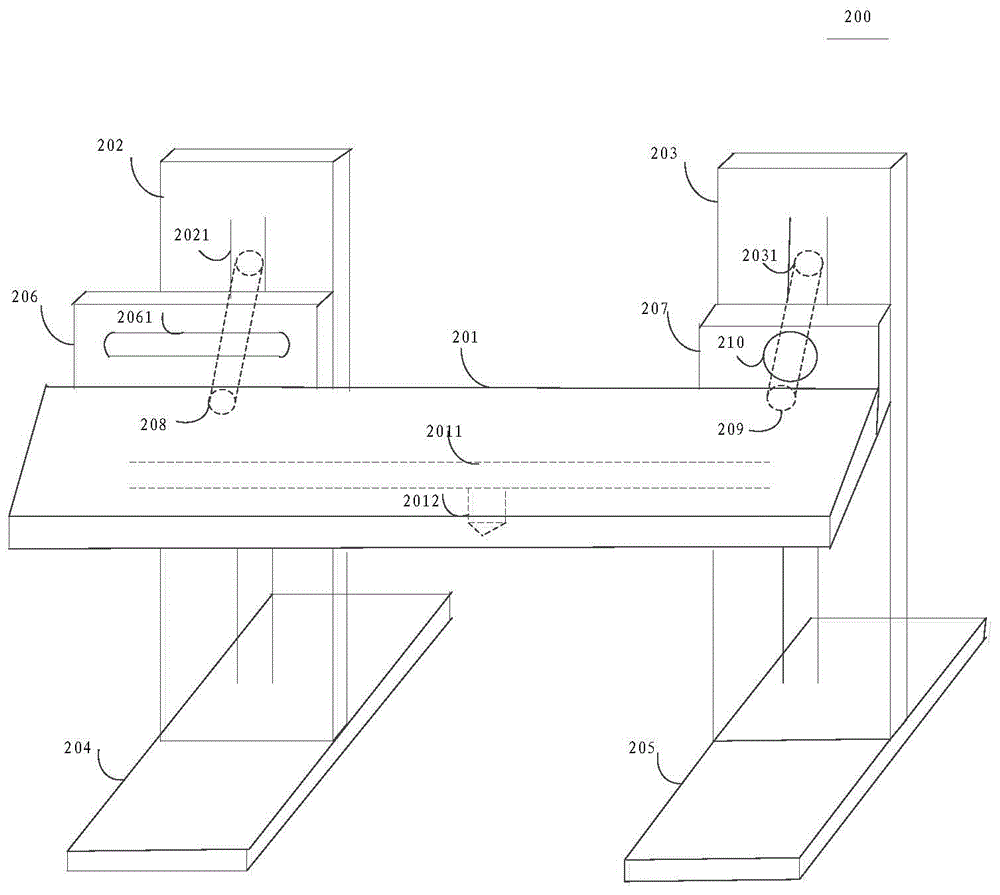

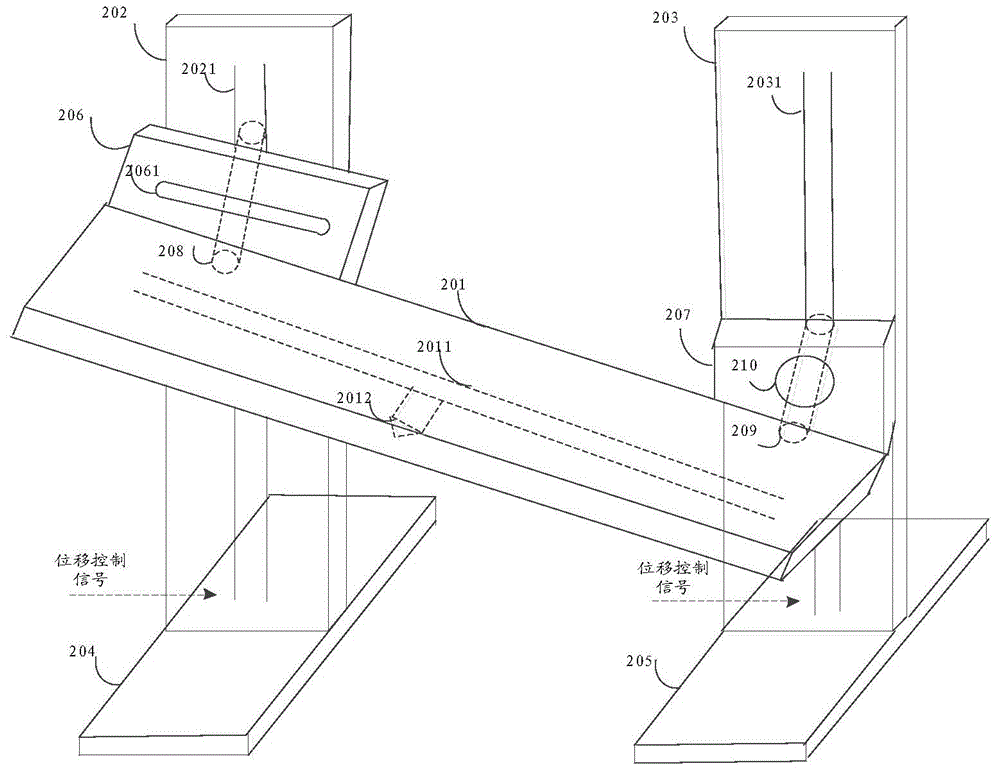

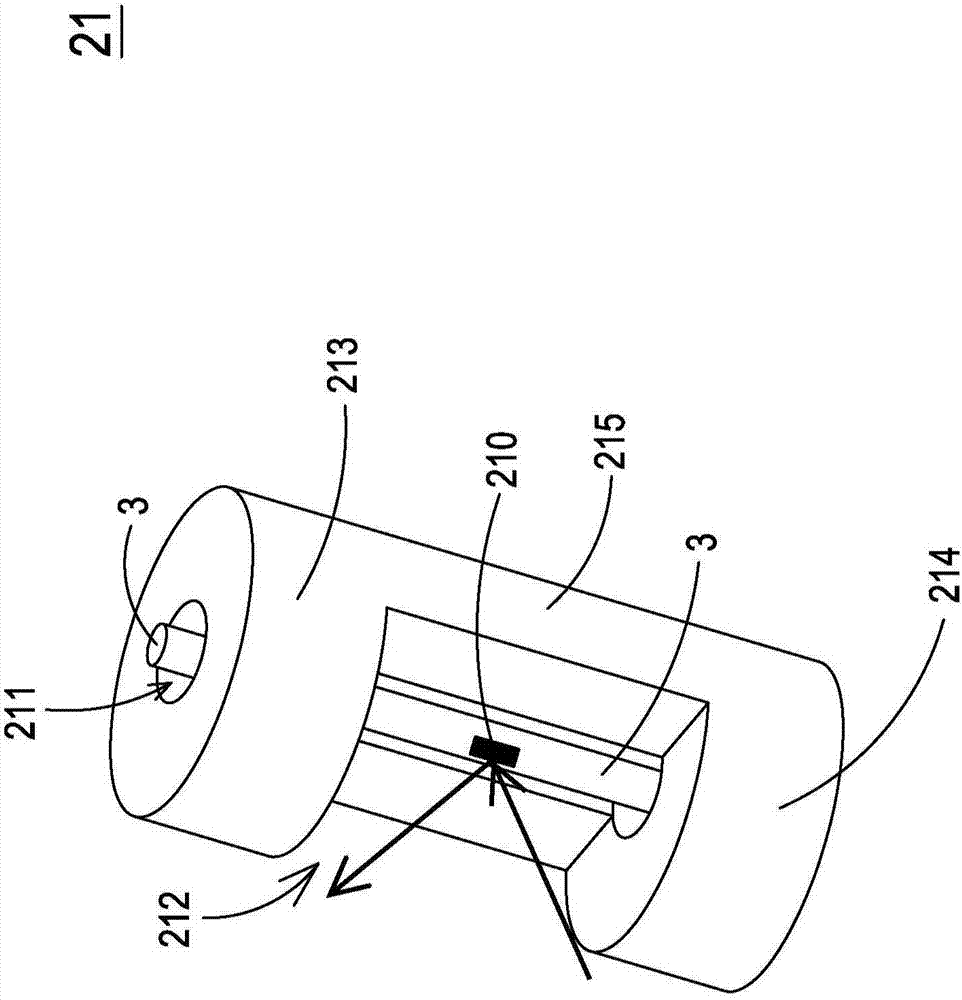

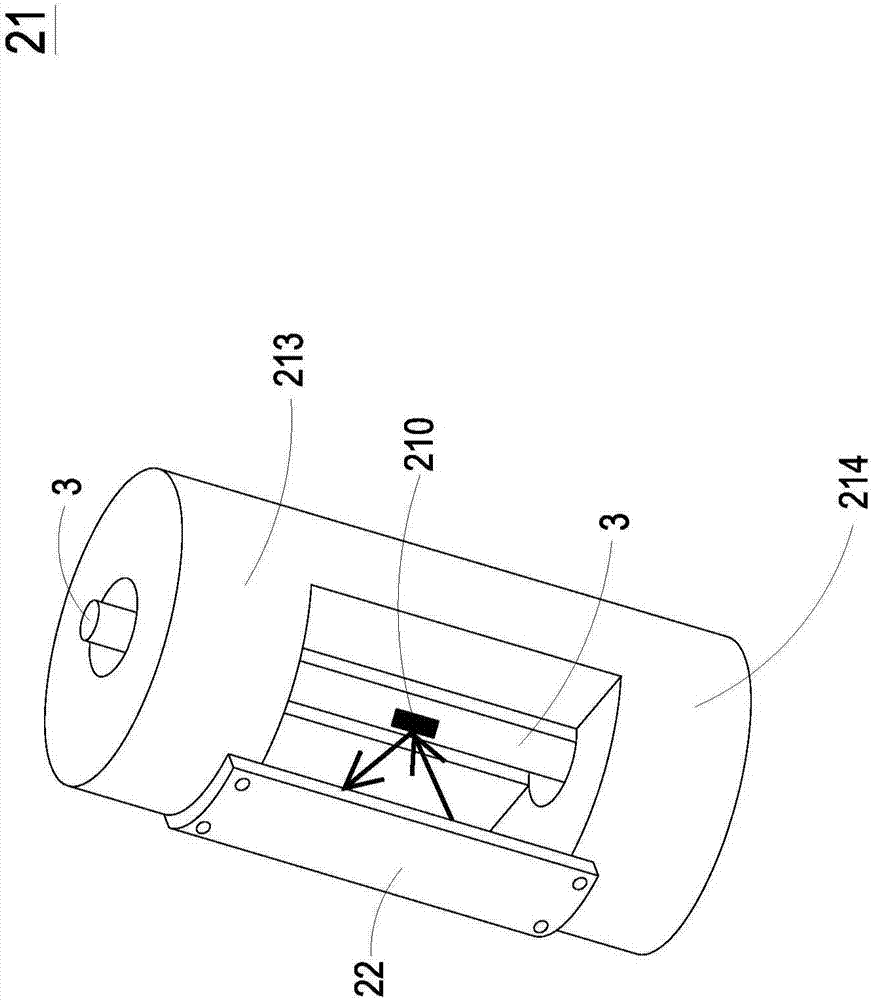

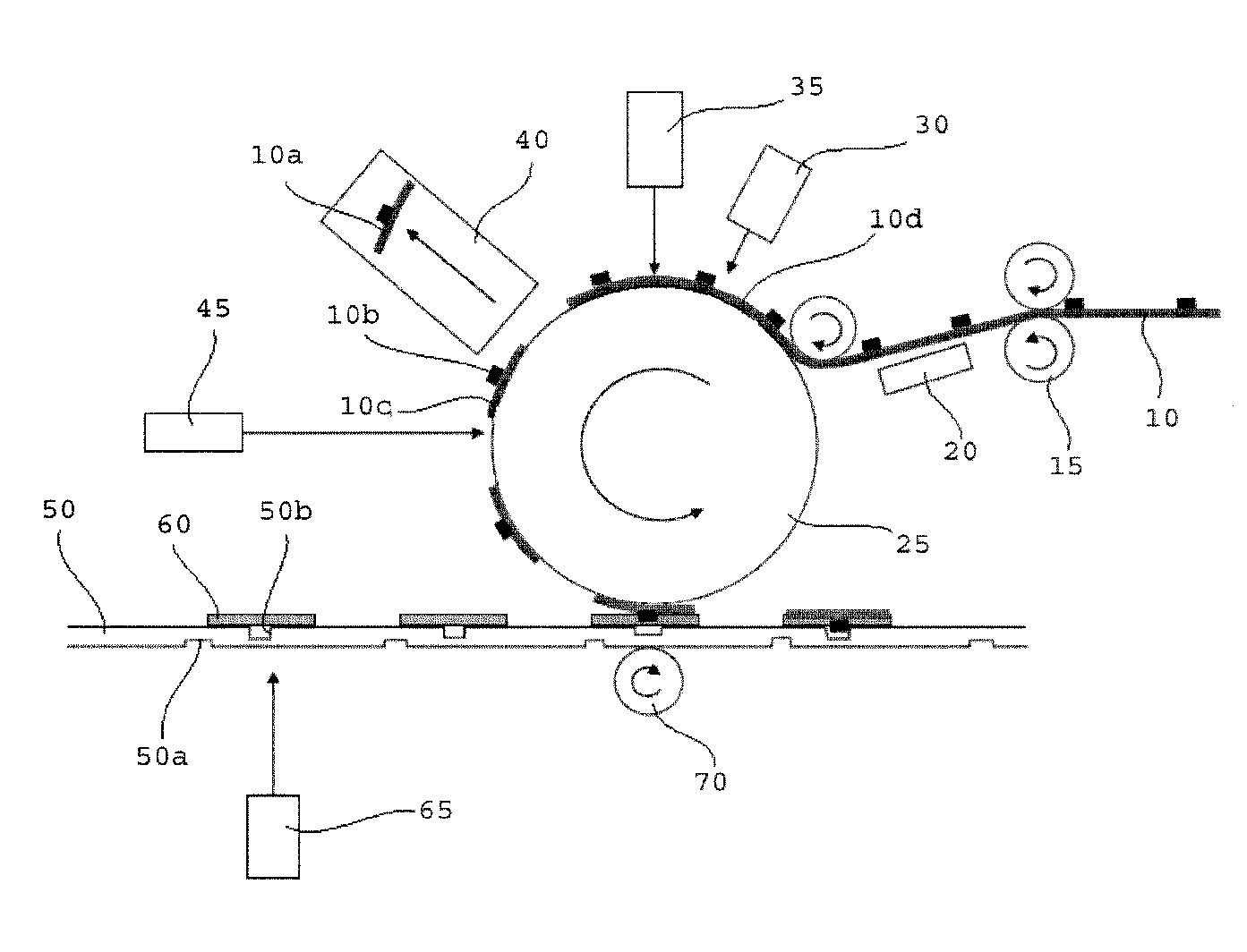

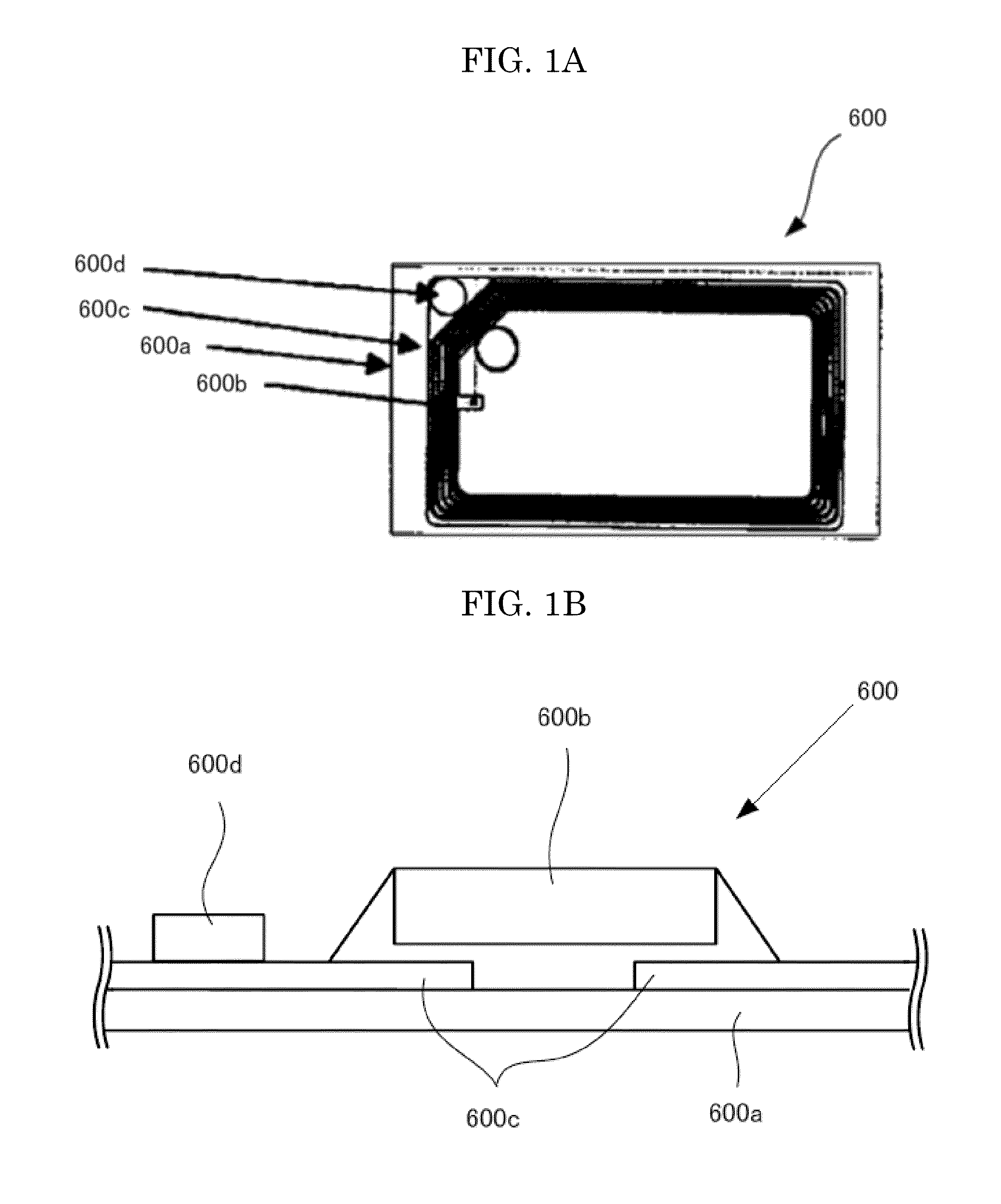

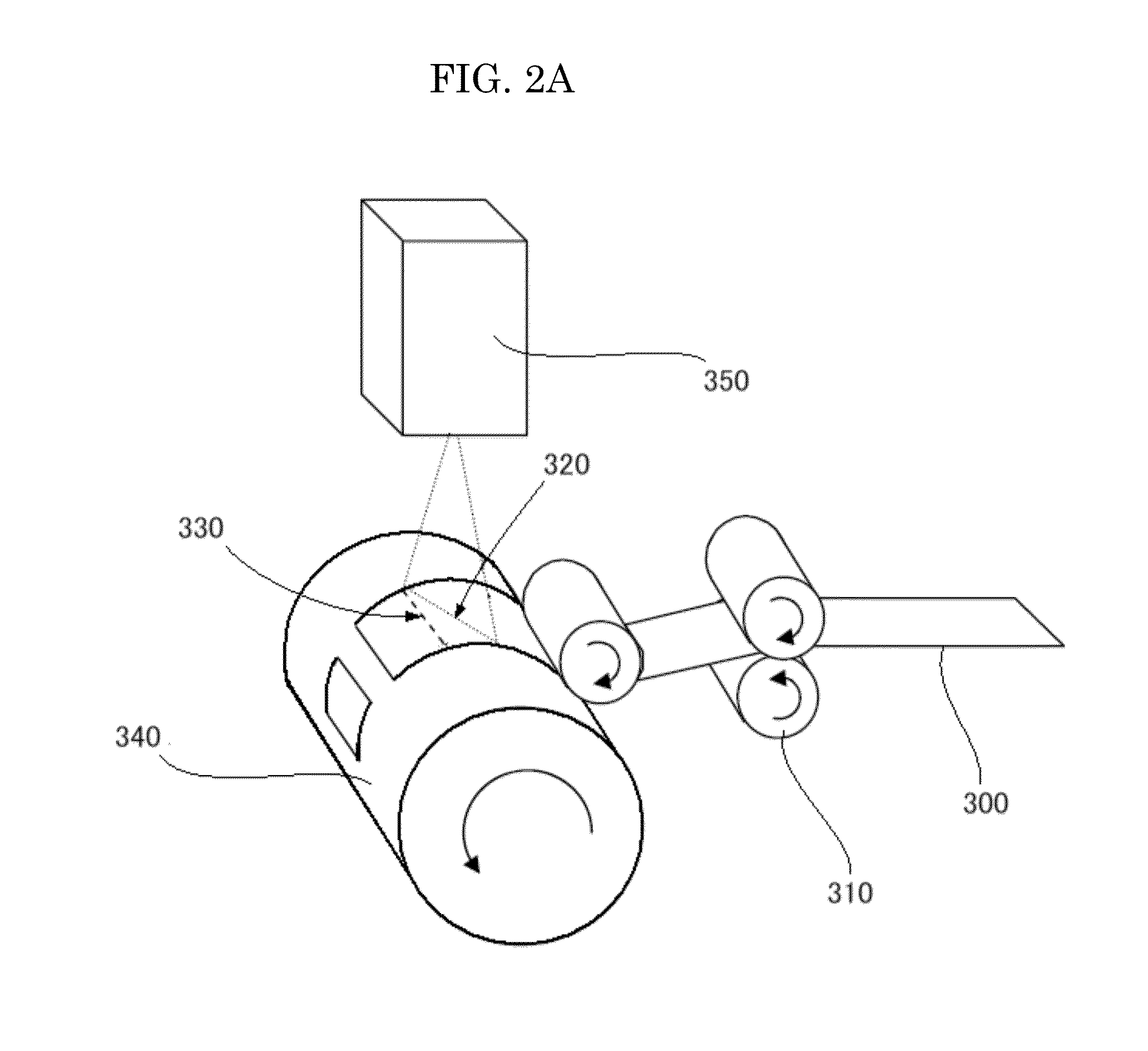

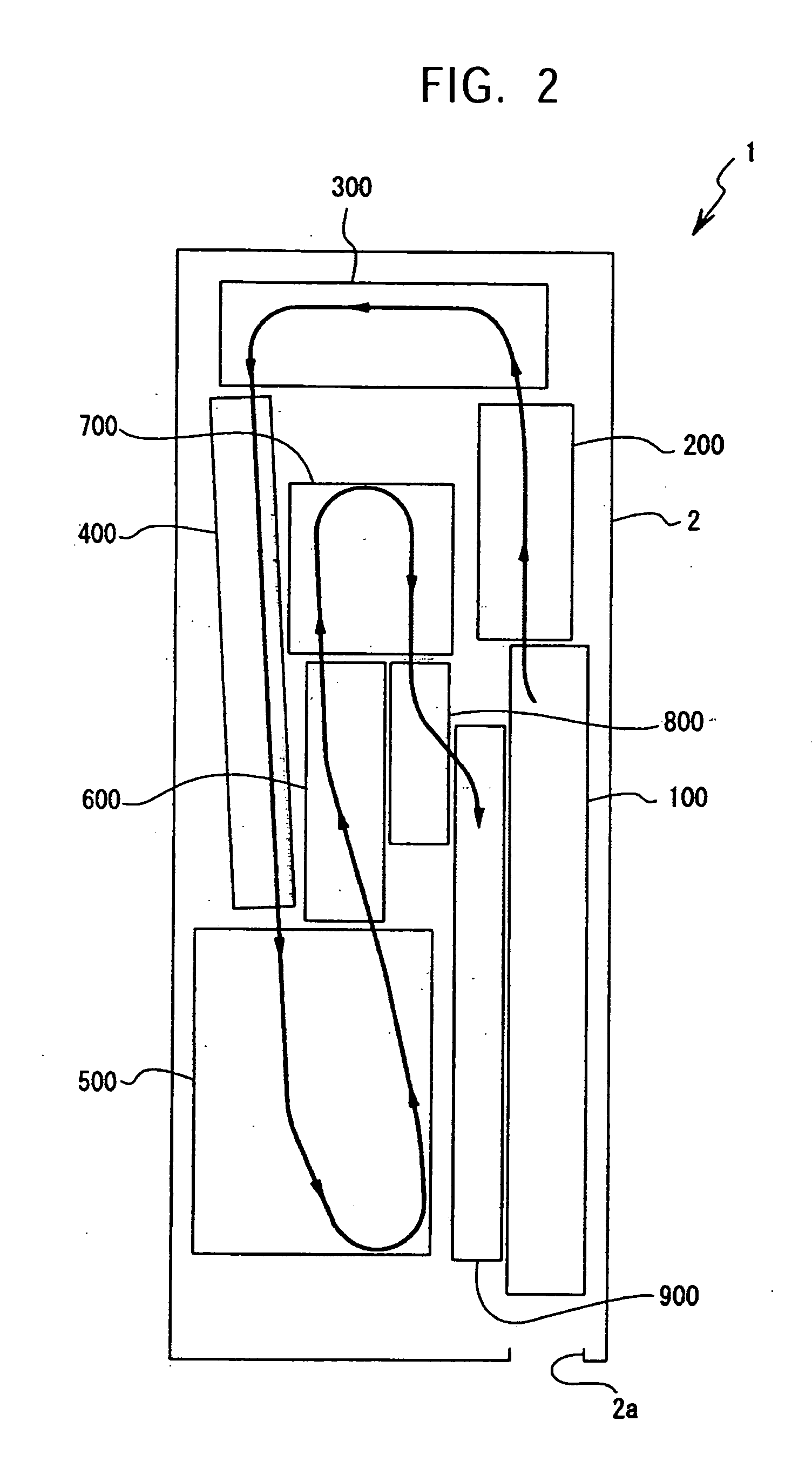

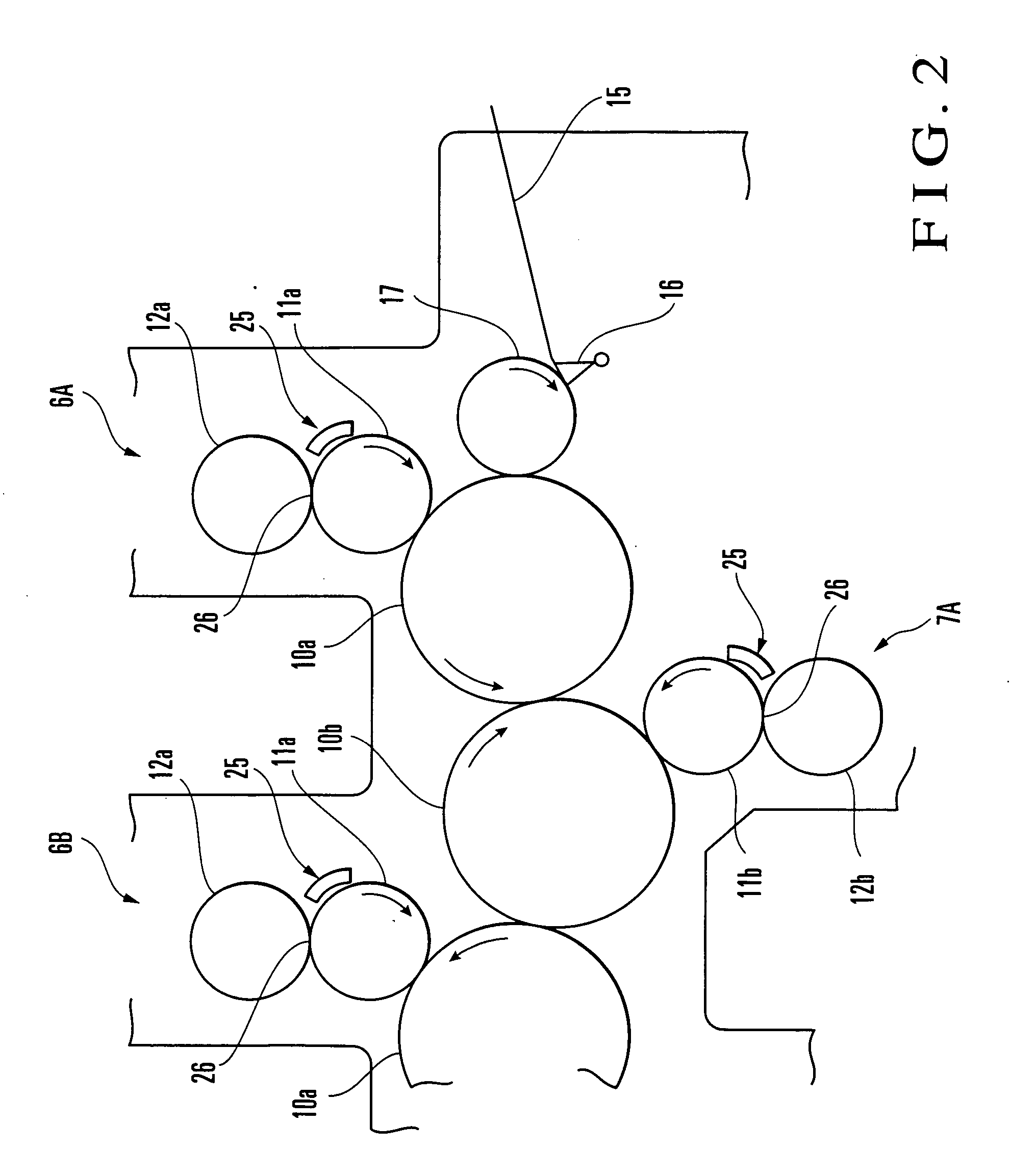

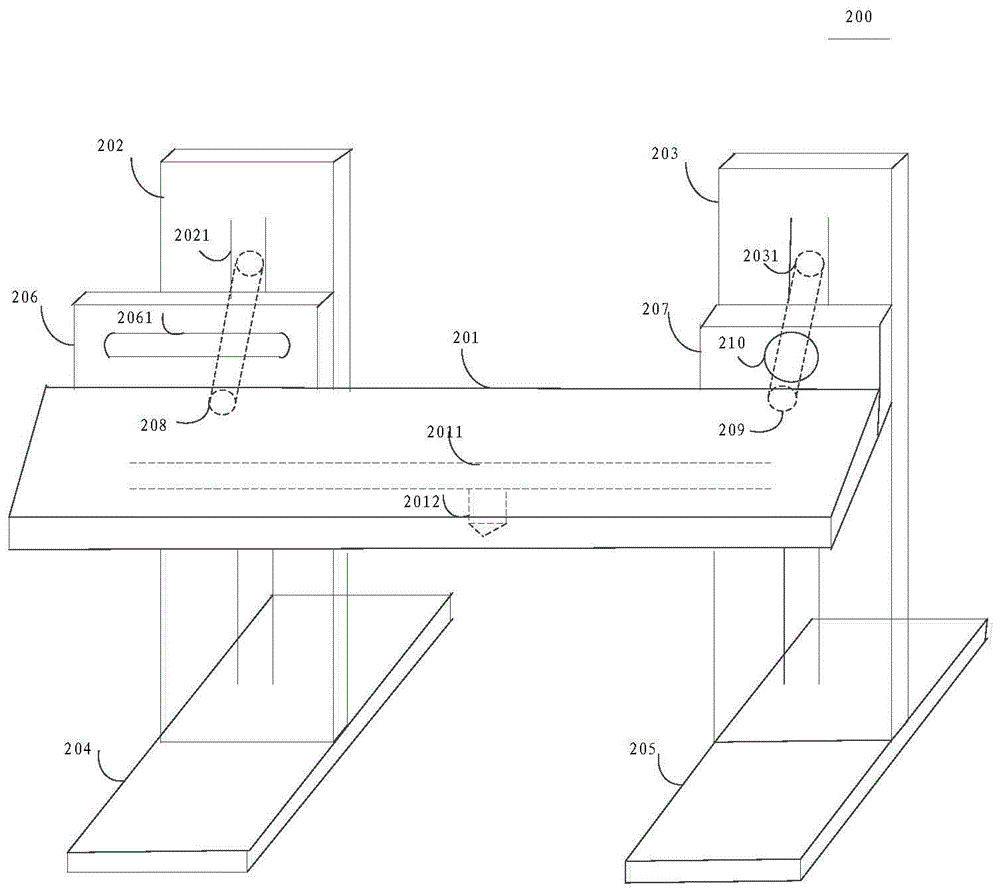

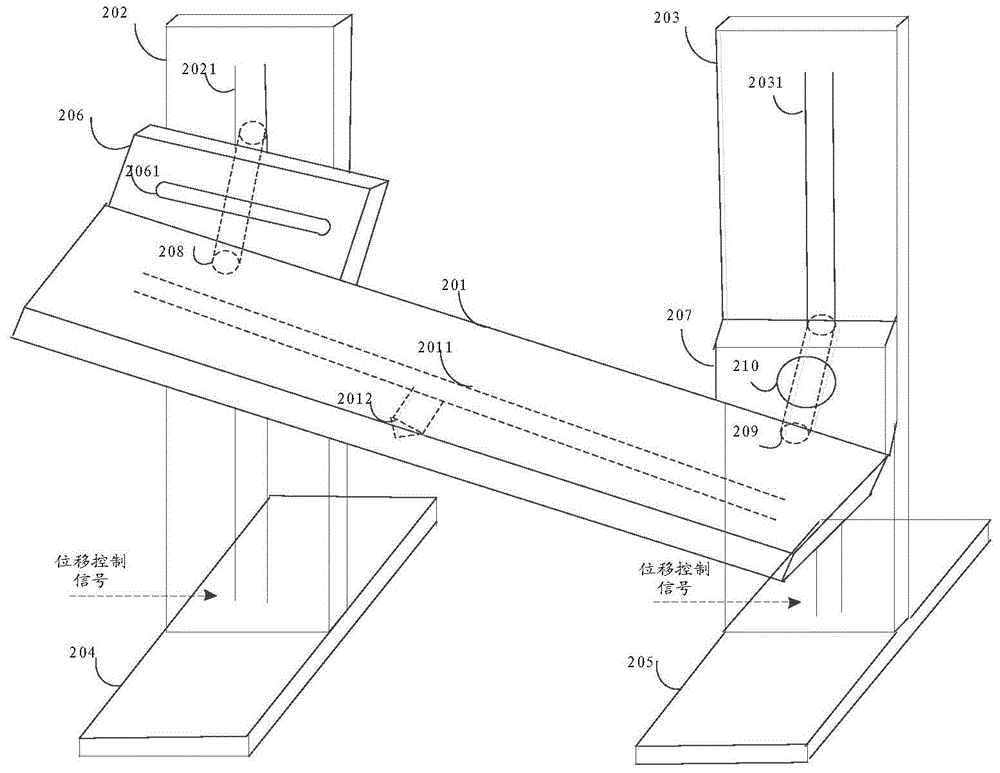

Method for producing reversible thermosensitive recording medium, production apparatus for the same, and reversible thermosensitive recording medium

InactiveUS20110224073A1High precisionHigh efficiencyLamination ancillary operationsLaminationElectronic informationEngineering

The present invention provides a method for producing a reversible thermosensitive recording medium, the method including: conveying an inlet sheet which includes inlets each having a convex-shaped electronic information recording element, retrieving positional information of the inlets, cutting the inlet sheet into individual inlets, retrieving positional information of the convex-shaped electronic information recording element in the individual inlets, conveying a base sheet, which includes concave portions, toward the vacuum suction roller, retrieving positional information of the concave portions, aligning the convex-shaped electronic information recording element with the concave portions so as to be inserted into the concave portion, and laminating the inlets and the base sheet.

