Glass emptying bracket

A glass and frame technology, which is applied in the field of glass placement devices, can solve problems such as poor stability, difficulty in placing and taking out the glass, and easy slipping and breaking, so as to prevent the glass from moving or turning over and falling off, convenient to place and take out, and prevent glass The effect of moving out or sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

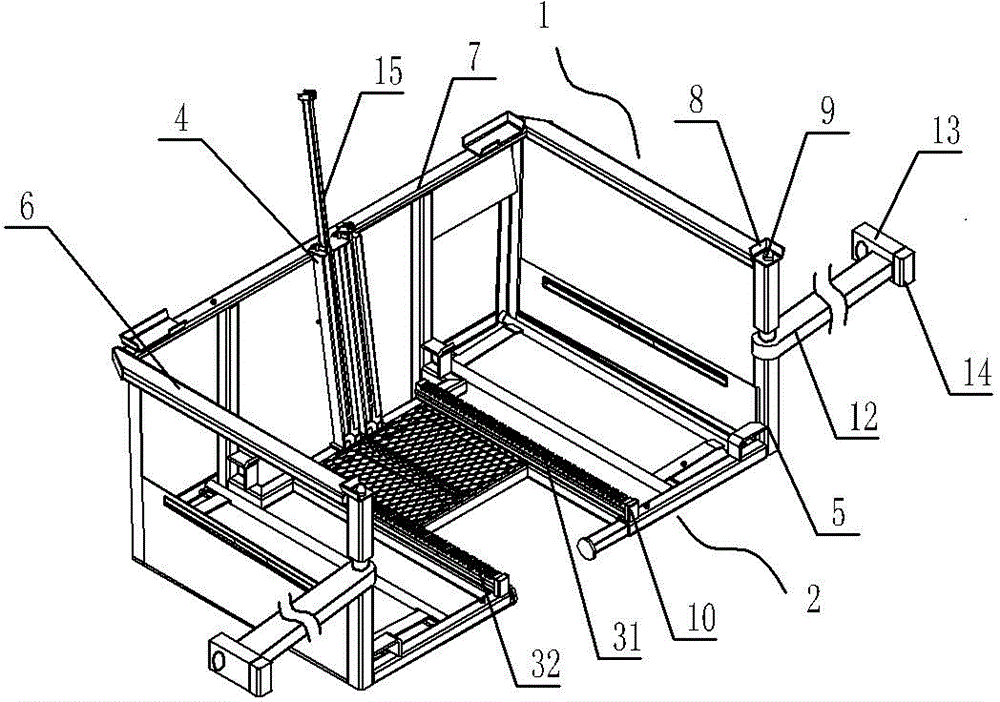

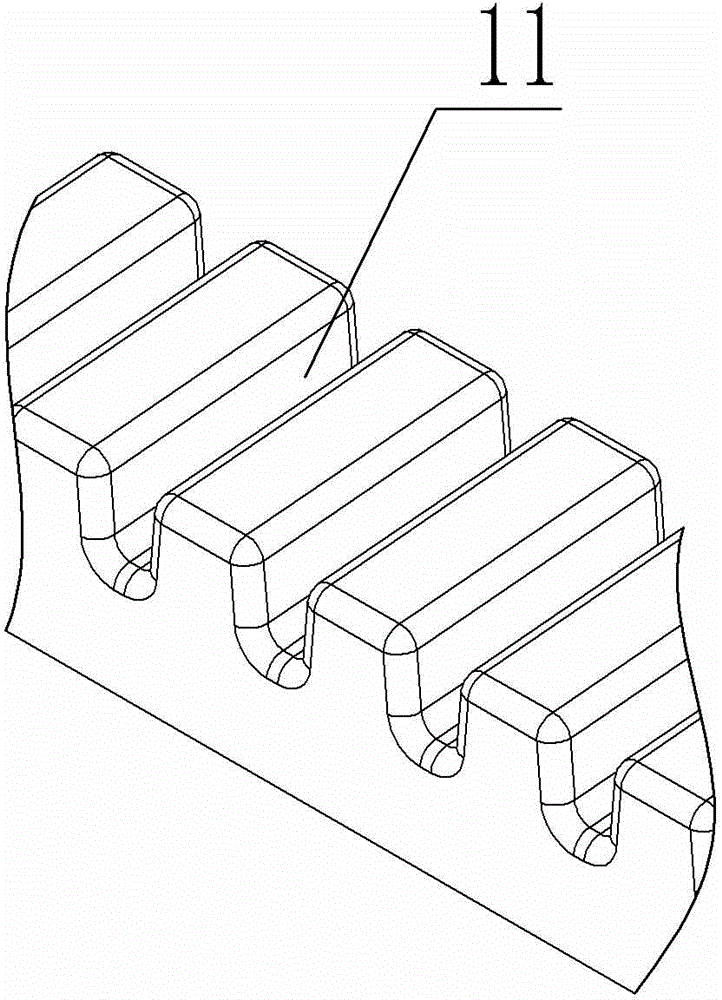

[0011] Such as figure 1 , figure 2 As shown, it includes an upper frame 1, a lower frame 2 and support beams 5, 6 for connecting the upper frame 1 and the lower frame 2, and the lower frame 2 is provided with a first mounting block 31 and a second mounting block 32 parallel to each other, Located at the front ends of the first mounting block 31 and the second mounting block 32, the lower frame 2 is provided with a stopper 10, and the upper parts of the first mounting block 31 and the second mounting block 32 are provided with a number of card slots 11 uniformly distributed along the length direction. Between the first mounting block 31 and the second mounting block 32, the lower frame 2 is provided with a block 4, the upper end of the block 4 is affixed to the upper frame 1, and the block 4 is provided with a telescopic rod 15, which can be Retractable along the length direction of the block 4, the upper frame 1 is "凵" shape, and the support beams 5 at both ends of the "凵" s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com