Patents

Literature

59results about How to "Guaranteed extrusion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

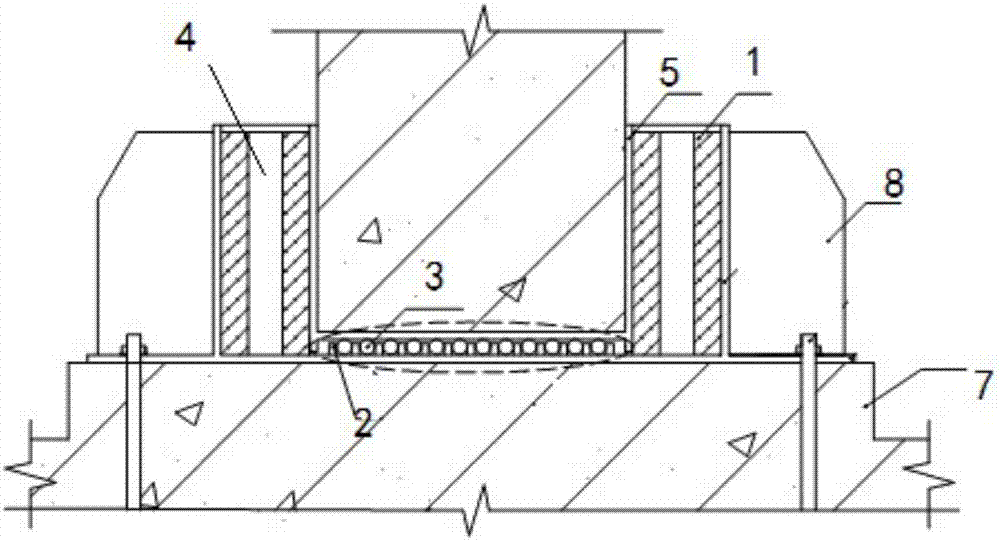

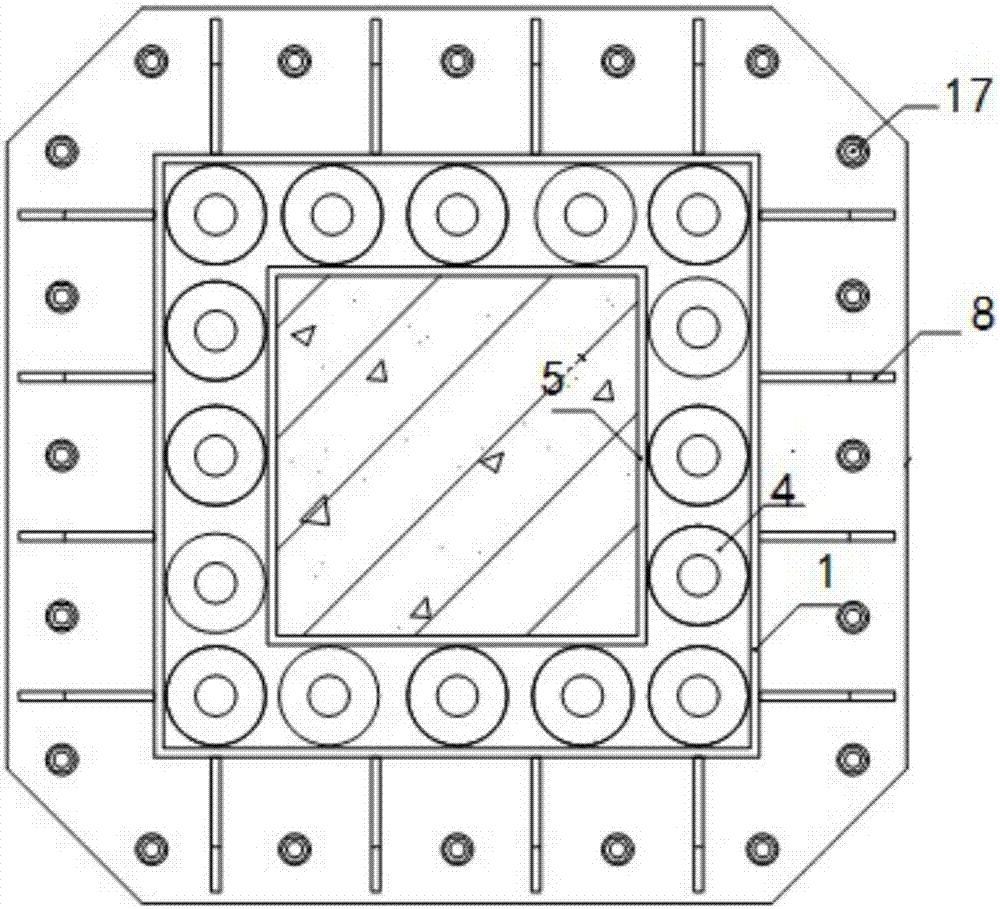

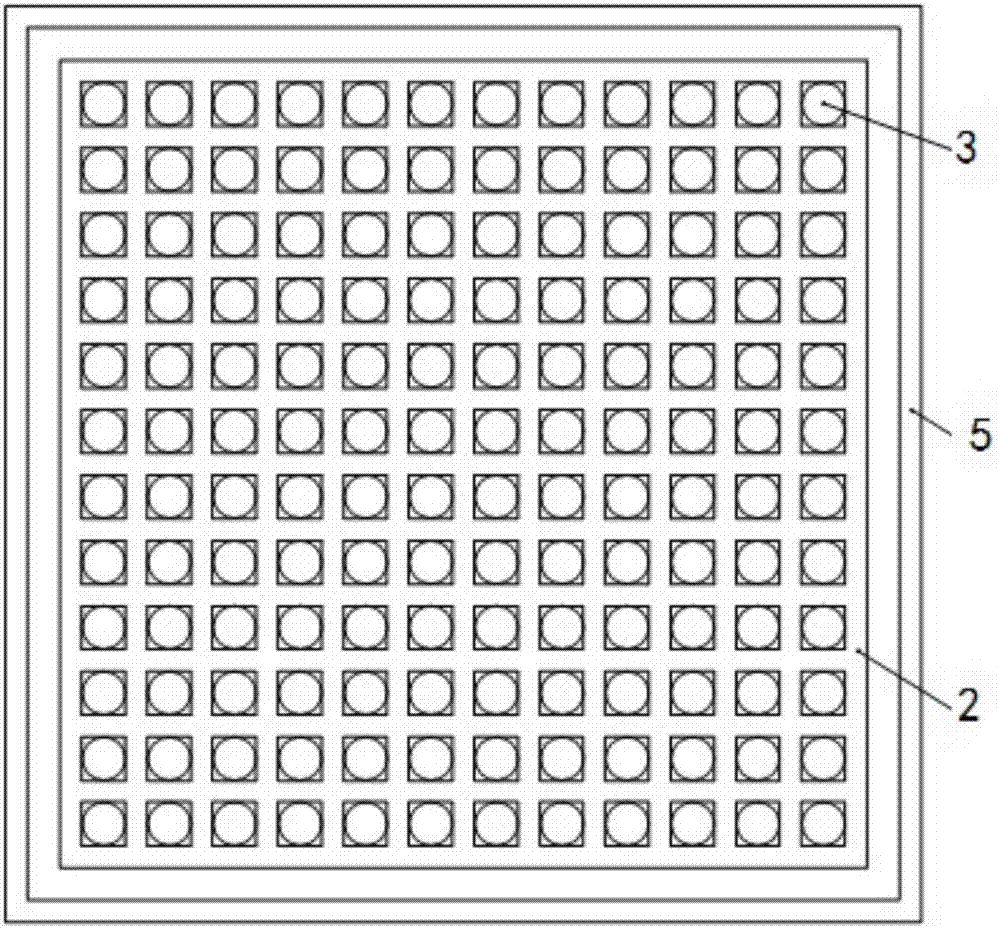

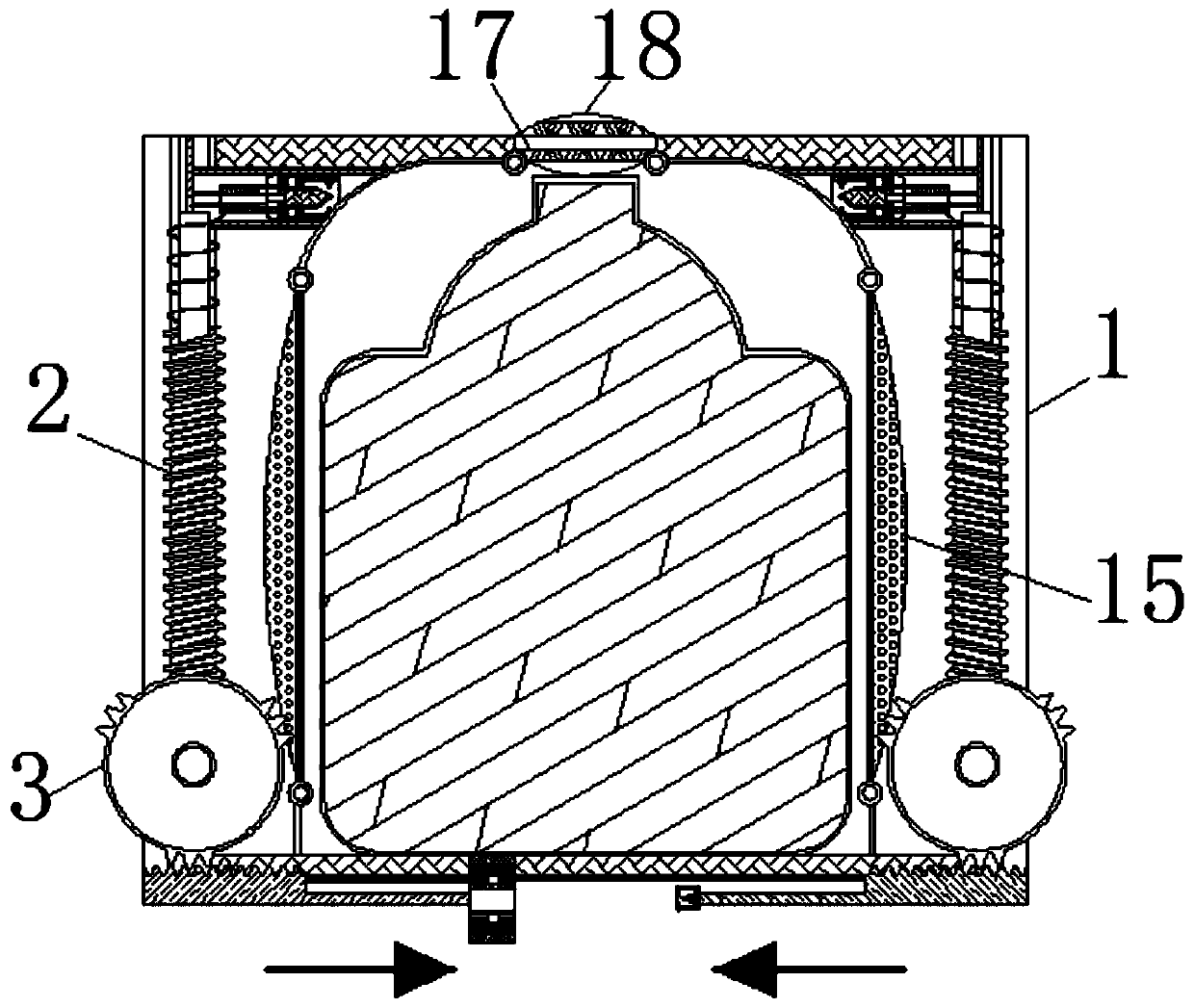

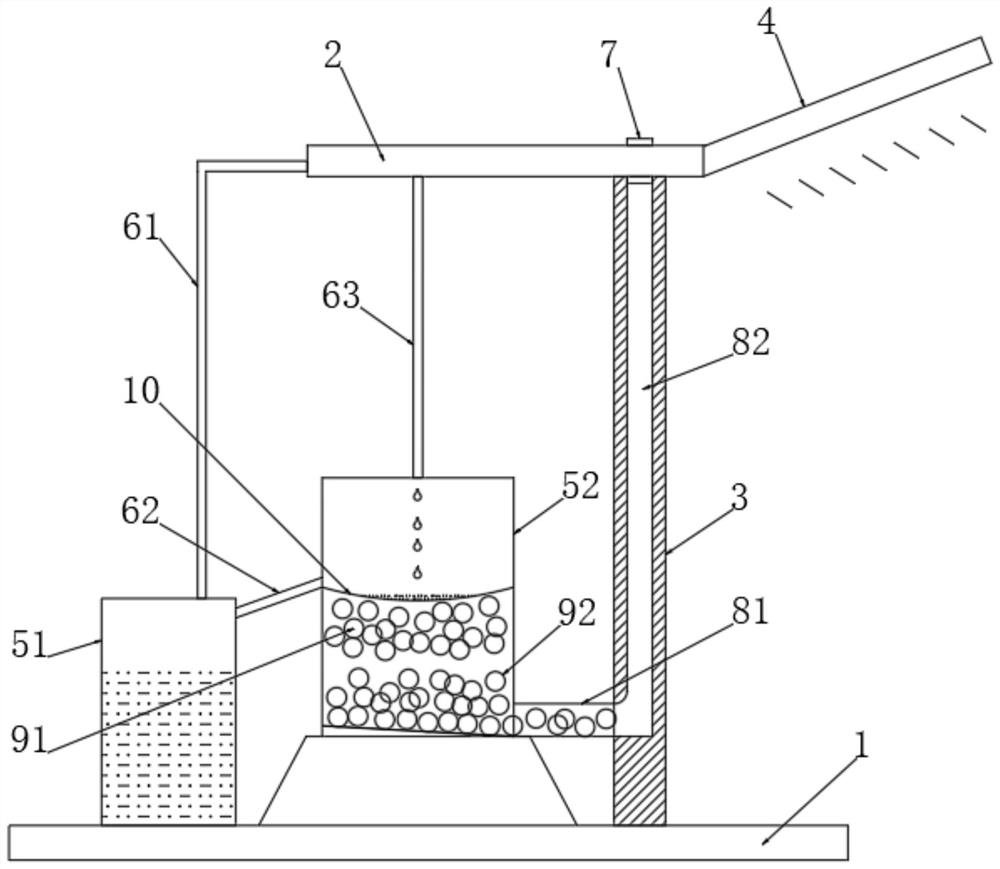

Rubber tube rolling shock insulation support for shock insulation of building structure foundation

PendingCN107190878AImprove earthquake resistanceMeet earthquake resistance requirementsProtective buildings/sheltersShock proofingEarthquake resistantInsulation layer

The invention provides a rubber tube rolling shock insulation support for shock insulation of a building structure foundation. The rubber tube rolling shock insulation support comprises a limiting seat, a ball limiting rack, multiple balls, multiple rubber tubes, a concrete column-column foot lining plate and a limiting stay rope. An upper-portion structure can produce a certain amplitude of horizontal displacement with respect to the shock insulation support fixed to the foundation through matching of the limiting seat, the rubber tubes, the balls and the ball limiting rack when horizontal shock occurs, the power effect of shock on the upper-portion structure is reduced, deformation of a shock insulation layer during earthquake can be limited, the support has a certain reset capability, the limiting stay rope can ensure that the upper-portion structure and the foundation do not produce overlarge displacement, the shock resistance capability of the structure is improved, and the shock resistance demand is met.

Owner:GUANGZHOU UNIVERSITY

Organic fertilizer dehydrating and smashing device

InactiveCN108889421AReduce volumeOverall small sizeGrain treatmentsPressesAgricultural engineeringEngineering

The invention discloses an organic fertilizer dehydrating and smashing device. The device comprises a dehydrating box and a smashing box, a feed inlet is formed in a side plate at one side of the dehydrating box, and another other side plate of the dehydrating box is connected with a side plate at one side of the smashing box; a communicated conveying opening is formed between the dehydrating boxand the smashing box, a conveying belt is arranged in the dehydrating box, a dehydrating device is arranged at one end of the conveying belt, and a water collecting box is arranged at the bottom of the dehydrating box; a water collecting opening is formed between the dehydrating box and the water collecting box, and a sliding plate is installed on the inner wall of the smashing box at the conveying opening; two smashing wheels are installed under the sliding plate, blades are installed on the outer walls of the smashing wheels, and a discharging opening is formed in a bottom plate of the smashing box; agricultural waste is placed on the conveyor belt from the feed inlet, the conveying belt drives the agricultural waste to move to the position of the dehydrating device, the dehydrating device conducts compressing and dehydrating on the agricultural waste, the dehydrated agricultural waste falls onto the sliding plate from the conveying opening, the sliding plate makes the agricultural waste slide to the smashing wheels, and the smashing wheels rotate to drive the blades to cut agricultural wastes, so that agricultural waste is smashed and finally falls out of the discharging opening.

