Confining pressure cylinder device for novel split Hopkinson pressure bar active confining pressure experiment

A Hopkinson compression rod and active technology, which is applied in the field of confining pressure cylinder device, can solve the problems of affecting the experiment, the rod is not pressed tightly to the test piece, etc., and achieves the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

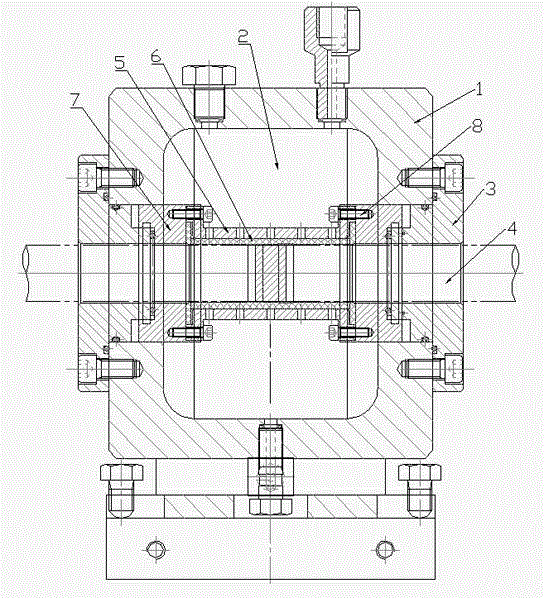

[0014] Such as figure 1 A new type of confining pressure cylinder device for active confining pressure experiment of Hopkinson pressure rod shown, including cylinder body 1, pressure chamber 2 in cylinder body 1, cylinder head 3, compression block 8, metal sleeve 6, rubber sleeve 5 and the shaft hole 4; the outer two ends of the cylinder body 1 are respectively provided with a cylinder head 3; the two ends of the pressure chamber 2 are respectively provided with a compression block 8 corresponding to the cylinder head 3, and one end of the compression block 8 extends into the cylinder Inside the body 1; a metal sleeve 6 is provided between the compression blocks 8 at both ends of the pressure chamber 2, and is connected by screws 9; a rubber sleeve 5 is provided inside the metal sleeve 6, and the rubber sleeve 5 is located on both sides of the pressure chamber 2 Between the compression block 8 at the end, the compression block 8 is formed with the metal sleeve 6 and the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com