Patents

Literature

51results about How to "Realize integrated forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silicon carbide particle-reinforced silicon nitride composite ceramic parts

The invention discloses a method for preparing silicon carbide particle-reinforced silicon nitride composite ceramic parts, and belongs to the technical field of ceramic part preparation. The method comprises the following steps of: mixing SiC powder, Si3N4 powder, a sintering acid and a paraffin base multicomponent binder into a uniform feed; and performing solvent-thermal debinding and presintering at the temperature of between 1,150 and 1,200 DEG C on a preformed blank obtained by injection molding of the feed, and sintering in a vacuum carbon tube furnace at the temperature of between 1,800 and 1,900 DEG C and at the normal pressure in the Ar atmosphere to prepare SiCp / Si3N4 composite ceramic parts. The method for preparing the silicon carbide particle-reinforced silicon nitride composite ceramic parts has the advantages of direct preparation of SiCp / Si3N4 composite ceramic products with complicated geometry, uniform texture, high dimensional accuracy and no need of subsequent processing, achievement of integrated molding of the SiCp / Si3N4 materials and the parts, and establishment of low-cost preparation technology for the SiCp / Si3N4 composite ceramic parts with complicated shapes and high dimensional accuracy.

Owner:UNIV OF SCI & TECH BEIJING

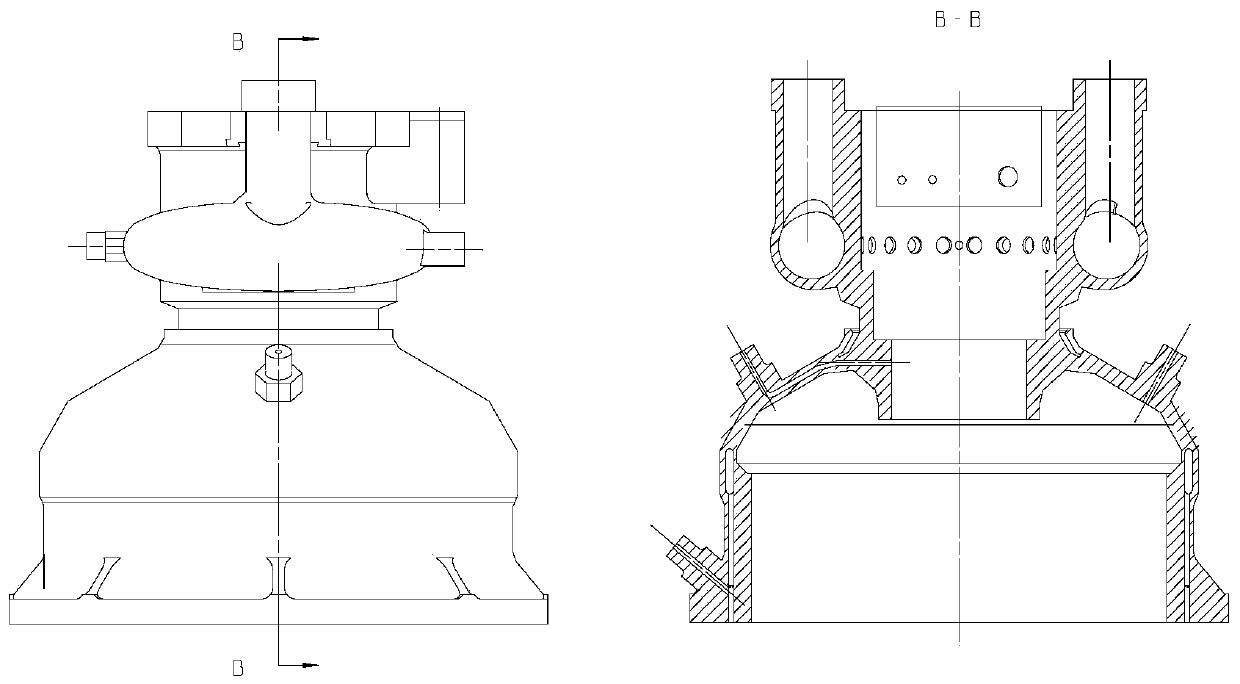

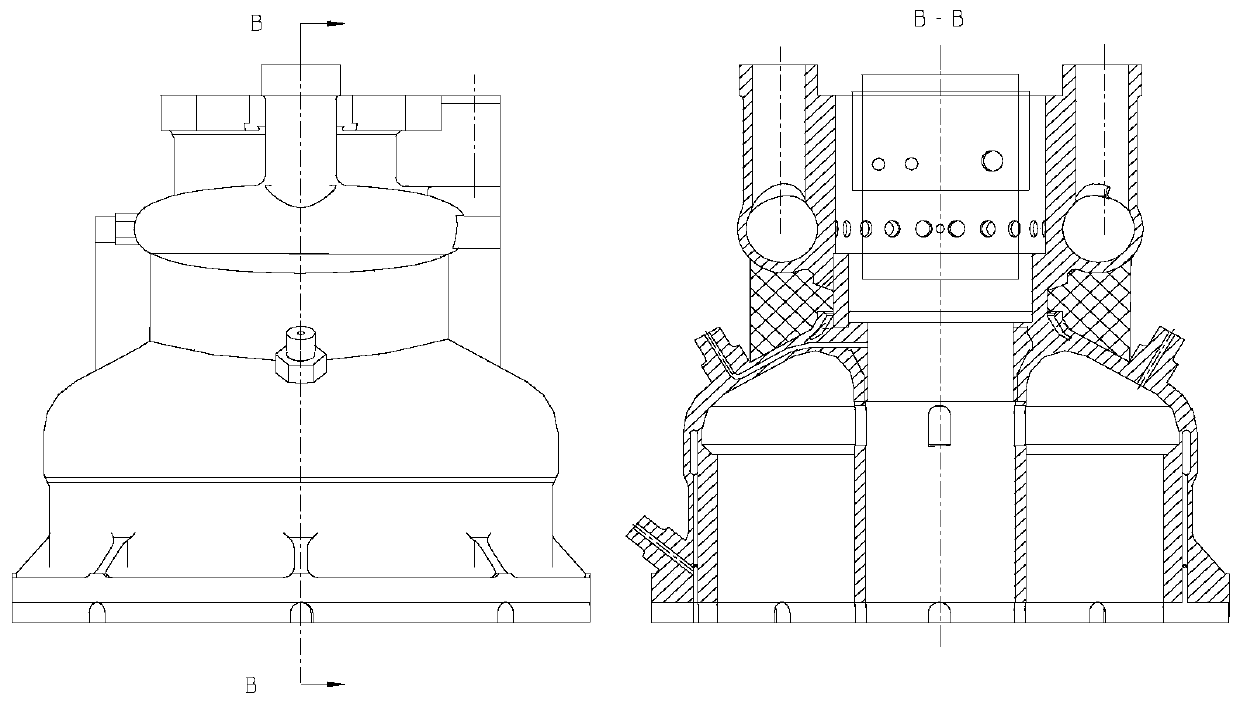

Integrated manufacturing method for pintle type head interlayer shell of airspace engine

InactiveCN111266574AImprove manufacturing quality reliabilityRealize integrated formingAdditive manufacturing apparatusIncreasing energy efficiencyTitanium alloyHeat treated

The invention relates to an integrated manufacturing method for a pintle type head interlayer shell of an airspace engine. A three-dimensional model of the metal shell is set up, and the STL formattedfile of the three-dimensional model is guided into a Magics additive manufacturing auxiliary software platform; according to the structure characteristics of the metal shell, the forming direction and the placement position are confirmed, and a process support is designed and added; TC4 titanium alloy laser selective melting forming processing technological parameters are input slice software, and the model added with the support is subjected to slicing treatment; forming is carried out under protection of inert gas; after forming is finished, floating powder is cleared away, and the shell issubjected to heat treatment; a substrate and the shell are linearly cut and separated, the auxiliary support is removed, and finishing and grinding are carried out; and the shell is subjected to surface treatment. By means of the method, the pintle type head interlayer shell of the airspace engine are designed and manufactured according to the additive manufacturing process technology, a shell component is integrally manufactured through the metal additive manufacturing method, and the manufacturing quality reliability of the pintle type head interlayer shell of the airspace engine is improved.