Owner:东至县雨庭畜禽有限公司

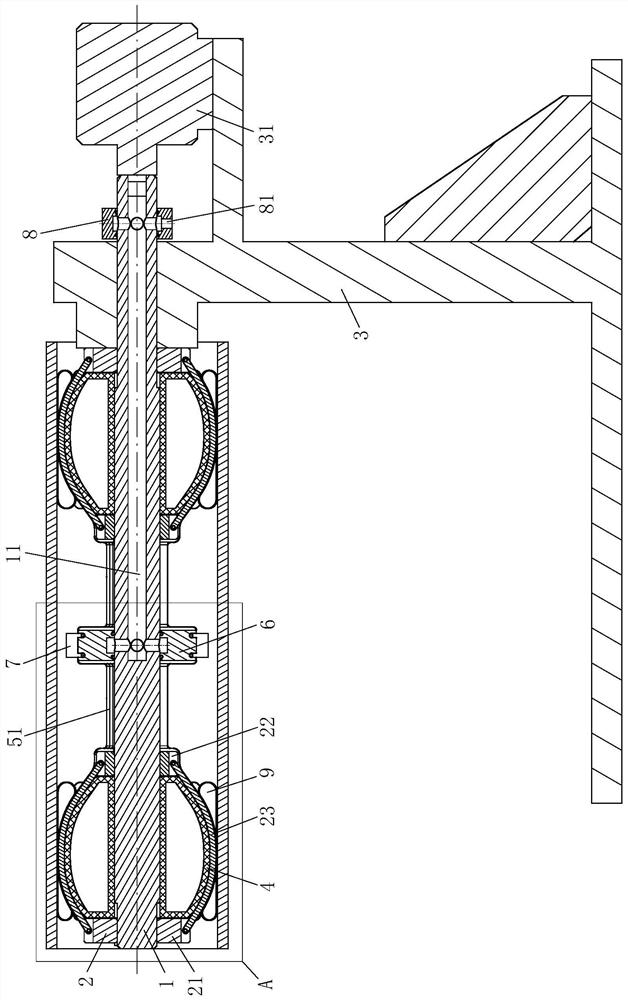

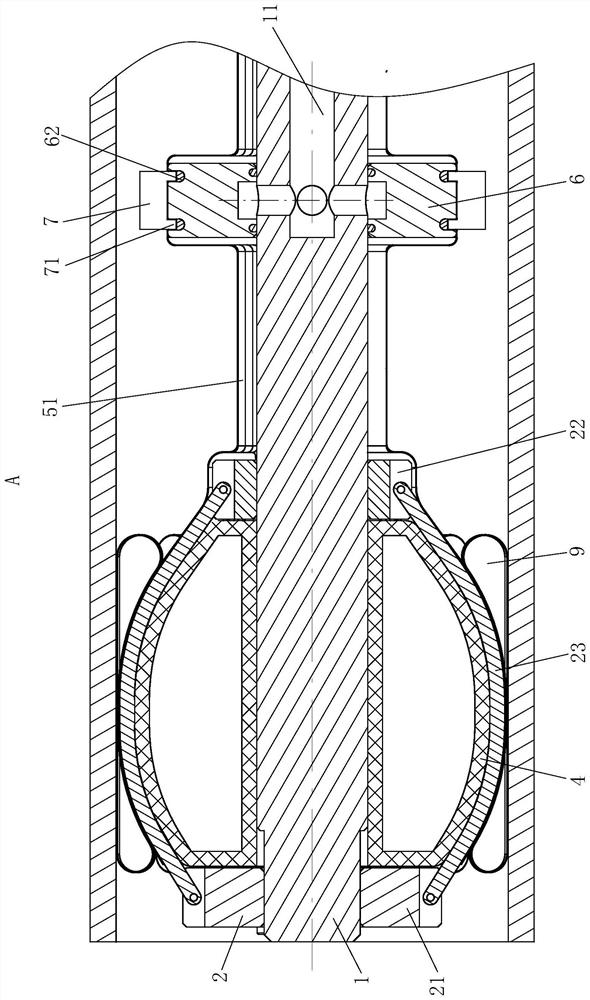

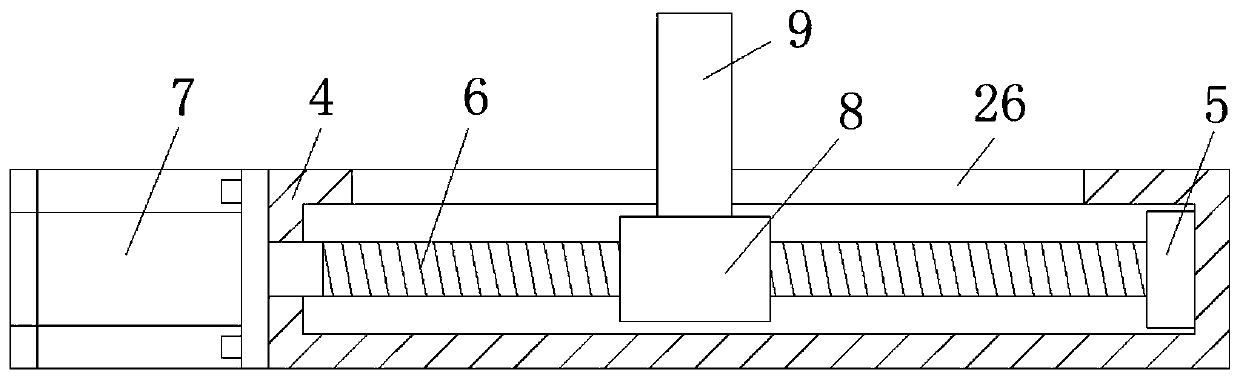

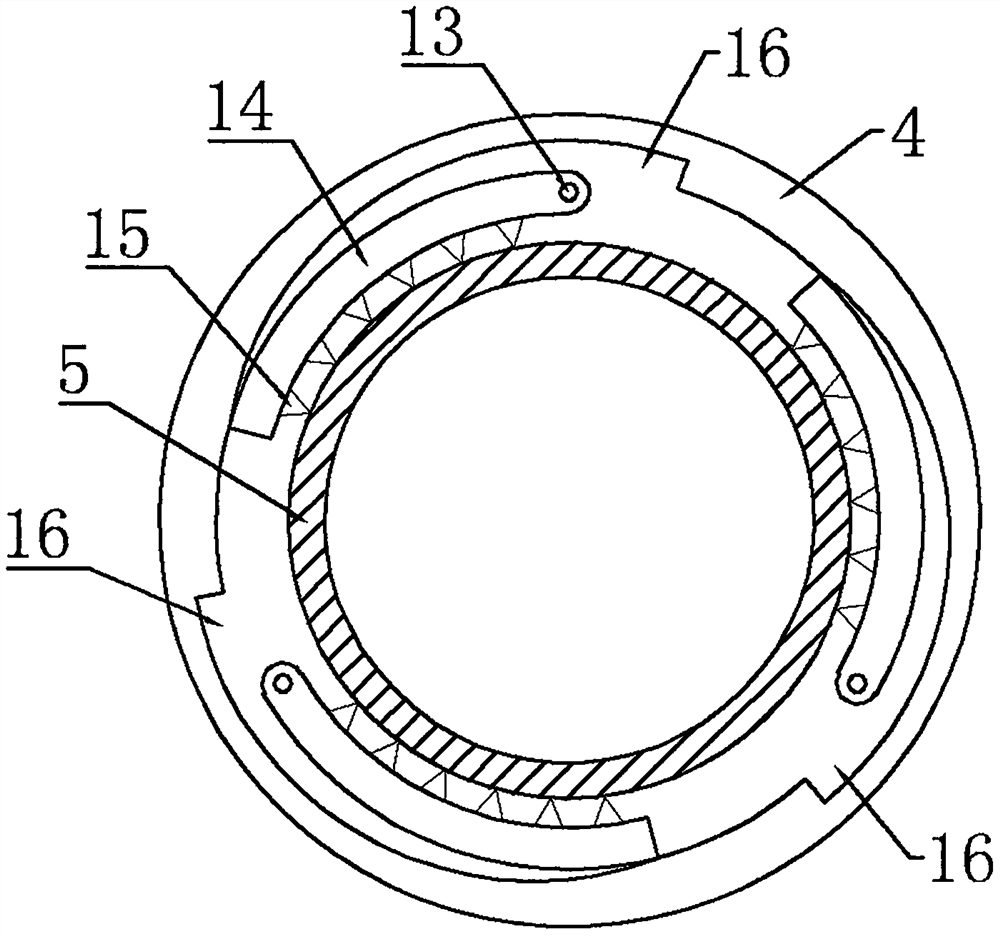

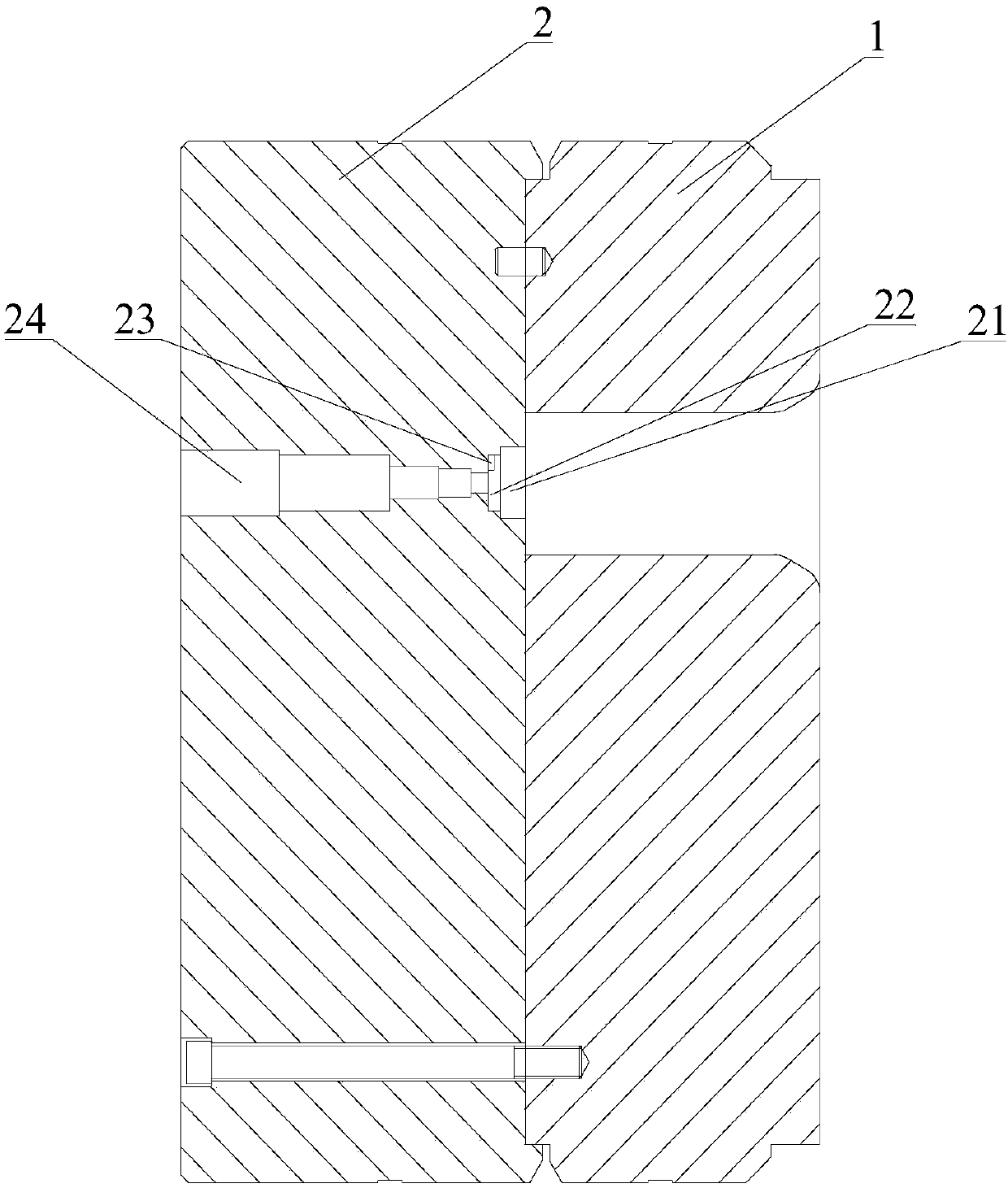

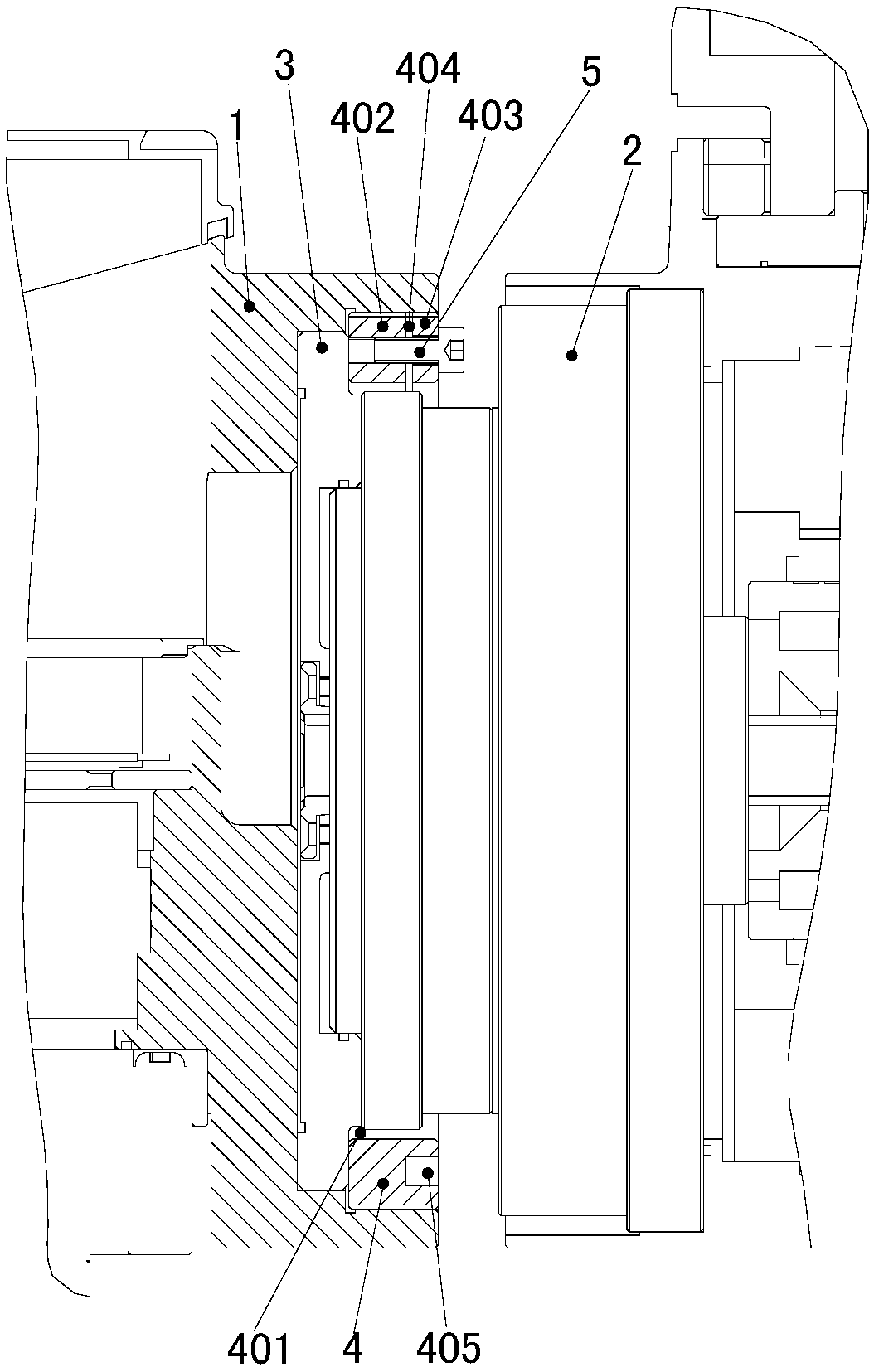

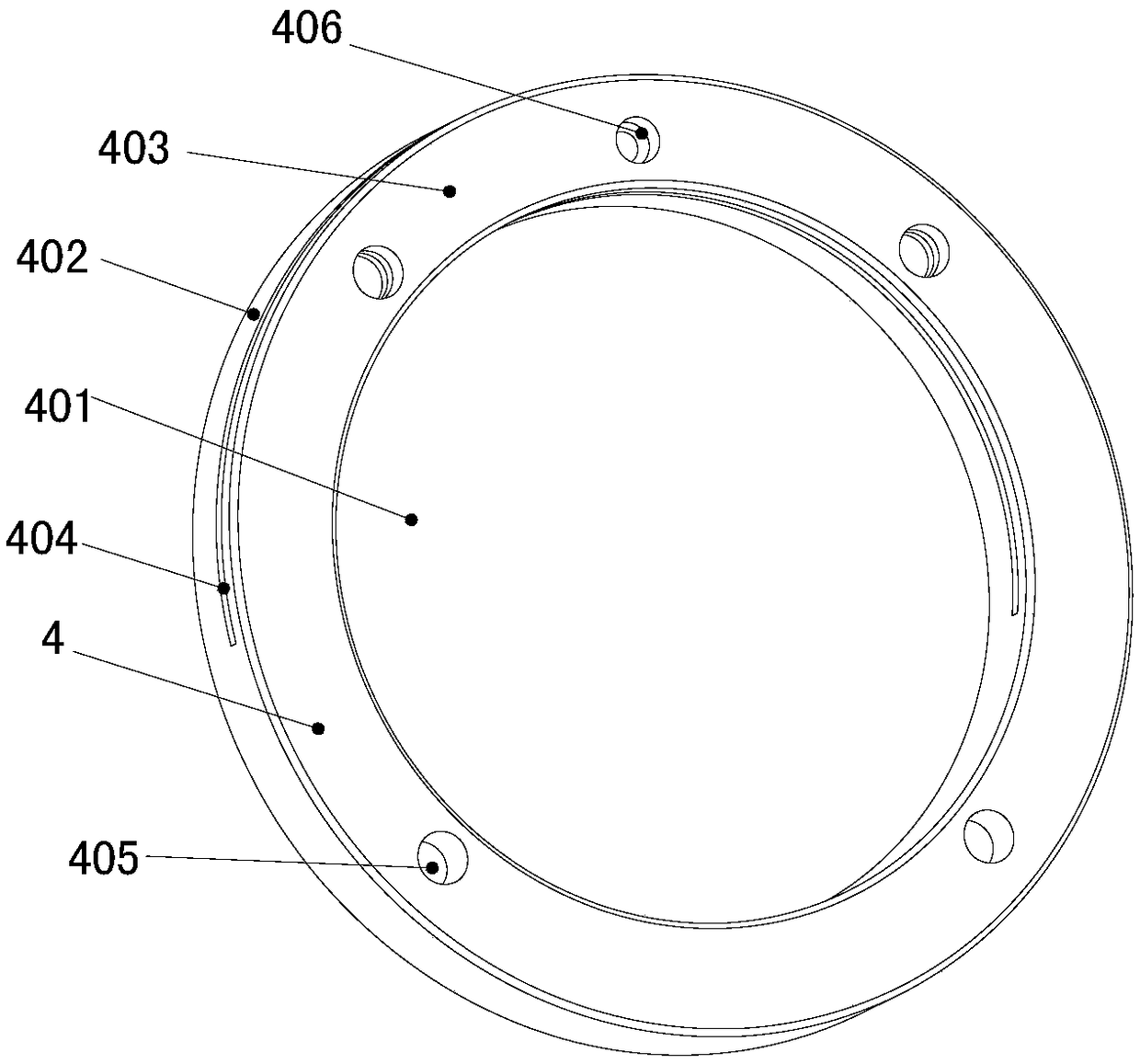

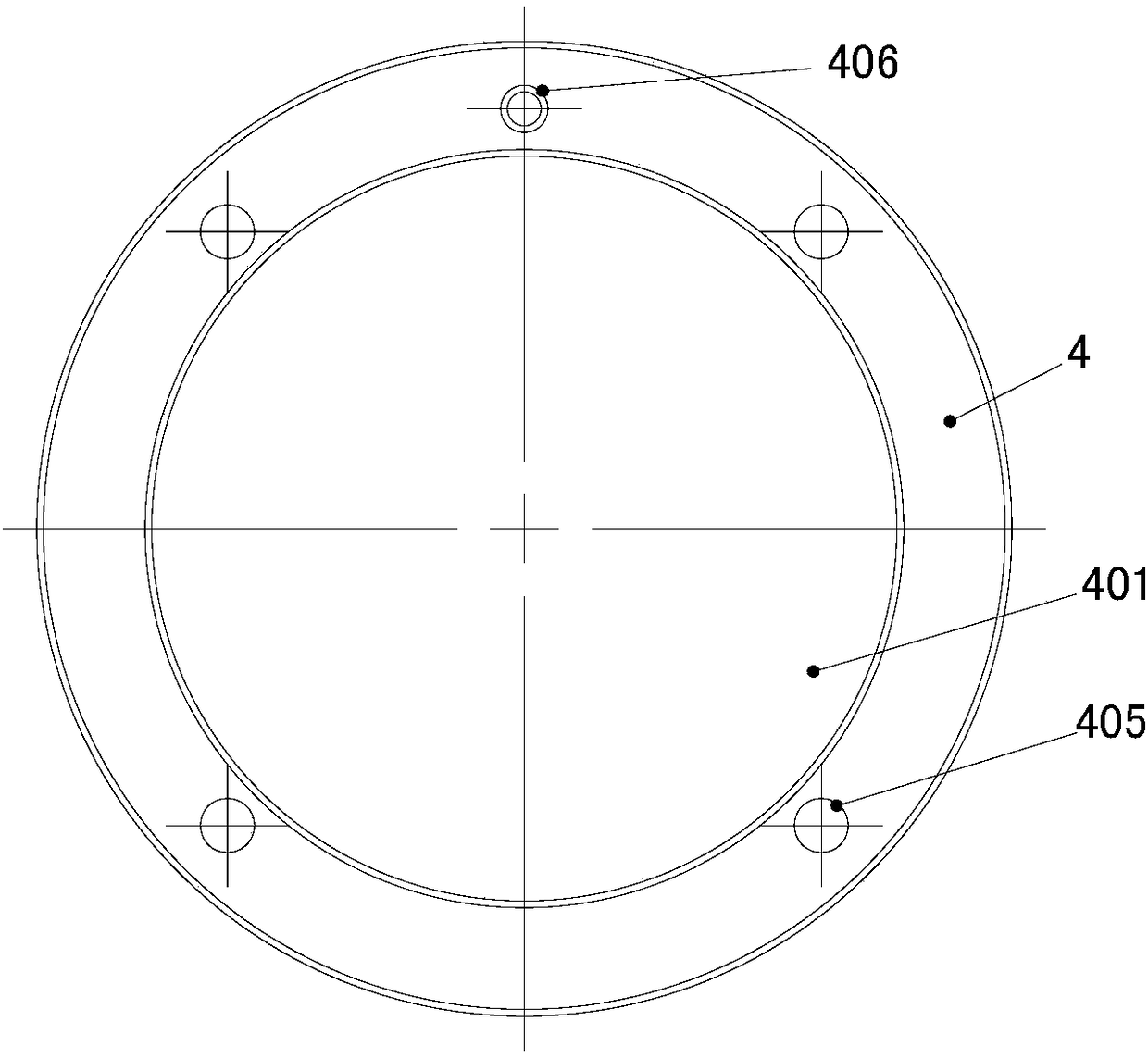

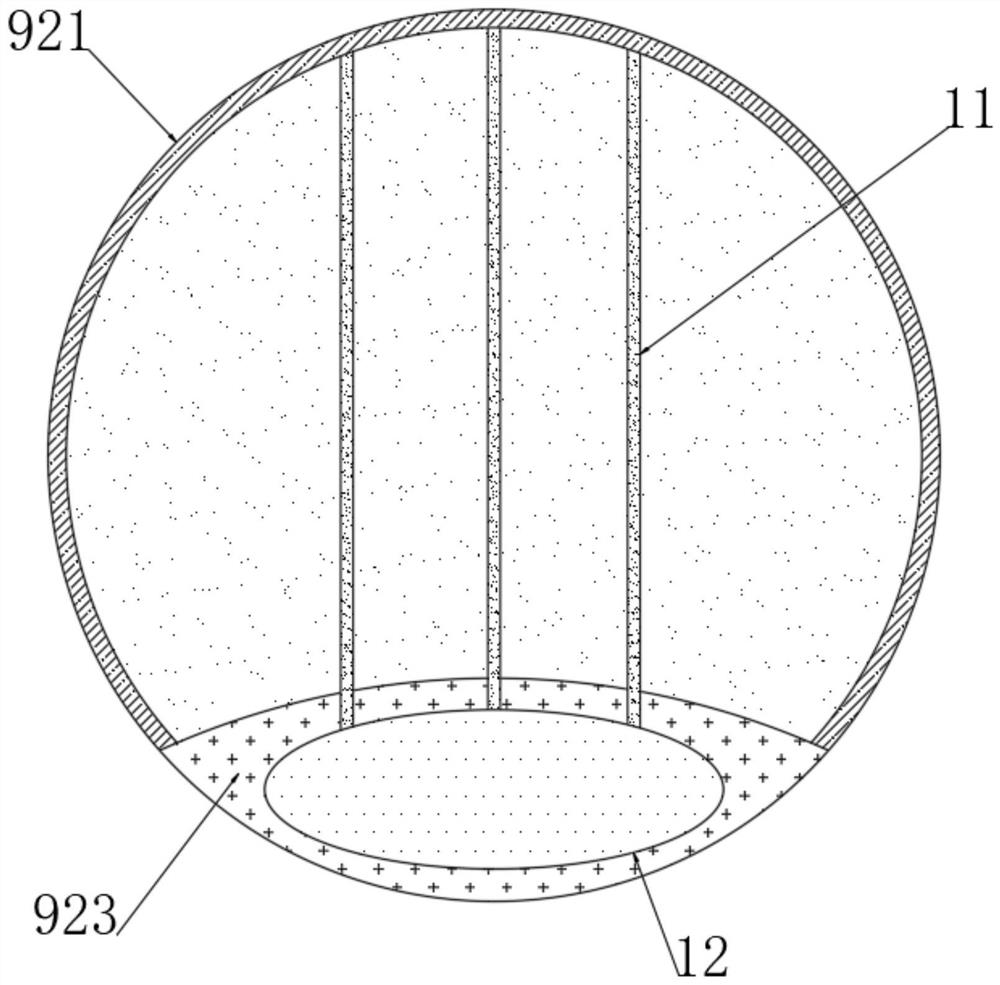

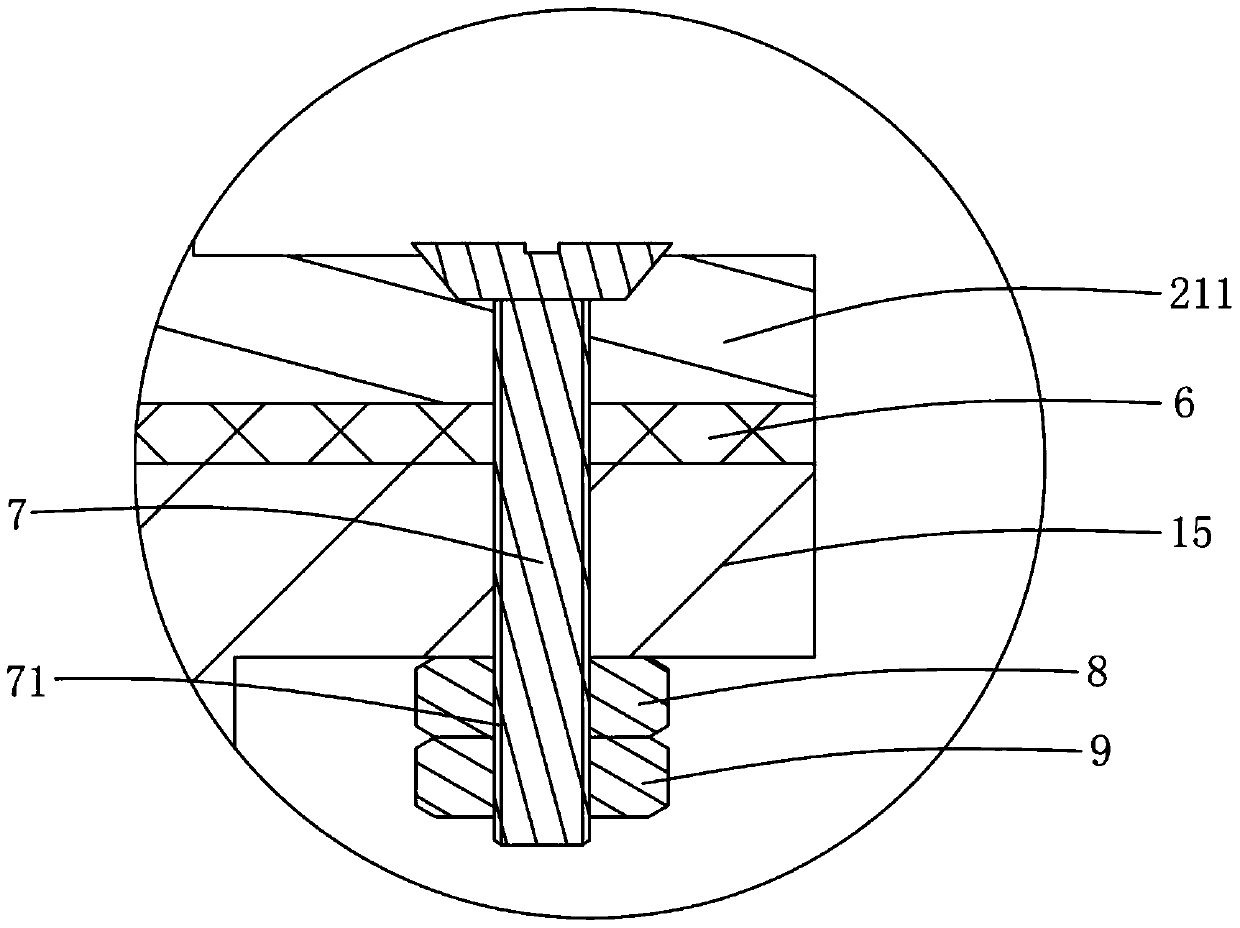

Confining pressure cylinder device for novel split Hopkinson pressure bar active confining pressure experiment

InactiveCN104677725APrevent outward movementSolve the problem of not pressing the test piece tightlyStrength propertiesPressure experimentHigh pressure

The invention relates to an impact loading experimental device for material dynamic mechanical property, and in particular relates to a confining pressure cylinder device for a novel split Hopkinson pressure bar active confining pressure experiment. The confining pressure cylinder device comprises a cylinder body, a pressure cavity in the cylinder body, cylinder covers, pressing blocks, a metal sleeve, a rubber sleeve and a shaft hole; the confining pressure cylinder device is characterized in that the cylinder covers are respectively arranged at two ends outside the cylinder body; corresponding to the cylinder covers, pressing blocks are respectively arranged at two ends of the pressure cavity, and one end of each pressing block extends into the cylinder body; the metal sleeve is arranged between the pressing blocks at two ends of the pressure cavity and is connected by virtue of a screw; the rubber sleeve is arranged on the inner side of the metal sleeve; and the rubber sleeve is arranged between the pressing blocks at two ends of the pressure cavity, so that the pressing blocks, the metal sleeve and the rubber sleeve are integrated. The device disclosed by the invention not only can prevent the rubber sleeve, in the case of deforming, from entering into a clearance formed between a sealing cover and a rod piece to drive the rod piece to move outwards, but also can solve a problem that a test piece cannot be tightly pressed by the rod piece since the rod piece is stressed to cause a trend of moving towards the outer side of the cavity body when the rod piece is closely held in the rubber sleeve under high pressure; and the confining pressure cylinder device is simple in structure.

Owner:LUOYANG LIWEI TECH

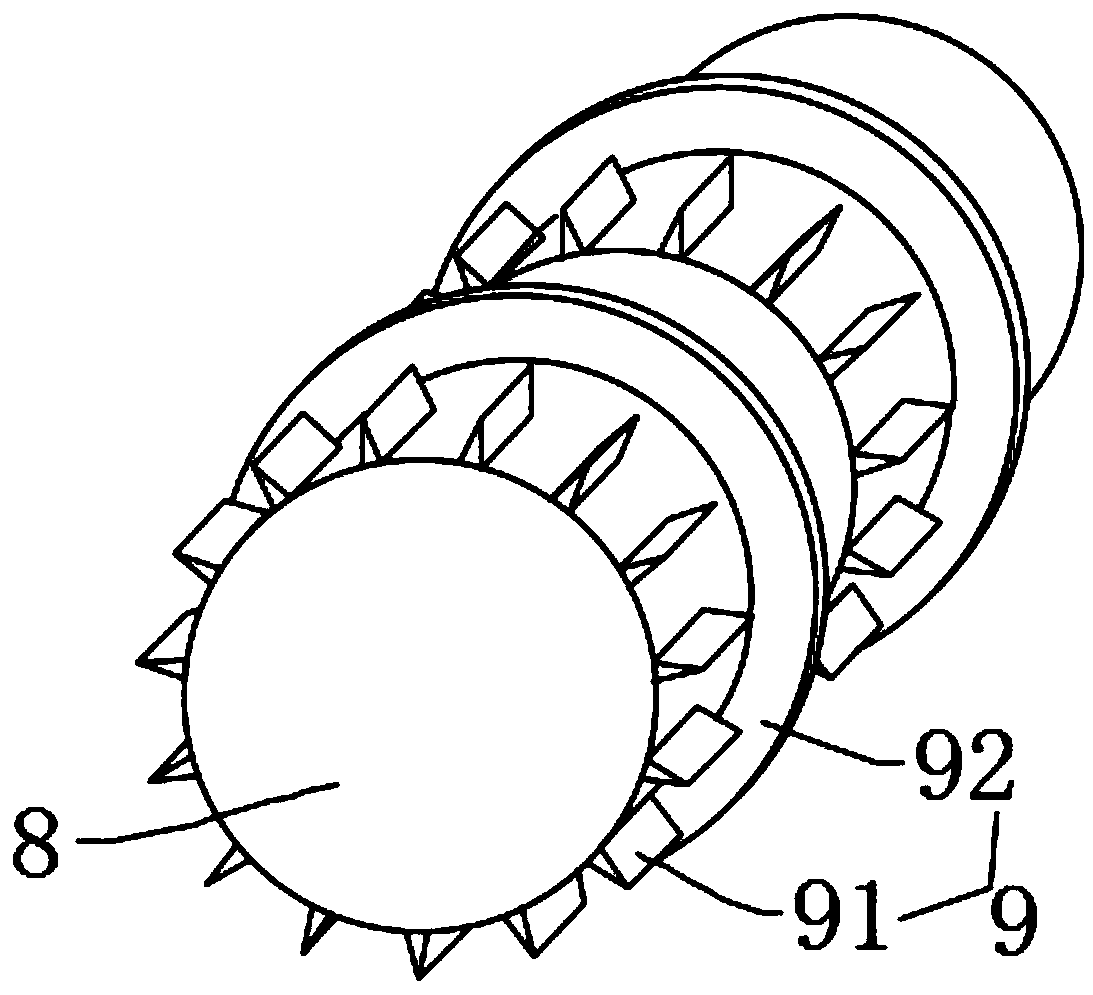

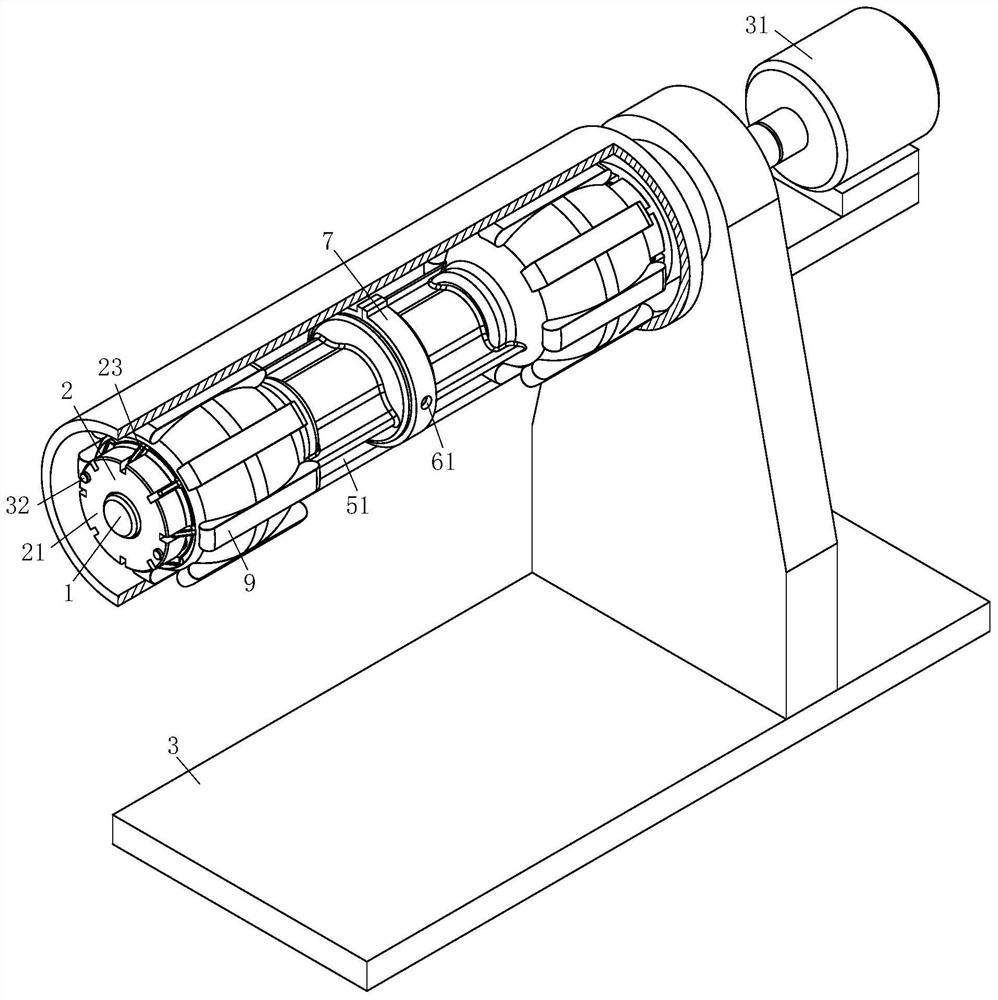

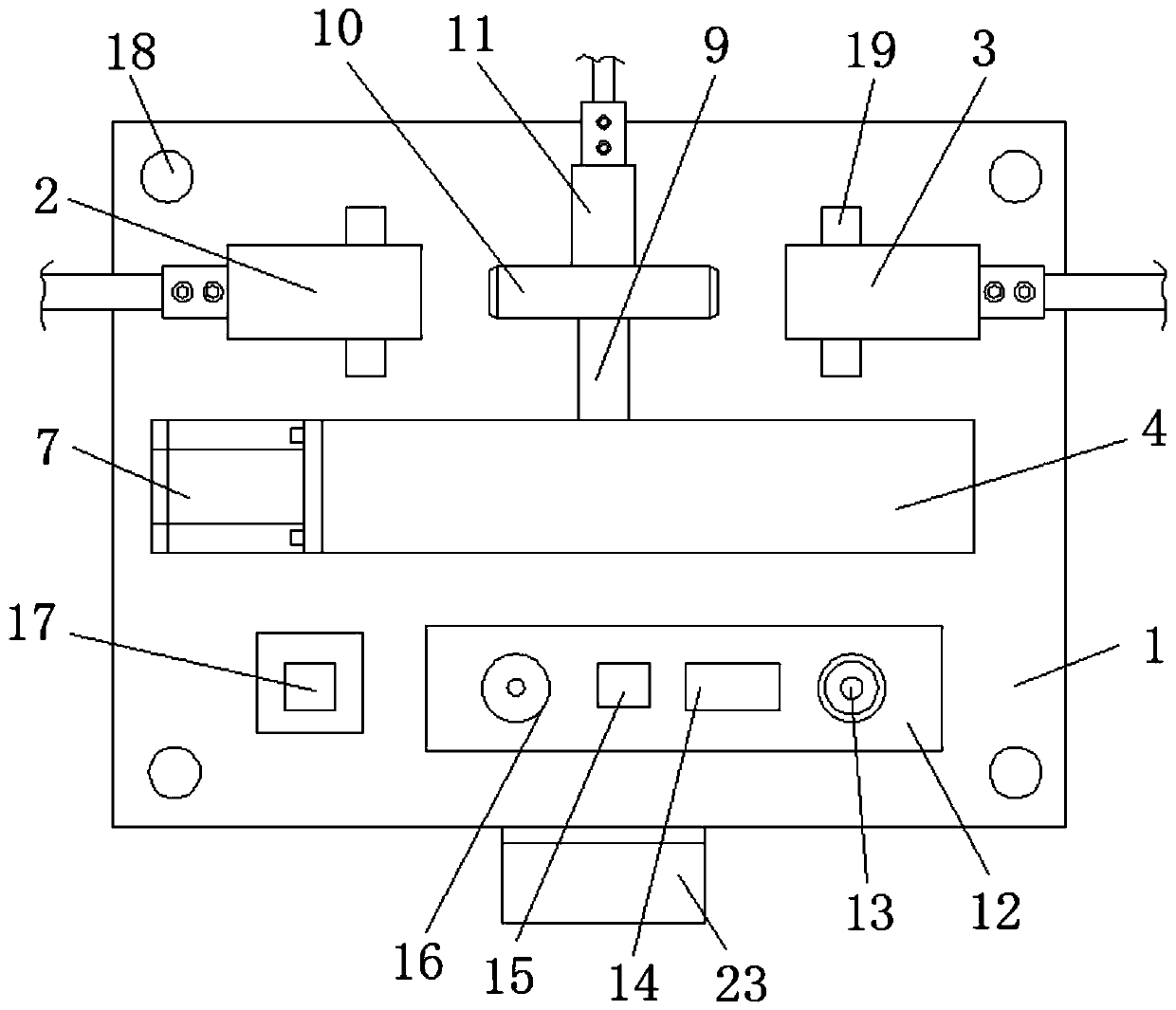

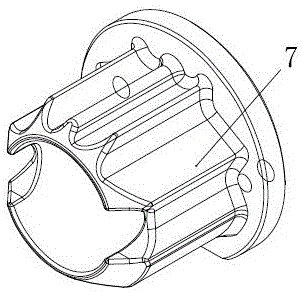

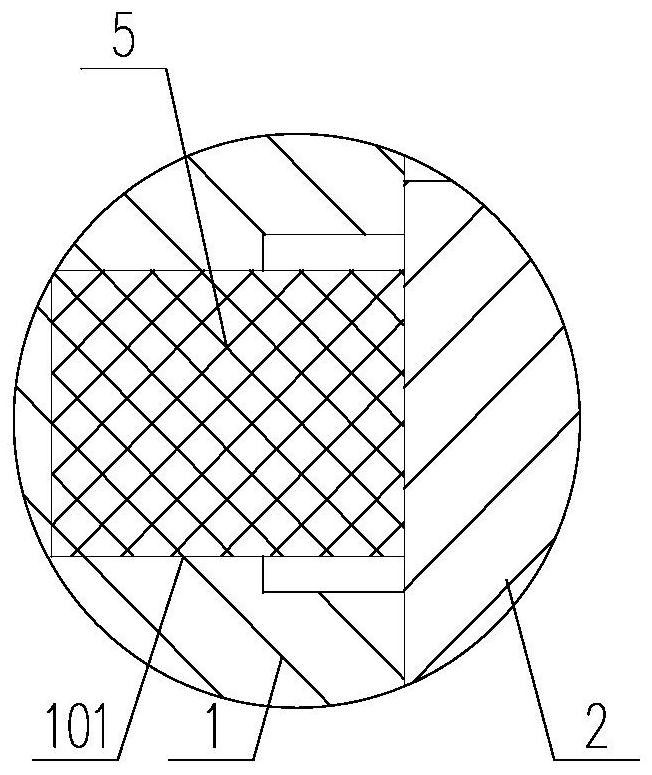

Self-centering clamp for grinding ceramic cylinder sleeve

ActiveCN111660173AGuaranteed stabilityPrevent movementGrinding drivesGrinding machinesElectric machineryComposite material

The invention belongs to the technical field of tool clamps, and particularly relates to a self-centering clamp for grinding a ceramic cylinder sleeve. The self-centering clamp comprises a rotating shaft, a jacking device, a supporting frame, a motor and a connecting rod. According to the self-centering clamp, the motor drives the rotating shaft to rotate, the rotating shaft drives a second rotating disc to move in the axial direction of the rotating shaft through threads, and the threads on the rotating shaft are left-handed thread and right-handed thread respectively, so that the second rotating disc moves to a first rotating disc; in the process, the second rotating disc extrudes elastic spokes, the elastic spokes are bent towards the inner wall of the ceramic cylinder sleeve, the middle portions of the elastic spokes extrude the inner wall of the ceramic cylinder sleeve, and the ceramic cylinder sleeve is clamped; and the elastic spokes are used for clamping the ceramic cylinder sleeve, so that the elastic spokes contact the inner wall of the ceramic cylinder sleeve more closely, the ceramic cylinder sleeve is prevented from being damaged in the clamping process, the elastic spokes are tightly pressed against the inner wall of the ceramic cylinder sleeve, the elastic spokes are integrally elastic, impact force is avoided in the machining process of the ceramic cylinder sleeve, and damage to the ceramic cylinder sleeve is avoided.

