Rapid turnover device for new energy automobile air conditioner compressor bearing machining

A technology for air-conditioning compressors and new energy vehicles, which can be used in auxiliary devices, metal processing equipment, turning equipment, etc., and can solve the problems of time-consuming and laborious operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

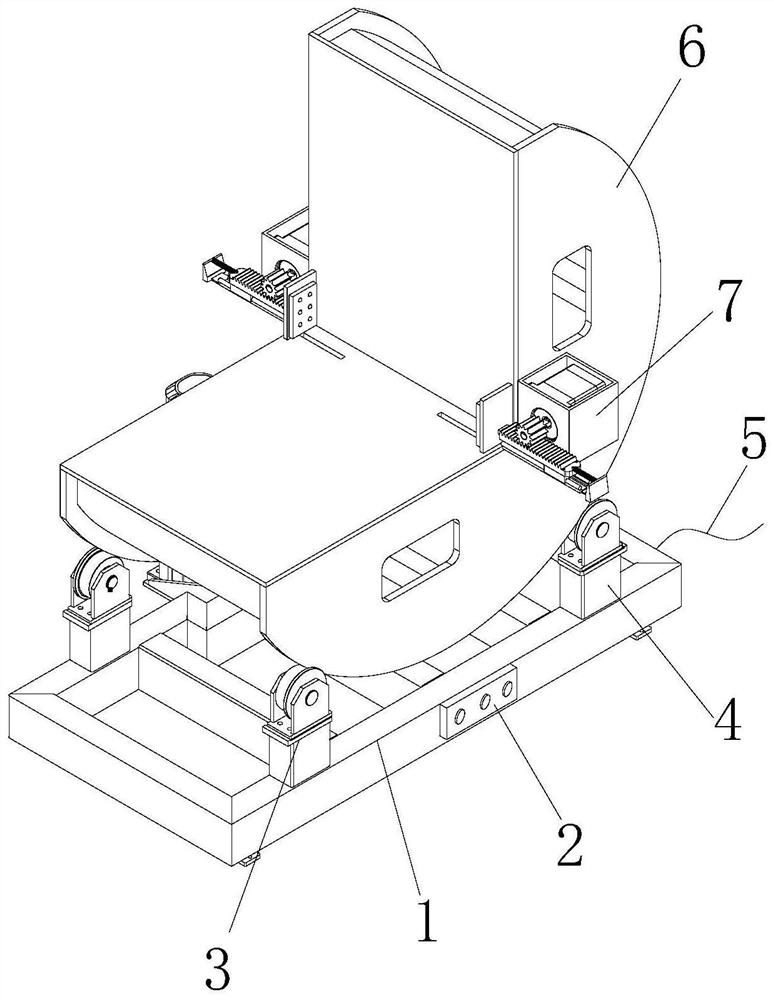

[0027] see figure 1 , the present invention provides a new energy automobile air-conditioning compressor bearing processing quick turning device through improvement, including a support frame 1, a control panel 2, a first guide seat 3, a second guide seat 4, a power wire 5, and a rotating disk 6 And the positioning mechanism 7, the right end of the support frame 1 is provided with a control panel 2, the front and rear sides of the support frame 1 top are oppositely provided with a first guide seat 3 and a second guide seat 4, the upper end of the rotating disk 6 is provided with a positioning mechanism 7, and the support frame 1 A power lead 5 is fixed at the rear end, and a rotating disk 6 is installed on the top of the support frame 1 , and the rotating disk 6 is slidingly matched with the inner sides of the first guide seat 3 and the second guide seat 4 .

