Patents

Literature

103results about How to "Reduce stress buildup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

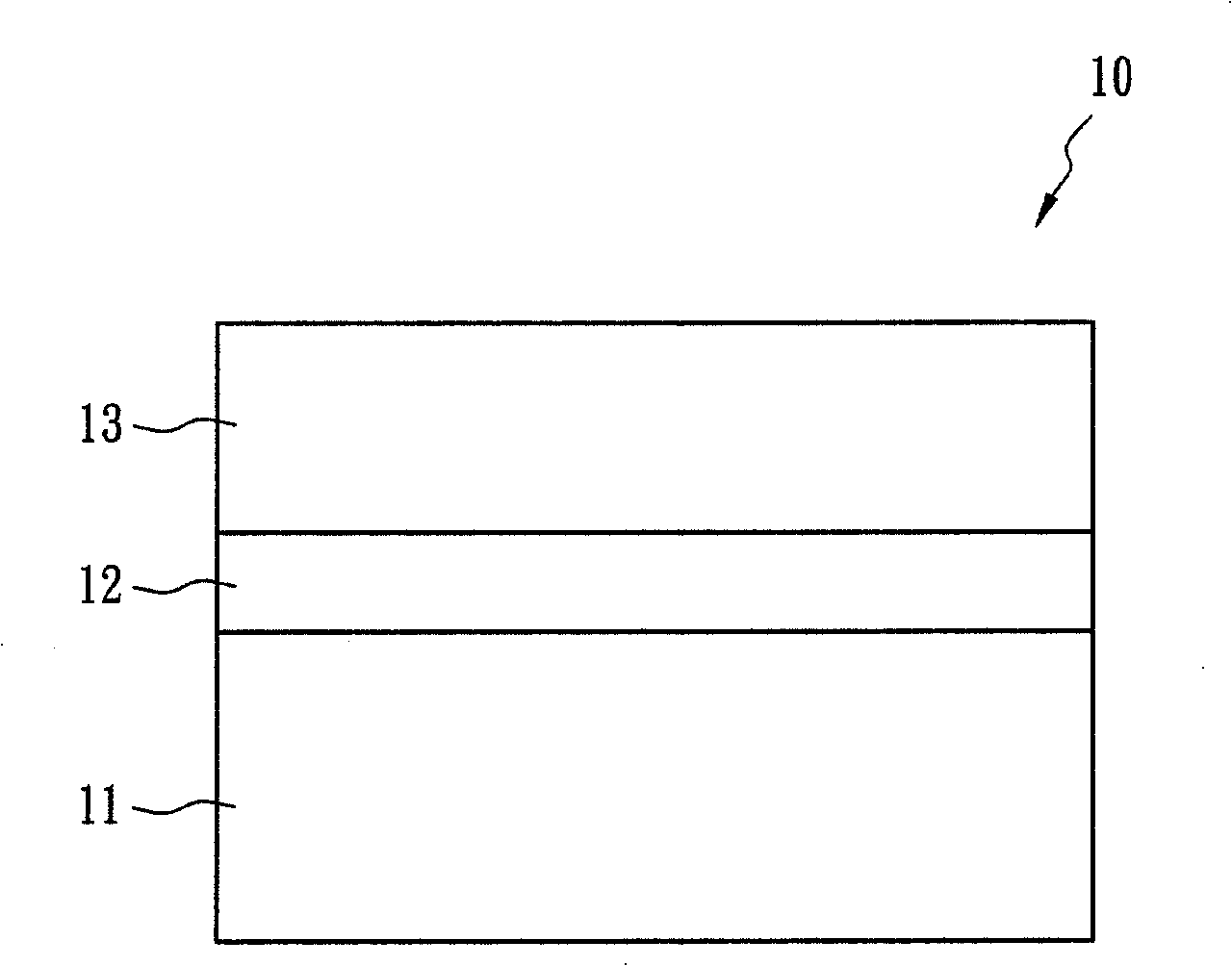

Structure and method of thermal stress compensation

InactiveUS20060204776A1Reduce stress buildupThermometers using material expansion/contactionVacuum evaporation coatingNegative coefficientMaterials science

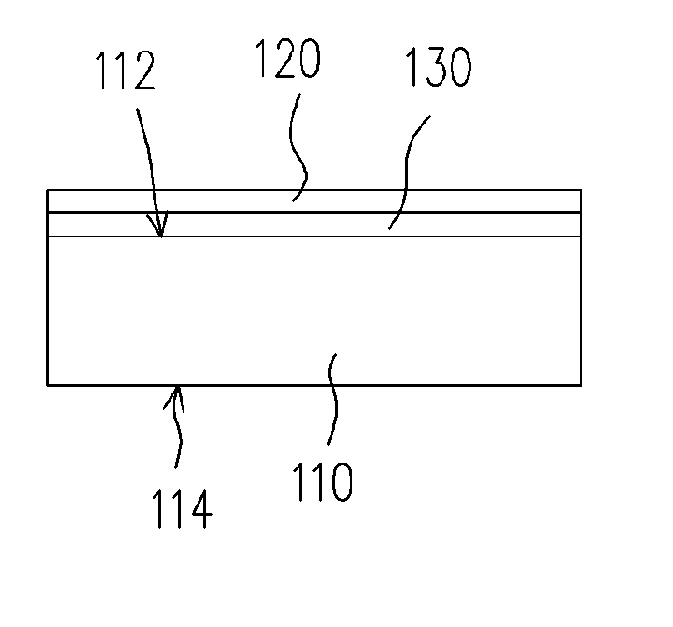

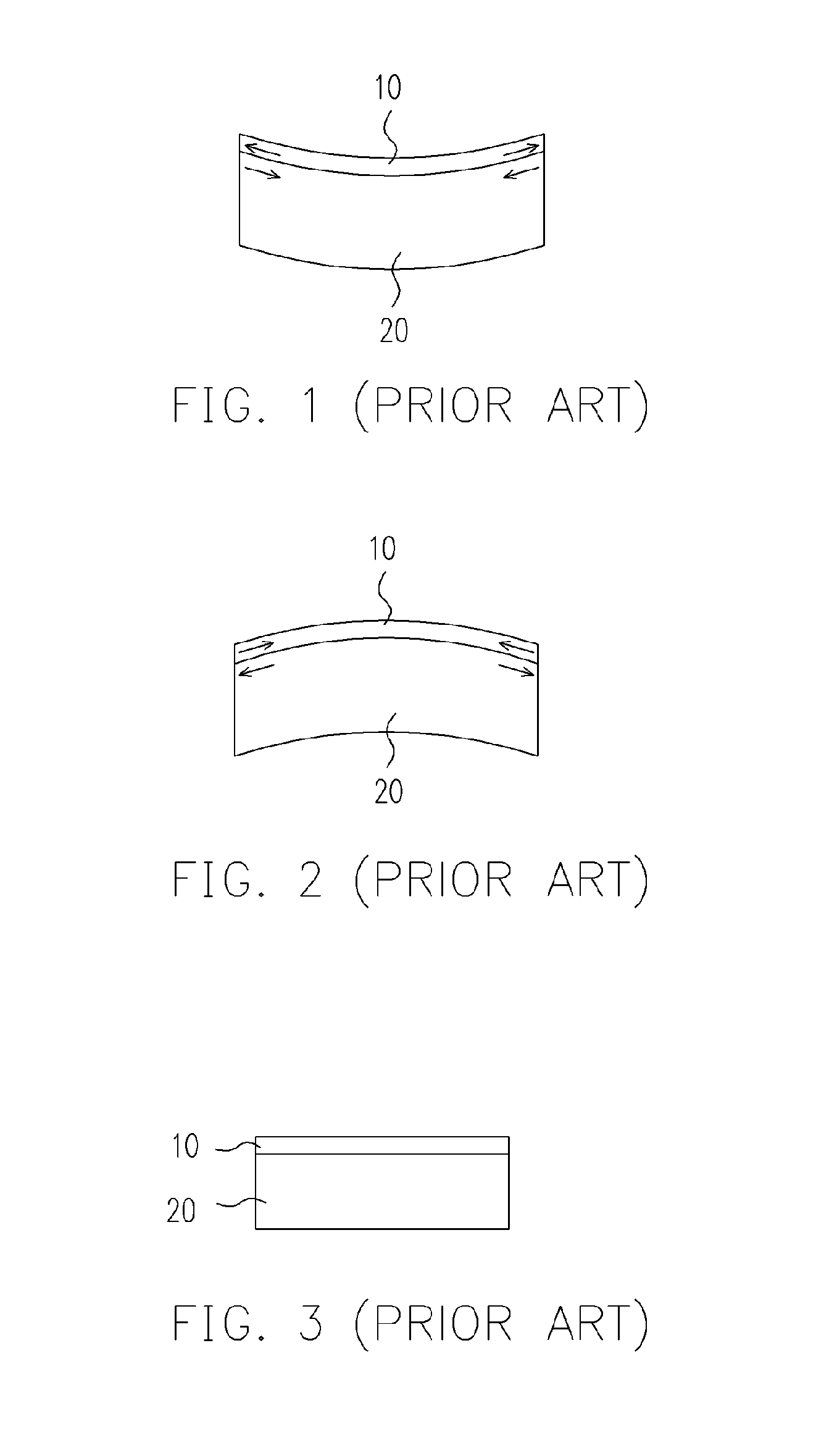

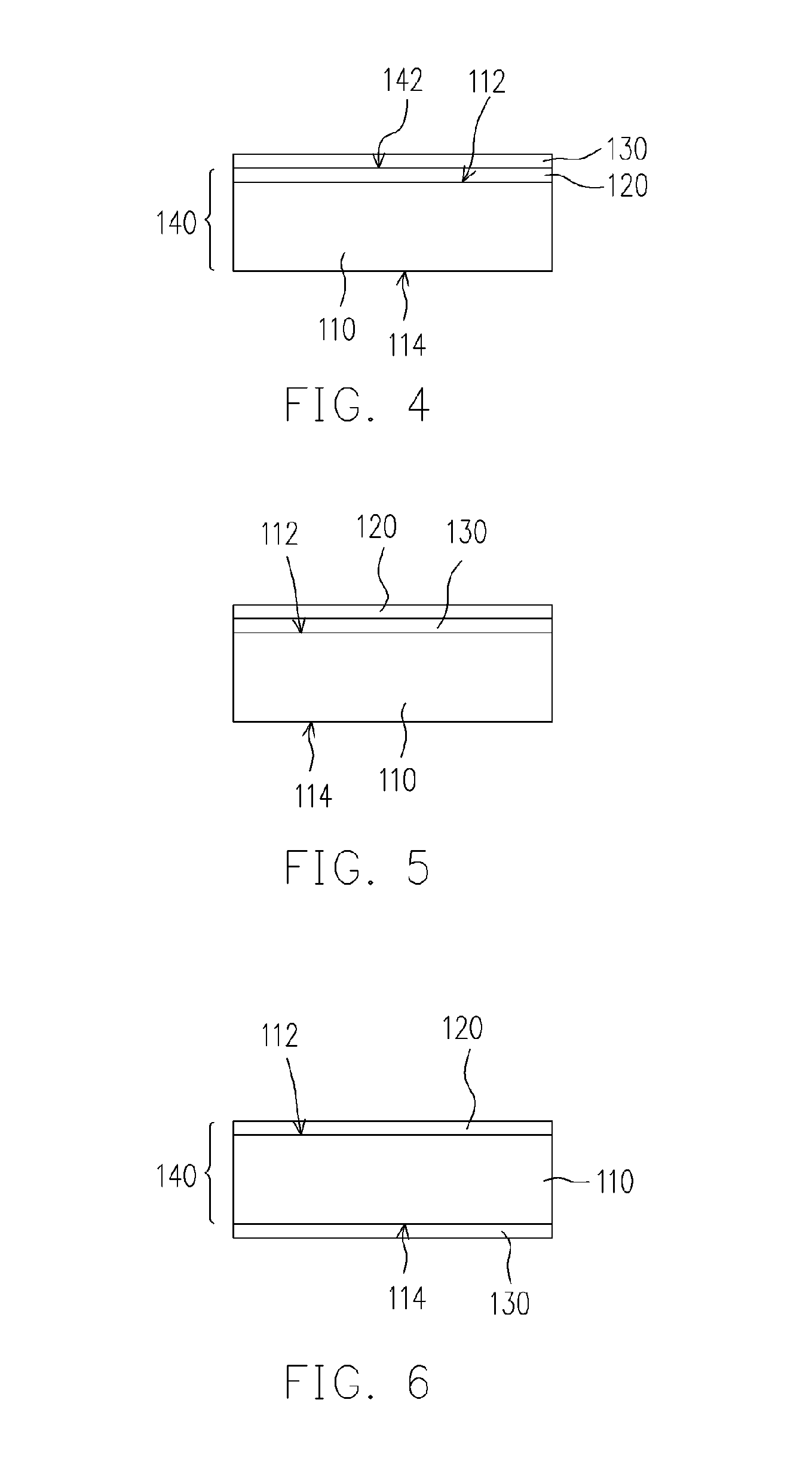

A structure of thermal stress compensation at least comprises a substrate, a first film and a second film. The substrate has a first positive coefficient of thermal expansion. The first film having a second positive coefficient of thermal expansion is over the substrate. The second film having a third negative coefficient of thermal expansion is over the substrate.

Owner:NAT CENT UNIV

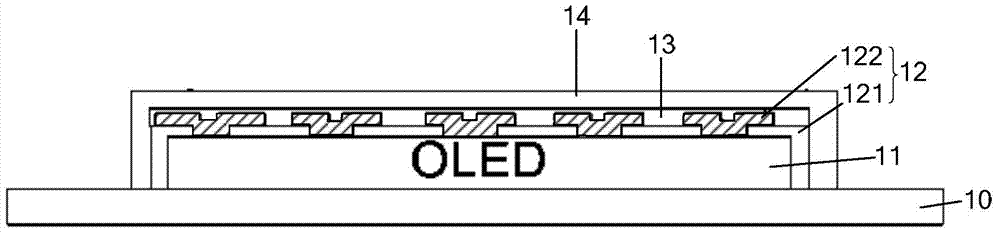

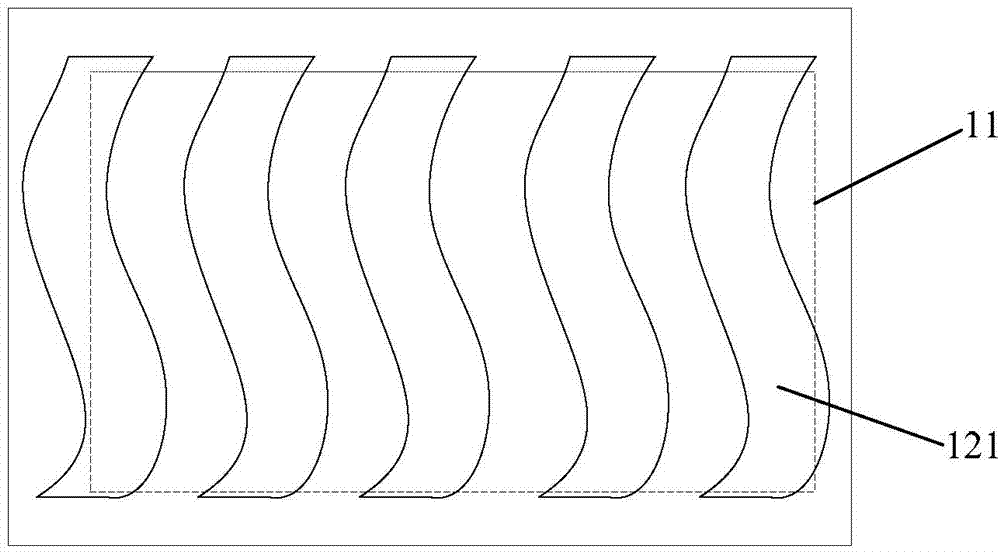

Flexible display device and packaging method of flexible display device

ActiveCN104733507APrevent immersionAvoid damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlexible display

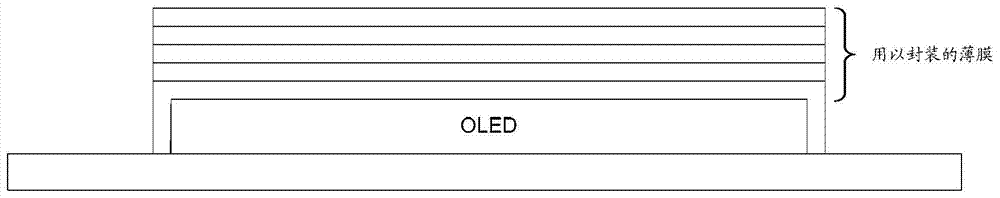

The invention discloses a flexible display device and a packaging method of the flexible display device, and relates to the field of display. The problem that bending cannot be resisted in existing thin film packaging can be solved. The flexible display device comprises a light emitting device and a packaging layer for packaging the light emitting device. The packaging layer comprises a first patterned film layer and a second film layer at least covering the pattern clearance of the first film layer.