Owner:济南宝山石油设备有限公司

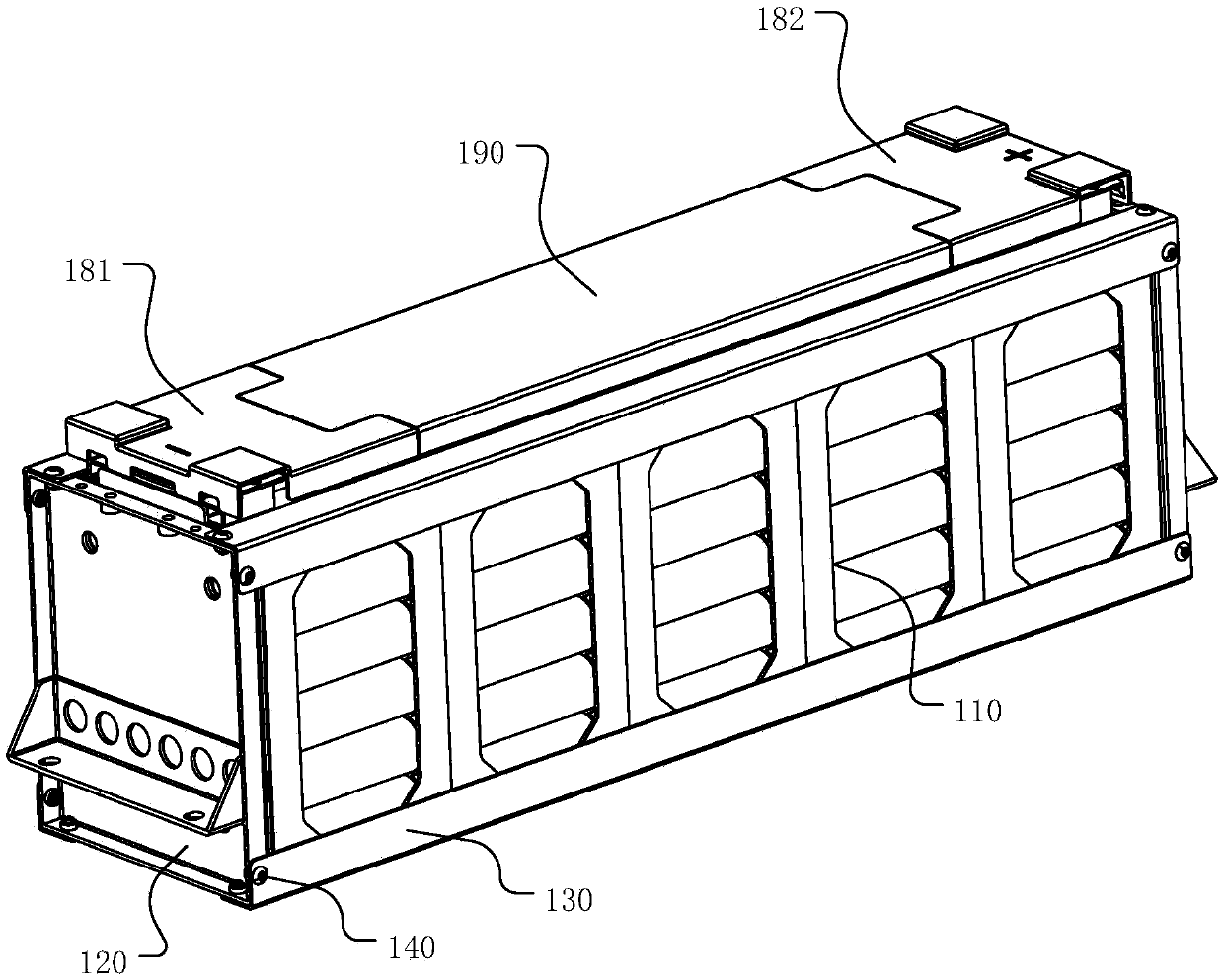

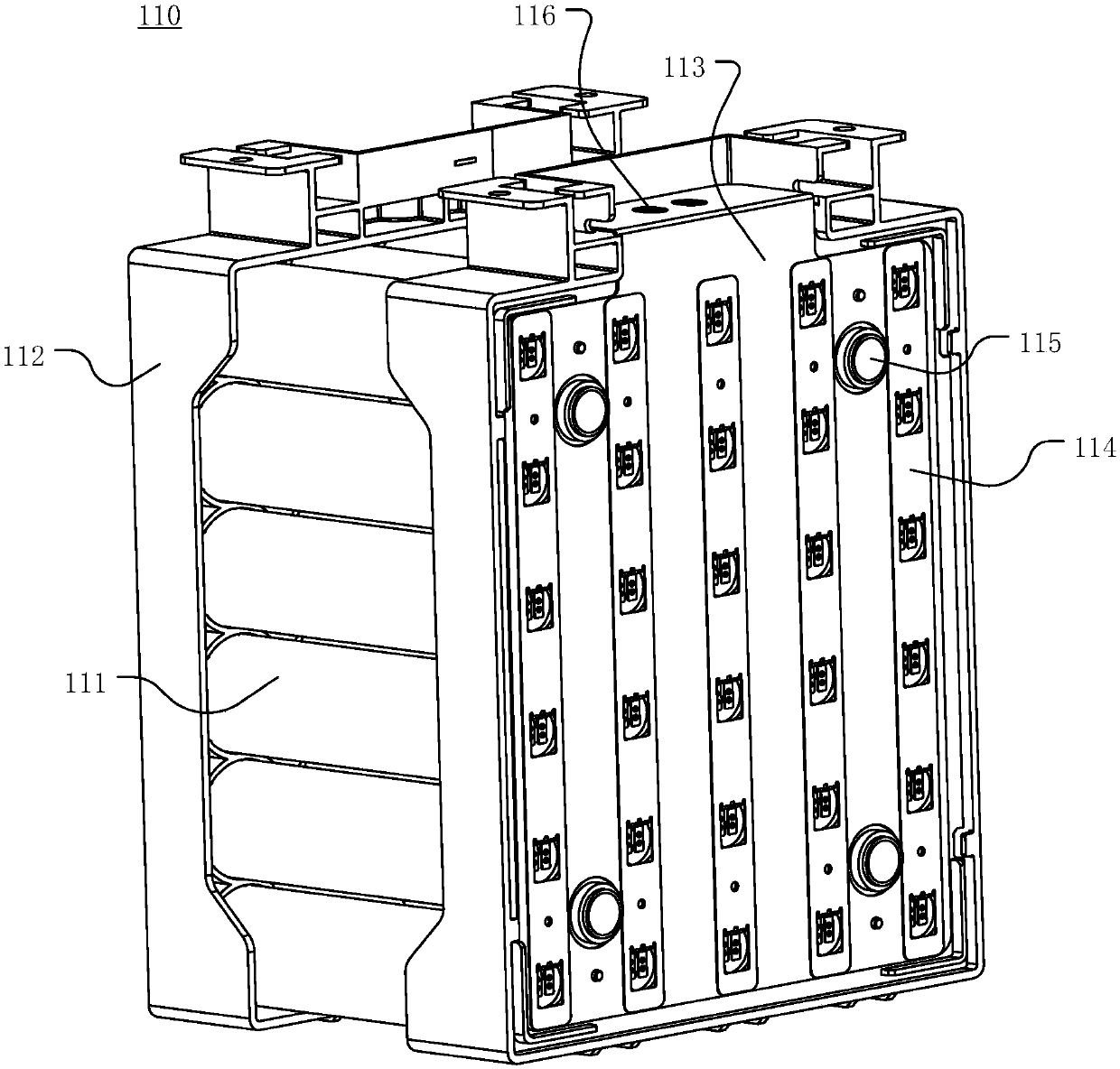

Cylindrical power battery module

PendingCN107681098AImprove shock resistanceImprove impact resistanceCell component detailsElectricityElectrical battery

The invention discloses a cylindrical power battery module. The cylindrical power battery module comprises a plurality of battery modules, a plurality of electric connecting sheets positioned among adjacent battery modules and used for connecting the multiple battery modules, a module frame used for accommodating and fixing the multiple battery modules, and a battery upper cover used for coveringand protecting the multiple battery modules, wherein the module frame comprises two end plates and four fixed steel angles; the fixed steel angles and the end plates are connected in a riveting manner; and the battery upper cover comprises a positive polar column upper cover, a negative polar column upper cover and a middle upper cover. The cylindrical power battery module provided by the invention adopts the multiple battery modules which can be freely assembled, so that a high-voltage and high-capacity battery system can be formed through series-parallel connection according to needs; the cylindrical power battery module is simple in structure, convenient to assemble and high in universality and interchangeability; and by virtue of the riveting mode, the overall impact resistance and vibration resistance of the module can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

Novel forklift hydraulic pipeline tee joint

ActiveCN104006252APrevent fallingMove quicklyLifting devicesJoints with fluid cut-off meansHigh pressurePetroleum engineering

The invention discloses a novel forklift hydraulic pipeline tee joint. The novel forklift hydraulic pipeline tee joint comprises a joint body which is provided with an oil cylinder connecting opening; a sliding valve is flexibly arranged in the oil cylinder connecting opening; the cylindrical wall of the oil cylinder connecting opening is provided with a rear external thread section and a front external thread section; the end portion of the oil cylinder connecting opening extends to form a small diameter connection portion which is matched and connected with an end cover; the sliding valve comprises a base and a valve body; the base is arranged in the oil cylinder connecting opening; the valve body is formed and arranged on the base; the side wall of the valve body is provided with a first oil hole; the end portion of the valve body is provided with a second oil hole; the first oil hole and the second oil hole are formed in a communicated mode; the rear external thread section is formed by left-hand threads and right-hand threads which are arranged correspondingly and matched with each other; the rear external thread section is provided with a fastening nut and a locking nut. According to the novel forklift hydraulic pipeline tee joint, the structure is simple and reasonable, the high pressure impact on the joint of the hydraulic oil can be avoided, the normal work of a hydraulic pipeline can be ensured, the sliding valve is high in action sensitivity, and the sealing effect is good.

Owner:NINGBO GUANTONG MACHINERY

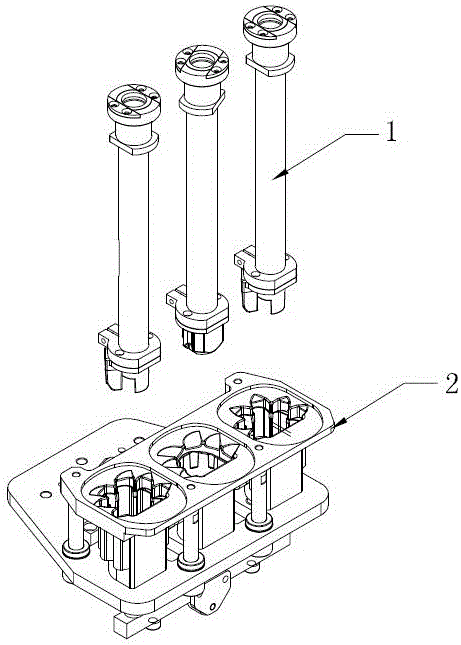

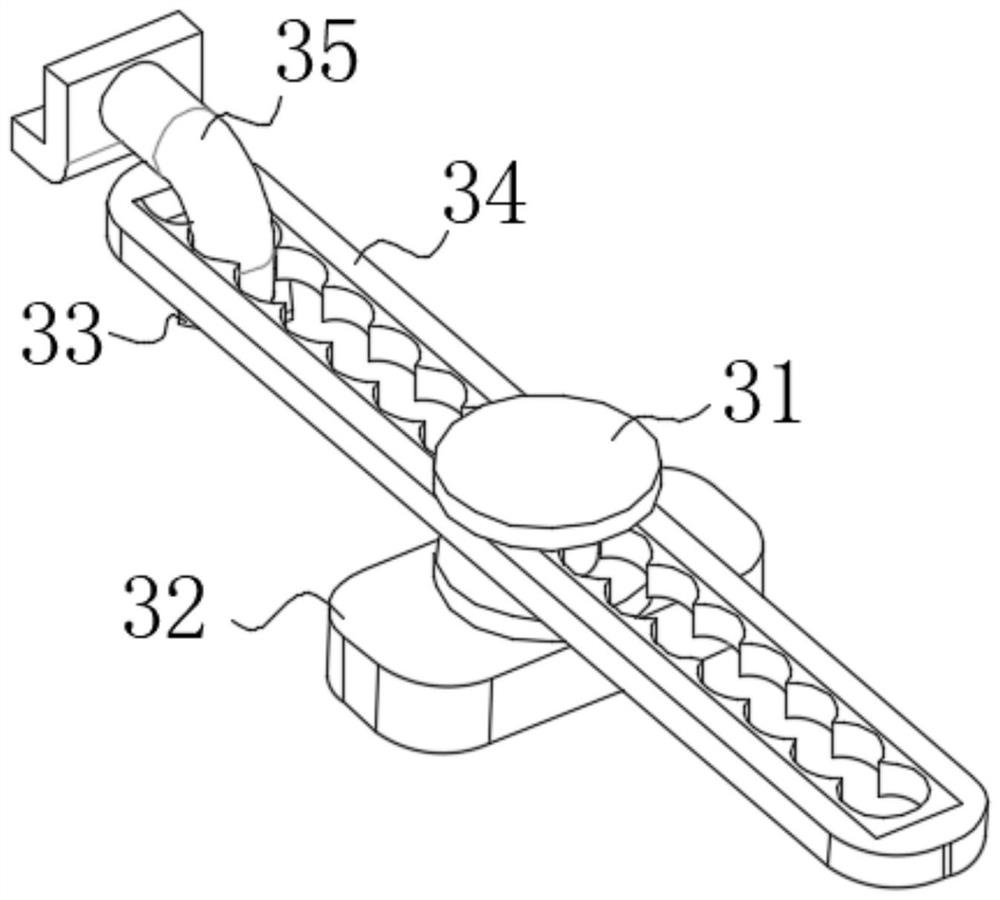

Laced farci food forming device

InactiveCN106509011AGood molding effectImprove aestheticsDough processingWave shapeBiomedical engineering

The invention belongs to the technical field of food processing and particularly relates to a laced farci food forming device. The laced farci food forming device comprises stuffing injection pipes and forming molds located below the stuffing injection pipes. Each forming mold comprises a wrapper receiving plate and a mold cup located under the wrapper receiving plate, the wrapper receiving plate is provided with a forming hole, the corresponding stuffing injection pipe is located above the forming hole, the mold cup is correspondingly arranged below the forming hole, a plurality of sequentially distributed wave-shaped through holes are formed in the periphery of the forming hole, and forming raised lines are arranged below the corresponding stuffing injection pipe. The forming raised lines are used for cooperating with the corresponding forming hole when a corresponding stuffing injection head pokes a wrapper downwards, so that a pattern is formed by squeezing the wrapper. The wave-shaped through holes formed in the periphery of each forming hole cooperate with the corresponding forming raised lines arranged on the corresponding stuffing injection head, the wave-shaped lace can be formed by squeezing the wrapper, the forming effect of appearance is good, and the attractiveness of farci food is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

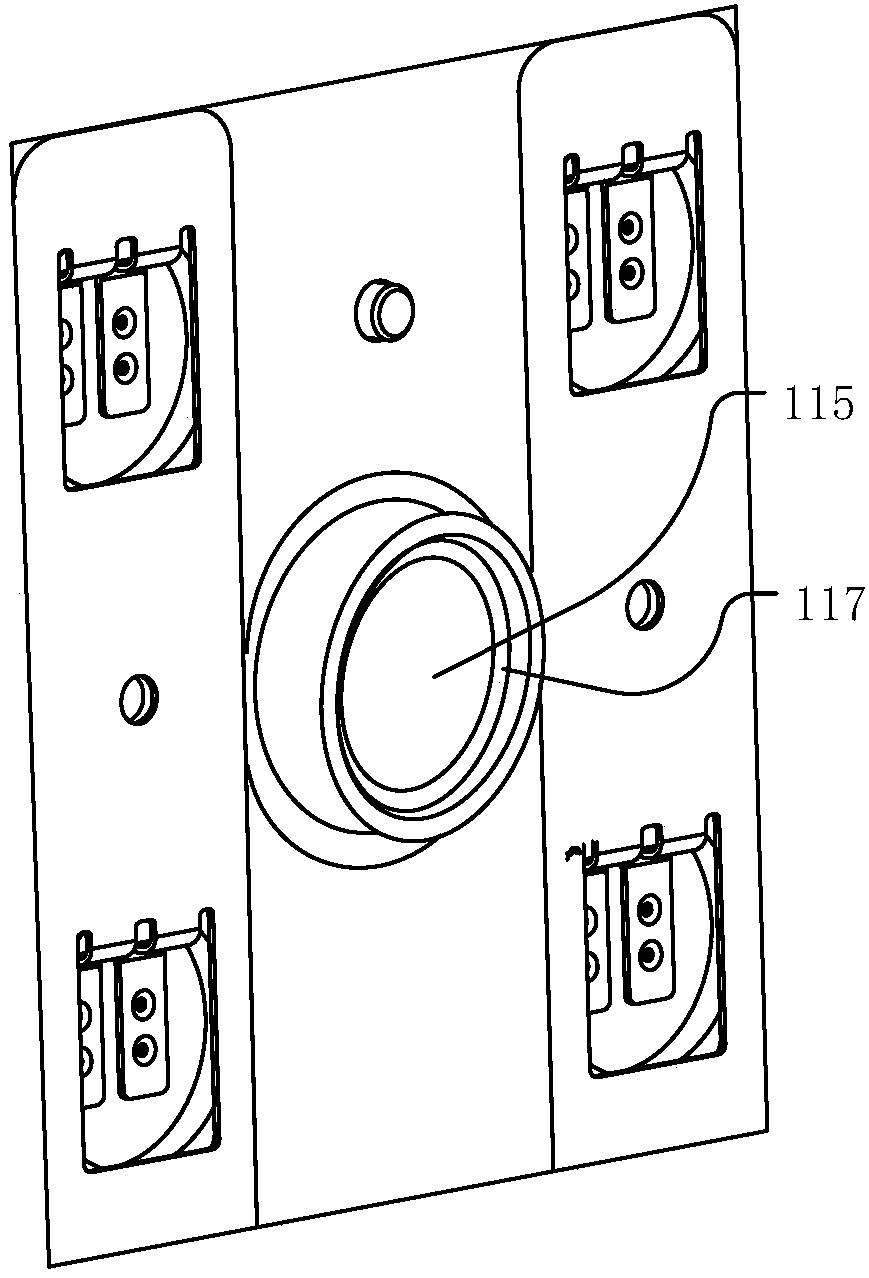

Industrial electricity utilization and leakage detection equipment

InactiveCN110988739ASimple structureEasy to useShort-circuit testingMeasurement instrument housingStandby powerHemt circuits

The invention discloses industrial electricity utilization and leakage detection equipment, which comprises an insulating installation plate, wherein installation holes used for installation are formed in four corners of the insulating installation plate; a main circuit fixing sleeve and an auxiliary circuit fixing sleeve are vertically, symmetrically and fixedly connected to the insulating installation plate; an insertion rod is arranged on the insulating installation plate and corresponds to a position between the main circuit fixing sleeve and the auxiliary circuit fixing sleeve; the top end of the outer surface wall of the insertion rod is fixedly connected with a fixing sleeve base, the main circuit fixing sleeve, the auxiliary circuit fixing sleeve and the fixing sleeve base are fixedly connected with cables, the insulating installation plate is fixedly connected with a fixing base corresponding to the lower portion of the insertion rod, the side wall of an inner cavity of the fixing base is fixedly connected with a rotating base, and the rotating base is rotationally connected with a lead screw. When electric leakage occurs, the industrial electricity utilization and leakagedetection equipment can automatically detect and cuts off a high-voltage line automatically, meanwhile, the high-voltage line is automatically powered off, a standby power supply is started, the problems that technicians conduct manual operation and are at risk are avoided, high industrial power consumption and the production schedule are not affected, and a large amount of time is saved.

Owner:克莱门斯工业传感器南京有限公司

Novel shaping device used for laced foods with stuffing

InactiveCN106614868AGood molding effectImprove aestheticsDough shapingDough processingWave shapeEngineering

The invention belongs to the technical filed of food processing, and especially relates to a novel shaping device used for laced foods with stuffing. The novel shaping device used for the laced foods with stuffing comprises a stuffing filling tube and a shaping mold arranged under the stuffing filling tube; the shaping mold comprises a wrapper receiving board and a mold cup arranged under the wrapper receiving board; a shaping hole is arranged on the wrapper receiving board; the stuffing filling tube is arranged above the shaping hole; the mold cup is arranged under the shaping hole in a corresponding way; the dough-made wrapper is placed on the shaping hole of the wrapper receiving board; the stuffing filling tube moves downwards so as to push the wrapper downwards; staggered extrusion is performed on the wrapper by the shaping convex strips arranged on the stuffing filling tube and the wave-shaped through-holes arranged around the shaping hole so as to form wave-shaped lace around the wrapper when the wrapper is pushed downwards by the stuffing filling tube. By adopting mutual match of the wave-shaped through-holes arranged at the outer edge of the shaping hole and the shaping convex strips arranged on the stuffing filling nozzle, the novel shaping device used for laced foods with stuffing is capable of extruding wrappers with wave-shaped laces, so that the device has good appearance shaping effects; thus, the prepared foods with stuffing have more beautiful appearance.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

