Shoe washing machine adopting belt drive type shoe washing mechanism

A belt drive and shoe washing machine technology, applied in the field of shoe washing machines, can solve the problems of serious interference, high cost, and restrictions on the development of shoe washing machines, and achieve the effects of reducing power mechanisms and transmission mechanisms, convenient operation, and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

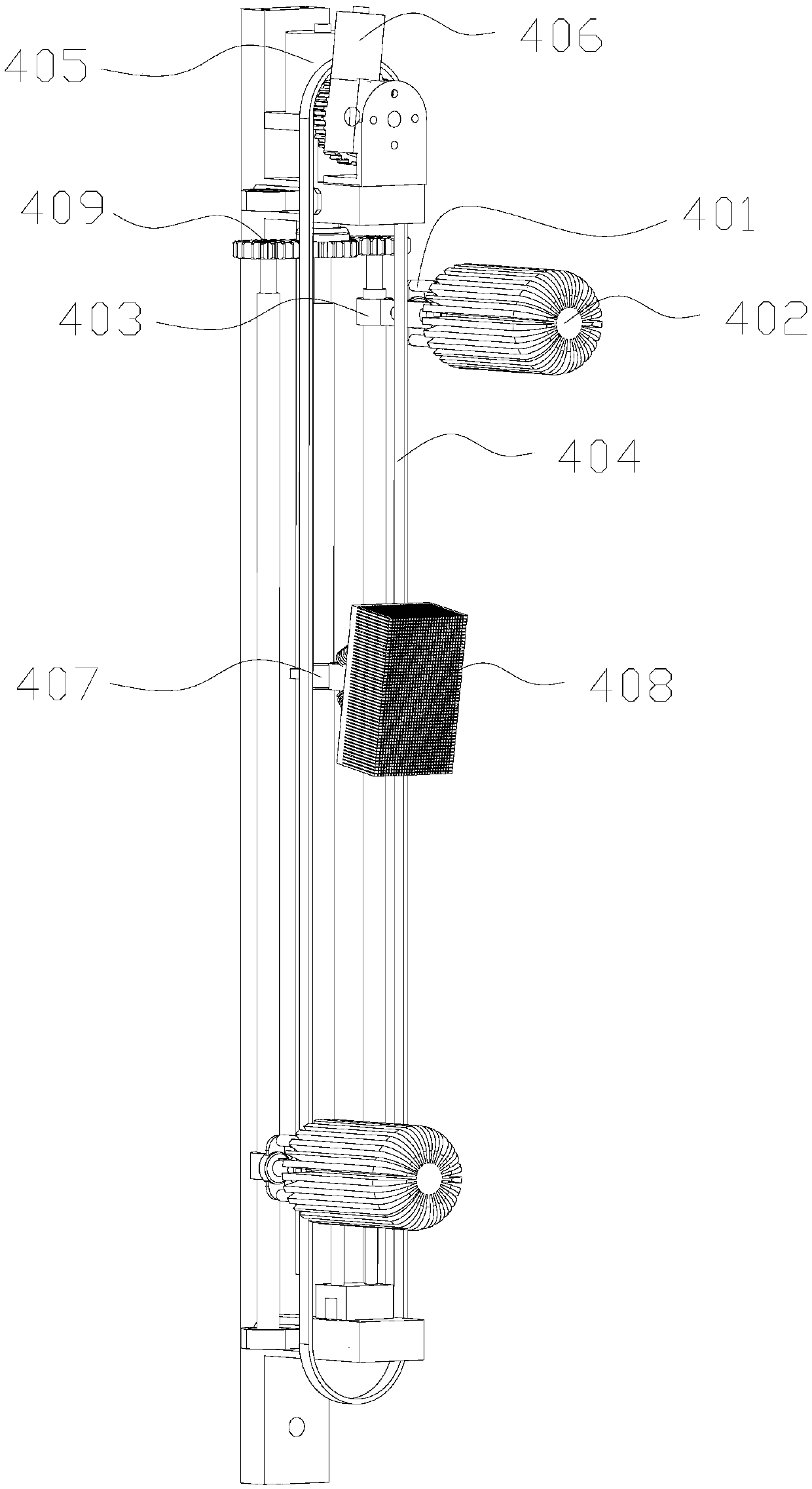

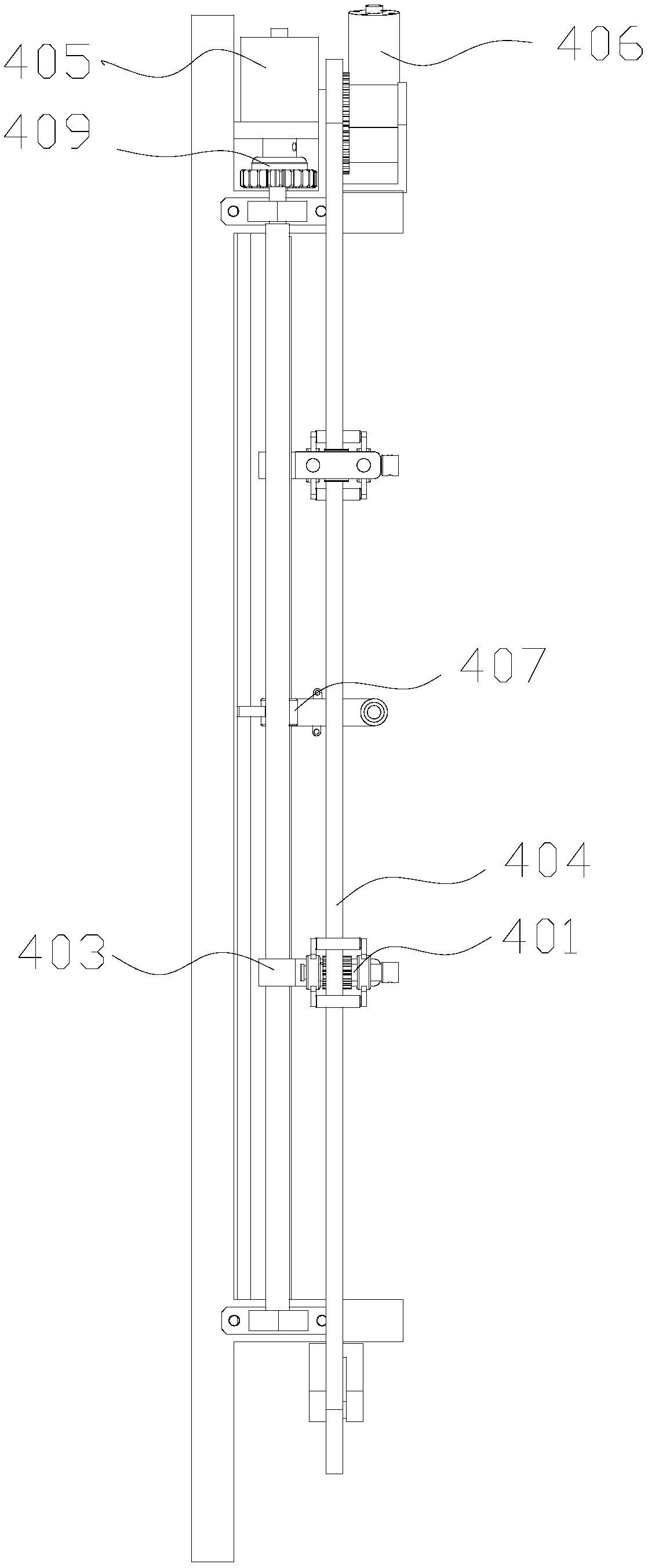

[0035] Such as Figure 1-3 As shown, this embodiment provides a belt-driven shoe washing mechanism, including: a shoe brush mounting base 401 for mounting a shoe brush 402 with a shaft, and the shoe brush 402 with a shaft can rotate on the shoe brush mounting base 401; The screw rod slider mechanism 403, the shoe brush mounting base 401 is installed on the slider of the first screw rod slider mechanism 403, the screw rod of the first screw rod slider mechanism 403 is connected with the first power mechanism 405 in transmission, and the slider is in the Driven by the rotation of the screw rod, it moves along the axial direction of the screw rod; the belt transmission mechanism 404, the synchronous belt of the belt transmission mechanism 404 passes through the shoe brush mounting seat 401, and the synchronous belt is connected with the rotating shaft of the belt shaft shoe brush 402. Specifically, The rotating shaft of the shoe brush with shaft 402 is equipped with a gear adapte...

