Air pipe connector for tight-lock coupler and coupler thereof

A connector and tight connection technology, which is applied in the field of rail transit, can solve the problems of short telescopic guide of the valve head of the air duct connector, complex structure of the main air duct connector, and many structural parameters of the air duct connector, so as to prevent expansion and contraction Effects of short guide, fewer required parts, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

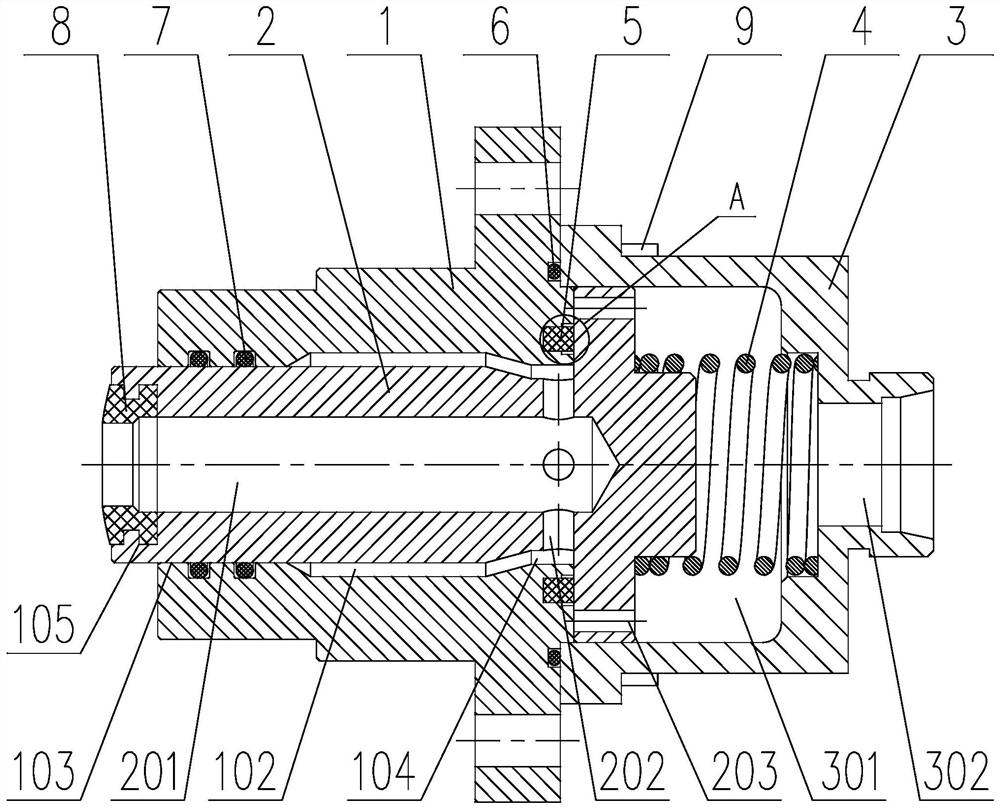

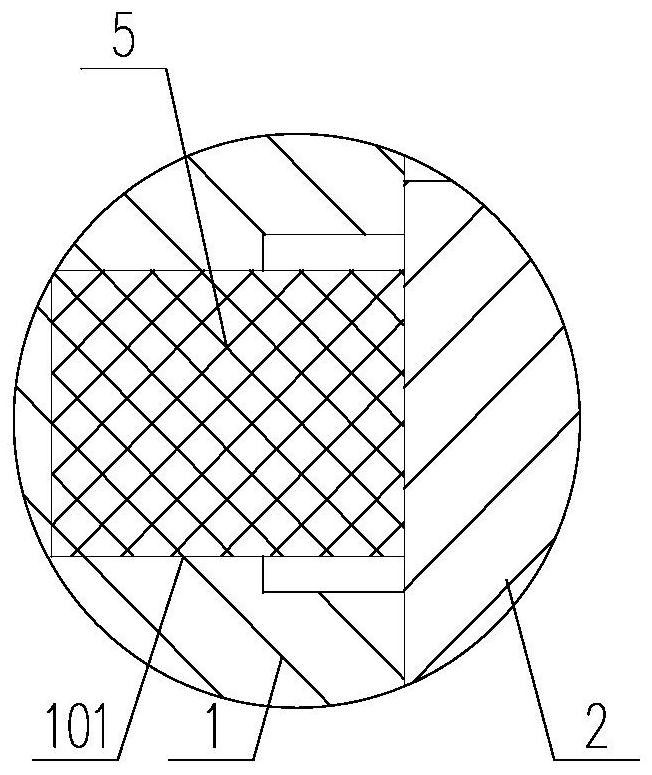

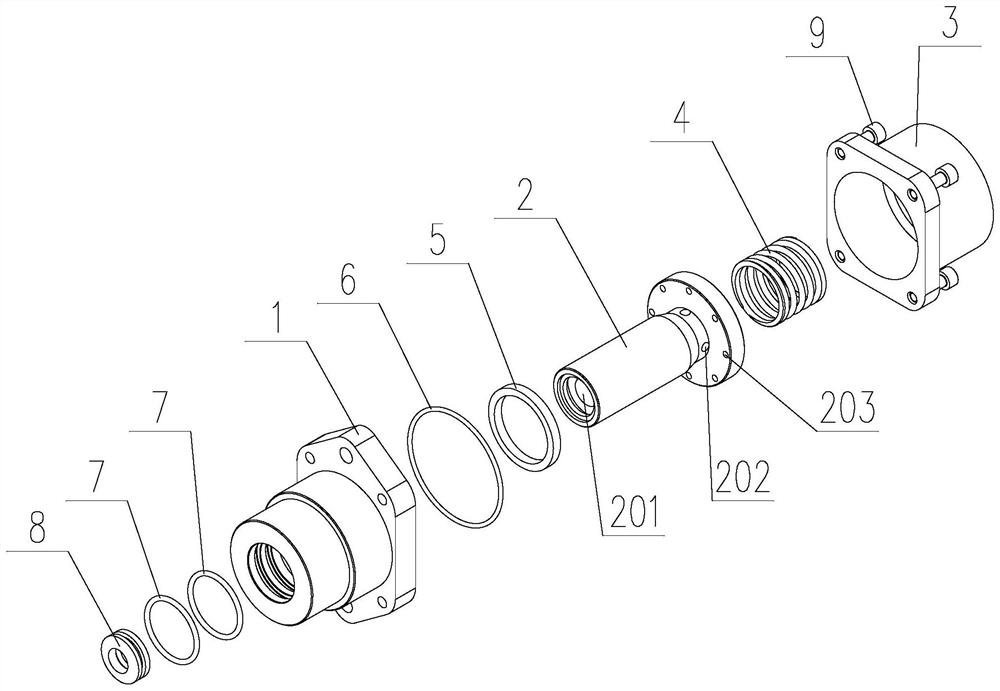

[0037] Such as Figure 1 ~ Figure 3 As shown, a air duct connector for a tight-fitting coupler includes a valve stem 2, a valve body 1 that fits with the outer circular surface of one end of the valve stem 2 and is tightly matched with it, and a large valve sleeve that is sleeved at the other end of the valve stem 2. The connecting seat 3 fixedly connected to the valve body 1 on the outer circular step, the elastic member 4 elastically contacting the valve stem 2 and the connecting seat 3, and the gasket 5 sealing the end face of the large outer circular step and the end face of the valve body 1, all The end of the valve stem 2 away from the connecting seat 3 is equipped with a valve port rubber 8, and one end of the valve stem 2 communicates with the outside world through the inner hole of the valve port rubber 8, and the other end communicates with the outside of the valve stem 2 through a radial communication hole 202. The main hole 201 connected to the cylindrical surface;...

Embodiment 2

[0045] In this embodiment, the elastic member 4 is preferably a compression spring.