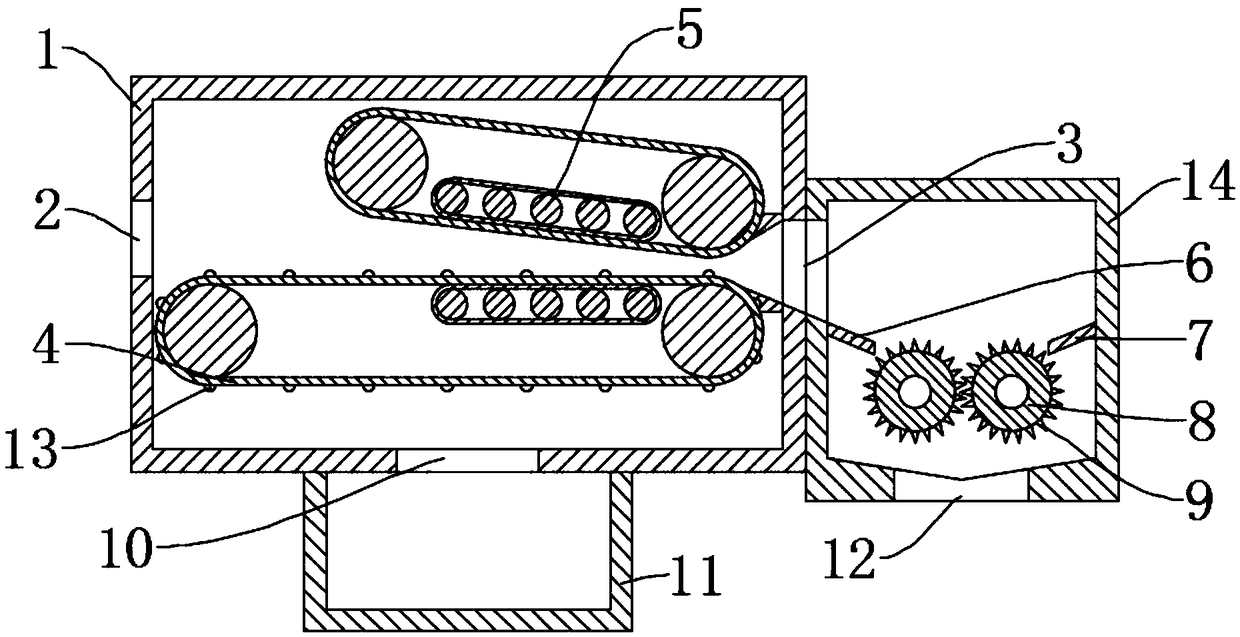

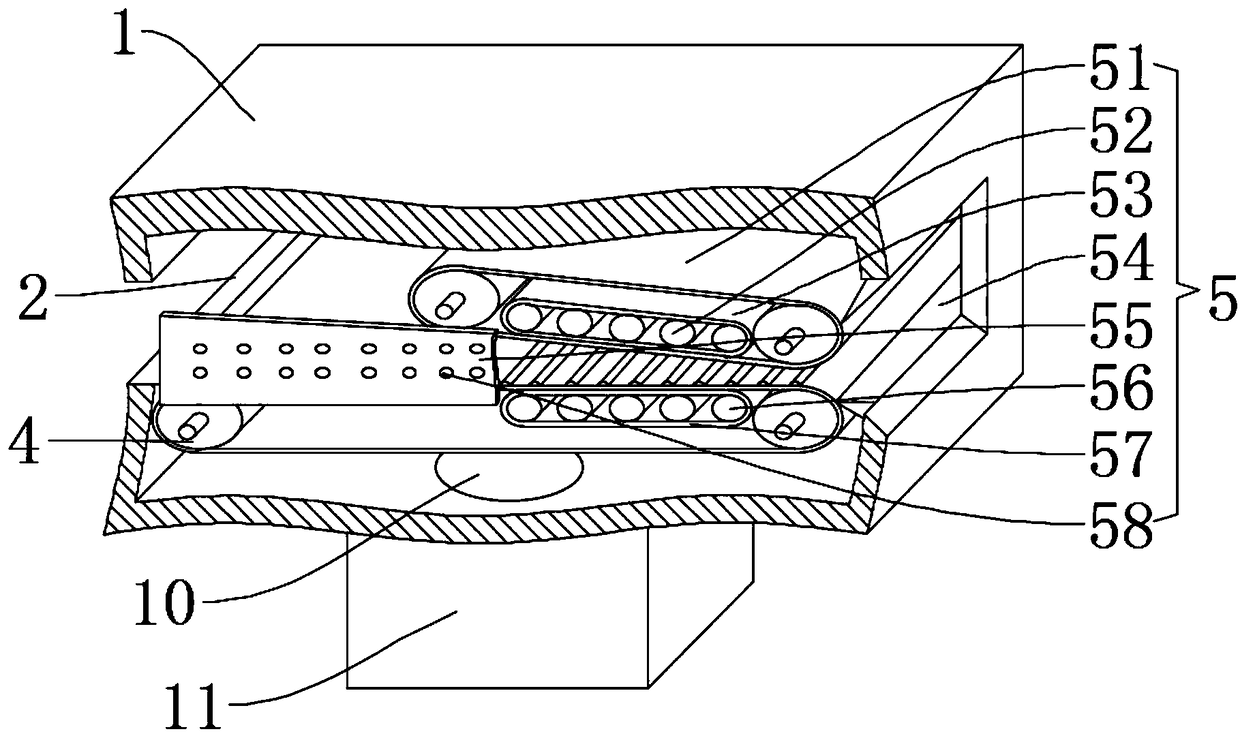

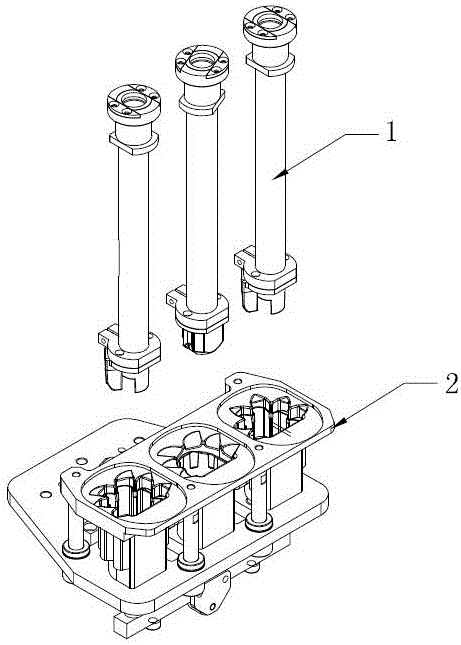

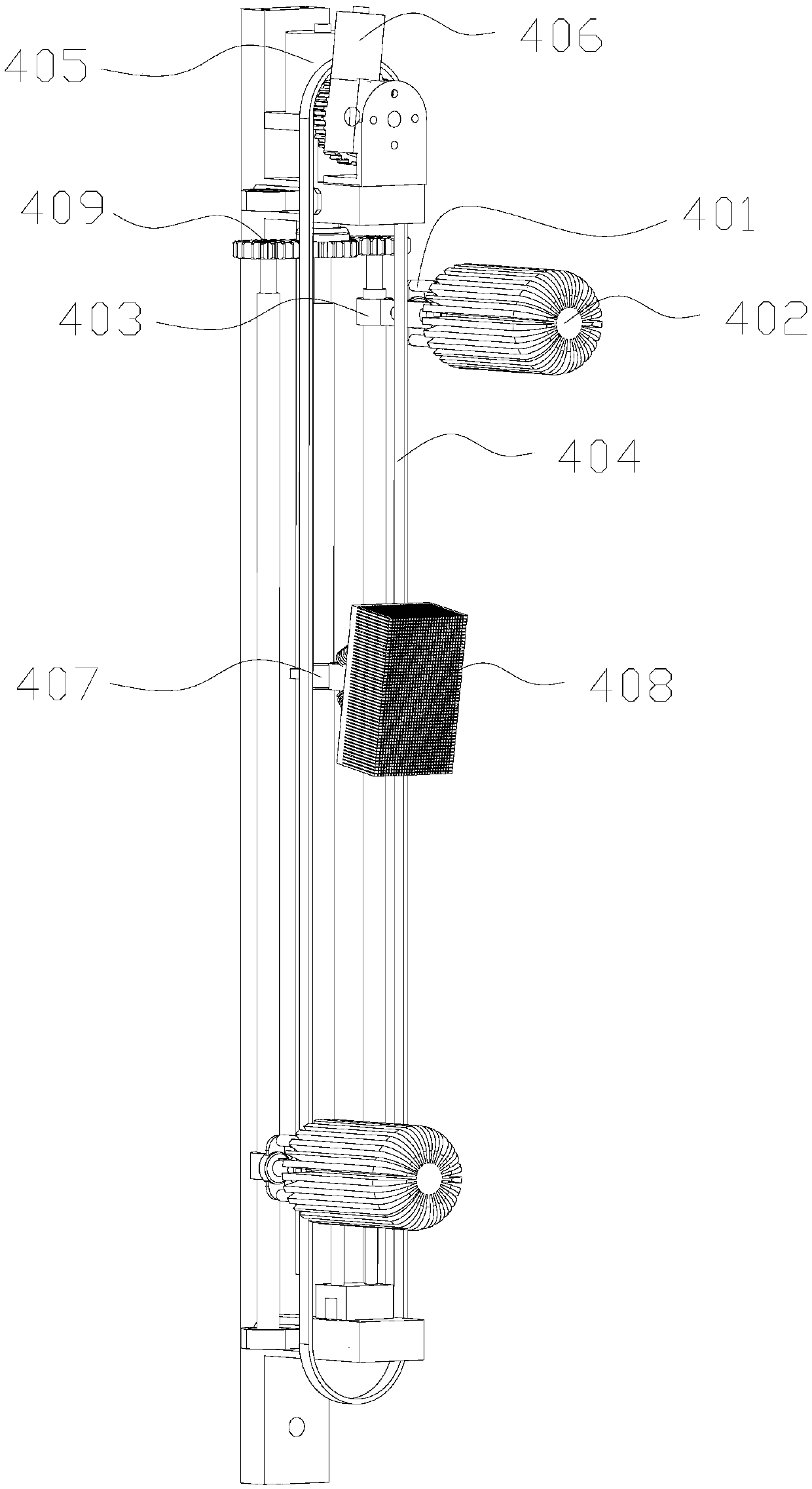

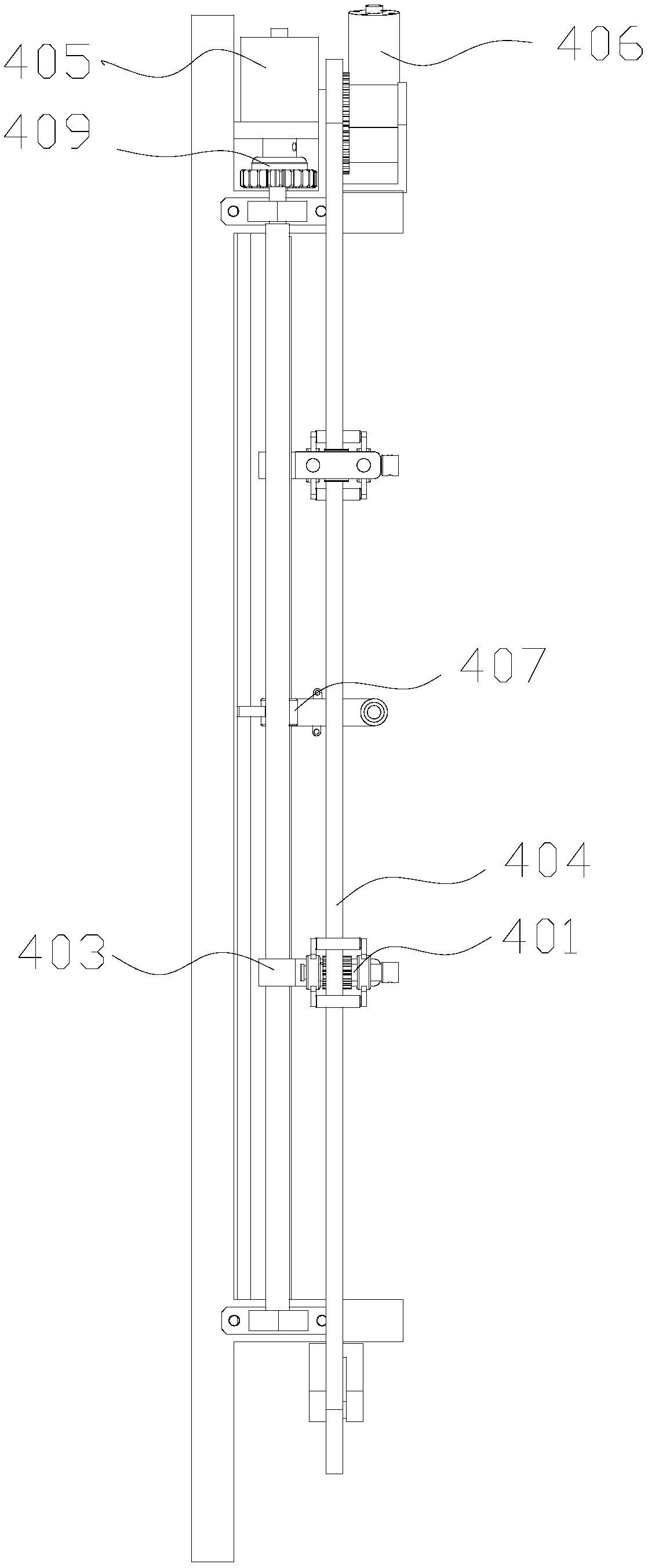

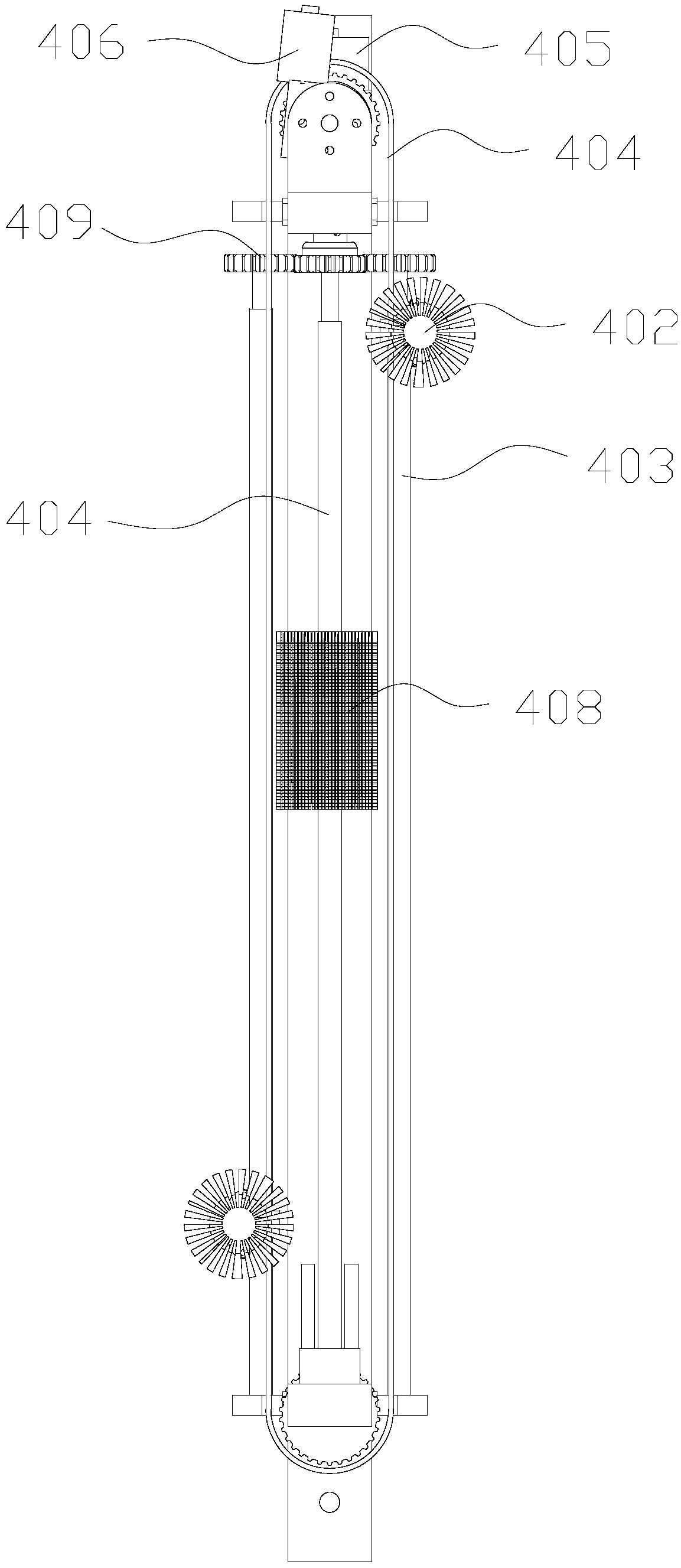

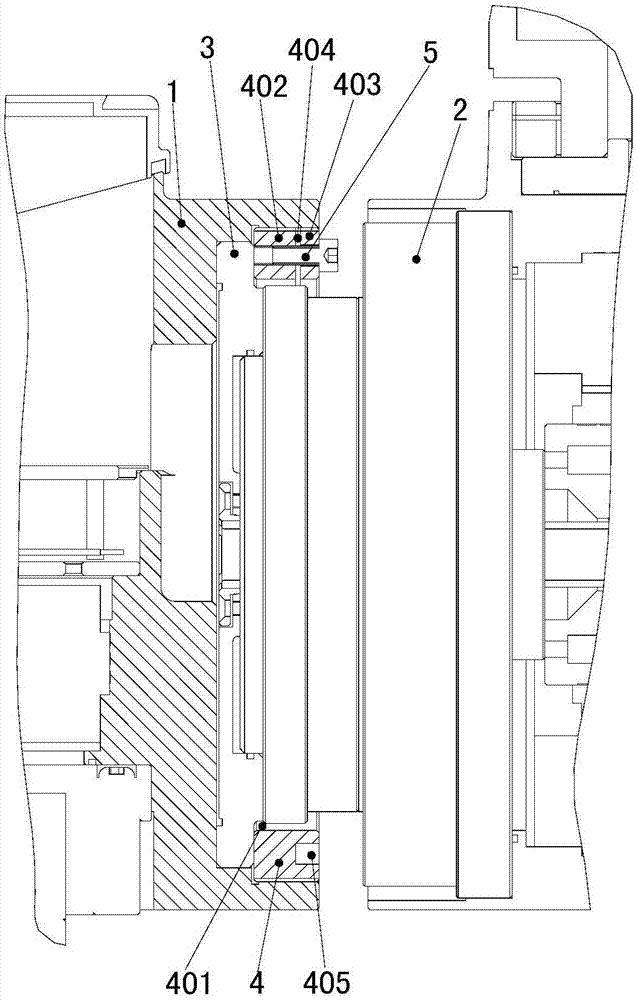

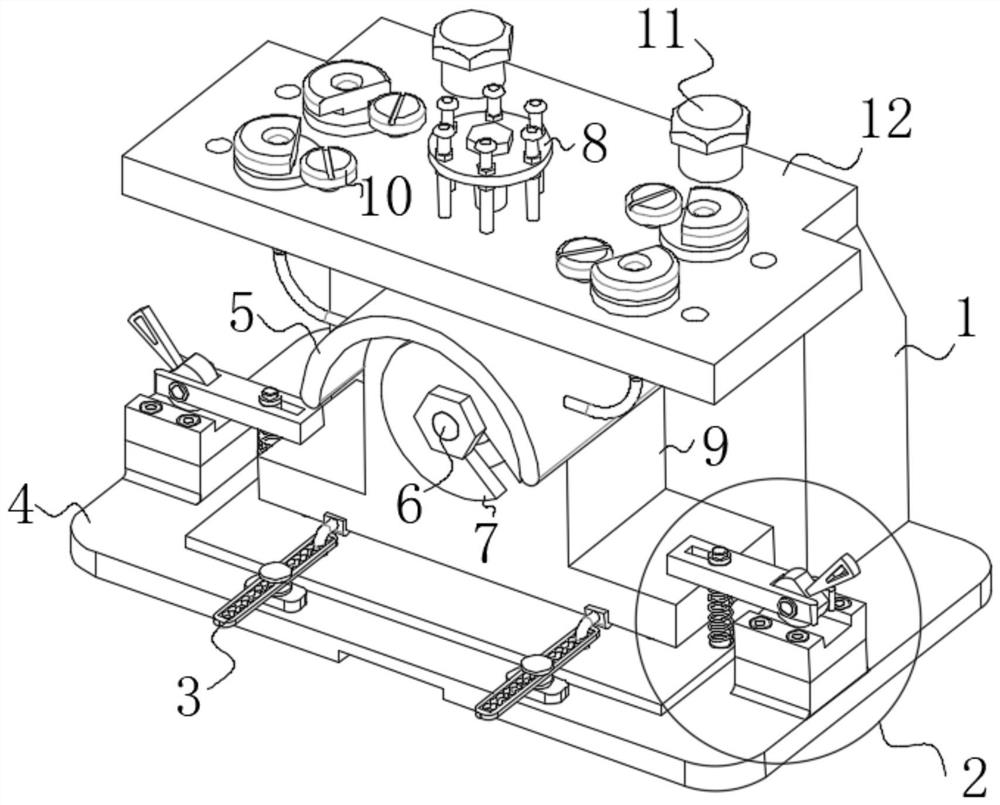

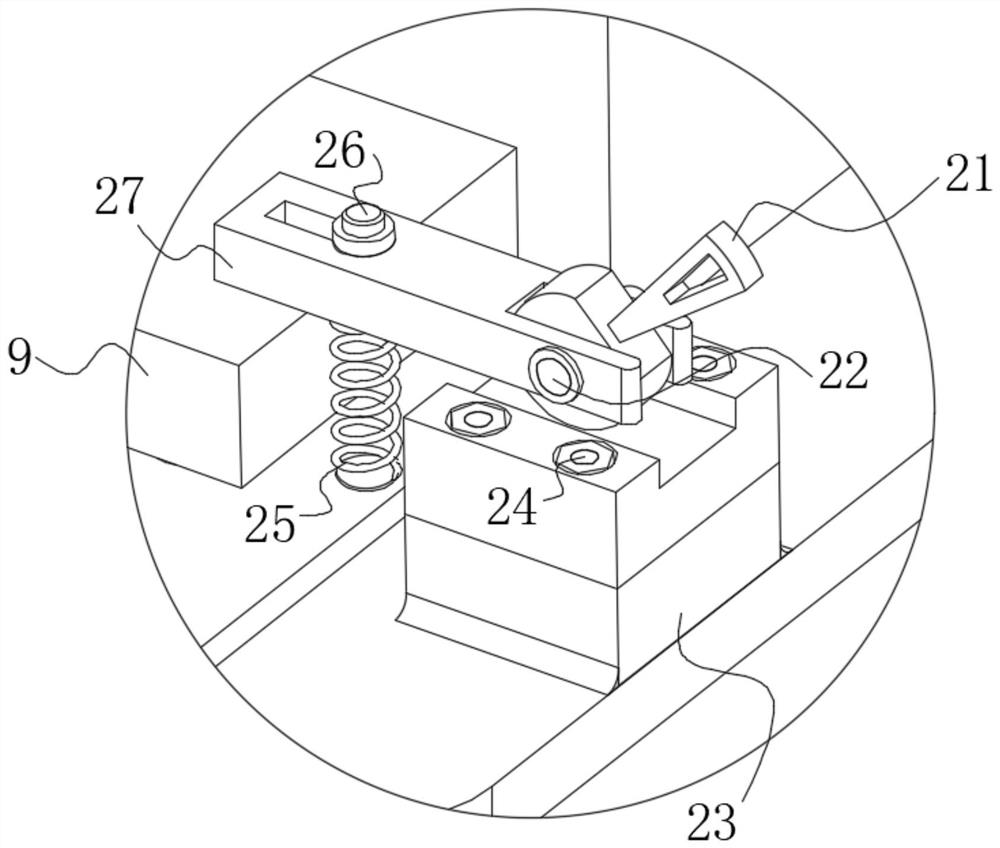

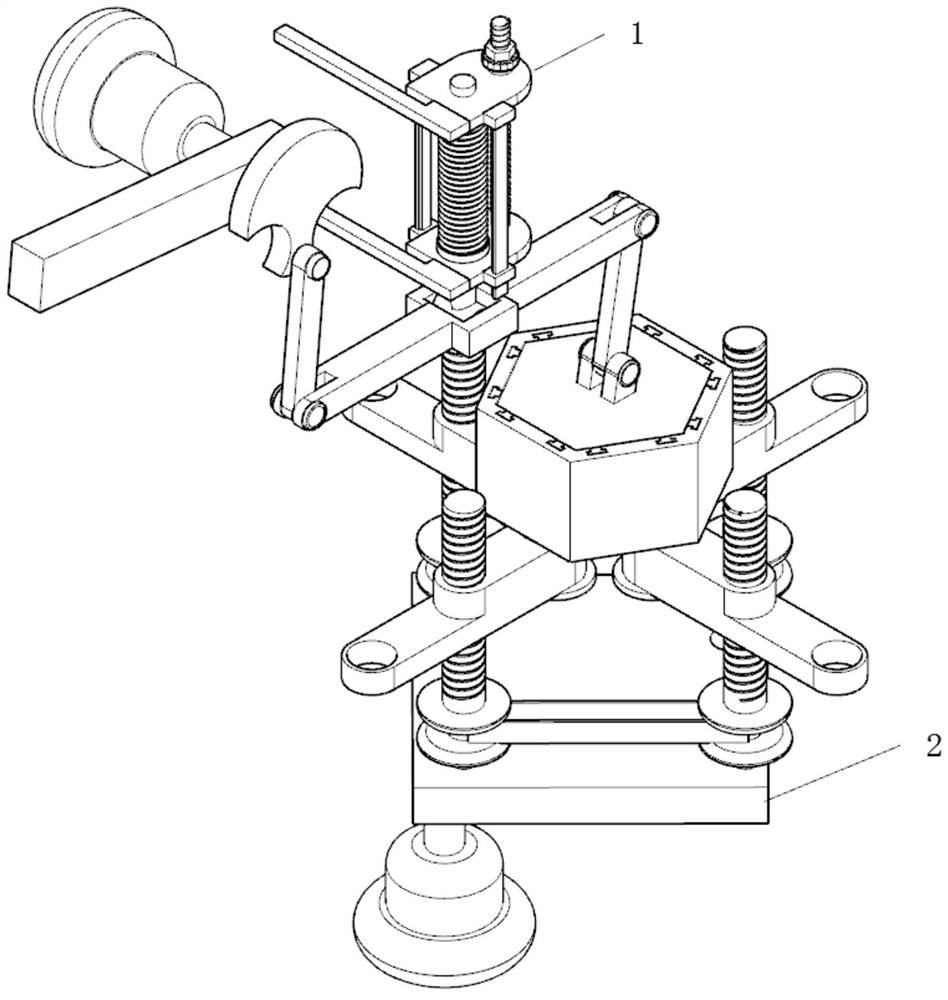

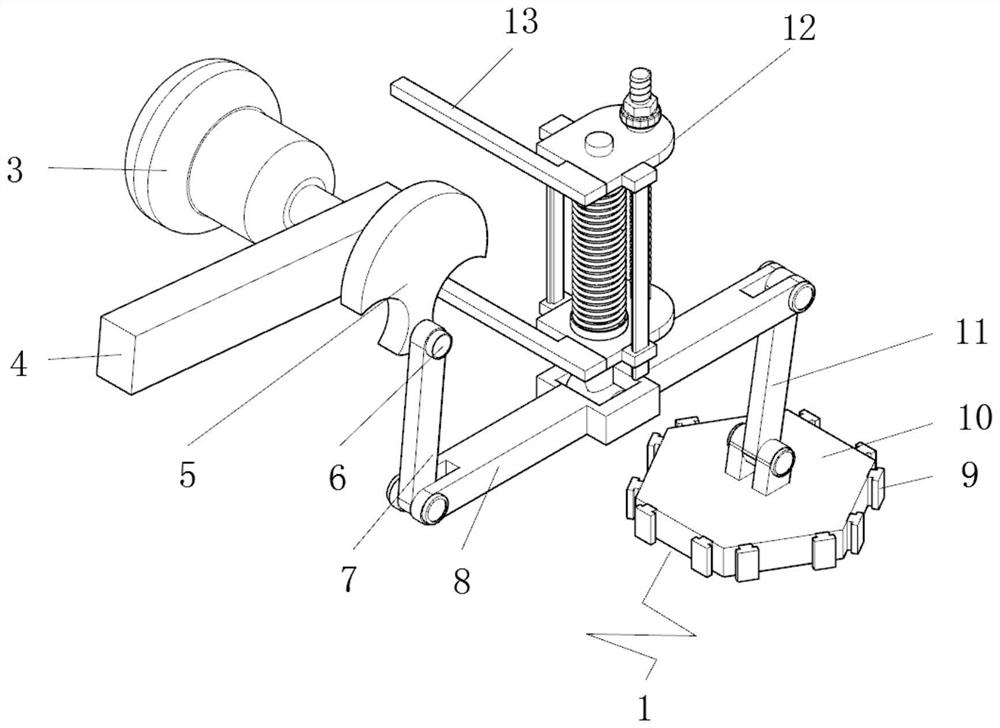

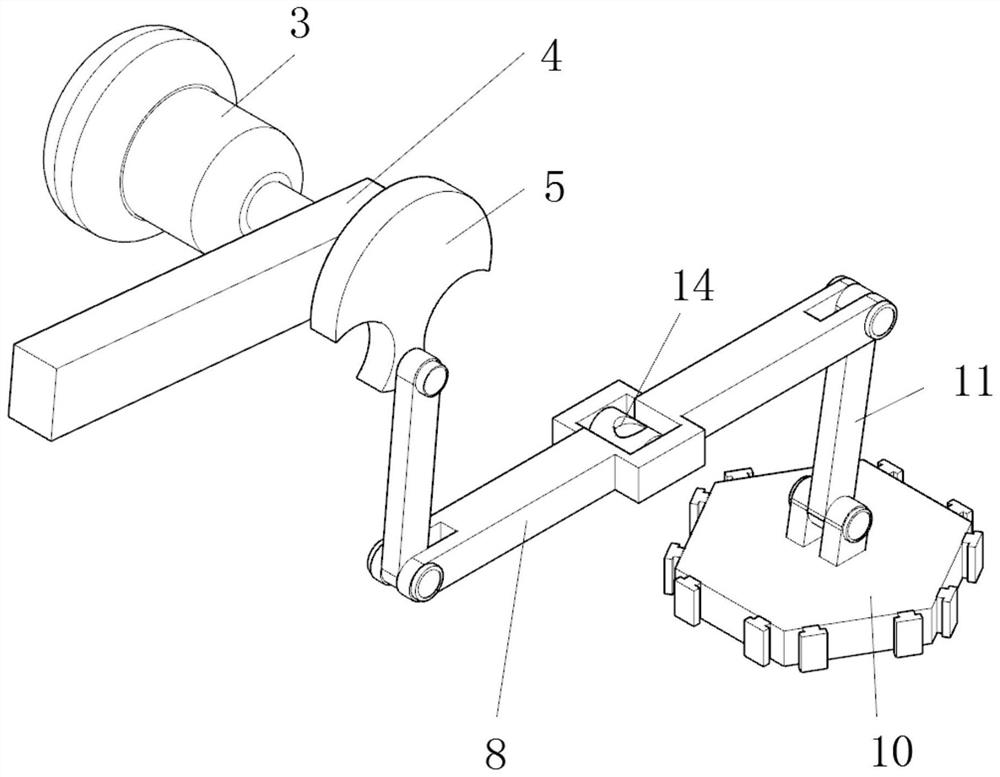

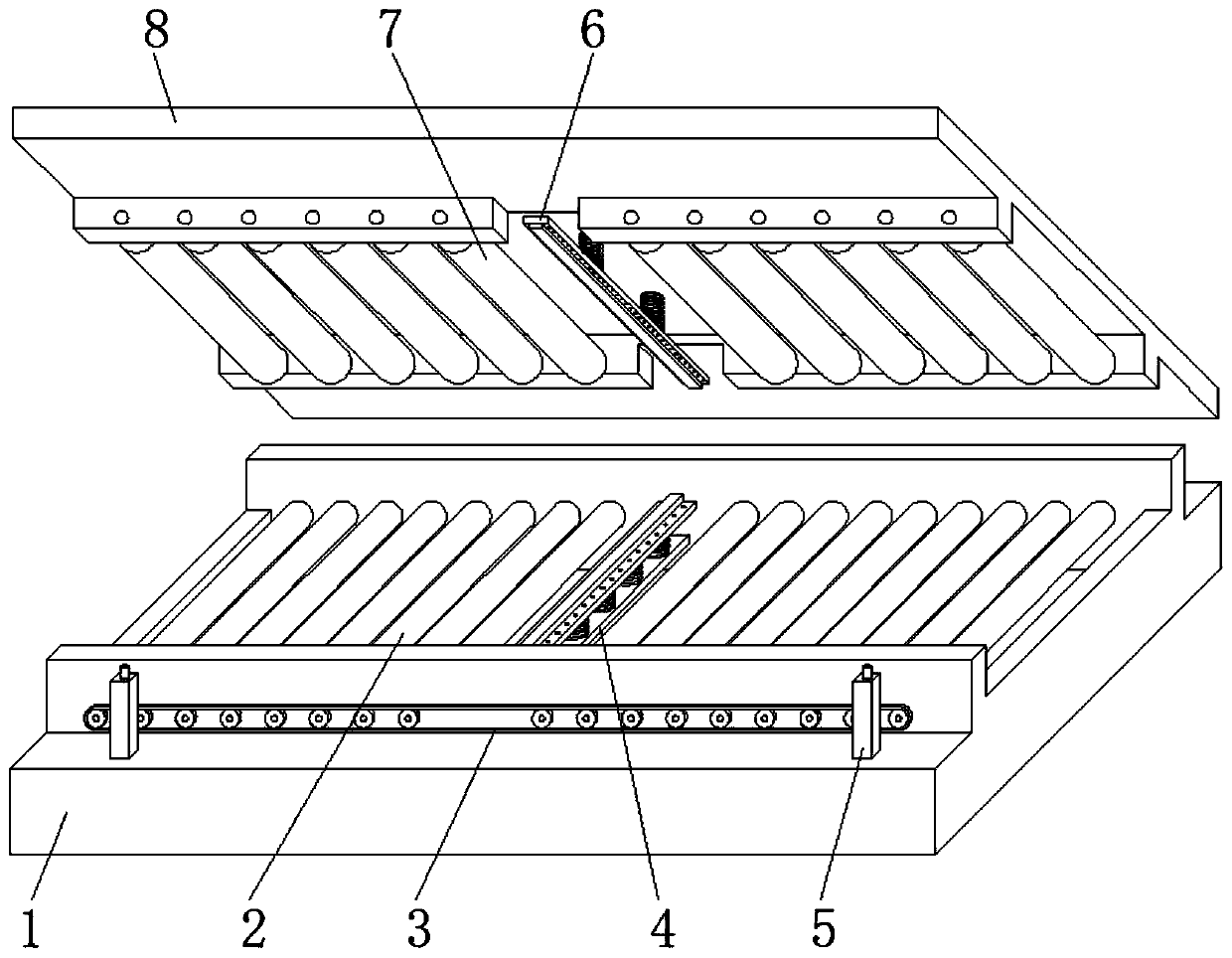

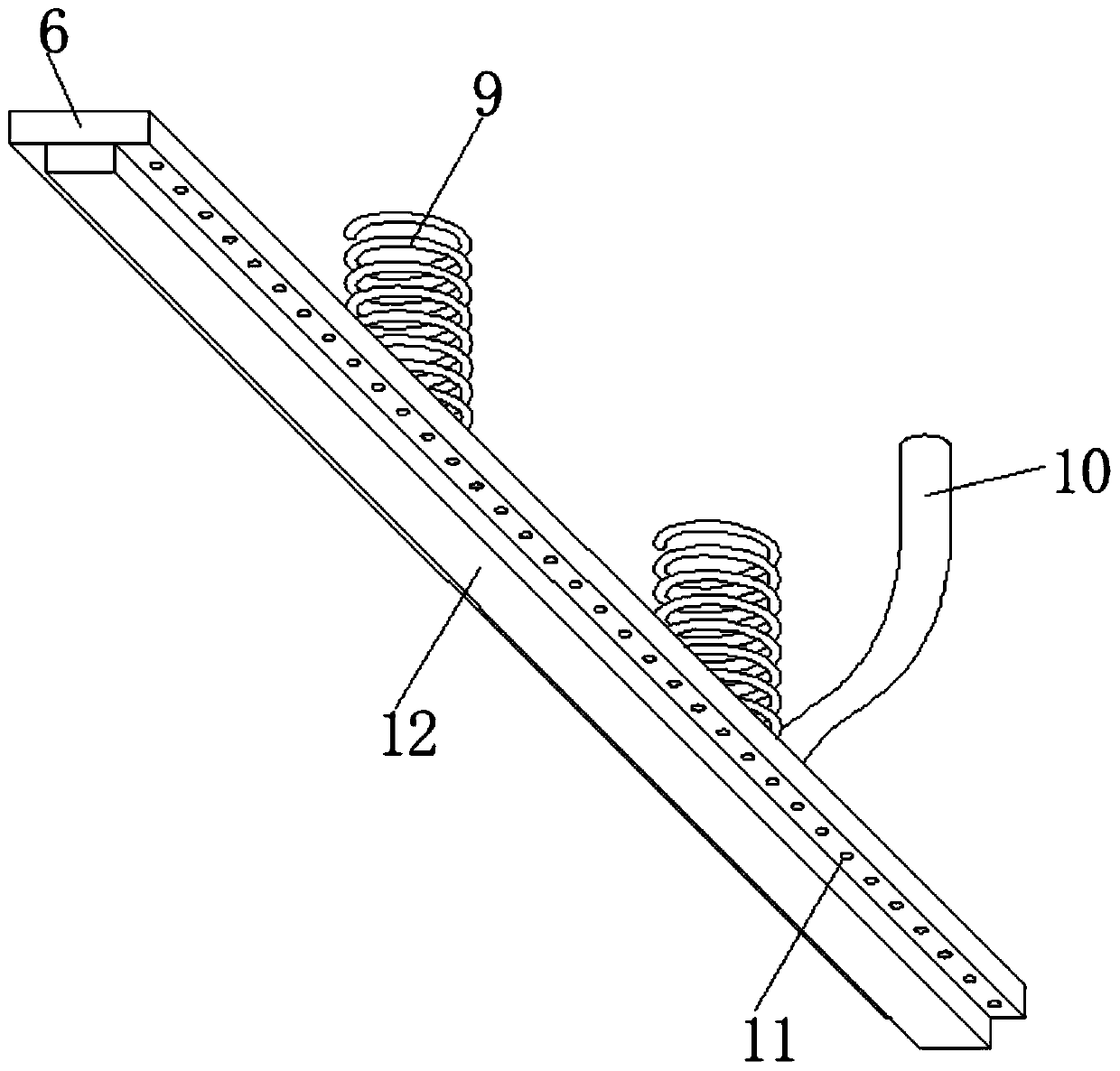

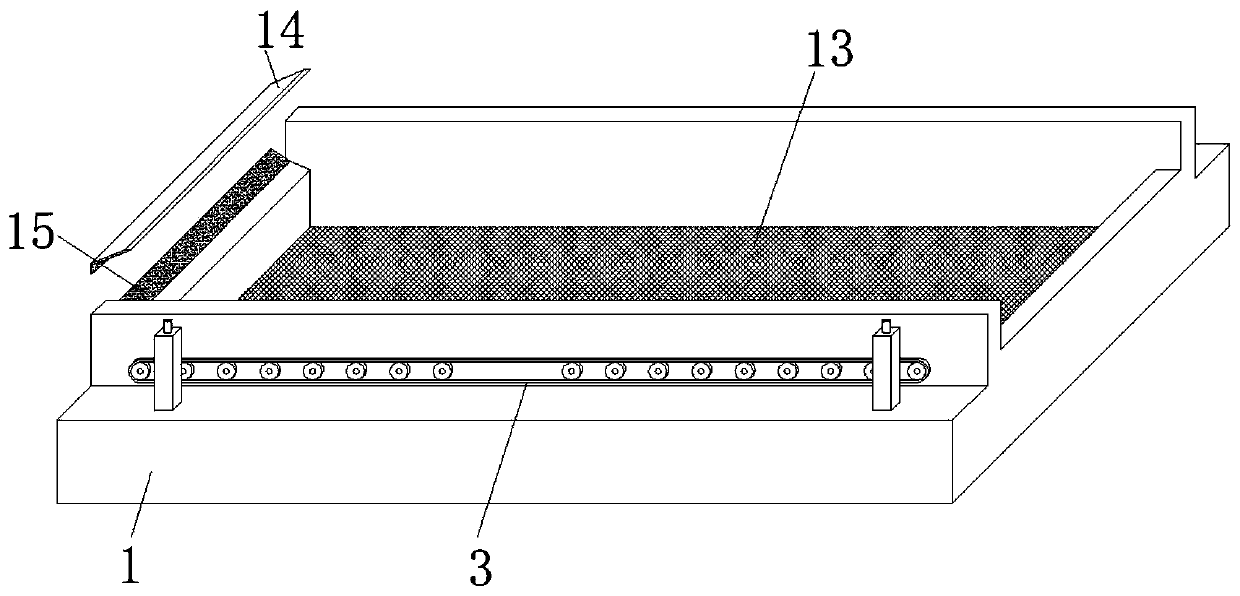

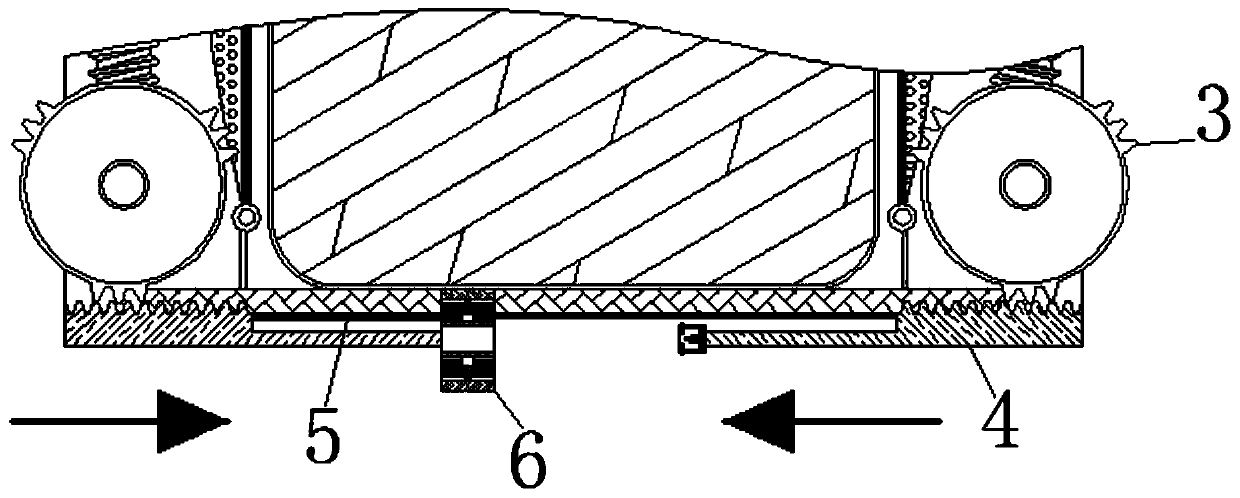

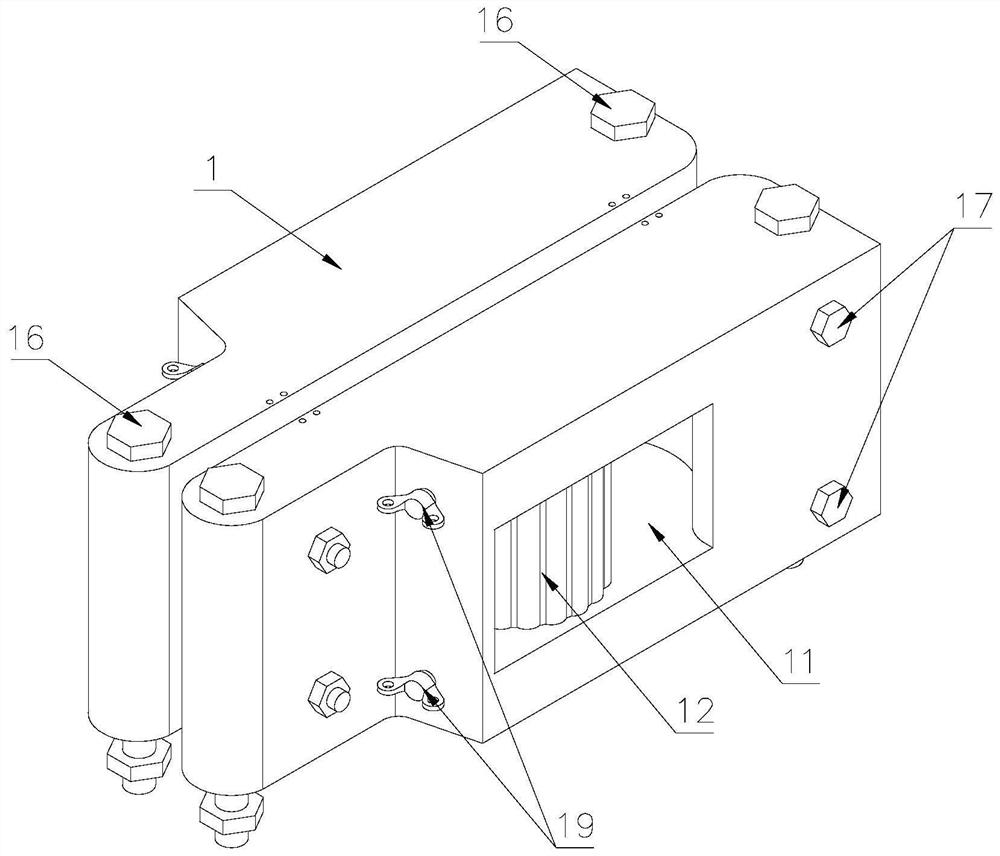

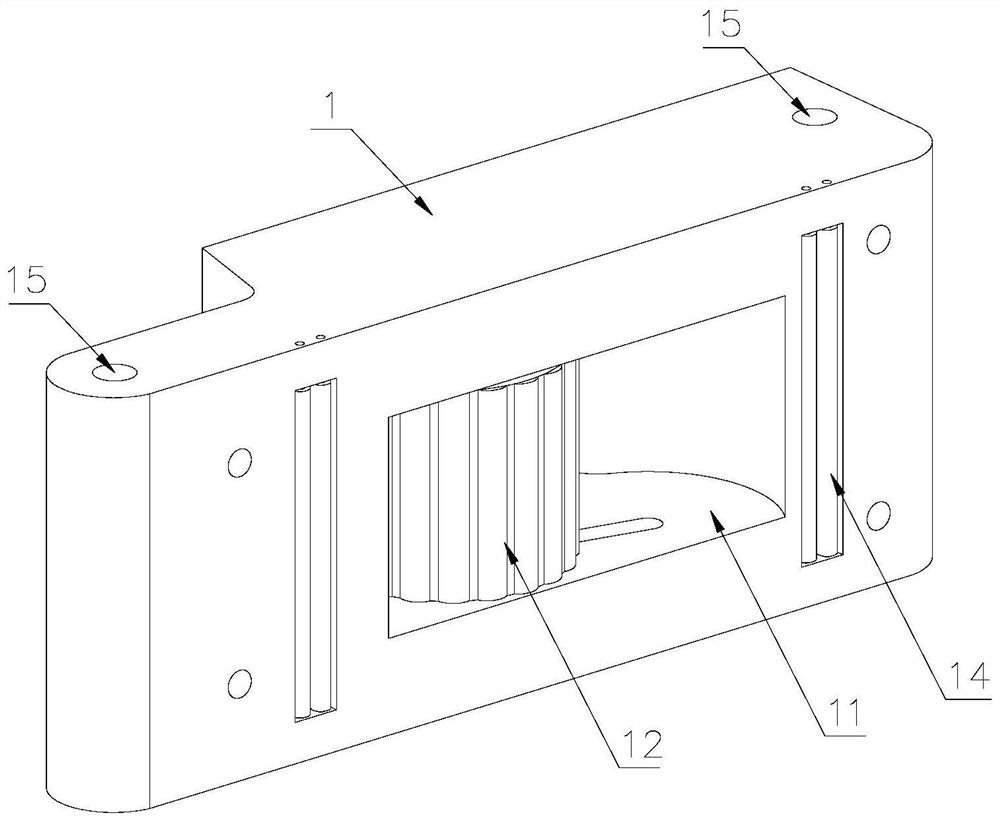

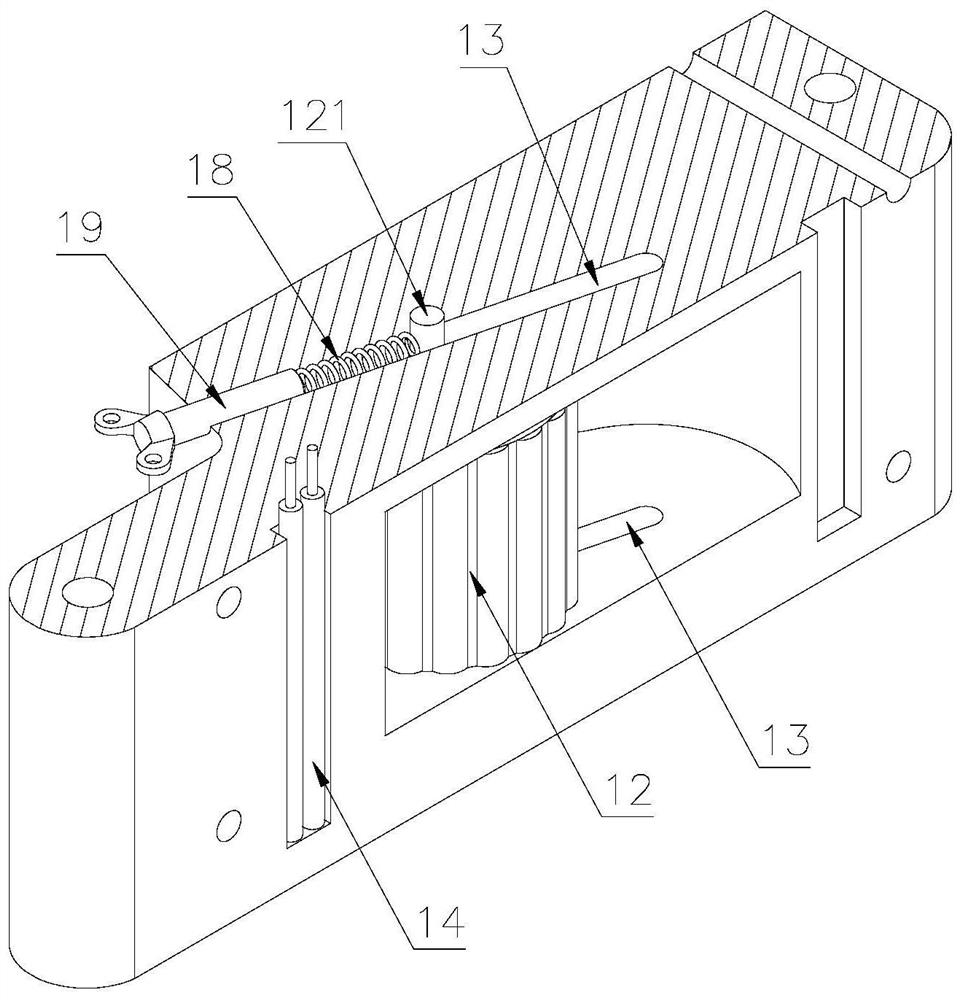

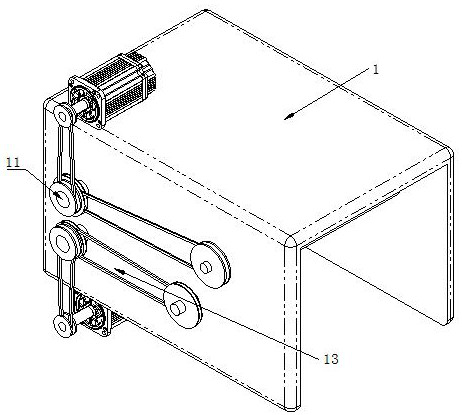

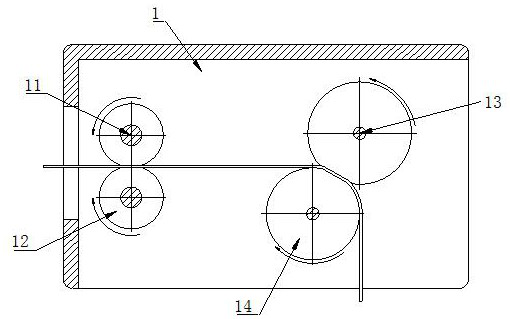

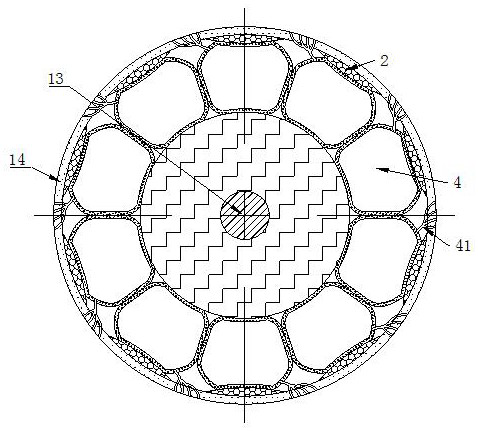

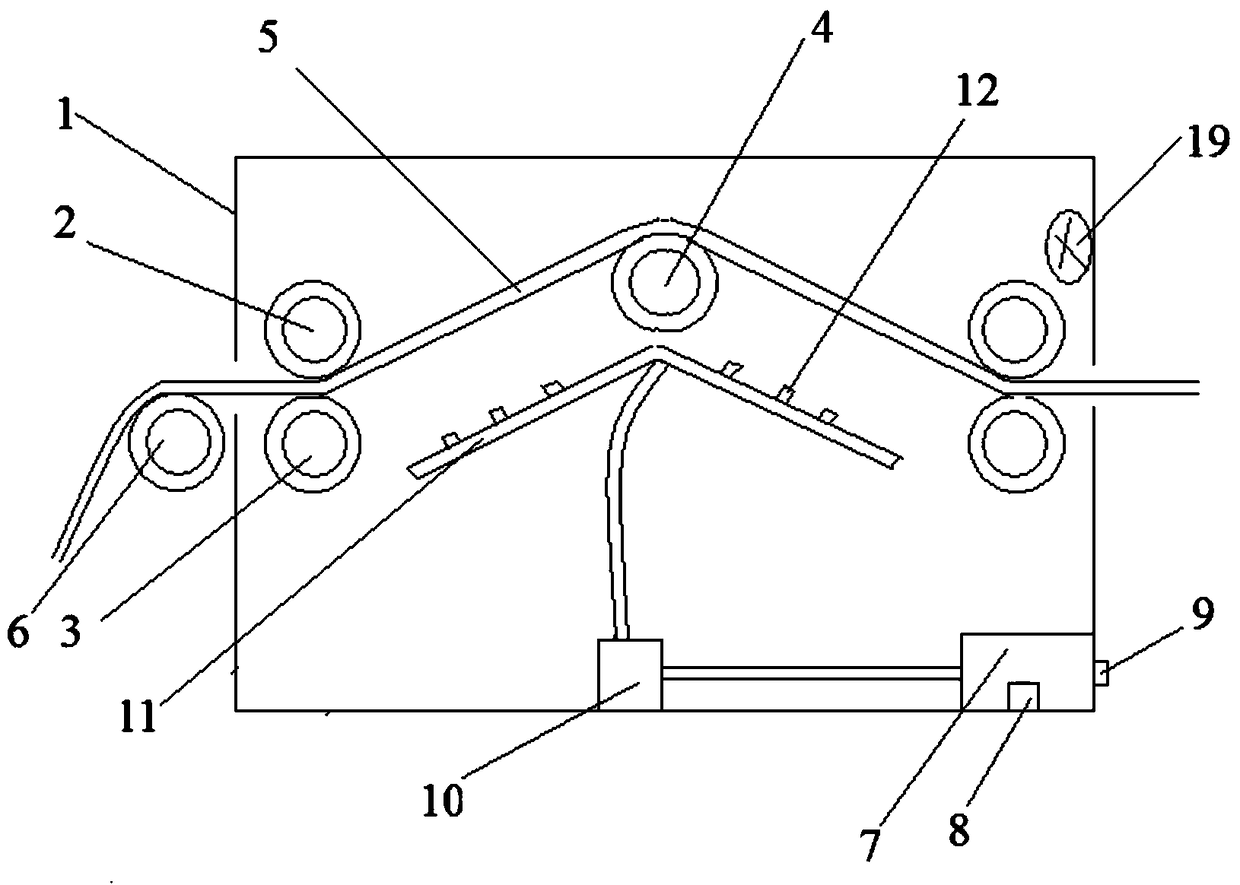

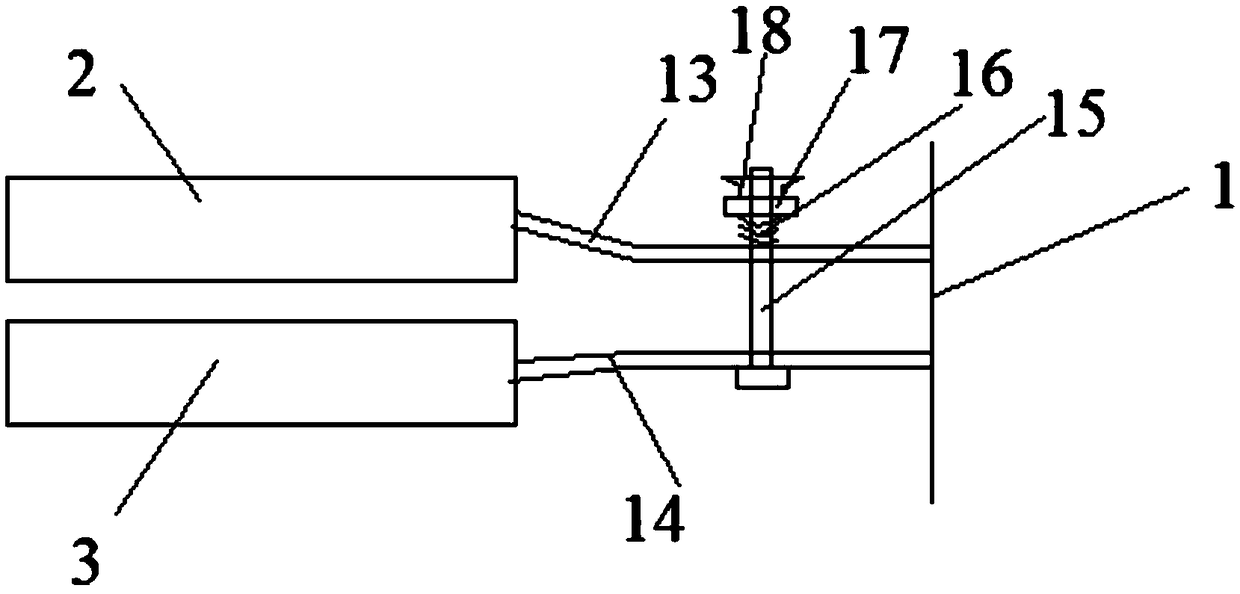

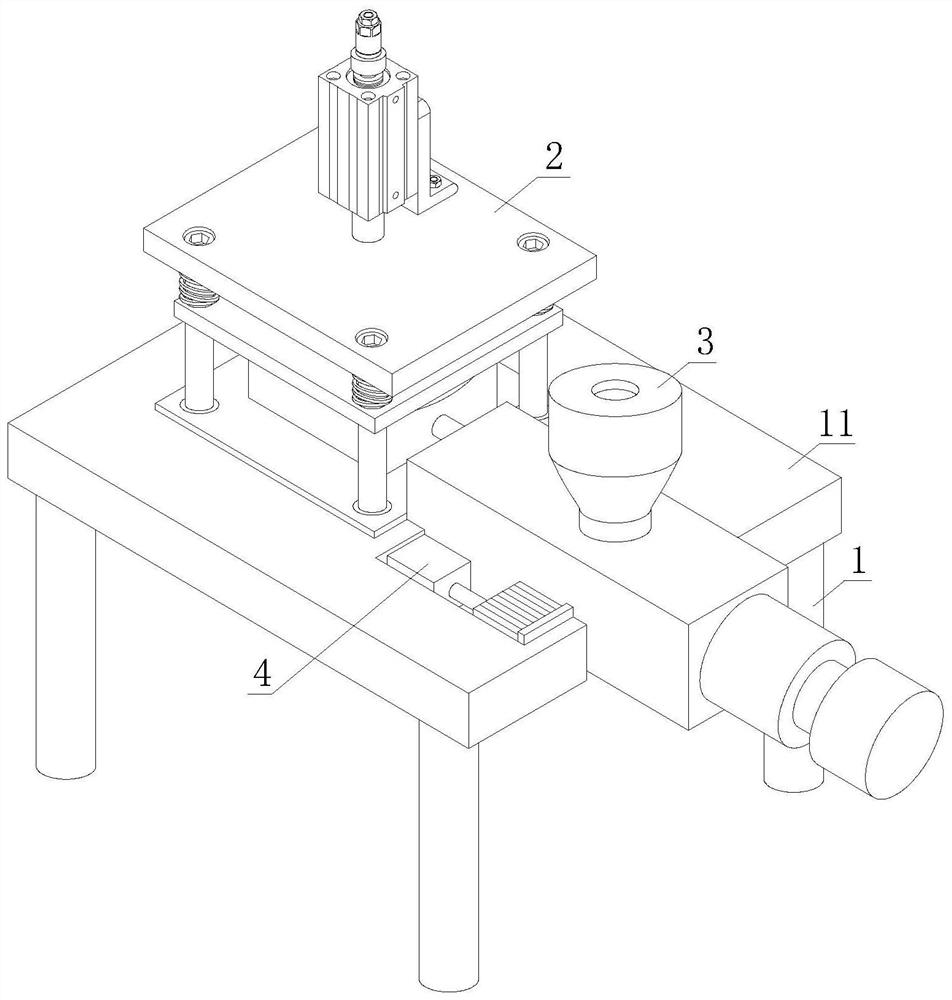

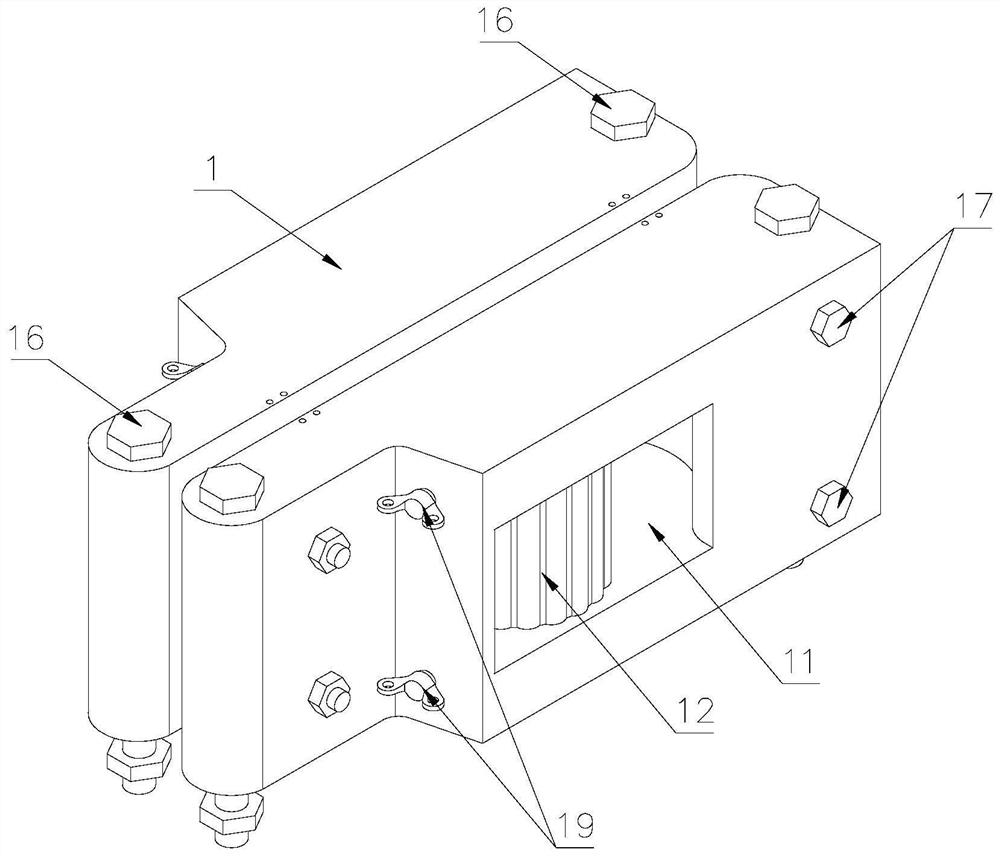

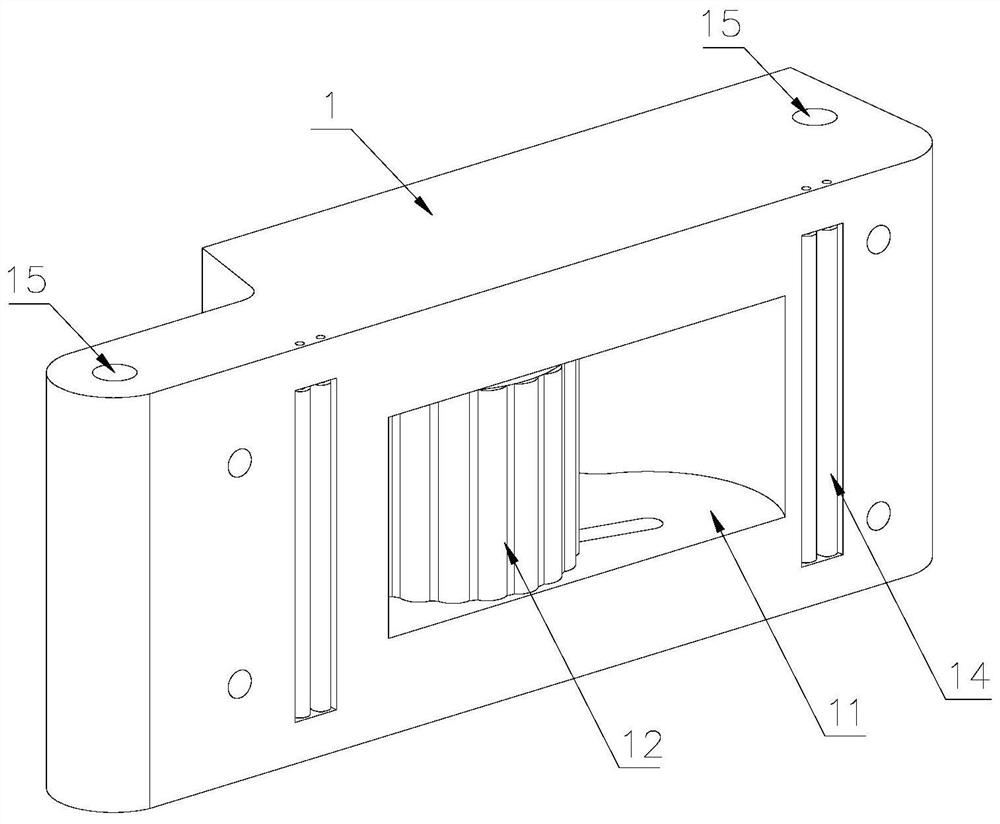

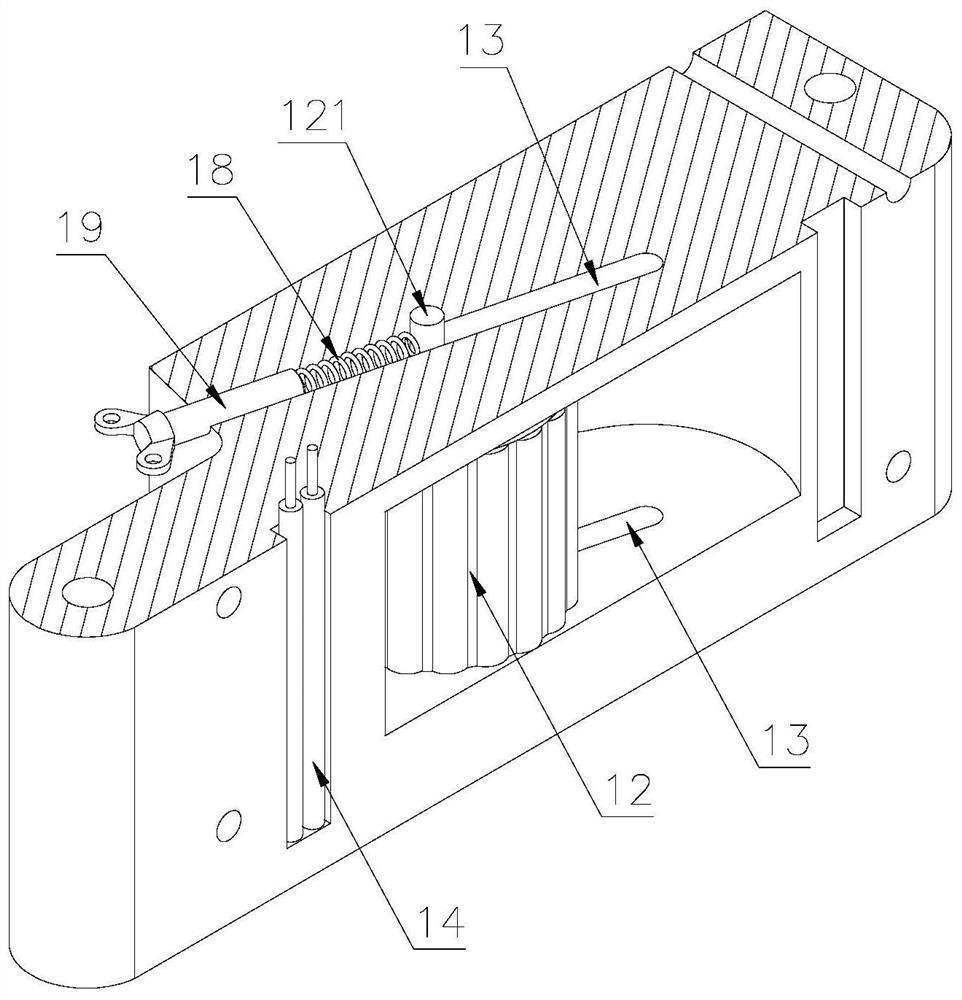

Shoe washing machine adopting belt drive type shoe washing mechanism

ActiveCN109528141AGuaranteed extrusion forceComprehensive cleaningFootwear cleanersEngineeringInstalled base

The invention discloses a shoe washing machine adopting a belt drive type shoe washing mechanism, and belongs to the technical field of shoe washing devices. The shoe washing machine comprises an outer frame support, an inner frame support, a shoe stretcher support and a belt drive type shoe washing mechanism. The belt drive type shoe washing mechanism is installed on the outer frame support; theshoe stretcher support is installed on the inner frame support; the inner frame support is rotationally connected with the outer frame support through a third power mechanism; the belt drive type shoewashing mechanism comprises a shoe brush installing base, a belt shaft shoe brush, a first lead screw sliding block mechanism and a belt drive mechanism. The belt shaft shoe brush is installed on theshoe brush installing base; the shoe brush installing base is installed on a sliding block of the first lead screw sliding block mechanism, a lead screw of the first lead screw sliding block mechanism is in transmission connection with the first power mechanism; a synchronous belt of the belt drive mechanism penetrates through the shoe brush installing base, and the synchronous belt is in transmission connection with a rotating shaft of the belt shaft shoe brush; the belt drive mechanism is in transmission connection with a second power mechanism. A shoe can be accurately washed, the shoe canalso be subjected to spin-dry operation, and the machine is exquisite in structure and convenient to operate.