Owner:BOE TECH GRP CO LTD

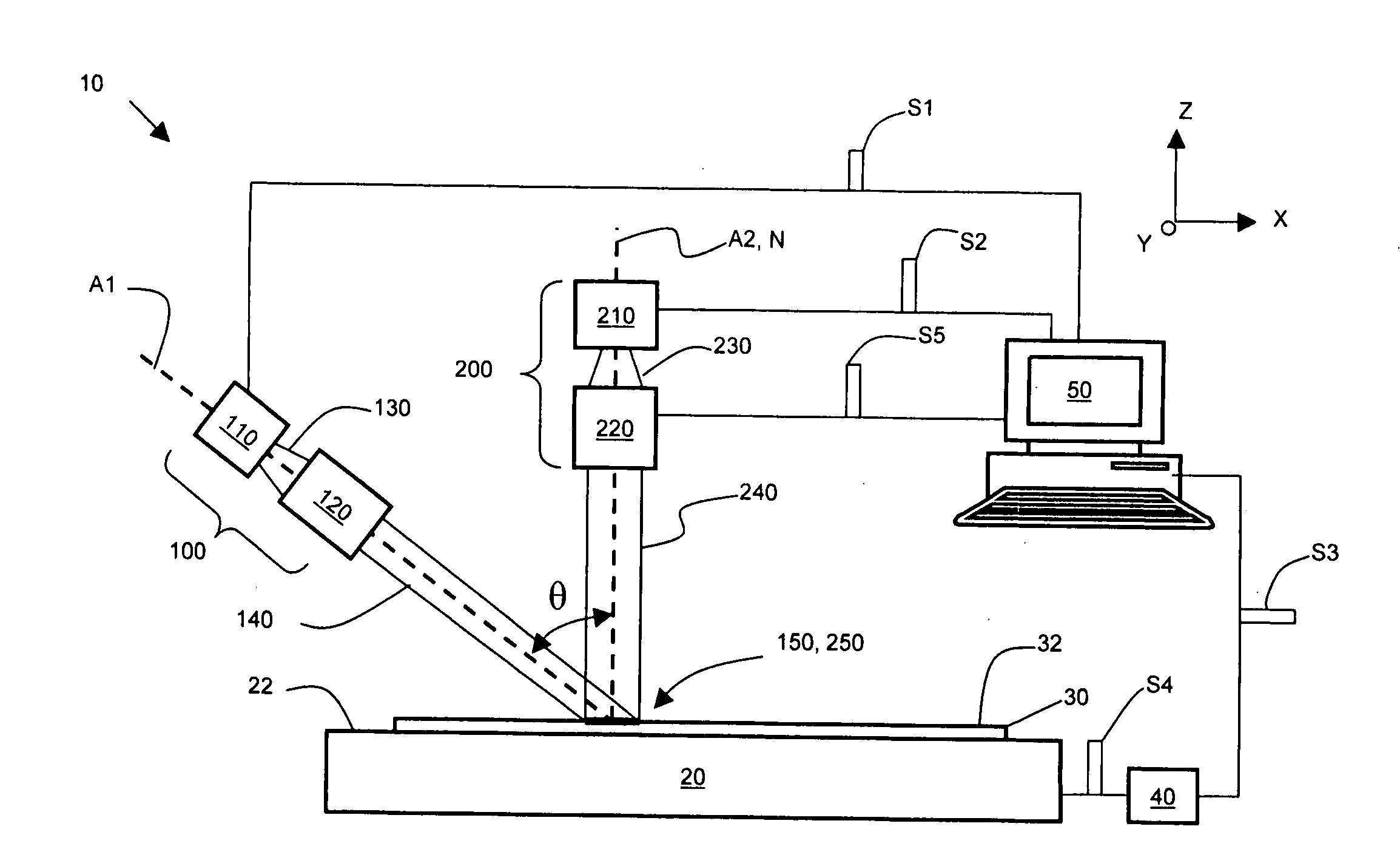

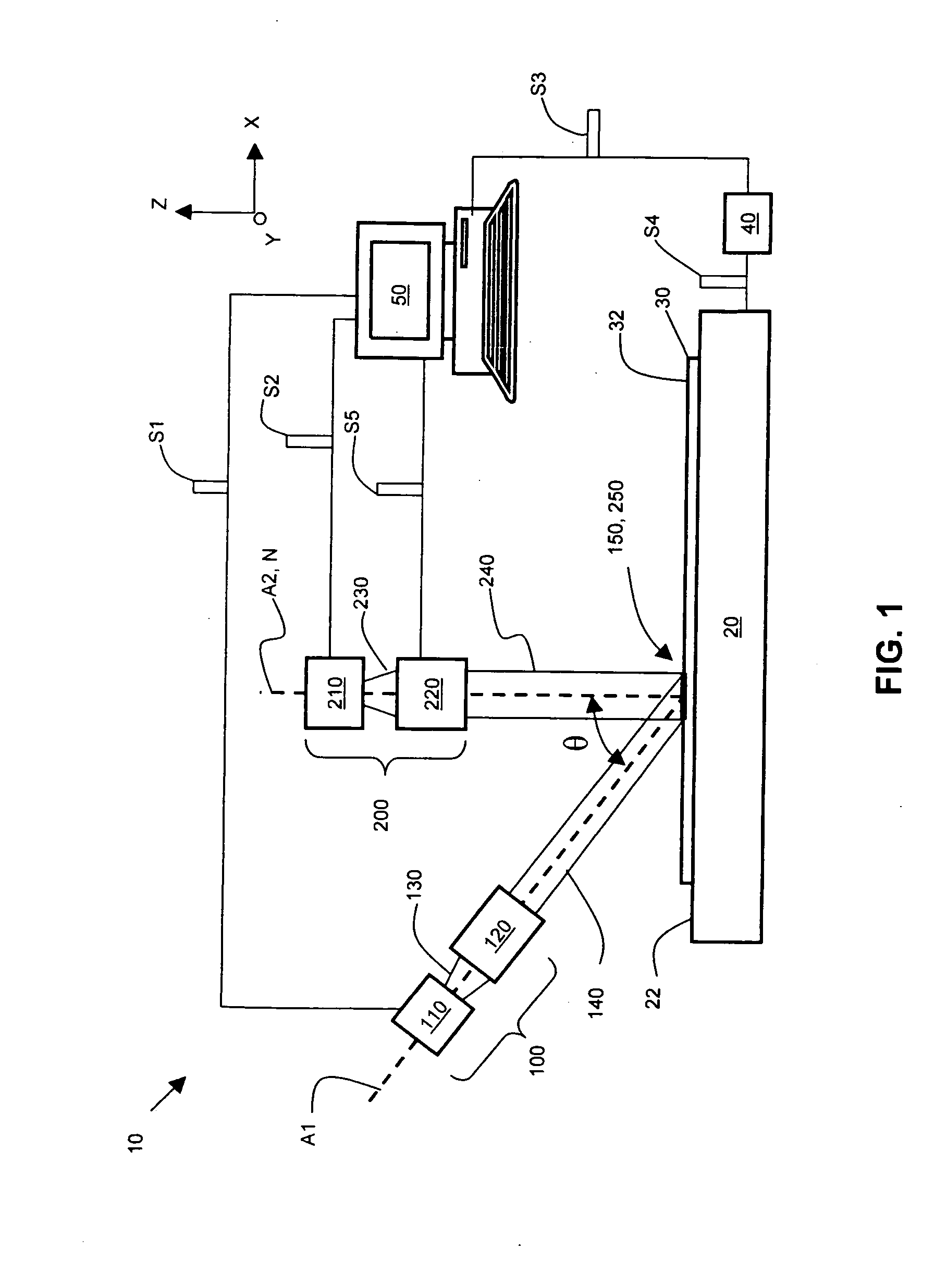

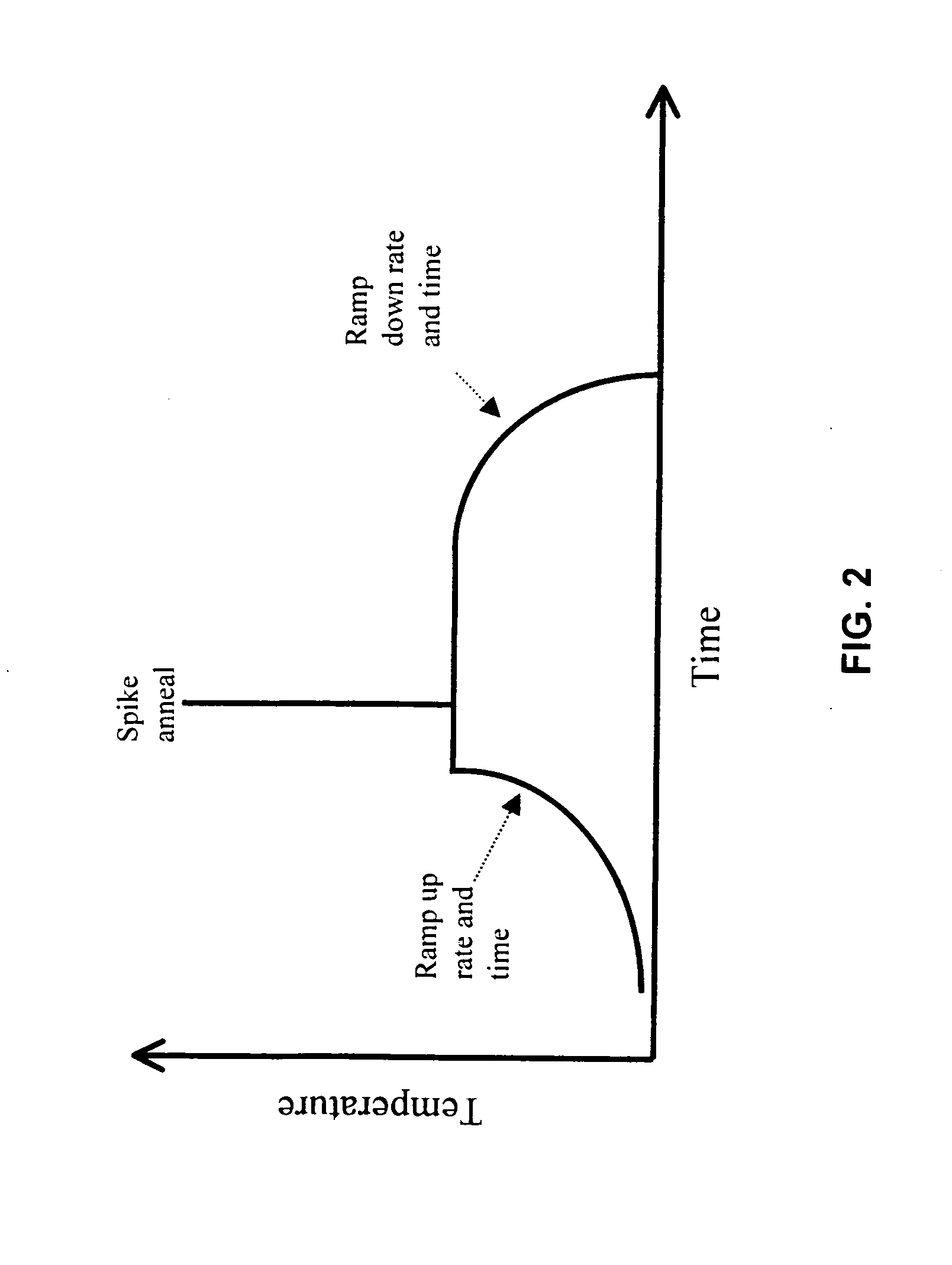

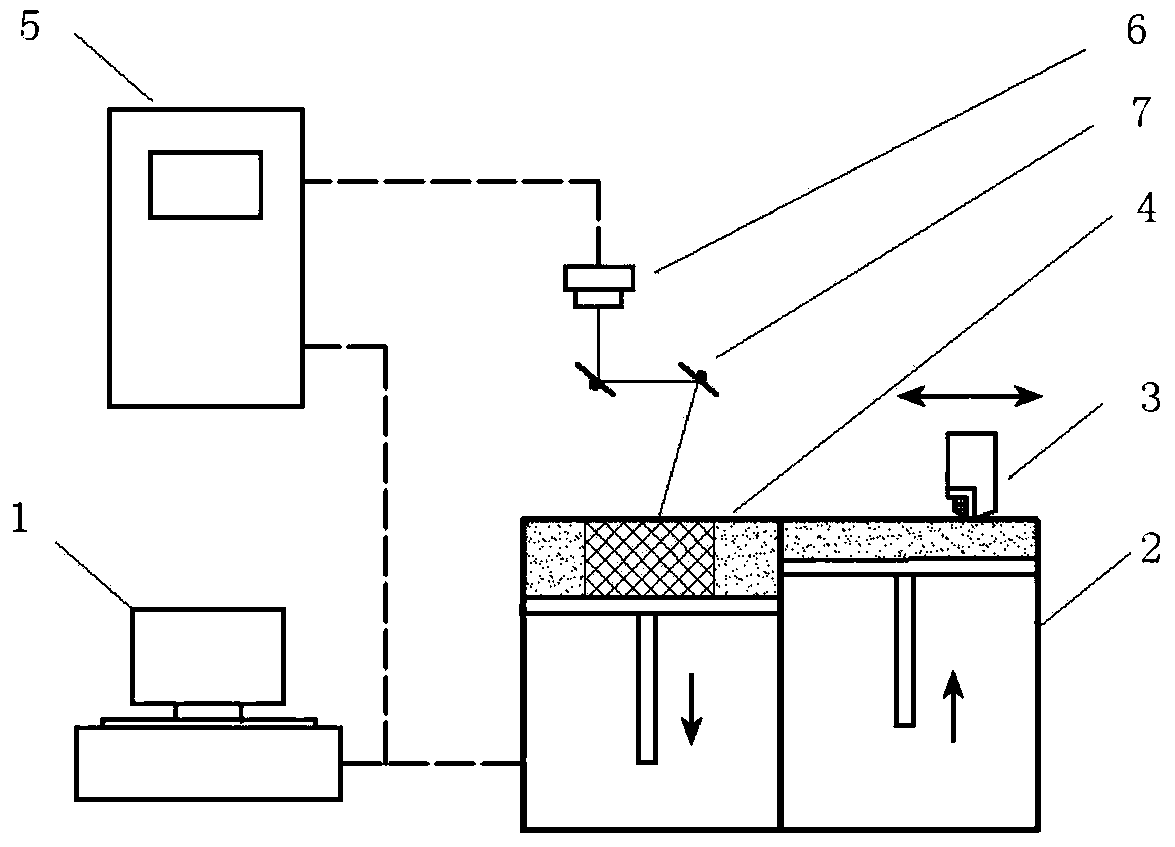

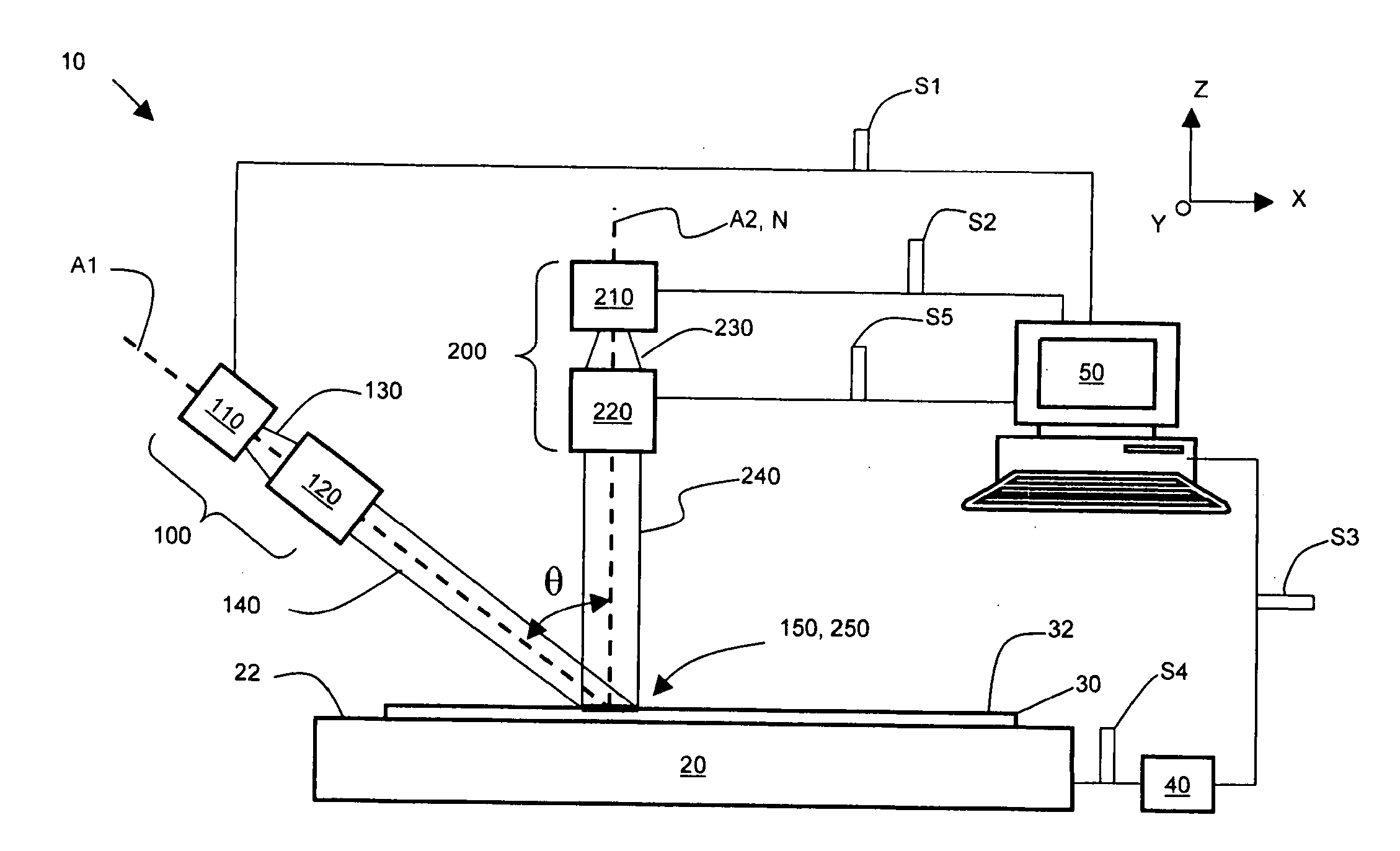

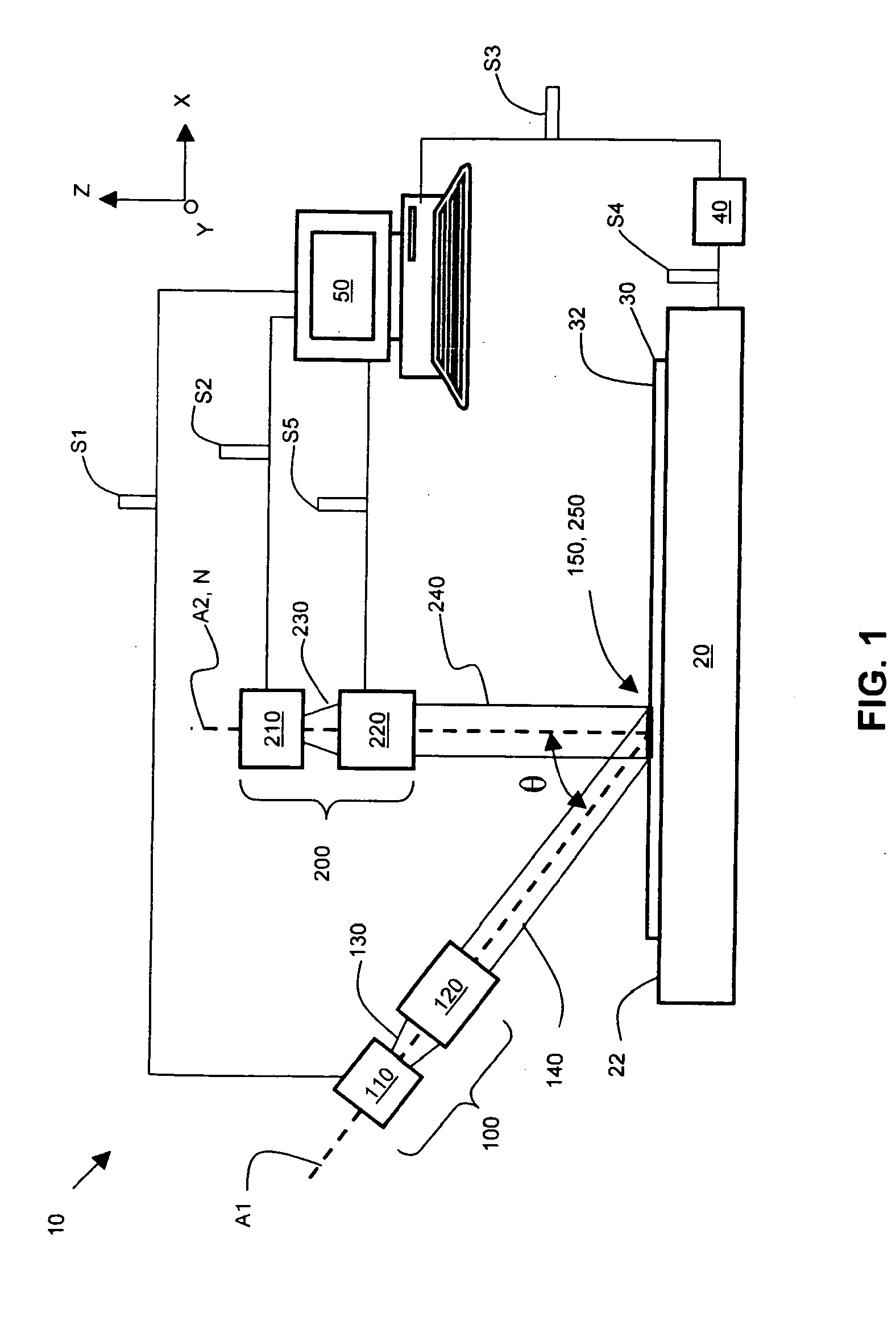

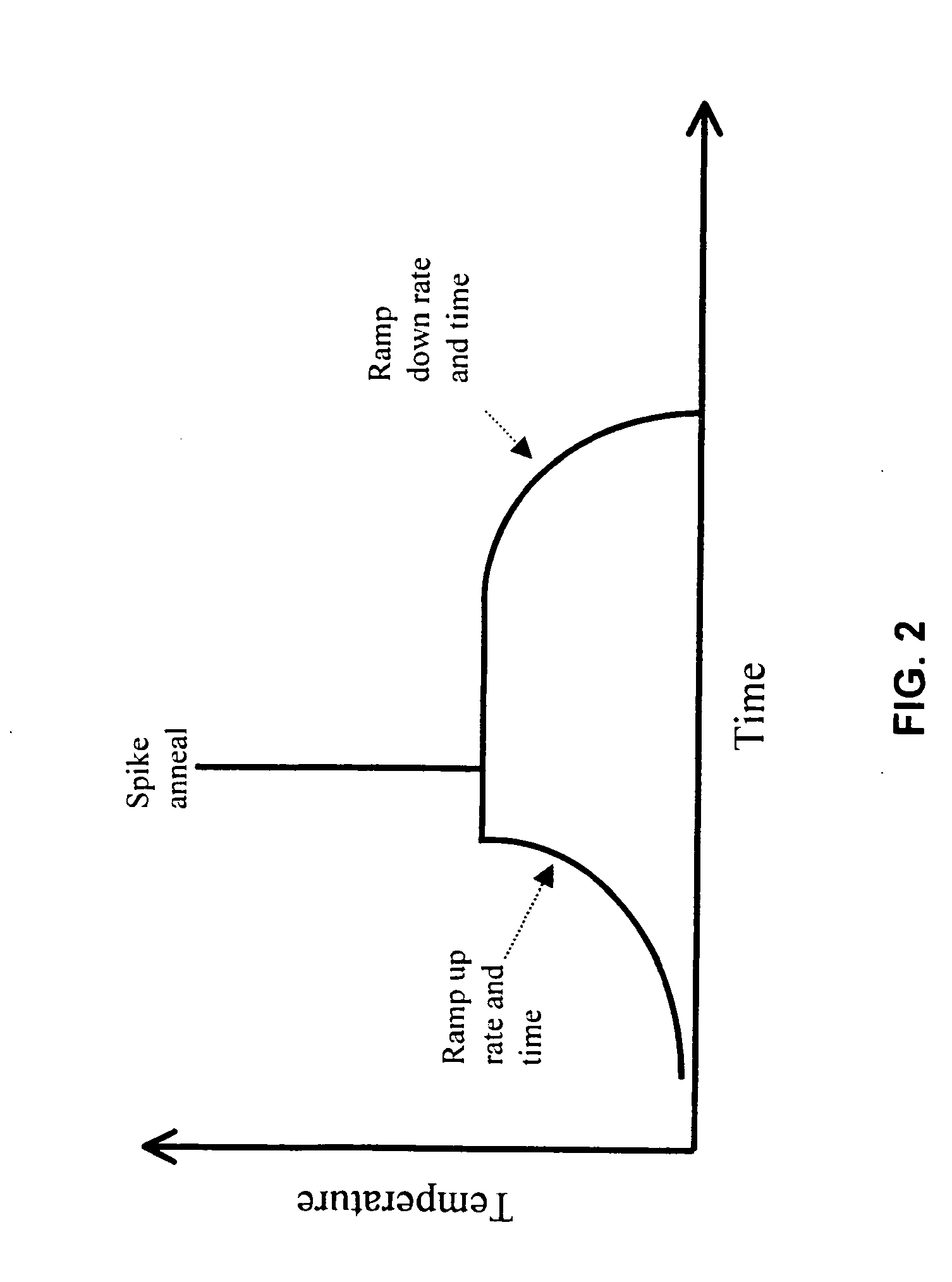

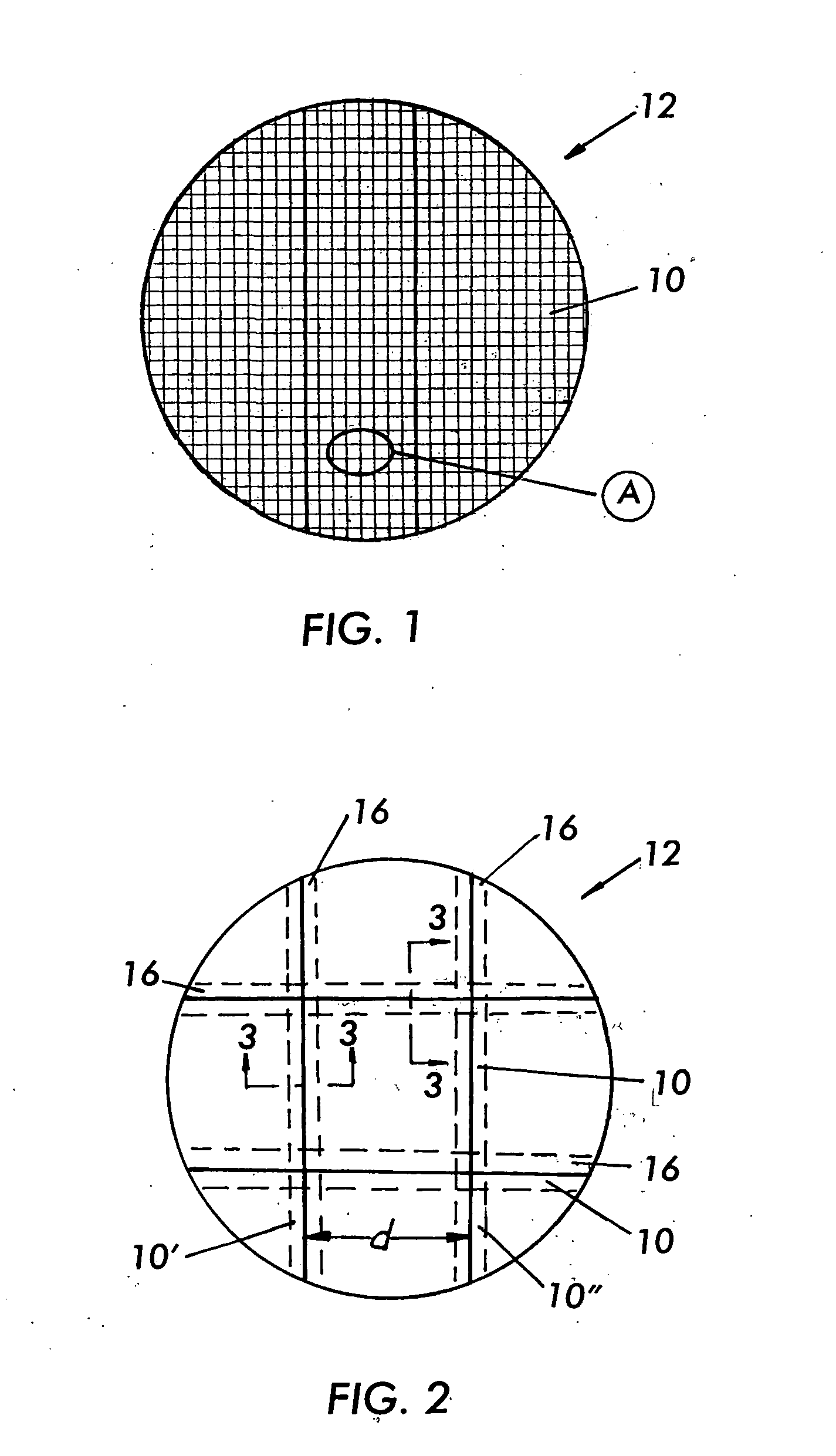

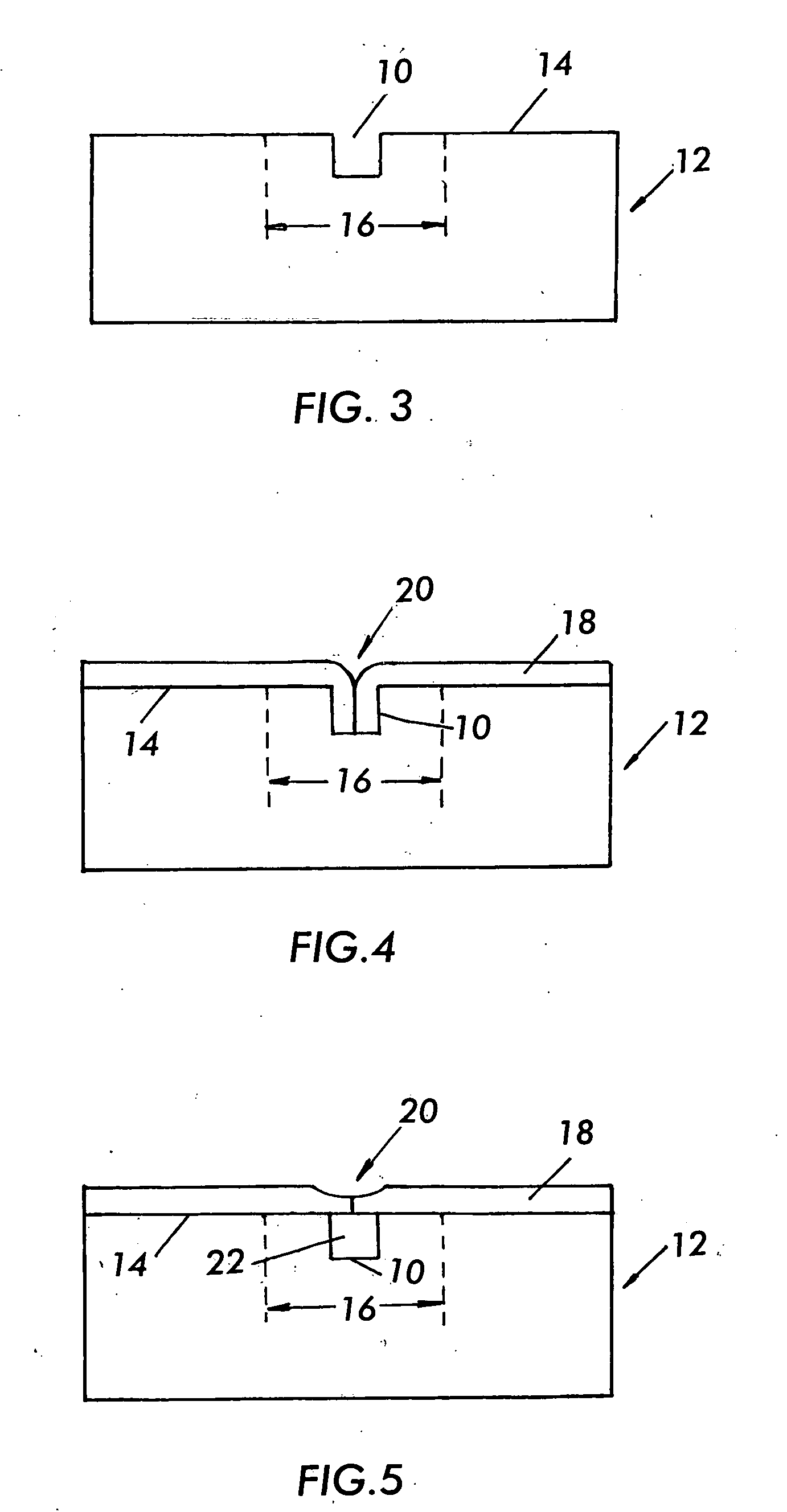

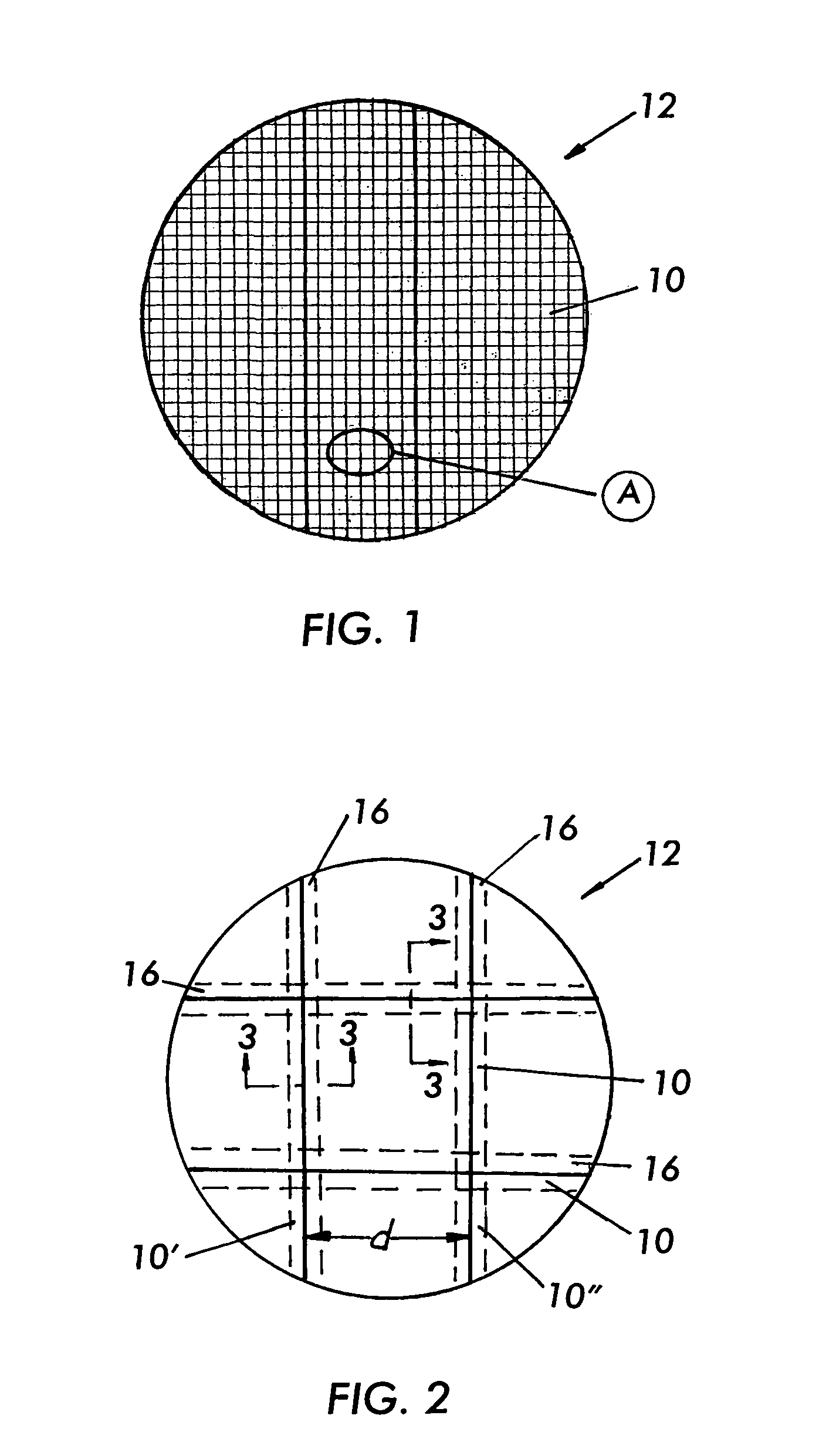

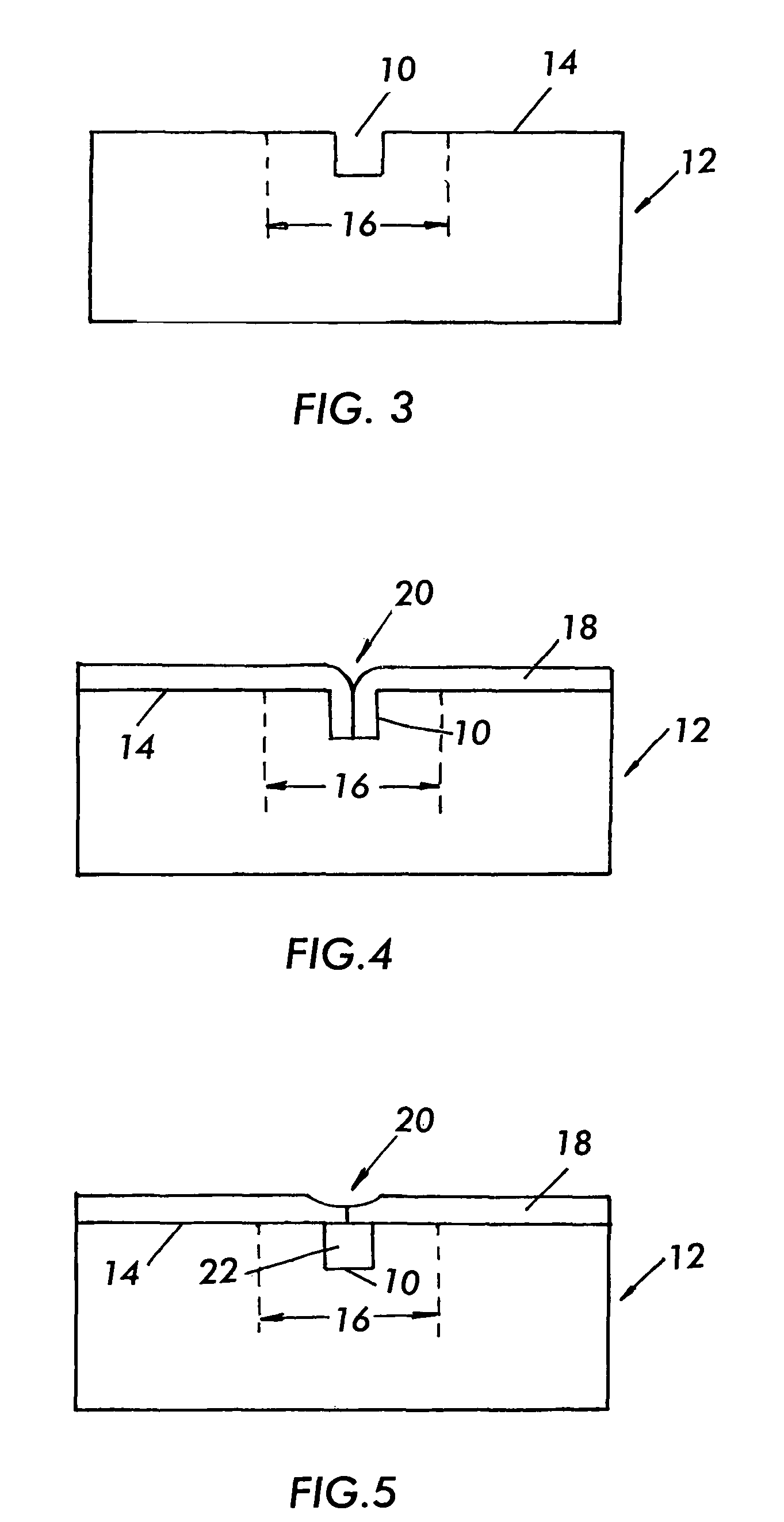

Thermal processing of substrates with pre- and post-spike temperature control

InactiveUS20100084744A1Reduce stress buildupImprove electronic performanceSemiconductor/solid-state device manufacturingElectric heating for furnacesTemperature controlDevice form

Provided are apparatuses and method for the thermal processing of a substrate surface, e.g., controlled laser thermal annealing (LTA) of substrates. The invention typically involves irradiating the substrate surface with first and second images to process regions of the substrate surface at a substantially uniform peak processing temperature along a scan path. A first image may serve to effect spike annealing of the substrates while another may be used to provide auxiliary heat treatment to the substrates before and / or after the spike annealing. Control over the temperature profile of the prespike and / or postspike may also reduce stresses and strains generated in the wafers. Also provided are microelectronic devices formed using the inventive apparatuses and methods.