Owner:XIAN SPACE ENGINE CO LTD

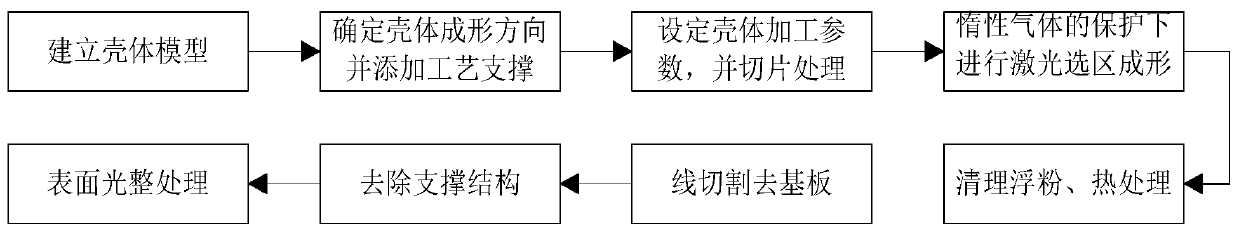

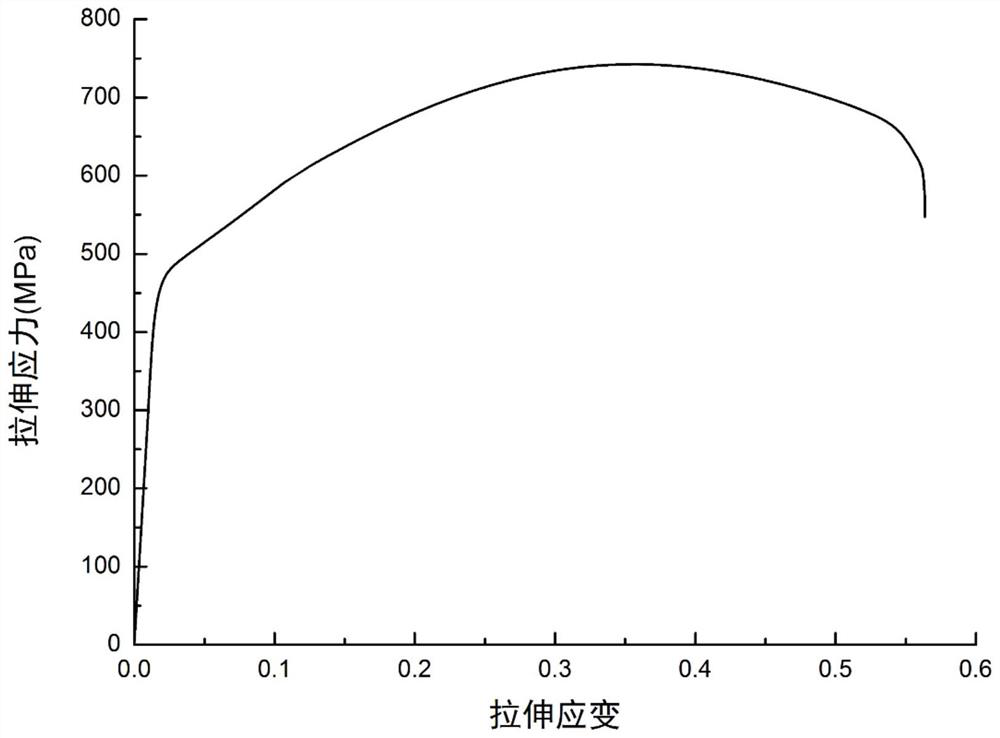

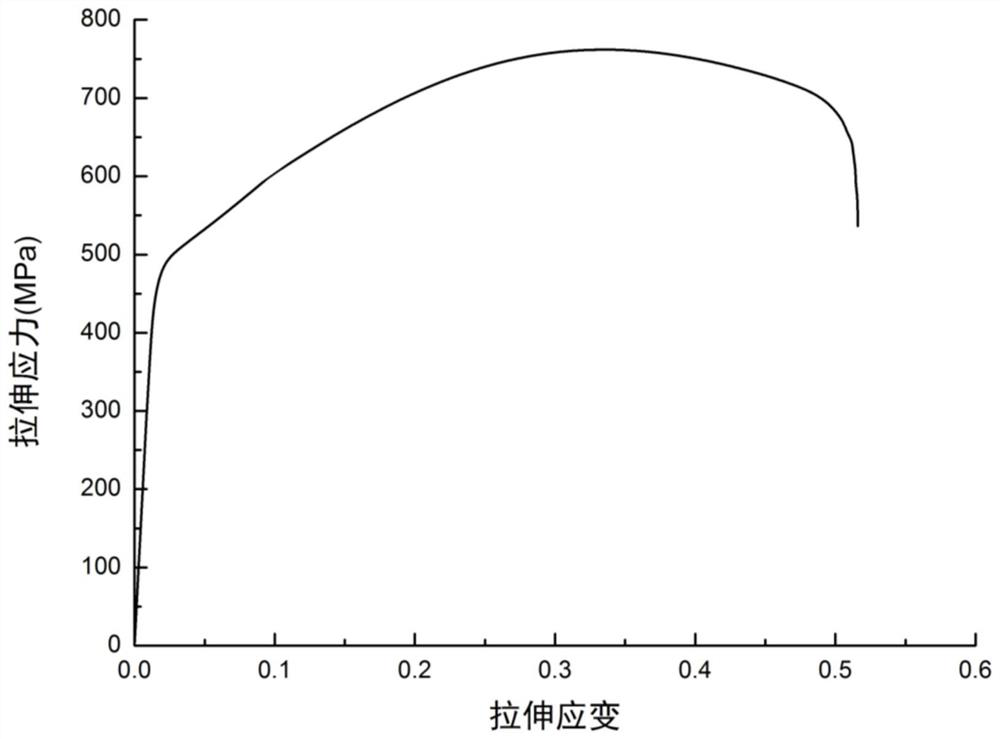

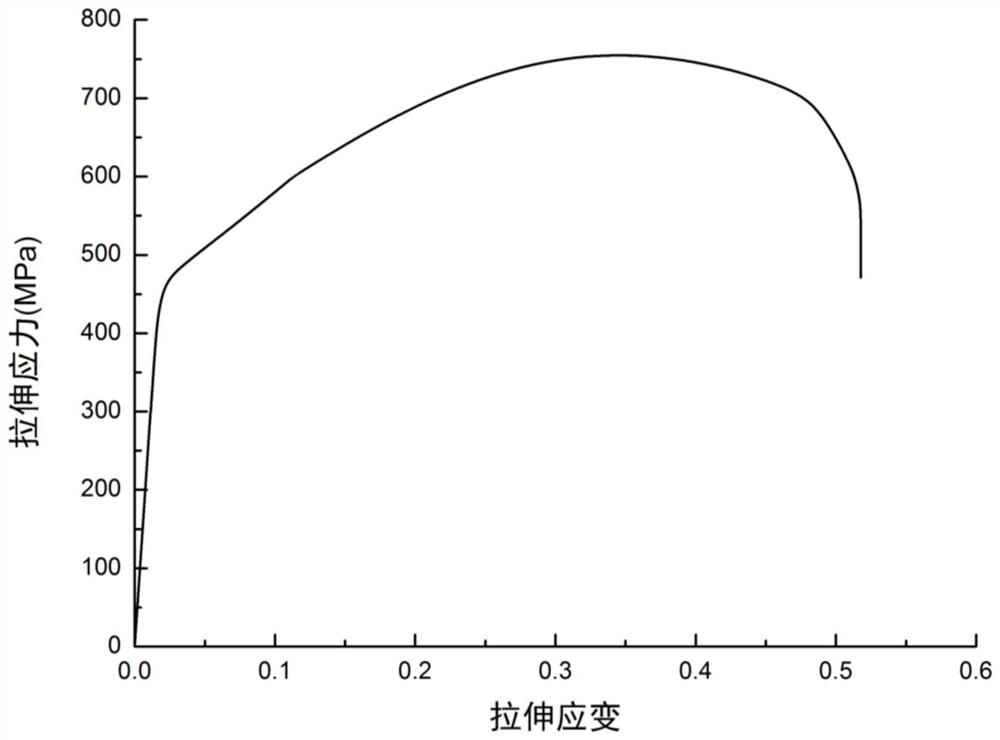

Technique for integrally and quickly forming special shaped rudder shaft of aircraft

ActiveCN108127117AIncrease profitShorten the production cycleAdditive manufacturing apparatusTransportation and packagingSelective laser meltingManufacturing technology

The invention belongs to the field of superalloy additive manufacturing, and particularly relates to a technique for integrally and quickly forming an special-shaped rudder shaft of an aircraft. An overall special-shaped rudder shaft structure formed by selective laser melting fully utilizes the characteristics of high flexibility and rapid response of an additive manufacturing technology. By means of a reasonable process supporting structure and a placement position, the integrated forming of the special-shaped rudder shaft is achieved. A selective laser melting forming process is rapid in solidification, grains of an alloy structure are refined, and the strength and plasticity of parts far exceed a traditional manufacturing process; secondly, the rapid forming method simplifies production process and improves production efficiency. Compared with the traditional manufacturing process, production cycle for rapid forming of the single-piece rudder shaft is shortened by 50%, the utilization rate of materials is increased by 30%, the processing cost is reduced by 30%, and model development demands are effectively ensured.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

