Die applicable to deflection of small and long cantilever

A technology of long cantilever and yaw, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult maintenance, increased cantilever compressive stress, low machine qualification rate, etc., to achieve simple and reasonable structural design, balanced metal flow, The effect of reducing the deflection of the waste mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

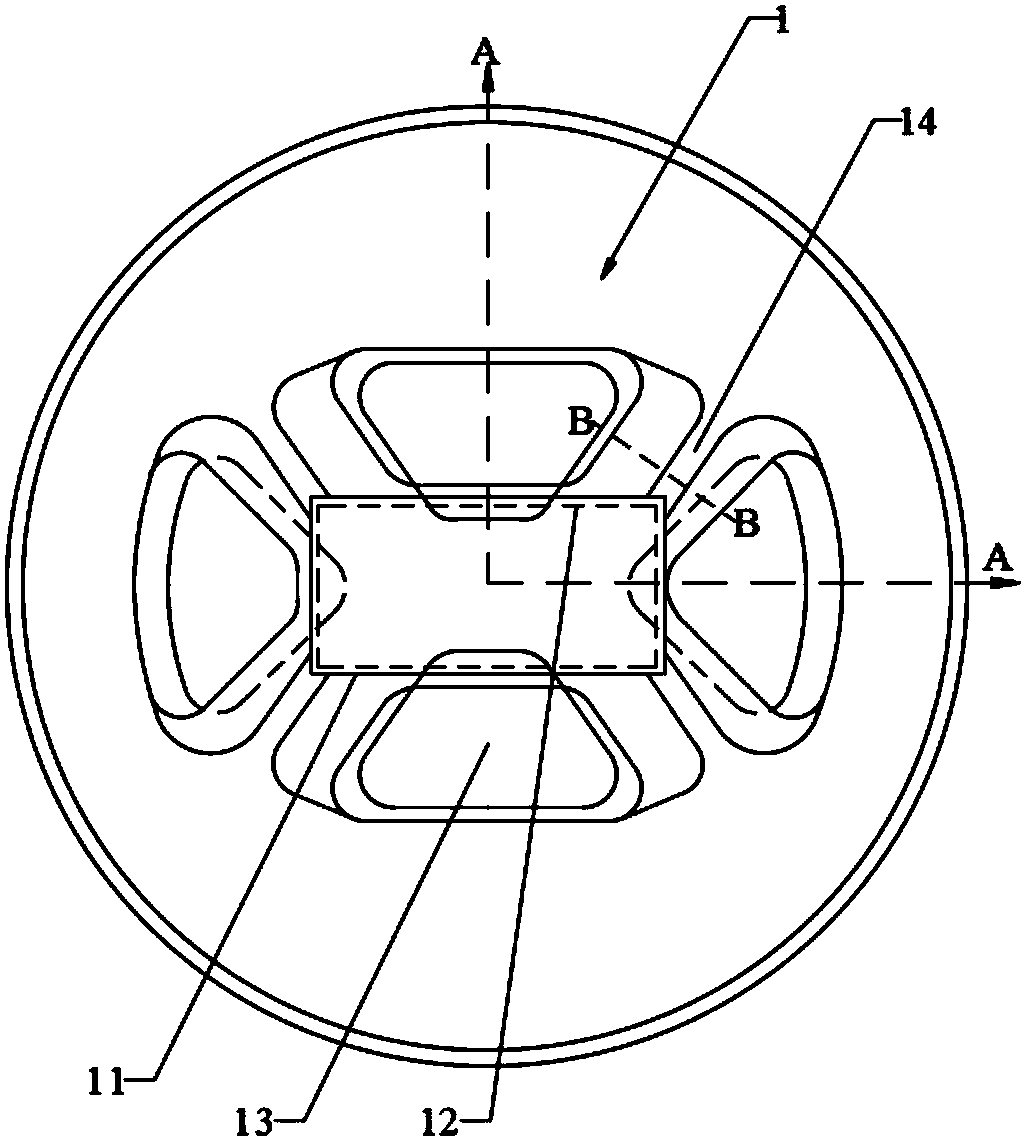

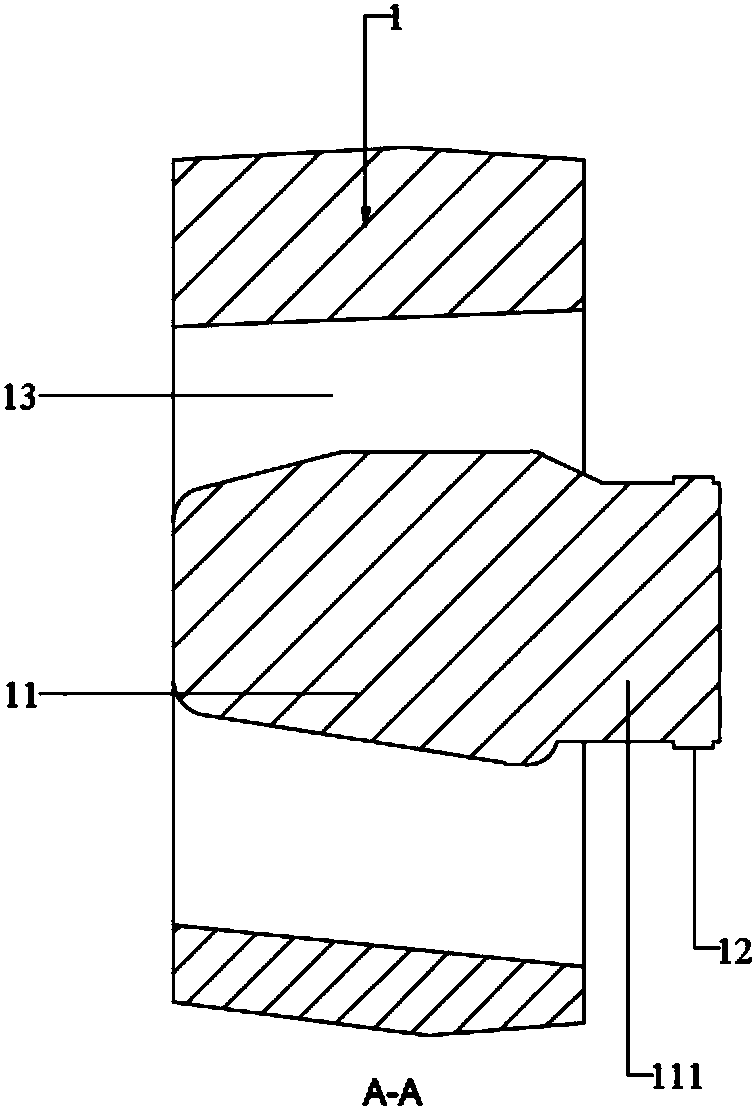

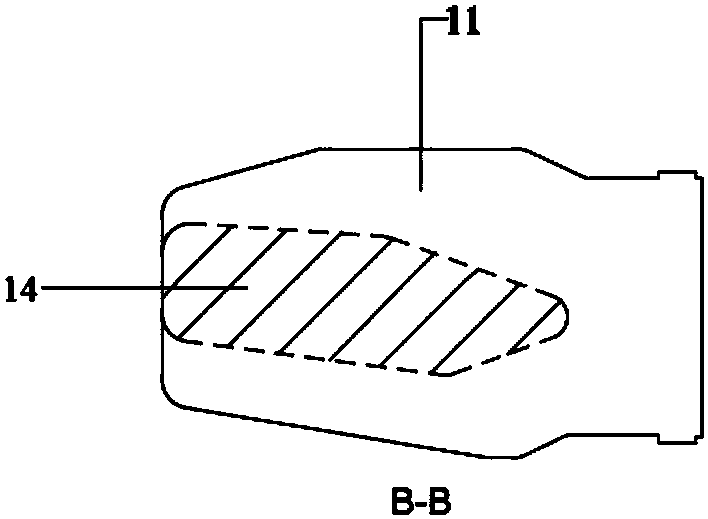

[0055] Please refer to Figure 1 to Figure 7 Shown, embodiment one of the present invention is:

[0056] A mold suitable for the deflection of a small and long cantilever, comprising an upper mold 1 and a lower mold 2 connected to each other;

[0057] The middle part of the upper die 1 is provided with a tongue core 11, and the tongue core 11 is arranged from the feed end of the upper die 1 to the discharge end of the upper die 1, and extends out of the discharge end of the upper die 1 to form a protrusion 111, the protrusion 111 is provided with a first working belt 12;

[0058] The feeding end circumference of the upper die 1 is provided with four distribution holes 13 passing through the upper die, the distribution holes 13 are evenly distributed around the tongue core 11, and the distribution bridges 14 are arranged between the distribution holes 13 ;

[0059] The lower mold 2 is provided with a welding chamber 21, a second working belt 22, a lower mold empty knife 23 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com