Embodiment 2

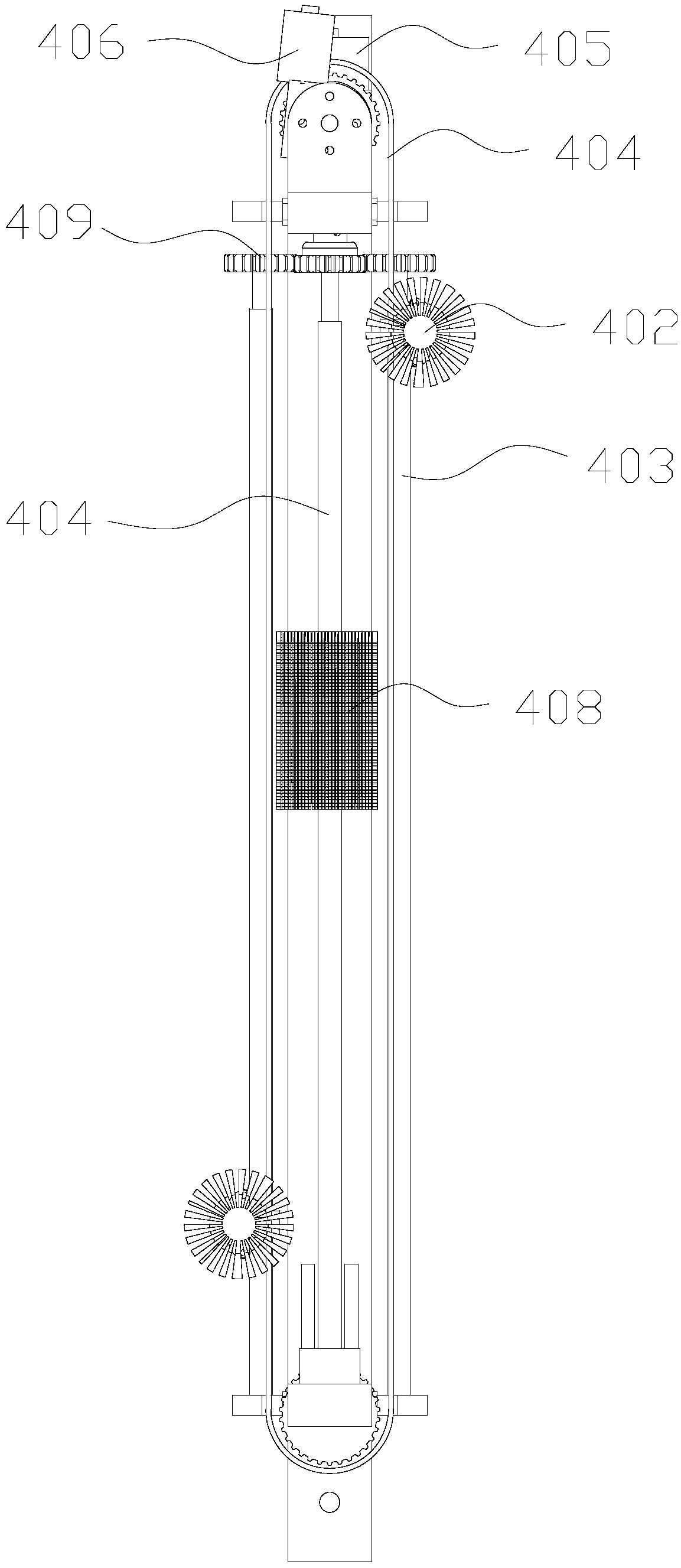

[0040] Such as Figure 4 As shown, this embodiment provides a belt-driven shoe washing mechanism, including: a shoe brush mounting base 401 for mounting a shoe brush 402 with a shaft, and the shoe brush 402 with a shaft can rotate on the shoe brush mounting base 401; The screw rod slider mechanism 403, the shoe brush mounting base 401 is installed on the slider of the first screw rod slider mechanism 403, the screw rod of the first screw rod slider mechanism 403 is connected with the first power mechanism 405 in transmission, and the slider is in the Driven by the rotation of the screw mandrel, it moves along the axial direction of the screw mandrel; the belt transmission mechanism 404, the synchronous belt of the belt transmission mechanism 404 passes through the shoe brush mounting seat 401, and the synchronous belt is connected with the shaft transmission of the belt shaft shoe brush 402, when the belt shaft When the shoe brush 402 and the synchronous belt move relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com