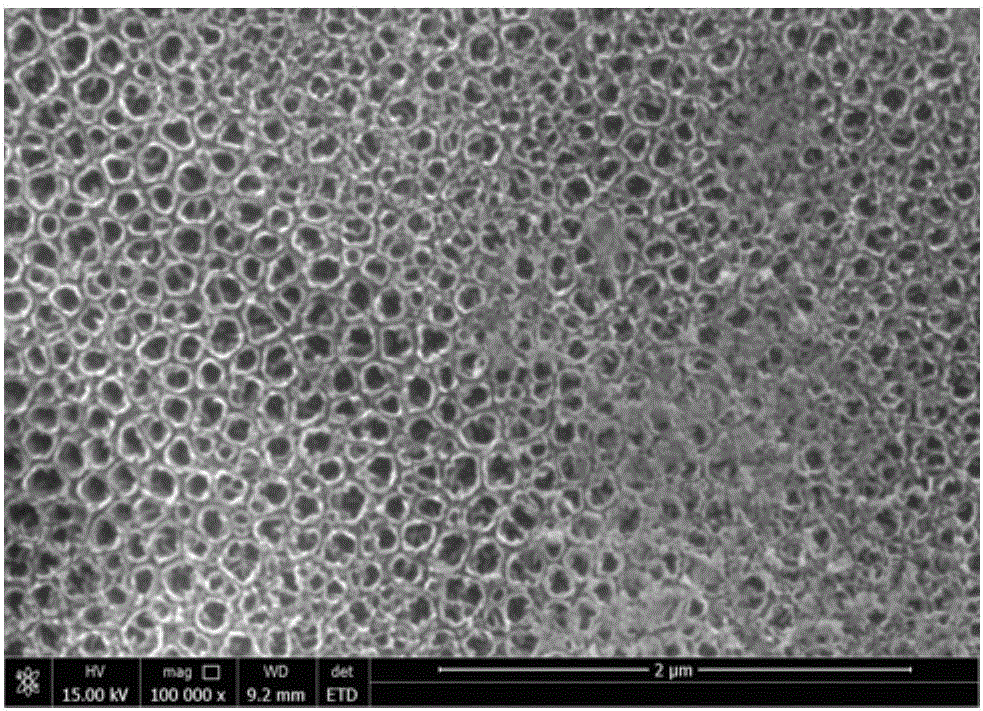

Method for forming high-anti-bacterial-performance titanium-alloy artificial hip joint

ActiveCN106420119AMeeting the Hip Performance Needs Needed for ReplacementRealize integrated formingAdditive manufacturing apparatusSurface reaction electrolytic coatingMicro nanoTitanium alloy

The invention discloses a method for forming a high-anti-bacterial-performance titanium-alloy artificial hip joint. The method includes the following technological steps that (1) CT scanning and layered slicing processing of a patient hip joint data model are carried out; (2) titanium-copper alloy powder is designed and prepared; (3) laser 3D printing forming of a titanium-alloy artificial hip joint is carried out; (4), a titanium-alloy artificial hip joint with micro-nano-size porous structure surface is constructed in situ with the anodic oxidation technology; (5) the anti-bacterial performance of the titanium-alloy artificial hip joint is further improved with the plasma high-temperature nitridation technology; (6) cleaning, sterilizing and drying are carried out, and then packaging is carried out. According to the method, the complex structure and the high anti-bacterial function of the artificial hip joint are integrally manufactured in sufficient cooperation with the laser 3D printing technology, the surface modification technology and the excellent anti-bacterial performance of copper elements. The forming method is simple, outstanding in performance, suitable for personalized customization of the high-anti-bacterial-performance titanium-alloy artificial hip joint, and has good social benefits and economic benefits.

Owner:金湖县综合检验检测中心

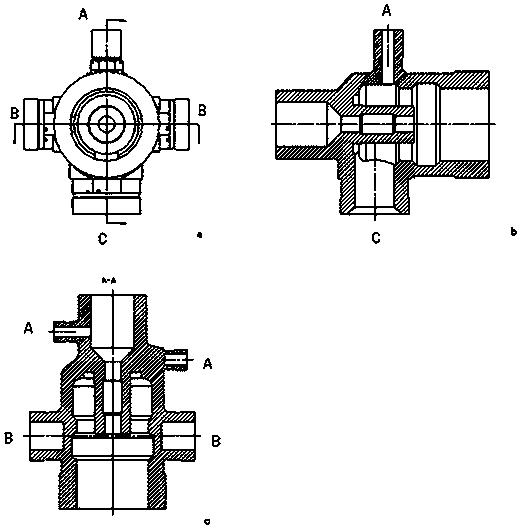

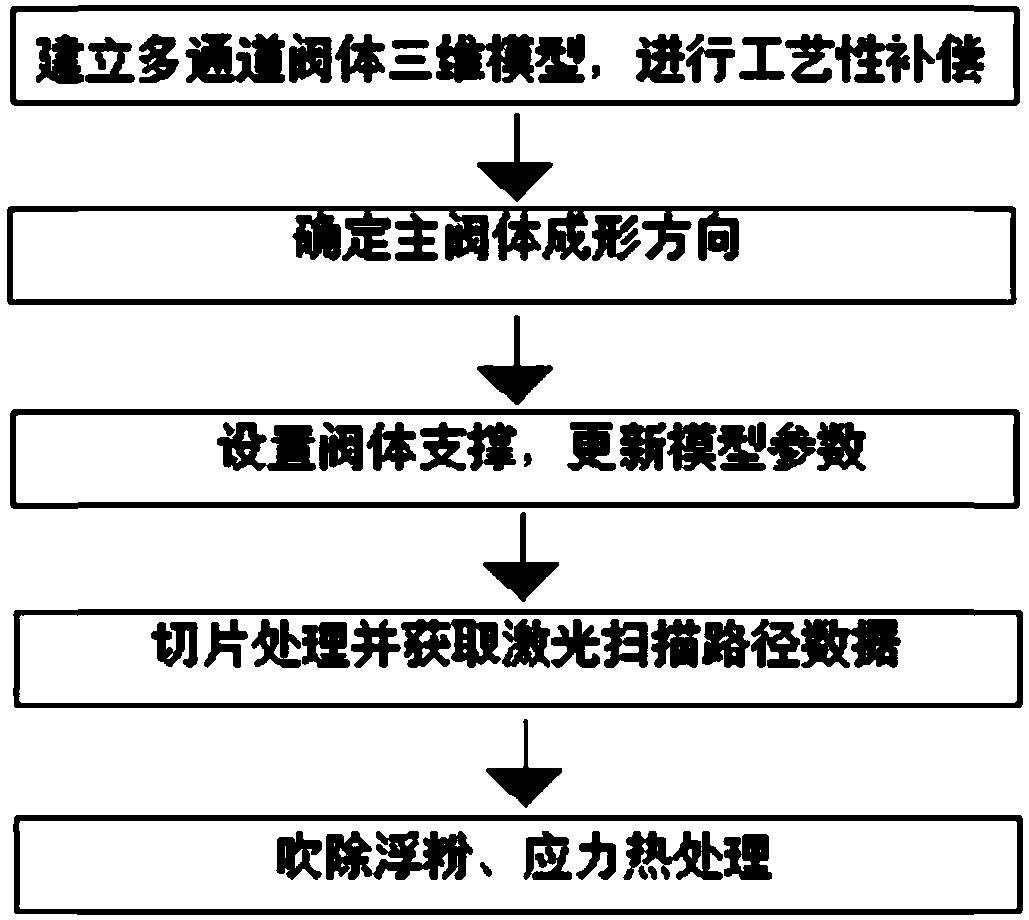

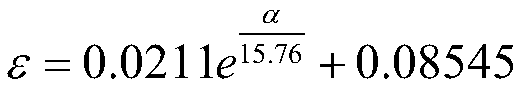

TC4 titanium alloy multi-channel valve body laser selective area melting forming method

ActiveCN109530694ARealize integrated formingEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationProcess support

The invention discloses a TC4 titanium alloy multi-channel valve body laser selective area melting forming method. A multi-channel valve body three-dimensional model is established, manufacturabilitycompensation is added, and the size precision and the shape precision are improved; meanwhile, the valve body character and a complex stress and strain environment formed in the valve body in the forming process are aimed, a stress / strain simulation result is utilized, and the forming direction is determined, a specially-made process support is arranged, alleviating the stress concentration phenomenon is optimized, and machining parameters with the minimum stress strain are selected; and then laser scanning path data of each slice layer are obtained by means of slicing software, and laser selective area melting forming is carried out according to the scanning path data; and finally, after the valve body removes floating powder and is subjected to thermal stress treatment, a substrate plateof the valve body is separated, and the problem that the size precision of the forming valve body is low by utilizing the laser selective area melting forming technology is solved.