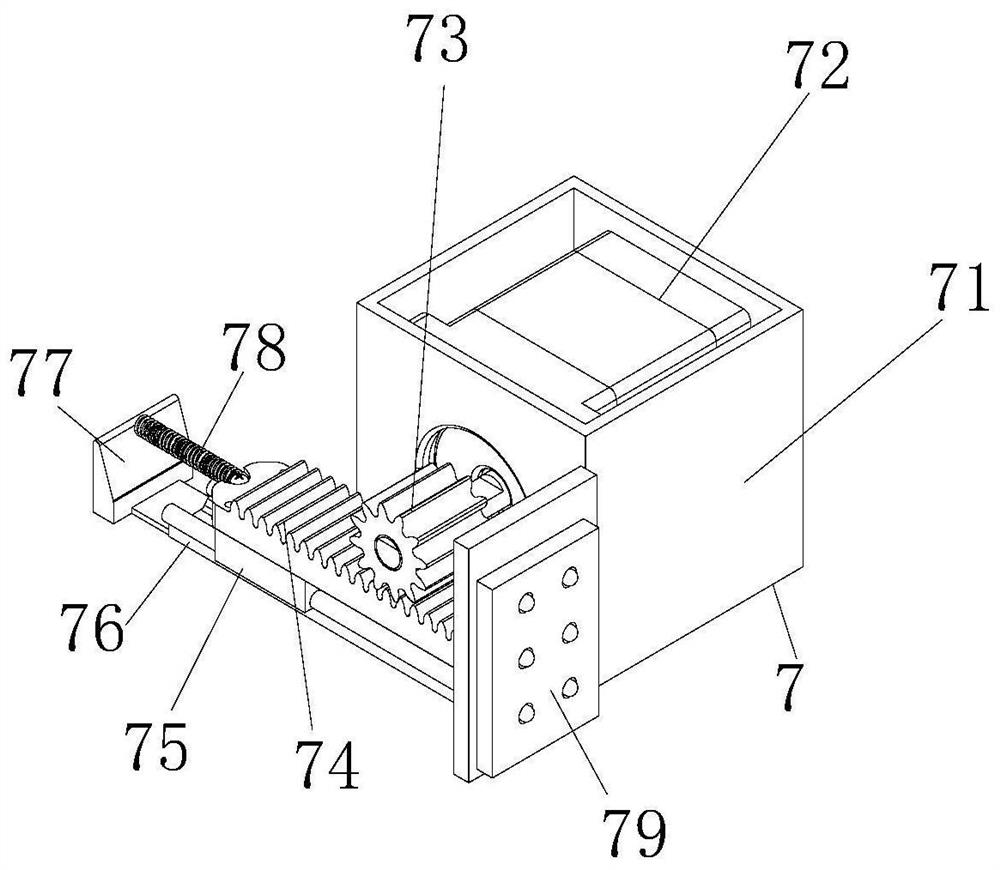

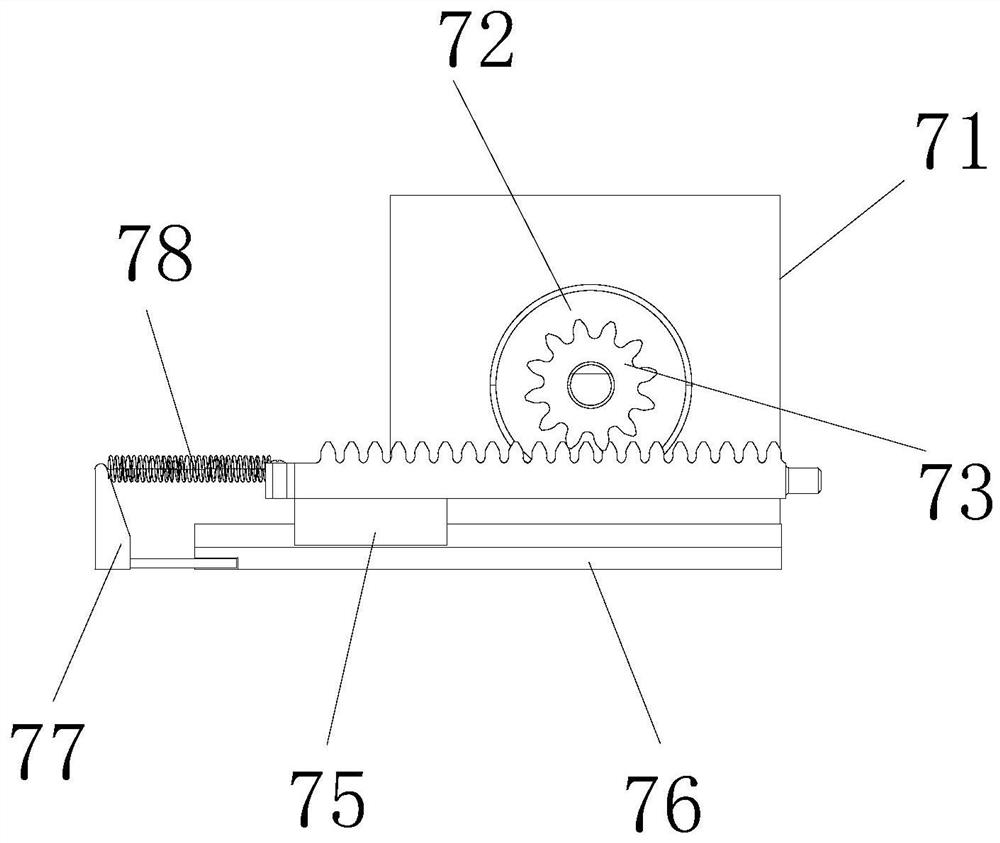

[0028] see figure 2 and image 3 , the present invention provides a new energy automobile air-conditioning compress...

Embodiment 2

[0032] The present invention provides a new energy automobile air-conditioning compressor bearing processing quick turning device through improvement. There are two positioning mechanisms 7 in total, and the positioning mechanisms 7 are arranged opposite to each other along the left and right sides of the upper end of the rotating disk 6, which is beneficial to the positioning of the bearings. For the function of fixing, the fixing frame 71 is in the shape of a square frame with an inner frame cavity, which is conducive to stably fixing the motor 72 .

[0033] The present invention provides a new energy automobile air-conditioning compressor bearing processing quick turning device through improvement, and its working principle is as follows;

[0034] First, before use, place the new energy automobile air-conditioning compressor bearing processing quick flip device horizontally, so that the support frame 1 can fix and support the device;

[0035] Second, when in use, connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com