Owner:ULTRATECH INT INC

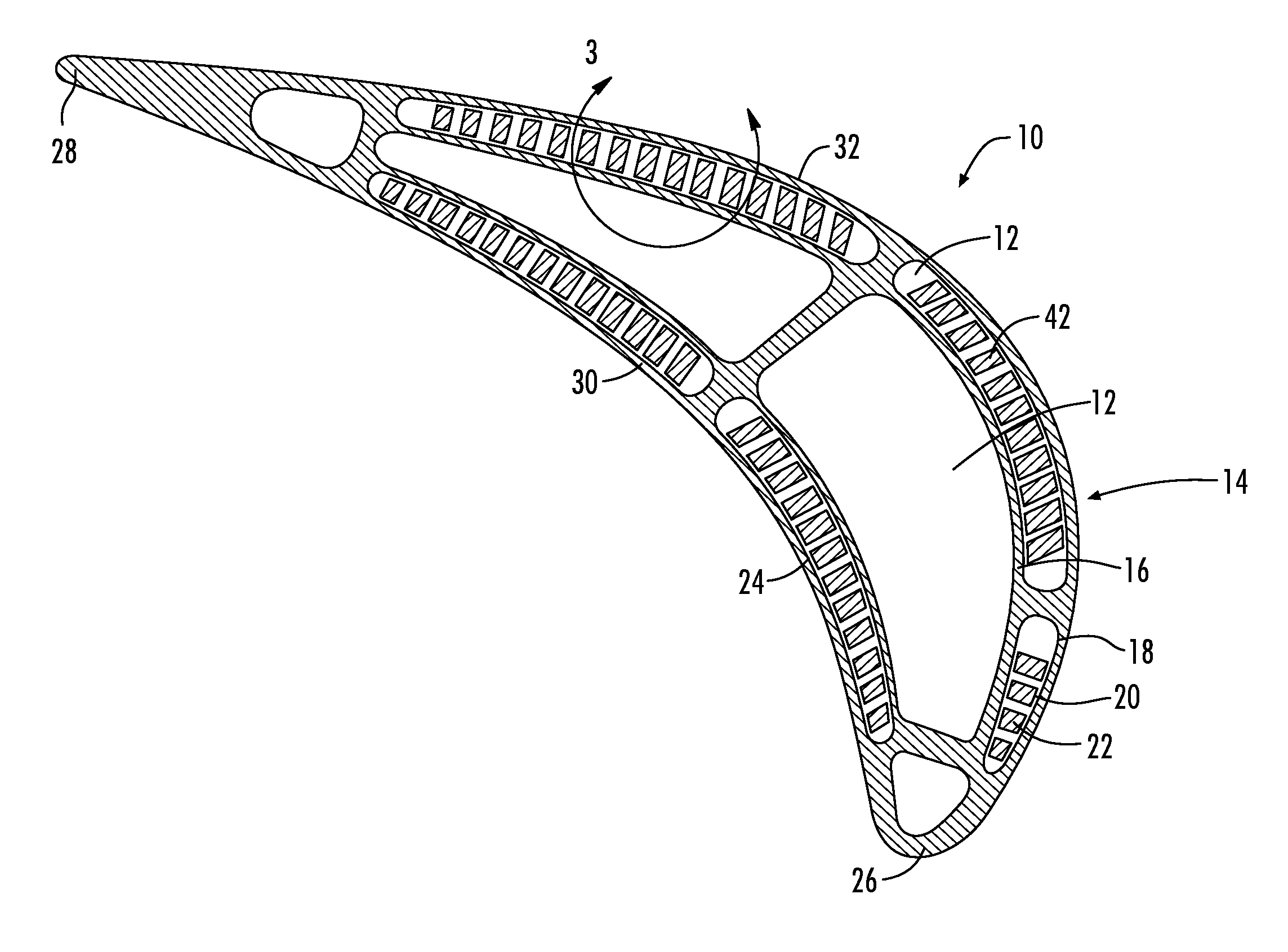

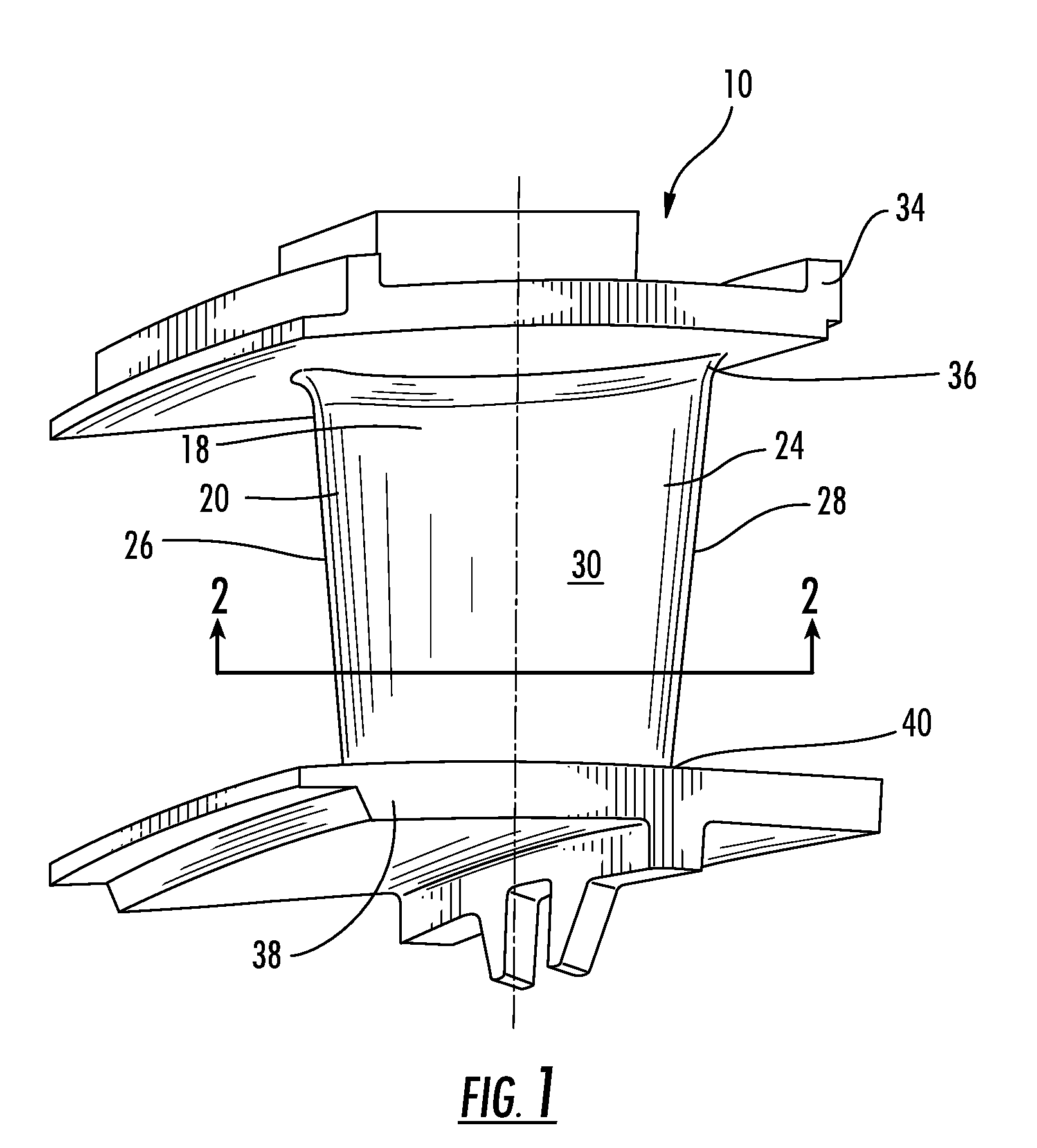

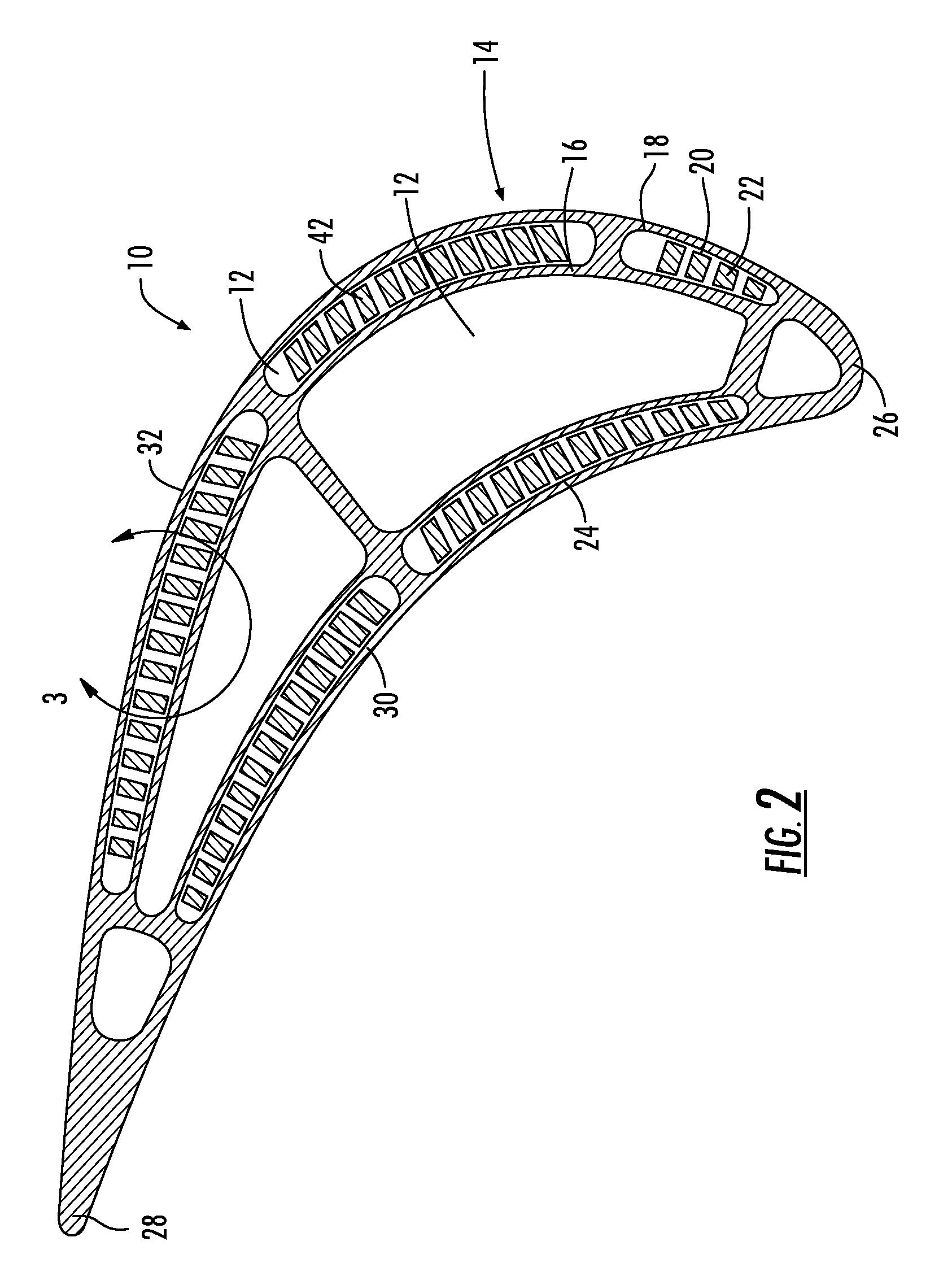

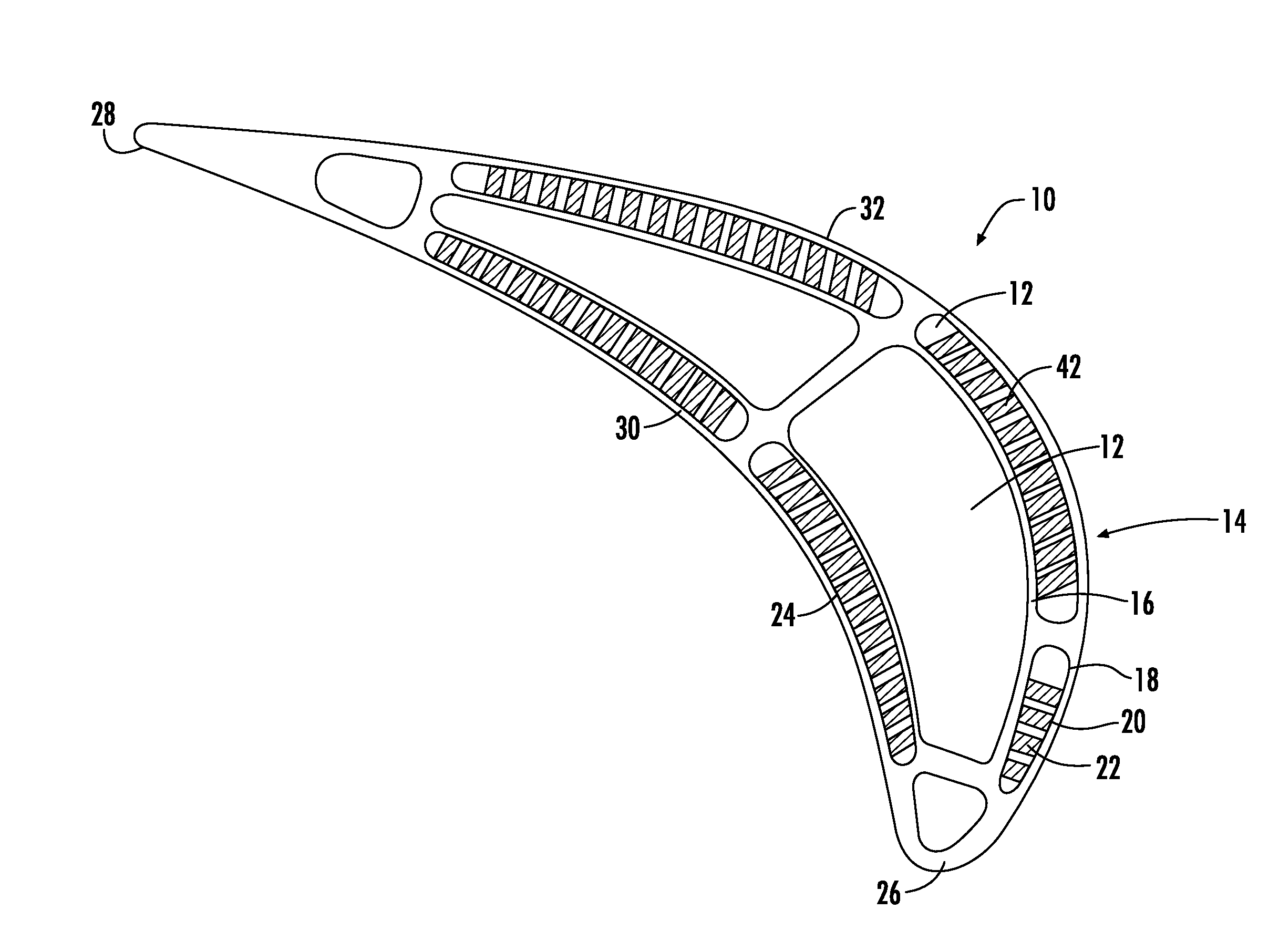

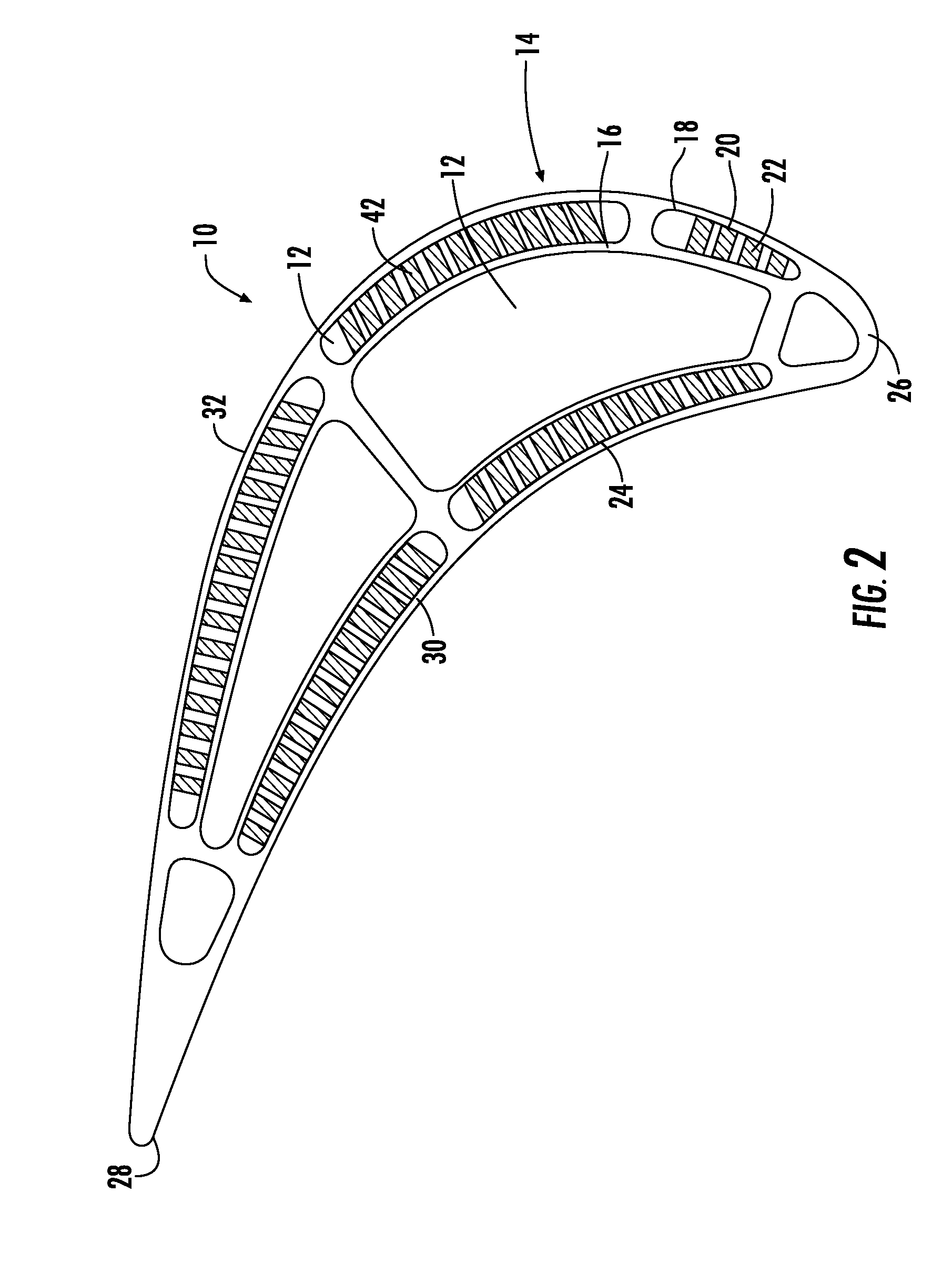

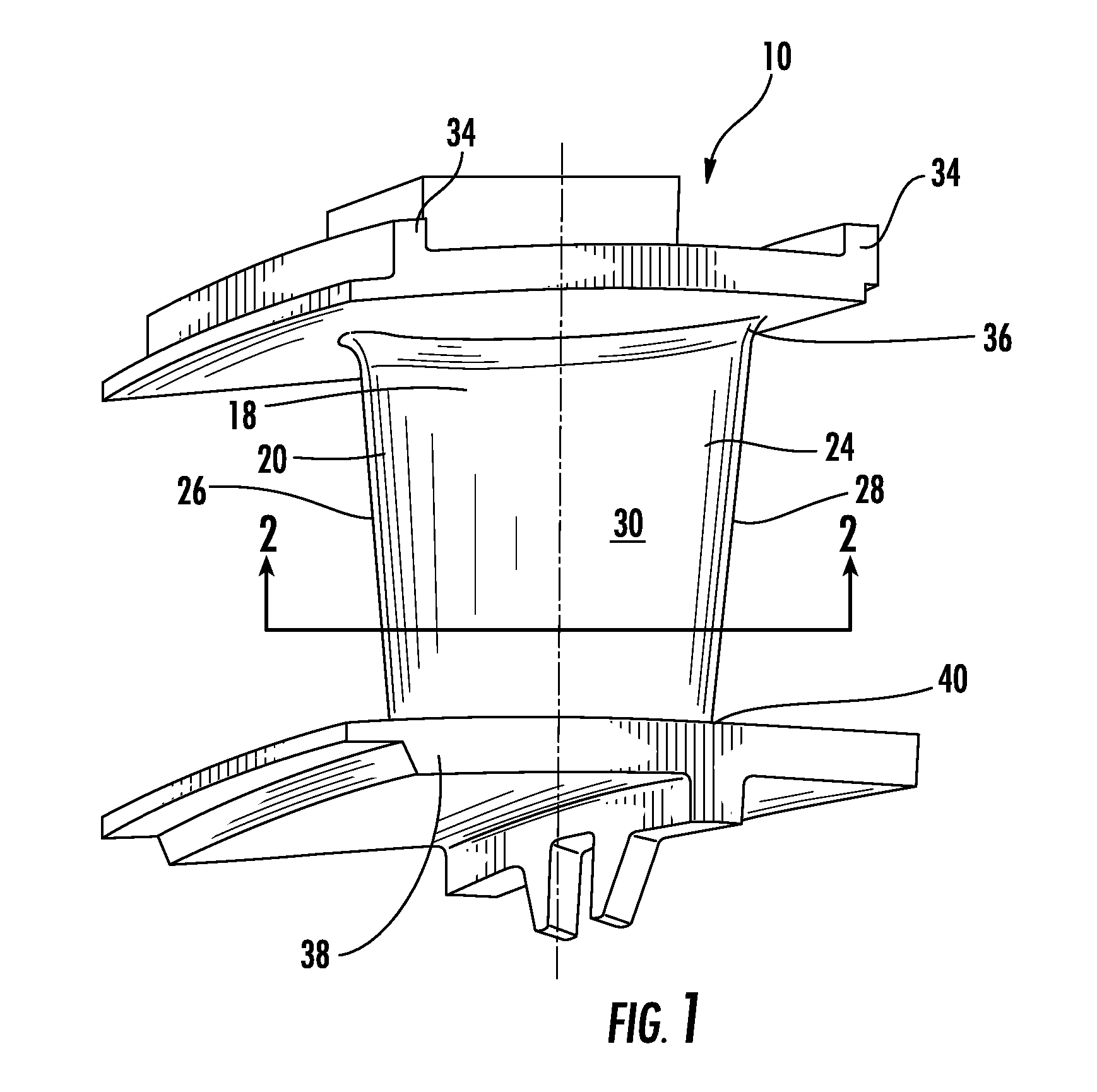

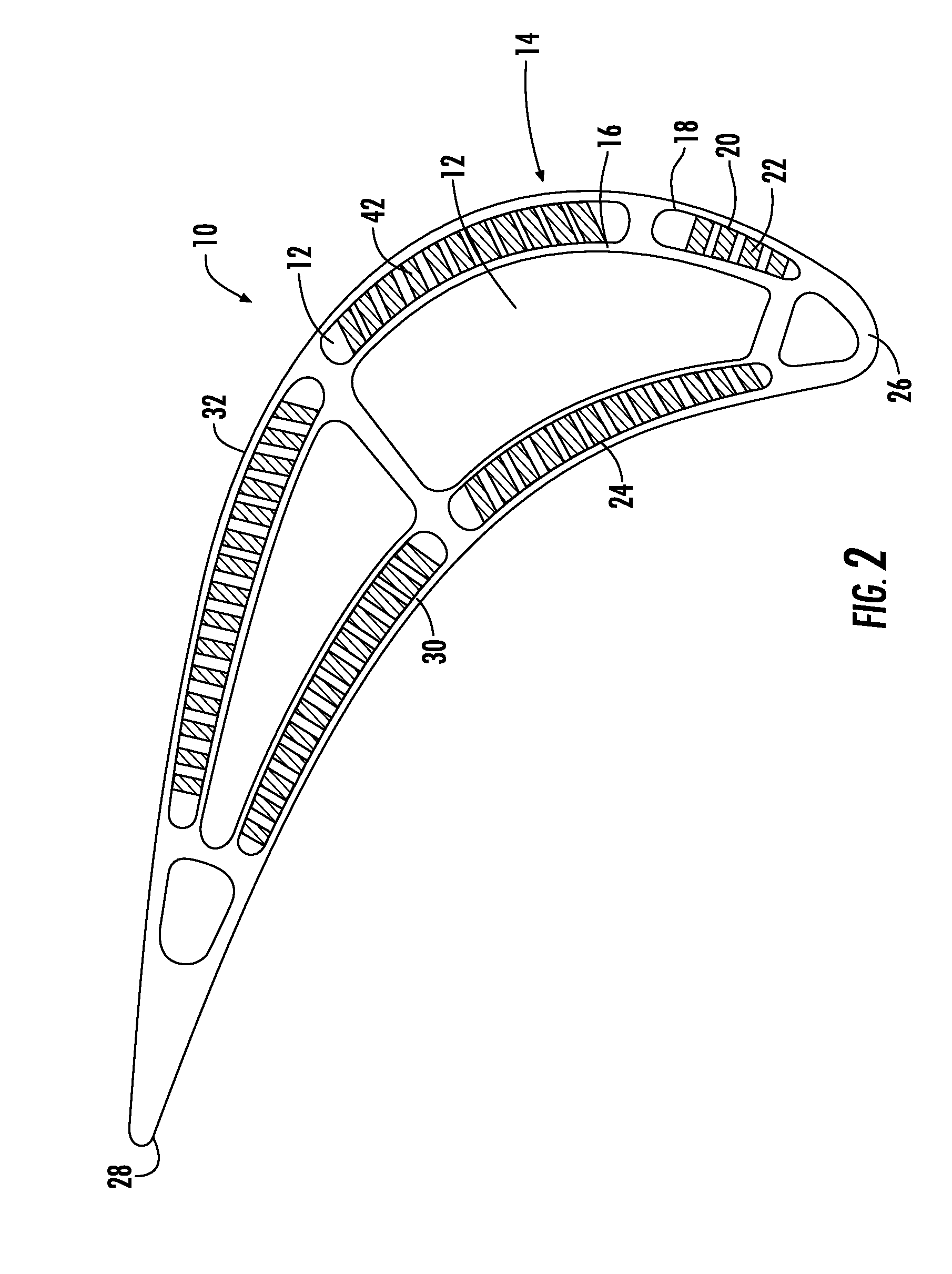

Turbine airfoil with a compliant outer wall

InactiveUS8147196B2Eliminating stress formationRelieve pressurePropellersPump componentsEngineeringThermal expansion

A turbine airfoil usable in a turbine engine with a cooling system and a compliant dual wall configuration configured to enable thermal expansion between inner and outer layers while eliminating stress formation in the outer layer is disclosed. The compliant dual wall configuration may be formed a dual wall formed from inner and outer layers separated by a support structure. The outer layer may be a compliant layer configured such that the outer layer may thermally expand and thereby reduce the stress within the outer layer. The outer layer may be formed from a nonplanar surface configured to thermally expand. In another embodiment, the outer layer may be planar and include a plurality of slots enabling unrestricted thermal expansion in a direction aligned with the outer layer.

Owner:SIEMENS ENERGY INC

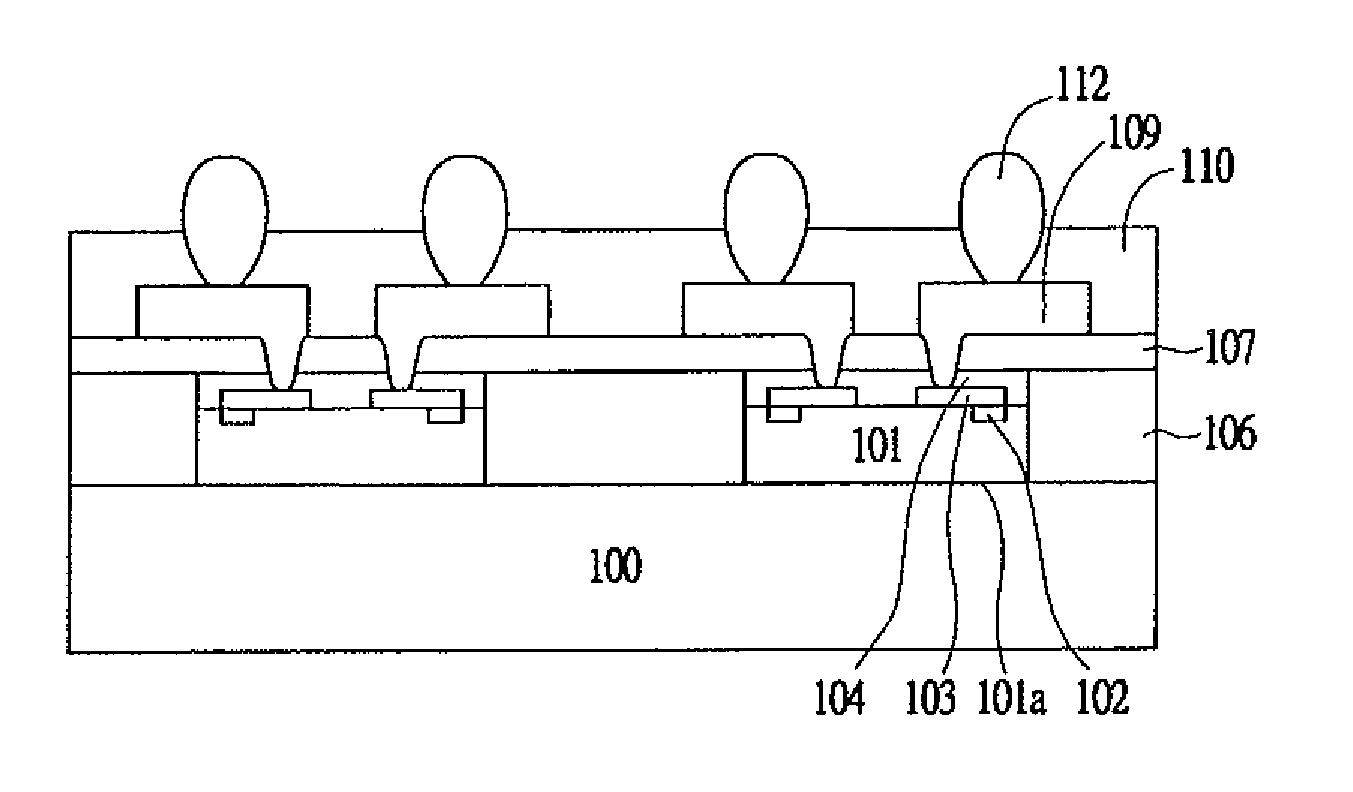

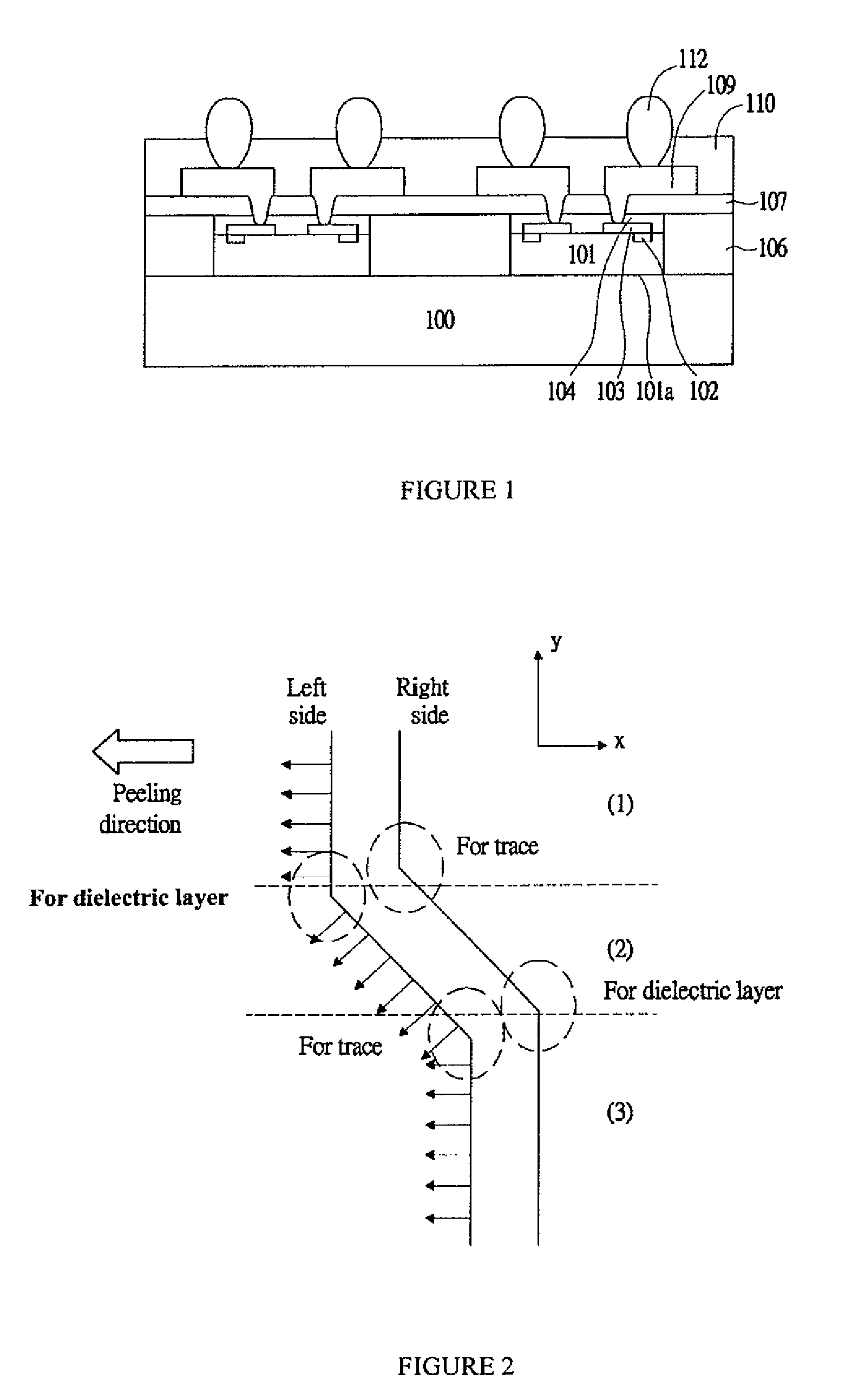

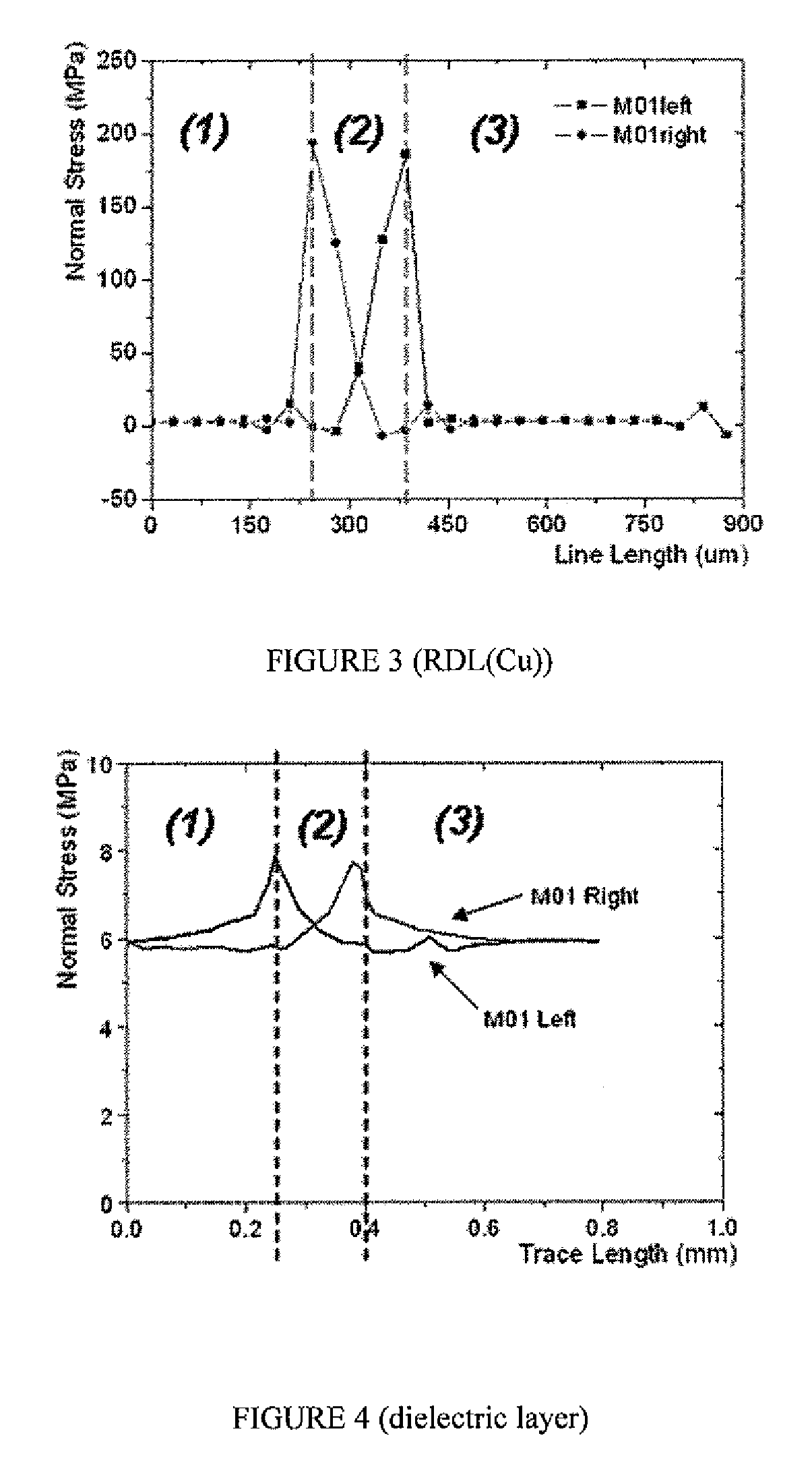

Structure of dielectric layers in built-up layers of wafer level package

InactiveUS7453148B2High mechanical reliabilityReduce stress buildupSemiconductor/solid-state device detailsSolid-state devicesMechanical reliabilityOptoelectronics

The present invention provides a structure of elastic dielectric layers with certain through holes adjacent to the angle of a RDL of WLP to absorb the stress. The elastic dielectric layer is made from silicone based materials with specific range of CTE, elongation rate and hardness, which can improve the mechanical reliability of the structure during temperature cycling test. The CTE difference between the RDL and the elastic dielectric material still may cause the elastic dielectric layer crack; to solve this problem, The present invention further provides a structure of dielectric layers with certain open through holes adjacent to the curve portion of a RDL of WLP which can reduce the stress accumulated at area of the dielectric layer adjacent to the RDL / dielectric layer interface to solve the crack problem of the dielectric layer.

Owner:ADVANCED CHIP ENG TECH INC

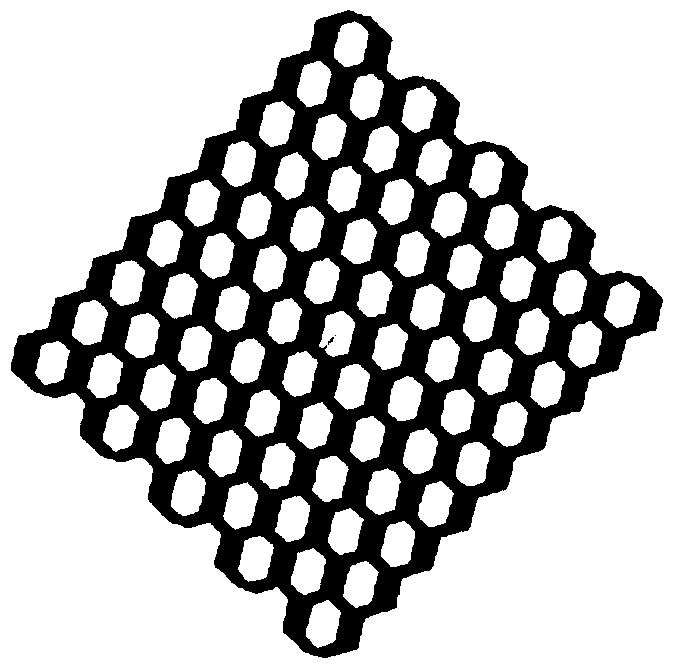

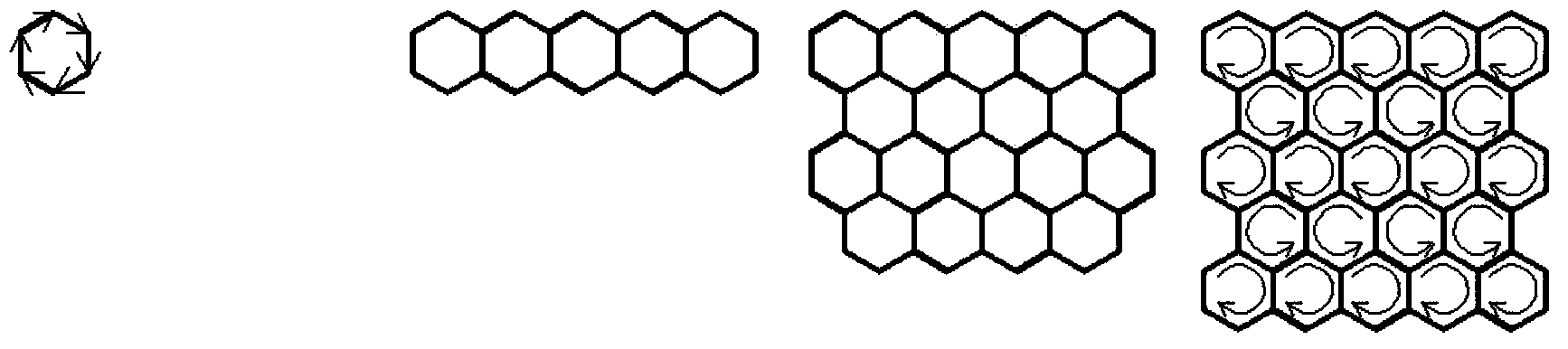

Preparation method of titanium alloy thin-wall honeycomb structure

The invention provides a preparation method of a titanium alloy thin-wall honeycomb structure. The preparation method comprises the steps that (a) a titanium alloy thin-wall honeycomb structure model is sliced and layered according to 20-30 mu m layer thickness; (2) titanium alloy powder is uniformly paved on a titanium alloy substrate, a laser beam which is emitted by a laser is used for selectively melting a titanium alloy powder layer according to the determined scan locus of the laser beam to complete the processing of one layer of titanium alloy thin-wall honeycomb structure; (c) the titanium alloy powder is paved on the layer of formed titanium alloy thin-wall honeycomb structure again, the laser beam which is emitted by the laser is used for selectively melting the titanium alloy powder layer according to the determined scan locus of the laser beam; (d) the titanium alloy thin-wall honeycomb structure is processed layer by layer, and the titanium alloy thin-wall honeycomb structure is finally formed. According to the method, the stress accumulation and the deformation of a forming piece in the forming process are reduced, the flexibility degree is high, and a thin-wall honeycomb component with variable honeycomb distance and a three-dimensional dot matrix structure can be prepared.

