TC4 titanium alloy multi-channel valve body laser selective area melting forming method

A laser selective melting, multi-channel technology, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve the problems of valve body deformation and cracking, low material utilization rate, and difficult quality control, etc., to achieve improved performance, Excellent mechanical properties, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

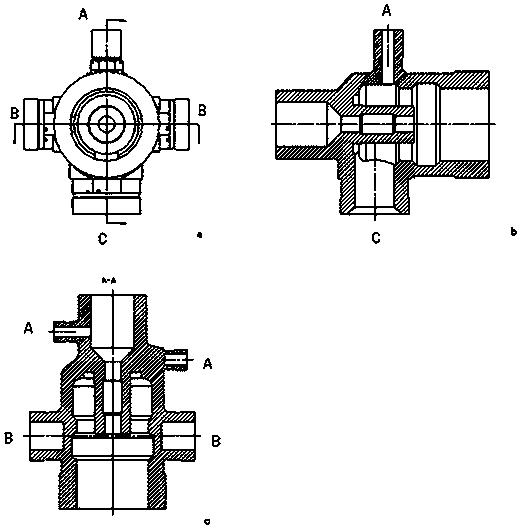

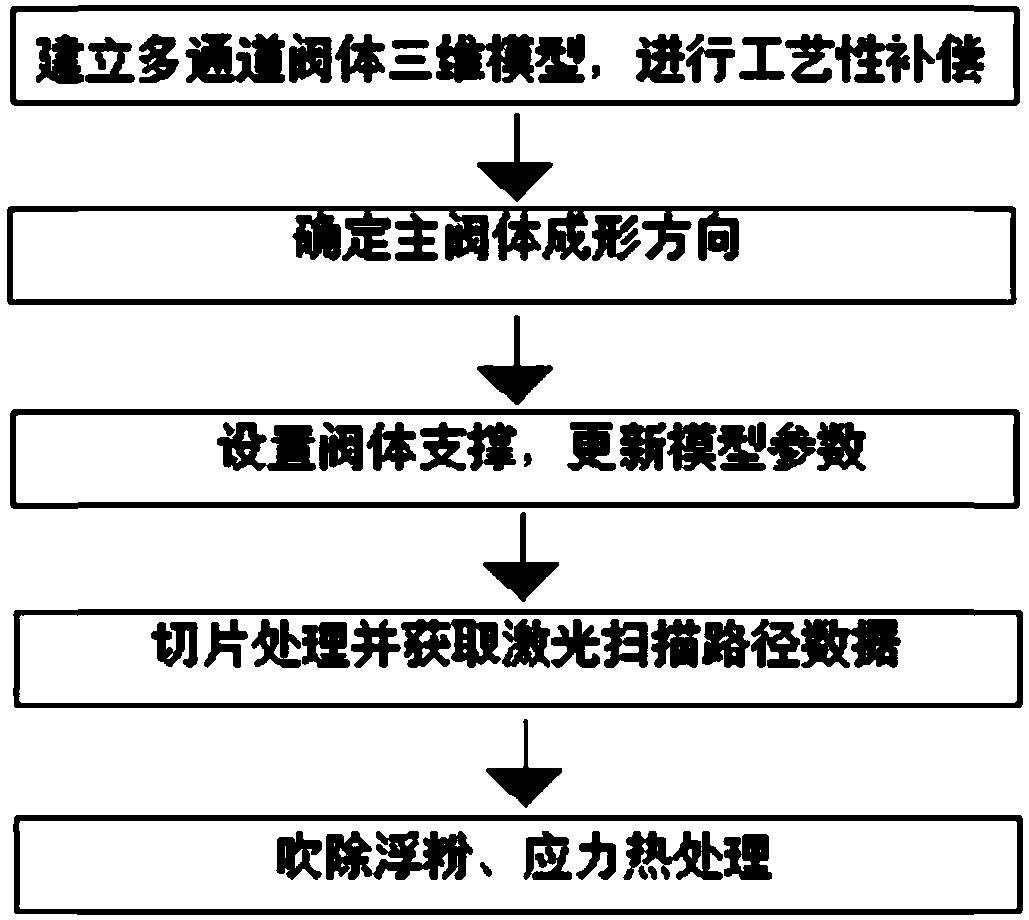

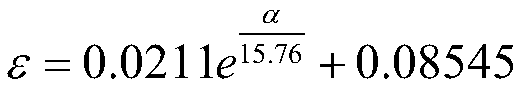

[0030] A TC4 titanium alloy multi-channel valve body laser selective melting forming method, by establishing a three-dimensional model of the multi-channel valve body, and adding process compensation to improve its dimensional accuracy and shape accuracy; In the internal complex stress-strain environment, use the stress / strain simulation results to determine the forming direction, set up special process support, optimize the mitigation of stress concentration, select the processing parameters with the smallest stress and strain, and then obtain the laser scan of each slice layer with the help of slicing software path data, and perform laser selective melting and forming according to the scanning path data, among which, such as figure 2 As shown, the specific steps are as follows:

[0031] (1) According to the task model requirements, the required TC4 titanium alloy multi-channel valve body model parameters are obtained and pre-set, the multi-channel valve body three-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com