Owner:四川鞋唰唰科技有限公司

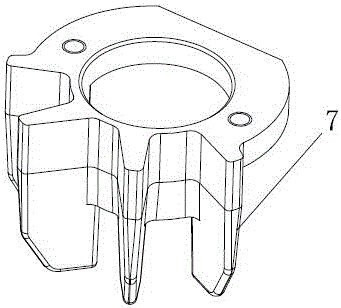

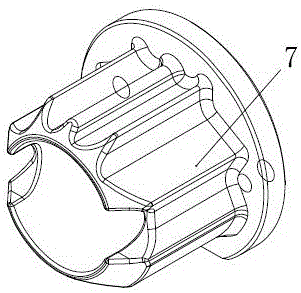

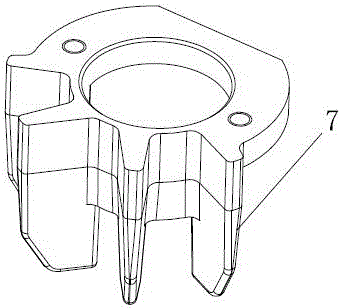

Robot joint connecting component

The embodiment of the invention provides a robot joint connecting component. The robot joint connecting component comprises a first joint, a second joint, a connecting flange and an outer thread connecting sleeve, wherein a mounting groove is formed in the first joint; the connecting flange is fixedly arranged on the second joint and mounted in the mounting groove in an inserting manner; the outer thread connecting sleeve is mounted on the second joint in a sleeving manner; the outer thread connecting sleeve is in threaded connection with the first joint; the connecting flange is tightly pressed at the inner bottom of the mounting groove; during concrete installation, the connecting flange is inserted into the mounting groove, the outer thread connecting sleeve is screwed in the first joint to tightly press the connecting flange, so as to complete the installation; and during concrete disassembly, the outer thread connecting sleeve is unscrewed from the first joint, the connecting flange is pulled out of the mounting groove, so as to complete the disassembly. According to the robot joint connecting component provided by the technical scheme of the embodiment, the fixed connection of the robot joints is realized, and the disassembly and assembly is relatively convenient.

Owner:遨博(北京)智能科技股份有限公司

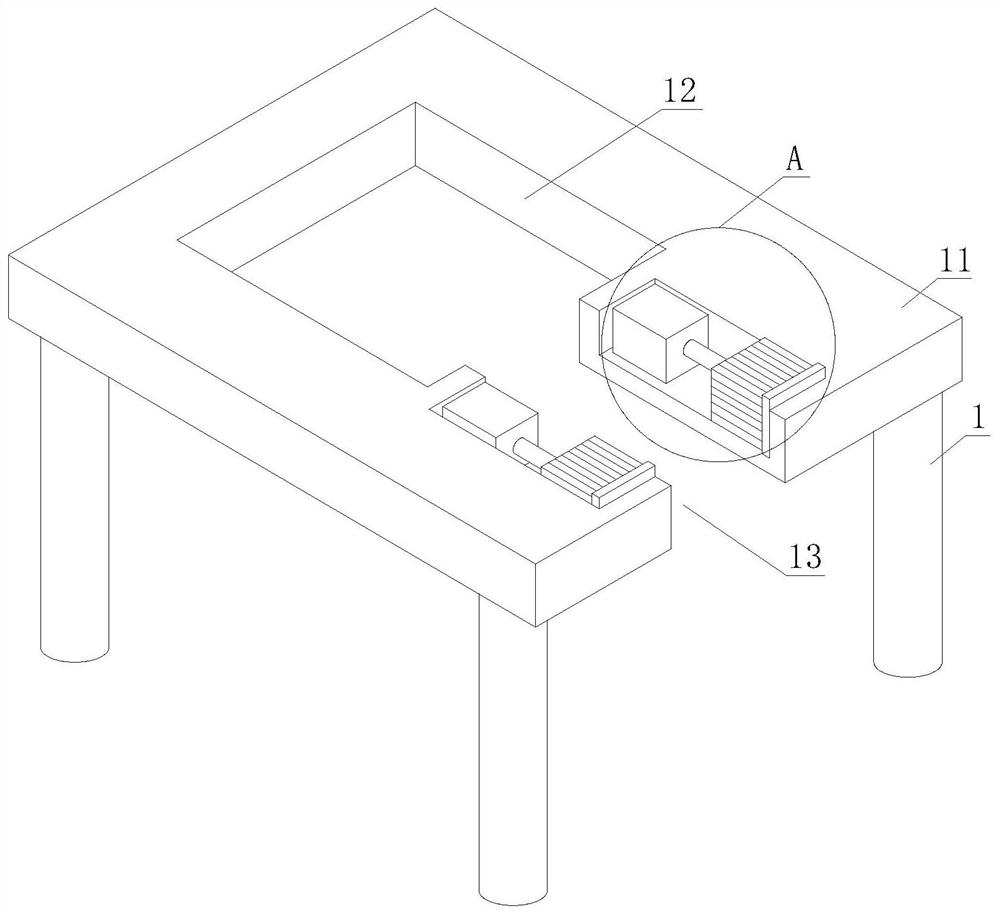

Clamp for finish machining of bearing hole of bearing block casting

InactiveCN113857904AEasy to useGuaranteed stabilityPositioning apparatusMetal-working holdersClassical mechanicsEngineering

The invention belongs to the field of bearing block castings, and particularly relates to a clamp for finish machining of the bearing hole of a bearing block casting. The clamp comprises a bottom plate. A supporting block is arranged on the rear side of the top of the bottom plate, the top of the bottom plate is fixedly connected with the bottom of the supporting block, a fixing column is arranged on the top of the supporting block, the top of the supporting block is fixedly connected with the bottom of the fixing column, a top plate is arranged on the outer surface of the fixing column, and the outer surface of the fixing column is fixedly connected with the inner wall of the top plate. A lifting device is arranged at the top of the top plate, the top of the top plate makes contact with the bottom of the lifting device, a limiting device is arranged at the bottom of the lifting device, the bottom of the lifting device is fixedly connected with the axis of the top of the limiting device, and limiting blocks are evenly arranged at the top of the limiting device. The top of the limiting device makes contact with the bottom of the limiting block, a main body is arranged at the bottom of the limiting device, and the top of the main body makes contact with the bottom of the limiting device.

Owner:何武侠

Tea pressing device with safety protection device

InactiveCN112006124AWon't breakQuality assurancePre-extraction tea treatmentMechanical pressure/force controlTea leafElectric motor

The invention discloses a tea pressing device with a safety protection device. The tea pressing device includes a tea pressing mechanism, and a containing adjusting mechanism is installed at the bottom of the tea pressing mechanism. A fixed supporting plate is mounted at the bottom of one side of the tea pressing mechanism; a tea pressing control motor is fixedly installed on the outer side of thefront end of the fixed supporting plate, a rotary driving disc is installed on the inner side of the front end of the fixed supporting plate, the tea pressing control motor is fixedly connected withthe rotary driving disc through a shaft body, and a connecting shaft is fixedly installed on the outer side of the rotary driving disc. In the using process of the tea pressing device, when more tea leaves are placed in an extrusion containing frame, automatic adjustment and protection effects can be achieved through the protection device in the tea pressing process; and it is ensured that the extrusion containing frame does not excessively press the tea leaves in the extrusion containing frame, and therefore the phenomenon that the tea leaves are excessively extruded and broken due to the fact that the tea leaves are placed excessively after being rapidly and normally pressed is avoided.

Owner:王新时

Cleaning device for glass processing

InactiveCN110773537AGuaranteed delivery efficiencyEasy height adjustmentFlexible article cleaningCleaning using toolsHydraulic cylinderWorking environment

The invention discloses a cleaning device for glass processing. The cleaning device comprises a base. Hydraulic cylinders are fixed to the two sides of the top outer wall of the base through screws correspondingly. A top plate is fixed to the top ends of piston rods of the hydraulic cylinders through screws. Pressing roller installing holes are formed in the inner wall of the top plate. Pressing rollers are connected with the inner walls of the pressing roller installing holes through bearings. Conveying roller installing holes are formed in the inner wall of the base. Conveying rollers are connected with the inner walls of the conveying roller installing holes through bearings. A supporting plate is welded to the middle of the inner wall of the base. Buffering springs are welded to the top outer wall of the supporting plate, and buffering springs are welded to the top inner wall of the top plate. A water spraying pipe is welded to one end of each buffering spring. Certain squeezing force can be exerted on glass, the friction force between the glass and the conveying rollers is ensured, the glass conveying efficiency can be easily ensured, and the cleaning device is suitable for glass with different thicknesses, is beneficial for ensuring the cleaning intensity, can recover water and meanwhile improves the protection on the working environment.

Owner:徐州市威固特种玻璃有限公司

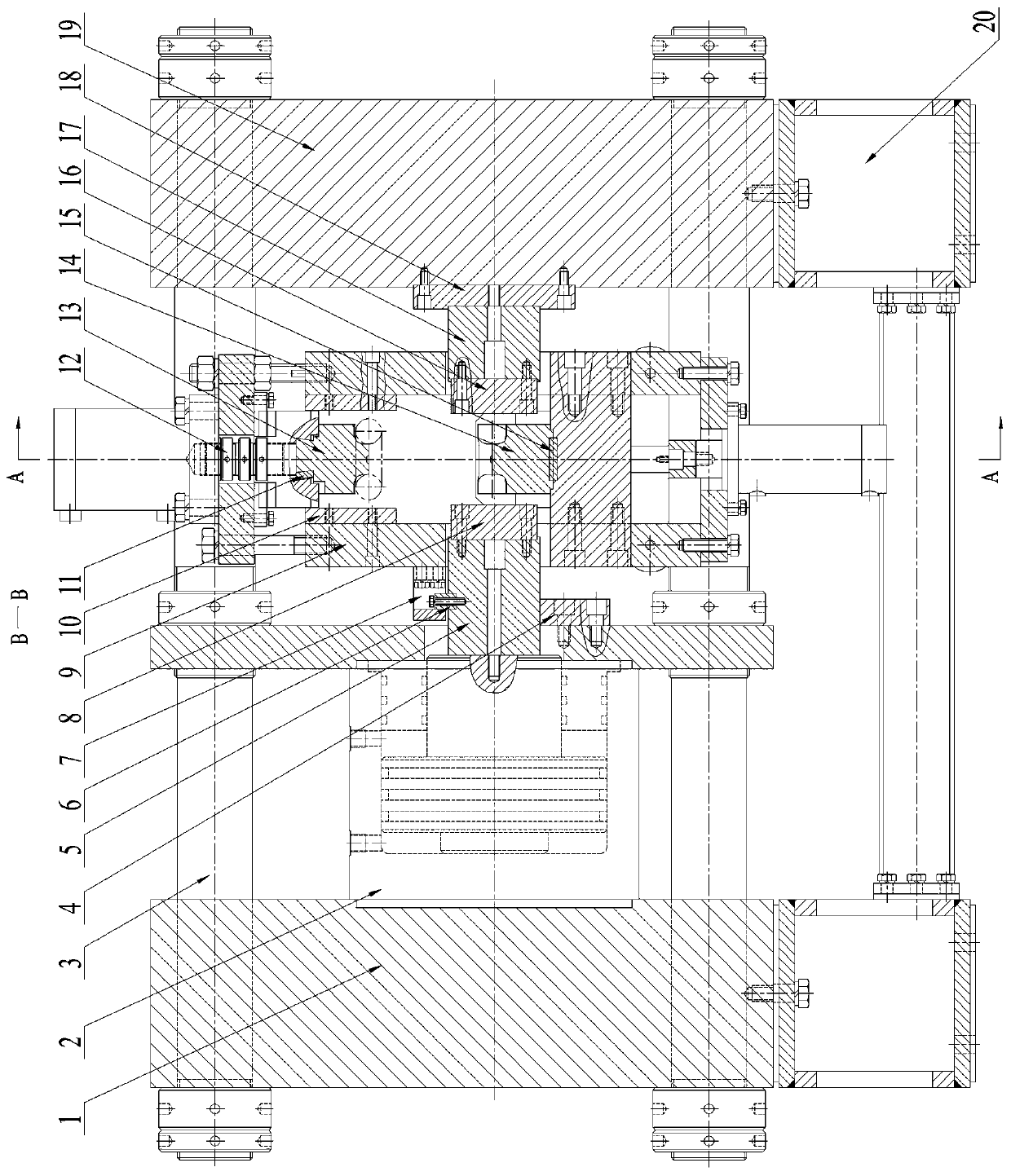

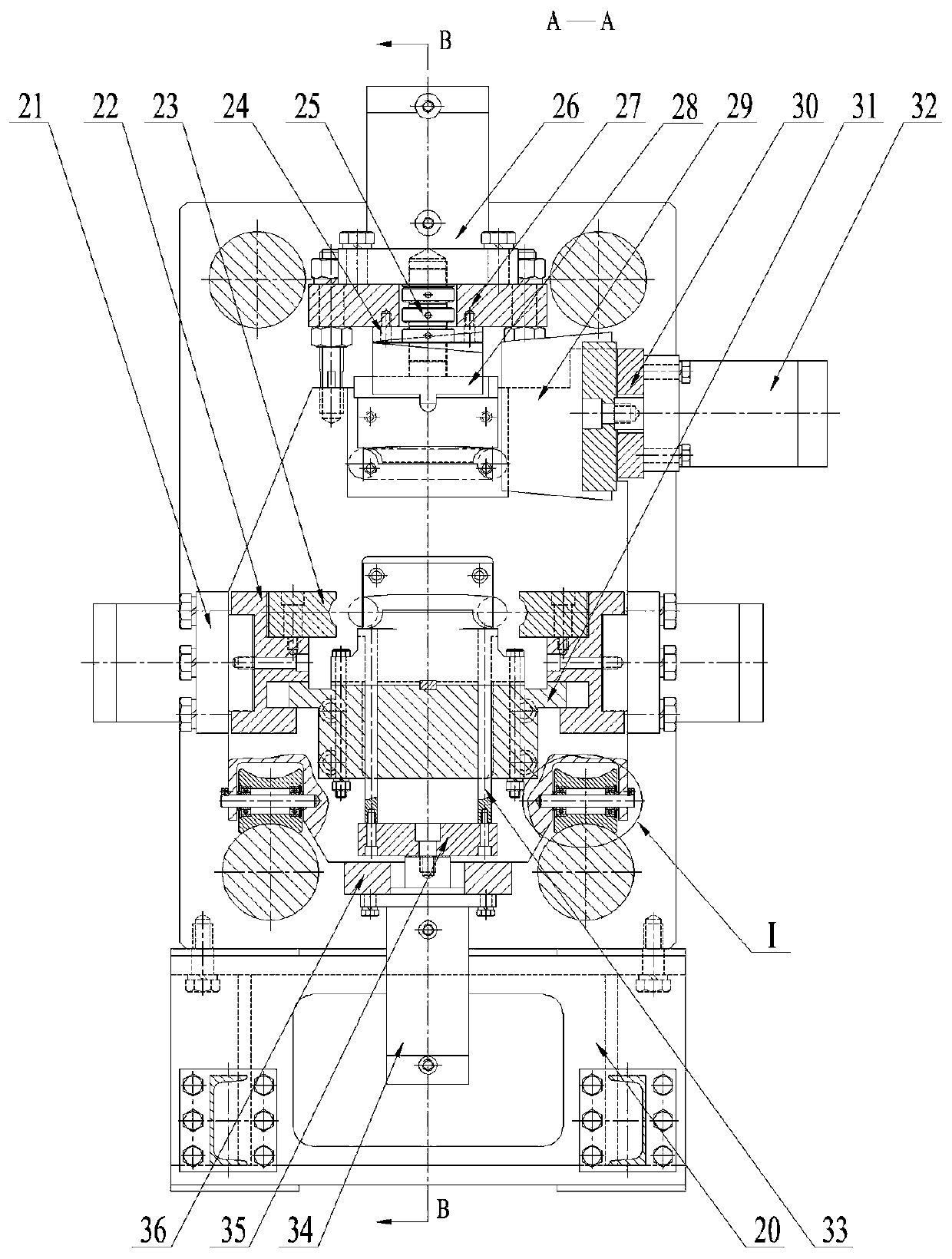

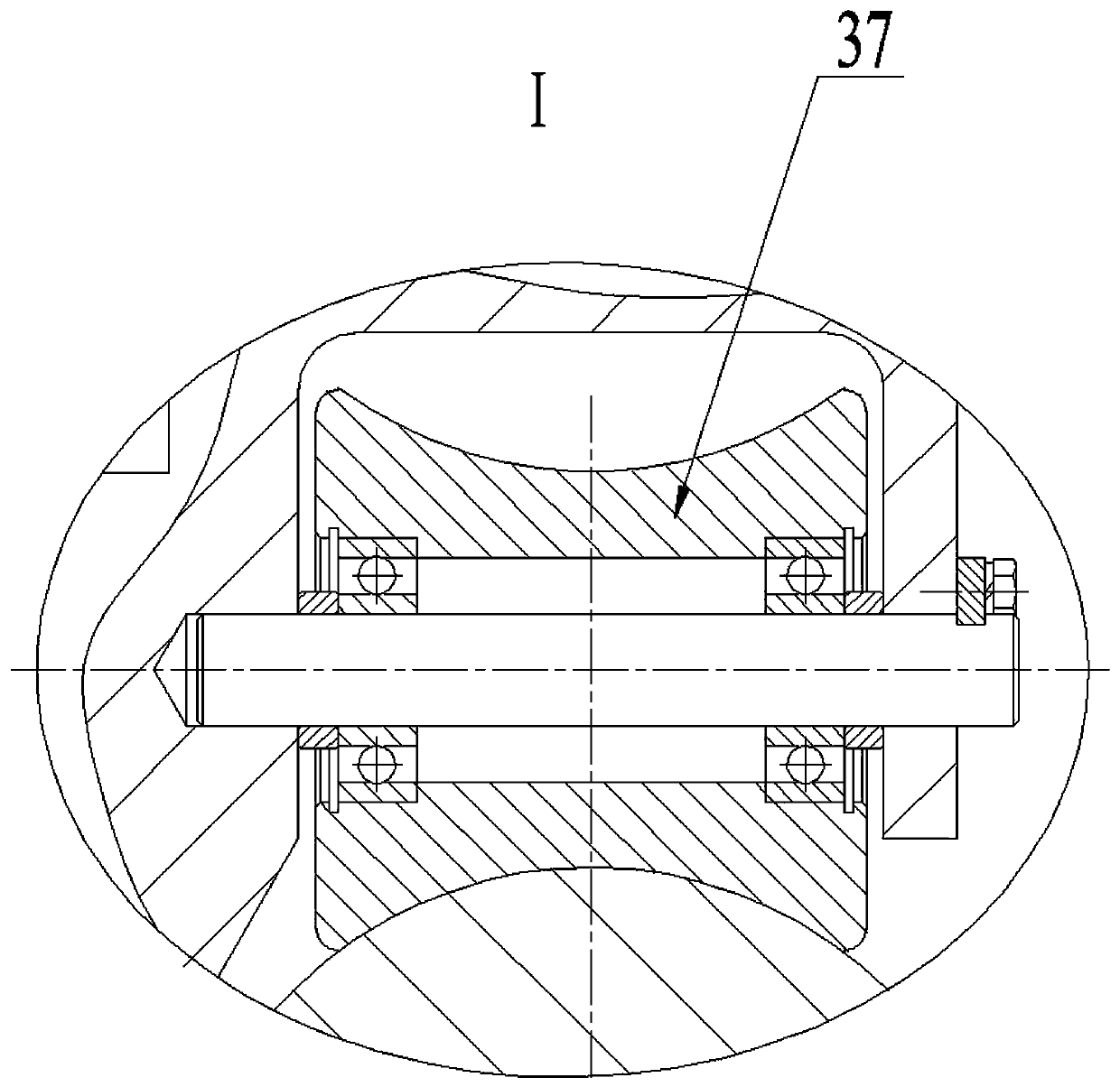

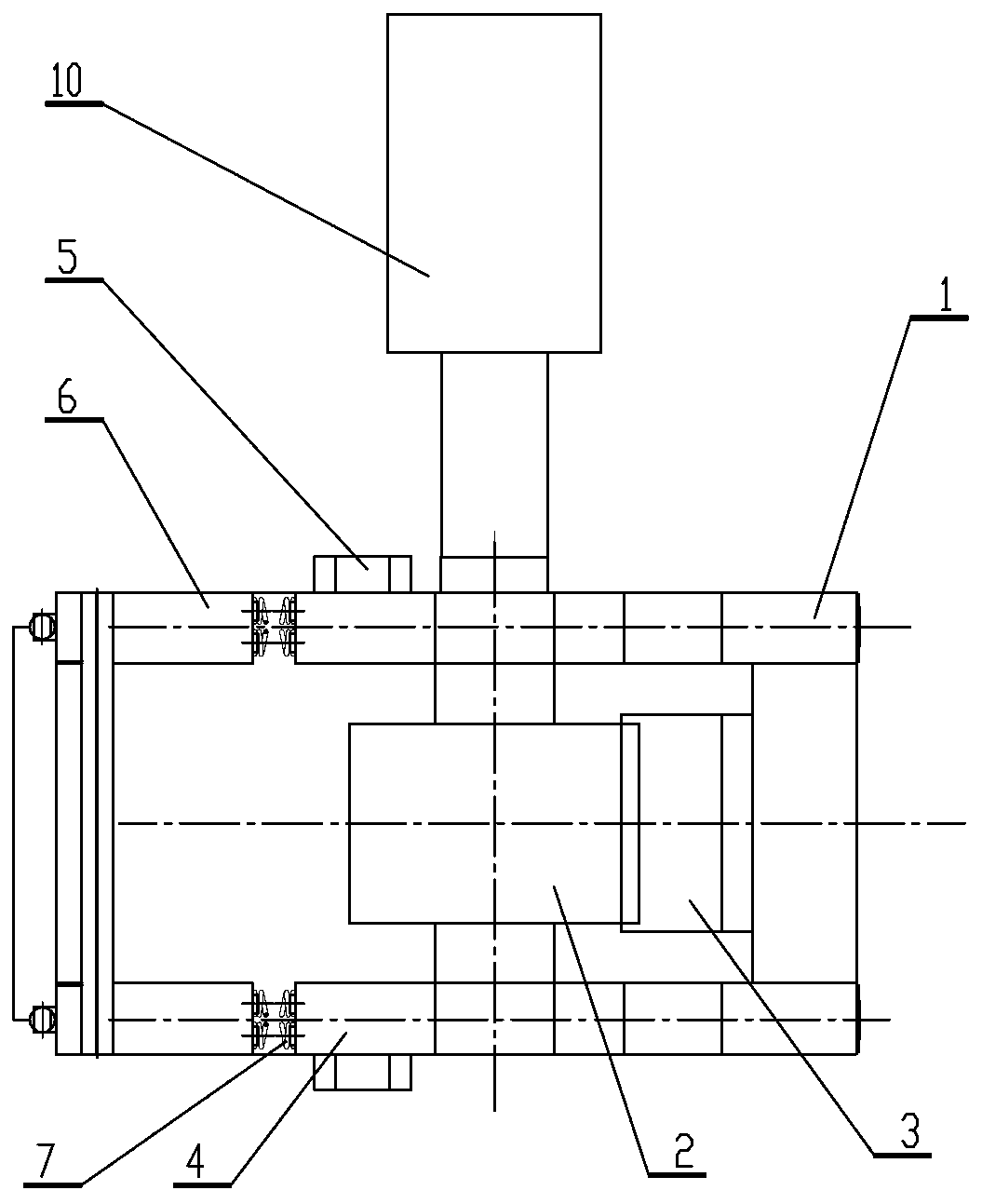

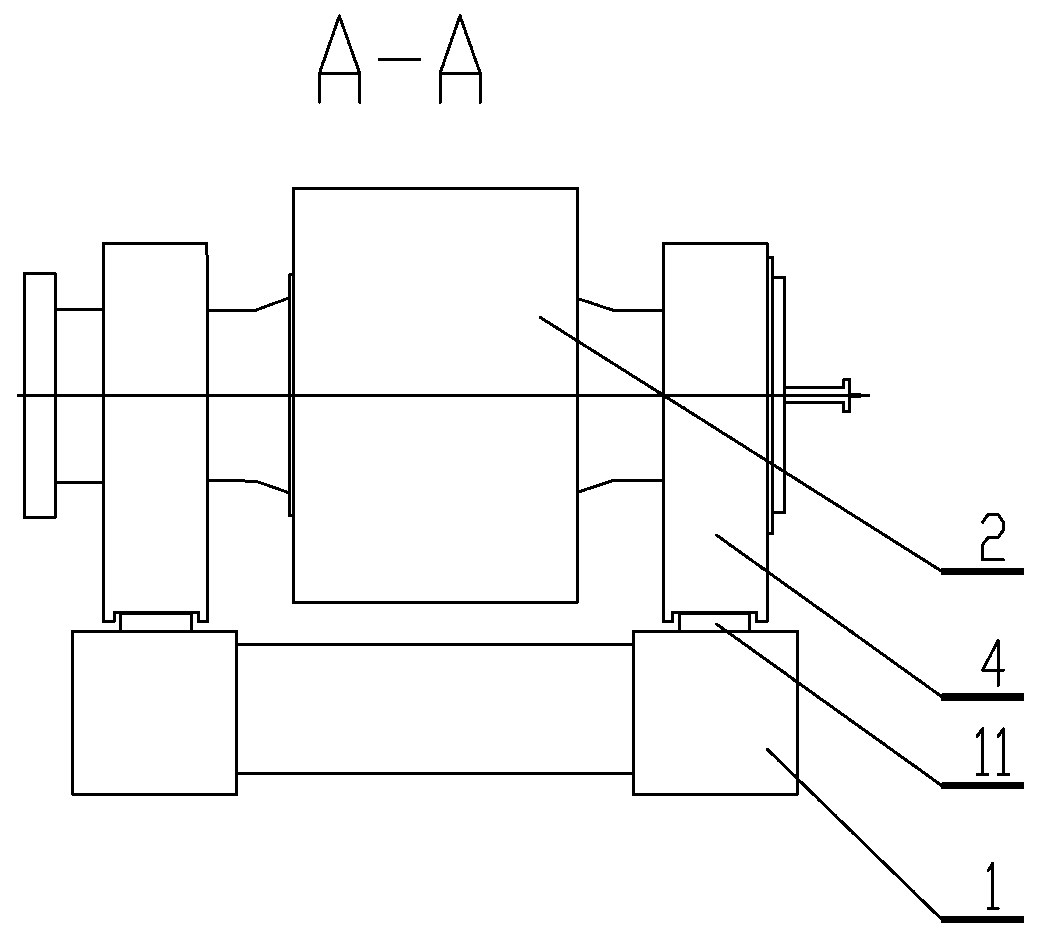

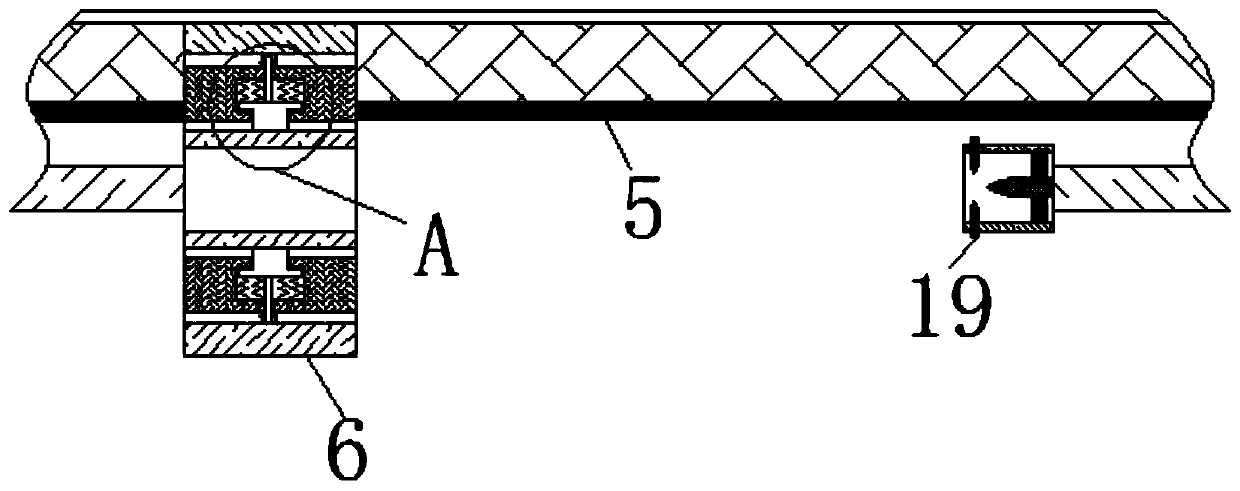

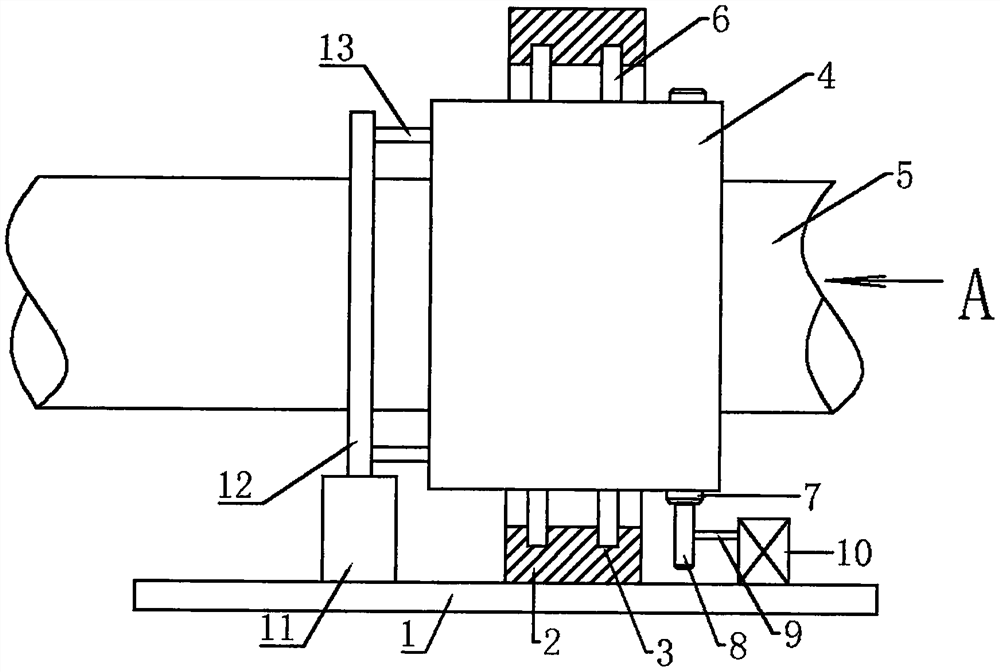

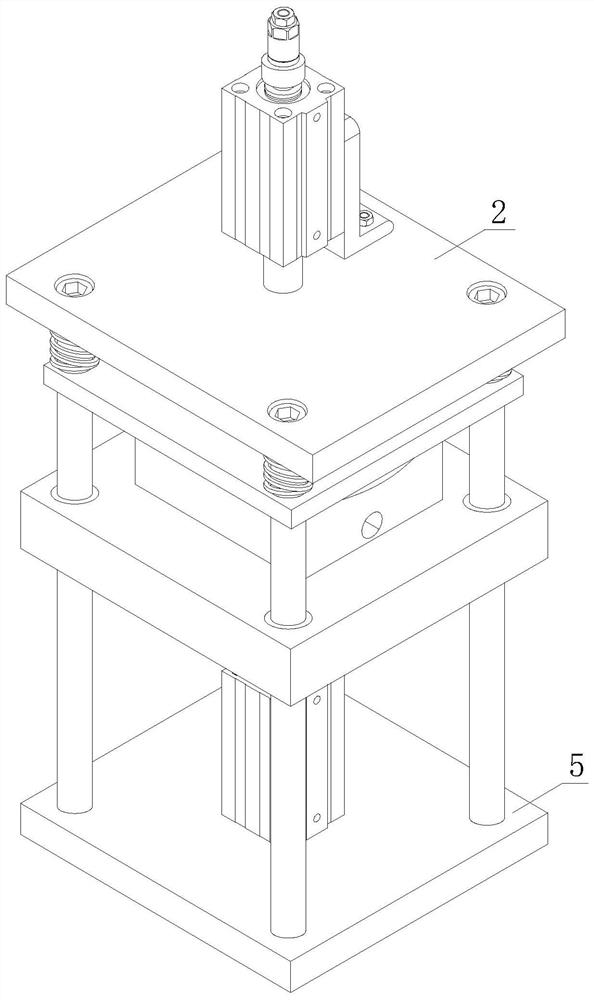

Ring extruder for chain ring of round-link chain

PendingCN110405133AReduce reactive power consumptionGuaranteed extrusion forceMetal chainsEngineeringMechanical efficiency

The invention relates to the technical field of mining round-link chain production equipment, in particular to a ring extruder for a chain ring of a round-link chain for processing and producing a flat chain. An existing ring extruder has a problem of defects in product quality and appearance as mandrels are separated up and down and are misplaced left and right. According to the technical scheme,the ring extruder comprises a rack, a movable rack, forming mechanisms, a resetting mechanism and a ring retracting mechanism. A first movable rack is arranged in the rack, the forming mechanism in avertical direction and the forming mechanism in a first horizontal direction are mounted on the movable rack, the forming mechanism in a second horizontal direction is formed on the rack, the movablerack moves along the extruding direction of the forming mechanism in the second horizontal direction in a chain ring extruding process and are matched with the forming mechanism in the vertical direction and the forming mechanism in the first horizontal direction, so that the extruding force of the chain ring and plastic deformation tension generated by the extruded chain ring are balanced by theforming mechanism on the rack and the movable rack in the respective directions. A phenomenon that the mandrels are separated is avoided, and the mechanical efficiency and the product quality are improved greatly.