Owner:CAPITAL AEROSPACE MACHINERY +1

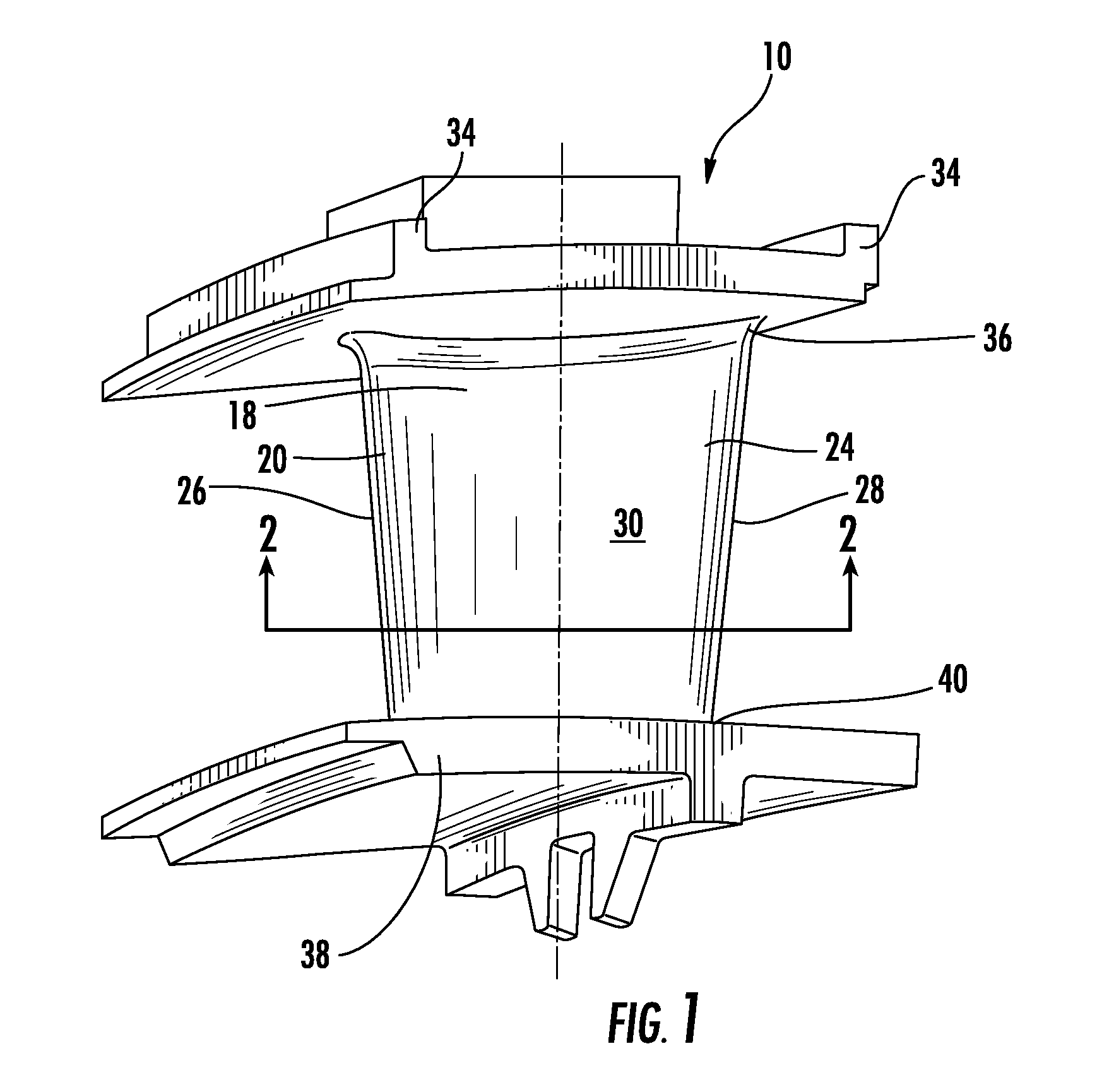

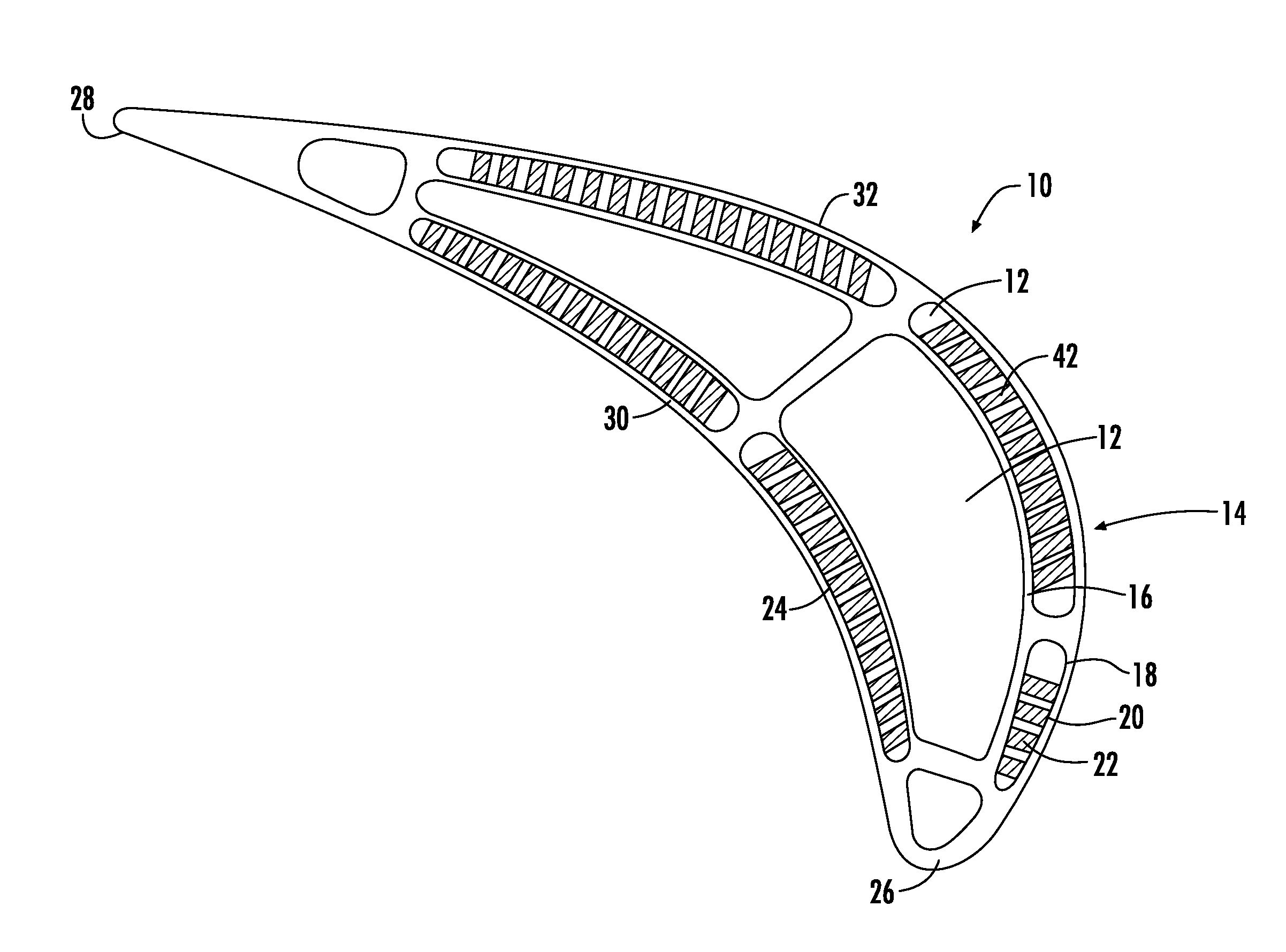

Turbine Airfoil With Dual Wall Formed from Inner and Outer Layers Separated by a Compliant Structure

InactiveUS20100284798A1Eliminating stress formationPreventing accumulation of stressPropellersRotary propellersDouble wallEngineering

A turbine airfoil usable in a turbine engine with a cooling system and a compliant dual wall configuration configured to enable thermal expansion between inner and outer layers while eliminating stress formation is disclosed. The compliant dual wall configuration may be formed a dual wall formed from inner and outer layers separated by a compliant structure. The compliant structure may be configured such that the outer layer may thermally expand without limitation by the inner layer. The compliant structure may be formed from a plurality of pedestals positioned generally parallel with each other. The pedestals may include a first foot attached to a first end of the pedestal and extending in a first direction aligned with the outer layer, and may include a second foot attached to a second end of the pedestal and extending in a second direction aligned with the inner layer.

Owner:SIEMENS ENERGY INC

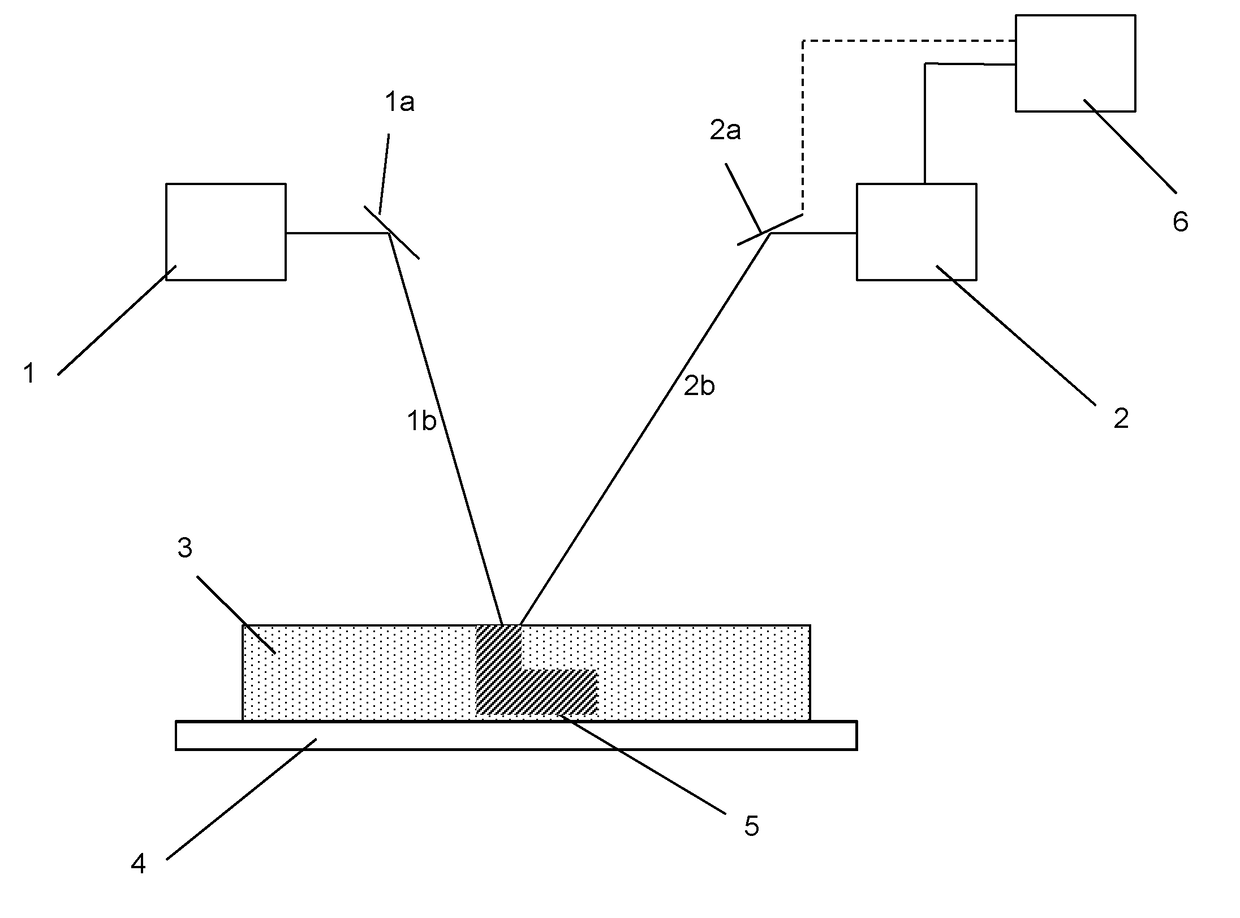

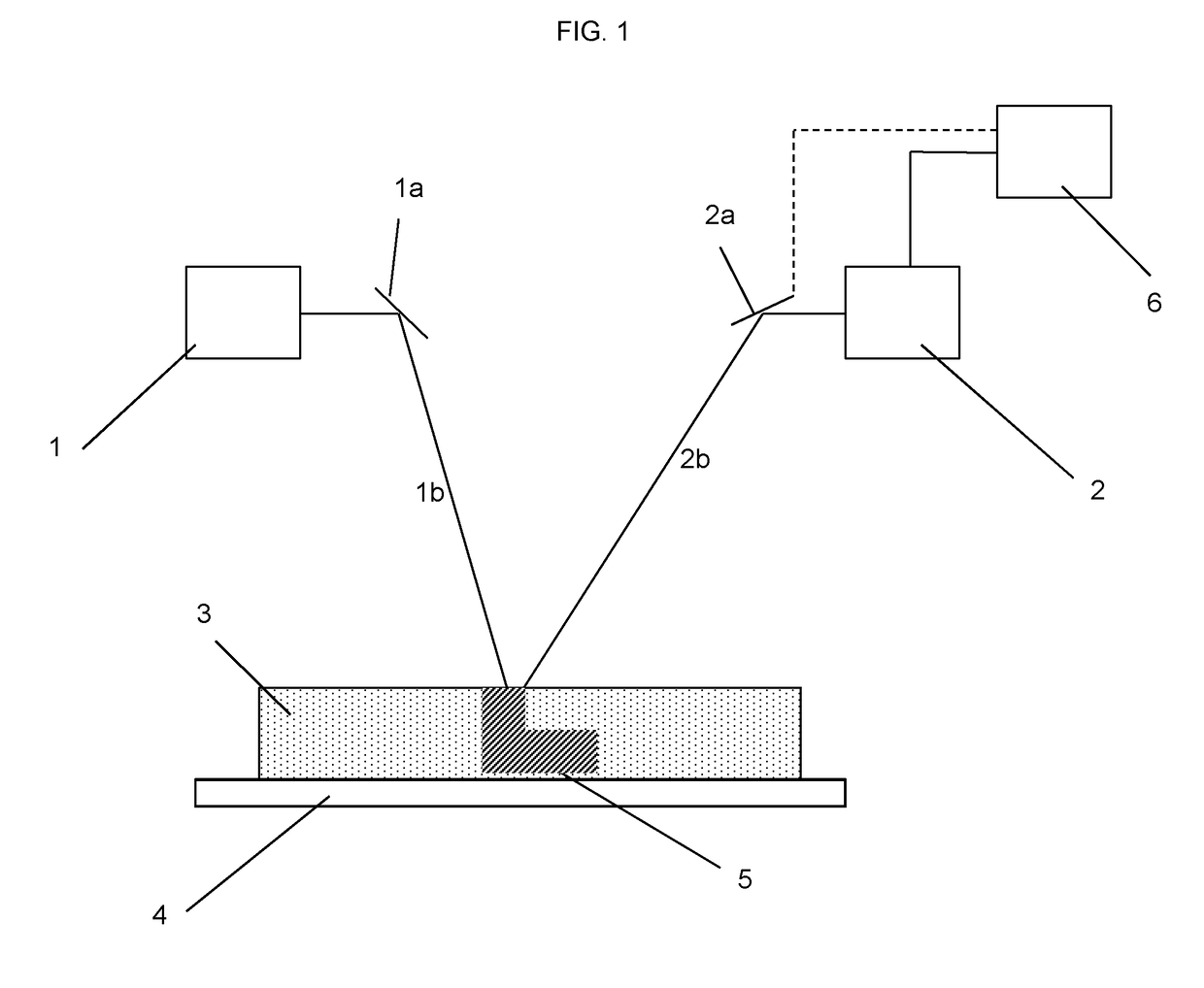

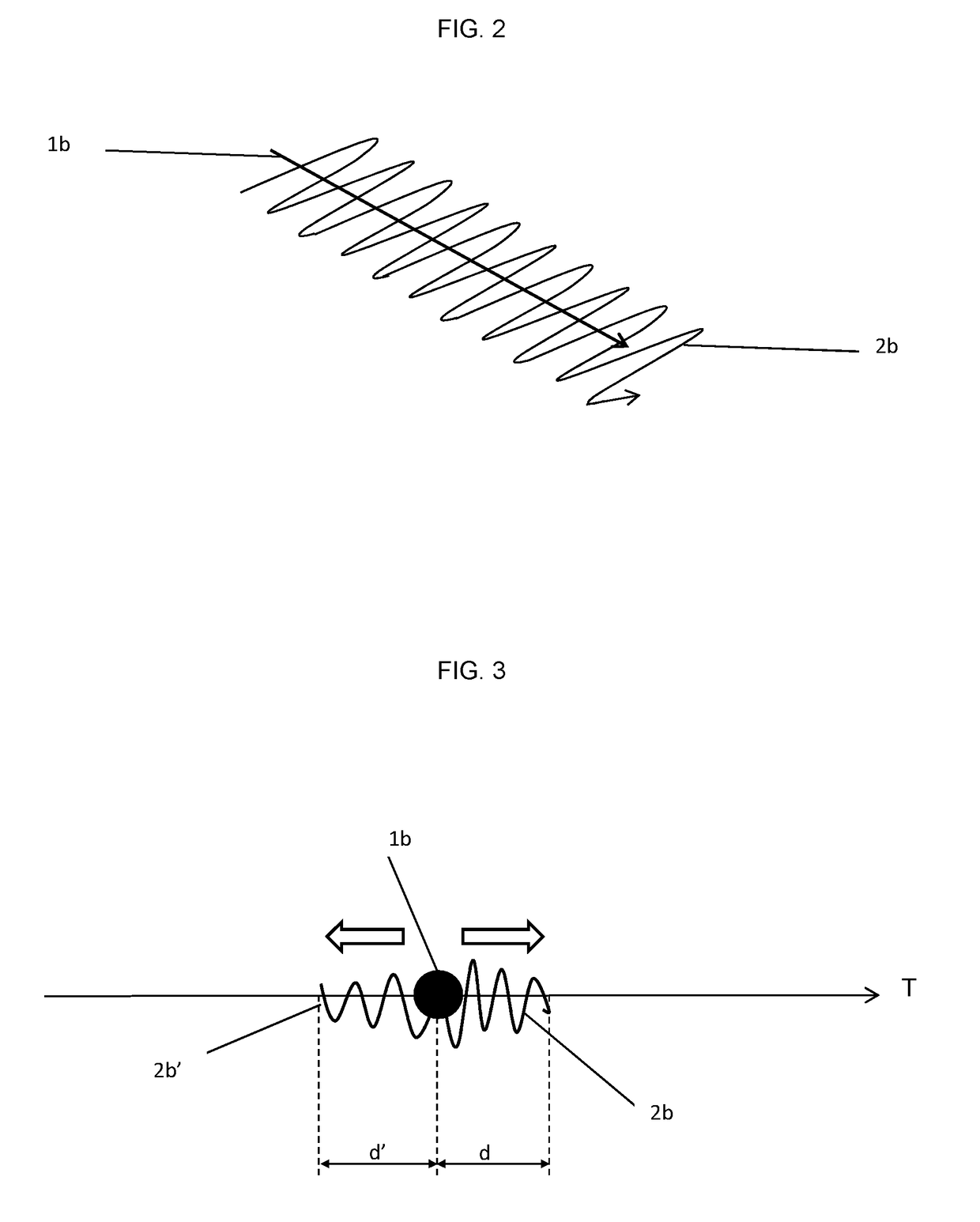

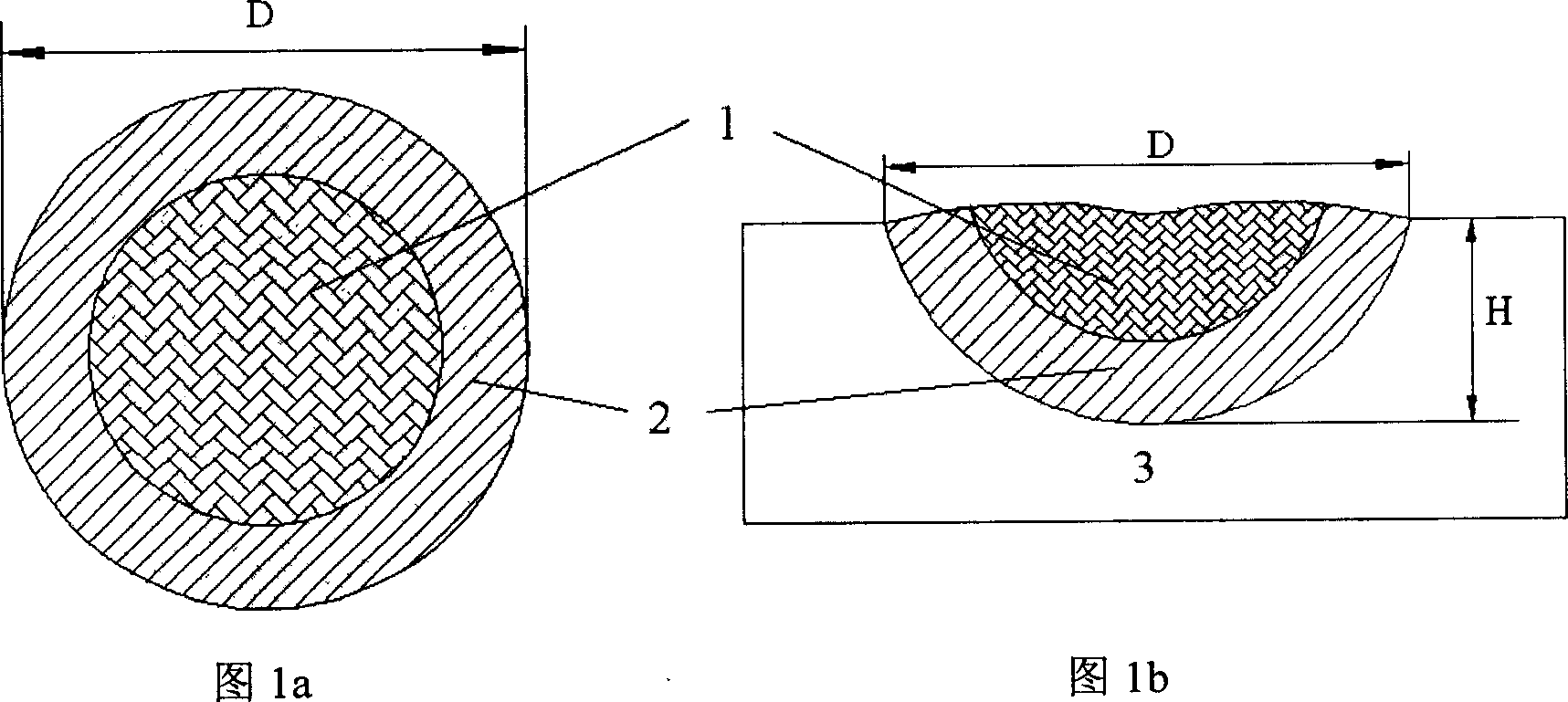

Additive layer manufacturing methods

InactiveUS20170197278A1More equi-axe grain structureReduce stress buildupTurbinesAdditive manufacturing apparatusBeam sourceEngineering

An apparatus and method for performing an ALM process is described. A first energy beam source (1) provides an energy beam (1b) which selectively melts a substrate powder (3) into a melt pool. A second energy beam source (2) provides an energy beam (2b) to heat condition substrate powder proximate to the melt pool. The path of the second energy beam (2b) is controlled by a controller (6) to oscillate independently of the path followed by the first energy beam (1b). The method may be applied to control and optimise heating and cooling rates of the sintered substrate during the ALM process enabling its microstructure to be controlled to suit the end use of the product and reduce the occurrence of residual stresses and consequent crack propagation.

Owner:ROLLS ROYCE PLC

Turbine airfoil with dual wall formed from inner and outer layers separated by a compliant structure

InactiveUS8079821B2Avoid accumulationEliminate stressPropellersPump componentsDouble wallThermal expansion

A turbine airfoil usable in a turbine engine with a cooling system and a compliant dual wall configuration configured to enable thermal expansion between inner and outer layers while eliminating stress formation is disclosed. The compliant dual wall configuration may be formed a dual wall formed from inner and outer layers separated by a compliant structure. The compliant structure may be configured such that the outer layer may thermally expand without limitation by the inner layer. The compliant structure may be formed from a plurality of pedestals positioned generally parallel with each other. The pedestals may include a first foot attached to a first end of the pedestal and extending in a first direction aligned with the outer layer, and may include a second foot attached to a second end of the pedestal and extending in a second direction aligned with the inner layer.

Owner:SIEMENS ENERGY INC

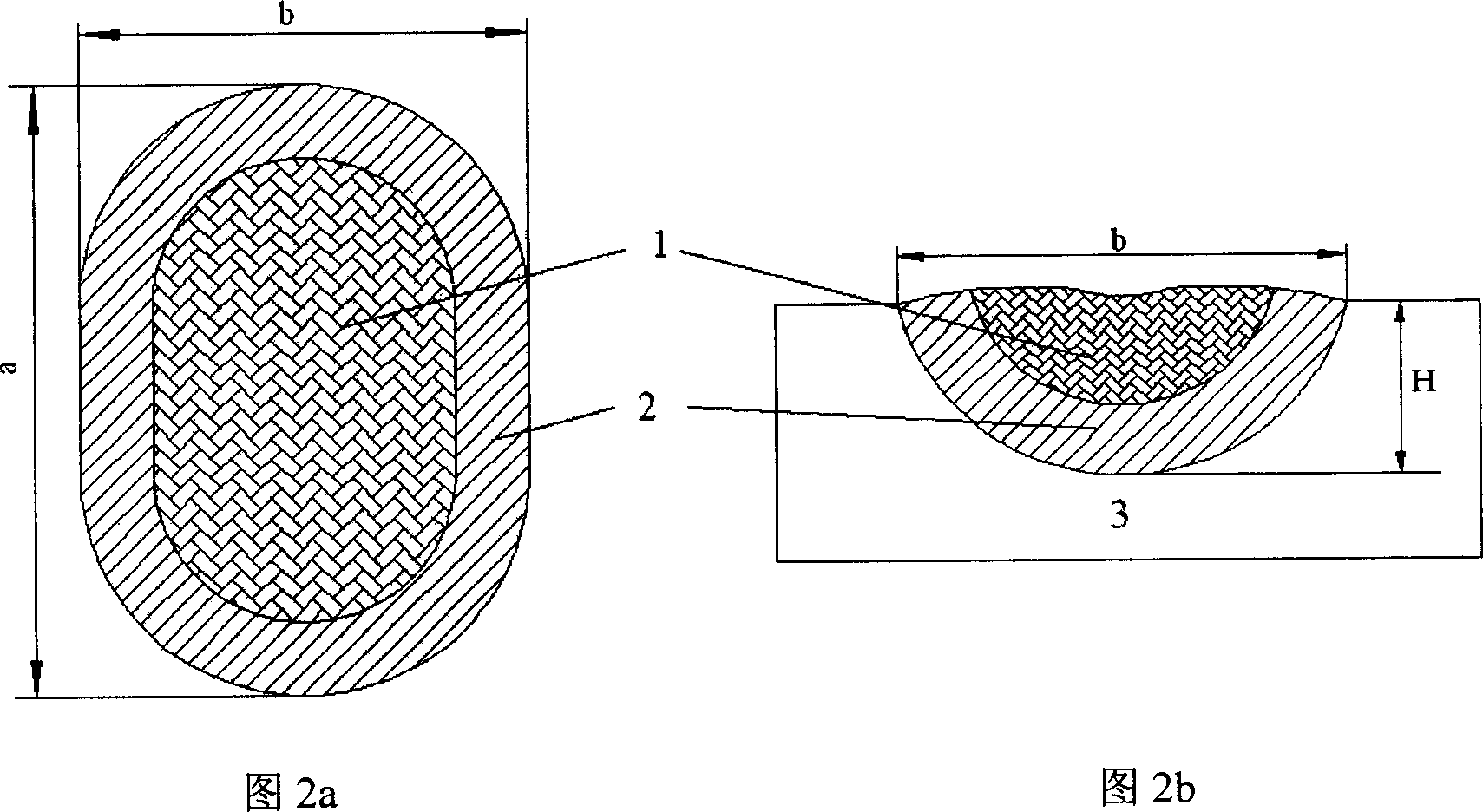

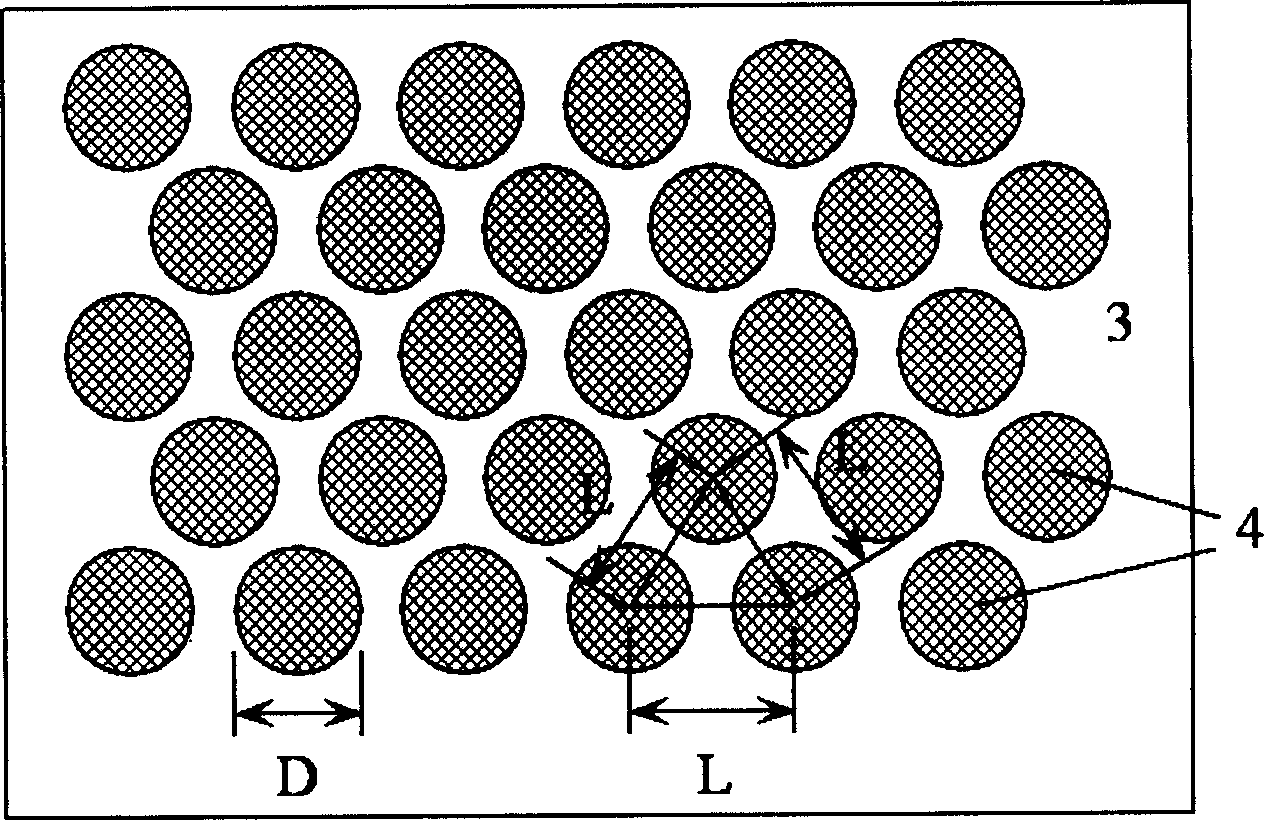

Distribution type laser spot alloying method

InactiveCN1831195AImprove wear performanceOvercoming temper softening problemsMetallic material coating processesLaser beam welding apparatusDepth enhancementAlloy

The invention relates to a distributed laser point-shaped alloying method that uses the small-hole effect caused by high power density laser effect to form mixing liquid bath by metal base and high performance alloy power sent by powder sending machine, the alloying point would be formed in the following rapid concreting. Controlling the laser beam processing point to point to form alloying points on the surface of the material, the distributed laser depth enhancement would be realized. The invention optimizes the alloying points and the distributing state to improve abrasion resistance of the surface, and the useful life of the component would be improved.

Owner:TSINGHUA UNIV

Force-resistant panel

ActiveUS8863440B1Reduce stress buildupSpace existsArmourProtective buildings/sheltersSash windowFlange

A force resistant panel system is provided where a window pane is bordered by a sash and magnetically attracted to an exterior flange. The exterior flange is attached to an opening in a wall, facing outward. An interior flange with a channel is attached to the inside and facing inward. The exterior flange and interior flange combine to form a channel for which the window pane can travel in the event of a blast. Decorative trim snaps into a groove on the interior flange and generates static outward pressure against the sash.