Owner:RICOH KK

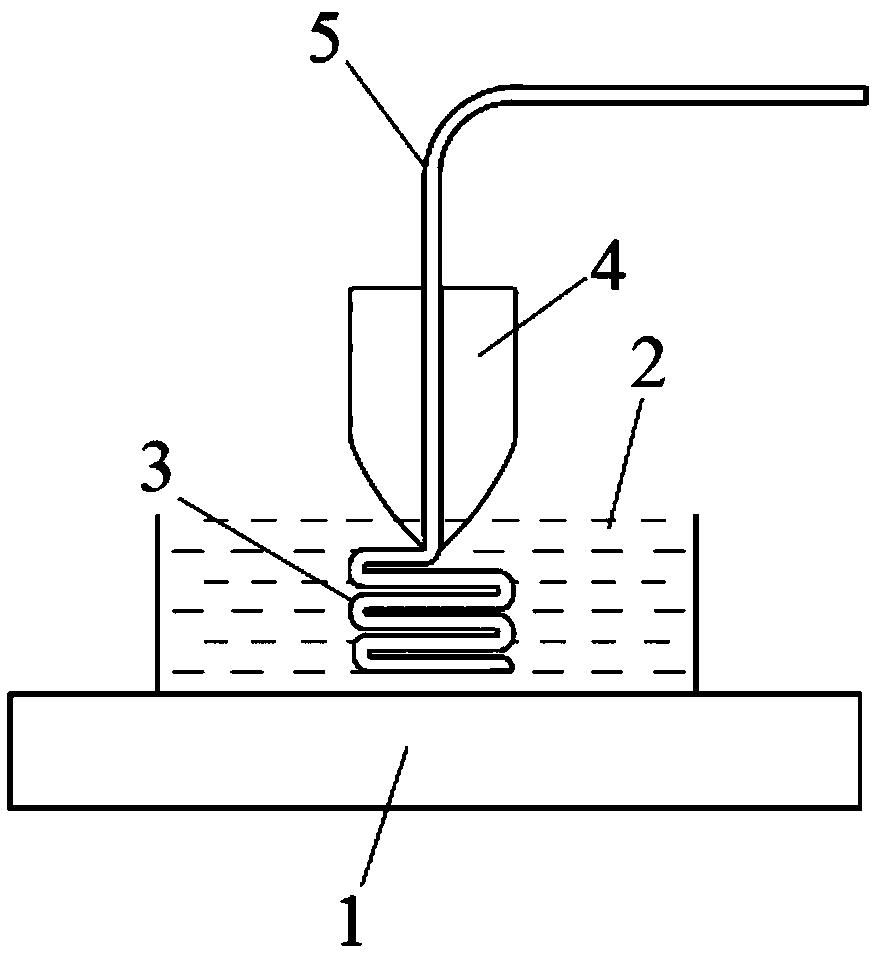

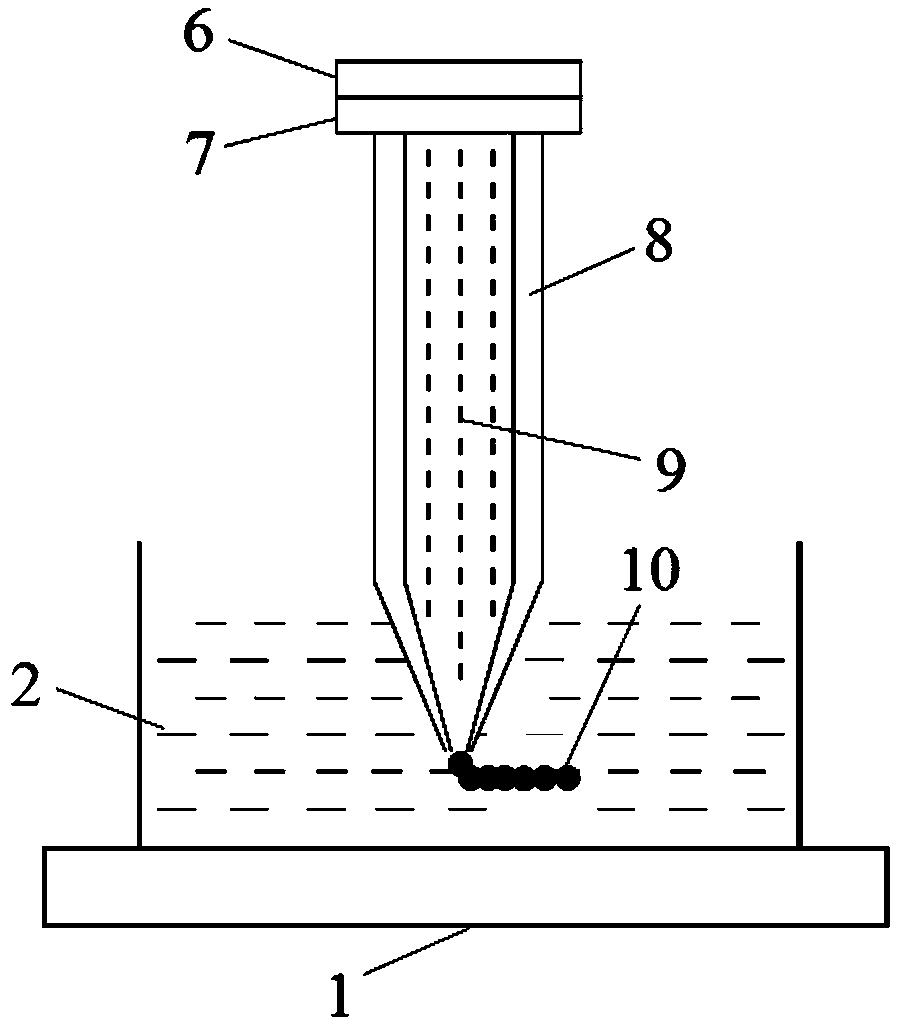

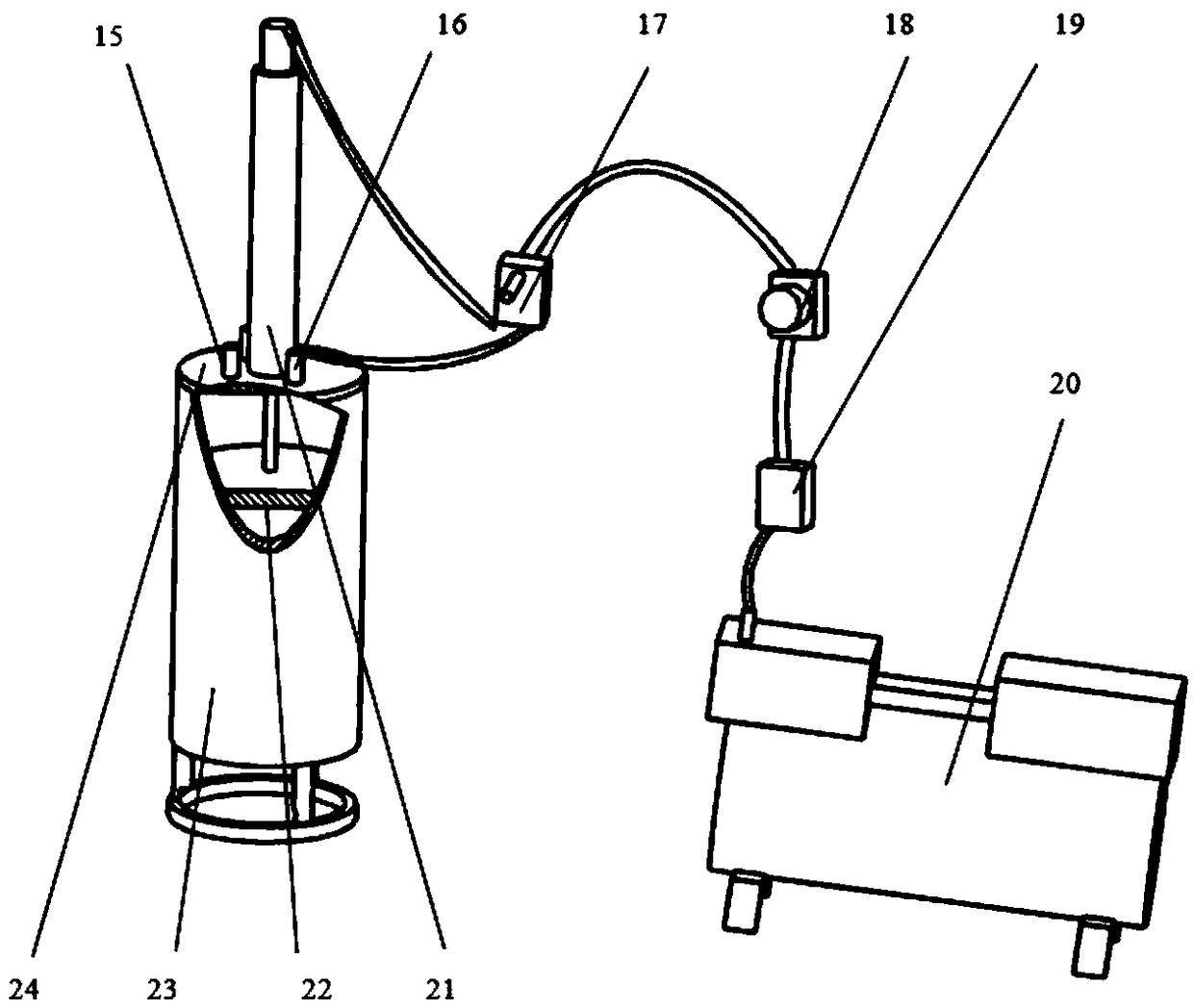

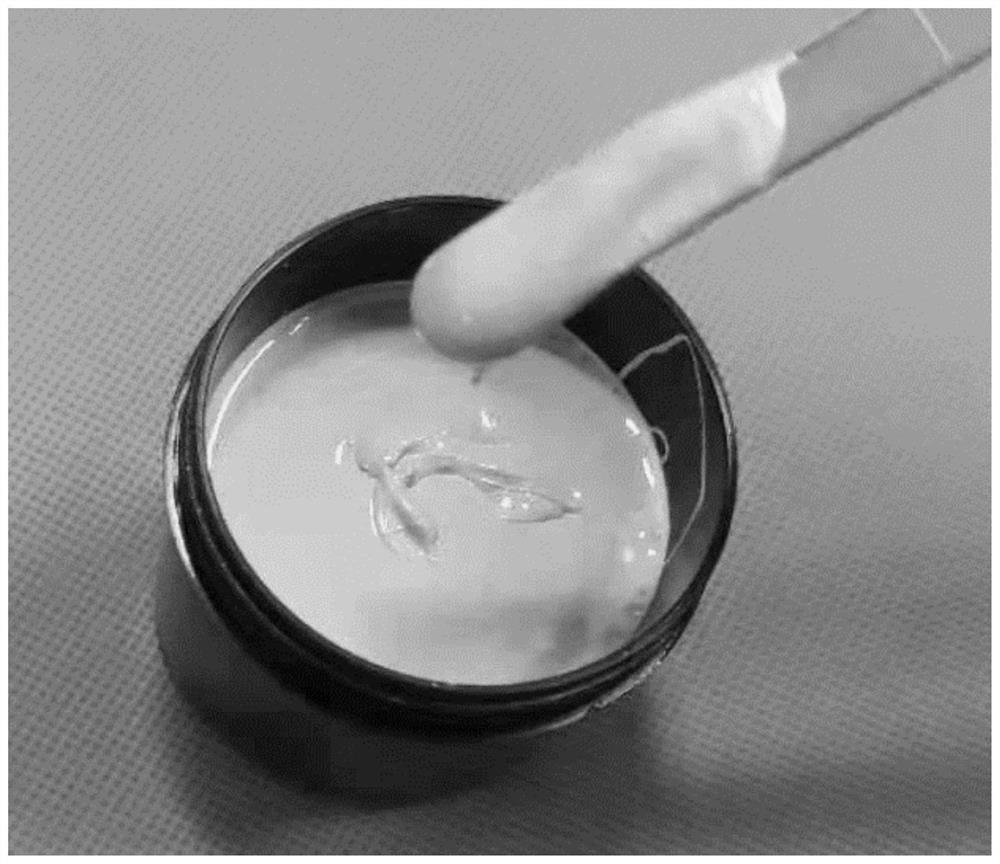

Three-dimensional printing method based on fluid support

InactiveCN108859097AExpand the scope of the structureImprove printing yieldManufacturing enclosuresAdditive manufacturing with liquids3 dimensional printingComputer engineering

The invention discloses a three-dimensional printing method based on fluid support. The printing method comprises the following steps that (1) a supporting fluid material is prepared, and then is putinto a container; (2) a three-dimensional model to be printed is sliced, and then a printer is used for printing a structure in the supporting fluid material in the step (1); (3) the structure which is printed in the step (2) is enabled to undergo post-curing in the supporting fluid material; and (4) after curing is completed, the printed structure is taken out by using a colander. According to the printing method, a supporting structure does not need to be designed and machined additionally, therefore, the structure range suitable for printing processing can be expanded, the printing yield isincreased, the post-processing process is simplified, and the printing cost is reduced.