Owner:ZHANGJIAKOU NORTH WELDING MACHINE CO LTD

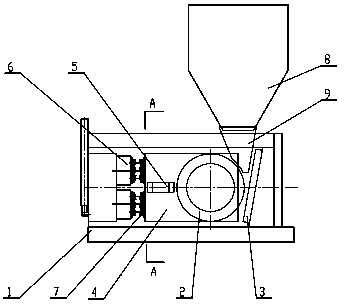

Single-roller high-pressure and high-frequency vibrating roller milling crusher

The invention relates to a single-roller high-pressure and high-frequency vibrating roller milling crusher which comprises a roller milling crusher main piece, a drive device, a stand, a feeding funnel and a guide plate; the roller milling crusher main piece is installed on the stand and is connected with the drive device and hydraulic devices. The single-roller high-pressure and high-frequency vibrating roller milling crusher is characterized in that the roller milling crusher main piece comprises two bearing seats which are arranged on stand rails respectively, an extrusion roller which is installed on the bearing seats, a fixed extrusion plate which is slantingly arranged on the surface of the extrusion roller correspondingly, and high-frequency vibration exciters which are installed onthe two sides of the bearing seats respectively and perform vibration in a horizontal direction; the bearing seats are connected with the hydraulic devices through springs respectively; the extrusionroller is connected with the drive device through a center axis. The single-roller high-pressure and high-frequency vibrating roller milling crusher has the advantages that 1) the fixed extrusion plate replaces a fixed roller of a high-pressure roller mill, and the equipment cost is lowered; 2) the high-frequency vibration exciters on the bearing seats enable the crushing effect to be better; 3)the springs for connecting the bearing seats with the hydraulic devices respectively enable equipment to be strong in adaptability and reliable in performance.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Burr correction blow molding equipment for plastic products

PendingCN111231275ATo achieve the effect of correcting flashGuaranteed extrusion forceBlow moldingPull force

The invention relates to the technical field of plastic product blow molding, and discloses burr correction blow molding equipment for plastic products. The equipment comprises a shell. The two side walls in the shell are movably connected with screws. The bottoms of the screws are movably connected with cams. The surfaces of the cams are movably connected with clamp plates. A sliding rail is formed at the bottom of the shell. The surface of the sliding rail is in sliding connection with a connecting block. The tops of the screws are movably connected with winding shafts. Pull ropes are woundon the surfaces of the winding shafts. The other ends of the pull ropes are movably connected with compression springs. The backs of the compression springs are movably connected with sliding grooves.The surfaces of the compression springs are movably connected with scraping knives. The two sides of each scraping knife are movably connected with guide wheels. The sides, away from the scraping knives, of the guide wheels are movably connected with spring rods. The left side and the right side of the shell get away from each other, the compression springs lose pulling force so as to release theforce that the compression springs are compressed previously, and therefore the scraping knives are pushed out, and the effect that burrs are corrected through the work track of pressurization equipment after blow molding is finished is achieved.

Owner:陆聆聆

Anti-running-grinding safety protection device and winching with same

ActiveCN111792550AReduce spacingWinch run mill avoidWinding mechanismsClassical mechanicsFriction force

The invention discloses an anti-running-grinding safety protection device. Shells on the two sides are connected through connecting bolts, and a steel wire rope is arranged in a gap between the shellson the two sides; and rolling wheels are arranged in a mounting groove and make contact with the steel wire rope, and first sliding grooves are formed in the upper side and the lower side of the mounting groove and are obliquely arranged in the direction from left to back to right to front. The invention further discloses a winching with the anti-running-grinding safety protection device. The winching comprises a base, vertical plates arranged on the two sides of one end of the base, a second rotating shaft arranged between the vertical plates on the two sides, a winding drum arranged outsidethe second rotating shaft in a sleeving mode and the anti-running-grinding safety protection device. When the winching normally works, the rolling wheels make contact with the steel wire rope, when the winching runs away, the steel wire rope reversely moves, the rolling wheels slide to the other sides of the first sliding grooves under the guiding effect of the first sliding grooves under the friction force of the steel wire rope, and thus the distance between the rolling wheels on the two sides is decreased; and meanwhile, the rolling wheels generate extrusion force on the steel wire rope, and thus the winching is prevented from running away.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

Anti-winding yacht lifting belt conveying structure

InactiveCN113651163AReduce wrinklesImprove flatnessLoad-engaging elementsWebs handlingClassical mechanicsElectric machinery

The invention belongs to the technical field of hoisting, and particularly relates to an anti-winding yacht lifting belt conveying structure. The anti-winding yacht lifting belt conveying structure comprises a conveying box; a plurality of groups of first rotating shafts are rotationally connected into the conveying box; the first rotating shafts are horizontally arranged in the conveying box and are matched with the conveying box; the first rotating shafts are sleeved with conveying rollers; the end portions of the first rotating shafts are connected to an electric motor through a belt; the electric motor is mounted on the conveying box; a plurality of groups of second rotating shafts are rotationally connected into the conveying box; and a belt is connected between the end portions of the second rotating shafts and the end portions of the first rotating shafts. A lifting belt is conveyed through the two groups of conveying rollers and flexible stretching rollers which are different in diameter, meanwhile, the diameter of the flexible stretching rollers is set to be larger than that of the conveying rollers, when the flexible stretching rollers rotate, the lifting belt between the flexible stretching rollers and the conveying rollers can be straightened, the problem that the lifting belt wrinkles caused by extrusion when the belt is conveyed is solved, and the flatness of the lifting belt is improved.

Owner:泰州市力夫特绳网带厂

Weaving cloth drying device

InactiveCN109405498AGuaranteed extrusion forceImprove dehydration effectDrying gas arrangementsDrying machines with progressive movementsAir pumpPulp and paper industry

The invention discloses a weaving cloth drying device. The device comprises a drying box body, openings for weaving cloth inlet and outlet are formed in the left side face and the right side face of the drying box body, an outer guide roller is arranged on the outer portion of the left side of the drying box body, an upper cloth pressing roller and a lower cloth pressing roller are arranged on theleft side and the right side in the drying box body, an inner guide roller is arranged in the middle in the drying box body, a heating cavity and an air pump are arranged in the drying box body, a heater is arranged in the heating cavity, an air inlet of the heating cavity is formed in the outer wall of the drying box body, an air inlet of the air pump communicates with the heating cavity, an airoutlet of the air pump is connected with an air outlet cavity, the air outlet cavity is of an inverted V structure, multiple hot air outlets are formed in the air outlet cavity, the hot air outlets are located below the weaving cloth, and an exhaust fan is arranged on the inner wall of the right side of the drying box body. The weaving cloth drying device is simple in structure and good in dryingeffect.

Owner:JURONG JIAYUN TEXTILE CO LTD

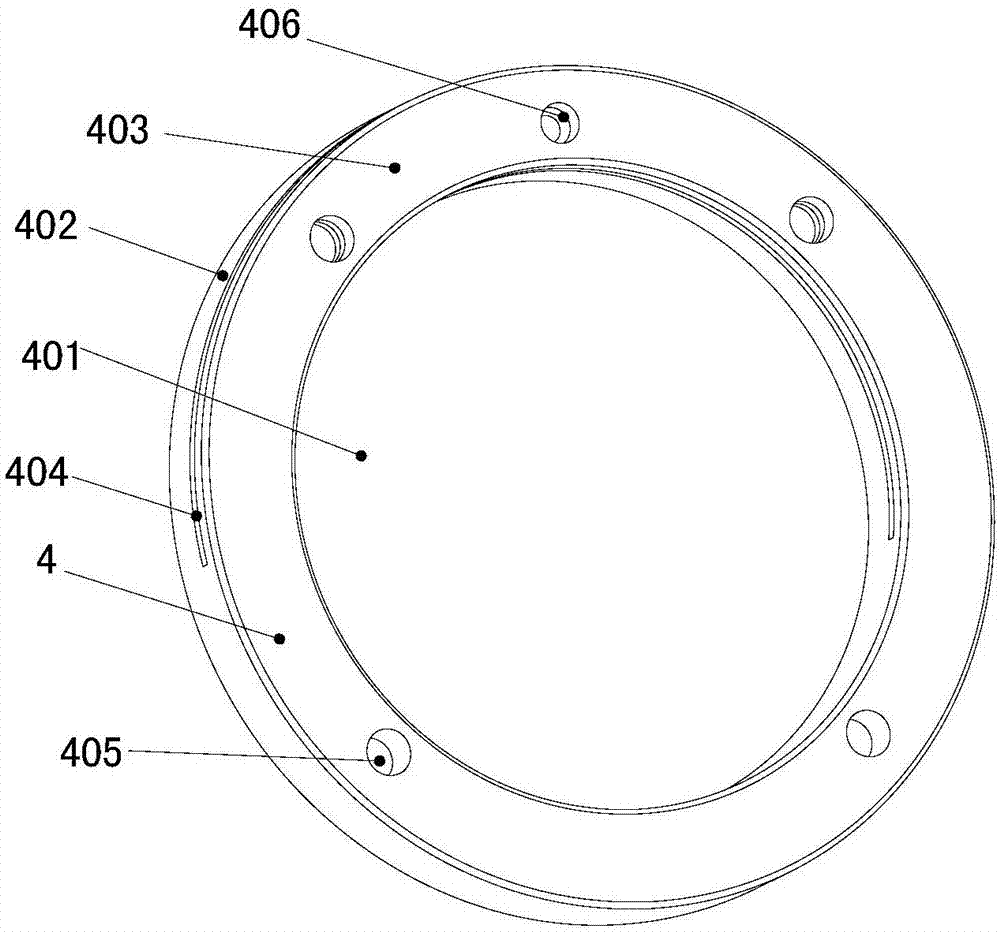

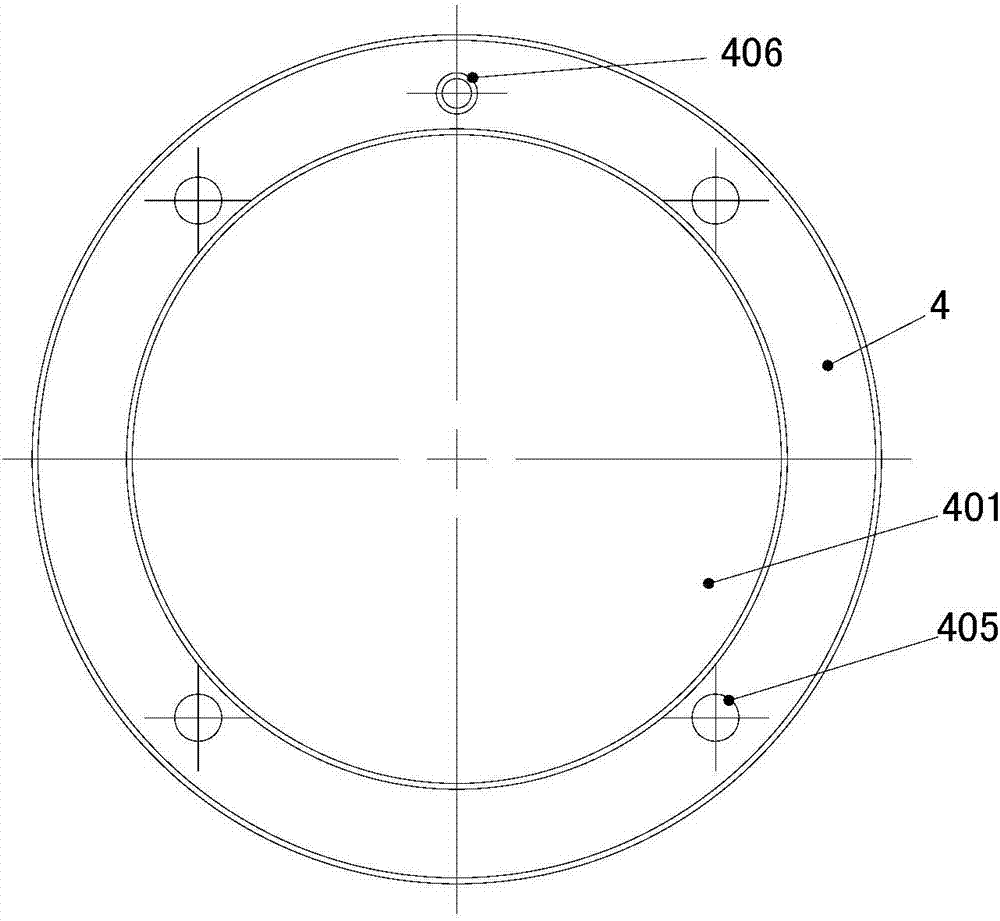

HDPE drainage pipe clamping device

InactiveCN112248086ANo squeeze forcePrevent rotationMetal working apparatusDrainage tubesMechanical engineering

The invention relates to the related technical field of drainage pipes, in particular to a HDPE drainage pipe clamping device. The HDPE drainage pipe clamping device comprises a bottom plate, a firstsupporting ring is fixedly connected to the upper side of the bottom plate, the first supporting ring is in a circular ring shape, two annular grooves are symmetrically formed in the inner side wall of the first supporting ring, a rotating sleeve penetrates through the middle of the first supporting ring, two circles of connecting columns are symmetrically and fixedly connected to the outer side wall of the rotating sleeve, and the other ends of the connecting columns are located in the annular grooves. The HDPE drainage pipe clamping device has the beneficial effects that after the rotating sleeve rotates, receding grooves in the rotating sleeve can gradually get away from clamping plates, the clamping plates can slowly move out of the receding grooves, so that the inner side wall of therotating sleeve is used for extruding the outer surfaces of the clamping plates, clamping protrusions on the inner sides of the clamping plates make contact with a drainage pipe, so that the drainagepipe is extruded, the drainage pipe can be effectively prevented from rotating, and the drainage pipe can be conveniently cut.

Owner:重庆泽通管业科技有限公司

Casting device for aluminum fixed-type automobile brake caliper and method

The invention discloses a casting device for an aluminum fixed-type automobile brake caliper and a method, and belongs to the technical field of brake caliper casting. The casting device for the aluminum fixed-type automobile brake caliper comprises a casting platform. A casting platen is arranged on the upper part of the casting platform, a demolding slot is formed in the casting platen, a casting assembly is arranged in the demolding slot, the side end of the casting assembly is connected to a feeding device, the feeding device is installed in a long notch in the casting platen, two side ends of the feeding device is connected with the casting platen through a shifting device, and the demolding assembly is connected to the lower part of the casting assembly. The casting device is more close in bonding, ensures the balance of the extrusion force, improves the stability of the press fit, avoids the situation that die-casting in the later stage is affected due to excessive extrusion resistance caused by a excessively low temperature, improves the delivery efficiency, slowly discharges air inside molten steel during the slow delivery of heat preservation extrusion, can eliminate pores of a die-casting fitting, improves the quality of the die-casting fitting, better discharges the air, improves the molding quality, and facilitates demolding.

Owner:HANSHAN DALI PRECISION MACHINERY

Shielding-type aluminum squeezing die with small opening and large pressure-bearing face

InactiveCN107931347AHigh machine pass rateLarge machine with high pass rate and mold throughputExtrusion diesMaterial supplySecondary layer

The invention discloses a shielding-type aluminum squeezing die with a small opening and a large pressure-bearing face. The shielding-type aluminum squeezing die comprises a flow guiding die and a pattern cushion die, a flow distribution bridge is distributed on a material supply face of the flow guiding face and comprises a center flow distributing bridge body and a peripheral flow distributing bridge body, and a flow distributing hole is formed in the peripheral flow distributing bridge body. A weld-joint chamber is formed in the material feeding face of the pattern cushion die, an outlet relief layer is arranged on the material discharging face, and a work belt is arranged between the weld-joint chamber and the outlet relief layer. The length of the work belt is 4-10 mm. the weld-jointchamber is a two-time weld-joint chamber and comprises a first weld-joint chamber body and a second weld-joint chamber body. Compared with the prior art, The shielding-type aluminum squeezing die withthe small opening and the large pressure-bearing face has the advantages of being simple in structure, good in machining effect and the like.

Owner:FUJIAN NANPING ALUMINUM +1

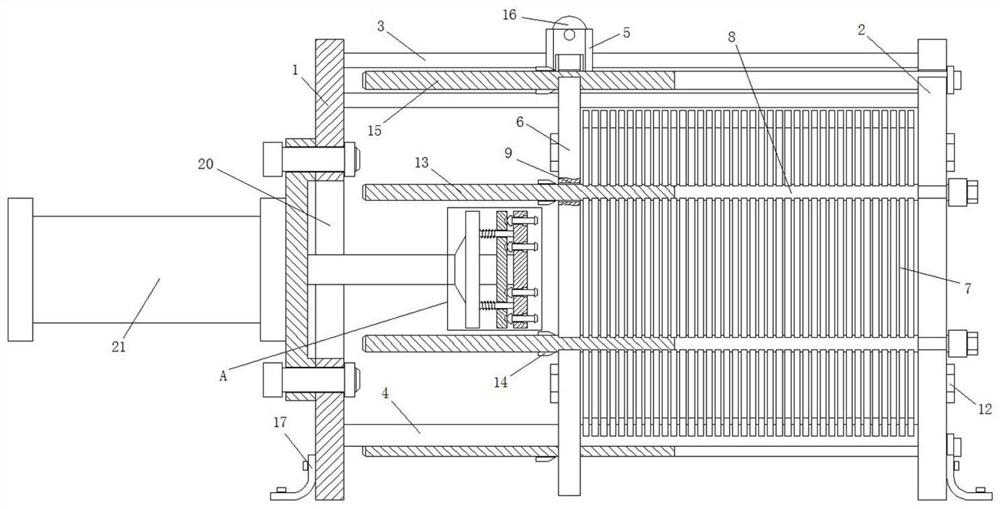

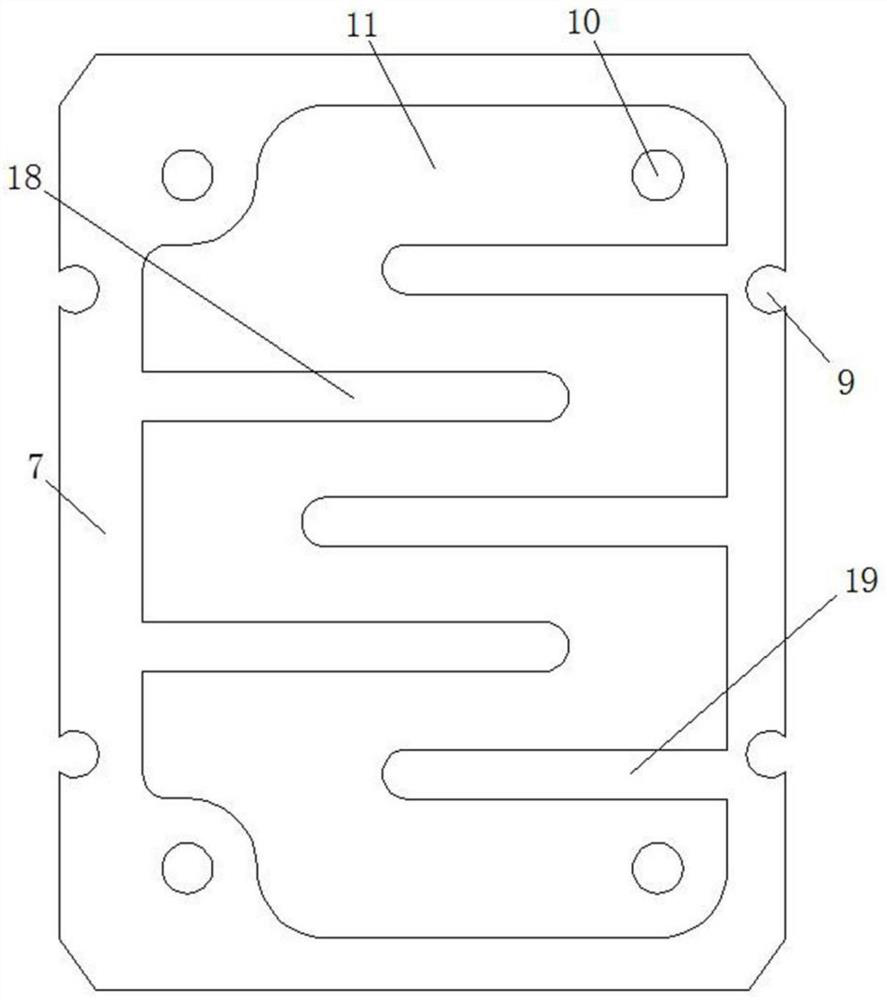

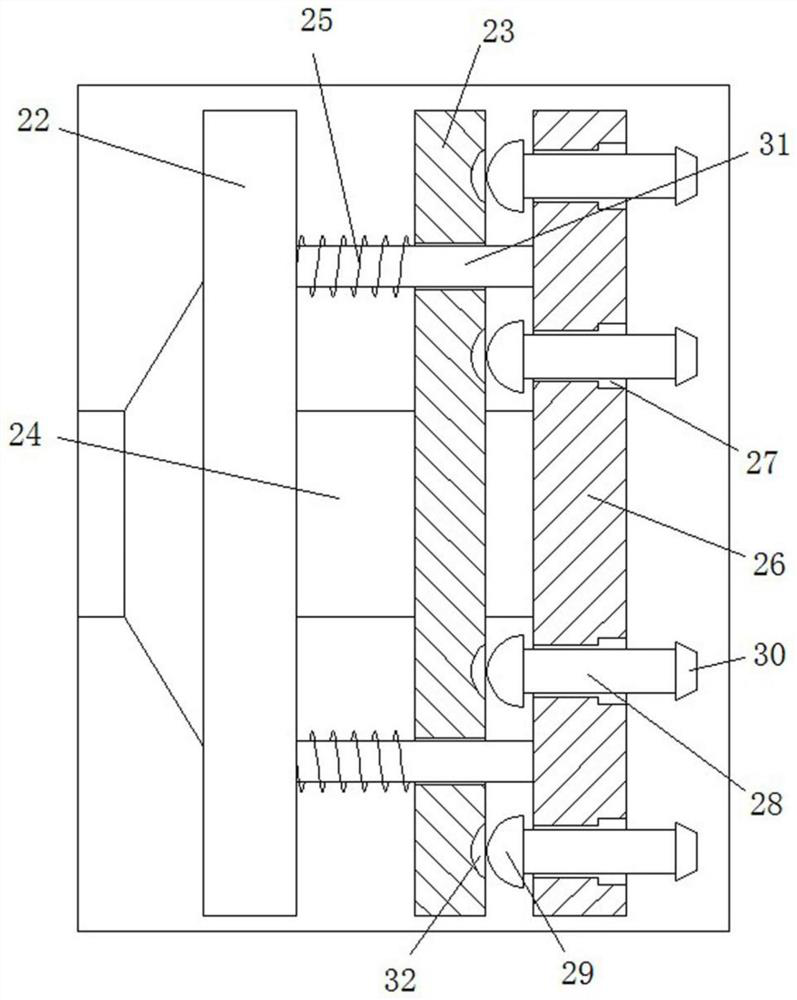

A kind of plate cooler applied in hydro-generator set

ActiveCN112229249BImprove heat exchange efficiencyIncrease cooling distanceHydro energy generationMachines/enginesEngineeringThermal water

Owner:湖南省水运建设投资集团有限公司

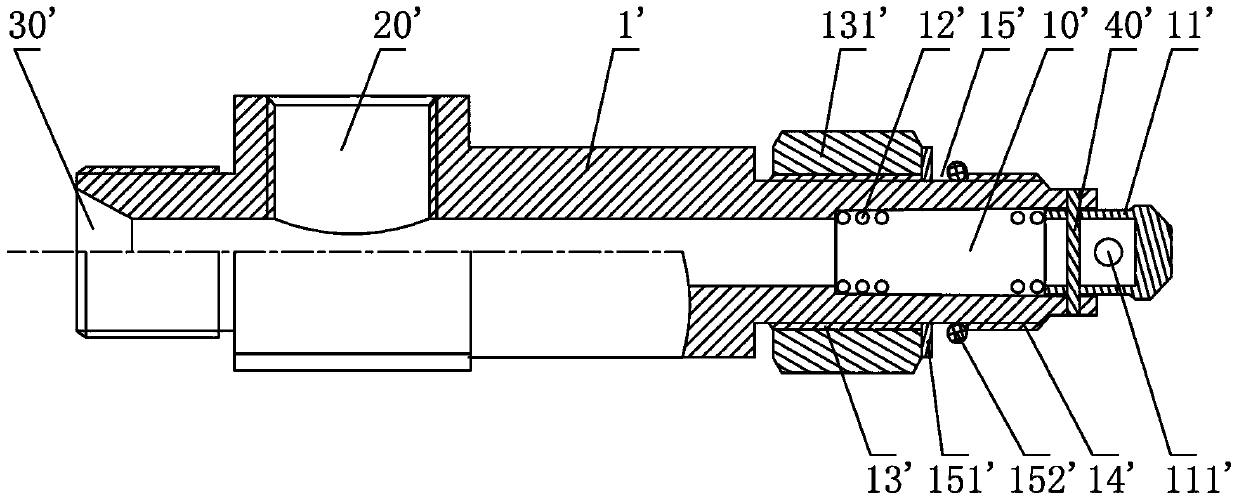

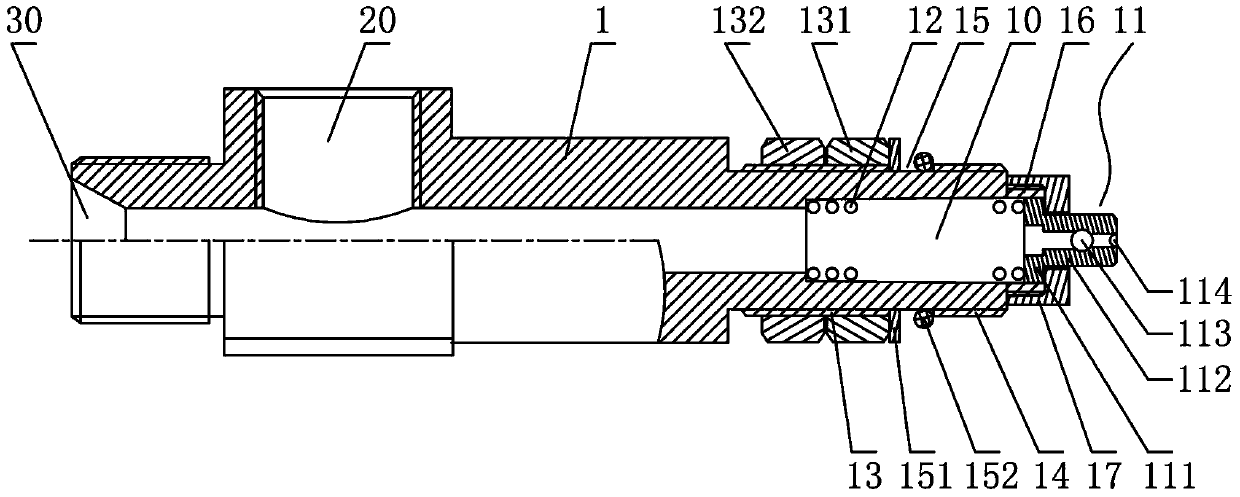

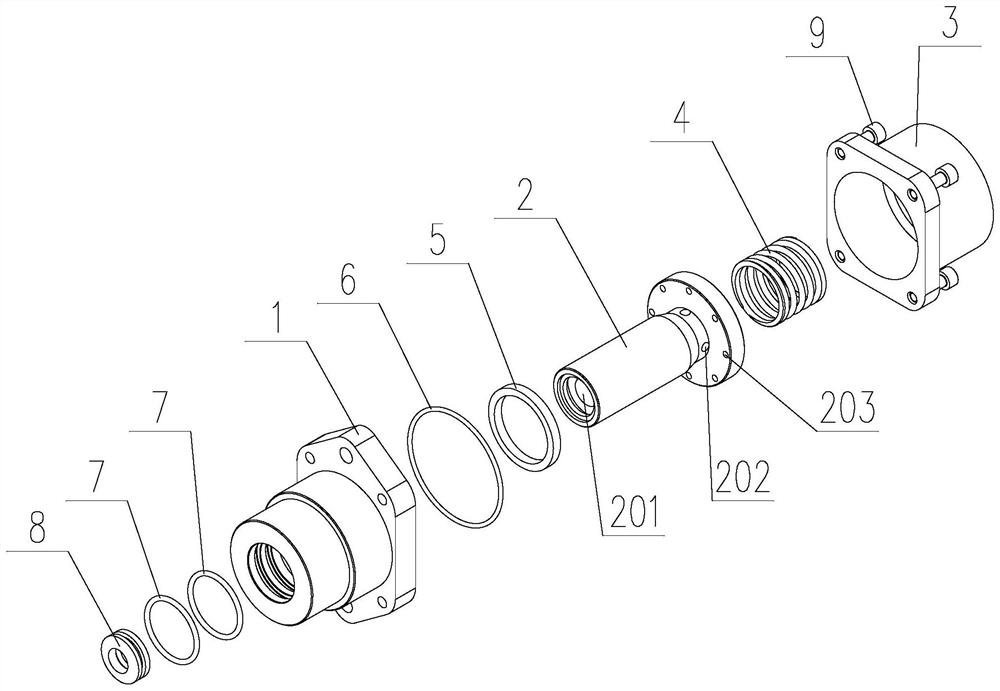

Air pipe connector for tight-lock coupler and coupler thereof

PendingCN114001216ASimple structureEasy to processJoints with fluid cut-off meansClassical mechanicsEngineering

The invention discloses an air pipe connector for a tight-lock coupler and a coupler thereof, relates to the technical field of rail transit, and solves the technical problems that an existing air pipe connector is inconvenient to assemble and the like. The air pipe connector comprises a valve rod, a valve body matched with one end of the valve rod, a connecting base arranged on a large outer circle step at the other end of the valve rod in a sleeving mode and fixedly connected with the valve body, an elastic piece enabling the valve rod to elastically abut against the connecting base and a sealing gasket for sealing the end face of the large outer circle step and the end face of the valve body, and valve port rubber is installed at one end of the valve rod. The valve rod is provided with a radial communicating hole and a main hole. The valve port rubber is arranged on the valve rod, so that the valve port rubber can move along with the movement of the valve rod, the elastic piece arranged at one position is used for achieving mutual attaching of the valve port rubber and automatic locking of the air pipe connector when air is communicated, the structure of the air pipe connector is simplified, needed parts are reduced, and the air pipe connector is convenient to process and assemble.