Owner:XIAN SPACE ENGINE CO LTD

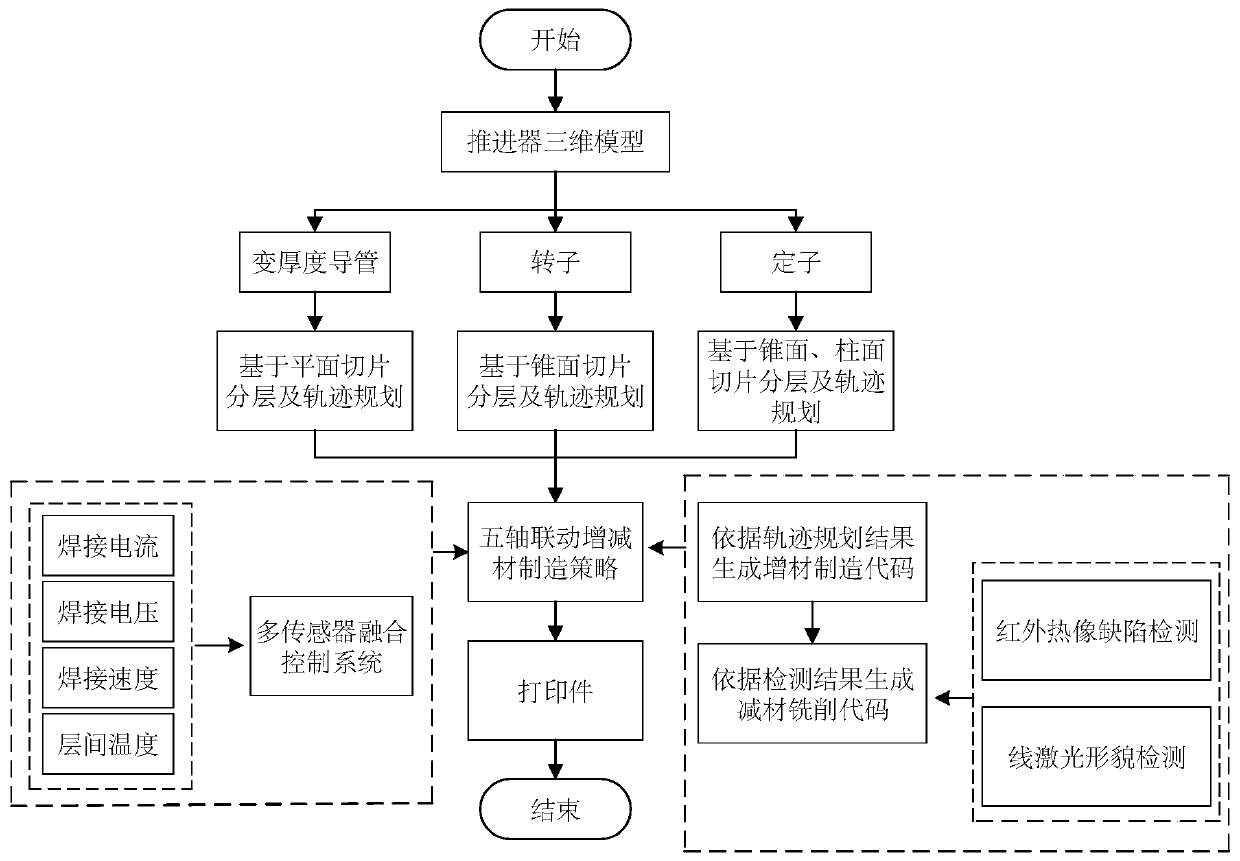

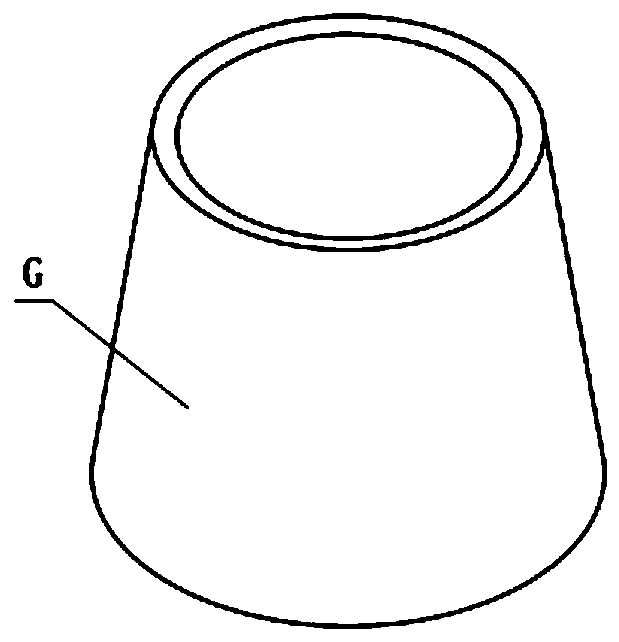

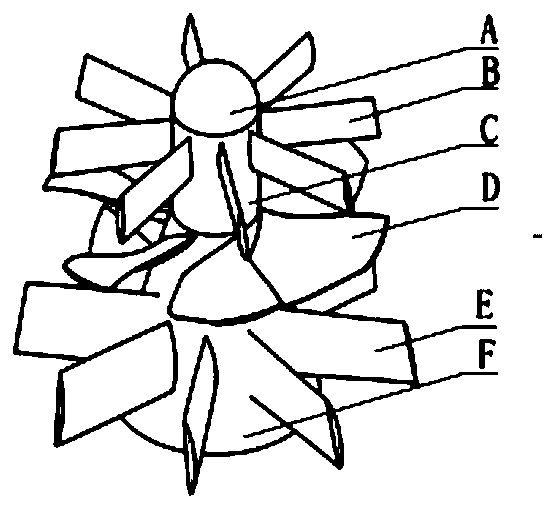

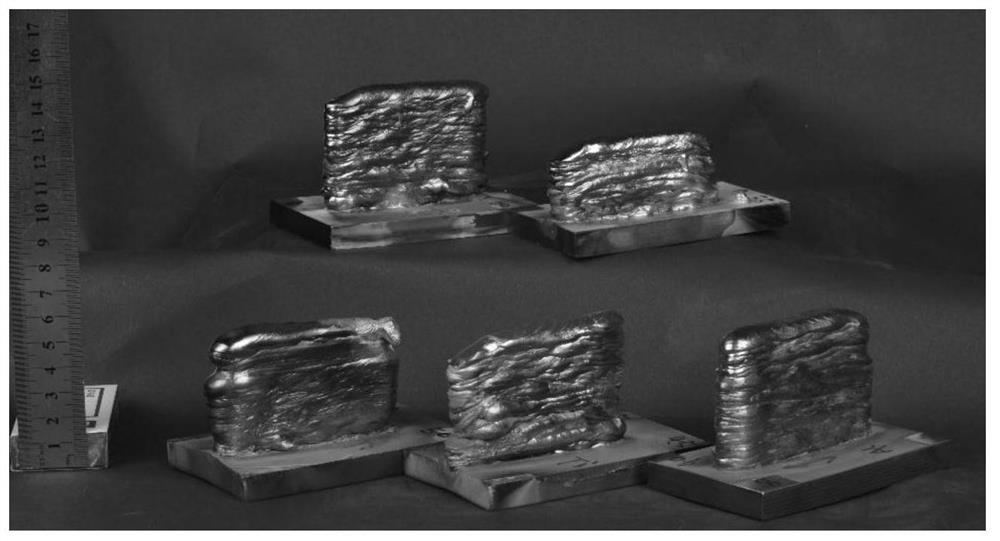

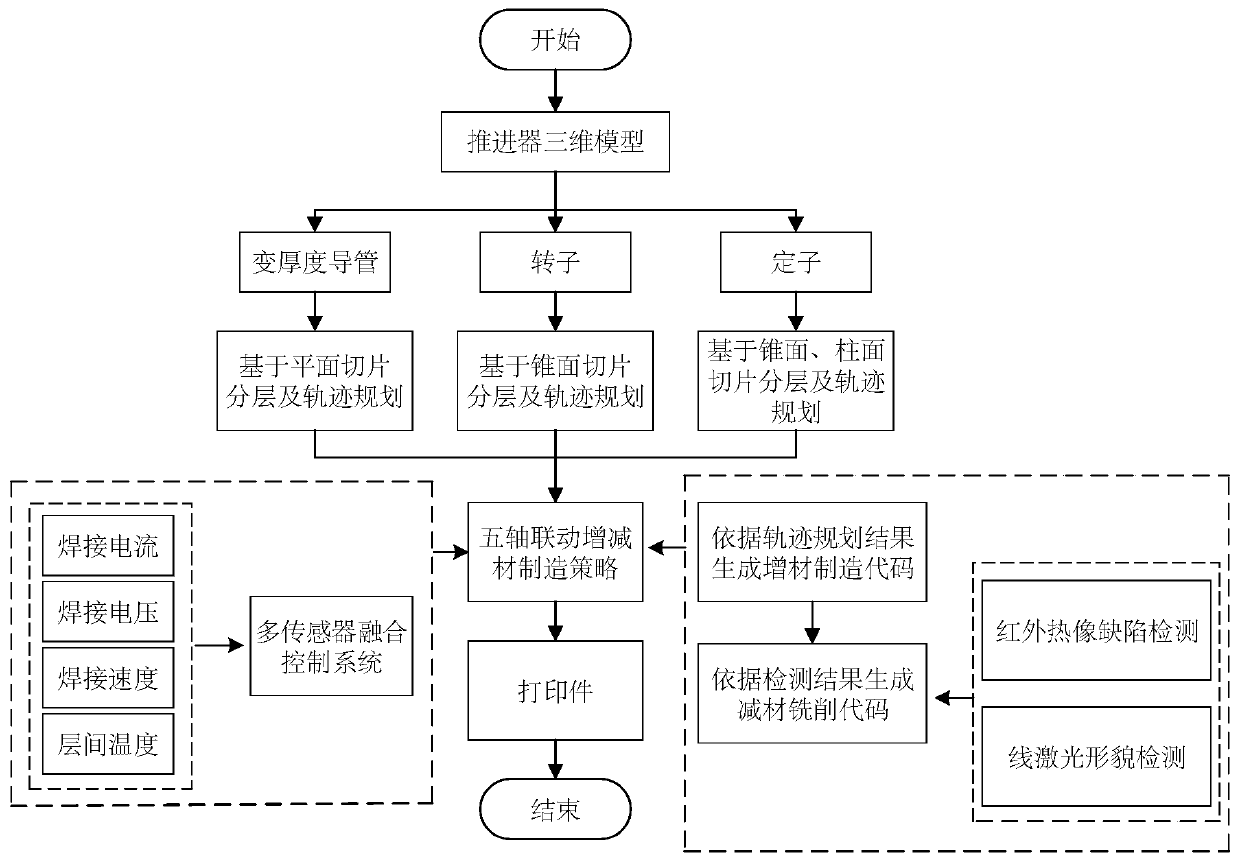

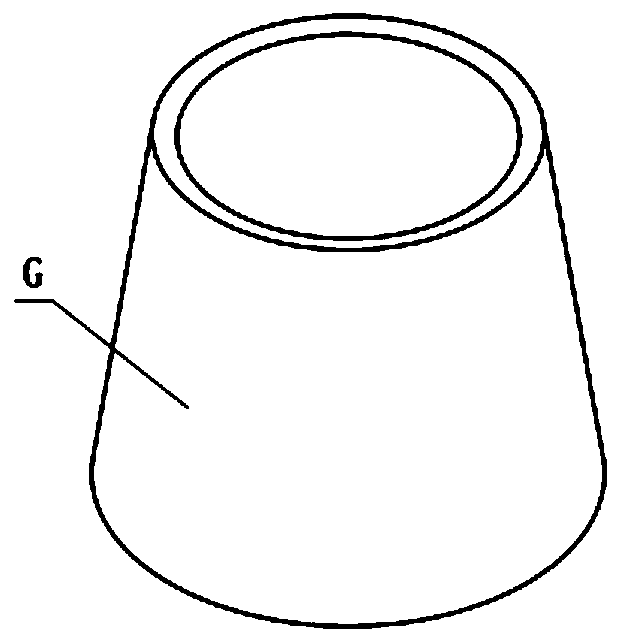

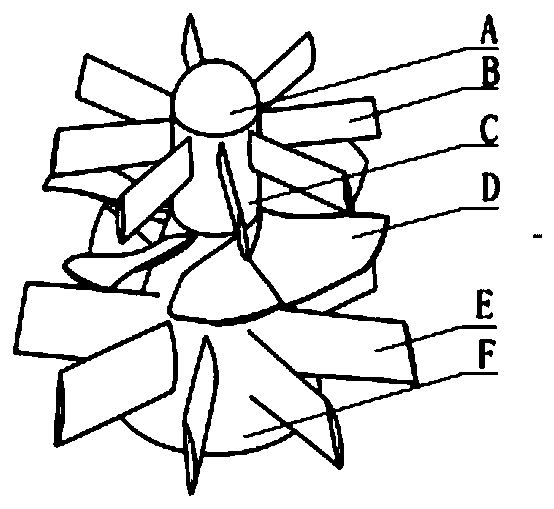

Electric arc additive and subtractive composite integrated manufacturing method of thruster model

ActiveCN110000381AReduce energy consumptionReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencyWaste productEngineering

The invention belongs to the field of electric arc additive manufacturing, and discloses an electric arc additive and subtractive composite integrated manufacturing method of a thruster model. The method comprises the steps of (a) dividing the thruster model into three parts, slicing and layering the three parts, and planning a filling trajectory of each slicing layer, wherein the slicing directions of a rotor and a stator are along the outer normal direction of a spindle, each slicing layer forms a slicing contour on the spindle, a filling trajectory is planned in each slicing contour, and obtaining the filling trajectory of each slicing layer; (b) molding the spindle; and (c) molding the rotor and the stator. In the project for layer-by-layer processing the slicing layers, the slicing layers are detected in real time through infrared thermography defect detecting and line laser appearance detecting, so that additive and subtractive composite integrated manufacturing is realized. Through the electric arc additive and subtractive composite integrated manufacturing method of the thruster model provided by the invention, the irreversible loss caused since waste products are detectedafter parts are printed is avoided, the energy and raw material consumption is reduced, and the manufacturing period is shortened.