Owner:NANJING UNIV

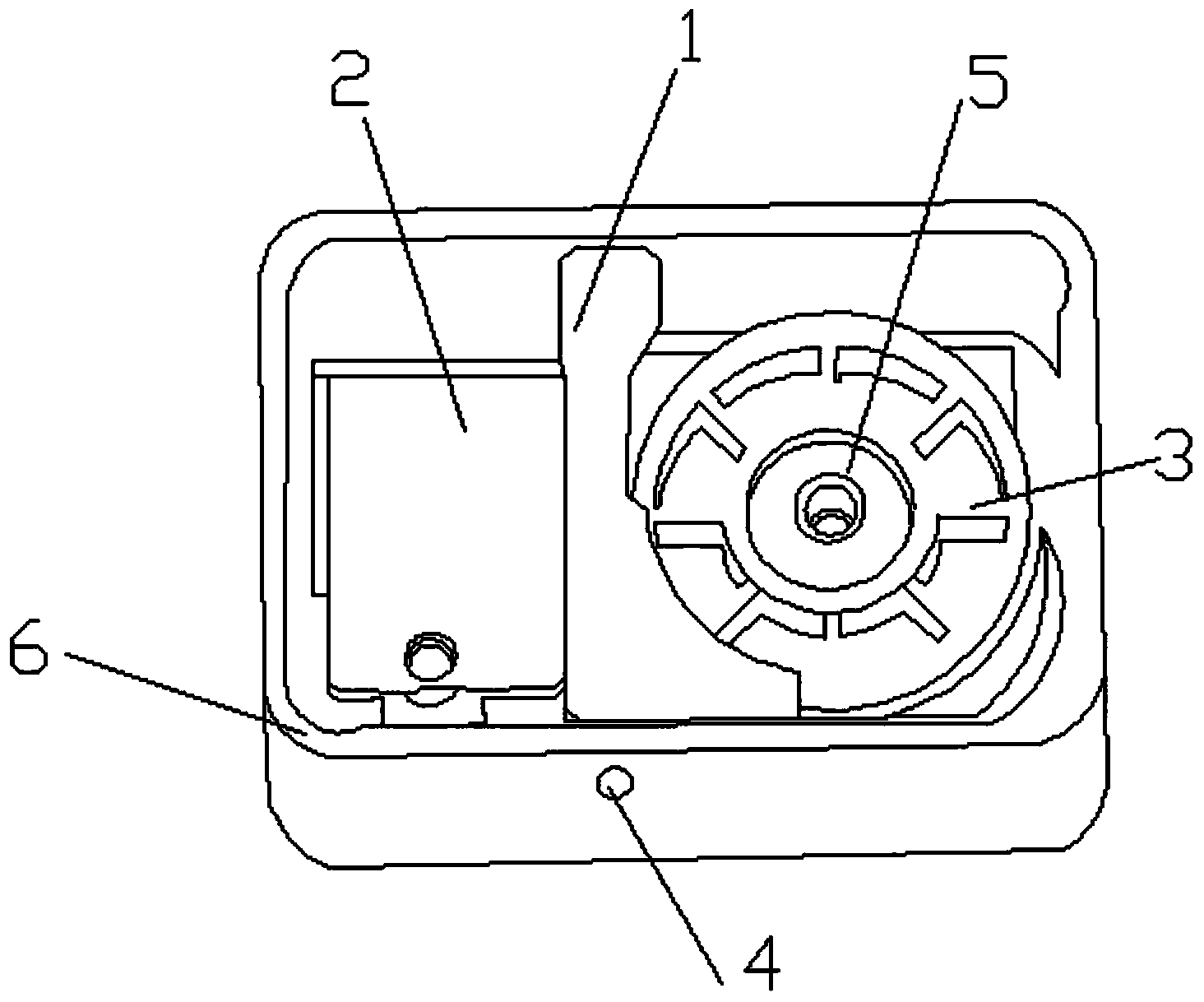

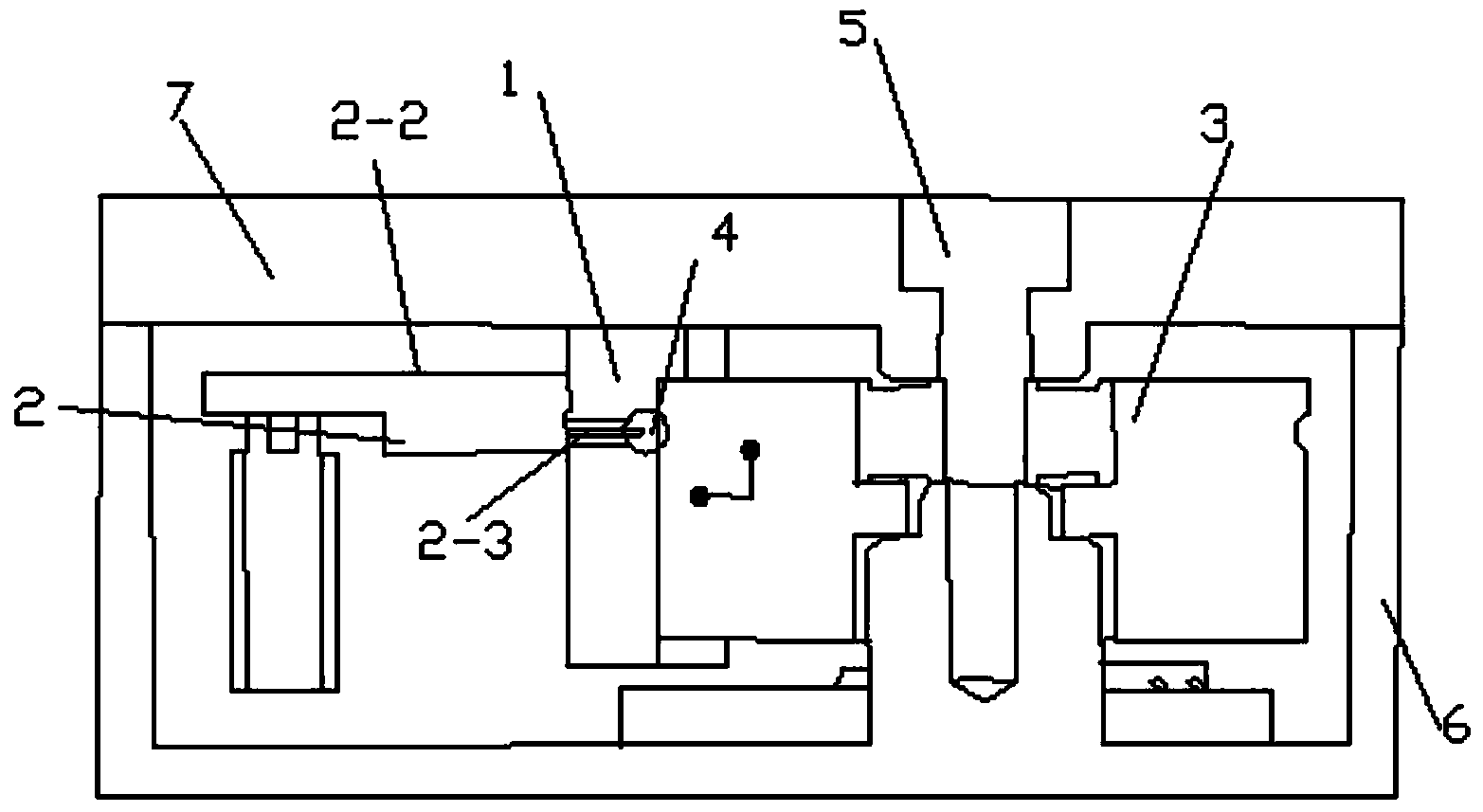

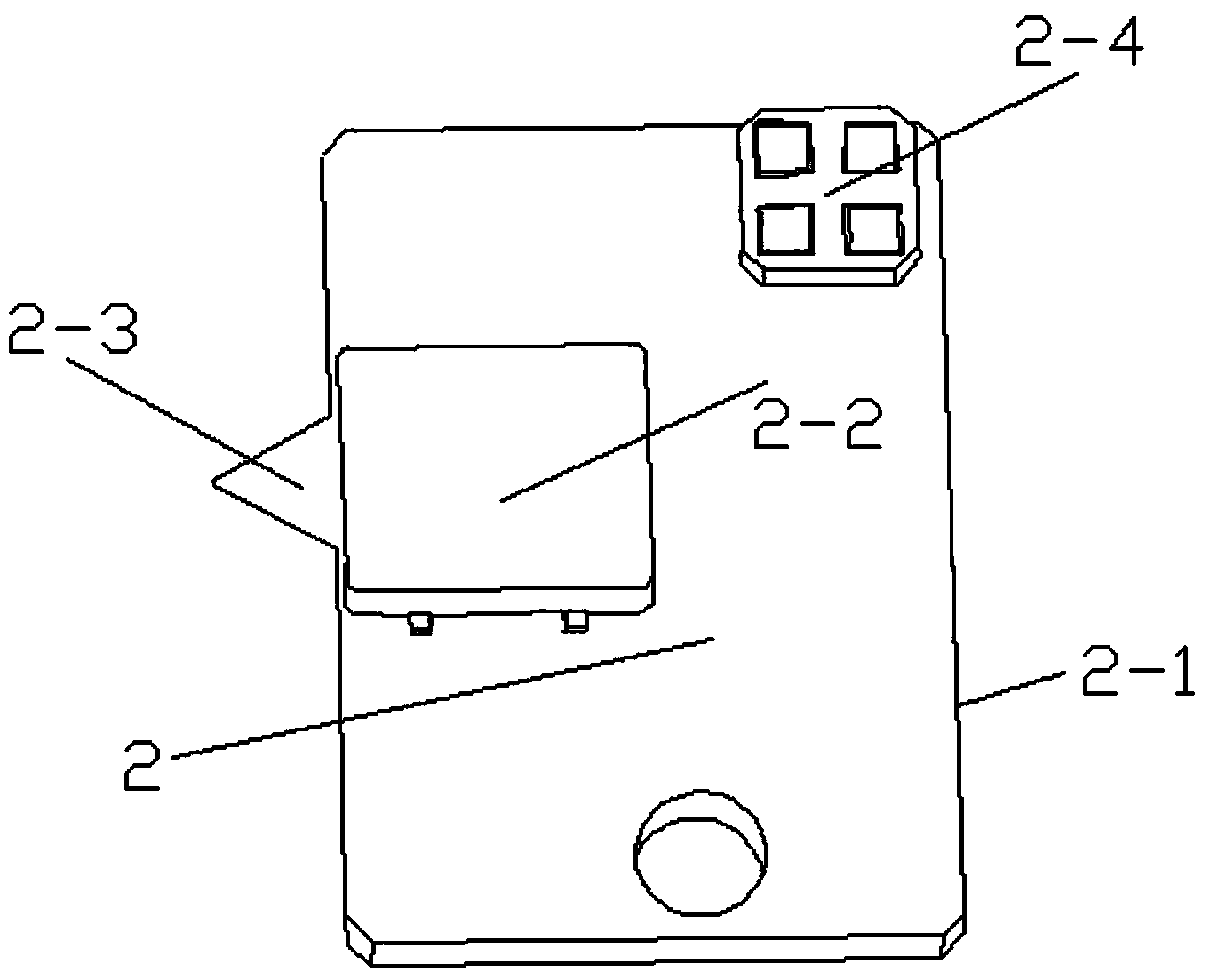

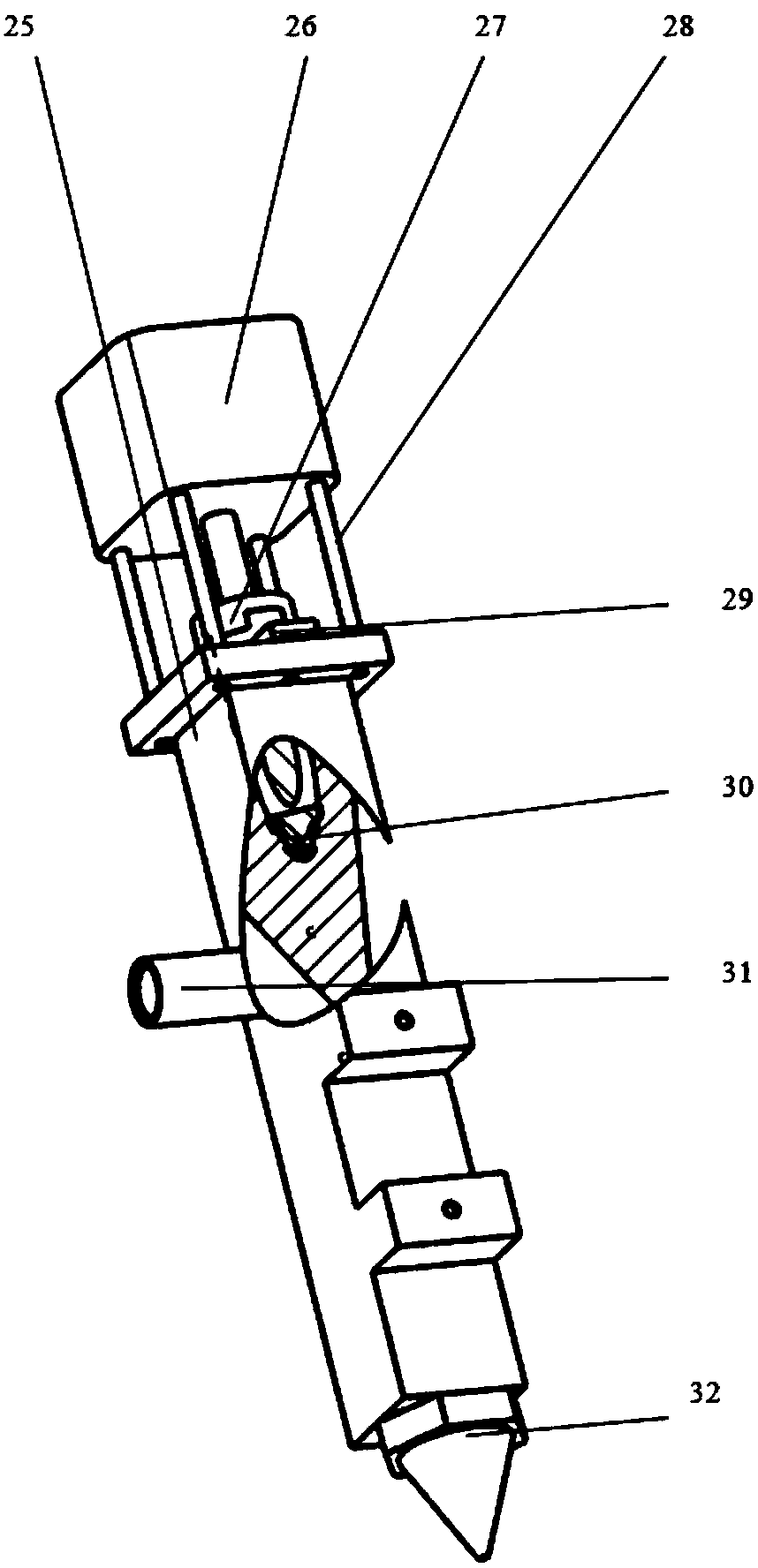

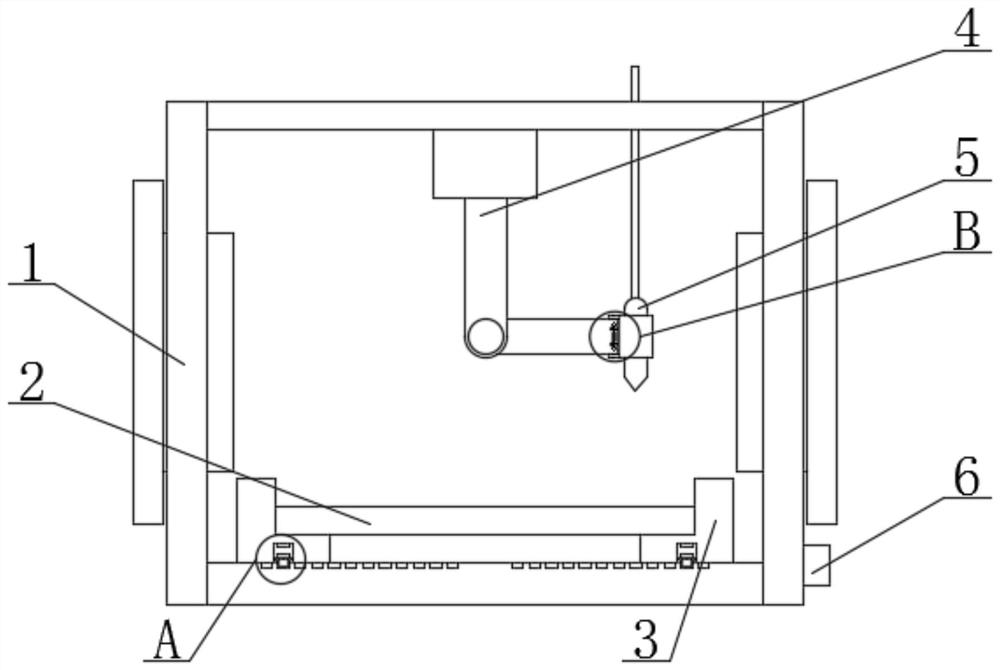

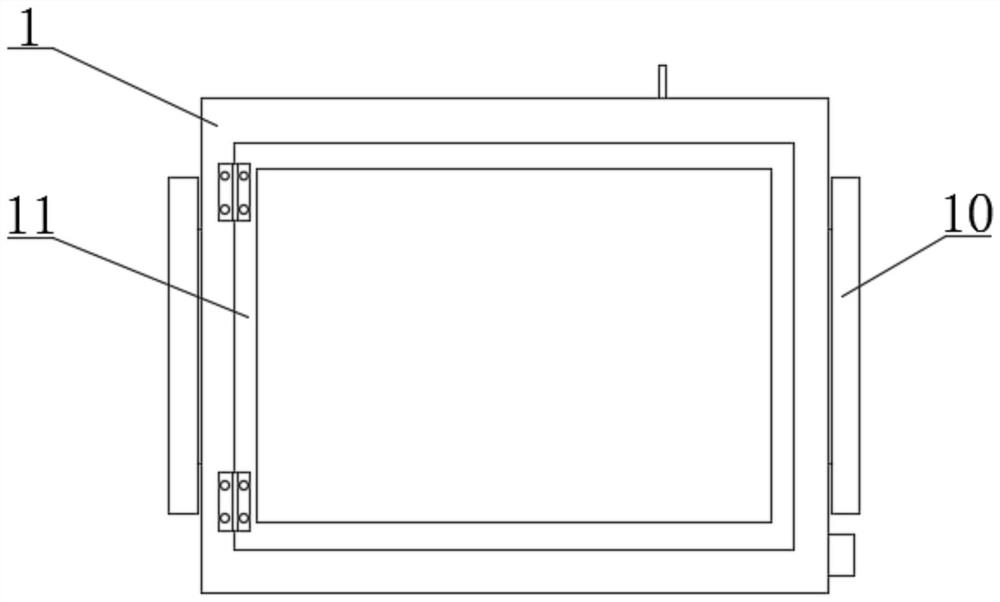

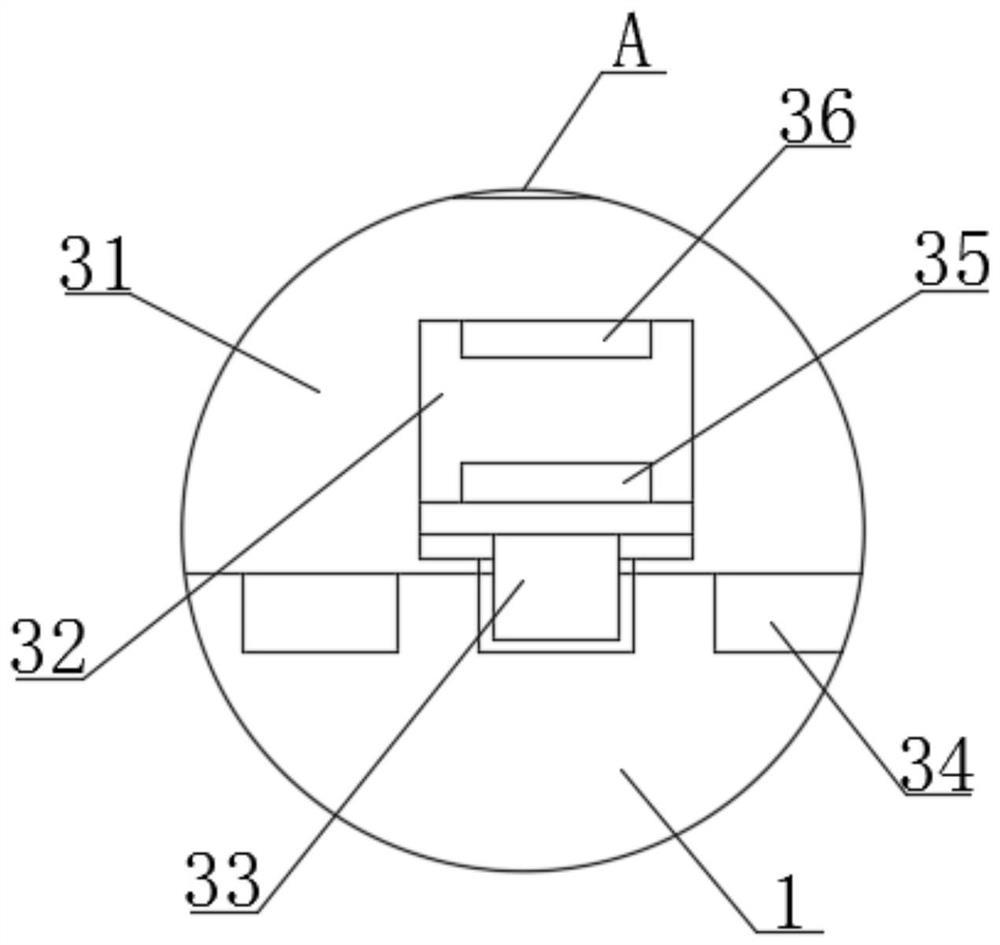

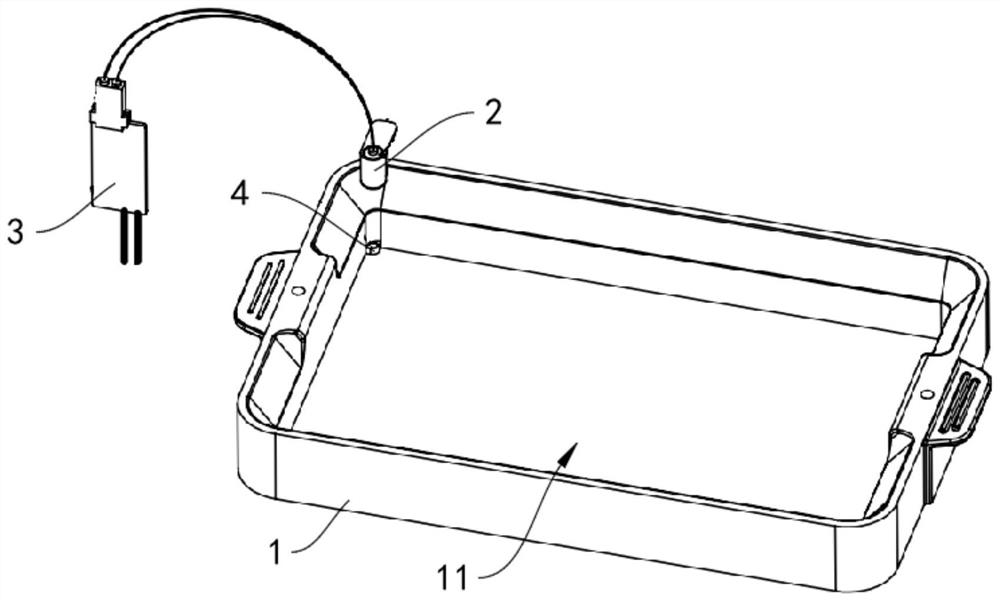

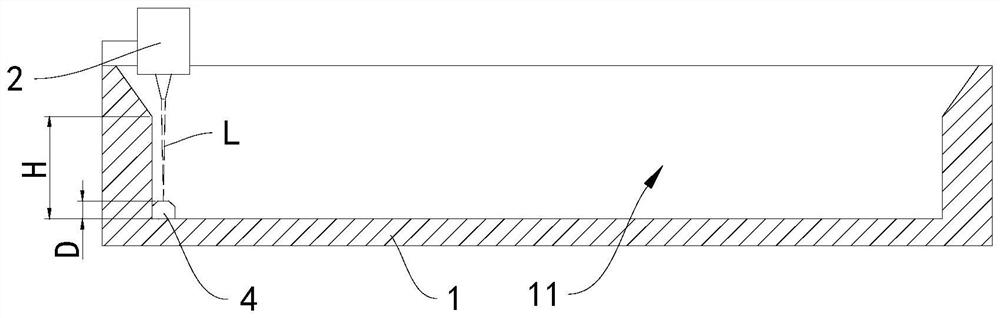

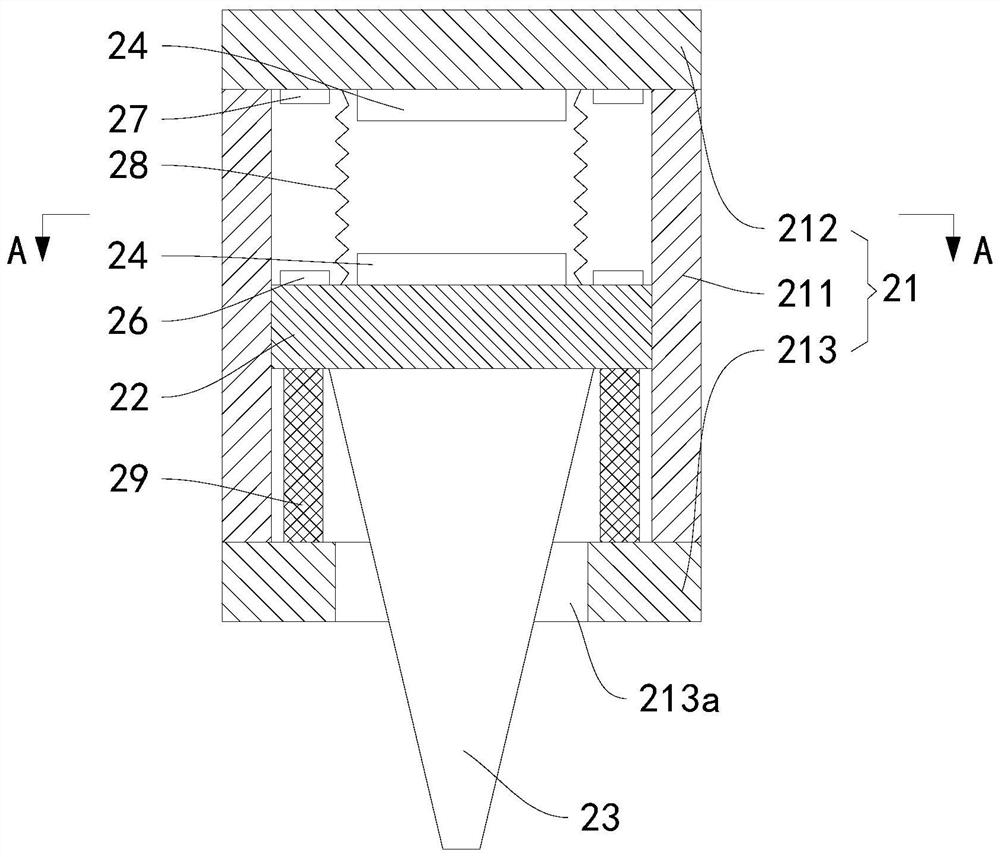

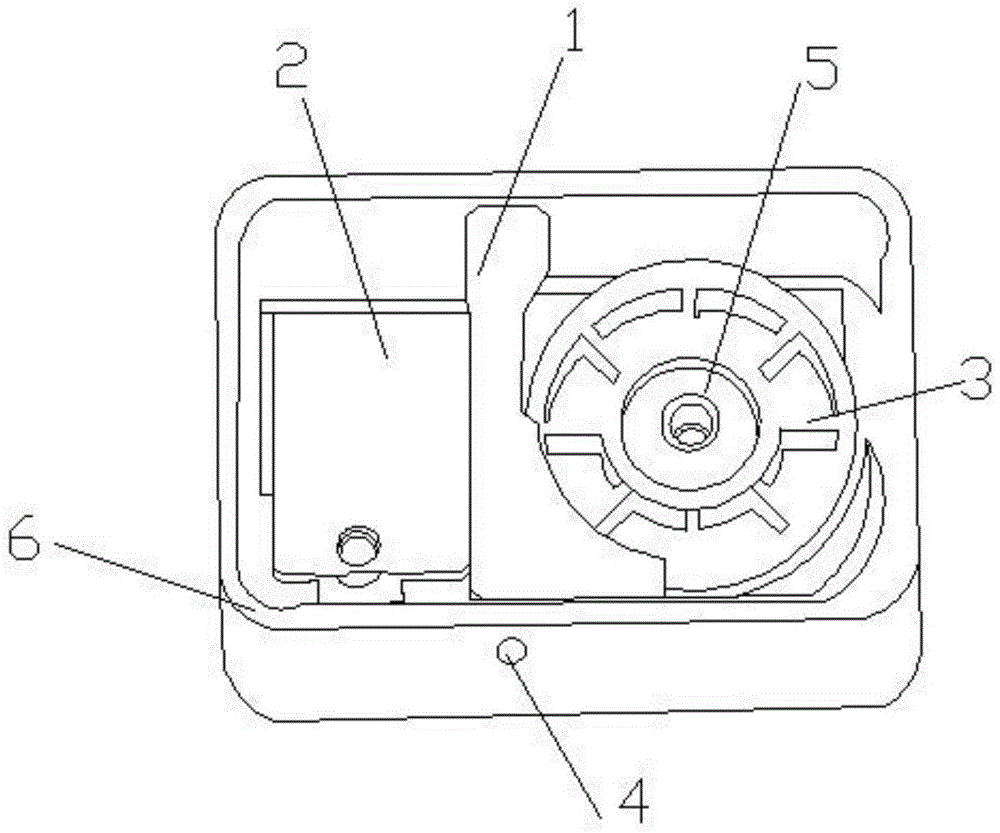

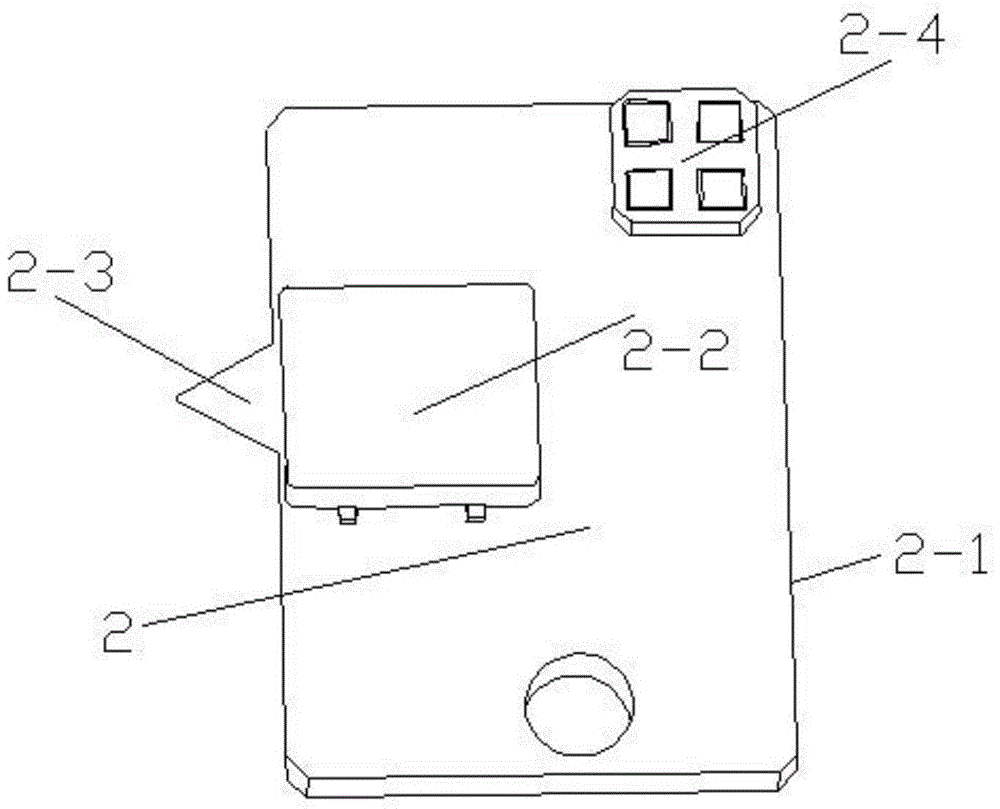

Intelligent feeding detection mechanism of 3D printer

The invention discloses an intelligent feeding detection mechanism of a 3D printer. The intelligent feeding detection mechanism comprises a channel as well as a feeding sensor, a feeding speed sensor and a control system, wherein a printing material passes through the channel; signal receiving ends of the feeding sensor and the feeding speed senor are both connected with the channel; the feeding sensor is used for acquiring whether the printing material passes through the channel; the feeding speed sensor is used for acquiring the feeding speed of the printing material inside the channel; the control system is used for controlling the printer to stop working and to make an alarm when the feeding sensor senses that no material is fed into the channel or the material is not sufficient and the information is transmitted to the control system, and used for controlling the printer to stop working when the feeding speed sensor senses that the feeding speed of the printing material is zero and the information is transmitted to the control system. Through the adoption of the intelligent feeding detection mechanism, whether the material is blocked or insufficient in the printing process or not can be tested, and material replacement can be promoted, so that the printing success rate is ensured.

Owner:西安非凡士机器人科技有限公司

Novel ceramic forming device based on 3D printing technology

InactiveCN108297244AReduce labor costsAchieve high-precision printingAdditive manufacturing apparatusCeramic shaping apparatusCeramic compositeCeramic molding

The invention relates to the technical field of 3D printing, in particular to a novel ceramic forming device based on the 3D printing technology. The device comprises a rack, a master controller, a three-dimension motion module, a feeding device and an extrusion device; the feeding device comprises a storage tank, a piston, an air cylinder, an air compressor, a conveying pipe, an electromagnetic valve, a pressure regulating valve and a reversing valve, the extrusion device comprises a stepping motor II, a screw rod, a coupler, a screw rod sleeve and a nozzle, and the device can be applied to printing molding of ceramic composite materials, cement and other building materials; manual cost is reduced, high-precision printing of 3D ceramic printing can be achieved, the 3D printing technology,ceramic forming, mechatronics and the three dimensional model design technology are fused, automatic molding of traditional ceramic is successfully achieved, the special form difficultly achieved through the traditional ceramic blank drawing technology can be achieved, according to customer needs, individual customizing is achieved, the device can be widely applied in the culture creativity field, and new forming breakthrough is achieved.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

