Printing forming chamber with local temperature control function and 3D printer with printing forming chamber

A technology of local temperature and molding chamber, which is applied in the field of 3D printing, can solve the problem of not being able to provide higher temperature during the printing process, achieve high heating utilization efficiency and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

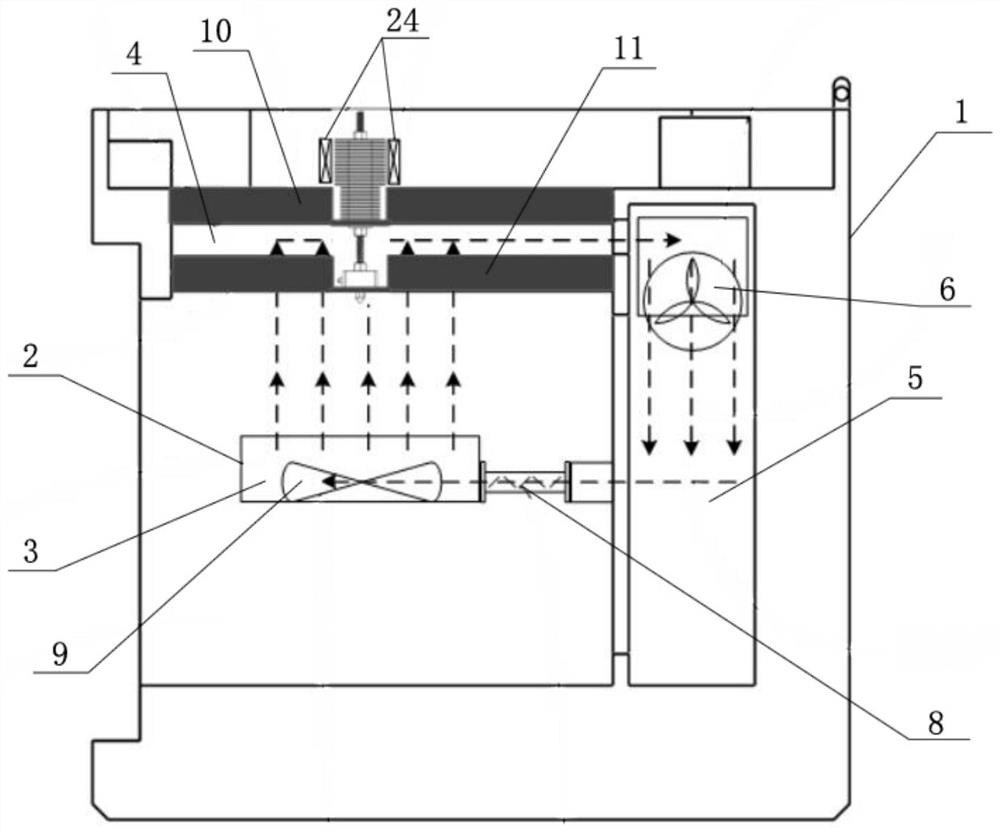

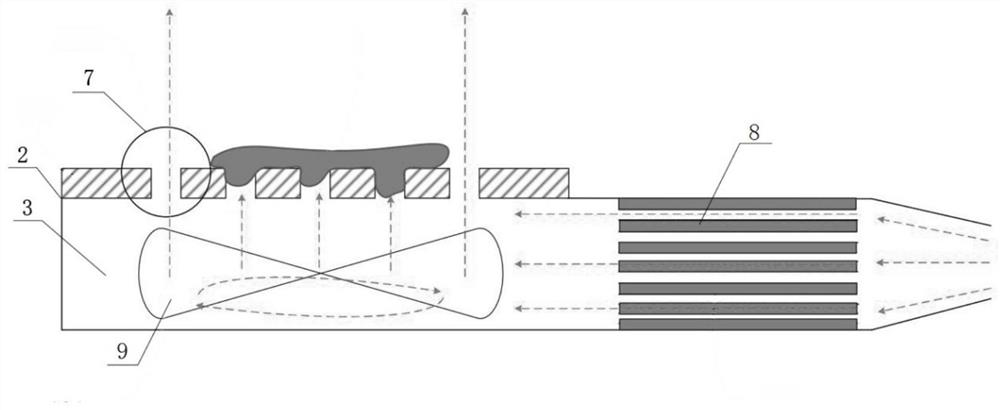

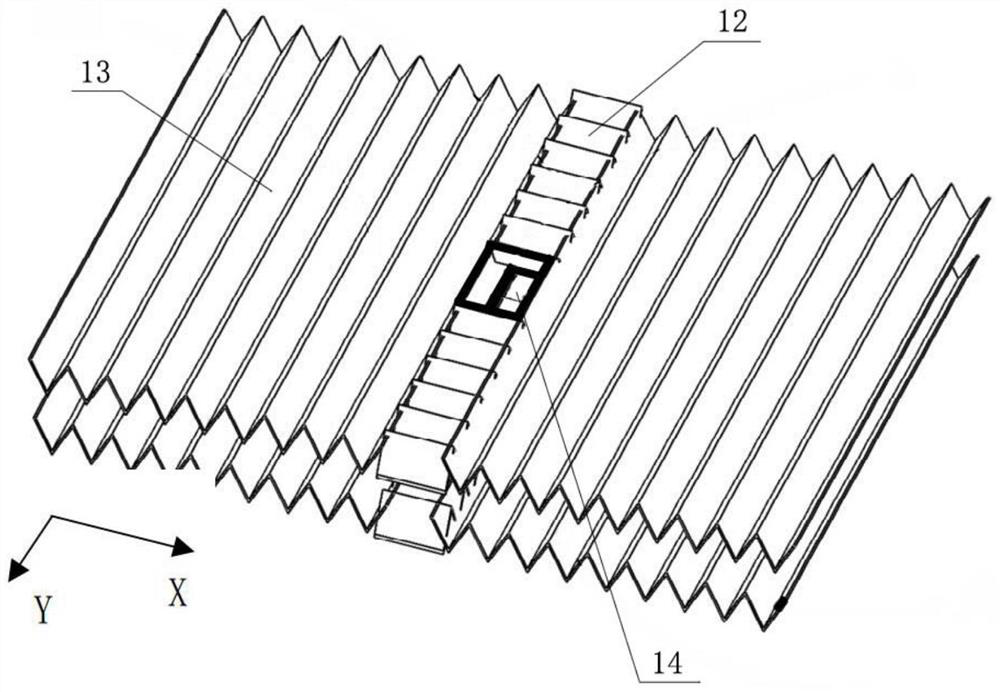

[0034] like Figure 1 to Figure 5 As shown, a printing and forming chamber with local temperature control includes an outer casing 1, a forming platform 2 arranged inside the outer casing 1, and a printing nozzle arranged above the forming platform 2, wherein the outer casing The inside of the body 1 is also provided with a hot air circulating air duct that enables the forming platform 2 to blow upward airflow that can wrap the printing model on the top surface of the forming platform 2 above the top surface; A throat 19 extending through the hot air circulation air duct to the top of the forming platform 2, connected to the nozzle 20 on the end of the throat 19 close to the forming platform 2, and passing through the throat The sprinkler heating module and the sprinkler heat dissipation module on 19 , the sprinkler heating module is located inside the hot air circulation air duct, and the sprinkler heat dissipation module is located outside the outer casing 1 . For polymer m...

Embodiment 2

[0048] A 3D printer, comprising the printing chamber with local temperature control described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com