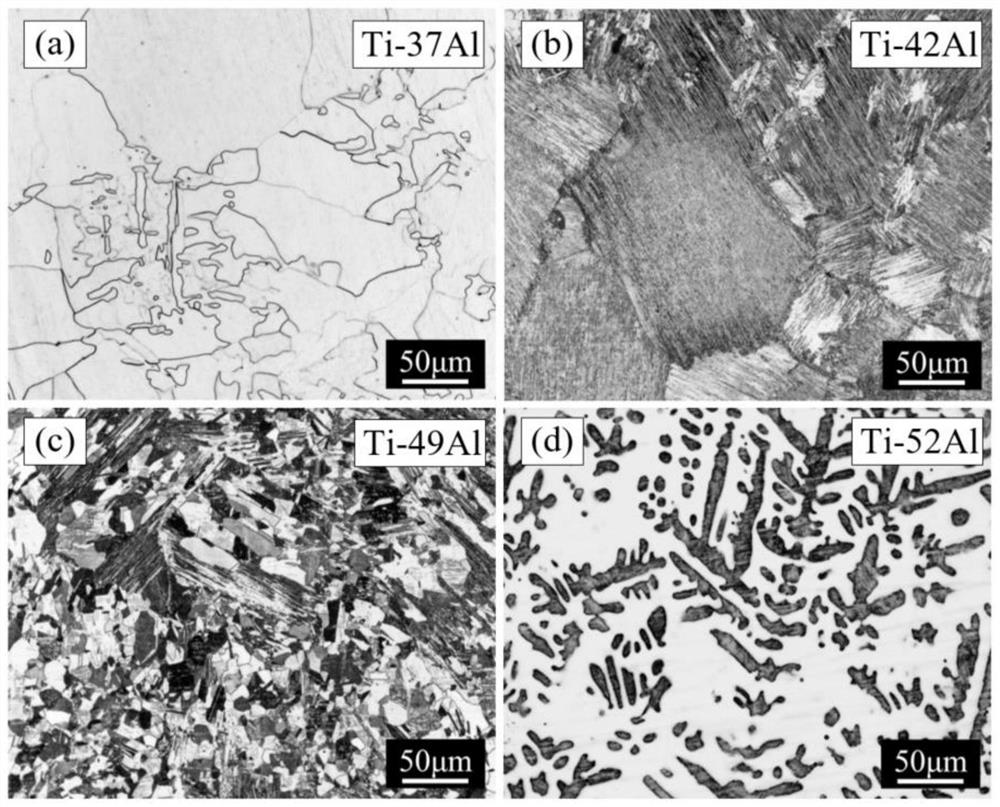

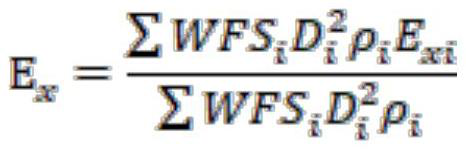

Method for preparing titanium-aluminum intermetallic compound based on electron beam twin-wire fuse in-situ additive

ActiveCN112139649ARealize integrated formingAchieve preparationAdditive manufacturing apparatusIncreasing energy efficiencyTitaniumAluminum metal

The invention discloses a method for preparing a titanium-aluminum intermetallic compound based on an electron beam twin-wire fuse in-situ additive. The method comprises the steps of 1, early-stage preparation, 2, in-situ additive manufacturing and 3, additive component cooling. In the step 3, a titanium-aluminum intermetallic compound component of the in-situ additive is placed in a vacuum environment for cooling until the titanium-aluminum intermetallic compound component is cooled to the room temperature. According to the method, a fuse wire additive mode is adopted, so that the integratedforming of materials is achieved; and due to the fact that the machining efficiency is high, large components can be manufactured. According to the method, the problems that the TiAl intermetallic compound has poor room-temperature plasticity and cannot be used for preparing wire material are solved; and a double-wire feeding method is provided, so that the titanium-aluminum intermetallic compoundwith a specific component proportion is obtained by controlling the wire feeding speed. According to the method, the electron beam fuse wire additive is carried out in a vacuum environment, the highenergy density of the electron beam can achieve an obvious purification effect, and the influence of impurity elements on the material performance is avoided.