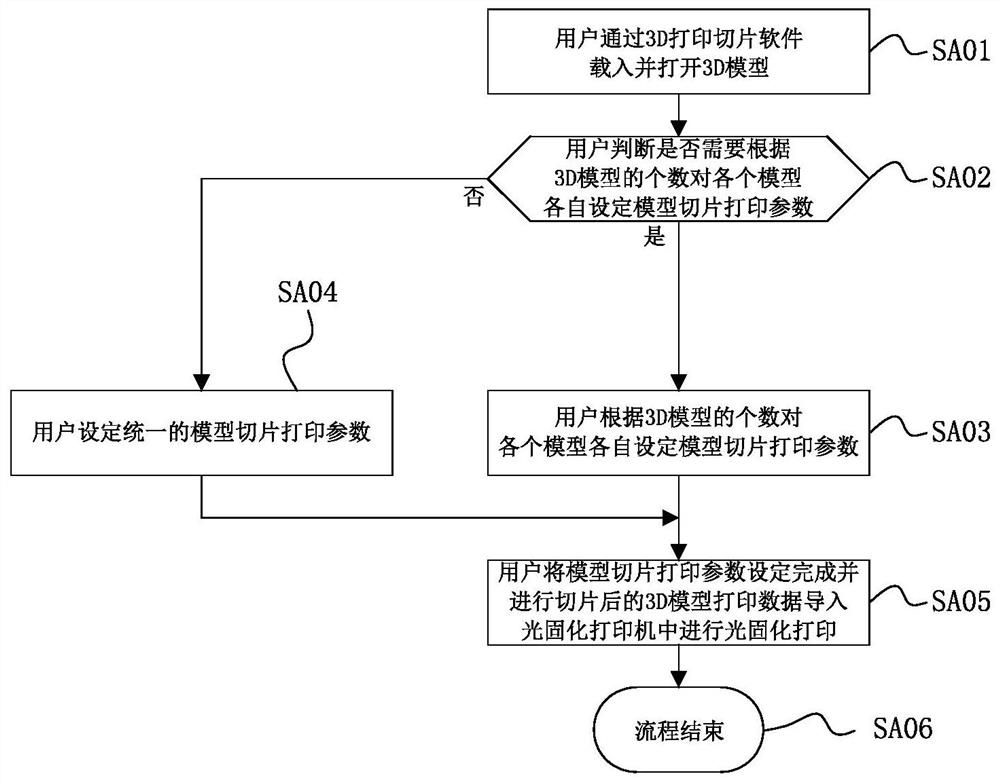

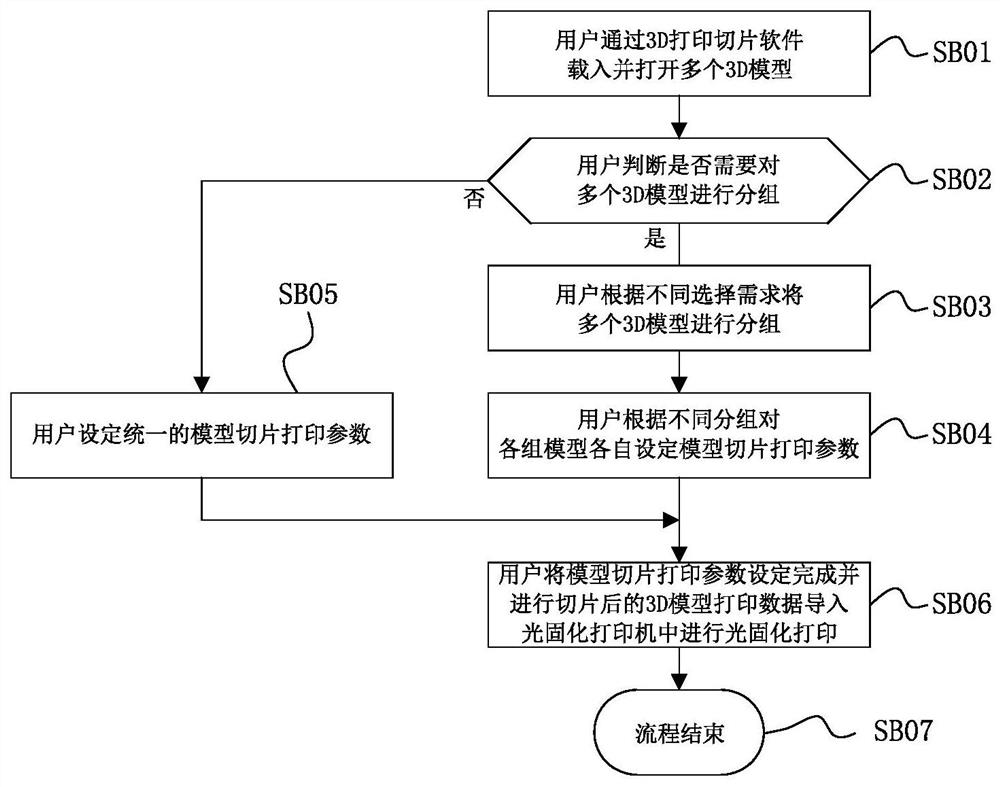

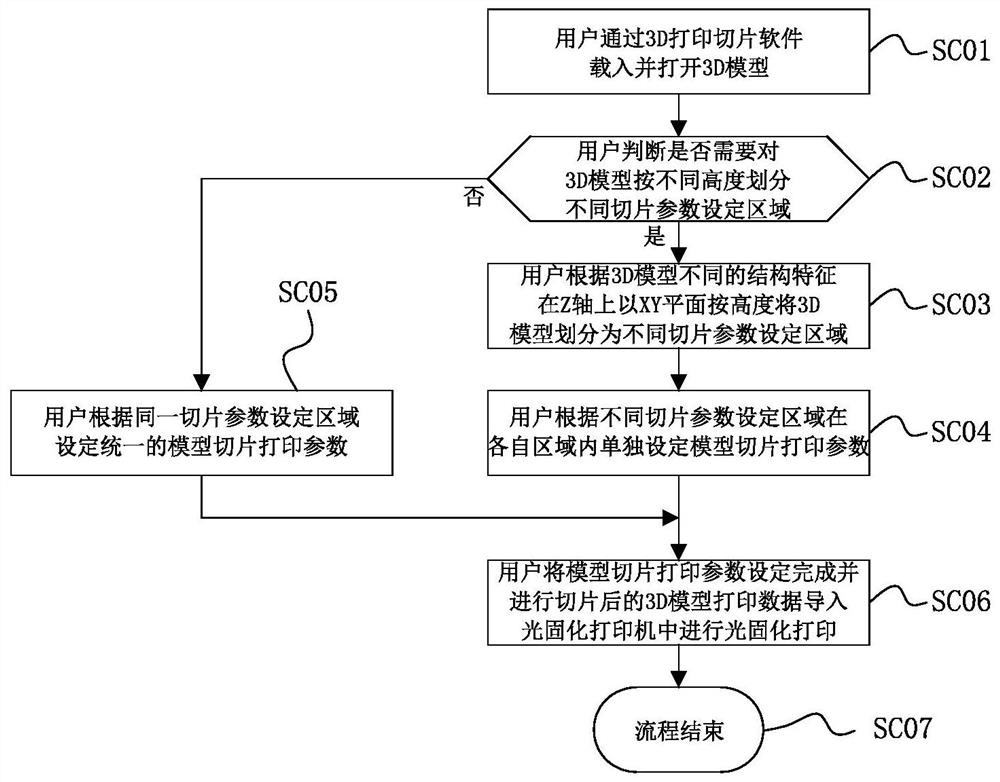

Methods for setting multiple sets of slice printing parameters of photocuring 3D printing models

PendingCN112976579AImprove finenessIncrease printing speedAdditive manufacturing apparatusManufacturing data aquisition/processingAlgorithmData mining

Owner:SHENZHEN CBD TECH CO LTD

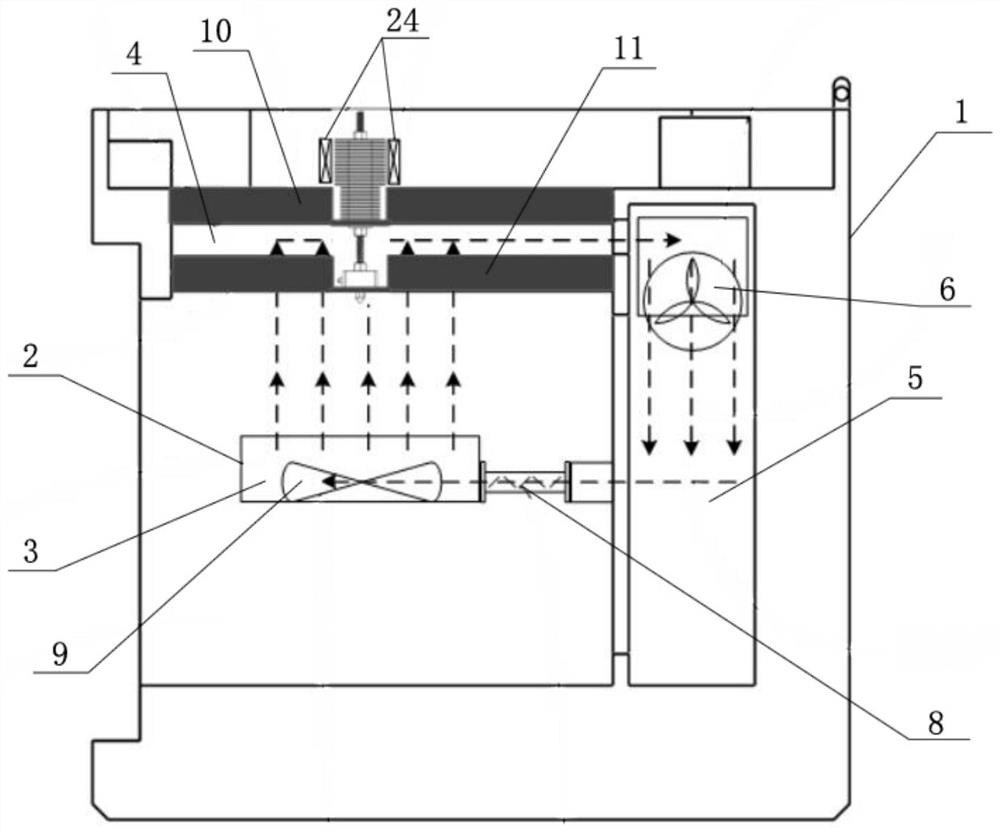

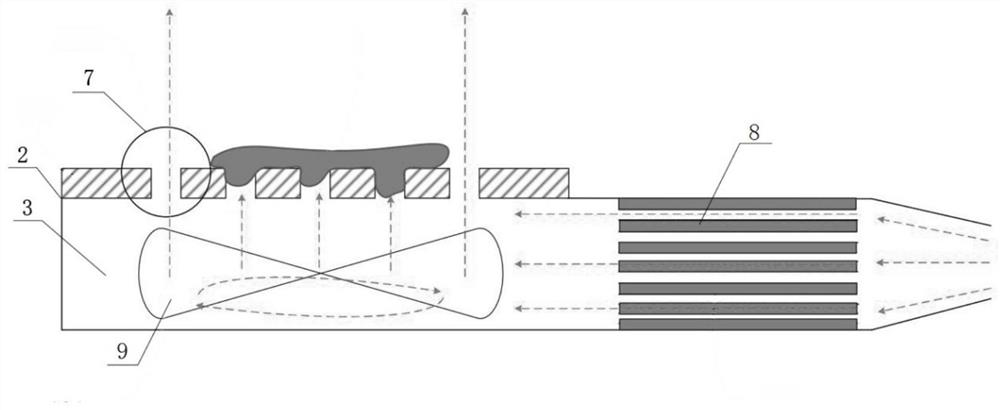

Printing forming chamber with local temperature control function and 3D printer with printing forming chamber

PendingCN112497746AHigh heating utilization efficiencyMeet the requirementsManufacturing platforms/substratesManufacturing heating elementsTemperature controlComputer printing

The invention provides a printing forming chamber with a local temperature control function. The printing forming chamber comprises an outer shell, a forming platform arranged in the outer shell and aprinting spray head arranged above the forming platform, wherein a hot air circulation air duct which enables the forming platform to blow out upward airflow capable of wrapping a printing model on the top face of the forming platform towards the position above the top face of the forming platform is further arranged in the outer shell; the printing spray head comprises a throat pipe, a nozzle, aspray head heating module and a spray head heat dissipation module, wherein one end of the throat pipe penetrates the hot air circulation air duct from the outer portion of the outer shell to stretchto the position above the forming platform, the nozzle is connected to the end, close to the forming platform, of the throat pipe, and the spray head heating module and the spray head heat dissipation module are arranged on the throat pipe in a penetrating manner and located on the inner side and the outer side of the hot air circulation air duct correspondingly; and the spray head heating moduleis located in the hot air circulation air duct, and the spray head heat dissipation module is located on the outer side of the outer shell. The invention further provides a 3D printer with the printing forming chamber. By means of the printing forming chamber with the local temperature control function and the 3D printer with the printing forming chamber, a high-temperature environment meeting the requirement for printing materials can be provided for the whole printing process.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

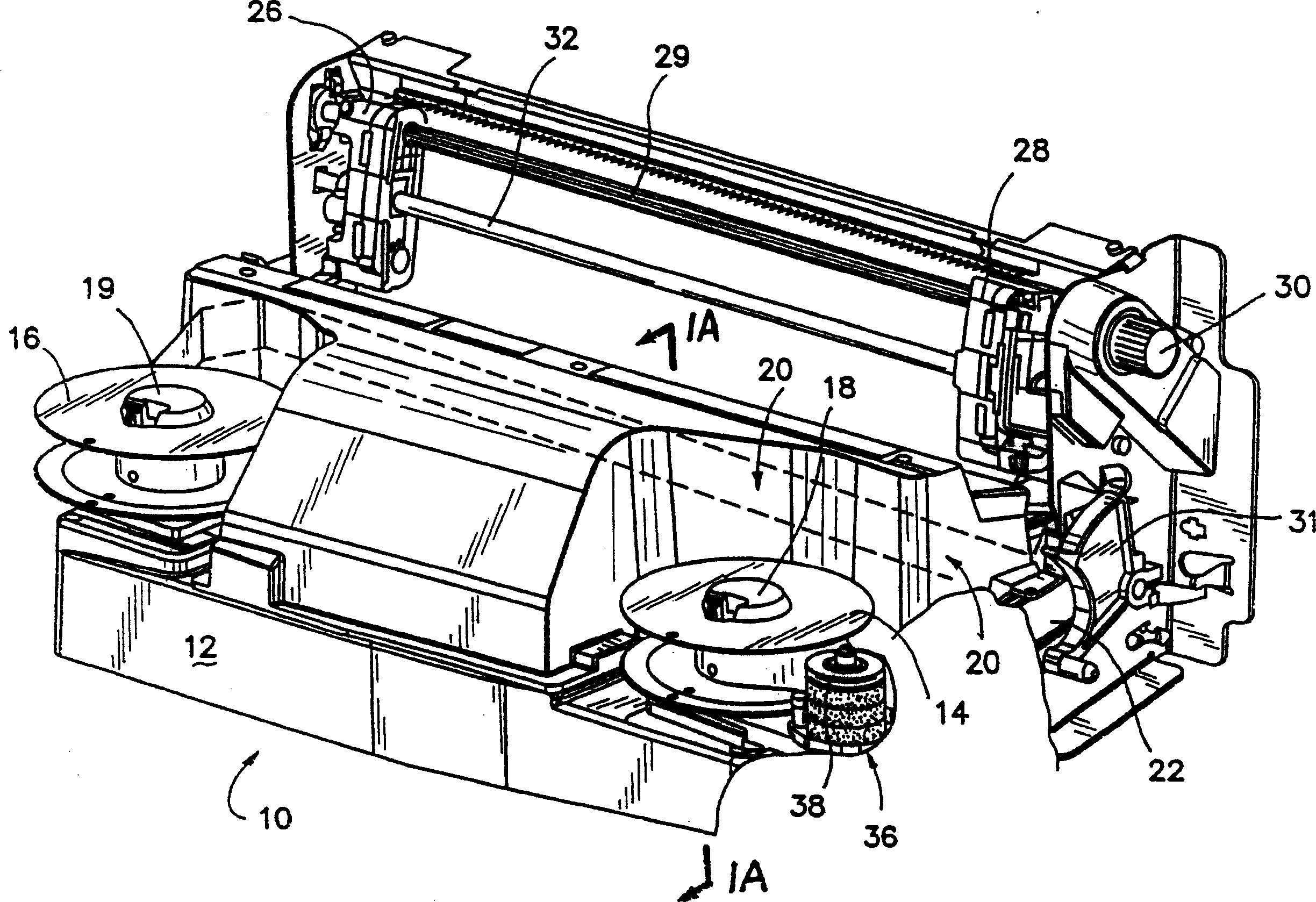

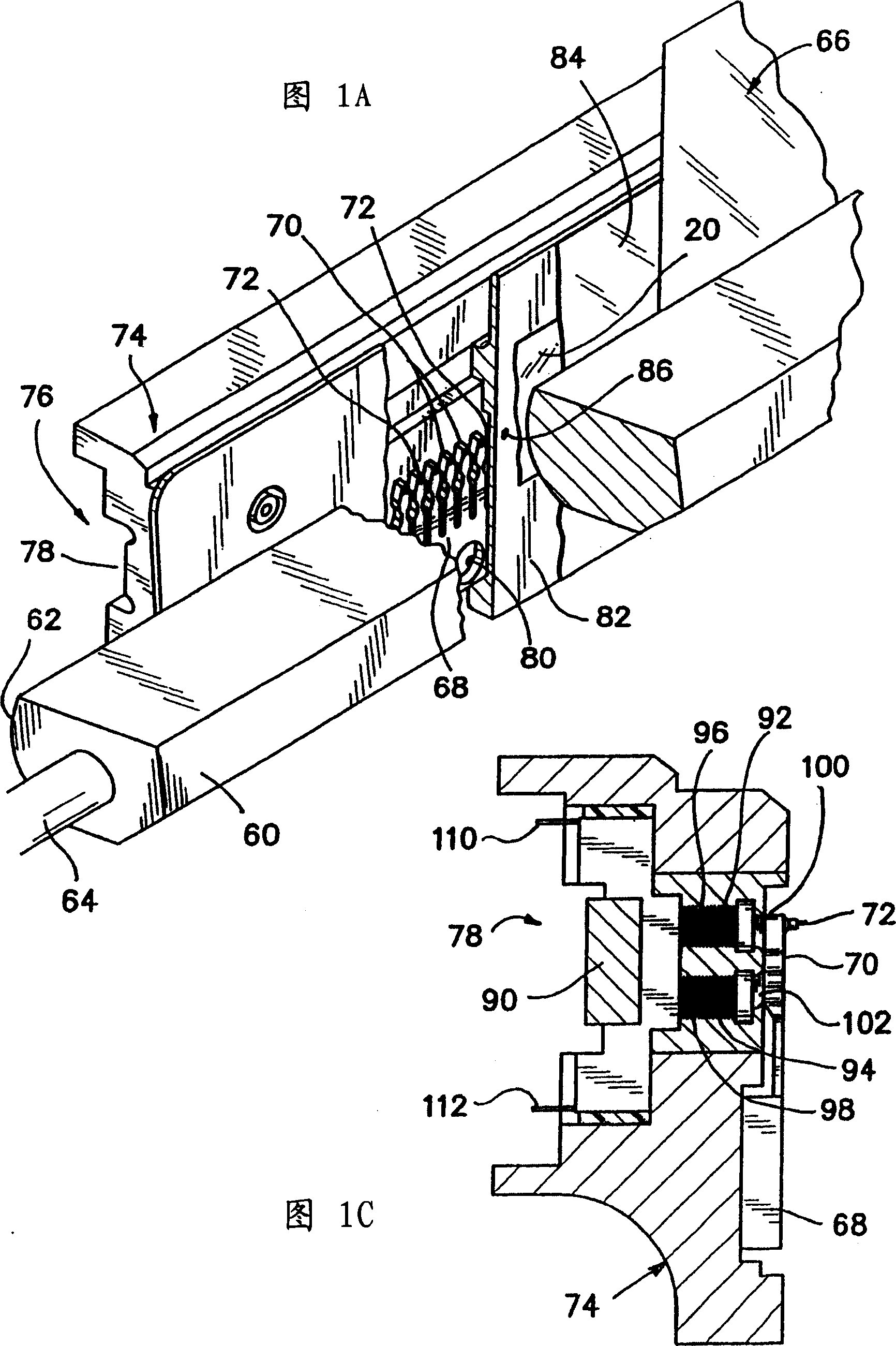

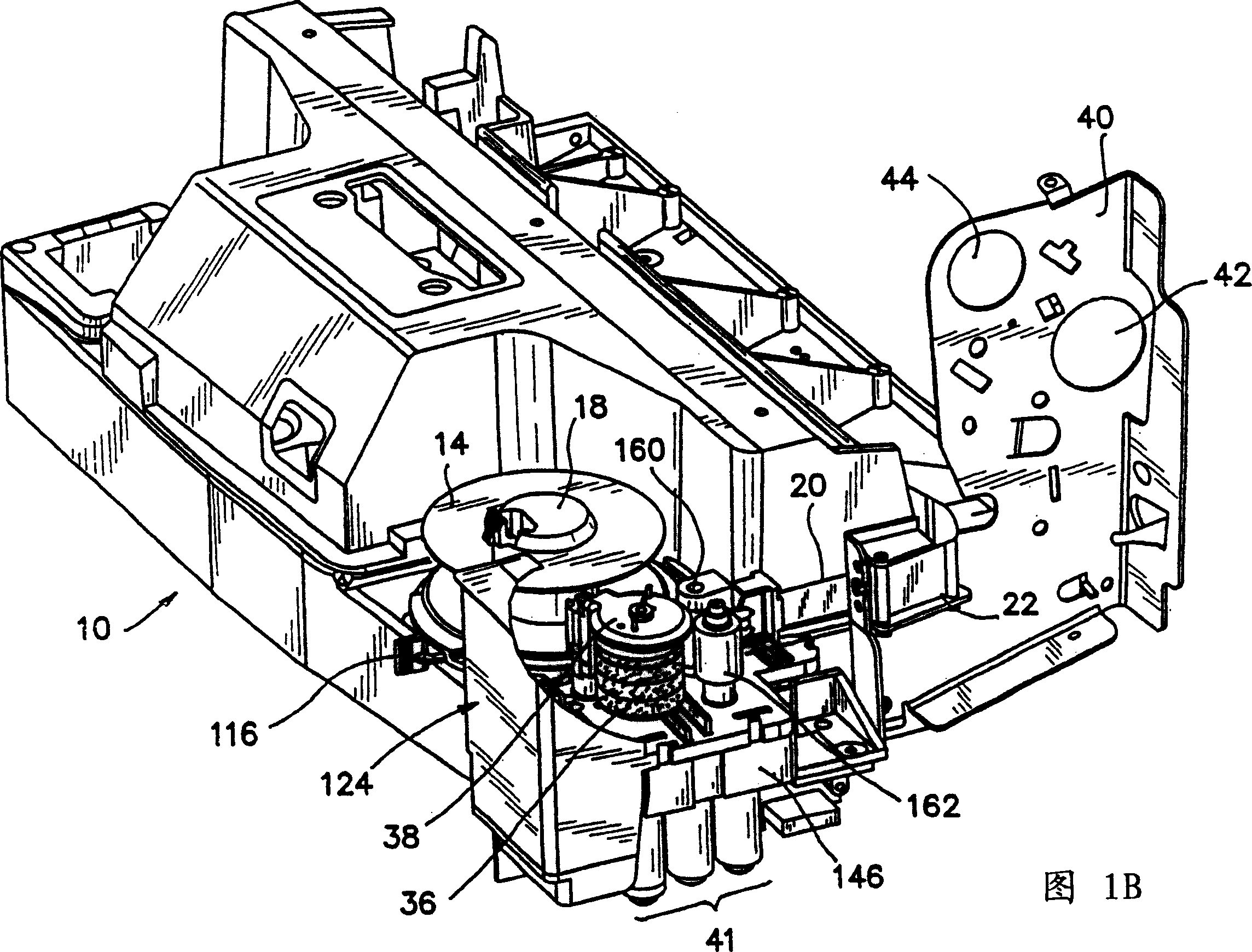

Constant density printer system

An ink density closed loop control system for an ink ribbon of an impact line printer having a reservoir roller fluidly connected to a pump and ink supply. A transfer roller can contact the reservoir roller for imparting ink to the ink ribbon. A sensor senses the relative amount of ink on the print ribbon and an electrical drive responsive to the sensor drives the pump for a flow of ink to the one or more channels. The sensor can sense ink on different segments of the ribbon and, with two or more channels in the reservoir roller can distribute ink to two or more segments of the reservoir roller depending upon the ink sensed at a particular segment of the ribbon. A further enhancement of the invention provides a multi-viscosity ink to compensate for changes in ambient temperature conditions.

Owner:PRINTRONIX INCORPORATED

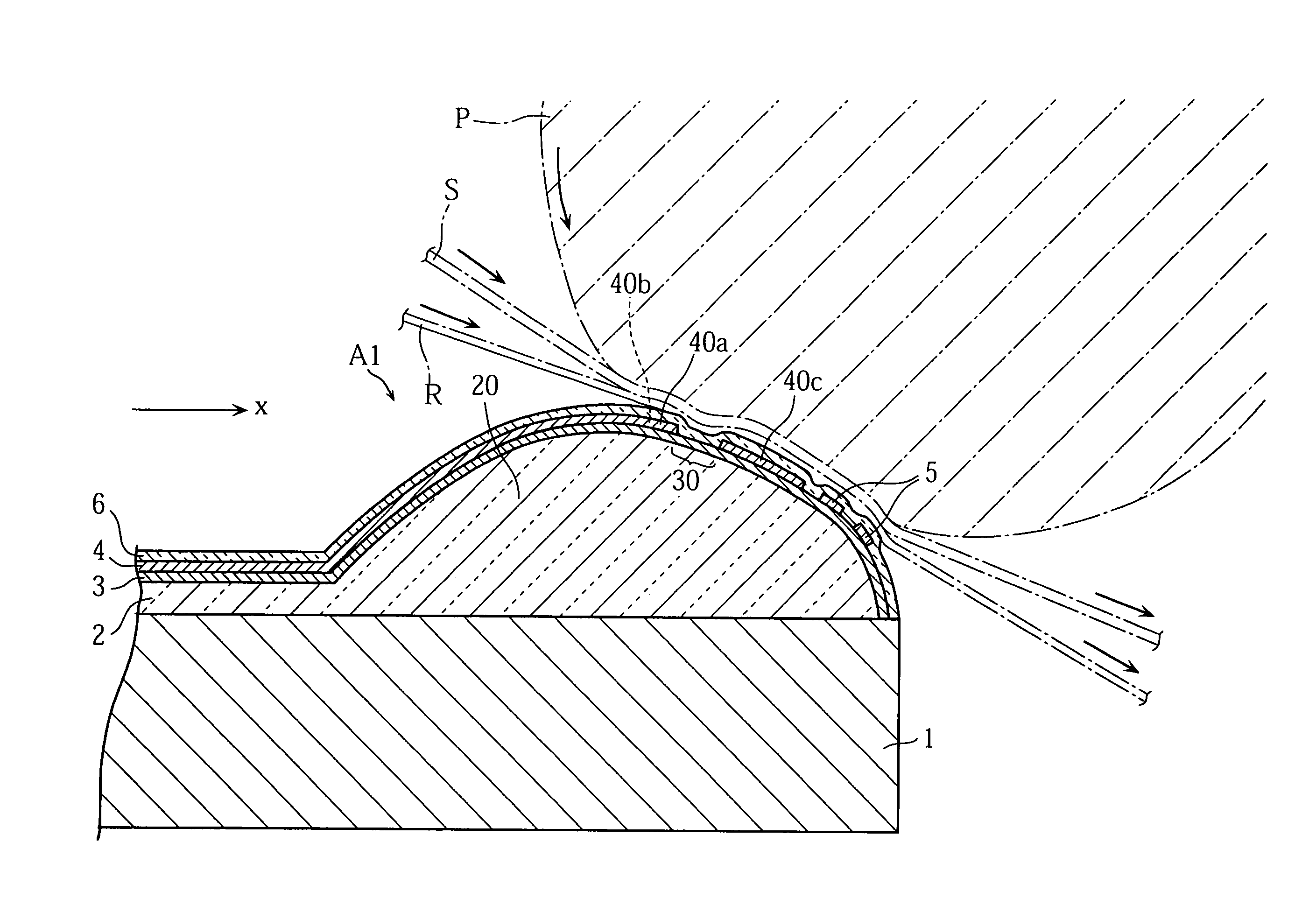

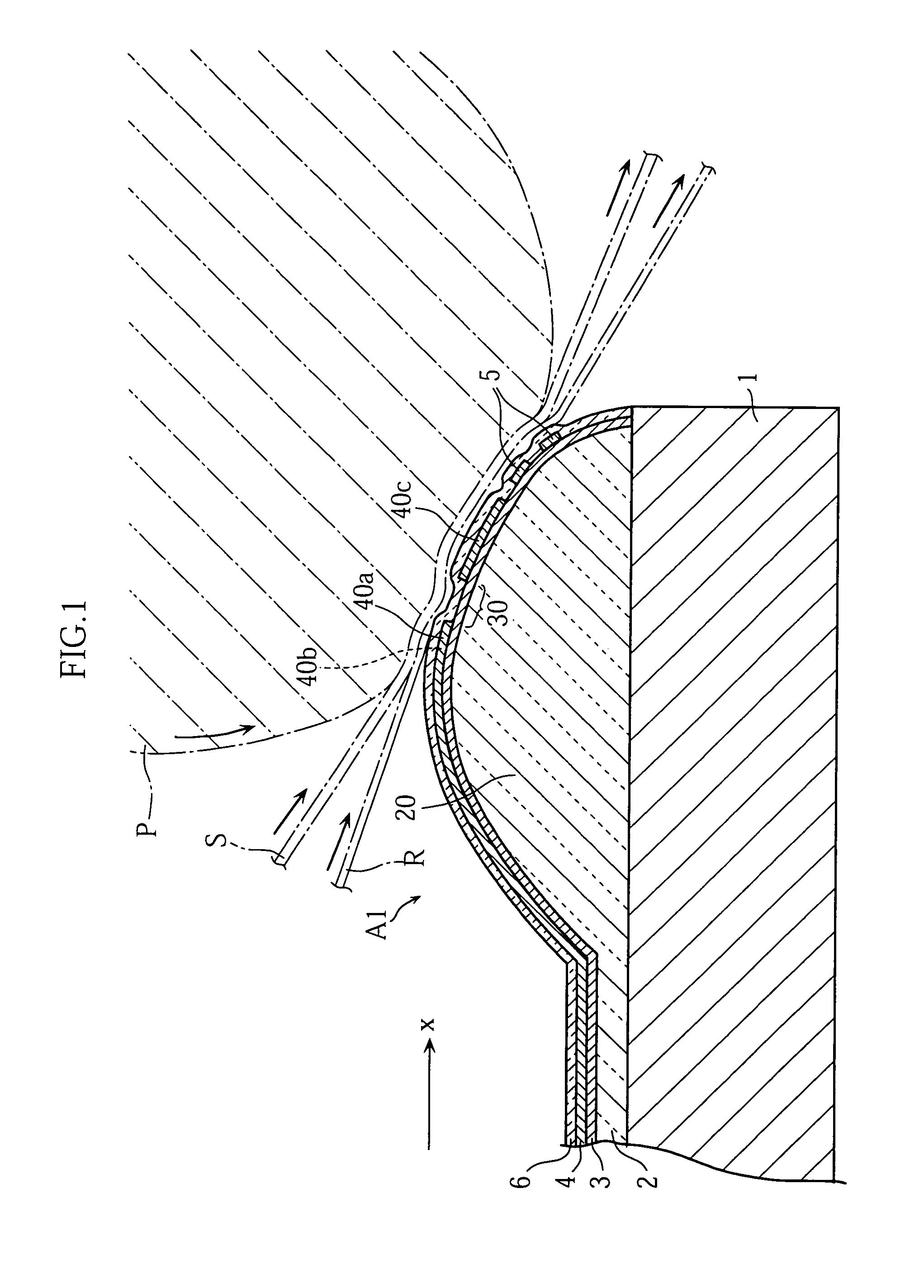

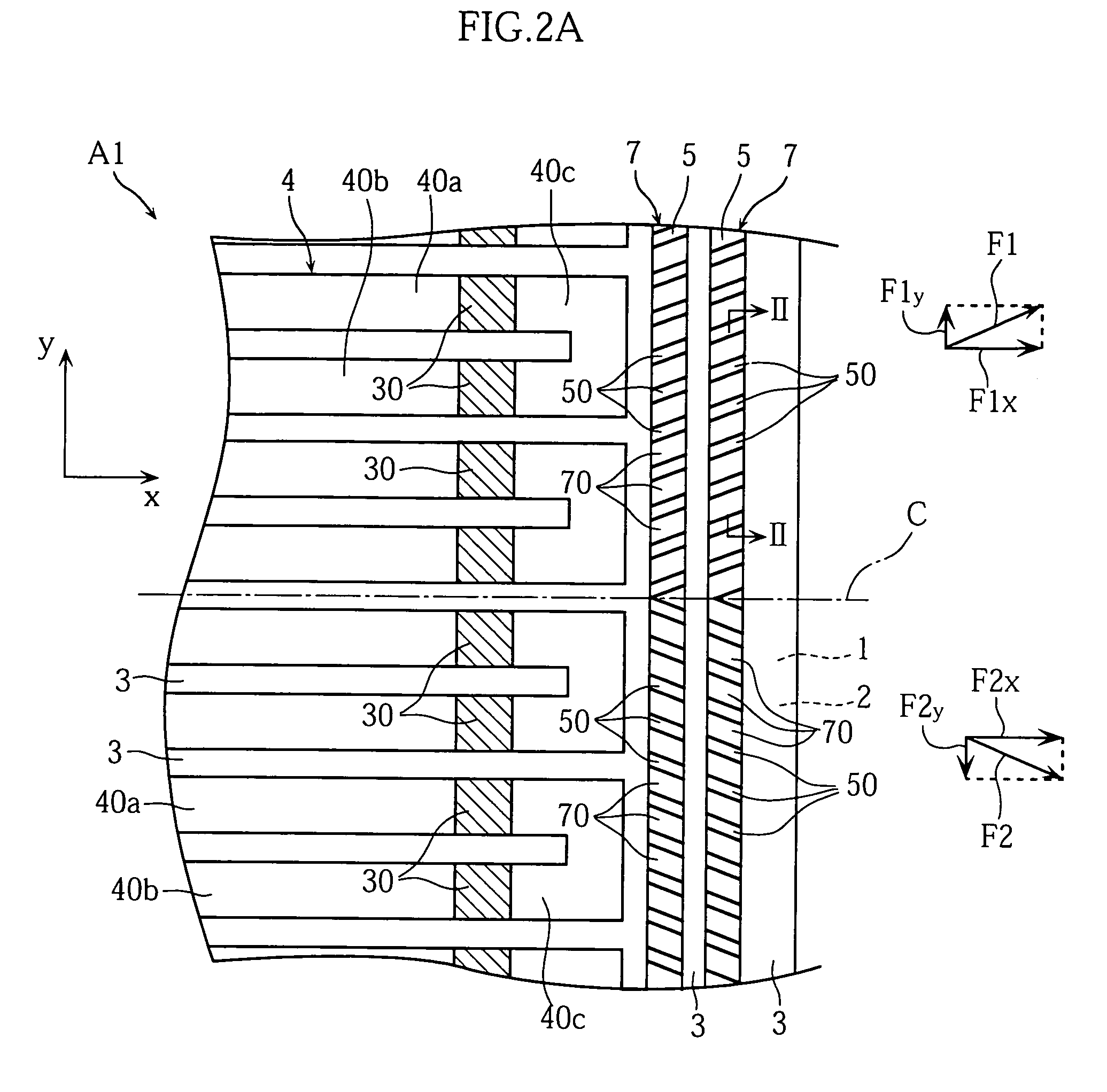

Mask for screen printing, screen printing device and screen printing method employing same

