A two-position two-way solenoid valve with improved structure

A two-position two-way, improved structure technology, applied in the valve shell structure, valve details, control valve and other directions, can solve the problems of affecting the service life of the valve, increasing the cost of use, complex installation structure, etc., to ensure stability and reliability. , prolong the service life, the effect of simple structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

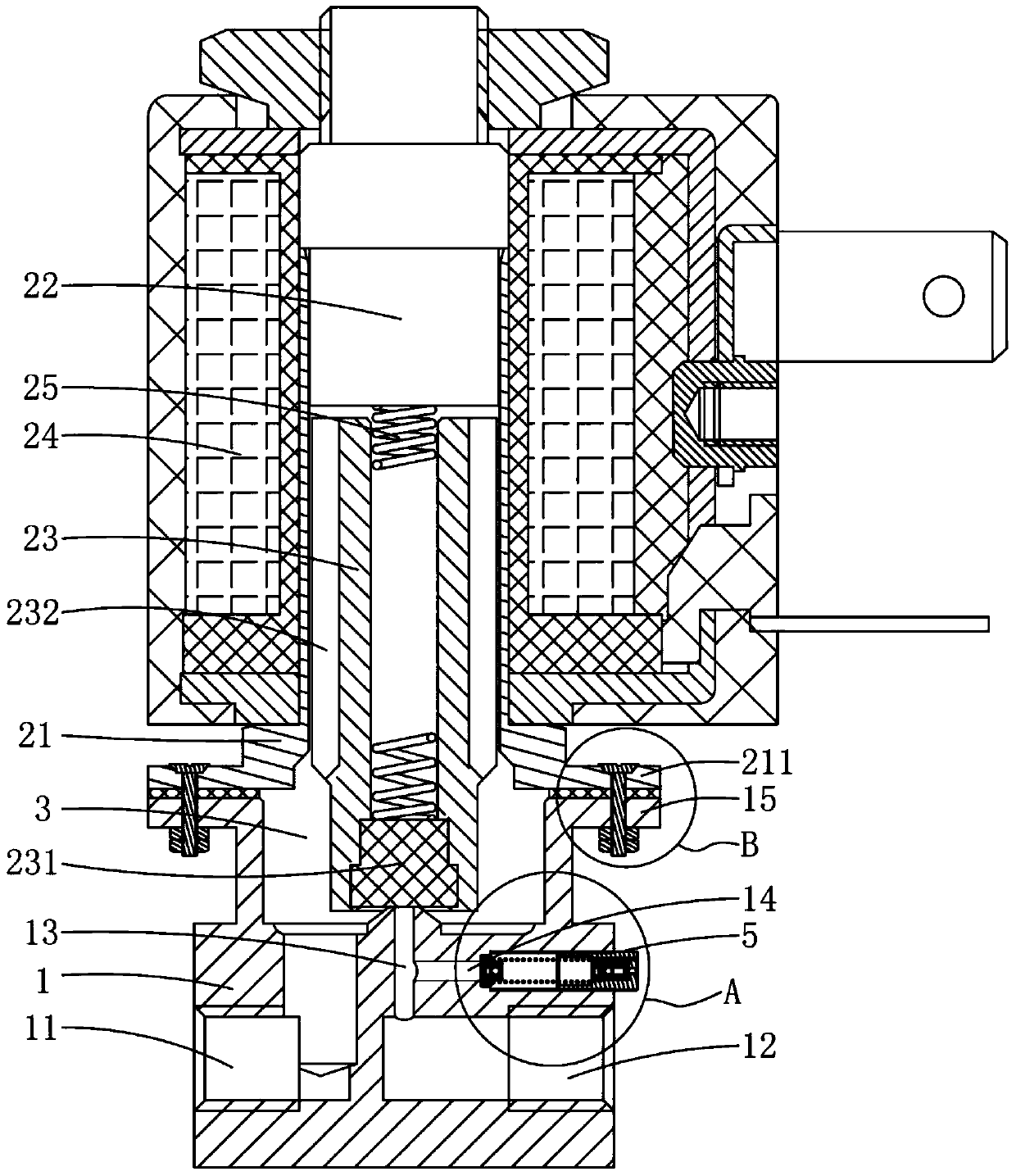