Owner:THERM O LITE

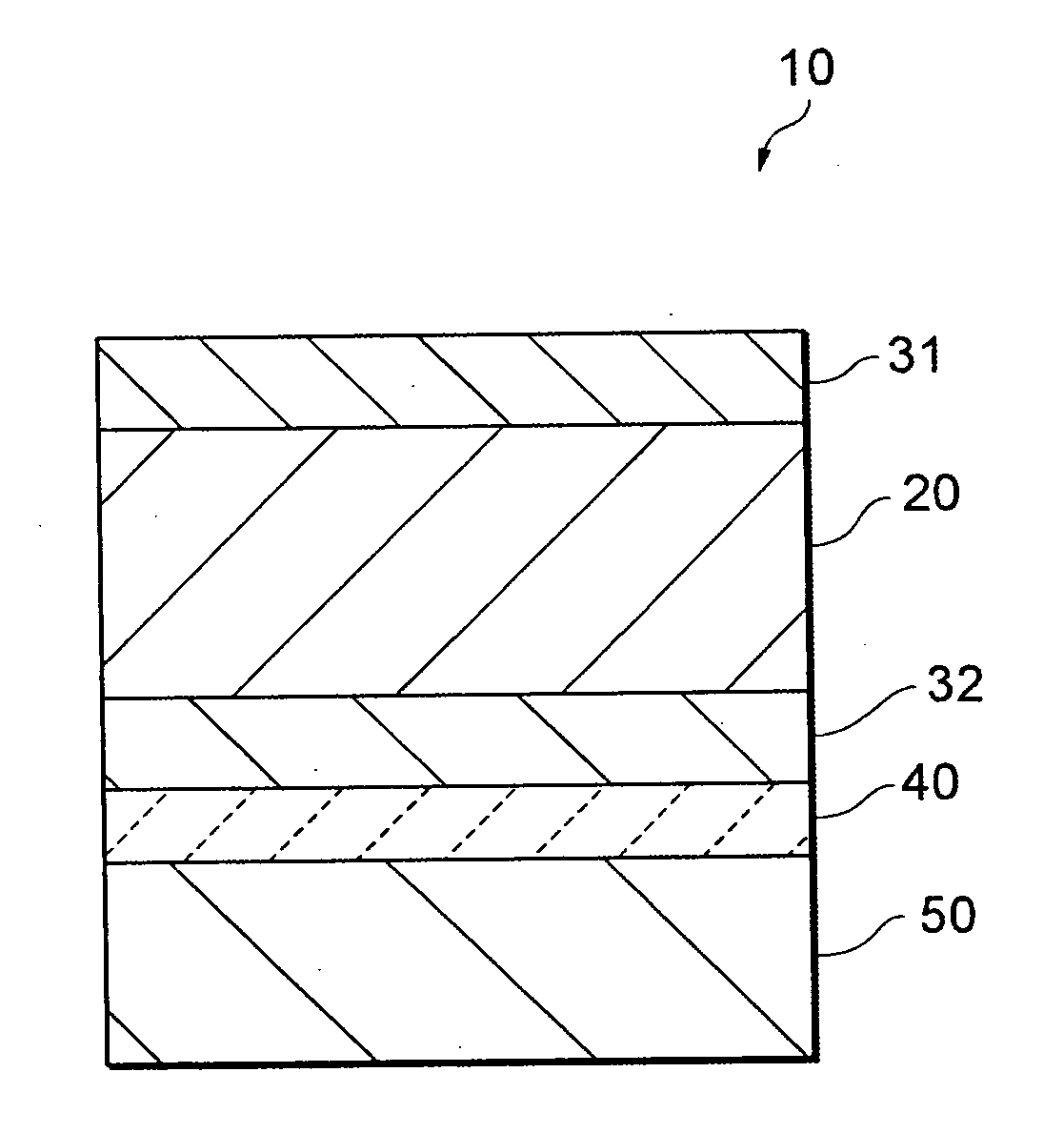

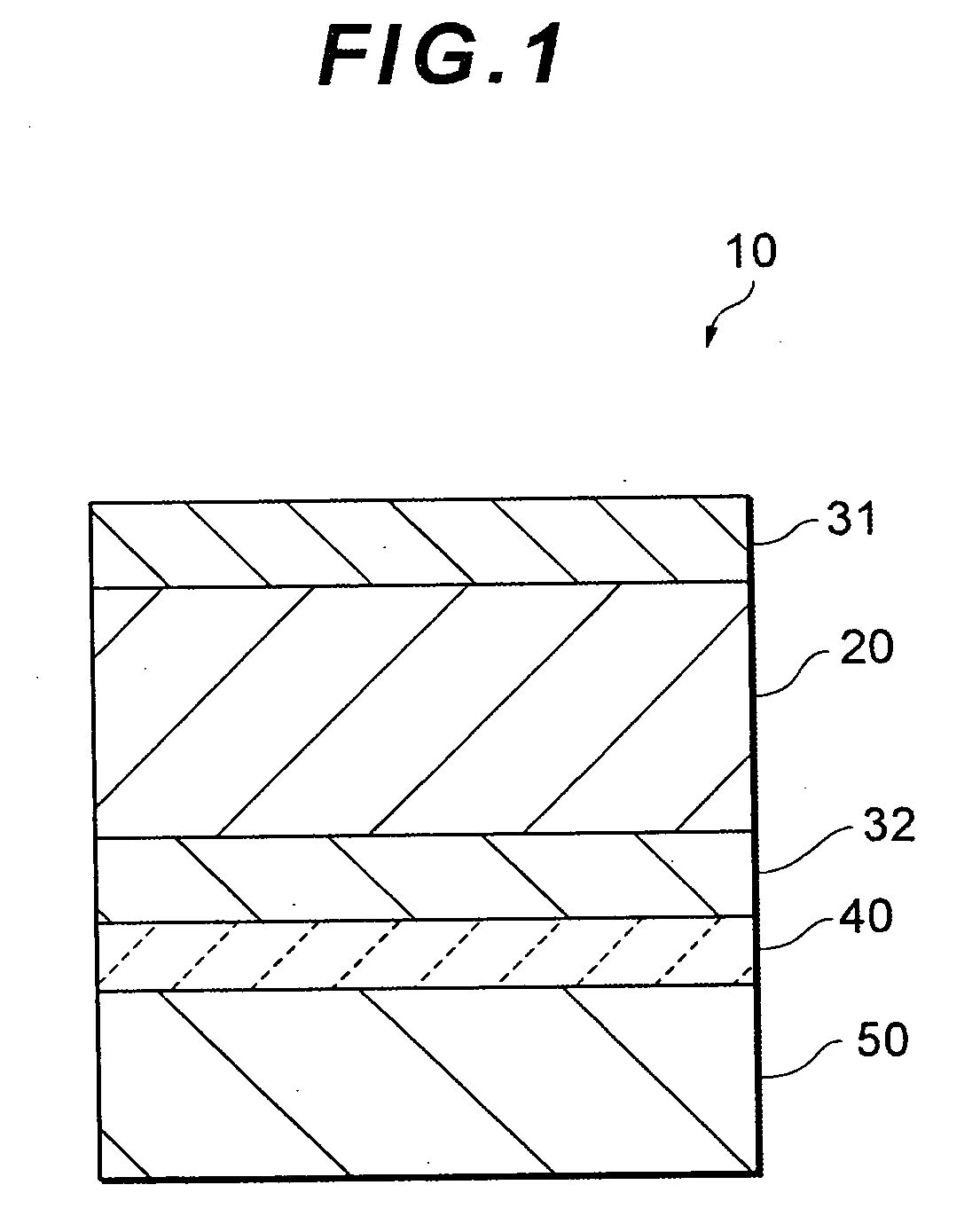

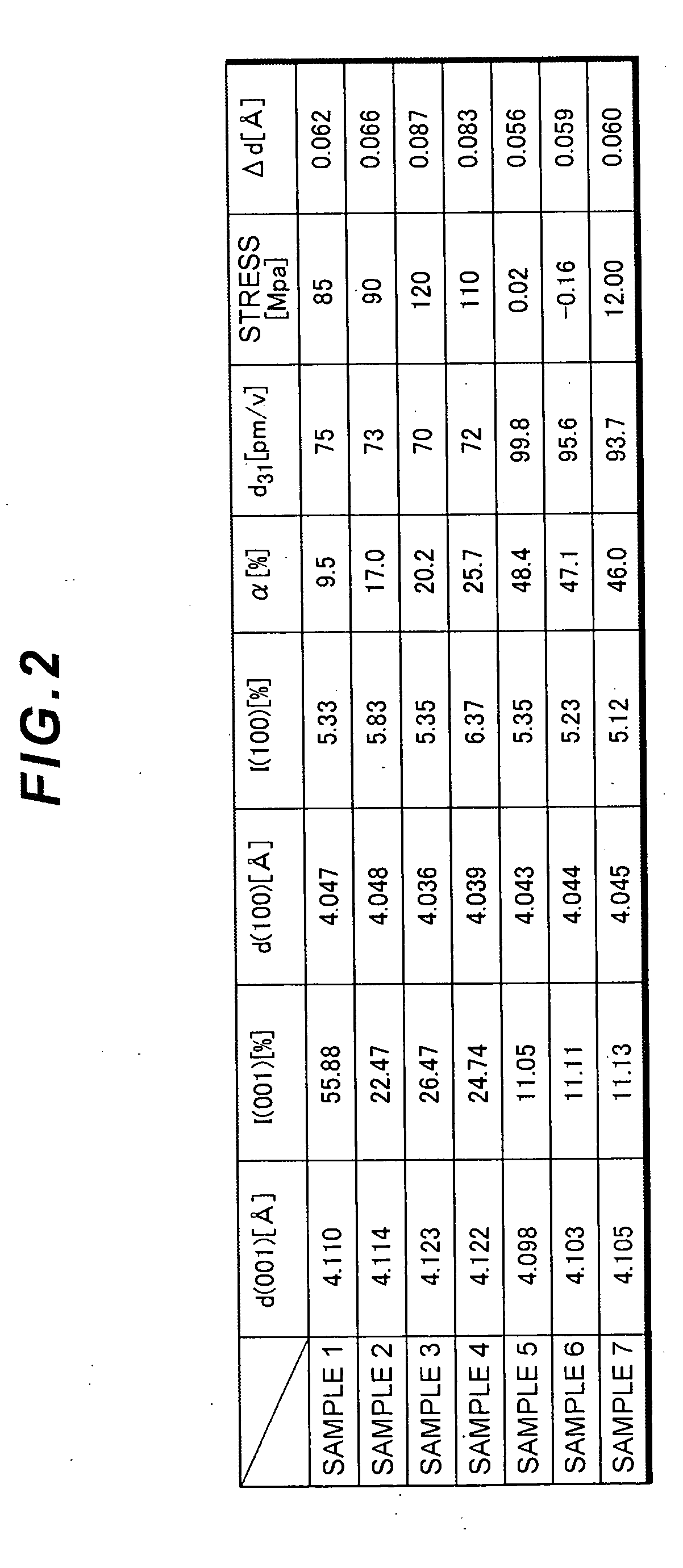

Piezoelectric element and gyroscope

ActiveUS20100244632A1Excellent piezoelectric propertiesHigh detection sensitivityPiezoelectric/electrostriction/magnetostriction machinesSpeed measurement using gyroscopic effectsGyroscopeCrystal structure

A piezoelectric element having a crystal structure that enables a piezoelectric film to be formed in an unstressed state is provided. The piezoelectric film contains an a-axis oriented crystal and a c-axis oriented crystal, where a difference in lattice constant between the a-axis oriented crystal and the c-axis oriented crystal is not more than 0.06 Å. The present inventors have newly found that a stress accumulated in the piezoelectric film can be reduced while maintaining favorable piezoelectric properties when a condition that the difference in lattice constant between the a-axis oriented crystal and the c-axis oriented crystal is not more than 0.06 Å is satisfied. When the condition is satisfied, the c-axis oriented crystal and the a-axis oriented crystal are properly balanced and as a result crystal particles of the piezoelectric film are closest-packed on its base in an ideal state, which contributes to a reduced stress.

Owner:TDK CORPARATION

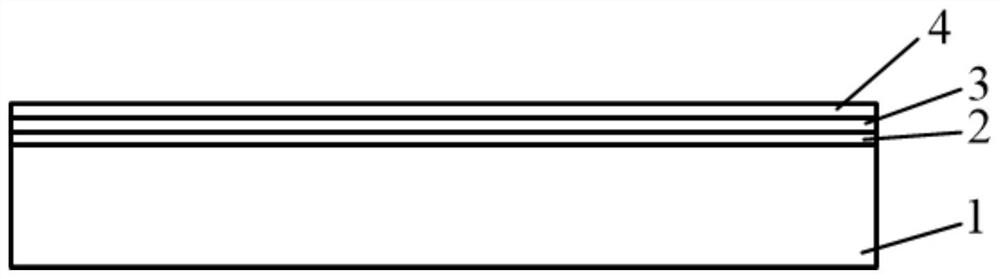

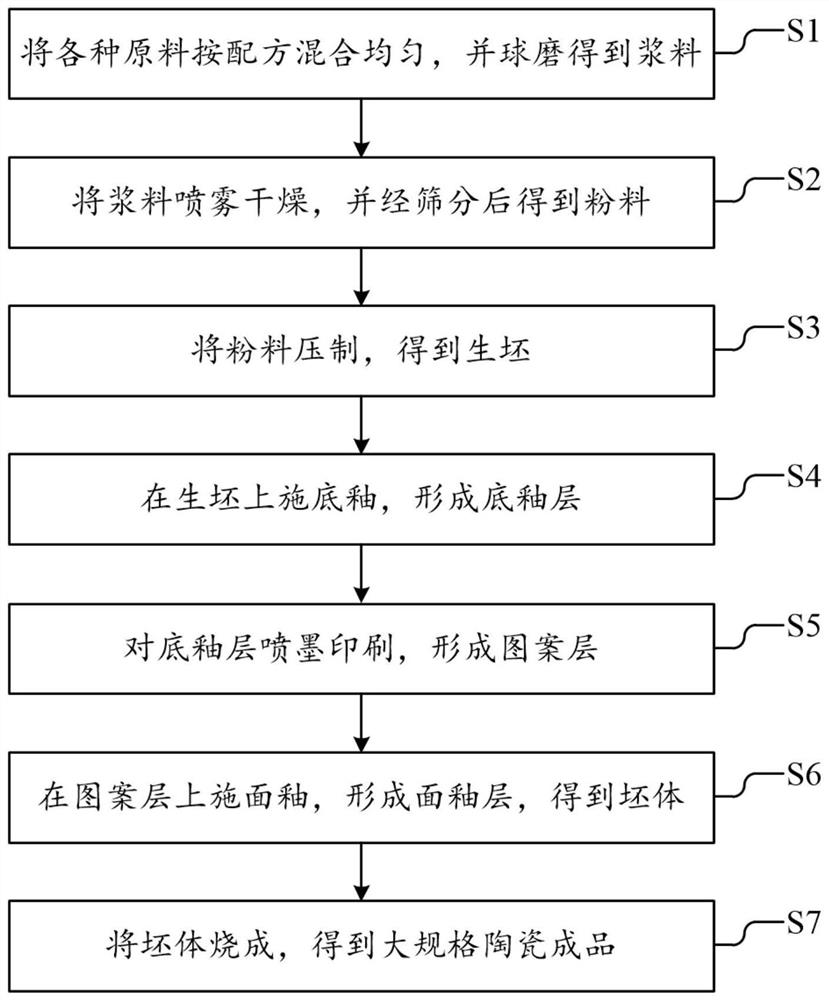

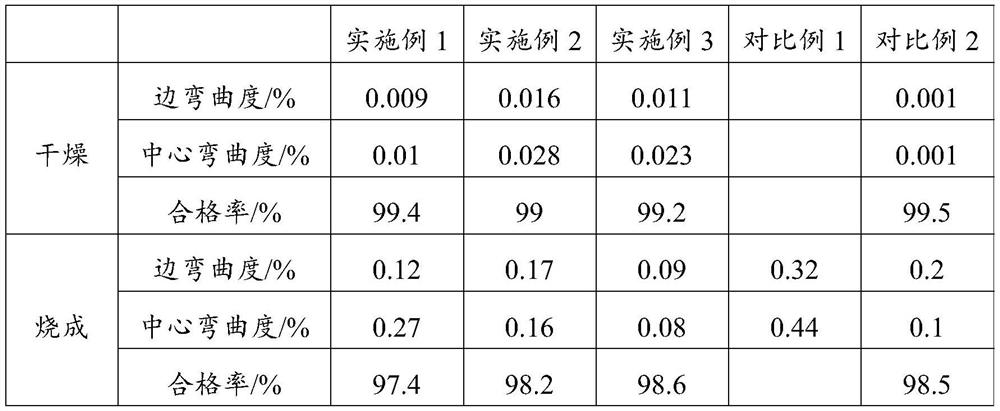

Large-size ceramic rock plate and preparation method thereof

ActiveCN111646788ALess stress buildupRelief of residual stressCovering/liningsPotassium feldsparKaolin clay

The invention discloses a large-size ceramic rock plate which has a surface area of 3-12m<2> and a thickness of 12-30mm. The large-size ceramic rock plate comprises a green body layer, a ground coat layer, a pattern layer and a cover coat layer; wherein the thickness of the green body layer is 11.5-29.5mm; the green body layer is mainly prepared from the following raw materials by weight: 15-20 parts of potassium feldspar, 8-15 parts of albite, 15-20 parts of calcined kaolin, 12-20 parts of black mud, 8-15 parts of white mud, 15-20 parts of pyrophyllite and 1-10 parts of a toughening agent; wherein the sum of the weight parts of the raw materials is 100 parts. The ceramic rock plate can well adapt to a later deep processing technology, can be widely applied to the fields of floors, curtainwalls and veneers, and has the advantages of high strength, high hardness, acid and alkali resistance, high temperature resistance and the like.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

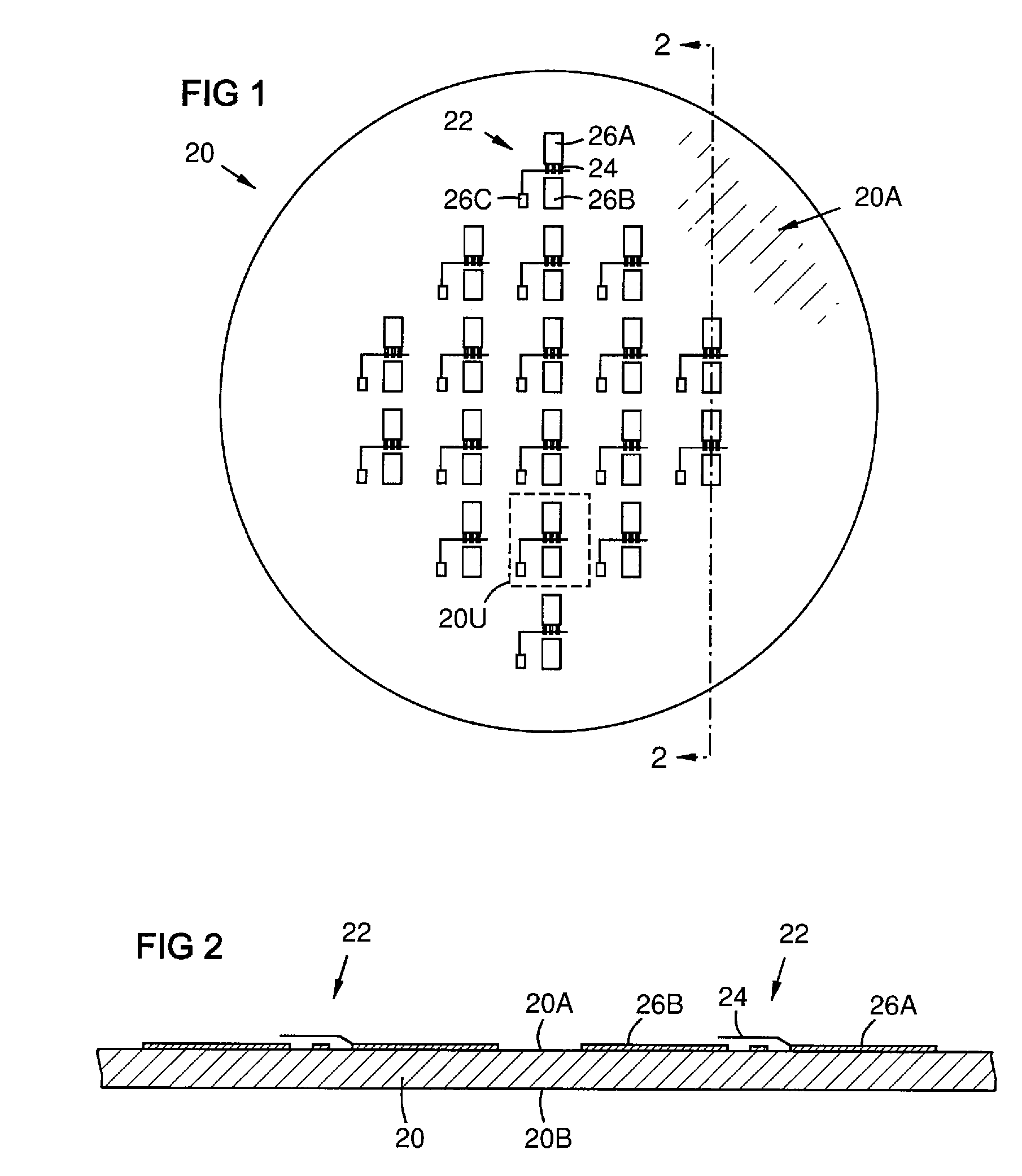

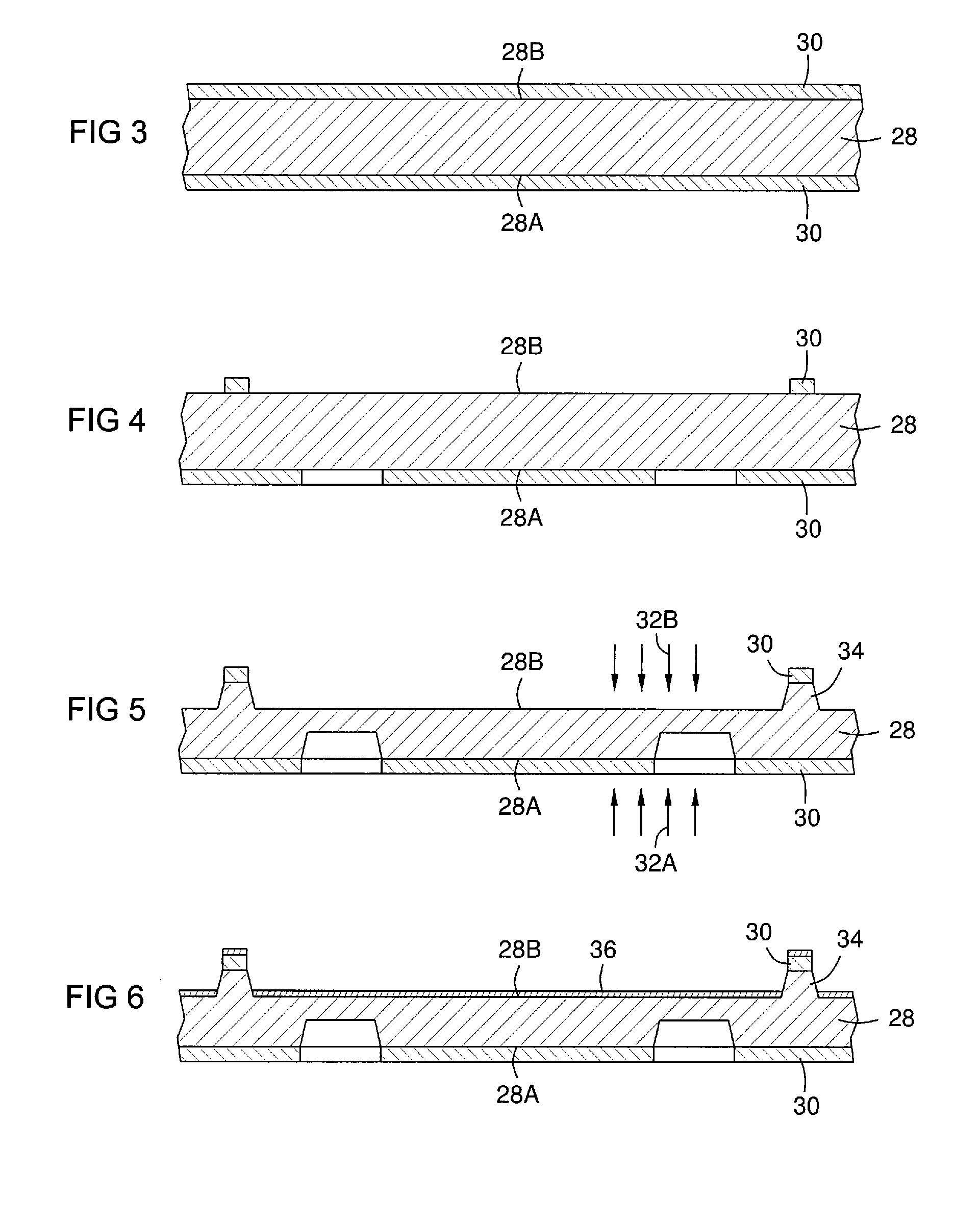

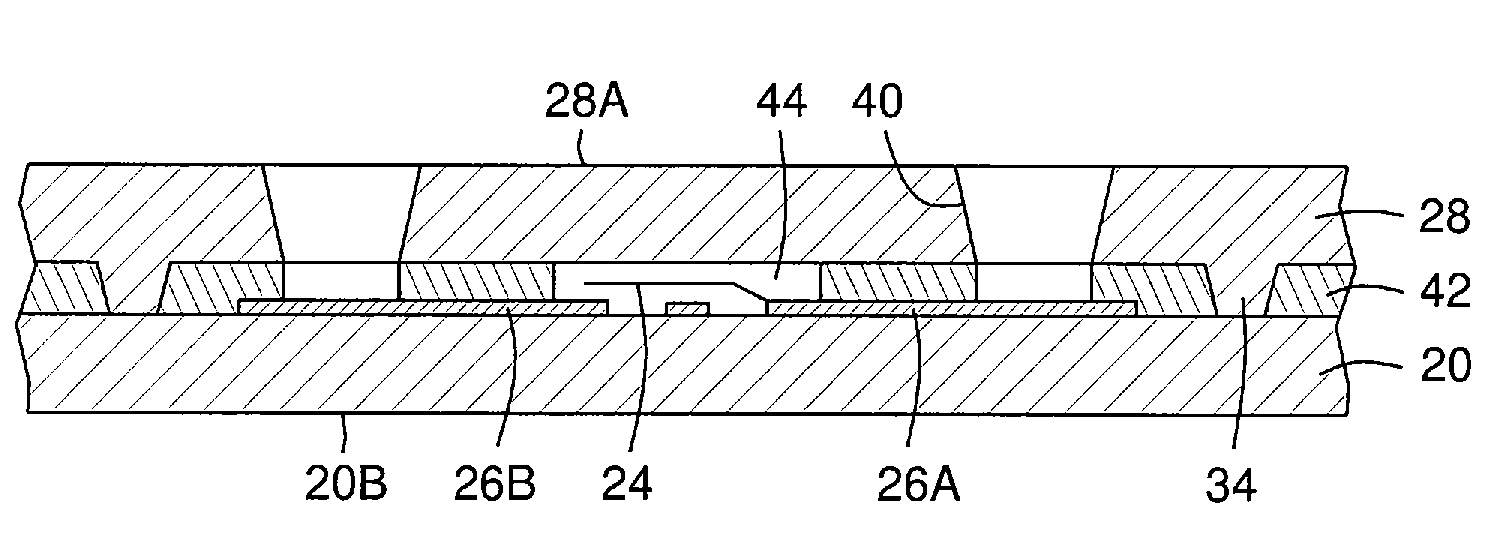

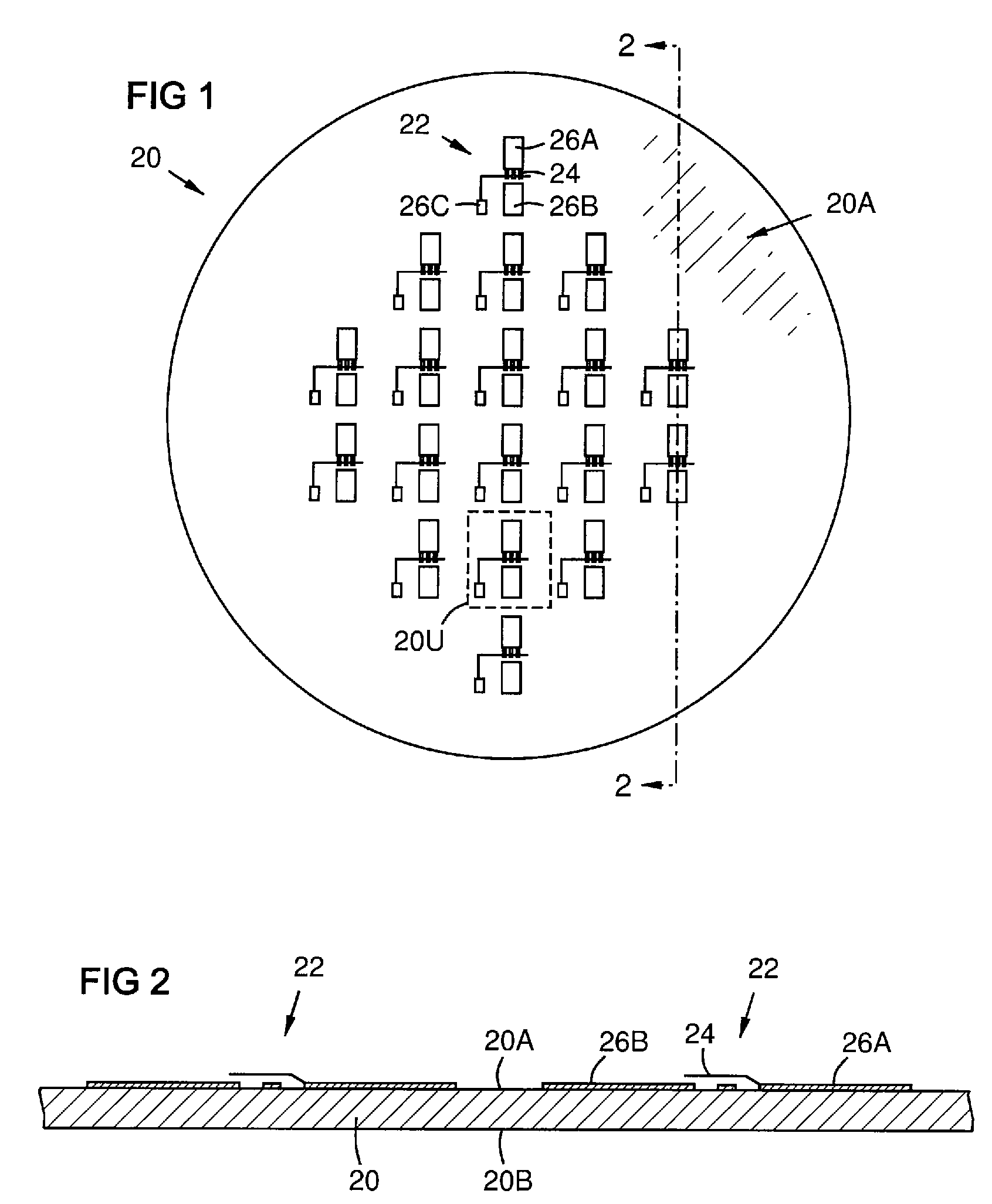

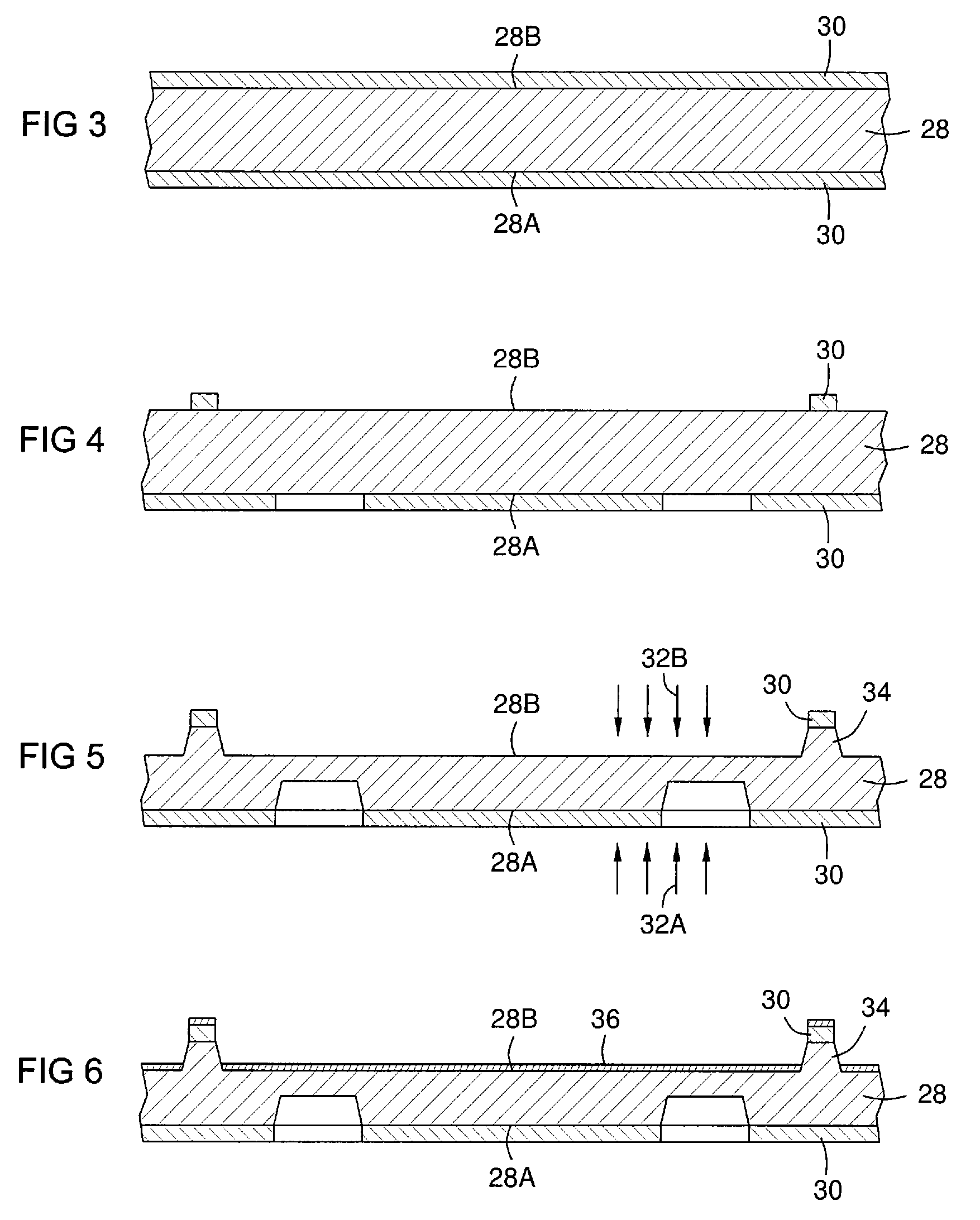

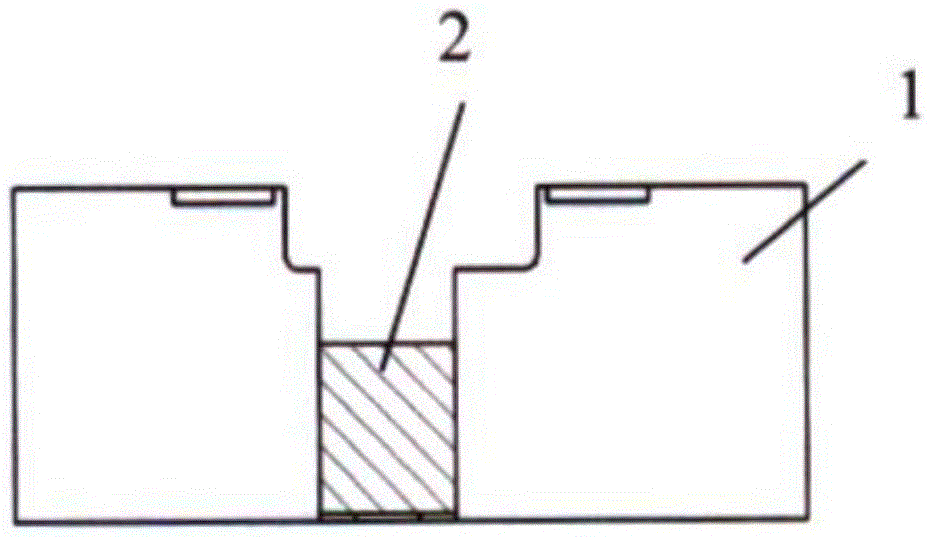

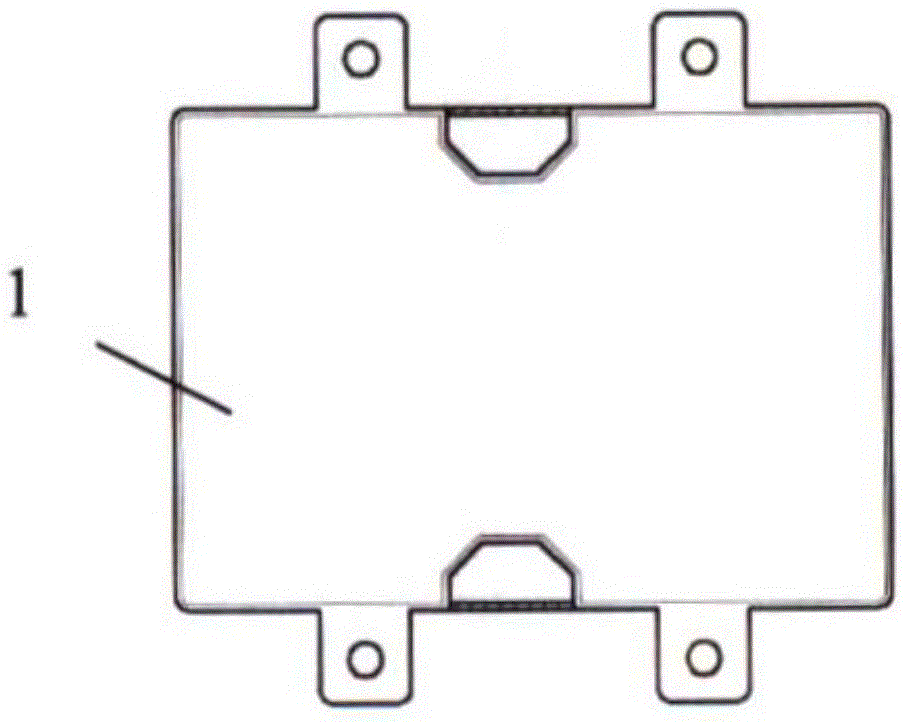

Sealed wafer packaging of microelectromechanical systems

ActiveUS20090096088A1Convenient registrationAvoid damageSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringHermetic seal

Multiple microelectromechanical systems (MEMS) on a substrate are capped with a cover using a layer that may function as a bonding agent, separation layer, and hermetic seal. A substrate has a first side with multiple MEMS devices. A cover is formed with through-holes for vias, and with standoff posts for layer registration and separation. An adhesive sheet is patterned with cutouts for the MEMS devices, vias, and standoff posts. The adhesive sheet is tacked to the cover, then placed on the MEMS substrate and heated to bond the layers. The via holes may be metalized with leads for circuit board connection. The MEMS units may be diced from the substrate after sealing, thus protecting them from contaminants.