Owner:NANJING UNIV OF SCI & TECH

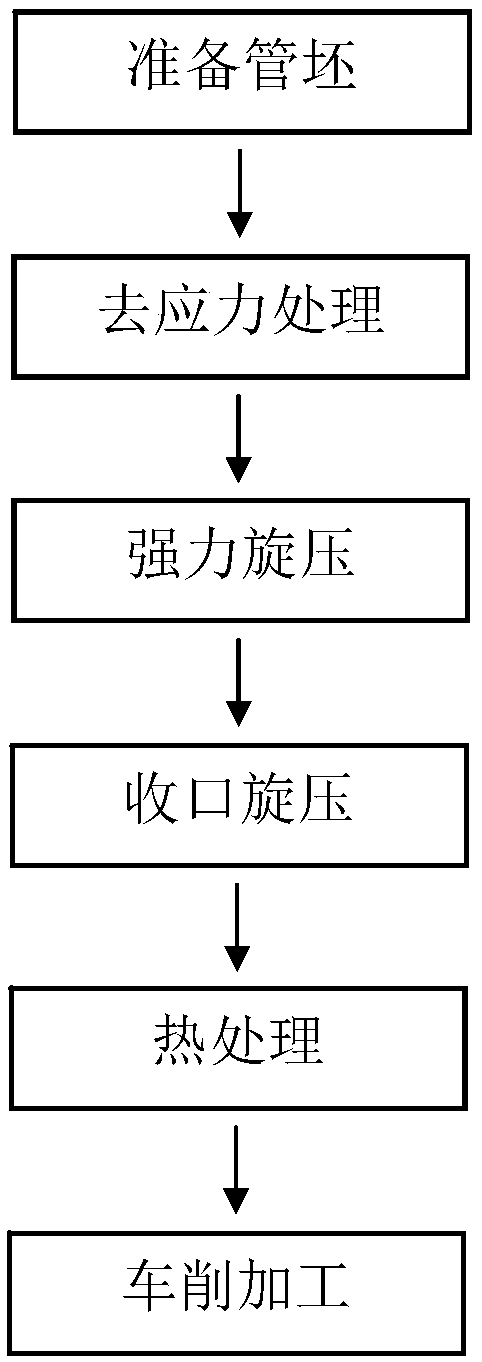

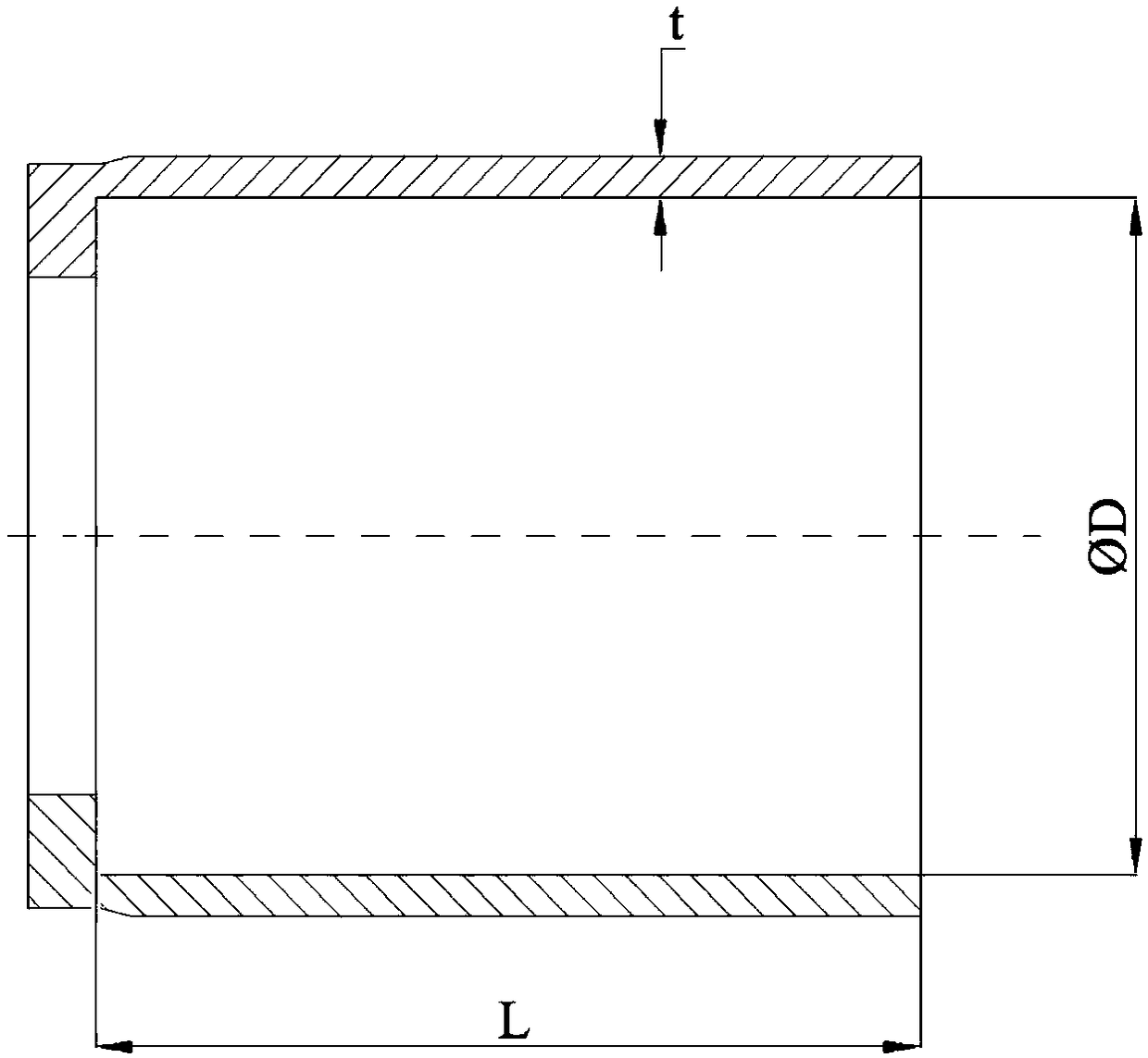

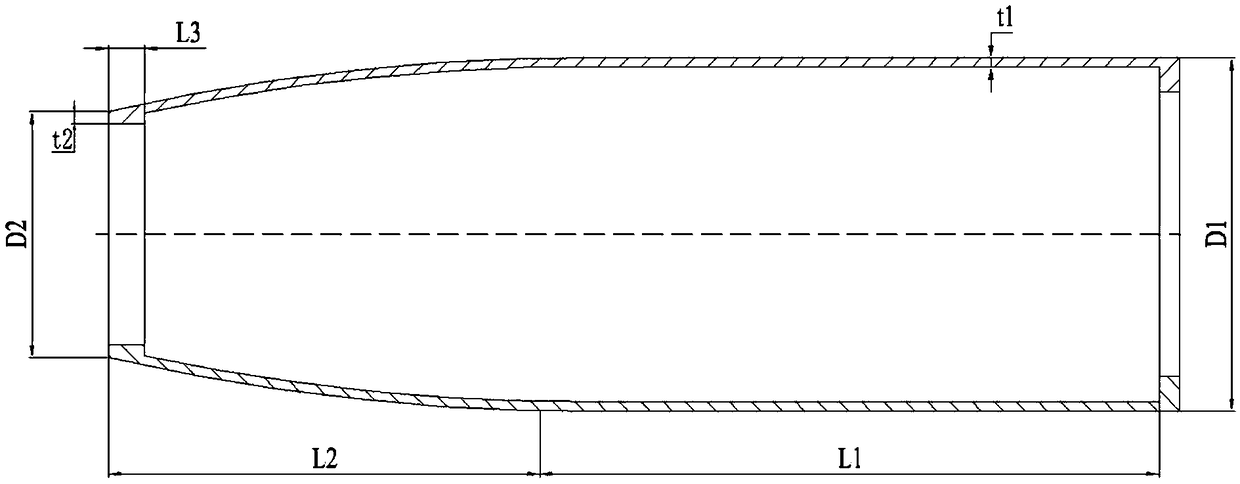

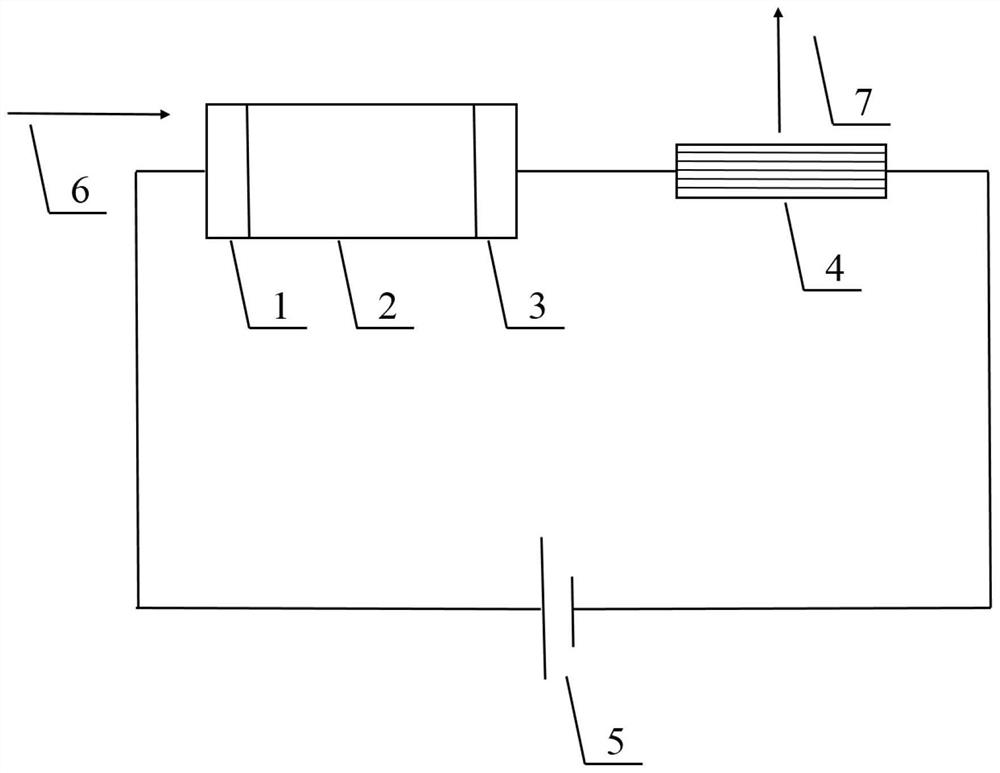

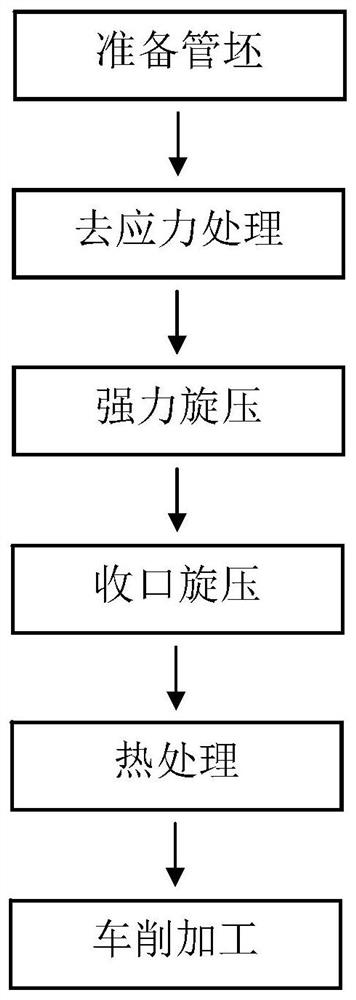

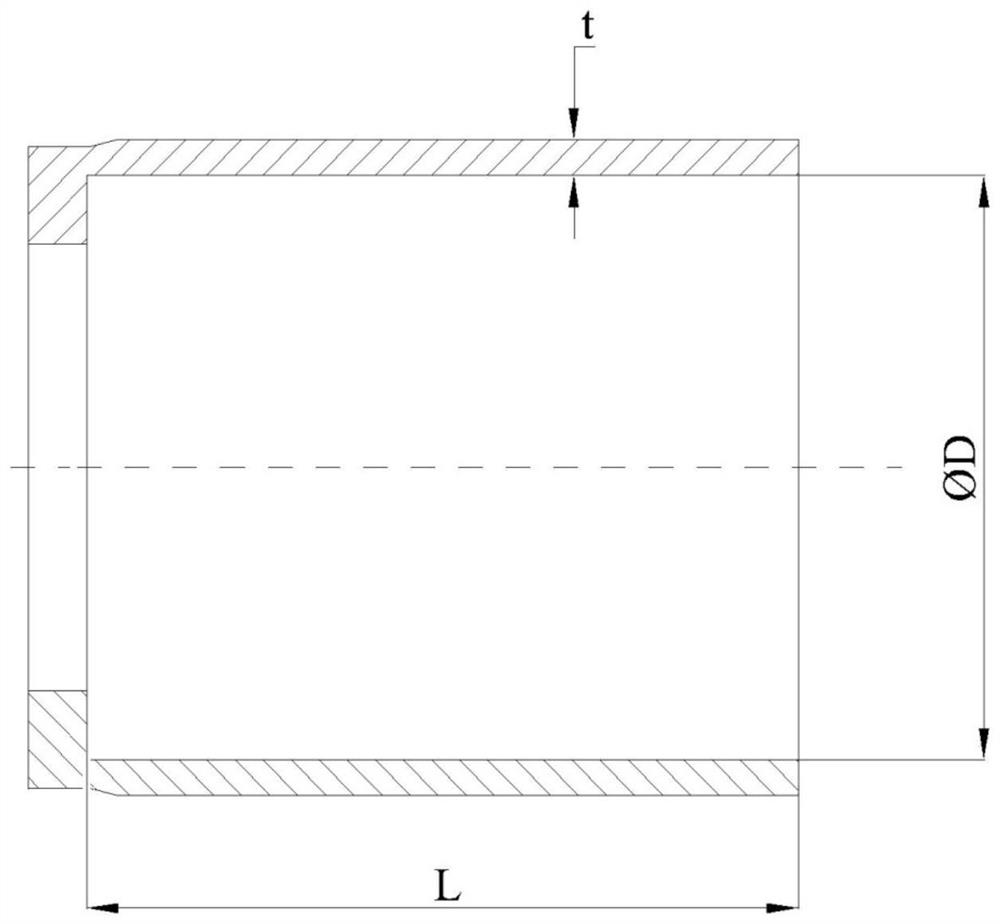

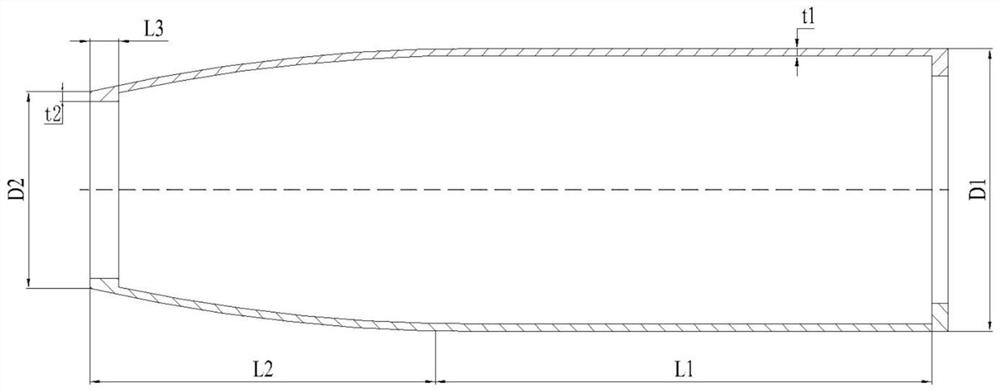

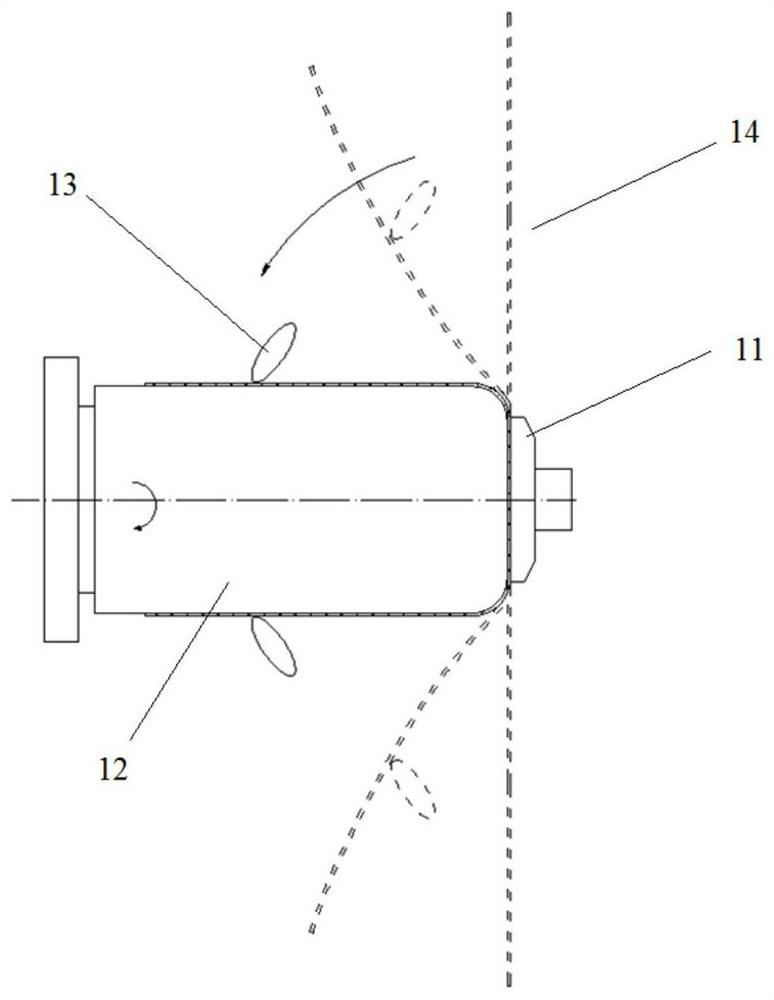

Integral spinning forming method for curved generatrix thin-walled shell with annular reinforcing ribs

The invention provides an integral spinning forming method for a curved generatrix thin-walled shell with annular reinforcing ribs. A tube blank is machined into the shell through the forming method.The shell comprises a curved generatrix tube section and a straight tube section. The curved generatrix tube section is provided with the annular reinforcing ribs. The forming method comprises the following steps that (1) the tube blank is prepared; (2) stress relief treatment is conducted; (3) power spinning is conducted, specifically, (3.1) the initial spinning position and the final spinning position of the tube blank are determined, (3.2) the number of times of power spinning is determined, and design of a power spinning track is completed, (3.3) the tube blank is mounted, (3.4) a power spinning program based on the power spinning track is designed, and the power spinning program is started for power spinning until the pass of power spinning is completed, and (3.5) the step 3.4 if repeated, after several times of power spinning, the power spinning forming process is completed, and a semi-finished tube blank with stagewise thicknesses is obtained; and (4) closing and spinning are conducted. Through the technical scheme, costs such as mold input and maintenance are greatly reduced, and the production cost is lowered.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