InactiveUS20120216690A1Simple structureAvoid print failuresInking apparatusLiquid surface applicatorsScreen printingEngineering

The screen printing mask is used for printing paste simultaneously on circuit boards held by the carrier. The mask has a flat mask plate. On the lower surface of the mask plate, a flat-bottomed recess capable to accommodating at least one of the circuit boards is formed so as to correspond to the array of the circuit boards on the carrier. A pattern hole is formed only in the recess.

Owner:PANASONIC CORP

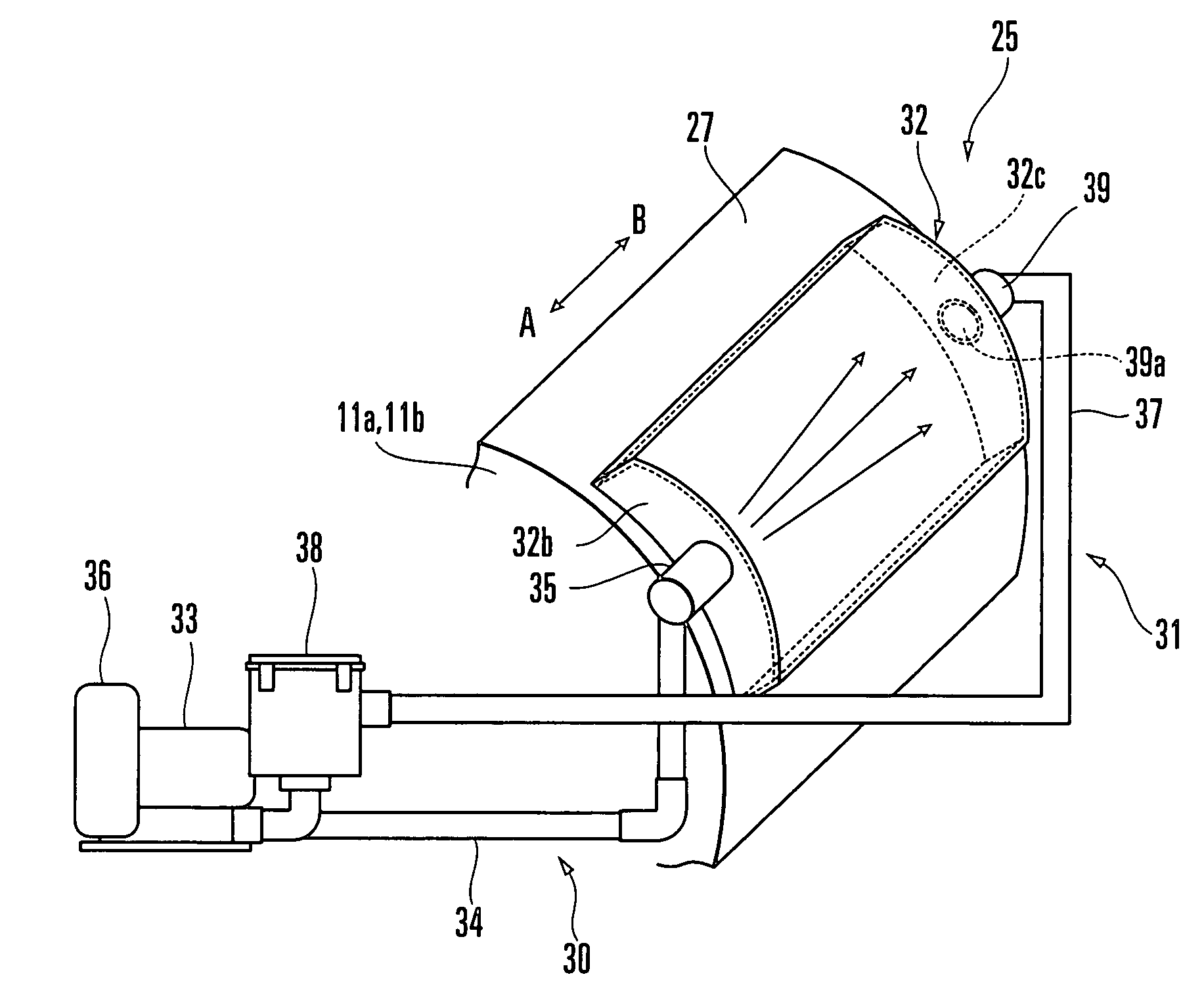

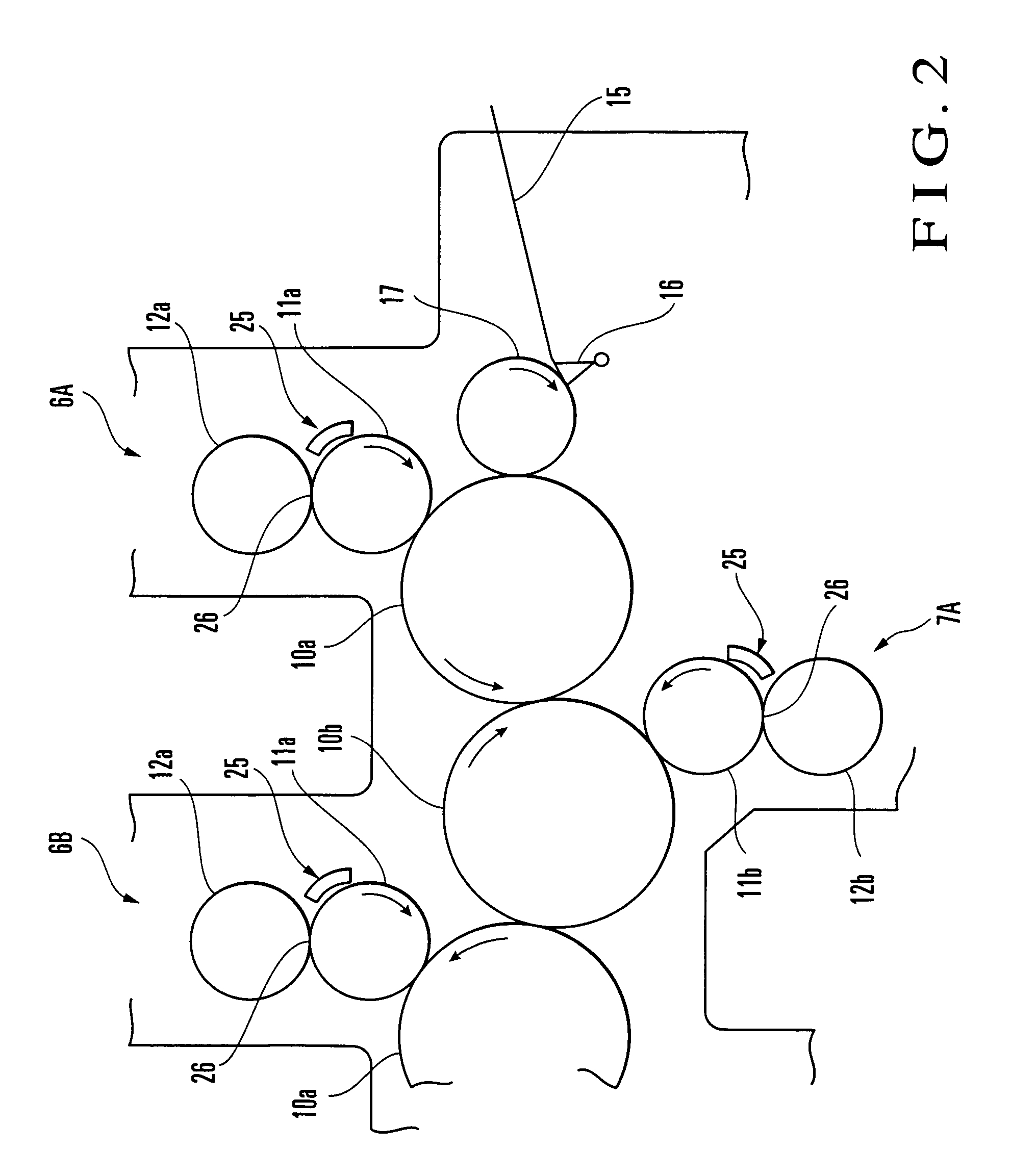

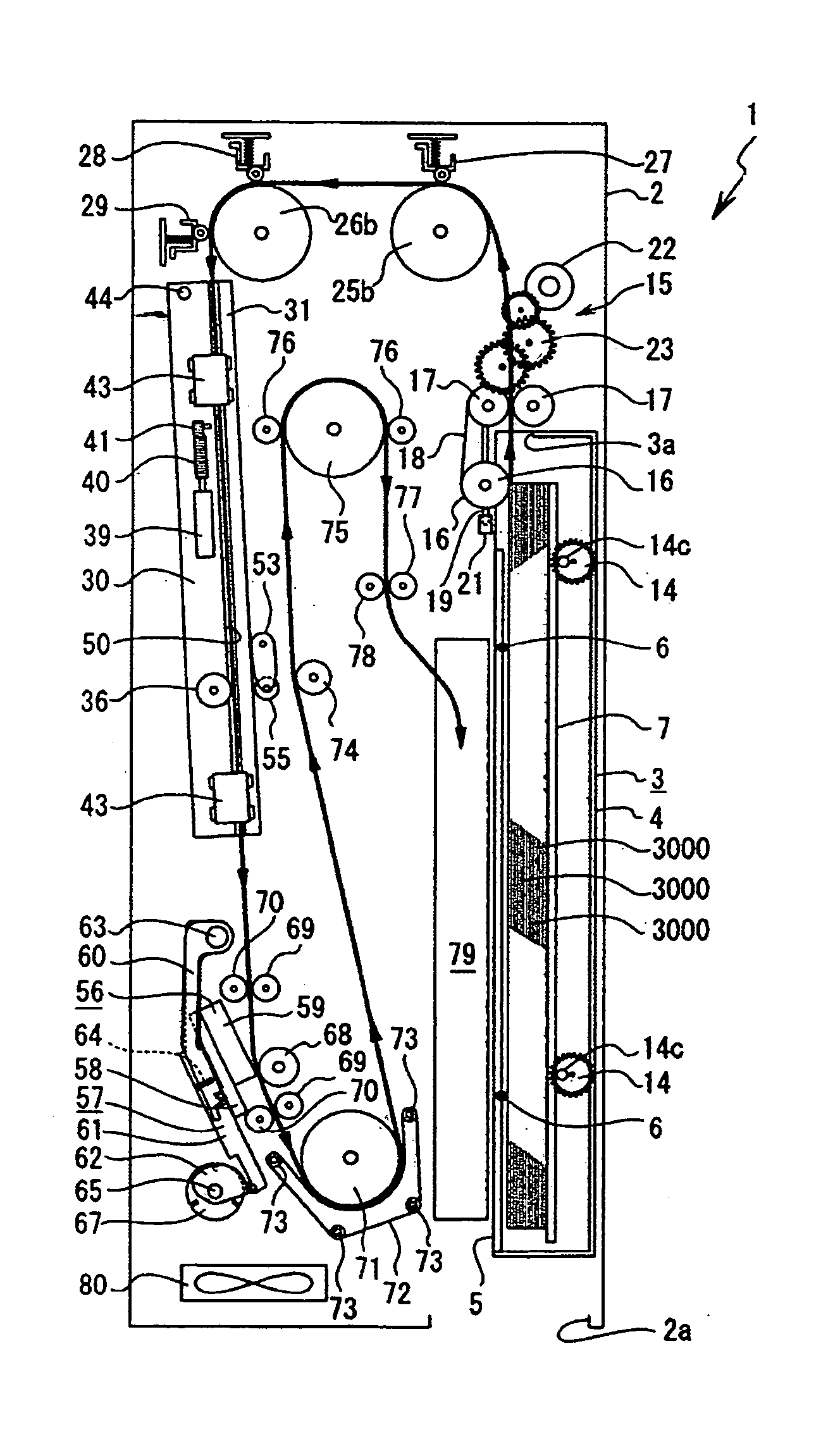

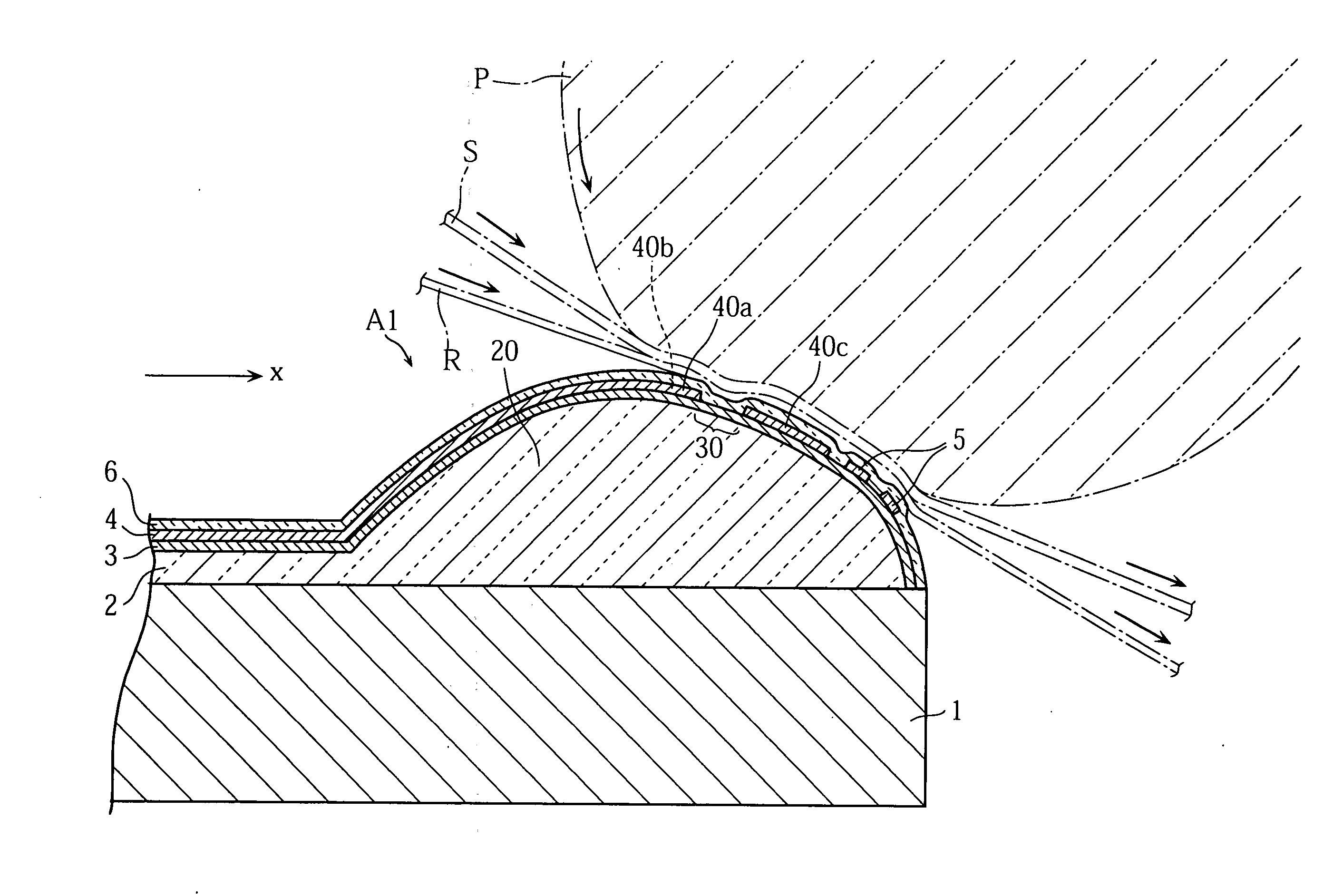

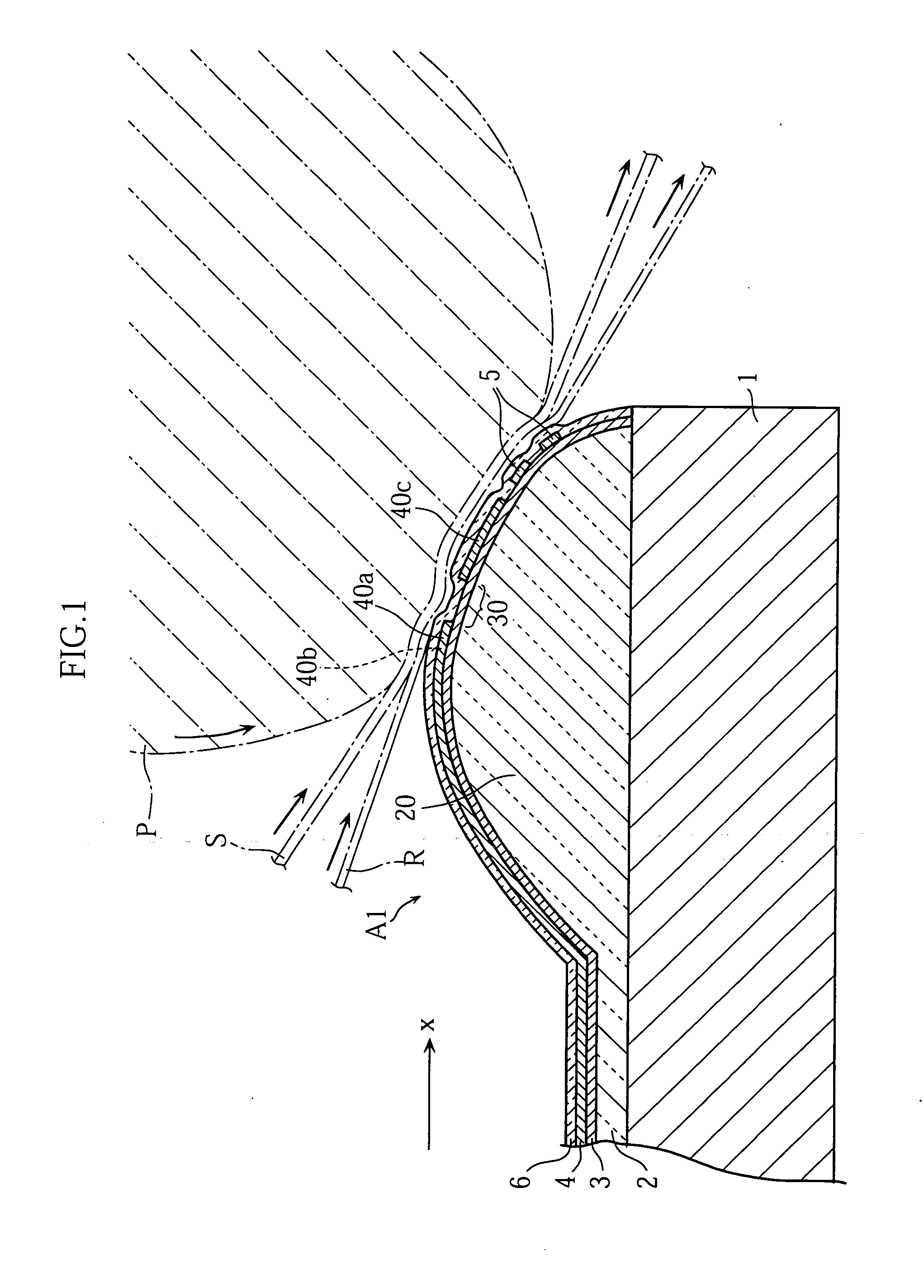

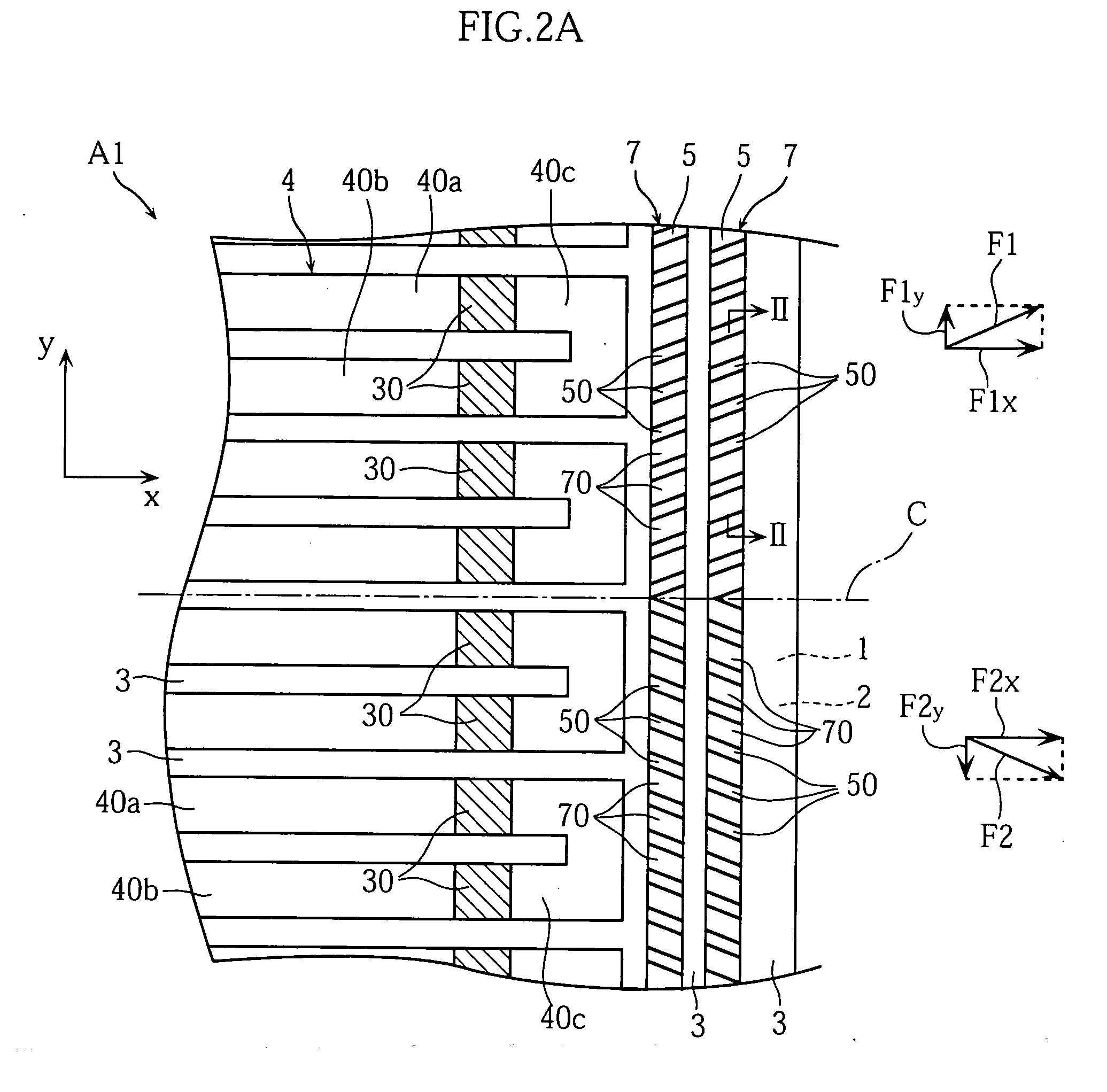

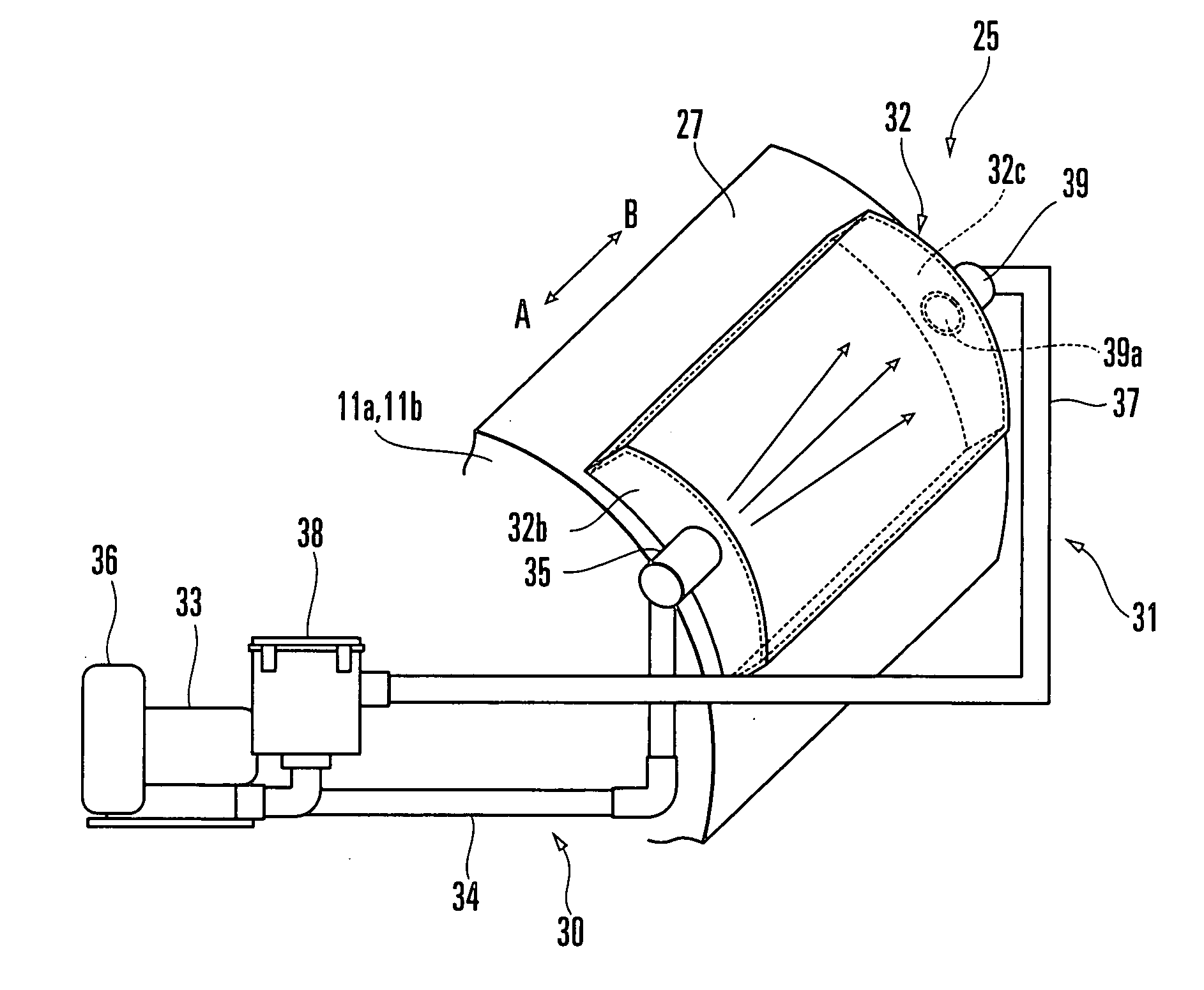

Air blowing device for printing press

InactiveUS7347143B2Avoid print failuresImprove printing qualityAddressographsLetterpress printingSuction equipmentEngineering

An air blowing device for a printing press includes a plate cylinder, blanket cylinder, impression cylinder, air blowing equipment, air suction equipment, and cover. The plate cylinder is rotatably supported. Ink from an inking device and dampening water from a dampening device are supplied to the outer surface of the plate cylinder. The blanket cylinder is rotatably supported in contact with the plate cylinder. The impression cylinder is rotatably supported in contact with the blanket cylinder and cooperates with the blanket cylinder to print on a printing target body under conveyance. The air blowing equipment discharges air from one end side toward the other end side of the blanket cylinder. The air suction equipment takes in air, discharged from the air blowing equipment, at the other end side of the blanket cylinder. The cover forms an air passage extending from the air blowing equipment to the air suction equipment in an axial direction of the blanket cylinder.