Owner:GENERAL ELECTRIC CO

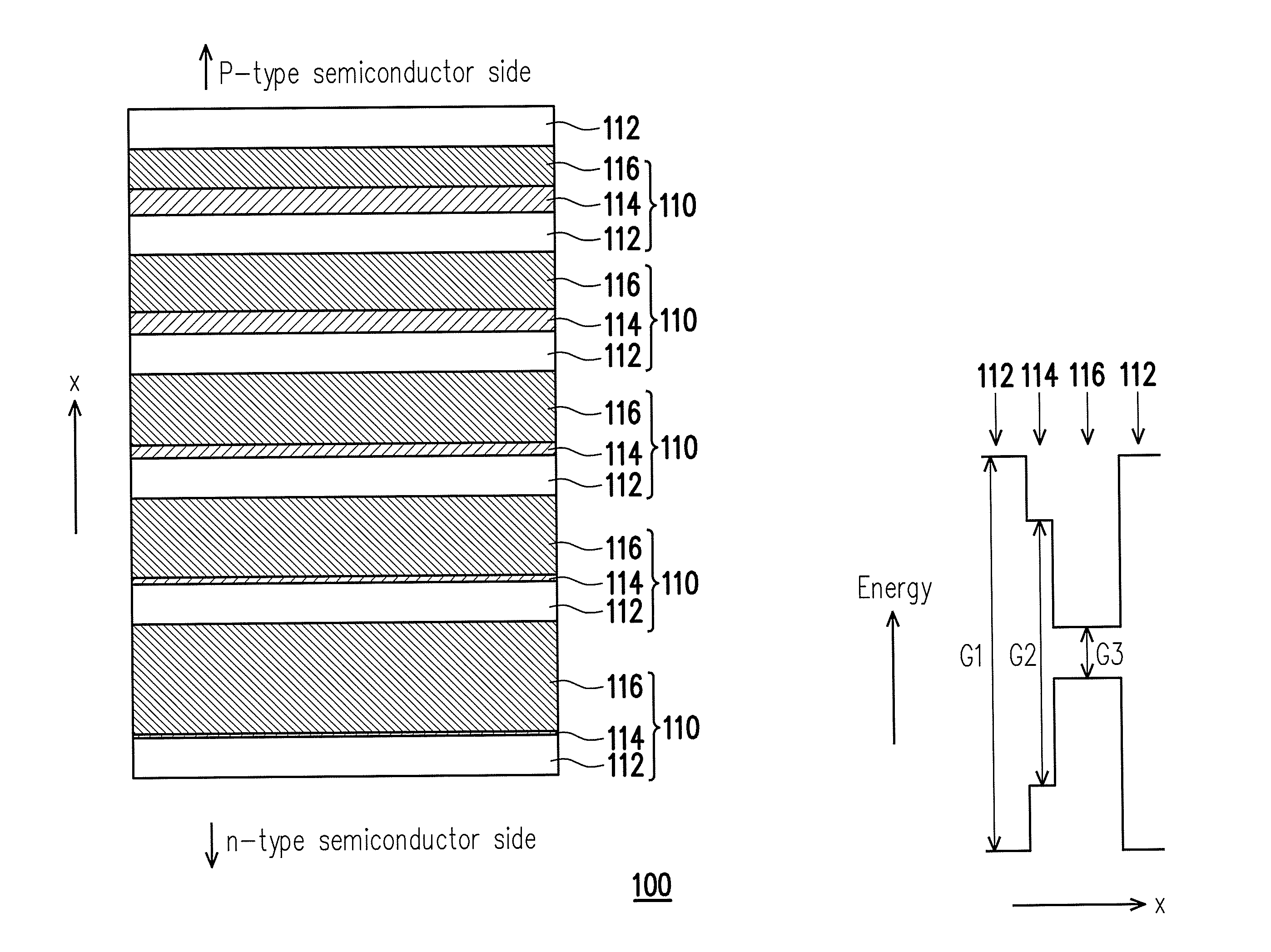

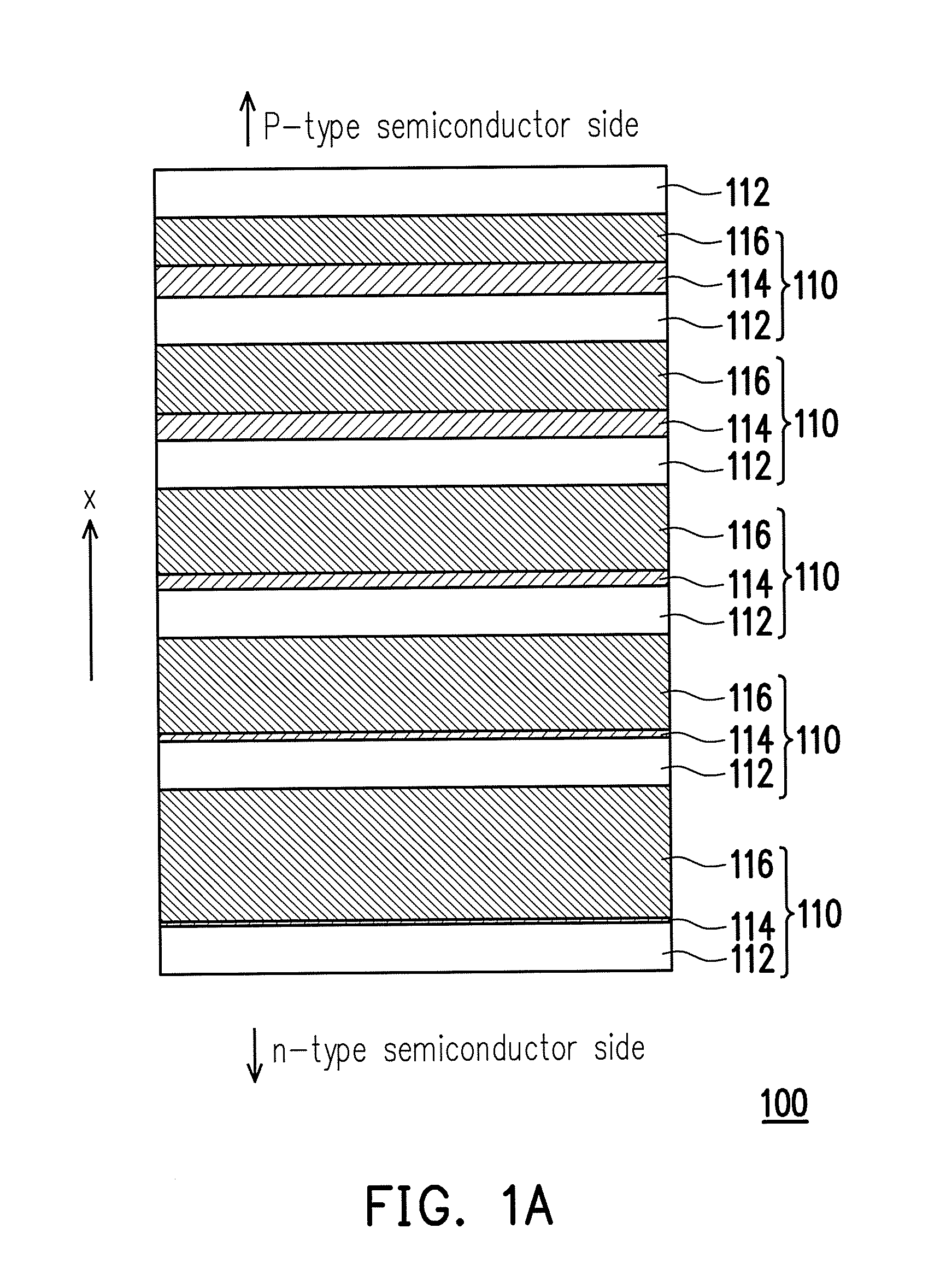

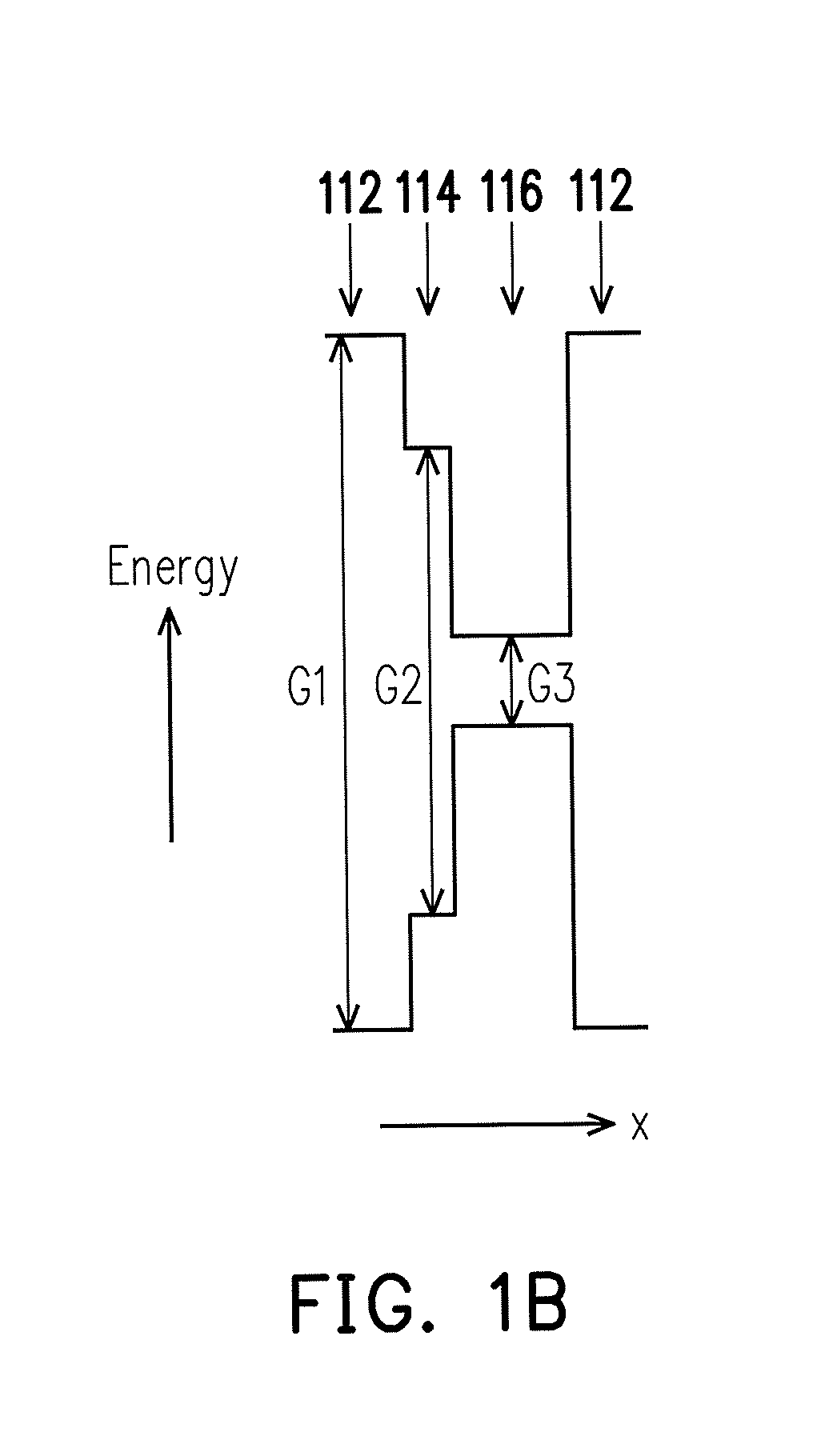

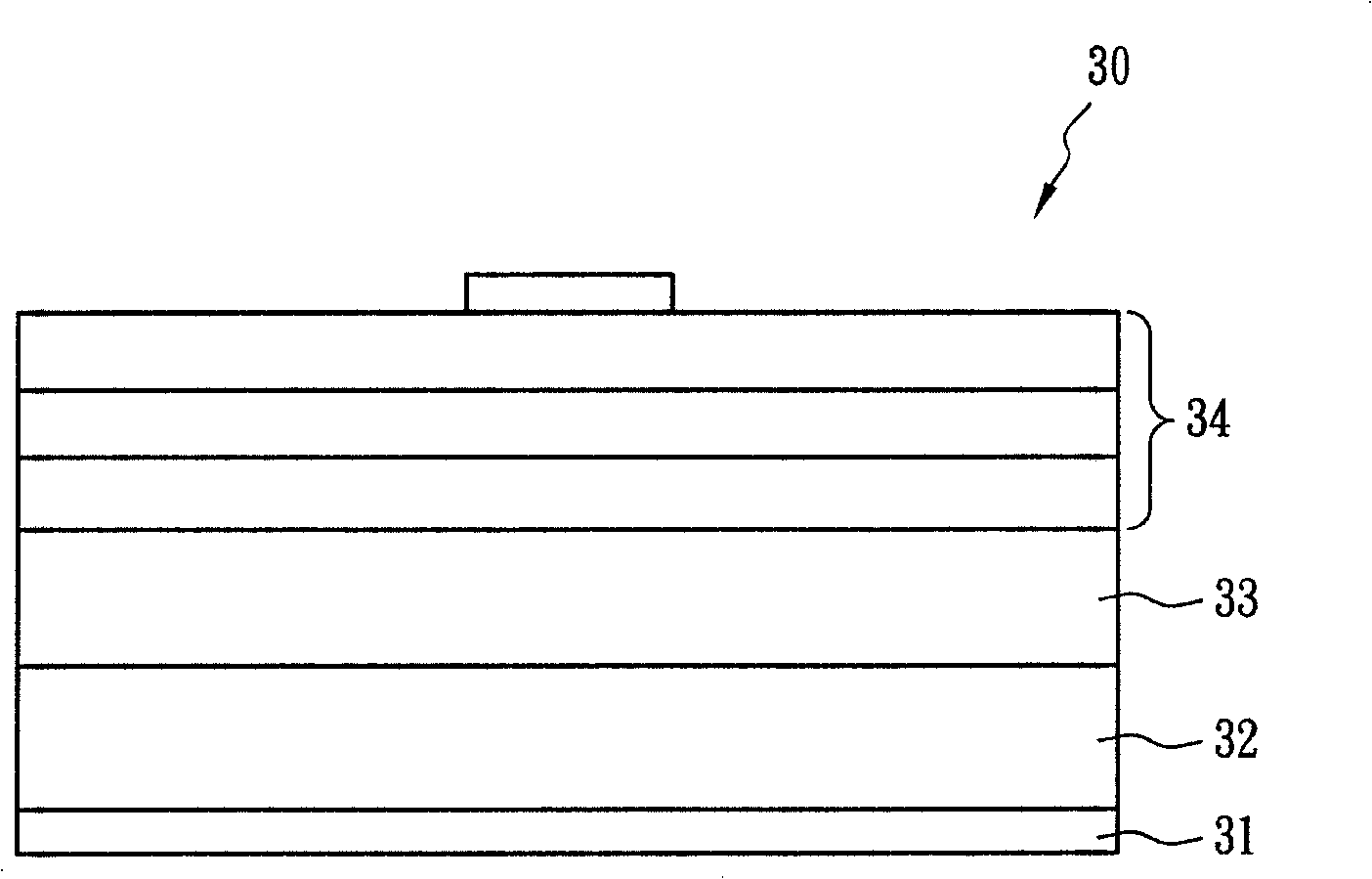

Multiple quantum well structure and method for manufacturing the same

ActiveUS20170033260A1Good optical performanceImprove epitaxy qualitySemiconductor devicesOptoelectronicsIntermediate level

A multiple quantum well structure includes a plurality of well-barrier sets arranged along a direction. Each of the well-barrier sets includes a barrier layer, at least one intermediate level layer, and a well layer. A bandgap of the barrier layer is greater than an average bandgap of the intermediate level layer, and the average bandgap of the intermediate level layer is greater than a bandgap of the well layer. The barrier layers, the intermediate level layers, and the well layers of the well-barrier sets are stacked by turns. Thicknesses of at least parts of the well layers in the direction gradually decrease along the direction, and thicknesses of at least parts of the intermediate level layers in the direction gradually increase along the direction. A method for manufacturing a multiple quantum well structure is also provided.

Owner:GENESIS PHOTONICS

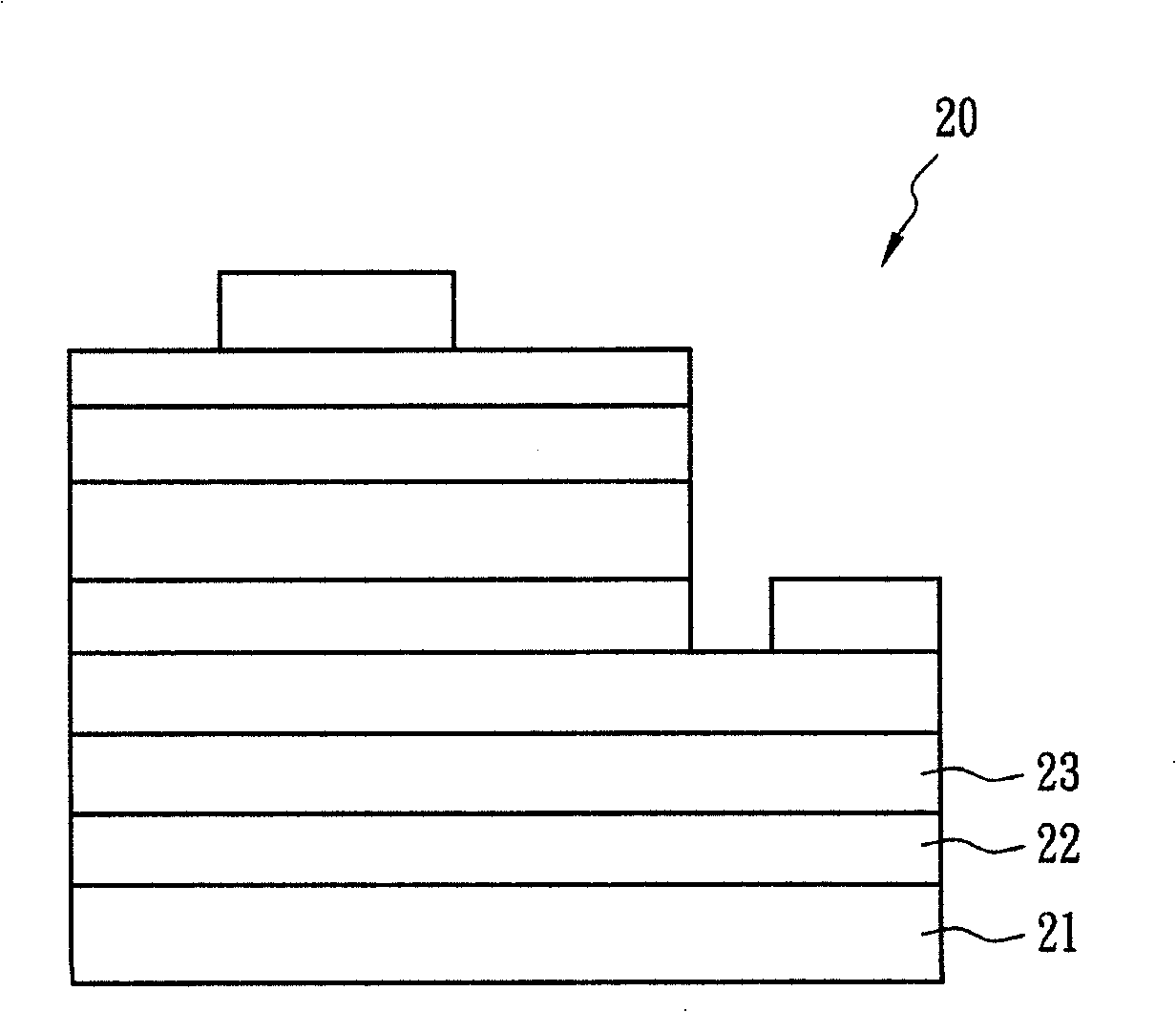

Photoelectrical semiconductor component with 3-familty Ni compound semiconductor buffer layer and its making method

InactiveCN101267008AEffective stress reliefAvoid crackingSemiconductor devicesNitrogenCompound semiconductor

A photoelectric semiconductor component with three families nitrogen compound semiconductor buffer layers is provided, which comprises a substrate, and at least two InGa<1-x>N layers and at least two InGa<1-y>N layers which superimposes on the substrate alternately, wherein the x not equals to the y. A luminescent epitaxial structure is located on the surface of the InGa<1-y>N layer which is at the upper layer. A superlattice buffer layer is formed by the InGa<1-x>N layer which is between the substrate and the luminescent epitaxial structure and the InGa<1-y>N layer to reduce stress.

Owner:ZHANJING TECH SHENZHEN +1

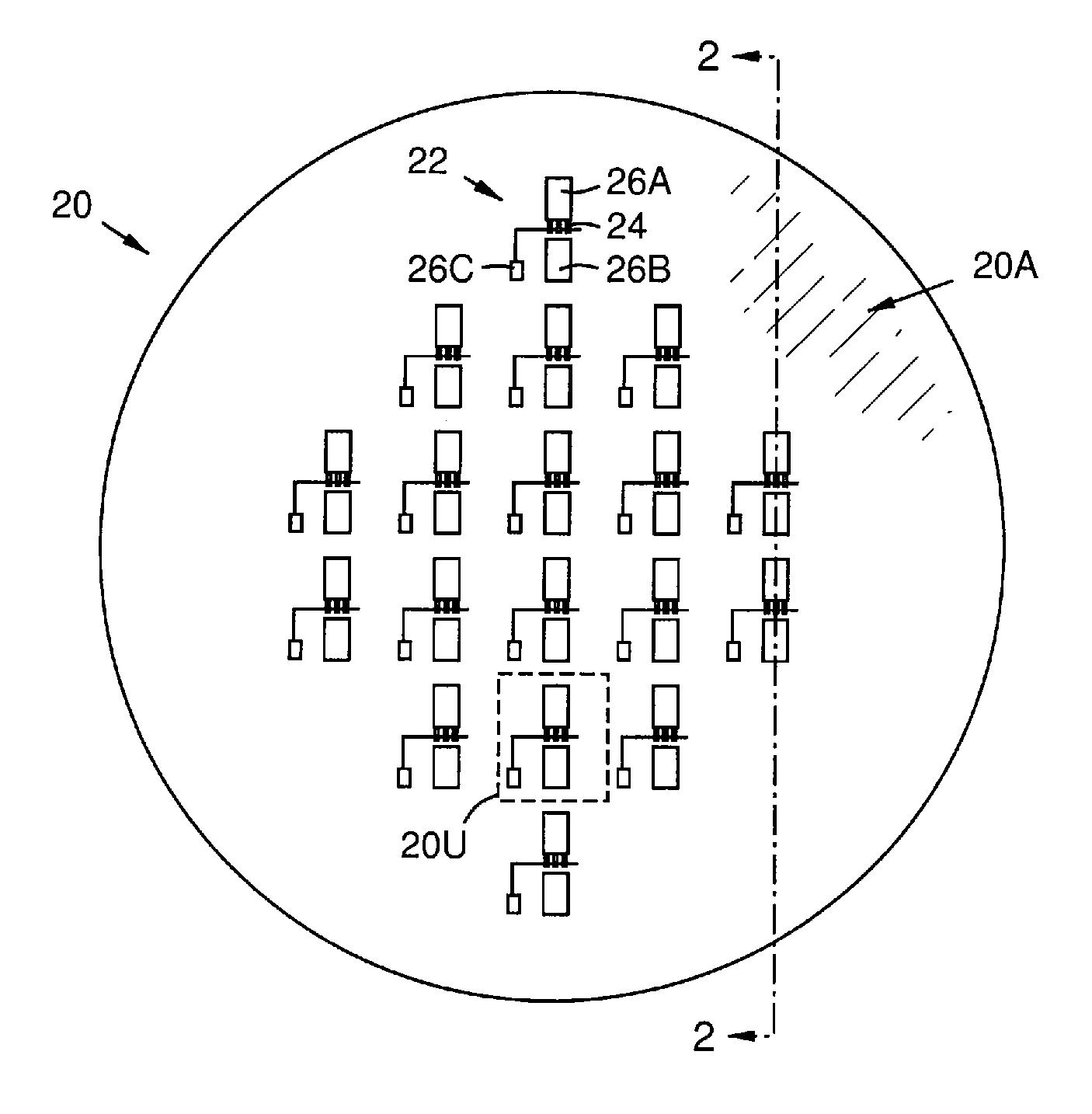

Sealed wafer packaging of microelectromechanical systems

ActiveUS7605466B2Avoid damageReduce the outgassing potentialSemiconductor/solid-state device detailsSolid-state devicesHermetic sealMicroelectromechanical systems

Multiple microelectromechanical systems (MEMS) on a substrate are capped with a cover using a layer that may function as a bonding agent, separation layer, and hermetic seal. A substrate has a first side with multiple MEMS devices. A cover is formed with through-holes for vias, and with standoff posts for layer registration and separation. An adhesive sheet is patterned with cutouts for the MEMS devices, vias, and standoff posts. The adhesive sheet is tacked to the cover, then placed on the MEMS substrate and heated to bond the layers. The via holes may be metalized with leads for circuit board connection. The MEMS units may be diced from the substrate after sealing, thus protecting them from contaminants.

Owner:GENERAL ELECTRIC CO

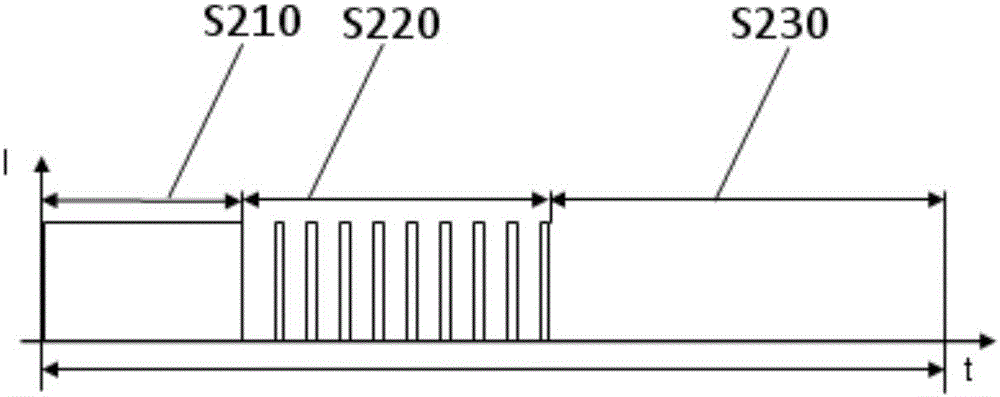

Thermal Processing of Substrates with Pre- and Post-Spike Temperature Control

InactiveUS20110298093A1Improve electronic performanceReduce stress buildupSemiconductor/solid-state device manufacturingLaser beam welding apparatusTemperature controlDevice form

Provided are apparatuses and method for the thermal processing of a substrate surface, e.g., controlled laser thermal annealing (LTA) of substrates. The invention typically involves irradiating the substrate surface with first and second images to process regions of the substrate surface at a substantially uniform peak processing temperature along a scan path. A first image may serve to effect spike annealing of the substrates while another may be used to provide auxiliary heat treatment to the substrates before and / or after the spike annealing. Control over the temperature profile of the prespike and / or postspike may also reduce stresses and strains generated in the wafers. Also provided are microelectronic devices formed using the inventive apparatuses and methods.

