Convenient 3D printing equipment

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems of not meeting the needs of use, easy to slip on the bolt, shaking of the spray gun and the mechanical arm, etc., to avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

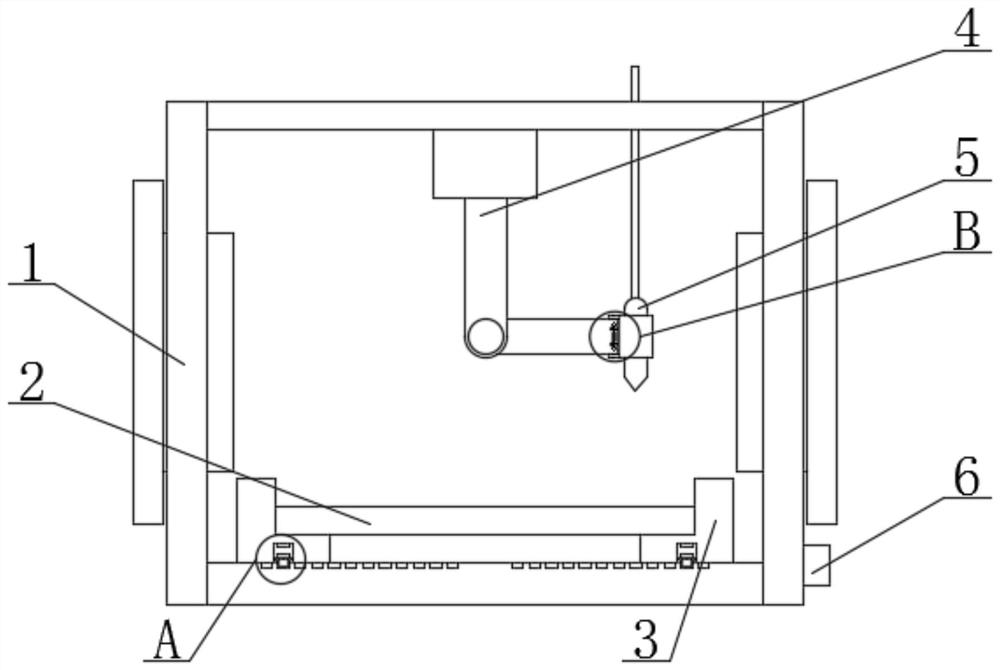

[0027] see Figure 1-5 , the present invention provides a technical solution: a convenient 3D printing device, comprising: a box body 1; Sectional structure, and the mechanical arm 4 is driven by a hydraulic device, and the hydraulic device is electrically connected to the controller; a spray gun 5, and the inside of the box 1 is fixedly installed with a spray gun 5 through a feeding pipe; a fixed sleeve 12 , the surface of the spray gun 5 is fixedly installed with a fixed sleeve 12; the fixed plate 7, the two ends of the fixed sleeve 12 and the adjacent side of the mechanical arm 4 are fixedly welded with the fixed plate 7; the installation mechanism 8, the installation mechanism 8 includes a sliding plate 81, a spring 82, a second mounting groove 83 and an insertion rod 84, the bottom side of the mechanical arm 4 is provided with a second mounting groove 83, and both ends of the second mounting groove 83 are movably inserted There is an insertion rod 84, and one end of the ...