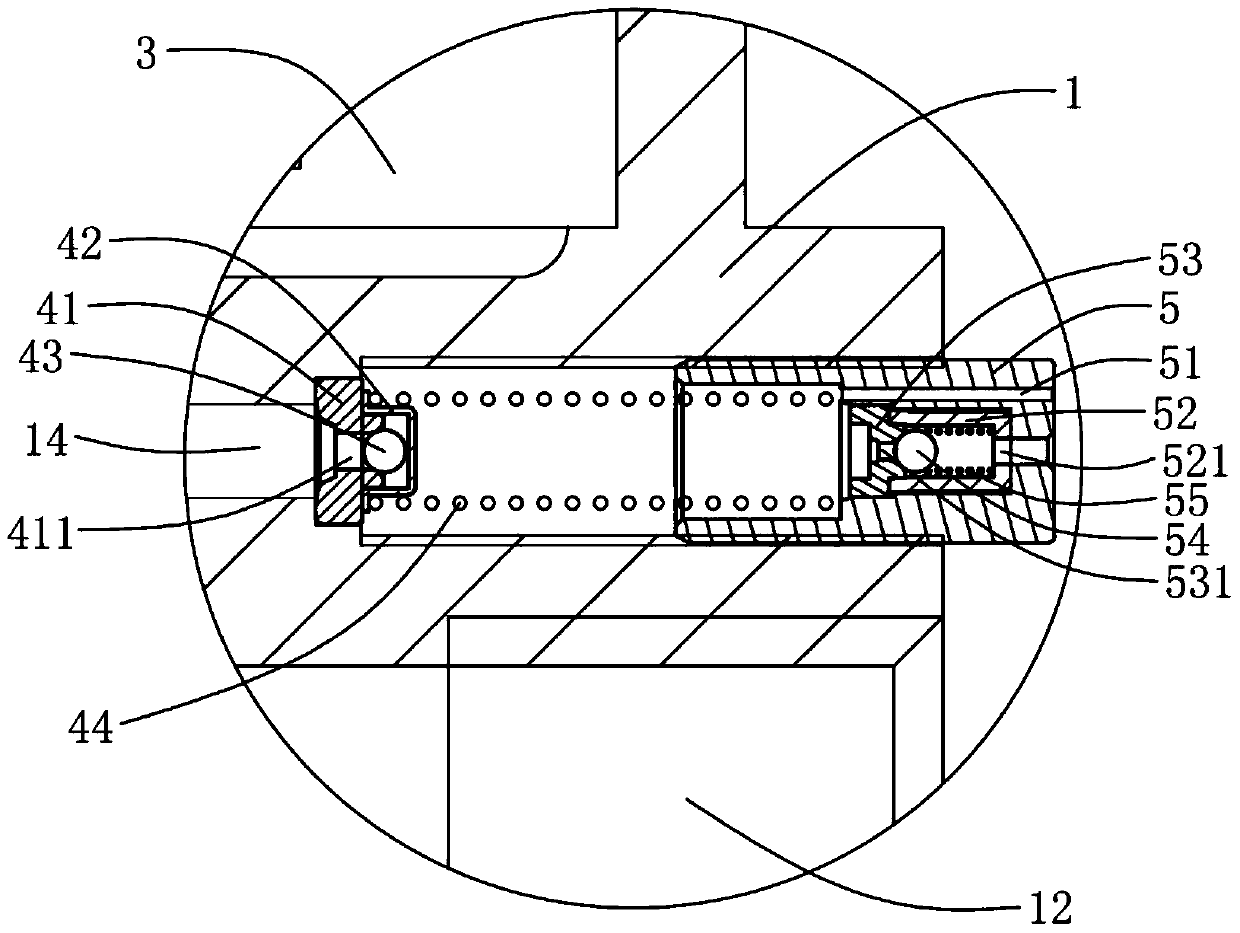

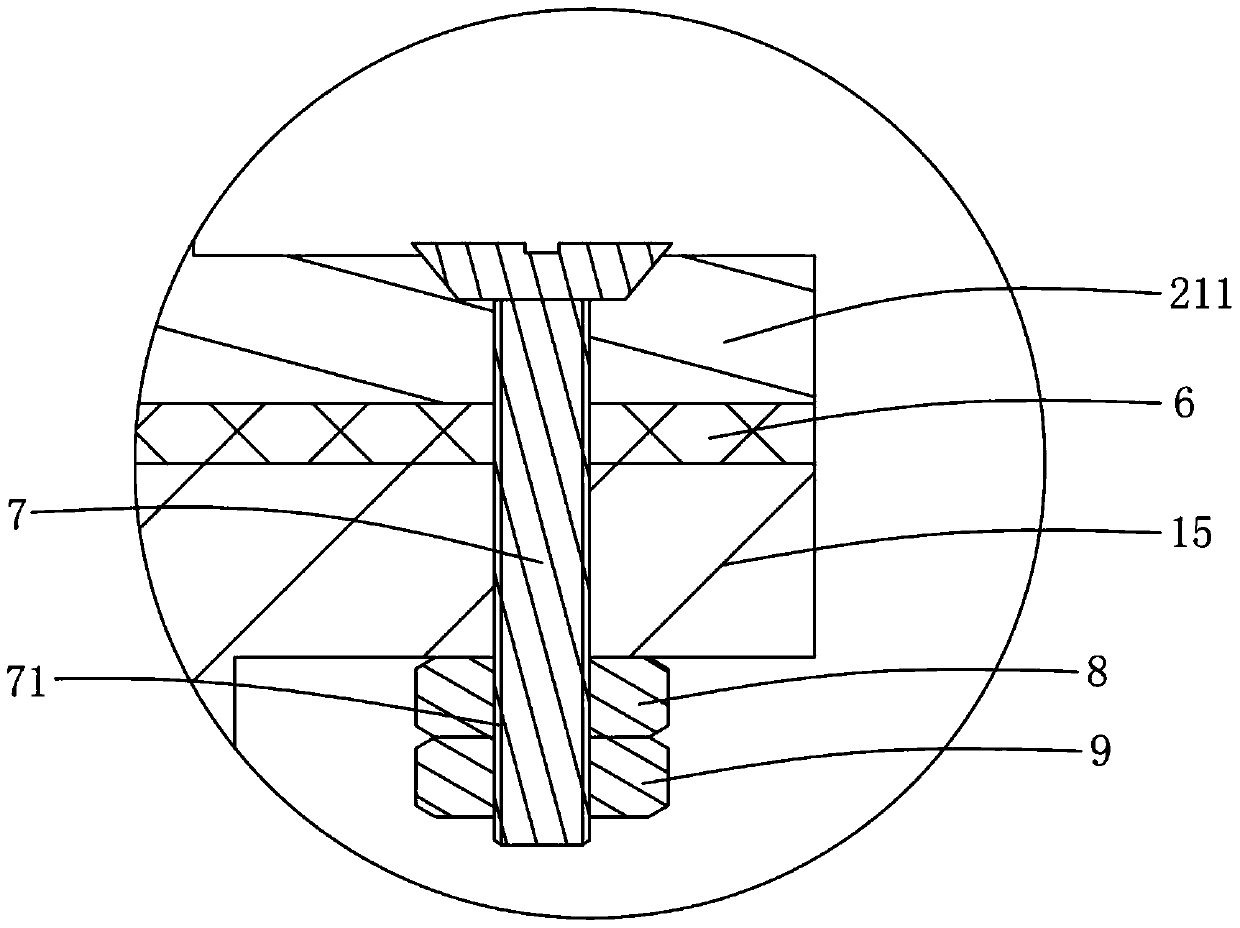

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 3 A two-position two-way solenoid valve with an improved structure is shown, including a valve body 1, the valve body 1 is respectively provided with an air inlet 11 and an air outlet 12, and the valve body 1 is provided with a valve communicating with the air outlet 12. The air guide hole 13, the valve body 1 is provided with a pilot assembly for controlling the conduction or cutoff of the passage between the air guide hole 13 and the air inlet 11.

[0024] The pilot assembly includes a sleeve 21, a static iron core 22, a moving iron core 23 and a coil assembly 24. The bottom end of the sleeve 21 is fixedly connected to the valve body 1. Specifically, the top end of the valve body extends with The first connecting part 15, the second connecting part 211 corresponding to the first connecting part 15 is extended from the bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com