Owner:ULTRATECH INT INC

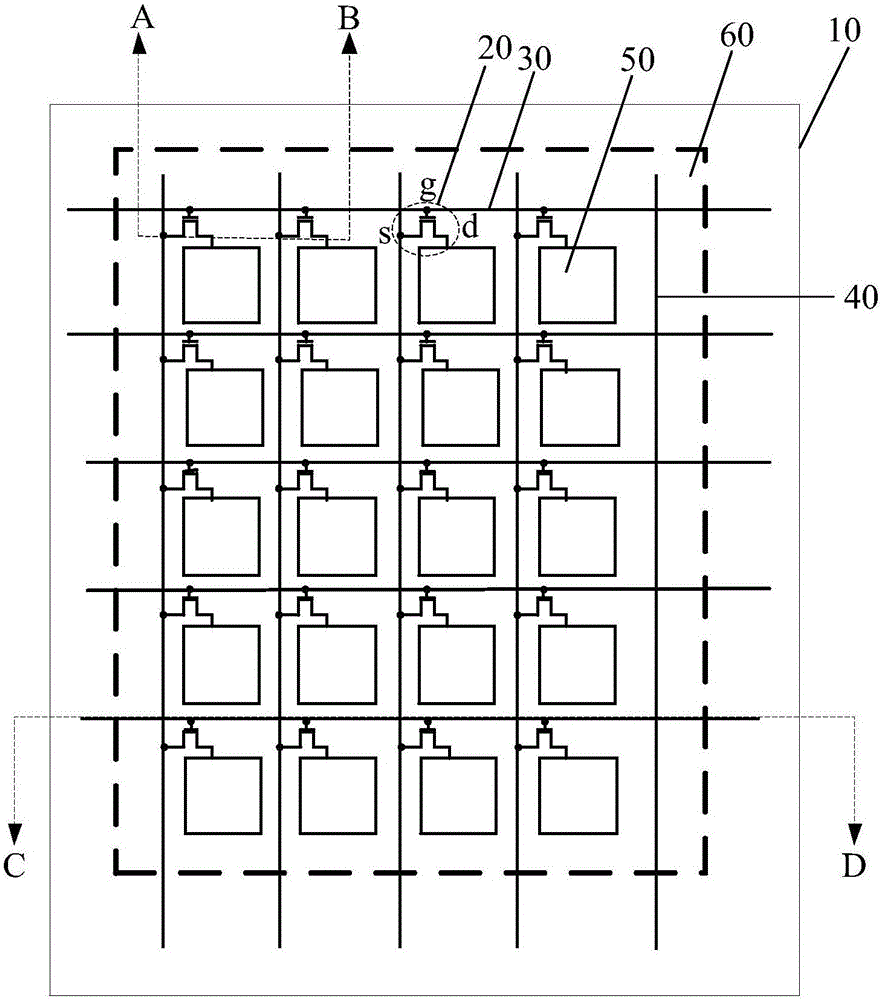

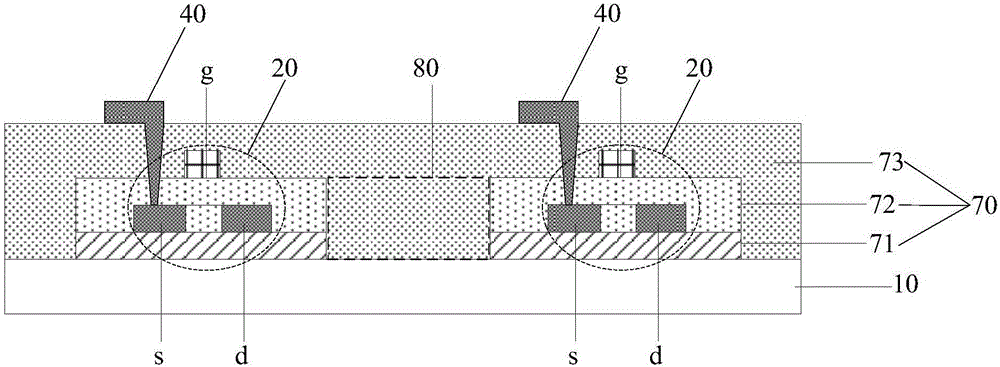

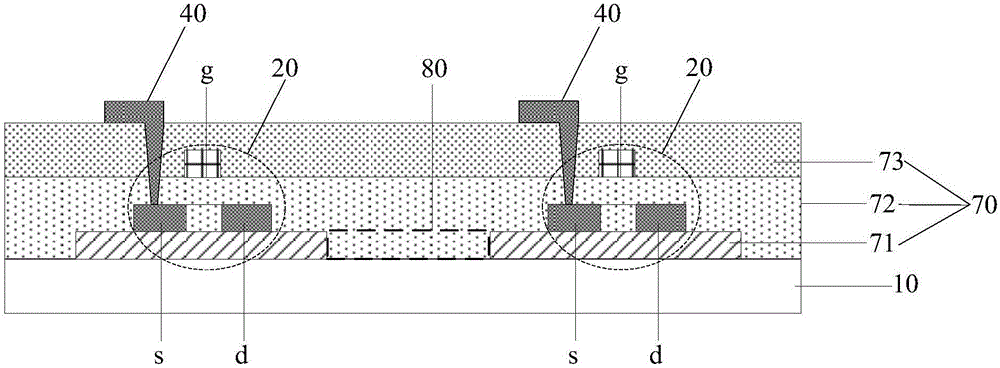

Array substrate and display panel

PendingCN106229321AReduce stress buildupAvoid enteringSolid-state devicesNon-linear opticsEngineeringFlexible display

The embodiment of the invention discloses an array substrate and a flexible display panel. The array substrate comprises a flexible substrate, a thin film transistor (TFT), a first metal layer, a second metal layer and a stacking structure, wherein the stacking structure comprises multiple layers of inorganic layers, the thin film transistor comprises a source electrode, a drain electrode, a channel and a grid electrode isolated from the source electrode, the channel and the drain electrode, the multiple layers of inorganic layers comprise one or more layers of buffering layers located between the flexible substrate and the thin film transistor, one or more layers of grid insulating layers located between the channel and the grid electrode, and a first isolating layer located between the TFT and the second metal layer, and at least one inorganic layer of the multiple layers of inorganic layers is provided with multiple openings at the position corresponding to a display area, so that the problem that normal work of the TFT and a light-emitting component is affected due to the bending of the array substrate after being made into the display panel is solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

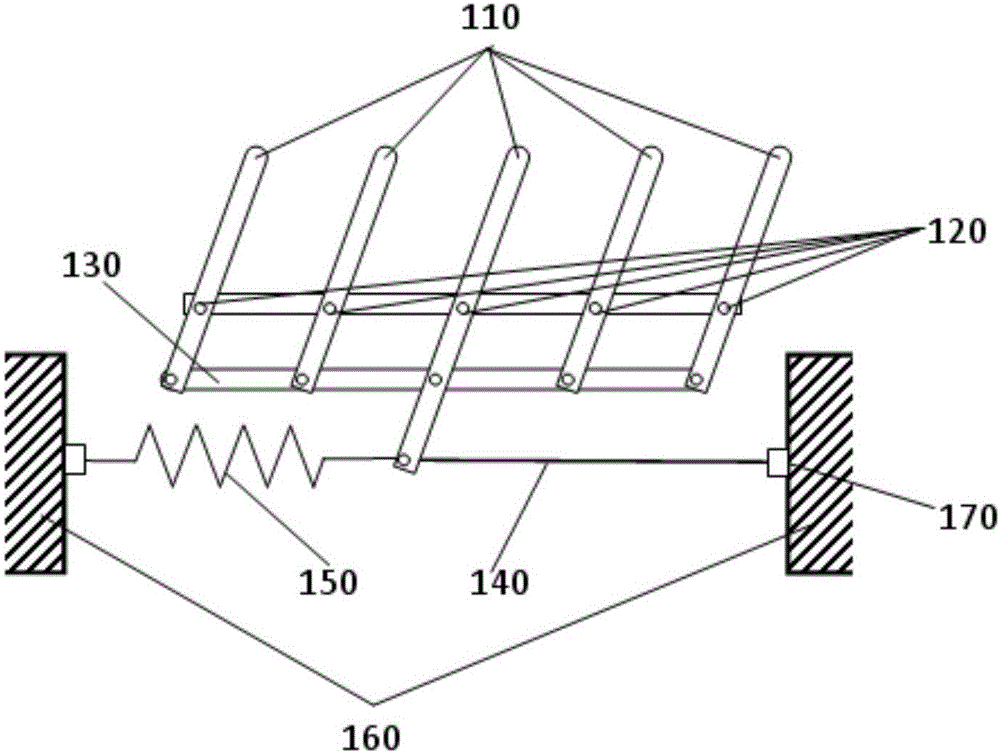

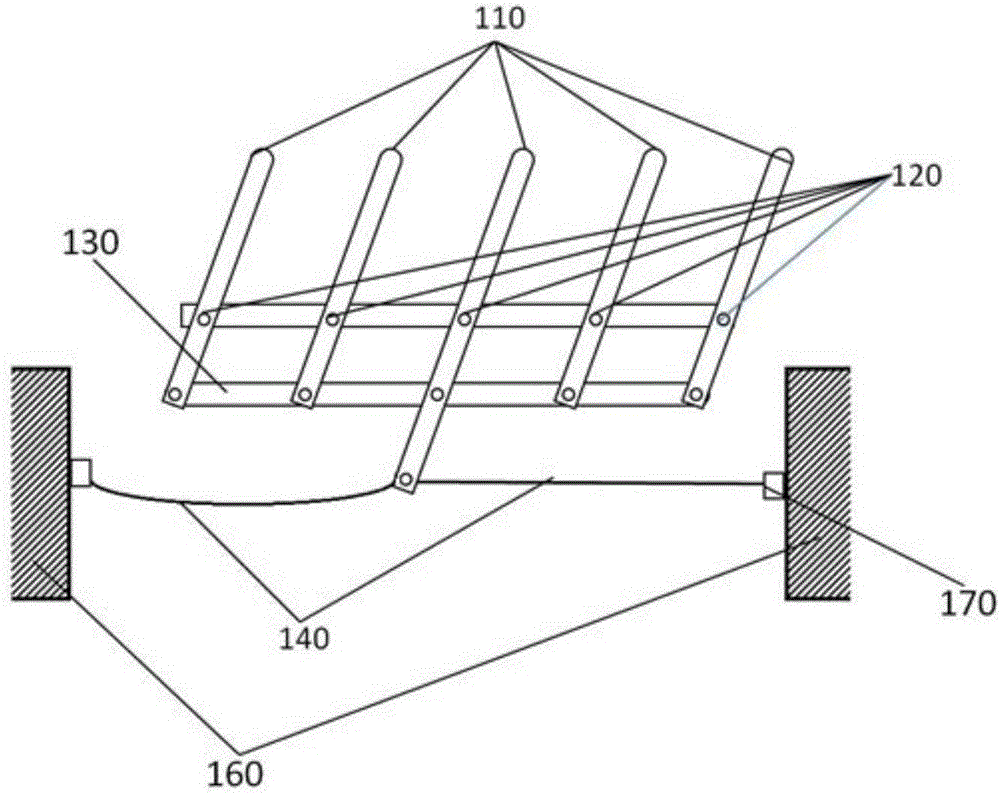

Vehicle-mounted air condition air sweeping device driven by electric control shape memory alloy

InactiveCN105946515AReduce volumeNo electromagnetic interferenceAir-treating devicesVehicle heating/cooling devicesMicrocontrollerMicrocomputer

The invention discloses a vehicle-mounted air condition air sweeping device driven by an electric control shape memory alloy. The vehicle-mounted air condition air sweeping device is composed of a drive part, a control part, a transmission part and an execution mechanism. The drive part adopts the shape memory alloy as a drive element, the shape memory alloy shrinks when electrified to be heated and is lengthened when cooled, and output of displacement and force of a driver is achieved. The control part is composed of a sensor, a single-chip microcomputer and a manual control key, the current on a shape memory alloy wire is controlled, and therefore the temperature of the shape memory alloy wire is controlled. The transmission part is mainly composed of a clutch device or a reset device. The execution mechanism is vehicle-mounted air conditioner air sweeping blades. The vehicle-mounted air condition air sweeping device has the beneficial effects of being small in size, simple in structure, convenient to install, easy to achieve, free of electromagnetic interference, good in periodical control effect and the like.

Owner:JILIN UNIV

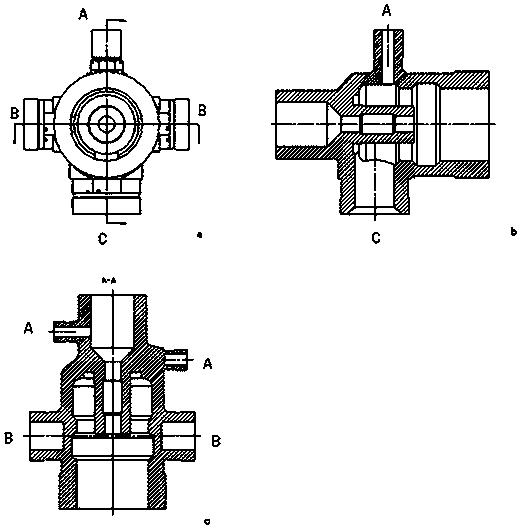

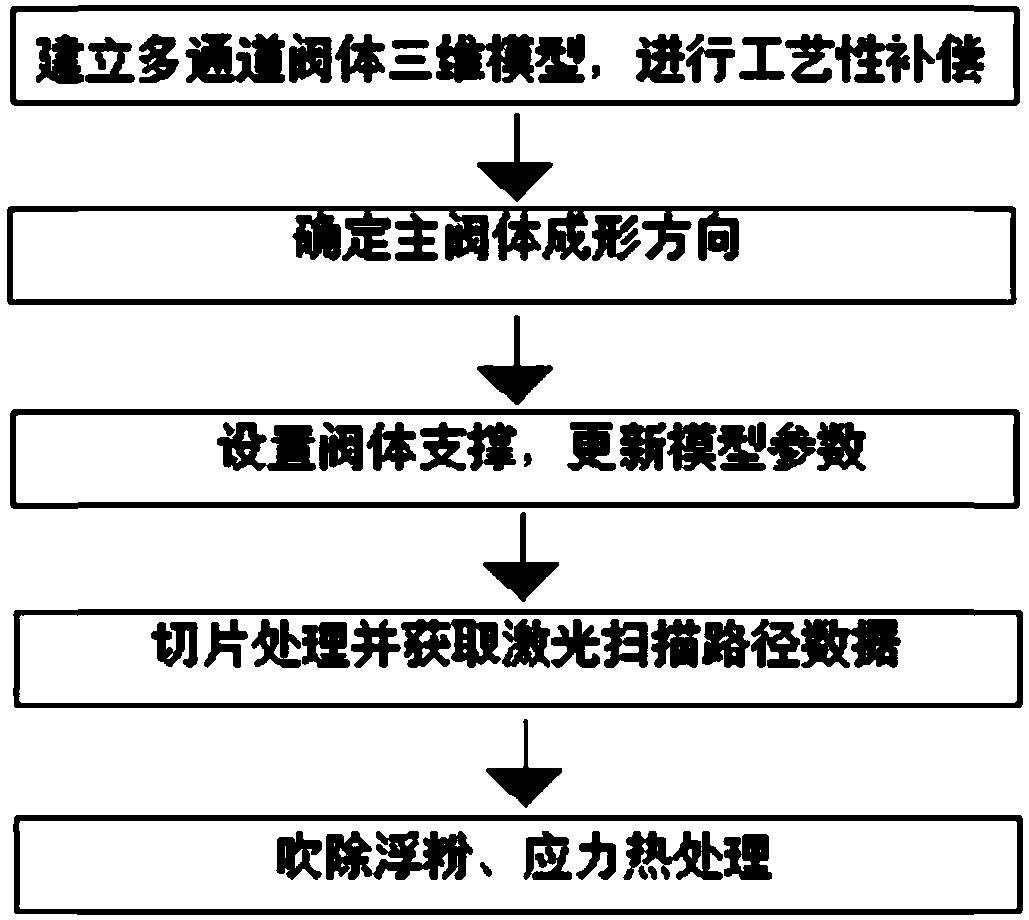

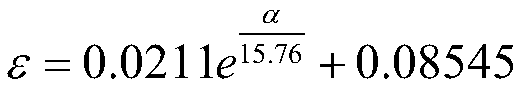

TC4 titanium alloy multi-channel valve body laser selective area melting forming method

ActiveCN109530694ARealize integrated formingEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationProcess support

The invention discloses a TC4 titanium alloy multi-channel valve body laser selective area melting forming method. A multi-channel valve body three-dimensional model is established, manufacturabilitycompensation is added, and the size precision and the shape precision are improved; meanwhile, the valve body character and a complex stress and strain environment formed in the valve body in the forming process are aimed, a stress / strain simulation result is utilized, and the forming direction is determined, a specially-made process support is arranged, alleviating the stress concentration phenomenon is optimized, and machining parameters with the minimum stress strain are selected; and then laser scanning path data of each slice layer are obtained by means of slicing software, and laser selective area melting forming is carried out according to the scanning path data; and finally, after the valve body removes floating powder and is subjected to thermal stress treatment, a substrate plateof the valve body is separated, and the problem that the size precision of the forming valve body is low by utilizing the laser selective area melting forming technology is solved.

Owner:XIAN SPACE ENGINE CO LTD

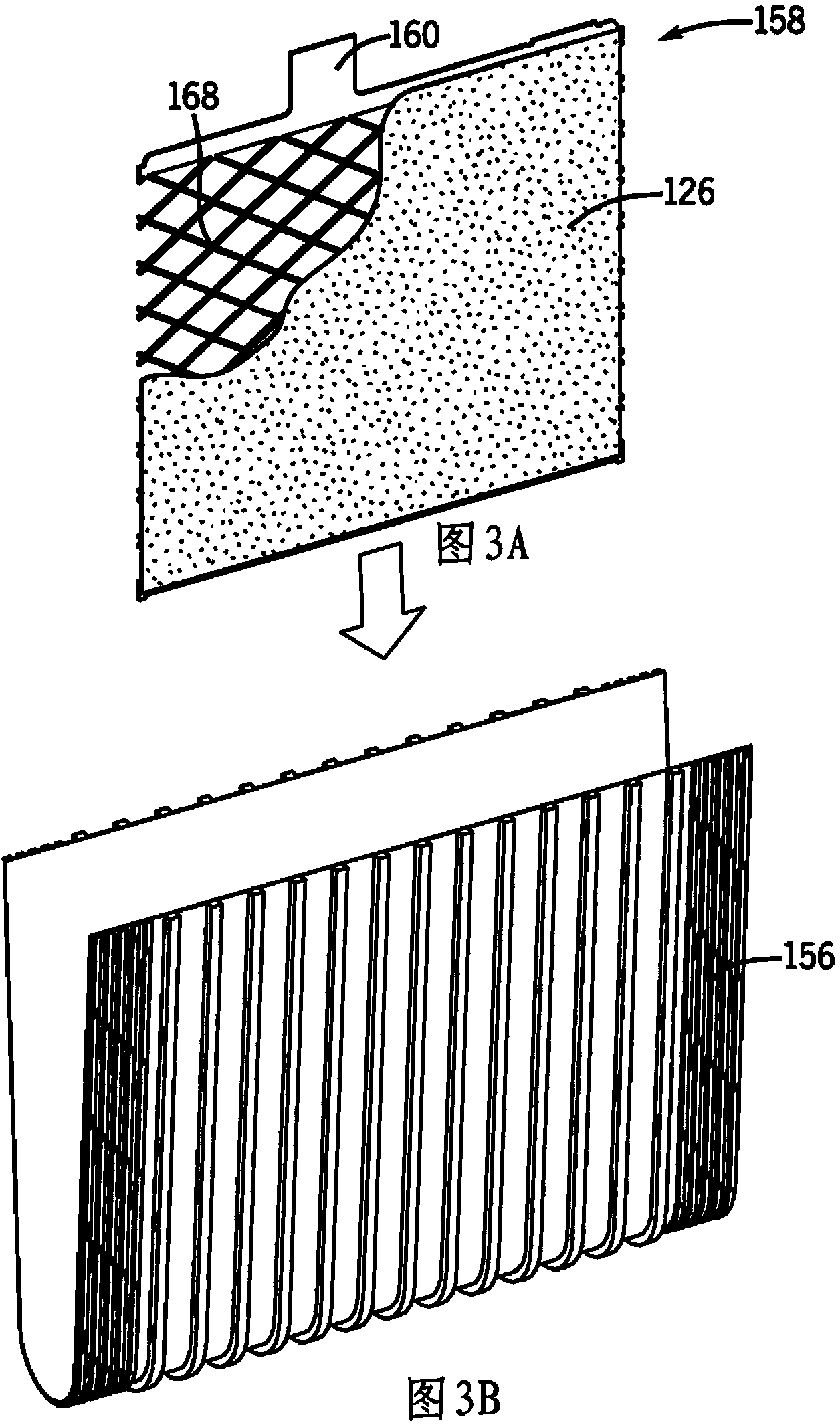

Process for treating substrate of epitaxial chip for high-brightness gallium nitride-base LED

InactiveCN1379484AIncrease brightnessImprove uniformitySemiconductor devicesAlternative methodsGallium nitride

A processing method for substrate of an epitaxial plate of a high-luminance gallium nitride base LED (light emitting diode) is characterized for external growing by that the substrate surface of sapphire awaiting epilocial growth is etched in to many small plots of slots whose width is 0.001-1000 micron, depth is 0.001-300 micron, and spacing is 0.01-10000 micron. An alternative method is first to deposit a film on the surface of sapphire awaiting epitaxial growth and them etching the film into many small blots of slots whose depth reaches the substrate surface of sapphire, width is 0.01-10000 micron, and spacing is 0.01-10000 micron therefore so as to greatly reduce the stress accumulation between the epitaxial layer and the substrate in the period of epitaxial growing to get high-luminance and good-homogeneity LED.

Owner:江苏北极皓天科技有限公司

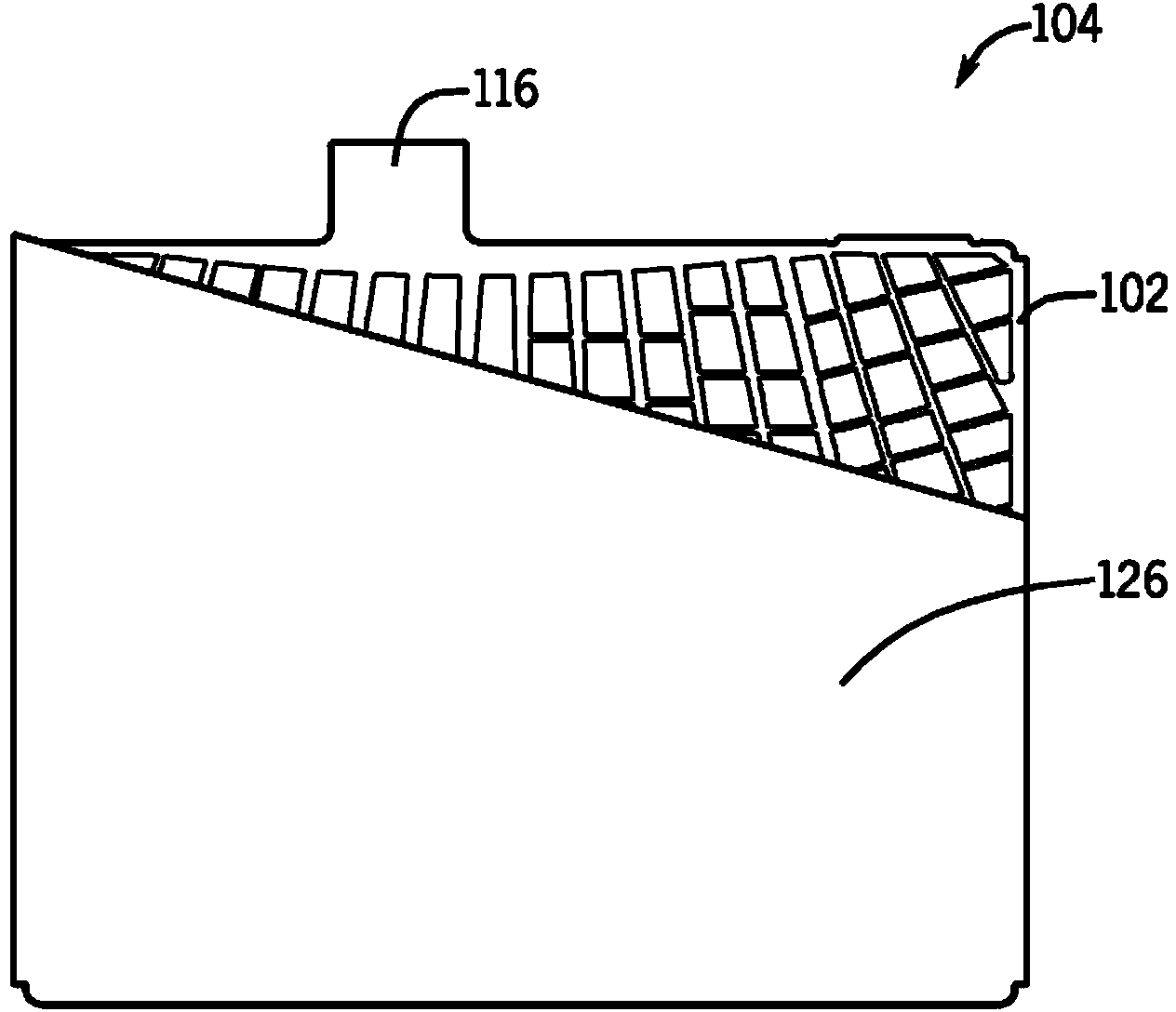

III-Nitride wafer fabrication

ActiveUS20080102598A1Reduce defectsReduce warpageSemiconductor/solid-state device manufacturingWafer fabricationEngineering

A method for fabrication of a III-nitride film over a silicon wafer that includes forming control joints to allow for overall stress relief in the III-nitride film during the growth thereof.