Owner:KOMORI CORP

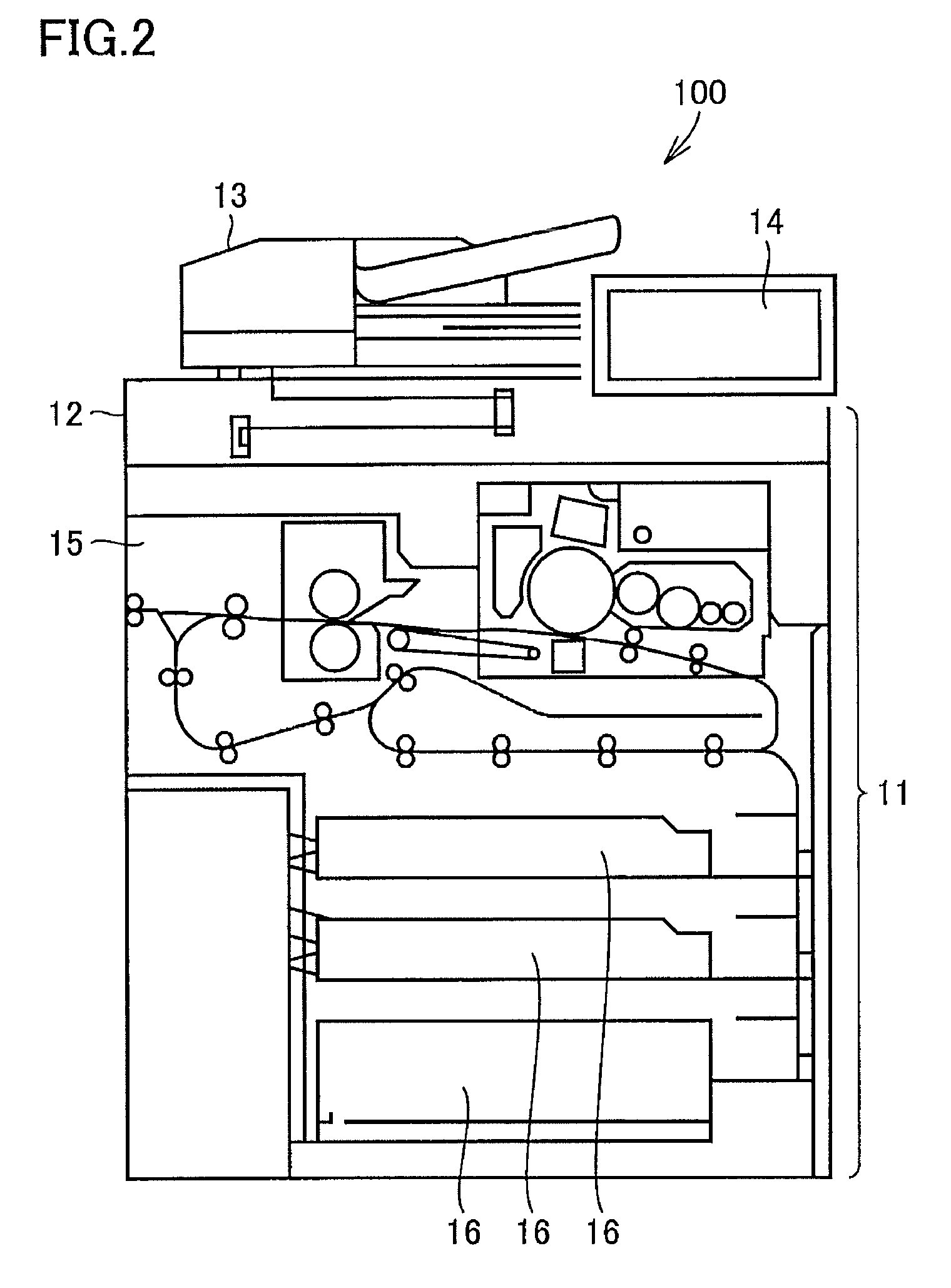

Image forming apparatus performing combine printing

ActiveUS8879114B2Easy to operateAvoid print failuresDigitally marking record carriersVisual presentation using printersImage formationReduction ratio

Owner:KONICA MINOLTA BUSINESS TECH INC

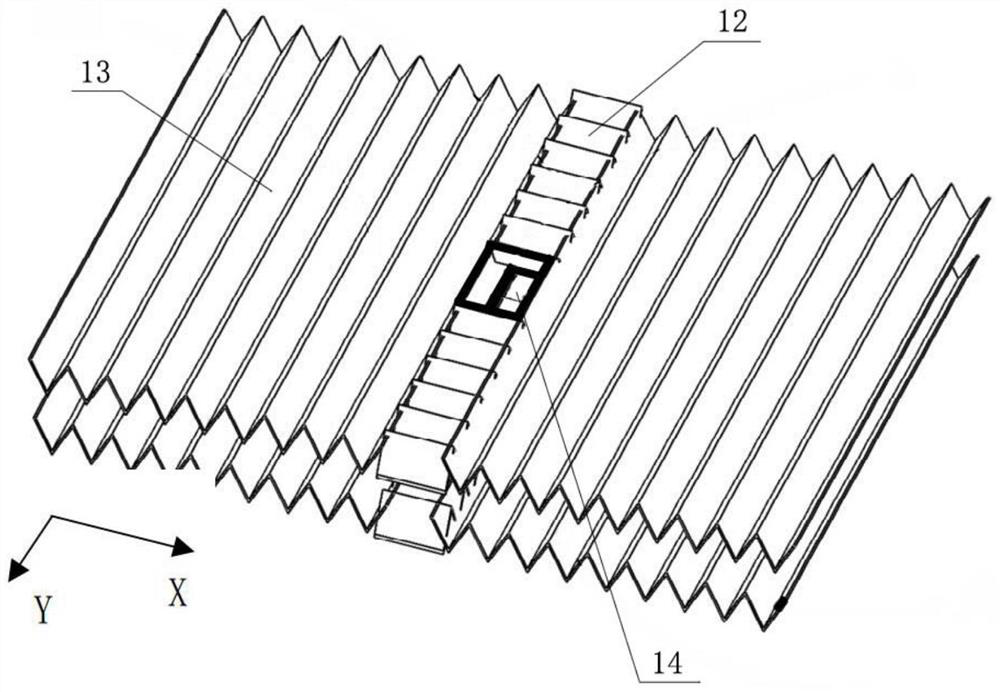

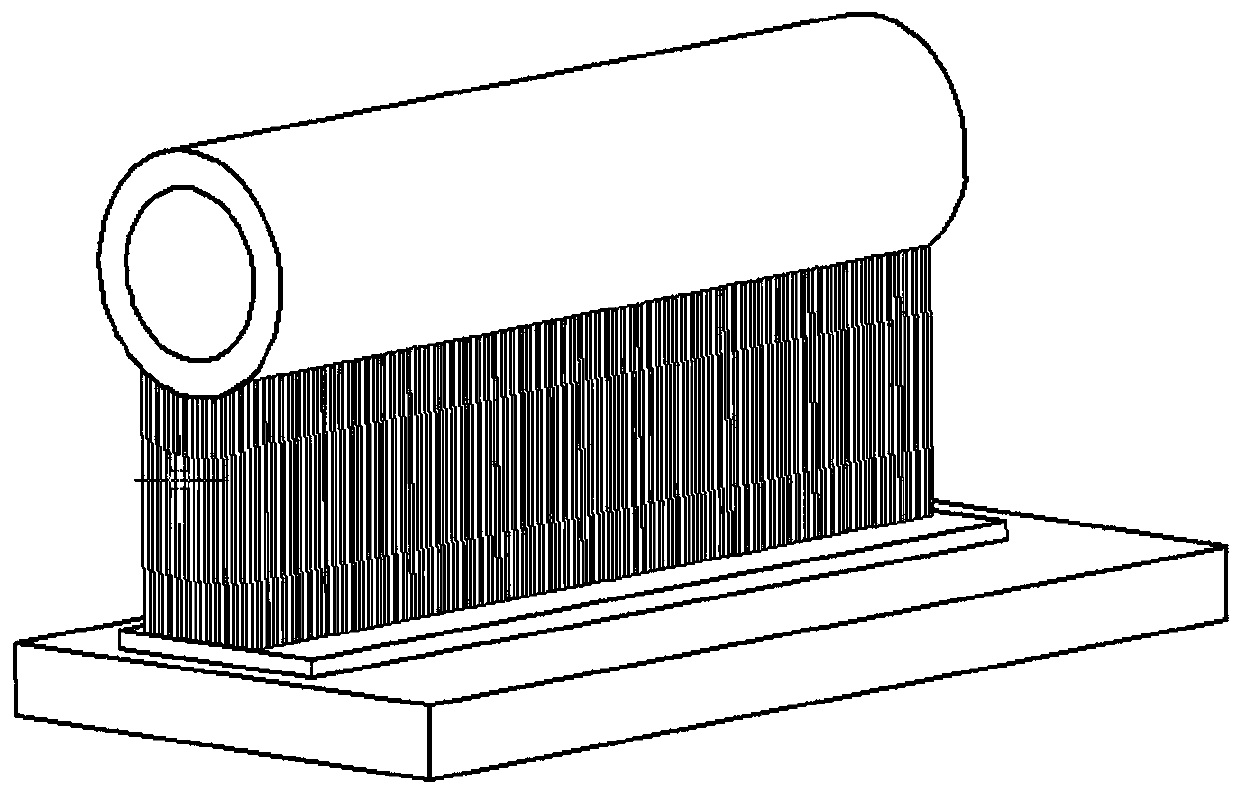

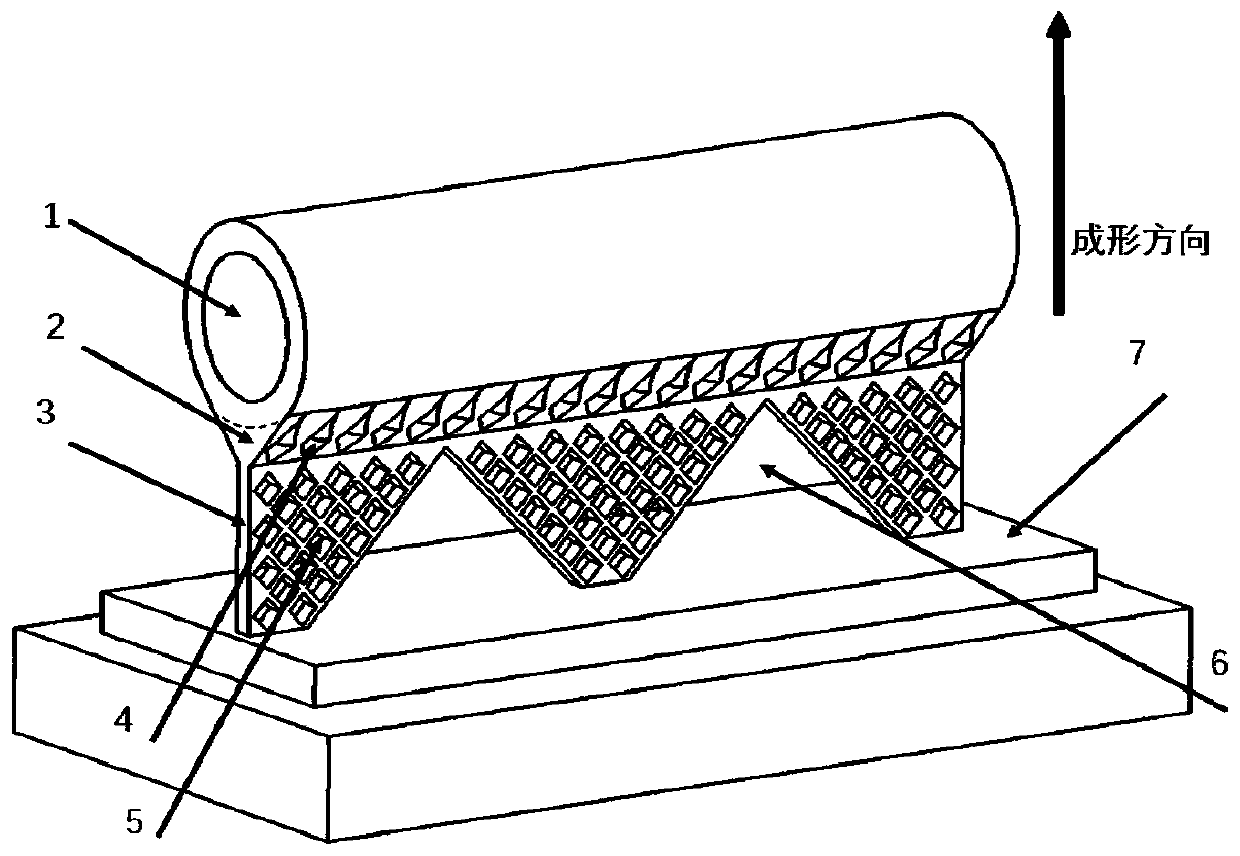

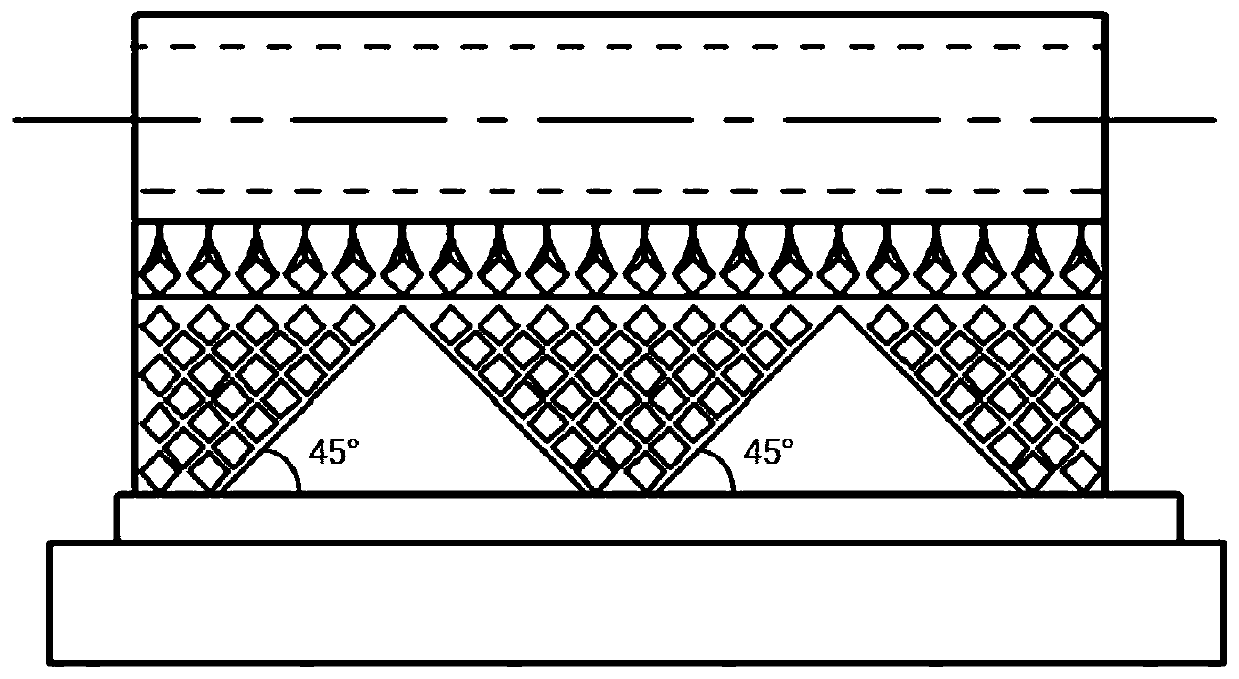

Lightweight active support structure of suspended circular-section flow passage

InactiveCN110465660AHigh thermal conductivityImprove forming qualityAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringActive support

The invention discloses a lightweight active support structure of a suspended circular-section flow passage. The structure comprises a convoluted rhombic active support structure and a stretching poreplate active support structure, the suspended circular-section flow passage is supported on the convoluted rhombic active support structure, and the stretching pore plate active support structure isfixed under the convoluted rhombic active support structure; the stretching pore plate active supporting structure is connected to an installation surface obtained by additive manufacturing, and the forming direction of the suspended circular-section flow passage is perpendicular to the installation surface; and the suspended circular-section flow passage is manufactured and formed by an SLM rapidprototyping technique. The lightweight active support structure realizes one-time forming of the suspended circular-section flow passage in an SLM manufacturing process without post-processing to remove a support, and simultaneously increases the strength and stability of connection of all parts.

Owner:ZHEJIANG UNIV

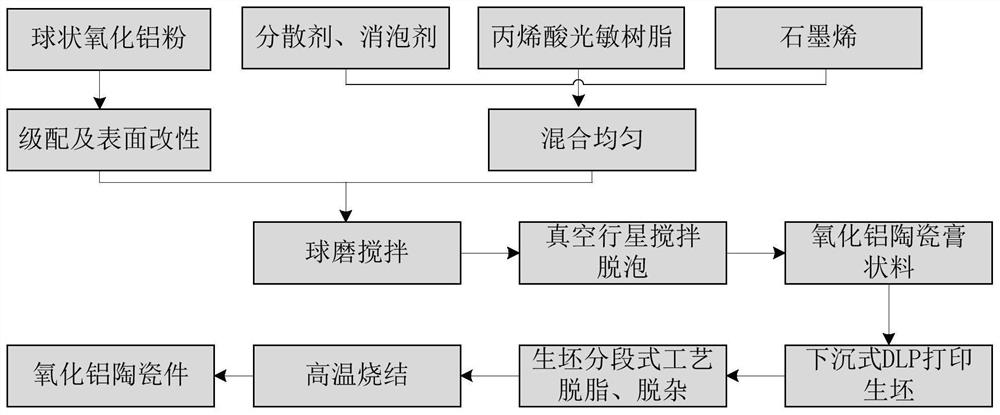

Method for preparing aluminum oxide ceramic based on sinking type DLP photocuring 3D printing

ActiveCN113956023AImprove stabilityReduce deformationAdditive manufacturing apparatusIncreasing energy efficiencyOxide ceramicDefoaming Agents

The invention discloses a method for preparing aluminum oxide ceramic based on sinking type DLP photocuring 3D printing, and the method comprises the following steps of: mixing and stirring aluminum oxide powder, a first dispersing agent and an organic solvent, conducting drying, crushing and sieving to obtain modified aluminum oxide powder, adding graphene, a second dispersing agent and a defoaming agent into acrylic photosensitive resin, performing mixing, then adding modified aluminum oxide powder, carrying out ball milling and defoaming treatment to obtain aluminum oxide ceramic paste, carrying out photocuring 3D printing by adopting a sunken DLP photocuring method, and then carrying out sectional process degreasing treatment and sintering to obtain the aluminum oxide ceramic. The method disclosed by the invention is suitable for preparation and industrial production of the large-size aluminum oxide ceramic piece with low deformation, high precision and complex structure, and the prepared aluminum oxide ceramic has the advantages of few microdefects, high density, good mechanical and physical properties and the like.

Owner:NAT UNIV OF DEFENSE TECH

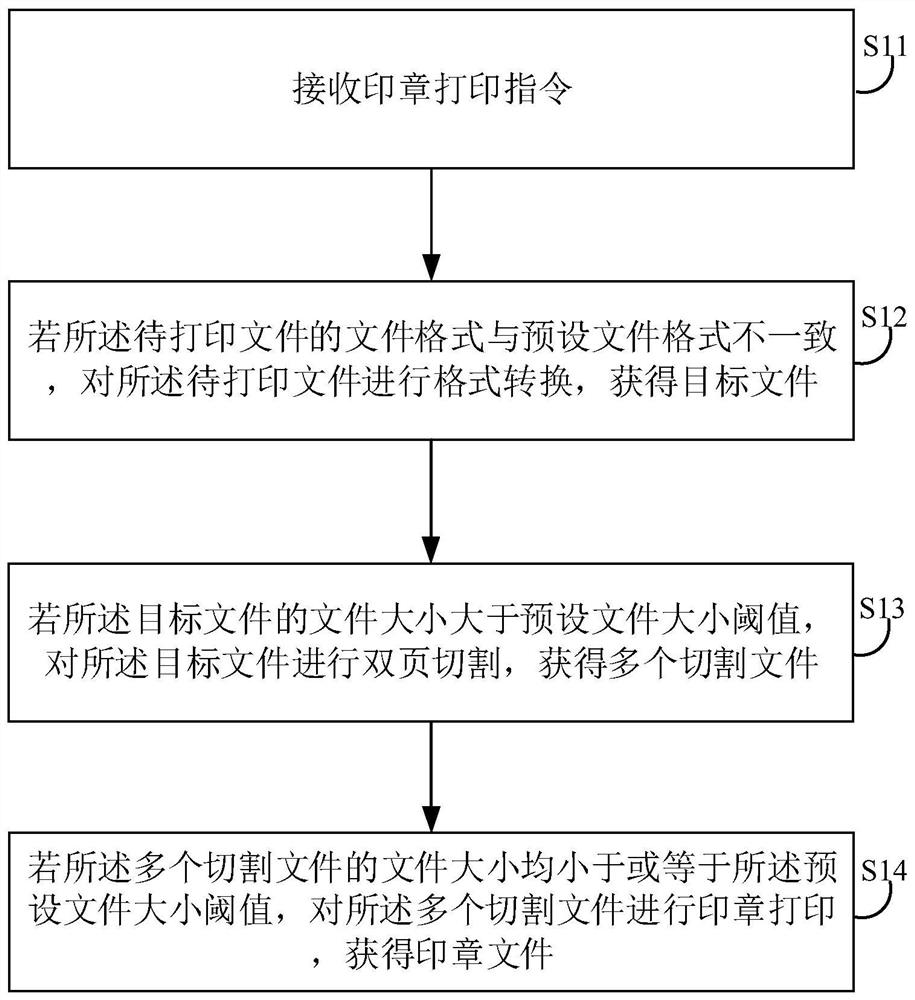

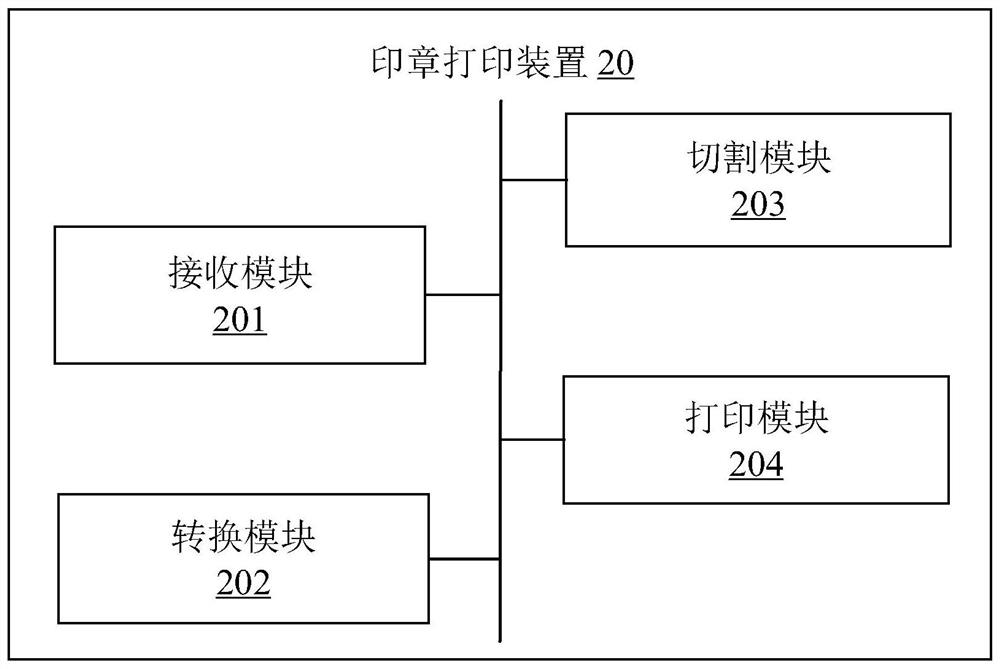

Seal printing method and device, electronic equipment and storage medium

ActiveCN111880752AImprove printing efficiencyGuaranteed normal printingDigital output to print unitsSoftware engineeringSmart government

The invention relates to the technical field of artificial intelligence, and can be applied to the field of smart government affairs, thereby promoting the construction of smart cities. The inventionprovides a seal printing method and device, electronic equipment and a storage medium, and the method comprises the steps: receiving a seal printing instruction which carries a to-be-printed file; ifthe file format of the to-be-printed file is inconsistent with a preset file format, performing format conversion on the to-be-printed file to obtain a target file; if the file size of the target fileis greater than a preset file size threshold, performing double-page cutting on the target file to obtain a plurality of cut files; and if the file sizes of the plurality of cut files are all smallerthan or equal to the preset file size threshold, performing seal printing on the plurality of cut files to obtain a seal file. The seal printing efficiency can be improved. In addition, the inventionfurther relates to a blockchain technology, and the seal file can be stored in a blockchain.