[0046] Such as Figure 1 ~ Figure 3 As shown, a air duct connector for a tight-fitting coupler includes a valve stem 2, a valve body 1 that fits with the outer circular surface of one end of the valve stem 2 and is tightly matched with it, and a large valve sleeve that is sleeved at the other end of the valve stem 2. The connecting seat 3 fixedly connected to the valve body 1 on the outer circular step, the pressure spring elastically abutting the valve stem 2 and the connecting seat 3, and the sealing gasket 5 sealing the end face of the large outer circular step and the end face of the valve body 1, said The end of the valve stem 2 away from the connecting seat 3 is equipped with a valve port rubber 8, and the valve stem 2 is provided with four valve ports. The main hole 201 connected to the outer cylindrical surface;

[0047] Under the pre-pressure of the elastic member 4, the cylindrica...

Embodiment 3

[0063] In the present embodiment, the implementation manner of the elastic member 4 is as follows:

[0064] At the end of the valve stem located in the inner cavity of the connecting seat 3, there are a plurality of installation holes evenly distributed along the circumference of the valve stem axis, and on the inner wall of the connection seat 3 opposite to the end face of the valve stem, there are installation holes that are distributed in the same manner as the installation holes. Consistent positioning holes, installation holes and positioning holes correspond one by one, and a tension spring is arranged between them, and the two ends of the tension spring are respectively inserted into the positioning hole and the installation hole.

[0065] In this way, multiple functional and structurally consistent spring members are installed at a position that requires elastic members, and they are evenly distributed along the axis of the valve stem to improve the uniformity of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com