Shielding-type aluminum squeezing die with small opening and large pressure-bearing face

A technology of aluminum extrusion and pressure bearing surface, which is applied in the direction of metal extrusion dies, etc., can solve the problems of difficult control of the deformation of the inner corner of the wall column, the difficulty of mold design, and the large deformation of the profile, so as to achieve good processing effect and reduce The effect of large expansion and mold throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0017] The most critical idea of the present invention is: the feed material flows in from the diversion hole on the feed surface of the diversion die, and after being extruded by the profile die, it is discharged from the empty knife layer at the outlet. Let the aluminum metal go straight, so that the extrusion force of the central cantilever part is greatly reduced, and the strength of the cantilever is guaranteed.

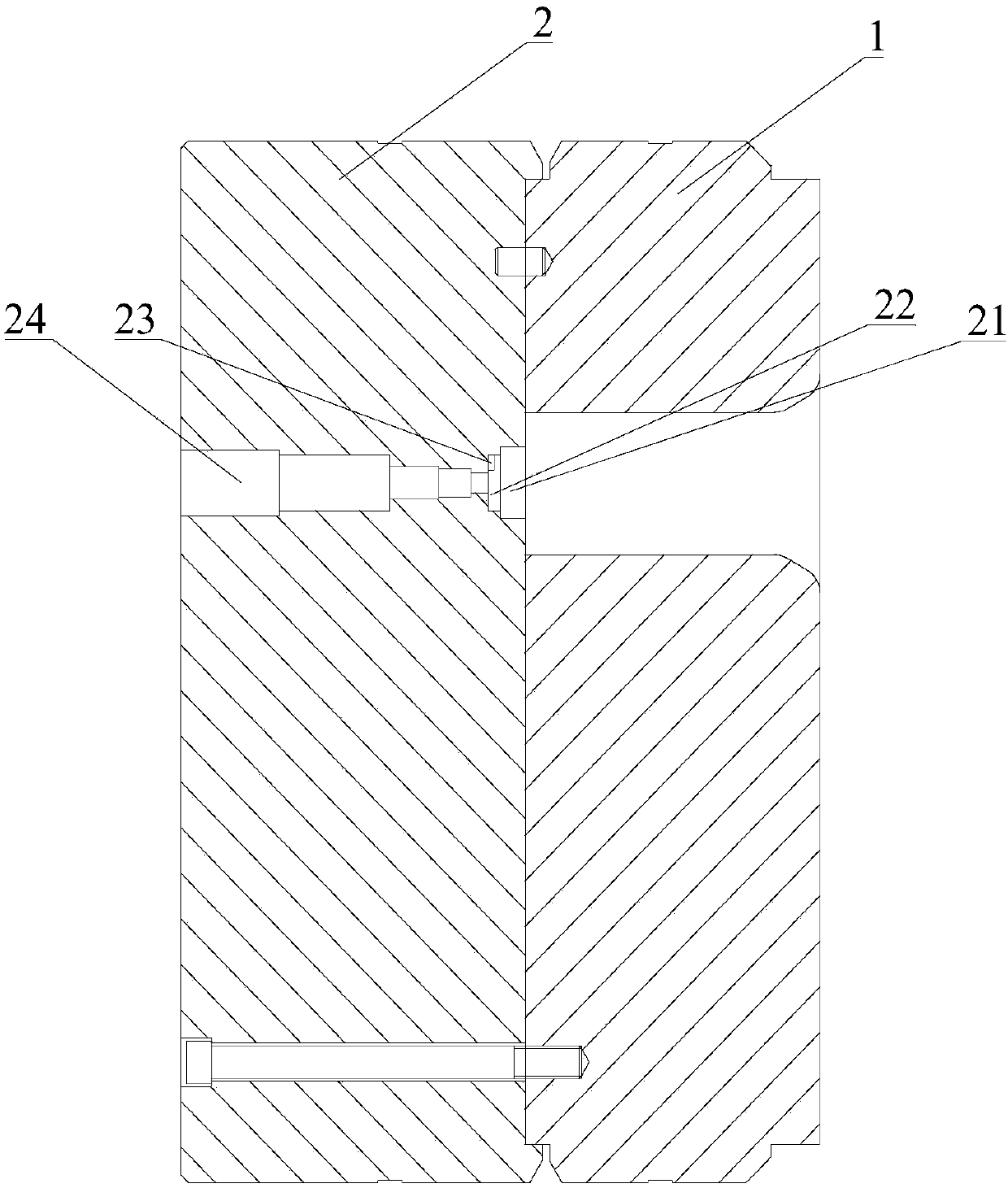

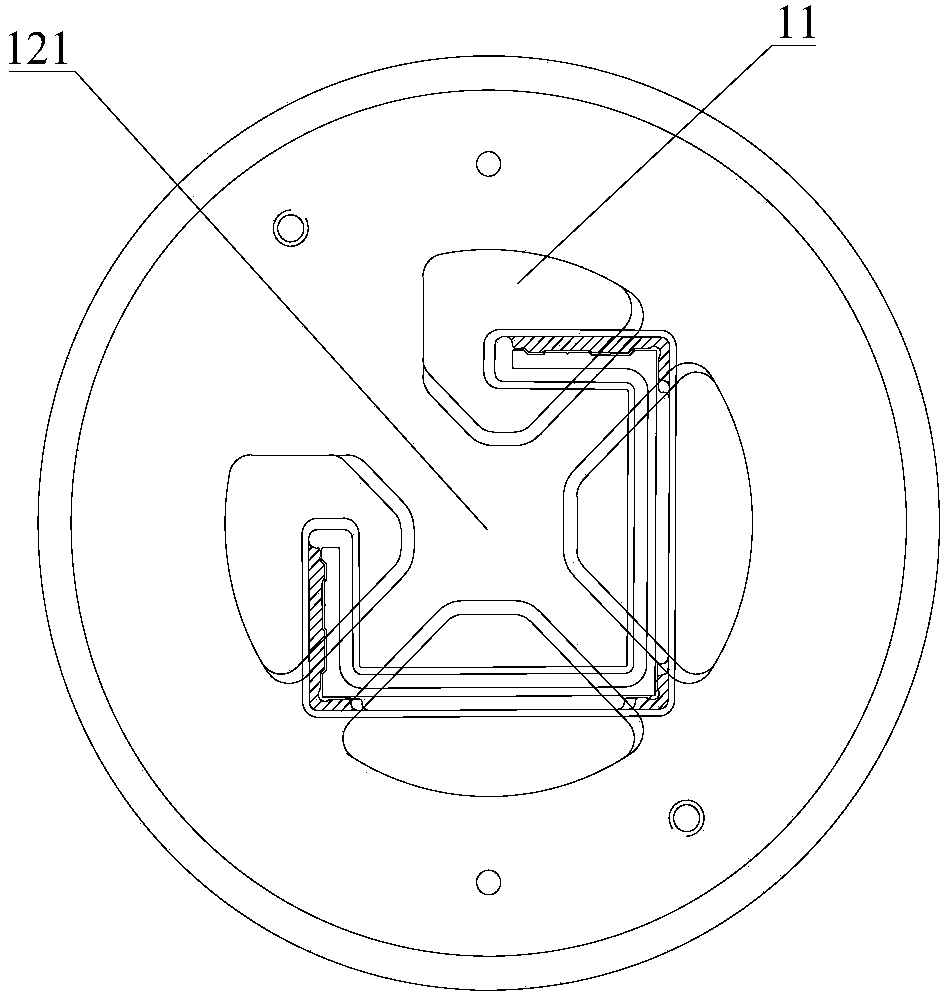

[0018] An aluminum extrusion die with a small opening and a large pressure-bearing surface shielding type, including a diversion die and a pad die, the diversion bridge is distributed on the feed surface of the diversion die, and the diversion bridge includes a central diversion bridge and a circumferential Splitter bridges, splitter holes are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com