Embodiment 2

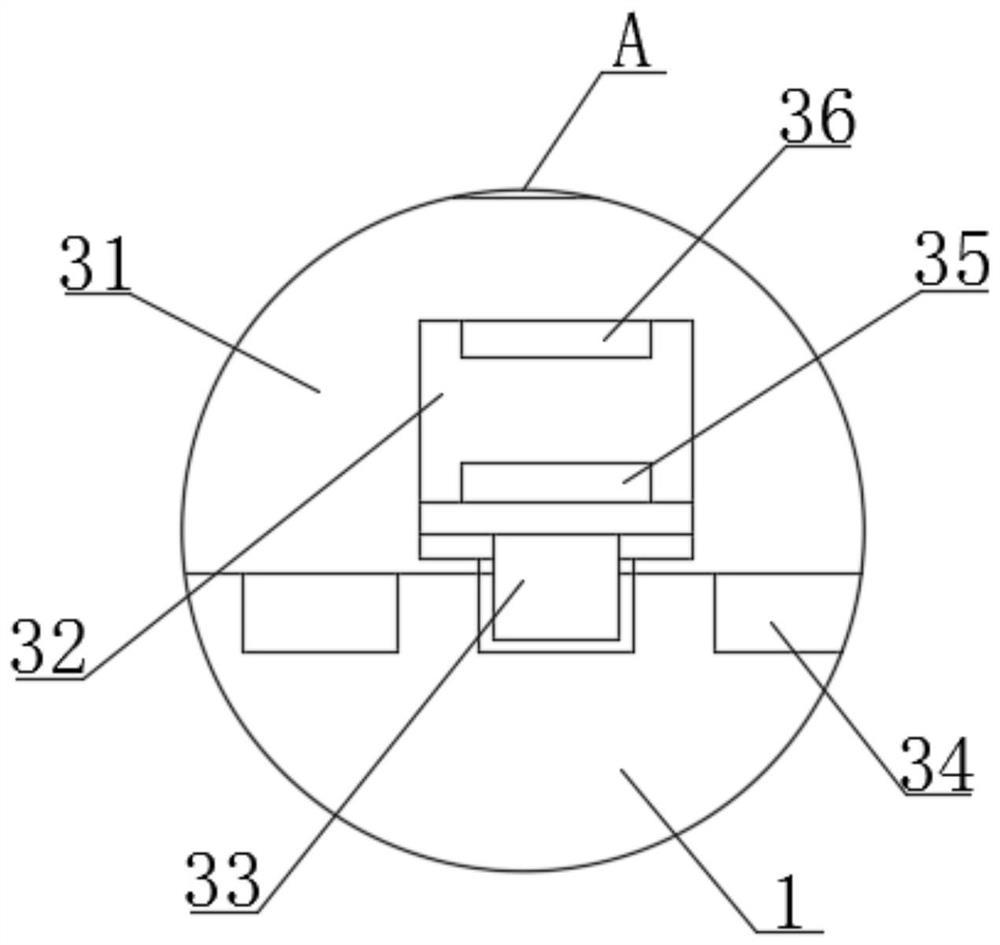

[0029] As a preferred solution of Embodiment 1, the adjustment mechanism 3 includes a limit plate 31, a first installation groove 32, a clamping column 33, an iron block 35 and an electromagnet 36, and the inner wall bottom of the box body 1 is on both sides. Slidingly connected to the limiting plate 31, the bottom of the limiting plate 31 is provided with a first installation groove 32, the bottom of the first installation groove 32 is movably inserted with a clamping column 33, and the top of the clamping column 33 is fixedly installed There is an iron block 35, an electromagnet 36 is fixedly installed on the top of the inner wall of the first installation groove 32, the electromagnet 36 is electrically connected with the controller 6, and the bottom of the clamping post 33 is engaged with the bottom of the inner wall of the box body 1. The positioning plate 2 is engaged and connected between the limiting plates 31, and the cross section of the limiting plate 31 is an L-shape...

Embodiment 3

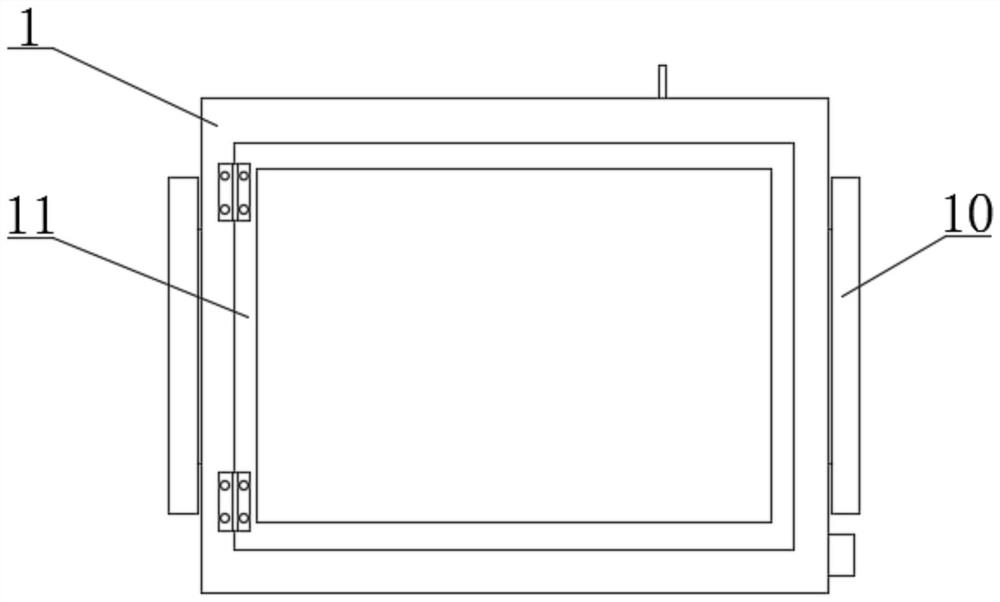

[0031]As a preferred solution of Embodiment 1, a limit mechanism 9 is fixedly installed between the sliding plates 81, the limit mechanism 9 includes a block 91 and a limit rod 92, and the slide plate 81 is located in the second installation groove One end of the outside of 83 is all engaged with a block 91, and the stop bar 92 is fixedly welded between the end of the block 91 away from the sliding plate 81, and the block 91 is engaged with the sliding plate 81, and the stop bar 92 Under the action of the sliding plate 81, it can effectively prevent the sliding plates 81 from moving towards each other, and the distance between the sliding plates 81 can be limited to avoid shaking during the printing process, and to avoid tight installation due to the contraction of the spring 82. For the problem, both sides of the box body 1 are fixedly equipped with a heat dissipation mechanism 10, the heat dissipation mechanism 10 includes a heat conduction plate and a heat dissipation plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com