Owner:INFINEON TECH AMERICAS CORP

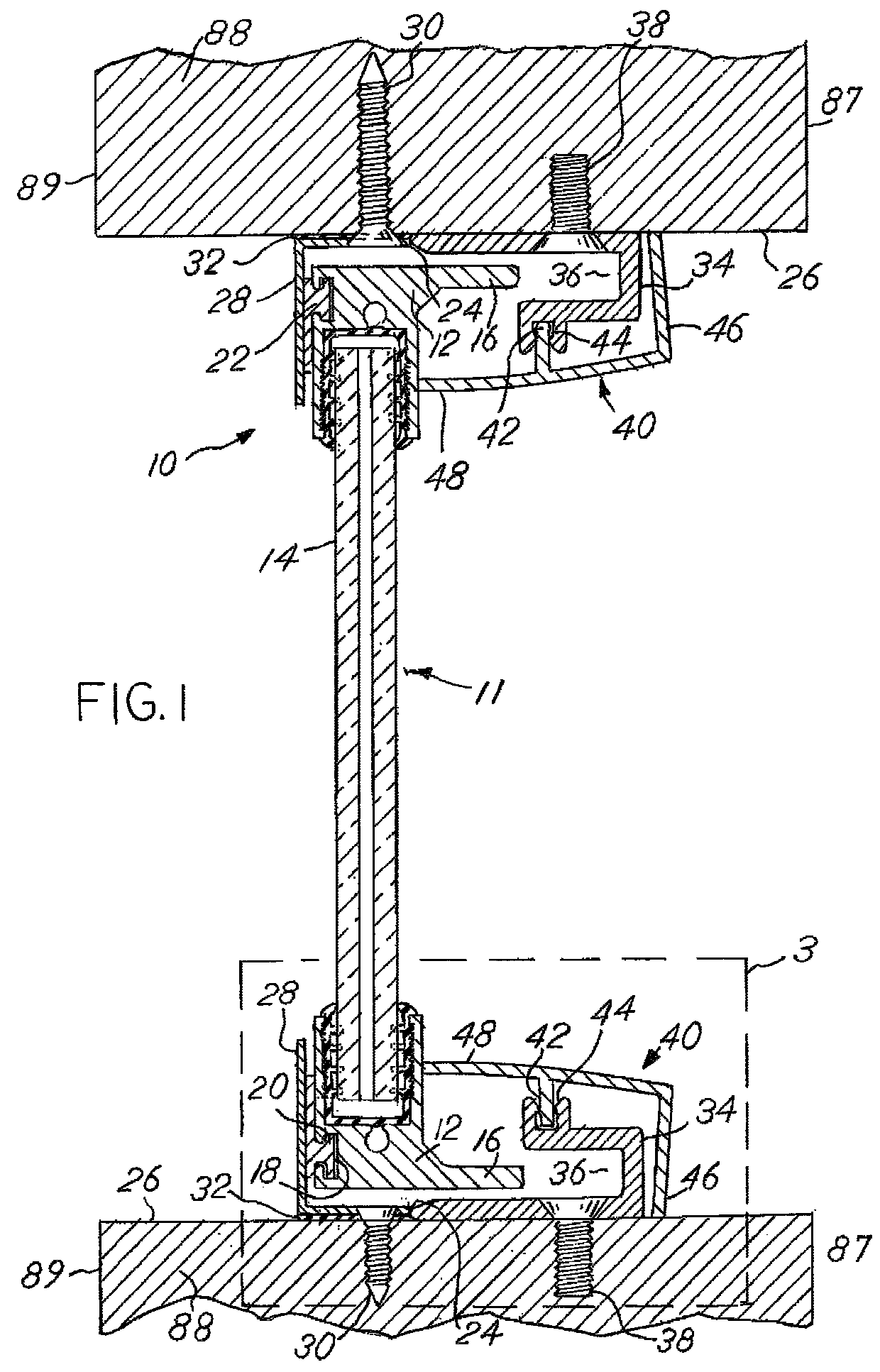

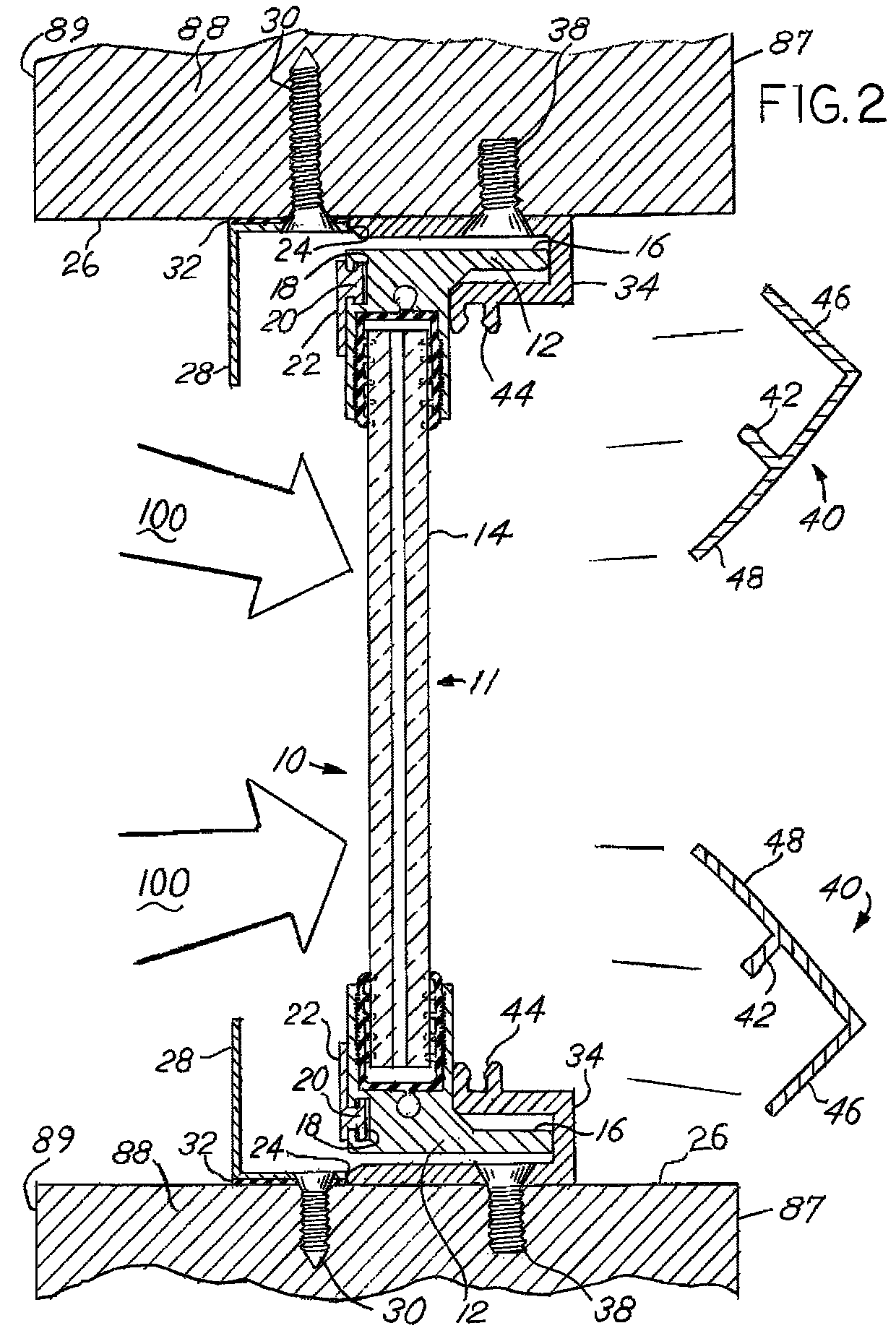

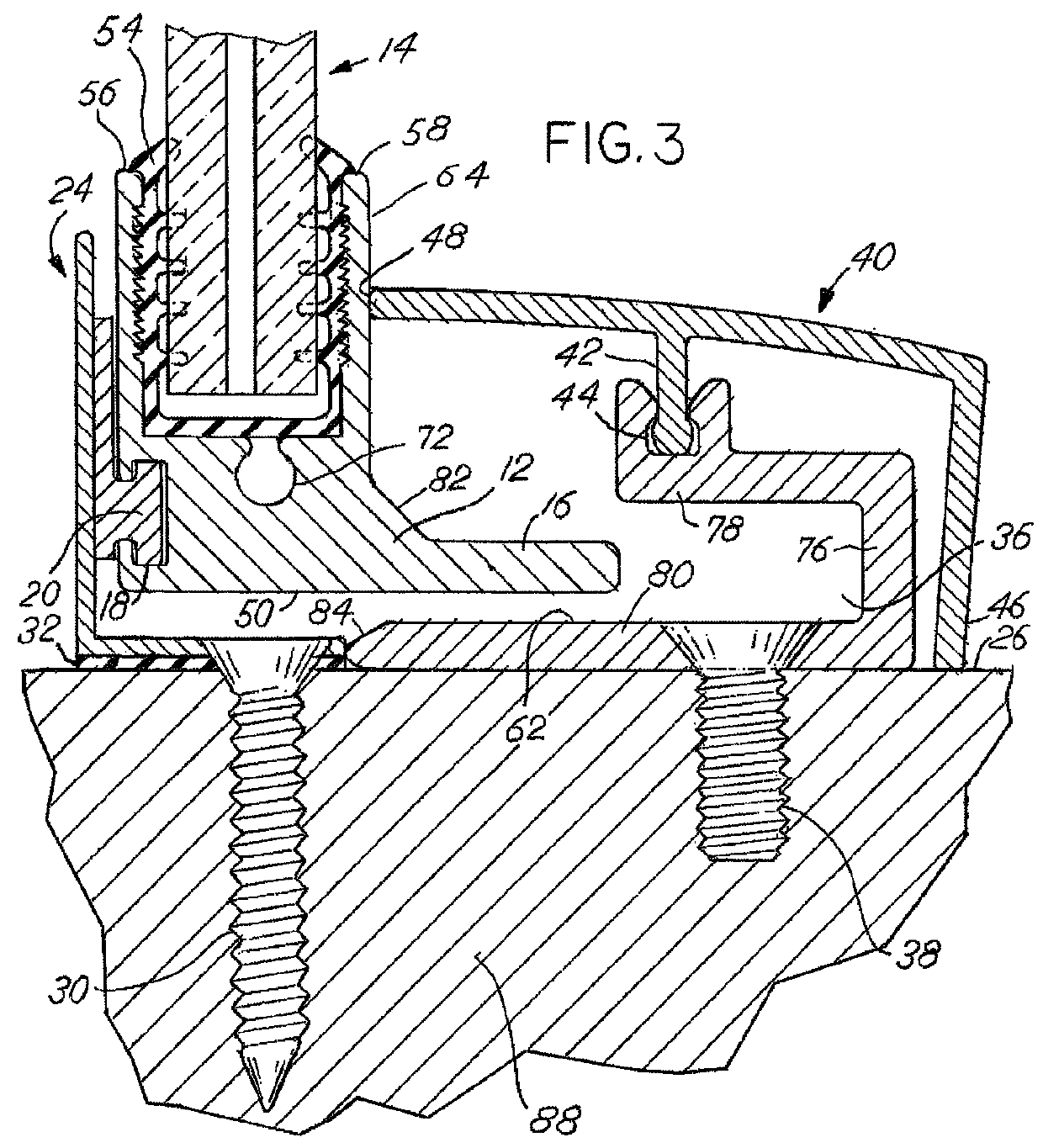

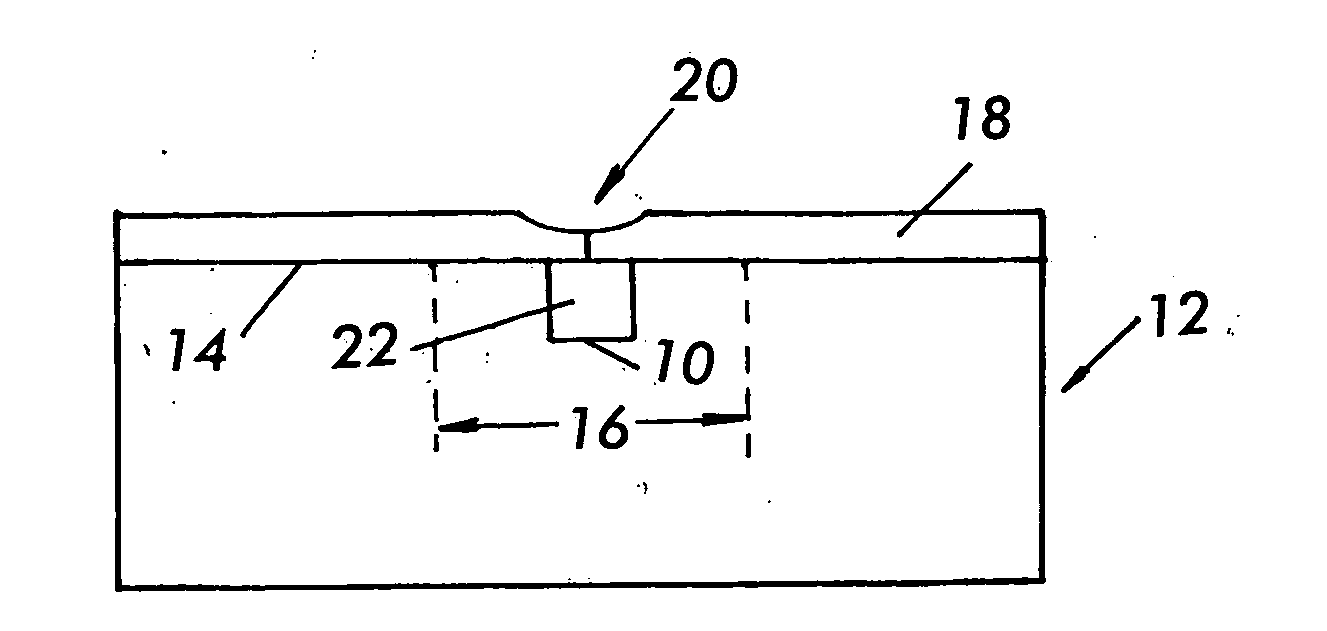

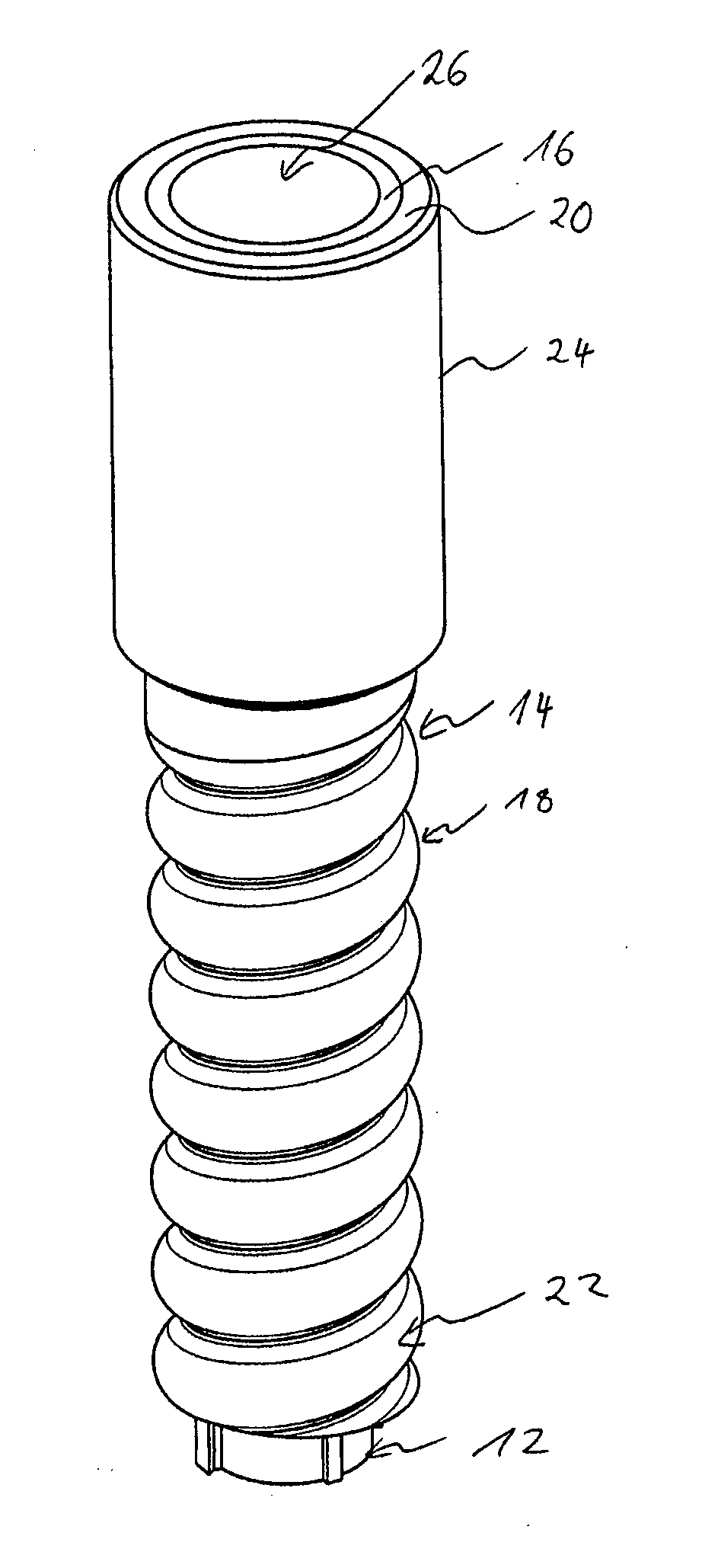

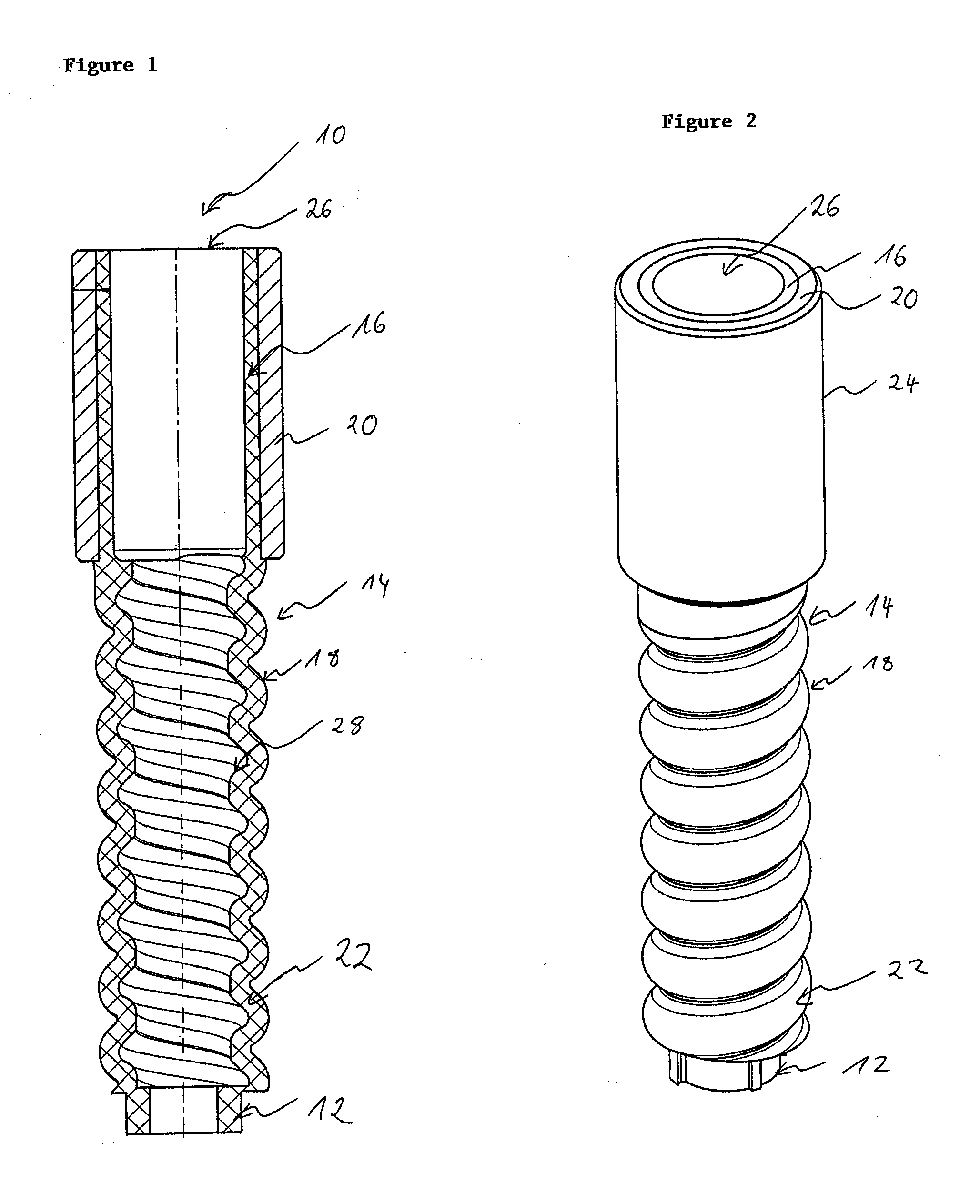

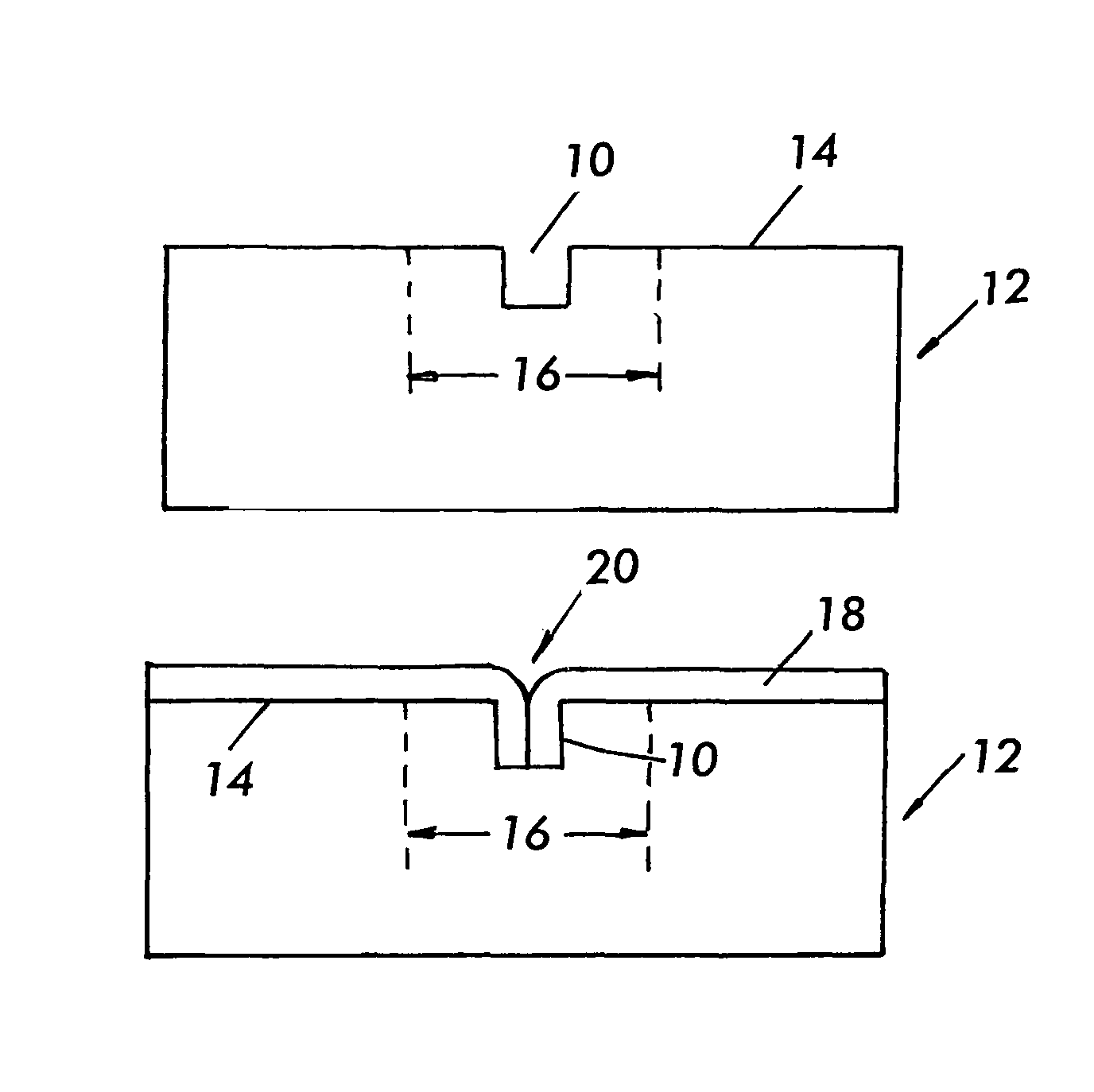

Screw dowel for fastening rails

InactiveUS20130228634A1Prevent of plastic materialHigh strengthRail fastenersTrack superstructureEngineeringScrew thread

Screw dowel for concreting into a railway sleeper or ballastless track and frictionally connecting to a sleeper screw, containing a threaded portion (14) with external thread flights (18) arranged on the outside of the screw dowel (10) and with internal thread flights (19) arranged on the inside of the screw dowel; and an upper subportion (16) without external thread that is situated close to the dowel opening (26) in the installed state; the screw dowel containing two constituent parts made of different materials, namely a basic body made of plastic and a cylindrical ring (20) made of a steel material and mounted with a form fit and / or force fit.

Owner:VOSSLOH WERKE GMBH

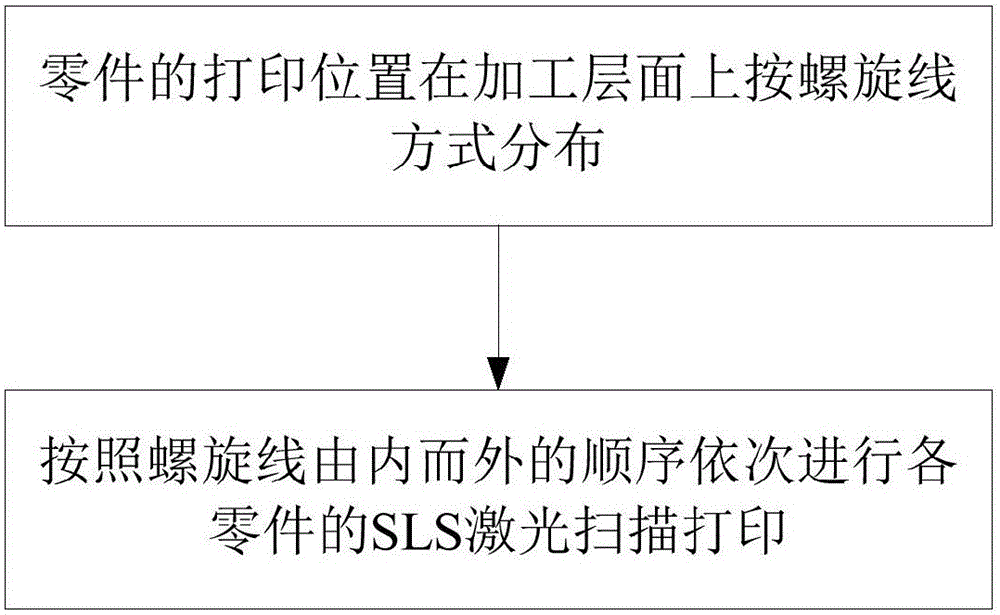

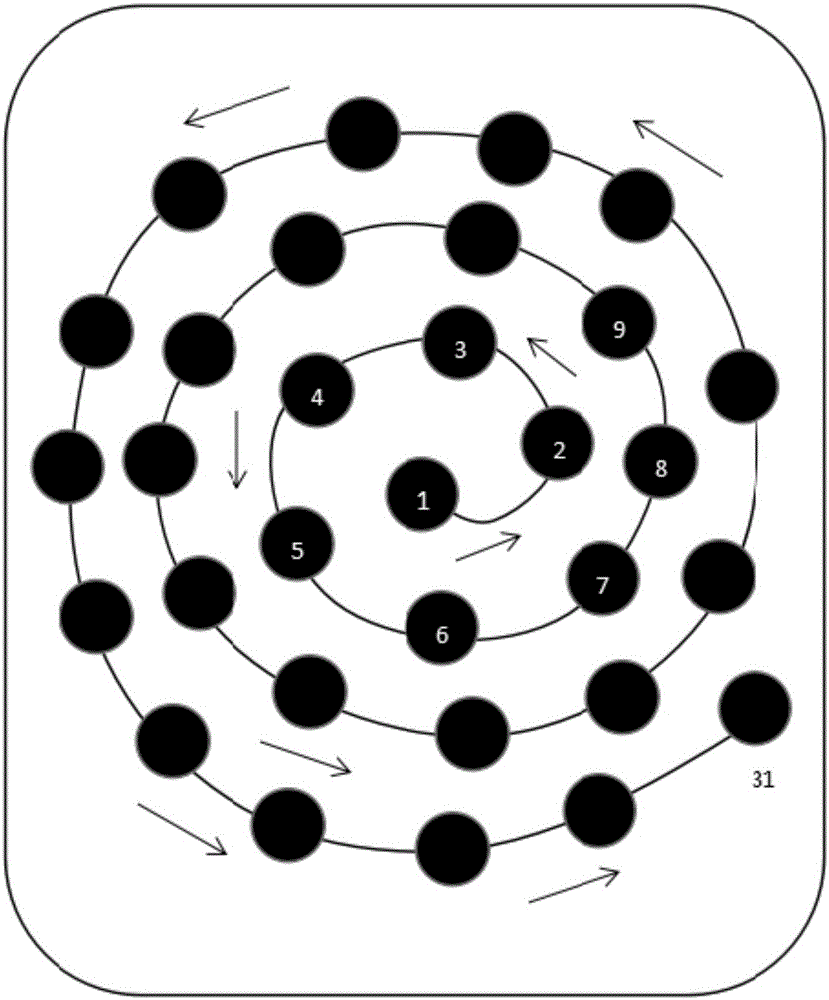

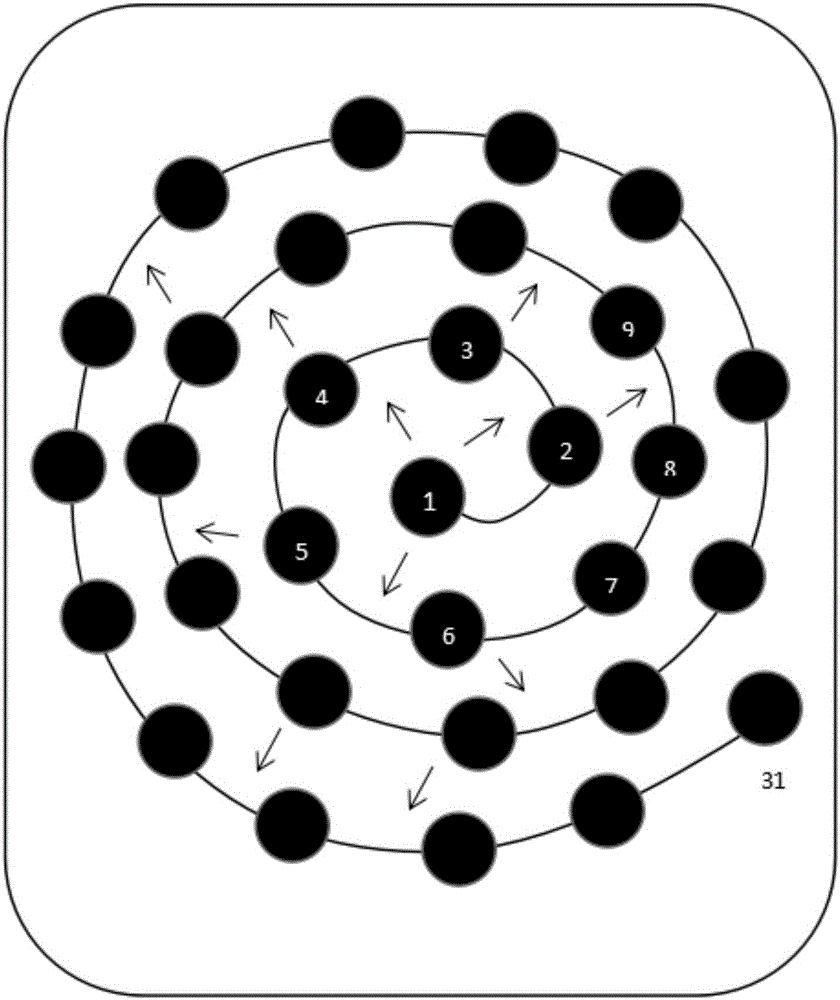

SLS scanning method and 3D printing method

ActiveCN106003713AFast processingExcellent temperature field controlAdditive manufacturing apparatusBatch productionLaser scanning

The invention discloses an SLS scanning method and a 3D printing method. The 3D printing method uses an SLS processing technology to conduct 3D printing on batches of parts and comprises the following steps that data treatment is conducted, specifically, the printing positions of multiple to-be-printed parts are set in the mode that the printing positions are sequentially distributed from interior to exterior in the helical line direction, and data slicing treatment is conducted according to the set printing positions; and scanning is conducted, specifically, all the printing positions are scanned with laser in the helical line direction from interior to exterior in sequence, same-layer SLS sintering of the different parts is conducted on all the printing positions in sequence, and circulated and repeated scanning is conducted along t a helical line so that the batches of parts can be printed. According to the SLS scanning method and the 3D printing method, the quality of all the parts in small batch production can be optimized; meanwhile, compared with a previous scanning strategy, the production time is shortened; and much equipment heat energy can further be saved.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

III-nitride wafer fabrication

ActiveUS8557681B2Reduce defectsReduce warpageSemiconductor/solid-state device manufacturingWafer fabricationEngineering

A method for fabrication of a III-nitride film over a silicon wafer that includes forming control joints to allow for overall stress relief in the III-nitride film during the growth thereof.

Owner:INFINEON TECH AMERICAS CORP

Selective laser melting and forming method of titanium alloy asymmetric protection shield

ActiveCN106702372AIncrease stiffnessGuaranteed forming qualityMetallic material coating processesSelective laser meltingSelective laser sintering

The invention provides a selective laser melting and forming method of a titanium alloy asymmetric protection shield. The method includes the following steps of (1) design of an additional constraint structure; (2), preparation of titanium alloy powder; (3), selective laser melting and forming of a protection shield product; (4), distressing and annealing; (5), linear cutting to take off the product and removal of the additional constraint structure. Stress deformation of a thin wall flexible component is controlled through an additional constraint condition; due to the fact that the product is of a thin wall flexible structure, buckling deformation is generated easily through direct forming, the additional constraint structure is added to the opening portion of the protection shield, the overall rigidity of the product is improved, and forming quality is guaranteed. Distressing and annealing treatment is performed, an optimized heat treatment system is adopted to perform distressing treatment on a forming part with the additional constraint structure, liner cutting is performed after residual stress is eliminated to remove the additional constraint structure, and product size precision is guaranteed.

Owner:CAPITAL AEROSPACE MACHINERY +1

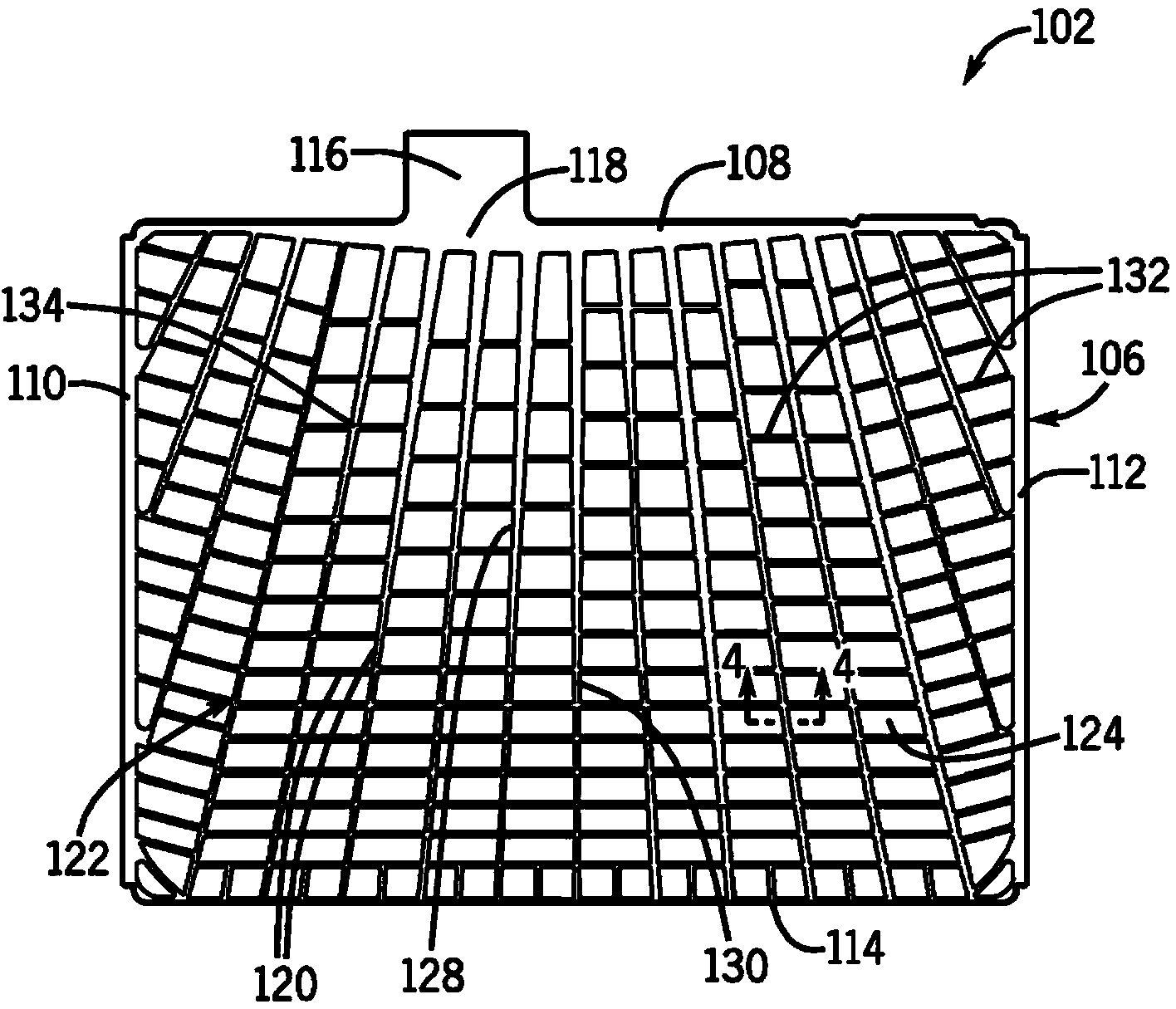

Battery grid with varied corrosion resistance

ActiveCN104115317AReduce stress buildupLead-acid accumulatorsElectrode carriers/collectorsMetallurgyElectrical battery

A battery grid is disclosed. The battery grid includes a pattern of grid wires. The pattern includes a grid wire having a first segment with a first corrosion resistance and a second segment with a second corrosion resistance which is less than the first corrosion resistance. The second segment corrodes at a rate which is faster than the corrosion rate of the first segment so as to dynamically release internal stress and control grid growth of the battery grid during its service life. A battery includes said grid and a method of forming said grid are also disclosed.

Owner:CPS TECH HLDG LLC

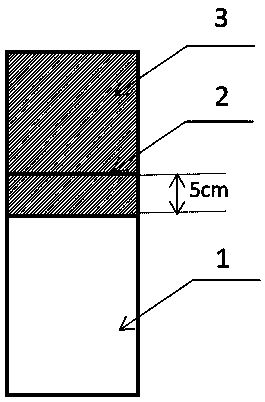

Preparation method of anticorrosive coating on surface of electrolytic zinc anode plate

The invention discloses an anticorrosive coating on surface of an electrolytic (deposited) zinc anode plate and a preparation method thereof. The method comprises the step that a spraying material resistant to sulfuric acid solution, fluoride ion and chloride ion corrosion is sprayed in a range from the upper end of the anode plate to 5 cm below a liquid level line so as to obtain the anticorrosive anode plate with a coating. The spraying material selected in the anticorrosive coating on the surface of an electrolytic (deposited) zinc anode plate and the preparation method thereof is sprayed on the anode plate, the electrolytic efficiency of zinc is not affected, the corrosion of the polar plate is effectively slowed down, so that the service life of the anode plate is prolonged by 2-3 months. The preparation method has small investment, simple process flow, no special requirements on equipment, low energy consumption, no pollution and wide application prospect.

Owner:FUZHOU UNIVERSITY

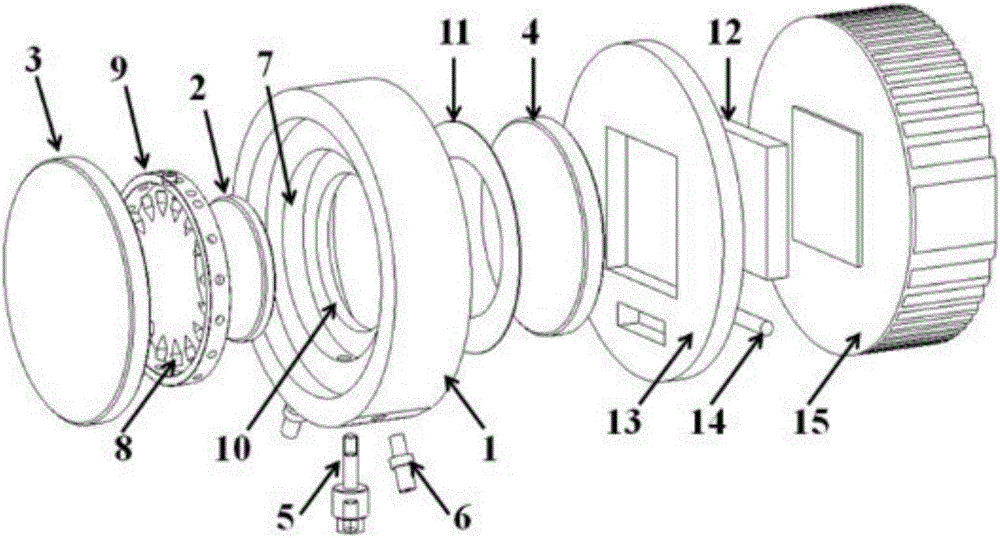

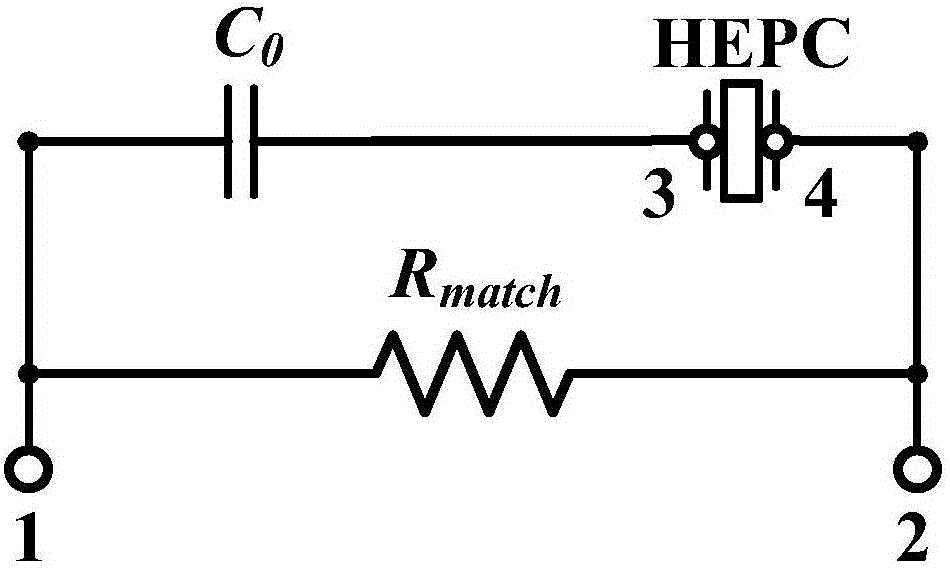

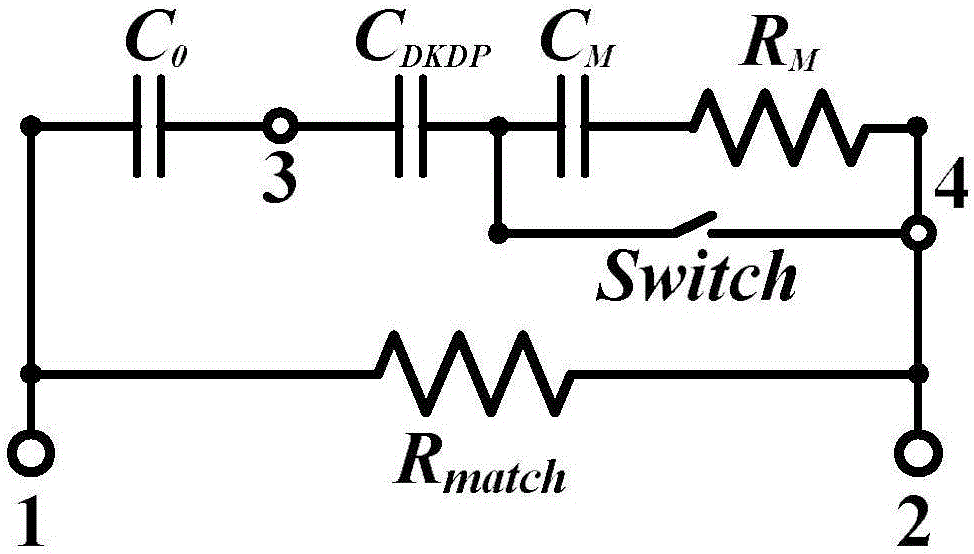

Hybrid-electrode Pockel's cell and time-sharing loop-sharing driving method

The invention discloses a hybrid-electrode Pockel's cell and a time-sharing loop-sharing driving method. Efficient cooling and low-voltage fast-response driving of the Pockel's cell are realized. The basic structure of the hybrid-electrode Pockel's cell is a sandwich structure in which a z-cut DKDP crystal is sandwiched between a discharge chamber and a high-reflectivity mirror. Longitudinal electro-optic effect use and longitudinal conduction cooling are adopted. The discharge chamber is used as an electrode at the laser incidence side. The high-reflectivity mirror integrates the functions of a mirror, a heat sink and an electrode. The diameter of the Pockel's cell can be calibrated and amplified. The Pockel's cell can bear high average power density, and can operate at high throughput and at repeated frequency. The Pockel's cell has low driving voltage, and is quick in response. The Pockel's cell is applicable to a high-energy repeated-frequency laser system.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com