Owner:PING AN TECH (SHENZHEN) CO LTD

Thermal printhead

Owner:ROHM CO LTD

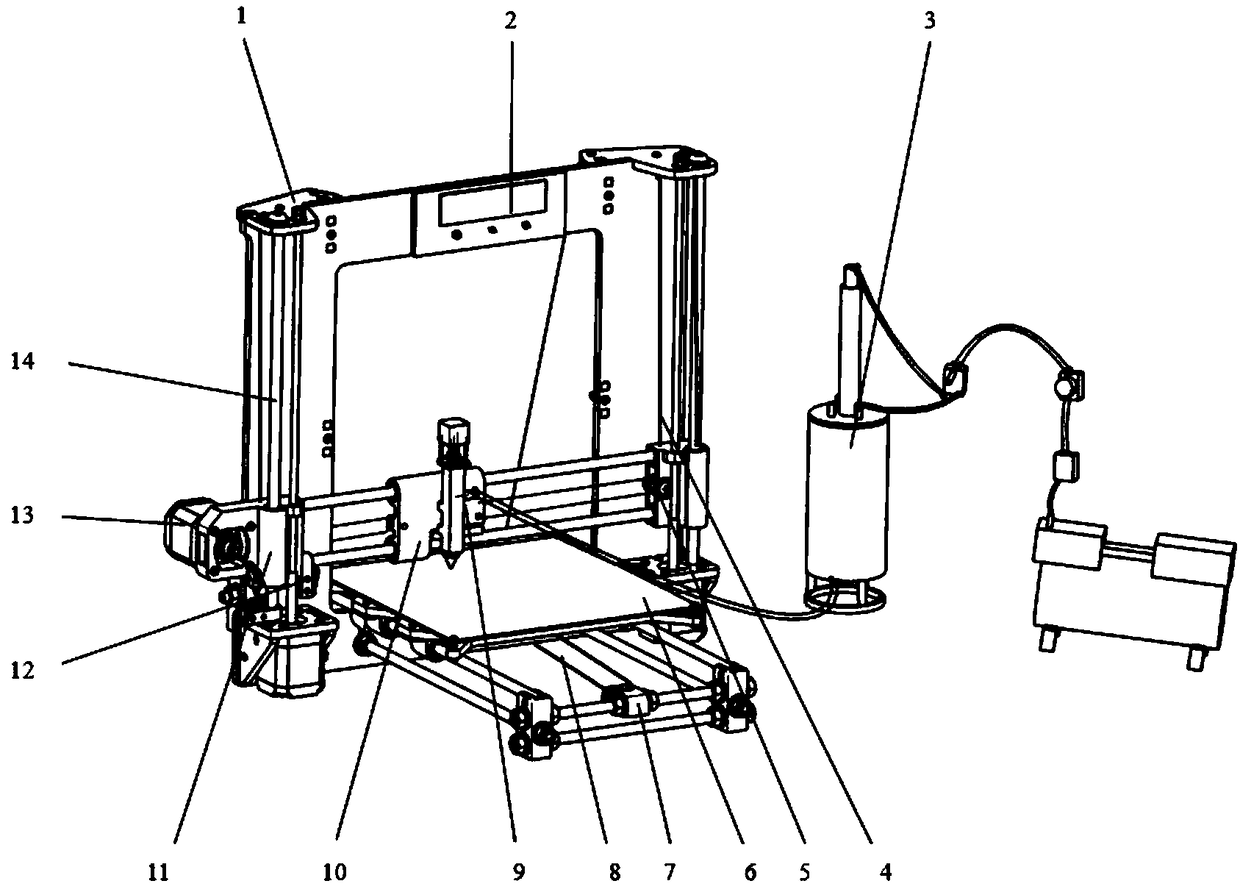

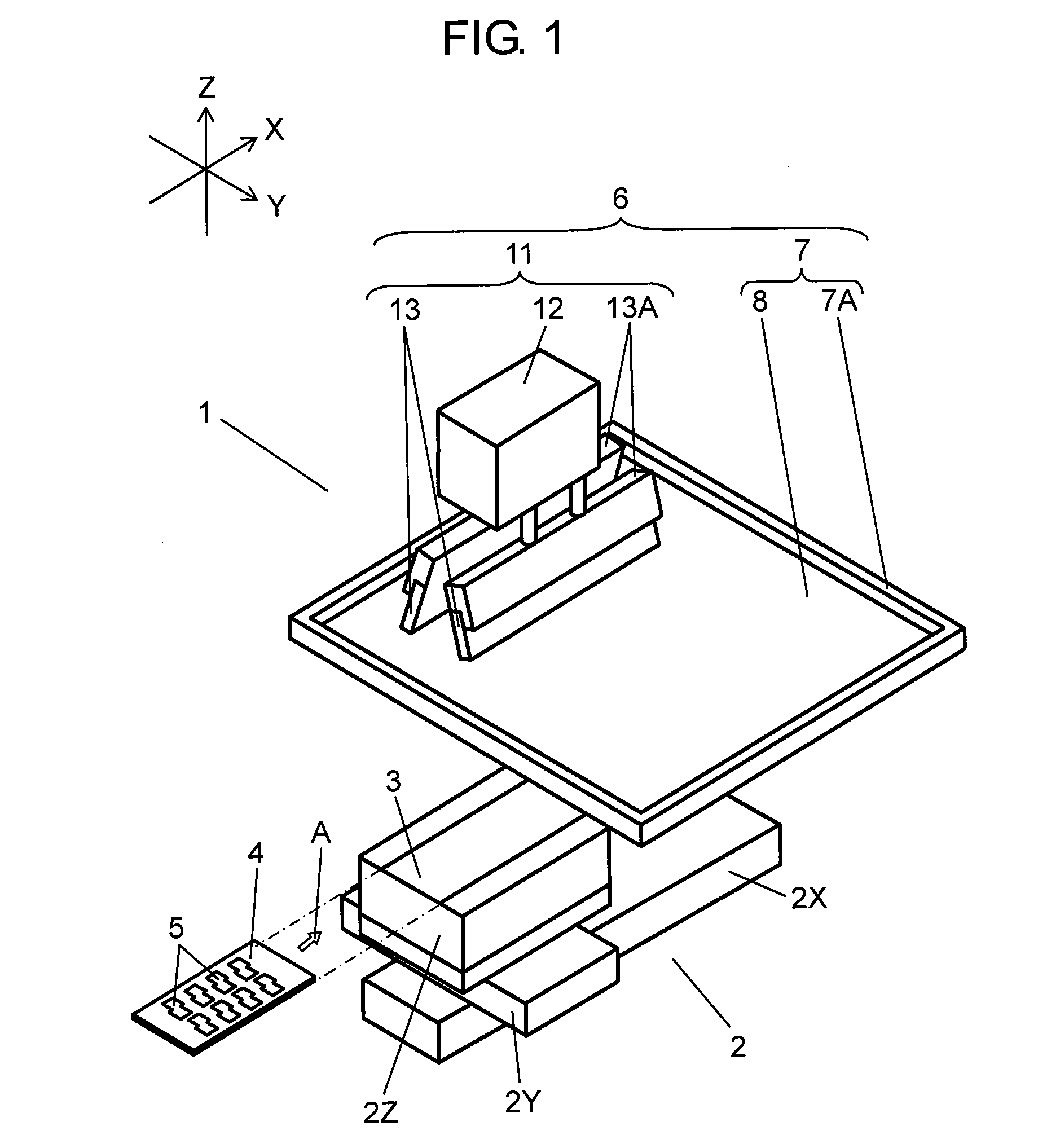

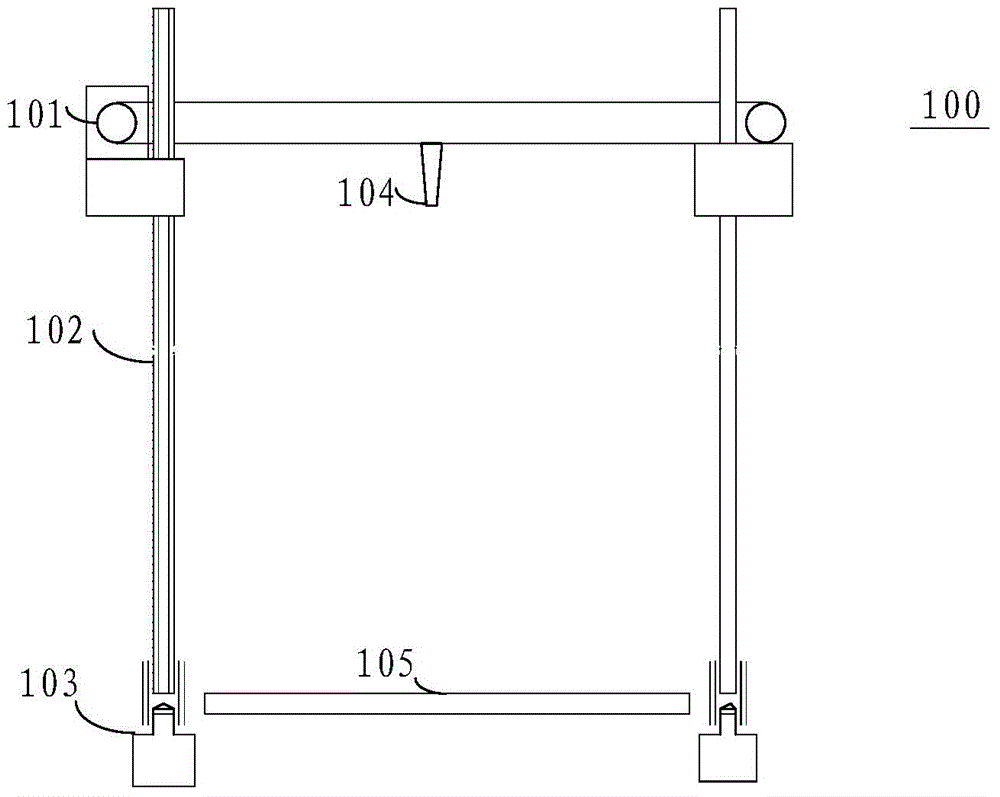

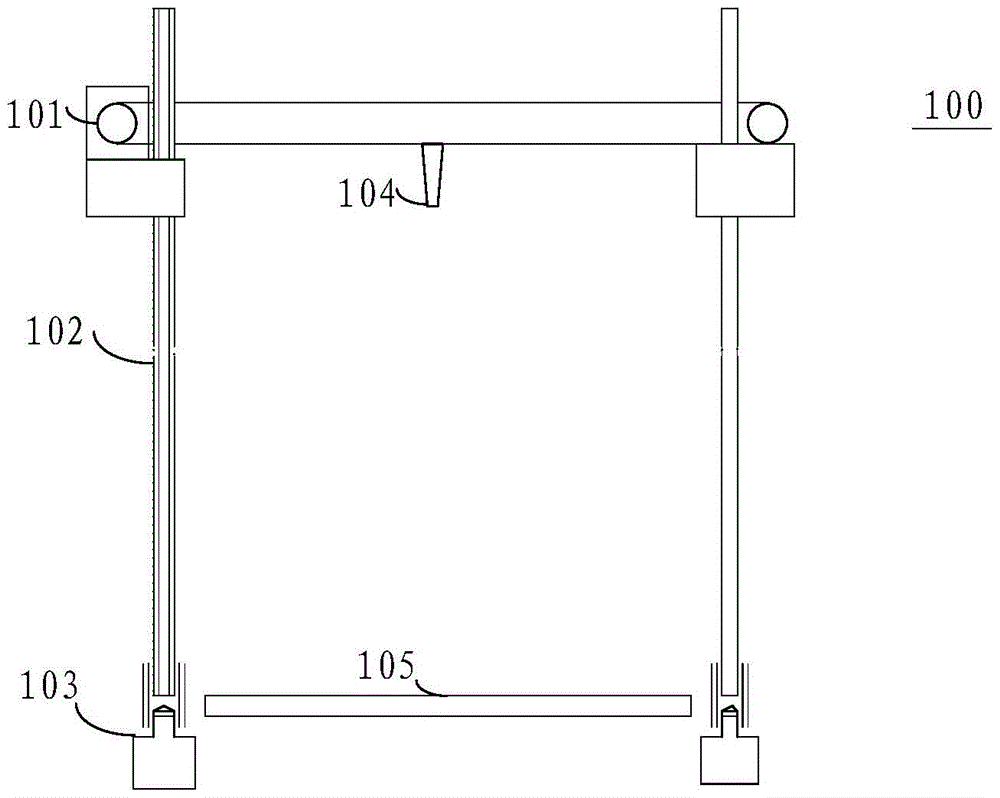

Step mechanism for fused deposition type 3D printer

ActiveCN104816481APrecise positioningAchieve precise positioningAdditive manufacturing apparatusCeramic shaping apparatusEngineering3d printer

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Extrusion device of three-dimensional printer and optical detection mechanism thereof

InactiveCN107471627AAvoid print failuresShorten the timeAdditive manufacturing apparatus3D object support structuresEngineeringOptical sensing

The invention discloses an extrusion device of a three-dimensional printer. The extrusion device comprises a ratchet, a nozzle, a pressurization idle pulley, a feeding rotary table and an optical detection mechanism, wherein the nozzle and the pressurization idle pulley are arranged near the ratchet; hot melting materials are fed to the nozzle by the feeding rotary table; and the optical detection mechanism comprises a guide assembly and an optical sensing assembly, the guide assembly is arranged between the ratchet and the feeding rotary table on a feeding path, and the optical sensing assembly is arranged near the guide assembly. When the ratchet rotates, the hot melting materials are driven to pass through the guide assembly, the ratchet and the pressurization idle pulley by the ratchet and friction between the hot melting materials and then are extruded by the nozzle, the hot melting materials are partially guided to be arranged in a sensing area by the guide assembly, wave band light is emitted to the sensing area by the optical sensing assembly, and an image generated by the wave band light reflected by the sensing area is sensed. Thus, the operation of a machine table can be fully monitored.

Owner:TECO IMAGE SYST

Convenient 3D printing equipment

InactiveCN113001963AFast limit fixationAvoid print failuresAdditive manufacturing apparatus3D object support structuresComputer printingSlide plate

The invention discloses convenient 3D printing equipment. The convenient 3D printing equipment comprises a box body, a mechanical arm, a spray gun, a fixed sleeve, fixed plates and a mounting mechanism.The mechanical arm is fixedly mounted at the top of the inner wall of the box body. The spray gun is fixedly mounted in the box body through a material conveying pipe. The fixed sleeve is fixedly mounted on the surface of the spray gun. The fixed plates are fixedly welded to the two ends of the side, adjacent to the mechanical arm, of the fixed sleeve. The mounting mechanism comprises a sliding plate, a spring, a second mounting groove and an insertion rod, and the second mounting groove is formed in one side of the bottom of the mechanical arm. The problems that most existing convenient 3D printing equipment adopts mechanical arms to drive spray guns to move to achieve printing, the mechanical arms and the spray guns are basically fixedly mounted through bolts, due to the fact that the bolts are prone to slipping in the mounting process, the spray guns and the mechanical arms shake, and the use requirement is not met are effectively solved.

Owner:威海杰凯智能科技有限公司

Photocuring 3D printer and printing method thereof

ActiveCN114683545AReduce labor costsAvoid print failuresAdditive manufacturing apparatus3D object support structuresEngineeringVideo camera

The invention relates to the technical field of 3D printing, and discloses a photocuring 3D printer and a printing method thereof.The photocuring 3D printer comprises a stock bin, a light source assembly, a camera shooting mechanism, a controller and an alarm; the stock bin is provided with an accommodating cavity for accommodating a liquid photosensitive material; the light source assembly is arranged on the edge of the opening of the containing cavity and used for forming a preset light spot on the liquid level of the photosensitive material, and the area of the preset light spot is reduced along with descending of the liquid level of the photosensitive material; the camera shooting mechanism is arranged on the stock bin and used for collecting an in-cavity image of the photosensitive material in the containing cavity; the controller is used for receiving the intracavity image and calculating the area of a preset light spot in the intracavity image; the alarm is used for giving out a material shortage alarm when the preset light spot area is smaller than or equal to a preset value. The remaining amount of the photosensitive material in the stock bin is automatically monitored, the labor cost is reduced, and meanwhile printing failure caused by insufficient liquid photosensitive material is avoided.

Owner:SHENZHEN ELEGOO TECH CO LTD

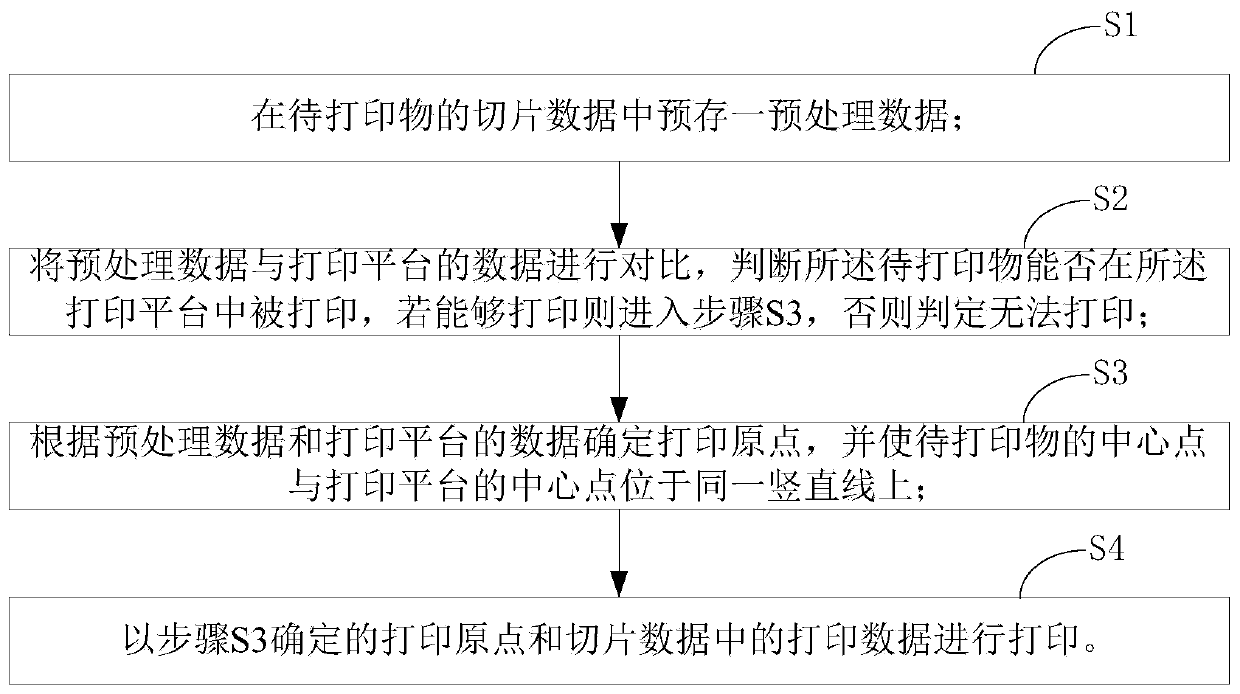

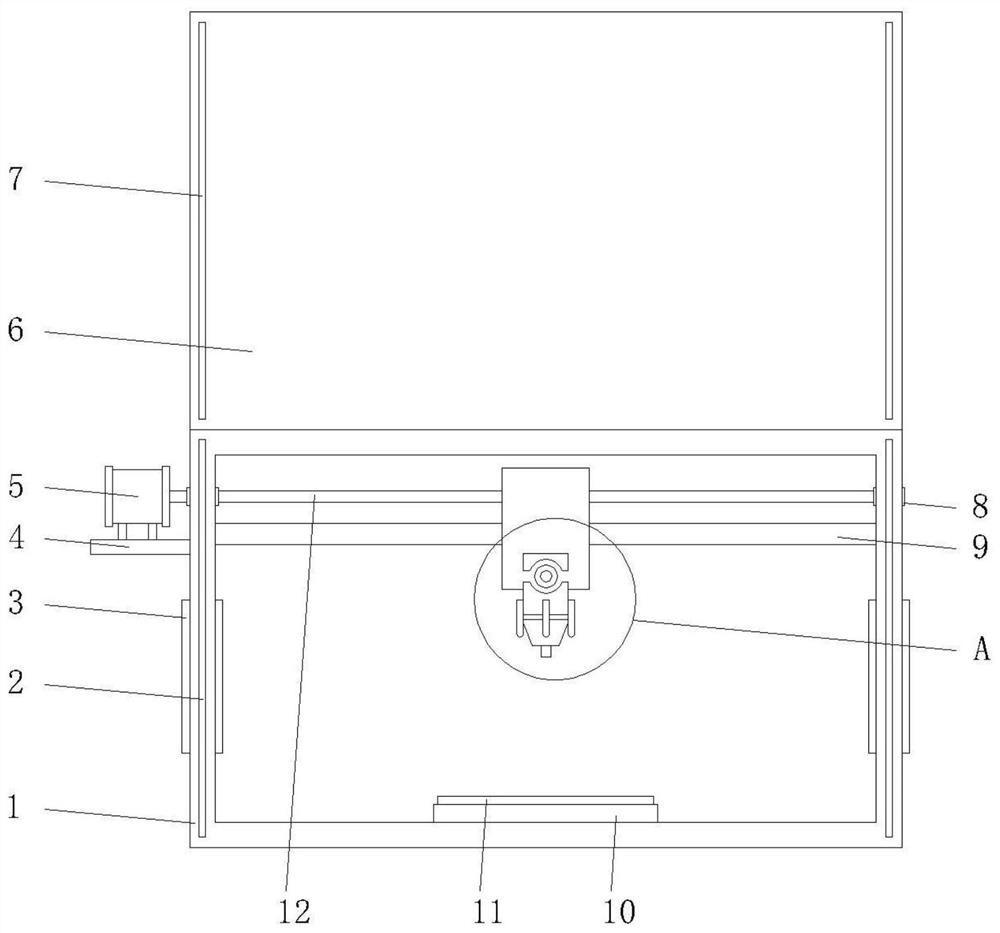

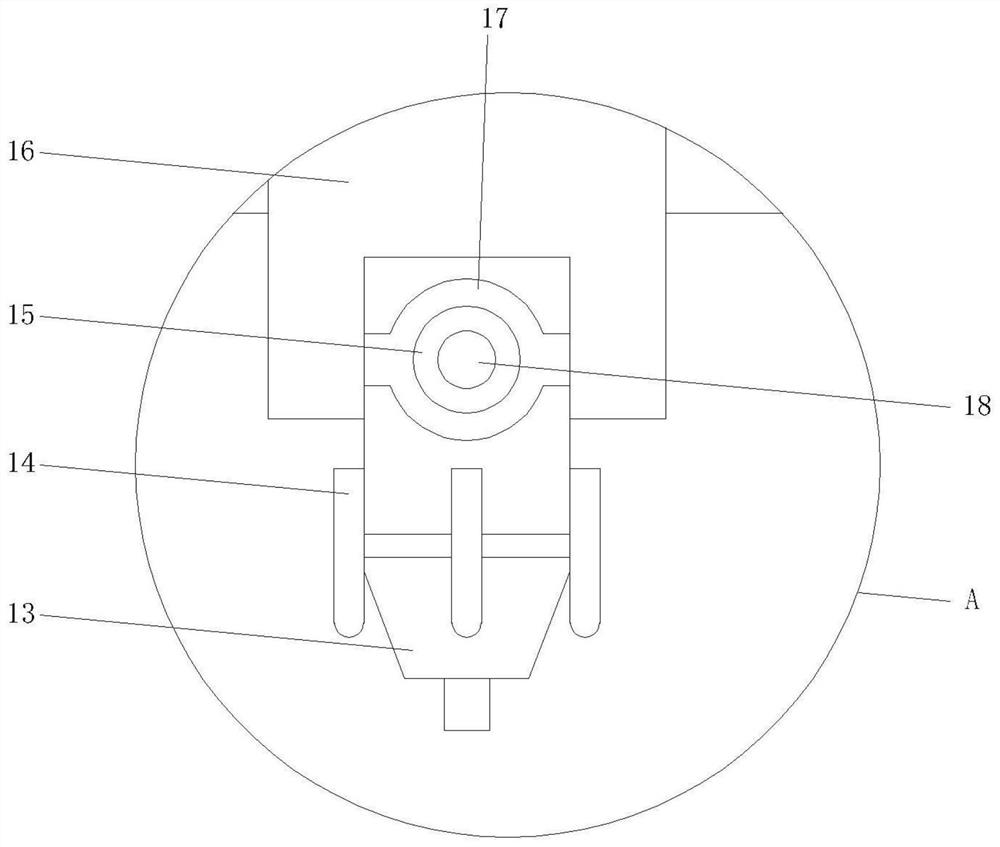

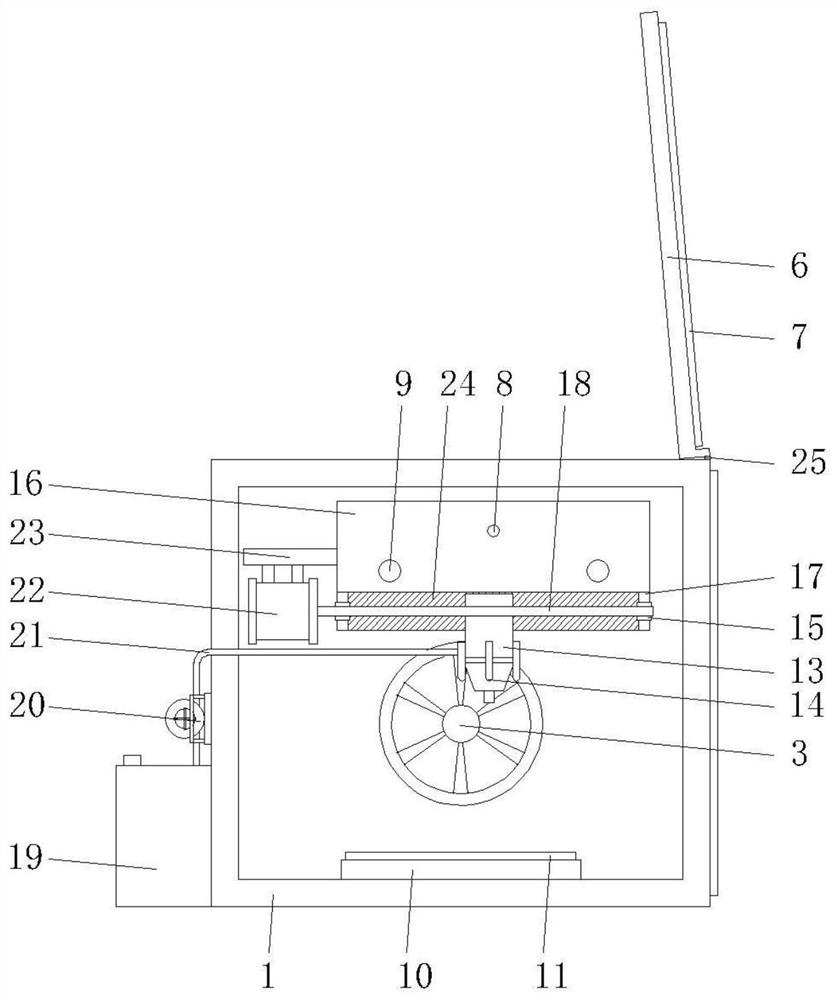

A Compatible 3D Printing Method for Slicing Data

ActiveCN106696276BImprove printing efficiencyAvoid print failuresAdditive manufacturing apparatusManufacturing data aquisition/processingDatabase3D printing

Owner:武汉达玩科技有限公司

Laser-based 3D printing system

InactiveCN112622263APrevent collapseAvoid print failuresManufacturing platforms/substrates3D object support structuresComputer printingEngineering

The invention relates to a laser-based 3D printing system. The laser-based 3D printing system comprises a machine shell, a dustproof cover, sliding rods, a first lead screw, a printing head, a second lead screw, a second servo motor and a second supporting frame, holes are formed in the upper portions of the two sides of the machine shell, first bearings are embedded in the holes, and the inner walls of the two first bearings are fixedly connected with the two ends of the first lead screw correspondingly. The two sides of the inner wall of the machine shell below the first lead screw are fixedly connected with one end of each sliding rod respectively, a movable block is installed on the first lead screw in a threaded mode, a stock bin is fixedly installed below the rear end of the machine shell, the front end of the upper surface of the machine shell is rotationally connected with the dustproof cover through a hinge, and holes are formed in the two sides of the machine shell and provided with fans in an embedded mode. A storage table is fixedly connected to the bottom end of the inner side of the machine shell. The problems of slow solidification, being prone to collapse a model, being prone to adhesion between the model and the bottom of a printer, complex structure of the printer and inconvenient maintenance are solved.

Owner:丹阳天禄三维科技有限公司

Method for producing reversible thermosensitive recording medium, production apparatus for the same, and reversible thermosensitive recording medium

InactiveUS8778107B2Improve accuracyAvoid recordingLamination ancillary operationsControlling laminationRecord elementElectronic information

The present invention provides a method for producing a reversible thermosensitive recording medium, the method including: conveying an inlet sheet which includes inlets each having a convex-shaped electronic information recording element, retrieving positional information of the inlets, cutting the inlet sheet into individual inlets, retrieving positional information of the convex-shaped electronic information recording element in the individual inlets, conveying a base sheet, which includes concave portions, toward the vacuum suction roller, retrieving positional information of the concave portions, aligning the convex-shaped electronic information recording element with the concave portions so as to be inserted into the concave portion, and laminating the inlets and the base sheet.