Owner:江苏肯耐特轨道装备科技有限公司

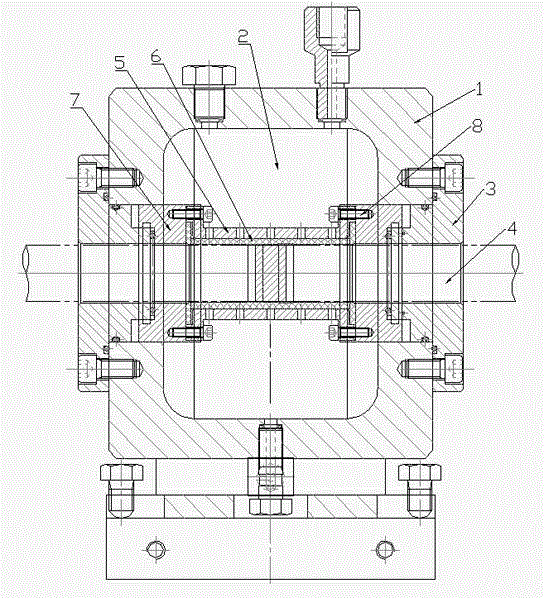

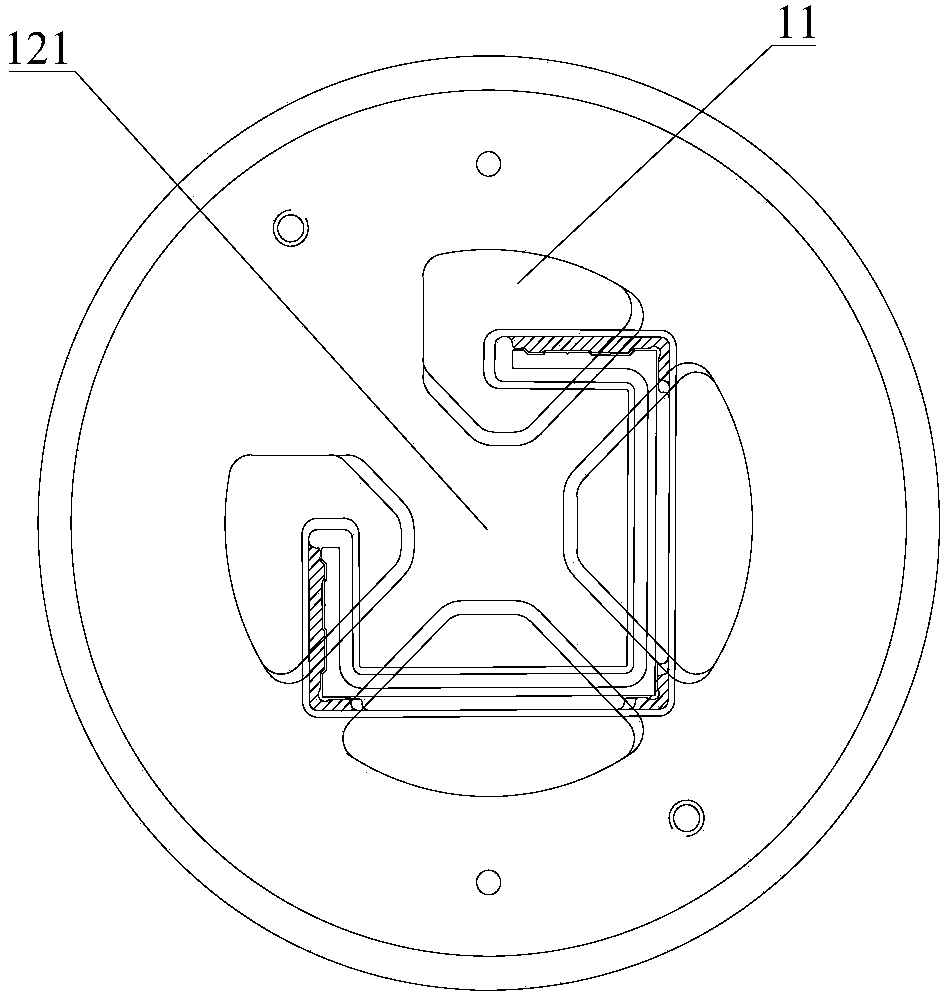

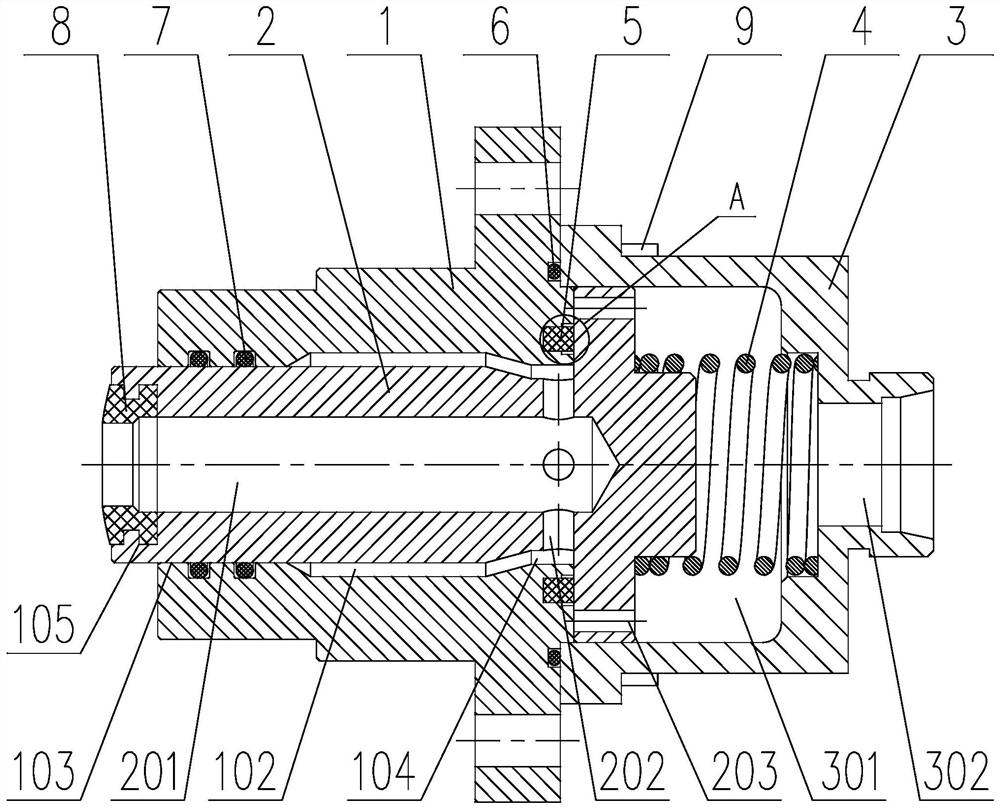

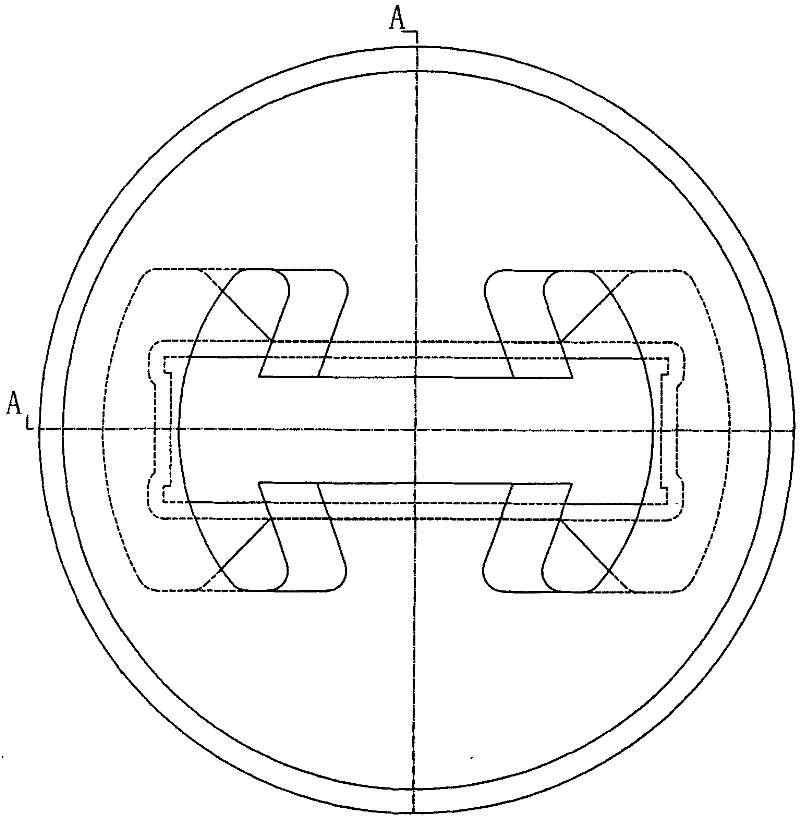

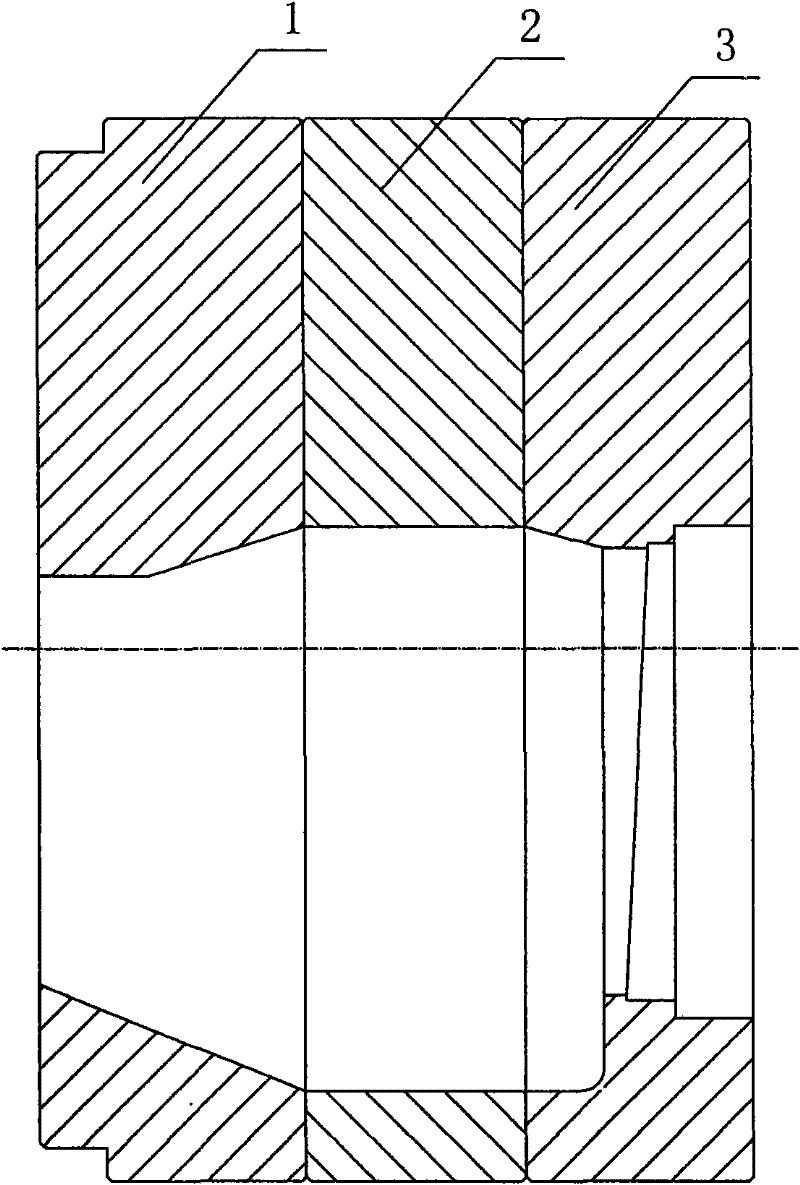

Large-scale solid profile hot extrusion mould of medium extruder

InactiveCN101658878BEnhanced feedingIncrease flow rateExtrusion diesVolumetric Mass DensityEngineering

The invention relates to a large-scale solid profile hot extrusion mould of a medium extruder, formed by orderly laying up a front guide plate (1), a secondary guide plate (2) and a mould surface (3) from front to back. The front guide plate (1) comprises a first center material inlet hole (11), and the upper hole wall and the lower hole wall of the first center material inlet hole (11) consist of a front straight hole wall (111) and a back inclined hole wall (112), the back inclined hole wall (112) is gradually extended from front to back, the left hole wall (113) and the right hole wall (113) form an inclined hole wall shape, and the inclined hole wall is gradually extended. The secondary guide plate (2) comprises a second center material inlet hole (21), and the second center material inlet hole (21) is in a dumbbell shape. The center part of the second center material inlet hole (2) is adjacent to a mould cavity of the mould surface, and the left end and the right end are extended. The mould surface (3) comprises a guide pit (31) and the mould cavity (32), the upper pit wall (311) and the lower pit wall (311) form an inclined surface shape, and the inclined surface is tapered.The invention can guarantee the sufficient material supply of large-scale solid profile angle positions, can effectively increase extruding force, and guarantee the density and the strength of profiles.

Owner:JIANGYIN GIANSUN MOLD

An anti-running grinding safety protection device and a winch with the same

The invention discloses an anti-running and grinding safety protection device. The shells on both sides are connected by connecting bolts, and the steel wire rope is arranged inside the gap between the shells on both sides; The first chute is arranged on the upper and lower sides of the hood, and the first chute is arranged obliquely from the left rear to the right front. The invention also discloses a winch mill with a safety protection device for anti-running grinding, which includes a base, vertical plates arranged on both sides of one end of the base, a second rotating shaft arranged between the vertical plates on both sides, and a second rotating shaft sheathed on the second rotating shaft. The external reel and the above-mentioned anti-running safety protection device. During the normal operation of the present invention, the rollers are in contact with the steel wire rope. When the winch mill runs, the steel wire rope moves in the opposite direction. The distance between the side rollers is reduced, and at the same time, the rollers exert a pressing force on the wire rope, thereby avoiding running grinding of the winch.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

A robot joint connection component

The embodiment of the invention provides a robot joint connecting component. The robot joint connecting component comprises a first joint, a second joint, a connecting flange and an outer thread connecting sleeve, wherein a mounting groove is formed in the first joint; the connecting flange is fixedly arranged on the second joint and mounted in the mounting groove in an inserting manner; the outer thread connecting sleeve is mounted on the second joint in a sleeving manner; the outer thread connecting sleeve is in threaded connection with the first joint; the connecting flange is tightly pressed at the inner bottom of the mounting groove; during concrete installation, the connecting flange is inserted into the mounting groove, the outer thread connecting sleeve is screwed in the first joint to tightly press the connecting flange, so as to complete the installation; and during concrete disassembly, the outer thread connecting sleeve is unscrewed from the first joint, the connecting flange is pulled out of the mounting groove, so as to complete the disassembly. According to the robot joint connecting component provided by the technical scheme of the embodiment, the fixed connection of the robot joints is realized, and the disassembly and assembly is relatively convenient.

Owner:AUBO BEIJING ROBOTICS TECH CO LTD

Ball transfer reminding type learning assistance system

ActiveCN113324193ARelieve fatigueImprove reminder effectElectric circuit arrangementsLighting elementsPhysicsEye Fatigue

The invention discloses a ball transfer reminding type learning assistance system, and belongs to the field of learning education. According to the ball transfer reminding type learning assistance system, along with the extension of desk learning time, more and more water is accumulated on a spacer, under the action of gravity, an air floating ball and a color column transfer ball are downwards extruded, and the color column transfer ball is transferred into a transparent column from a water transfer barrel. On the one hand, along with the increase of the number of the color column transfer balls in the transparent column, the color column transfer balls gradually move upwards to be close to a double-control switch and generate an extrusion effect on the double-control switch, so that light of a lamp holder is extinguished, and primary and secondary school students who learn for a long time are reminded in time to properly have a rest on eyes and relieve eye fatigue. On the other hand, under the action of gravity, the lower end part of the color column transfer ball deforms, the color liquid enters an air support column, and a discontinuous color column is formed in the transparent column, so that the reminding effect is further improved, and the myopia rate caused by a long-term fatigue state is reduced.

Owner:GUANGDONG UNIV OF TECH

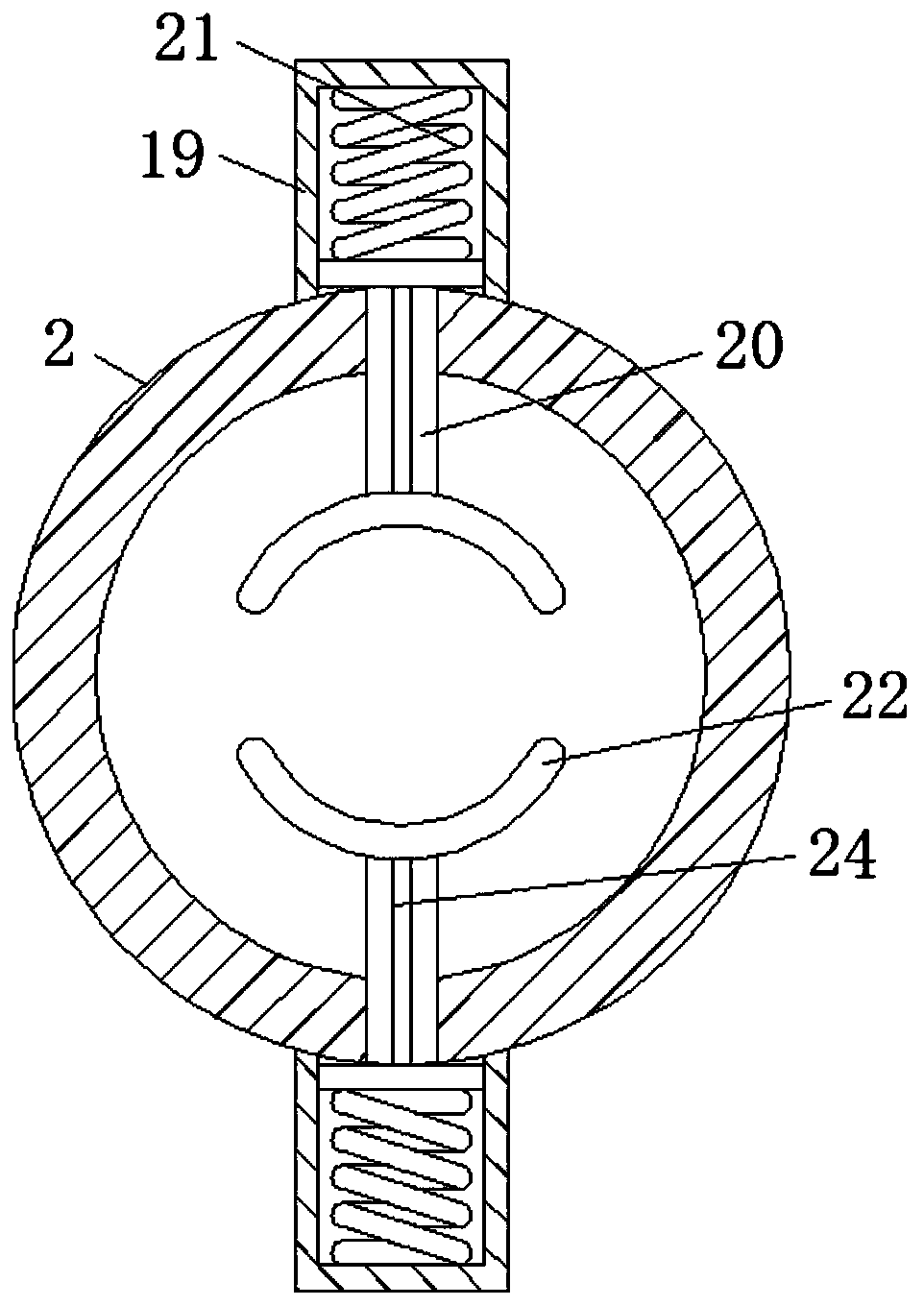

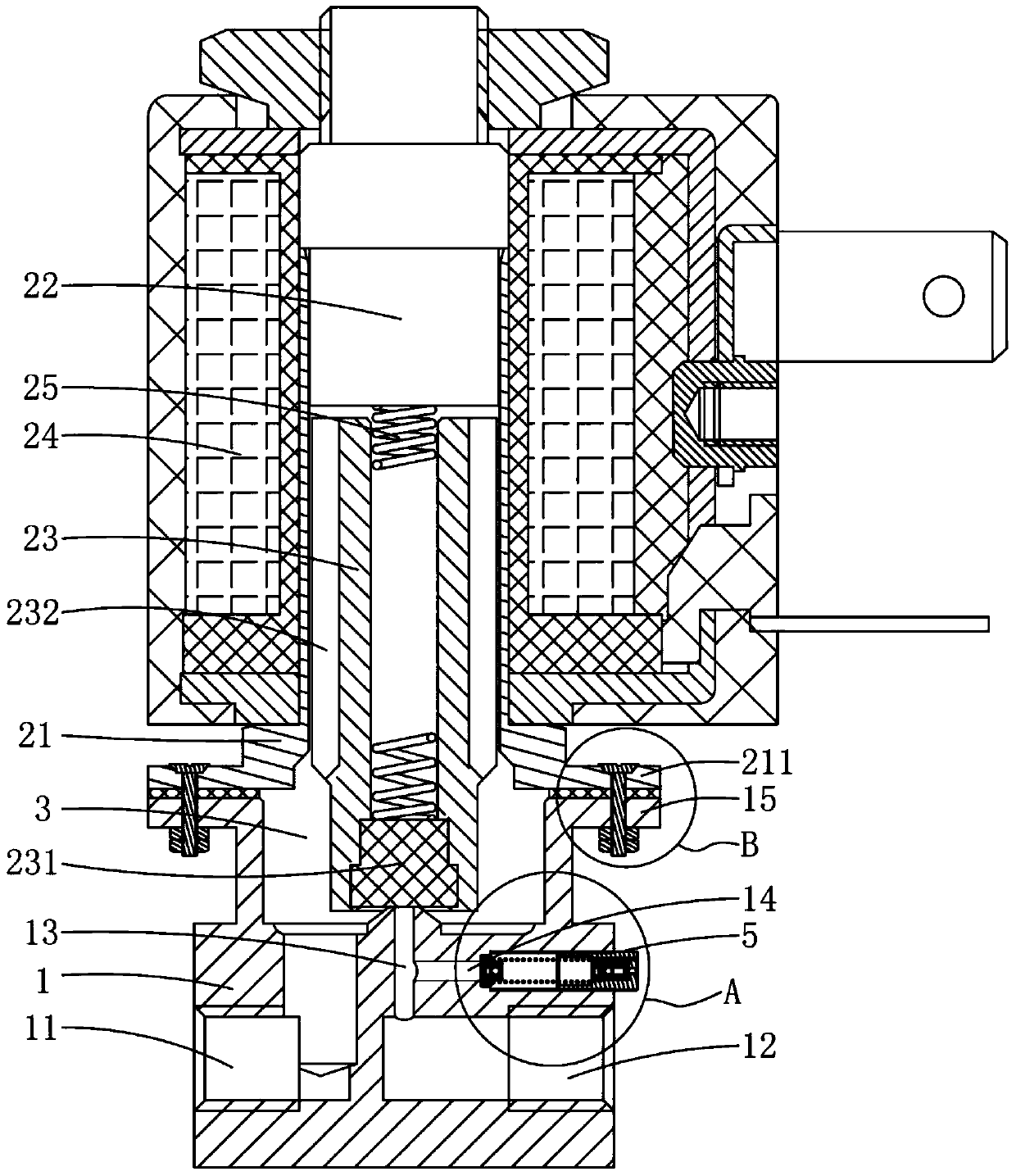

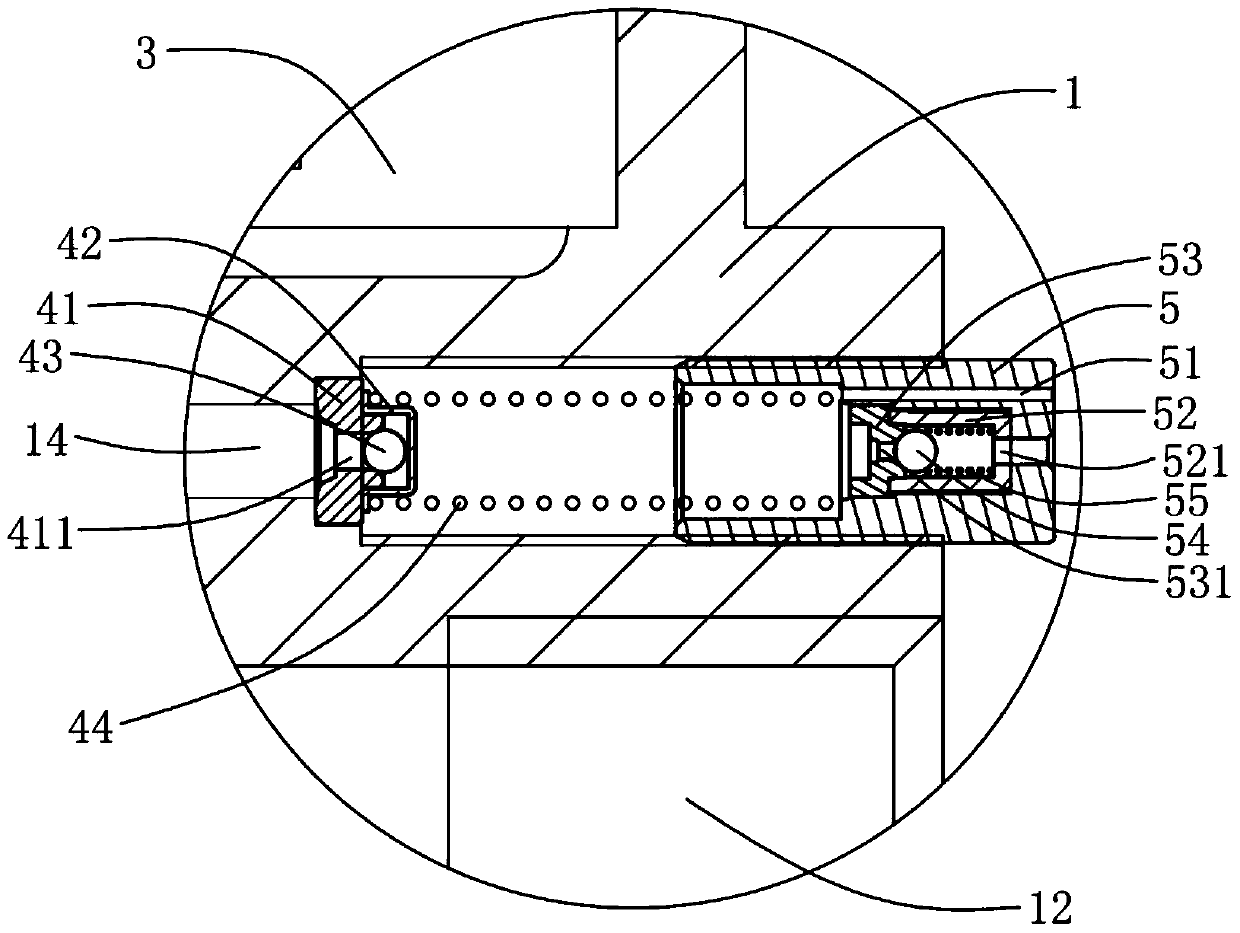

A two-position two-way solenoid valve with improved structure

ActiveCN105299298BQuick releaseReduce manufacturing costOperating means/releasing devices for valvesCheck valvesSolenoid valveCheck valve

The invention discloses a two-position two-way electromagnetic valve with an improved structure. The two-position two-way electromagnetic valve comprises a valve body and a pilot assembly, wherein a gas guide hole is formed in the valve body; the pilot assembly comprises a sleeve; a first connection part extends from the top end of the valve body; a second connection part extends from the bottom end of the sleeve; the first connection part is in fastening connection with the second connection part through a bolt; a thread part is arranged on the outer wall of the bolt; the thread part is composed of a left-hand thread and a right-hand thread which are correspondingly arranged in a matching manner; a fastening nut matched with the left-hand thread and a locking nut matched with the right-hand thread are connected to the bottom end of the bolt; the valve body is further provided with a valve hole; the inner end of the valve hole is communicated with the gas guide hole; a check valve is arranged at the middle part of the valve hole; the outer end of the valve hole is fixedly connected with a valve seat; the valve seat is provided with a thin hole; the valve hole is communicated with the atmosphere through the thin hole; and a pressure release valve is arranged in the valve seat. The two-position two-way electromagnetic valve disclosed by the invention is simple and reasonable in structure, convenient and fast to install, low in manufacturing cost, and good in voltage stabilization effect; a connection structure between the valve body and the sleeve is stable and reliable; and the service life of the two-position two-way electromagnetic valve is long.

Owner:佛山市南海科惠汽配有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com