Owner:RICOH KK

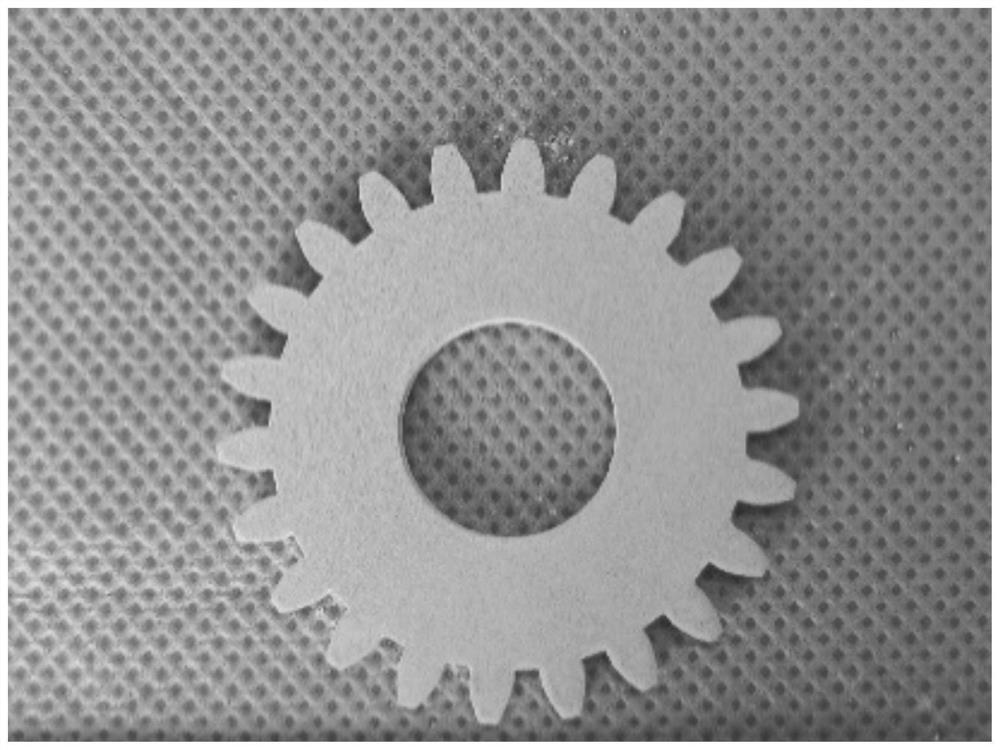

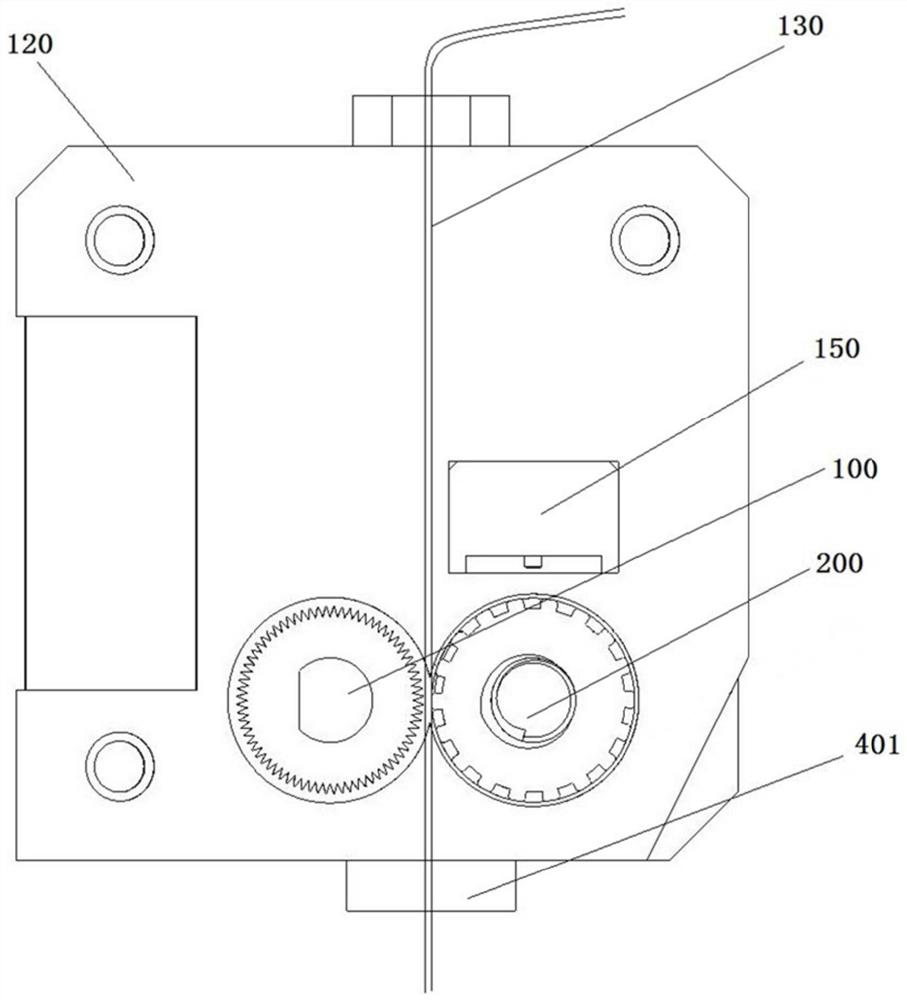

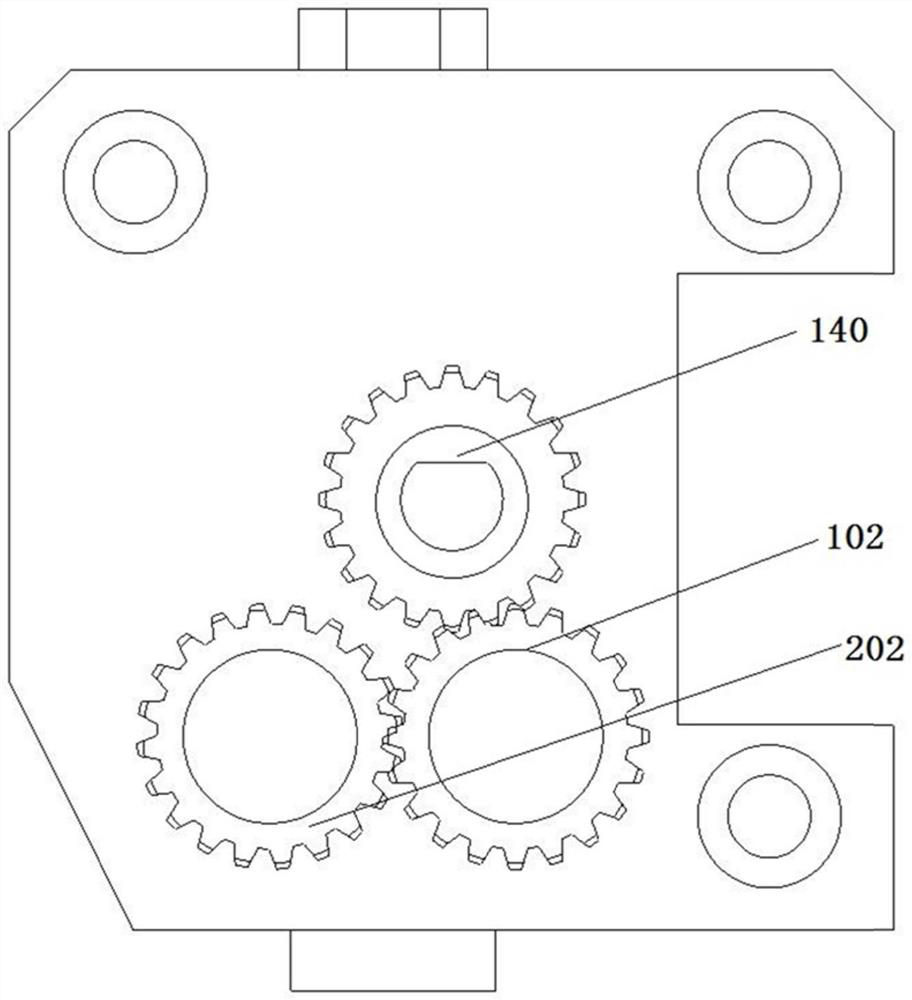

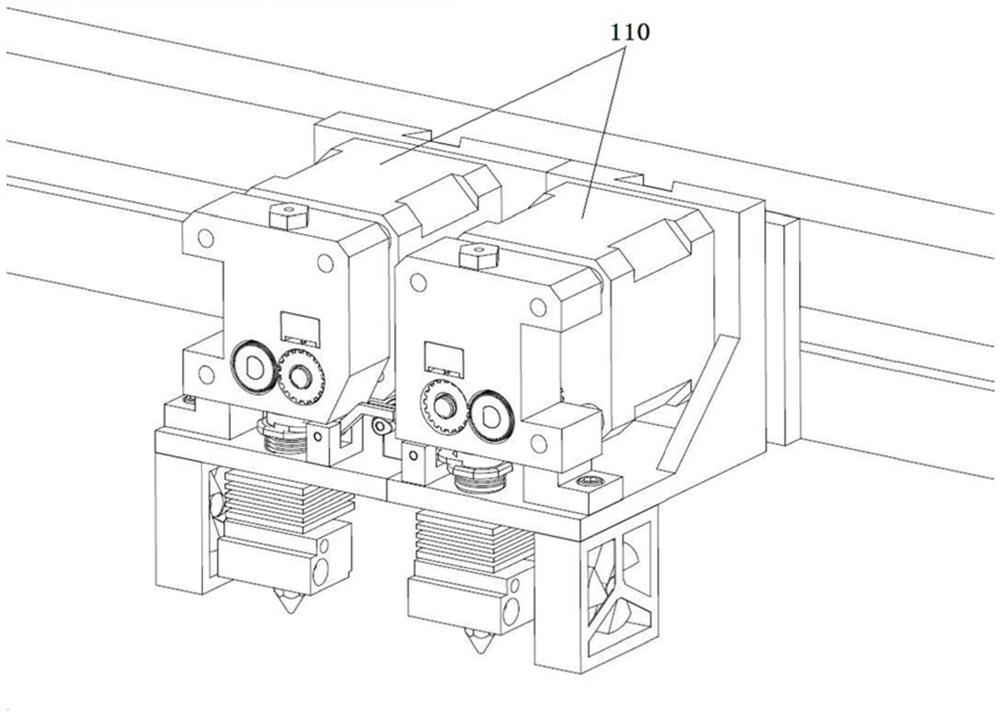

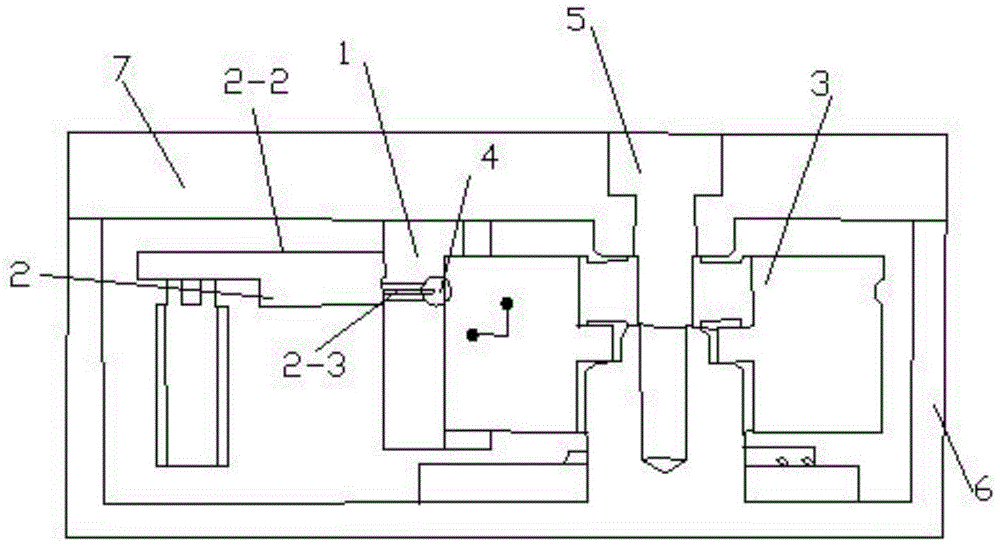

A 3D printing self-adaptive compression feeding mechanism and printing method

ActiveCN110744819BReal-time adjustment of pressing forceImprove compatibility3D object support structuresManufacturing data aquisition/processing3d printGear wheel

The invention belongs to the technical field of printing equipment, and discloses a 3D printing adaptive compression feeding mechanism and a printing method thereof. A left feeding mechanism and a right feeding mechanism of the 3D printing adaptive compression feeding mechanism are the same in structure and are symmetrically arranged on the same horizontal plane; and the left feeding mechanism isprovided with a motor, a feeding gear mechanism, a V-shaped grooved wheel mechanism arranged on the same horizontal plane of the feeding gear mechanism, a guiding pipe arranged on the lower parts of afeeding gear and the V-shaped grooved wheel mechanism, and a stopping pin device arranged on the upper part of the V-shaped grooved wheel mechanism. According to the 3D printing adaptive compressionfeeding mechanism, the feeding devices are suitable for simultaneous printing of different materials, and the printing efficiency can be effectively improved; and before each layer of printing and spraying head alternate work, a working spraying head prints a layer of detecting samples in advance, flow materials are prevented from scratching the surfaces of the samples in the printing process, byprinting the detecting samples, the printing defect caused by insufficient discharging at the exchange printing initial period of double spraying heads is prevented, and thus the printing quality is improved.

Owner:CENT SOUTH UNIV

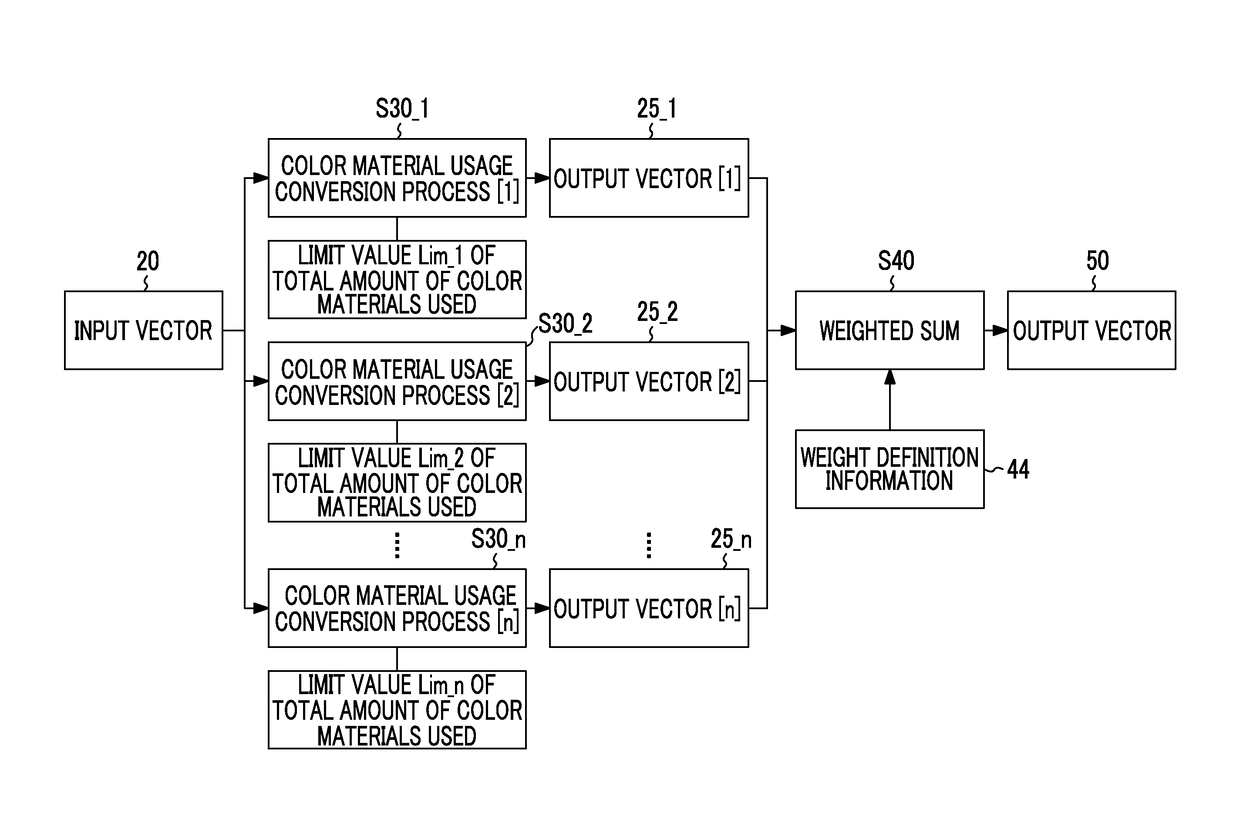

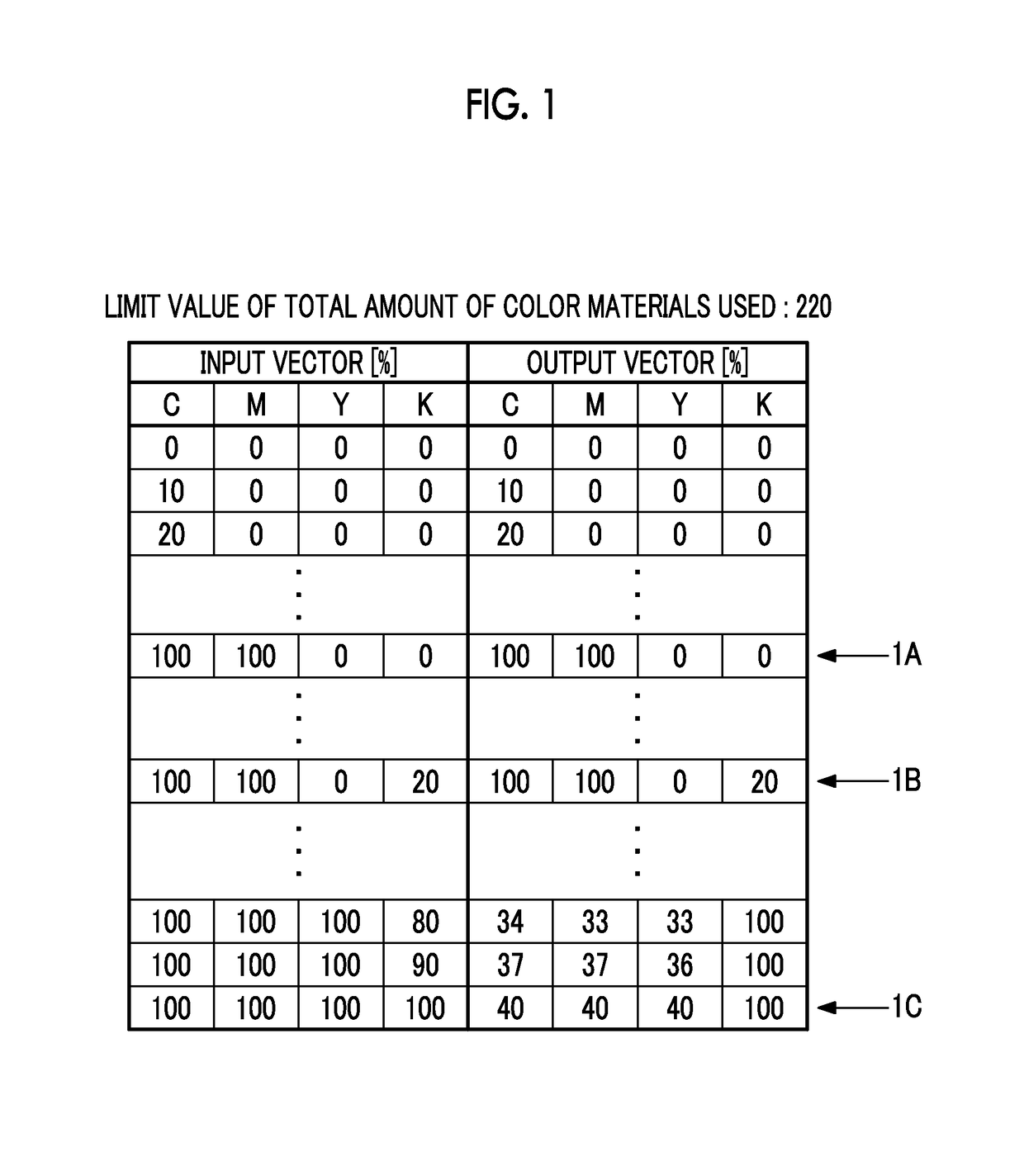

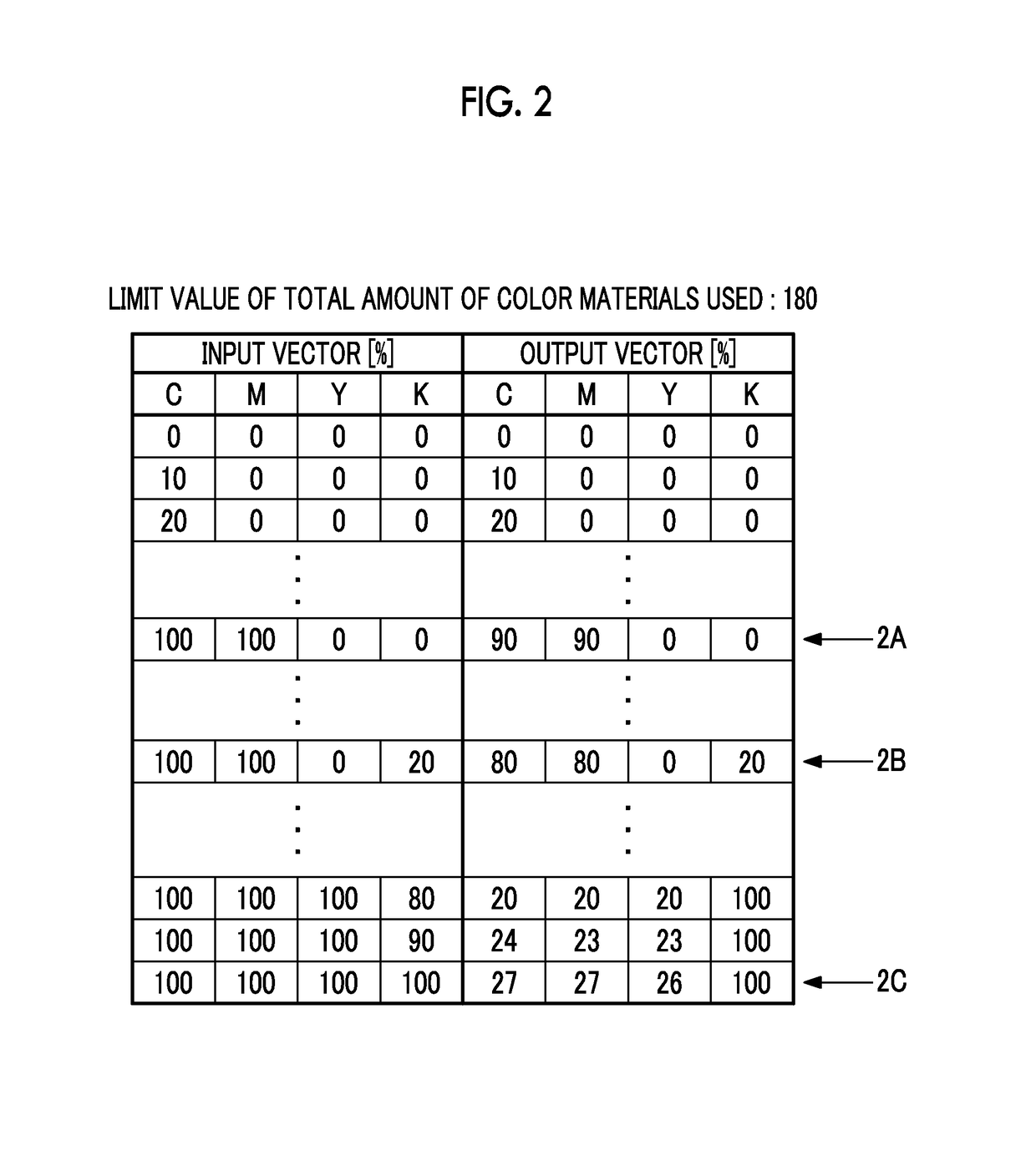

Signal conversion method and apparatus, program, and print system

ActiveUS9596384B2Inhibition of reproductionAvoid print failuresInput/output to record carriersVisual representation by matrix printersGamutFailure causes

Provided are a signal conversion method and apparatus, a recording medium storing non-transitory program, and a print system which can prevent a color reproduction gamut from being excessively narrowed while avoiding a print failure caused by excess color material. A signal conversion method for limiting the total amount of color materials used in a printing device that forms an image on a recording medium using a plurality of color materials includes determining a final output vector after the total amount of color materials used is limited for an input vector, on the basis of a plurality of input / output signal conversion processes based on different limit values of the total amount of color materials used and weight definition information in which weights applied to the conversion results of the plurality of input / output signal conversion processes are determined according to the input vector.

Owner:FUJIFILM CORP

Printer

InactiveUS20050180798A1Avoid print failuresAccurate operationRegistering devicesPile receiversEngineeringMechanical engineering

Owner:SONY CORP

Thermal Printhead

InactiveUS20080239058A1Avoid formingAvoid print failuresPrintingElectrical and Electronics engineeringEngineering

Owner:ROHM CO LTD

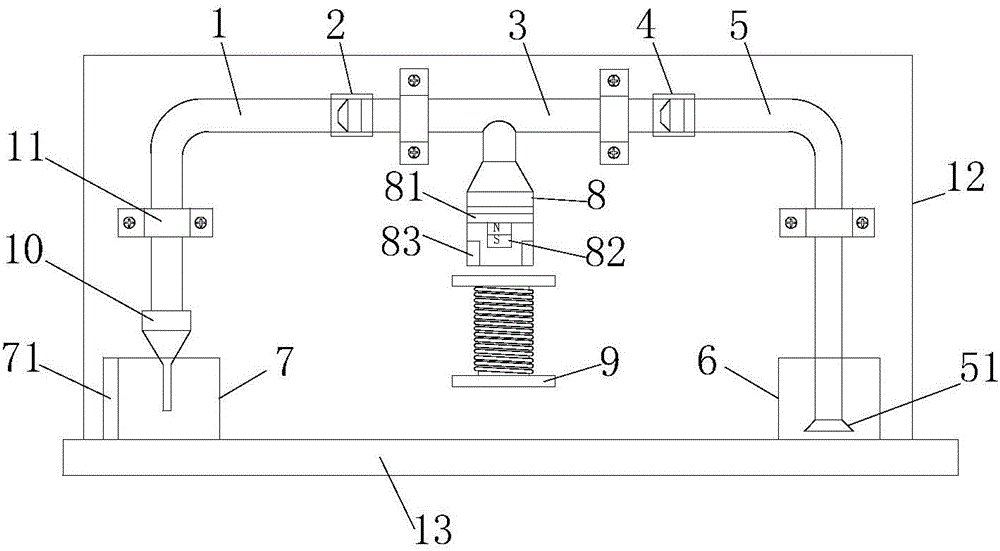

Fluid material conveying device for 3D printing machine

The invention discloses a fluid material conveying device for 3D printing machine. The fluid material conveying device comprises a discharging pipe, a connection pipe, a feeding pipe, a pneumatic pipe, a mounting plate and a bottom plate. The discharging pipe, the connection pipe and the feeding pipe are all mounted on the mounting plate through fixing parts, the mounting plate is arranged on the bottom plate, a discharging tank and a feeding tank are arranged on two sides of the bottom plate respectively, and a liquid level sensor is arranged on one side of the discharging tank. The fluid material conveying device for the 3D printing machine has advantages that by constant changing of electromagnet poles, a cylindrical magnet drives a piston to continuously move up and down so as to change internal air pressure of the pneumatic pipe, then fluid materials in the feeding tank are conveyed into the discharging tank, a user can precisely control feeding speed only by changing exchange frequency of the electromagnet poles, liquid level change of the fluid materials in the discharging tank can be sensed by the liquid level sensor on the side wall of the discharging tank, and accordingly precision in feeding quantity control is realized.

Owner:新昌县城关升华机械厂

Air blowing device for printing press

InactiveUS20060236881A1Avoid print failuresImprove printing qualityCylinder pressesAddressographsSuction equipmentEngineering

An air blowing device for a printing press includes a plate cylinder, blanket cylinder, impression cylinder, air blowing equipment, air suction equipment, and cover. The plate cylinder is rotatably supported. Ink from an inking device and dampening water from a dampening device are supplied to the outer surface of the plate cylinder. The blanket cylinder is rotatably supported in contact with the plate cylinder. The impression cylinder is rotatably supported in contact with the blanket cylinder and cooperates with the blanket cylinder to print on a printing target body under conveyance. The air blowing equipment discharges air from one end side toward the other end side of the blanket cylinder. The air suction equipment takes in air, discharged from the air blowing equipment, at the other end side of the blanket cylinder. The cover forms an air passage extending from the air blowing equipment to the air suction equipment in an axial direction of the blanket cylinder.

Owner:KOMORI CORP

Stepping mechanism of fused deposition 3d printer

ActiveCN104816481BPrecise positioningAchieve precise positioningAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineering3d printer

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

3d printer intelligent feeding detection mechanism

ActiveCN104309130BEnsure continuityRealize online testAdditive manufacturing apparatus3D object support structuresStopped workControl system

The invention discloses an intelligent feeding detection mechanism for a 3D printer, which includes a channel for printing materials to pass through, and also includes a feeding sensor and a feeding speed sensor, and the signal receiving ends of the feeding sensor and the feeding speed sensor are both Connected with the channel, the feeding sensor is used to know whether there is printing material passing through the channel, and the feeding speed sensor is used to obtain the transmission speed of the printing material in the channel; a control system is also included, and the control system is used for: When the material sensor senses that there is no material or no material in the channel, it transmits the information to the control system, and the control system controls the printer to stop working and gives an alarm; and, when the feed speed sensor senses that the transmission speed of the printing material is zero , and transmit the signal to the control system, and the control system controls the printer to stop working. The invention can test whether there is a material blockage or lack of material during the printing process, and prompts to change the material, thus ensuring the success rate of printing.

Owner:西安非凡士机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com