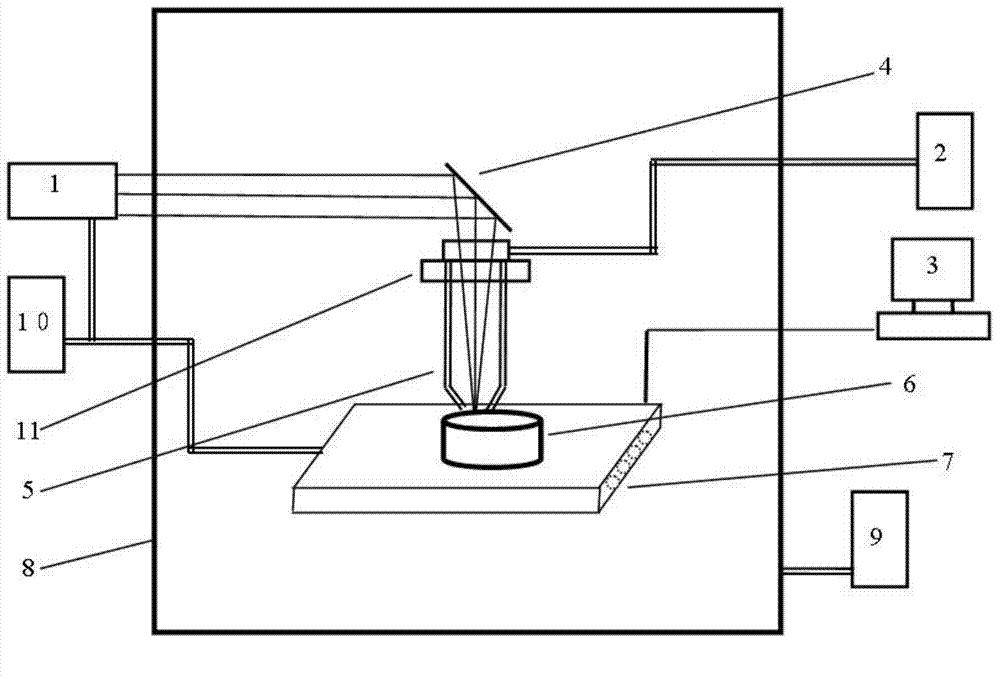

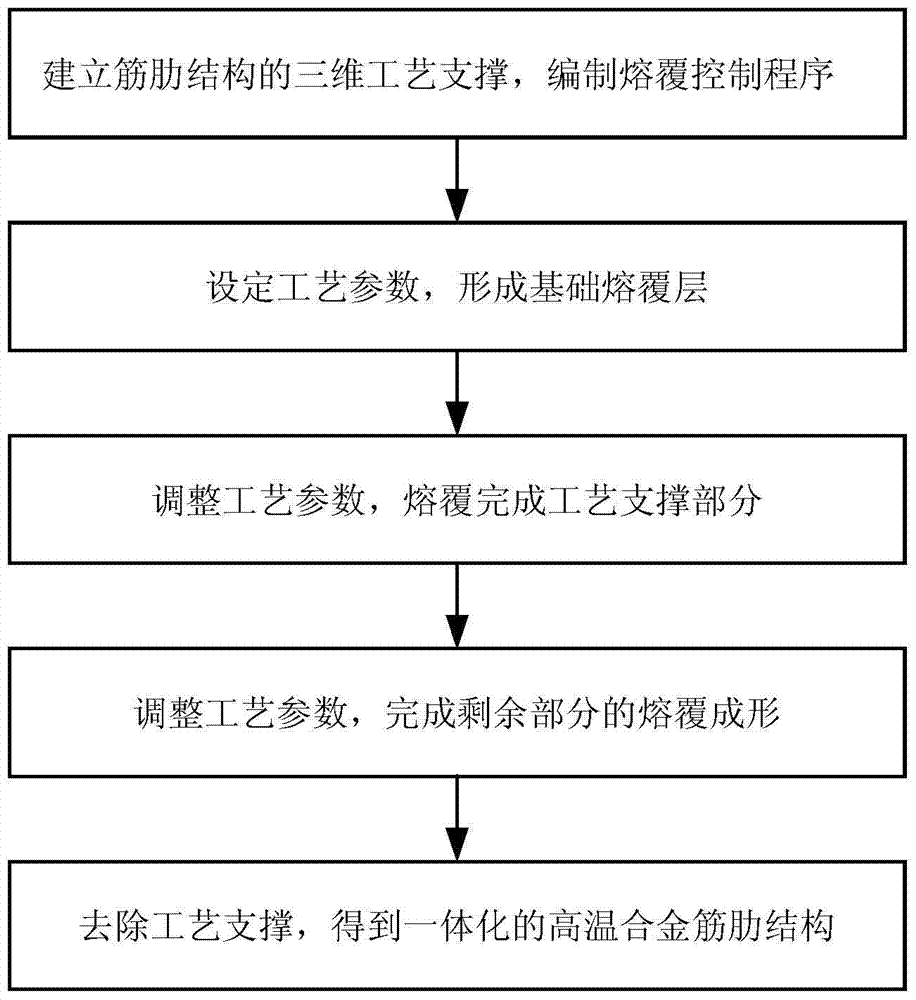

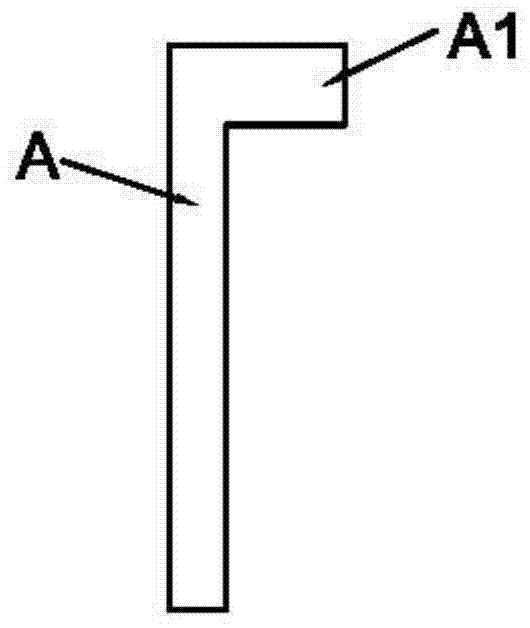

High-temperature alloy rib structure laser solid forming method

ActiveCN103498141AHigh strengthIncrease stiffnessMetallic material coating processesProcess supportSuperalloy

The invention relates to a high-temperature alloy rib structure laser solid forming method. According to the method, a rib structure three-dimensional model is constructed, three-dimensional process support is designed according to the place of the rib structure; the model is split, and a cladding control program is programmed. When forming is carried out, cladding forming of the process support part is first carried out on a part on which the rib structure is required to be formed; forming process parameters are adjusted; uniform and stable forming of the rib structure part is carried out; and the process support is removed, such that an integral high-temperature alloy rib structure is obtained. With the method provided by the invention, high-temperature alloy structural parts with rib structures such as lugs and bosses can be integrally manufactured. The invention establishes a basis for realizing engineering in the field of rapid manufacturing.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

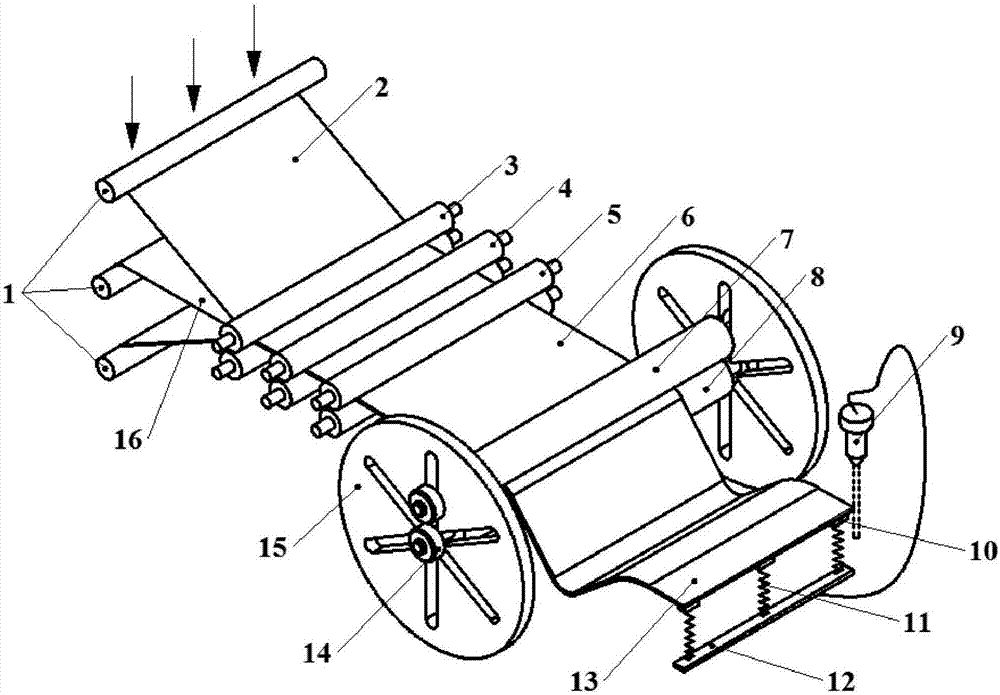

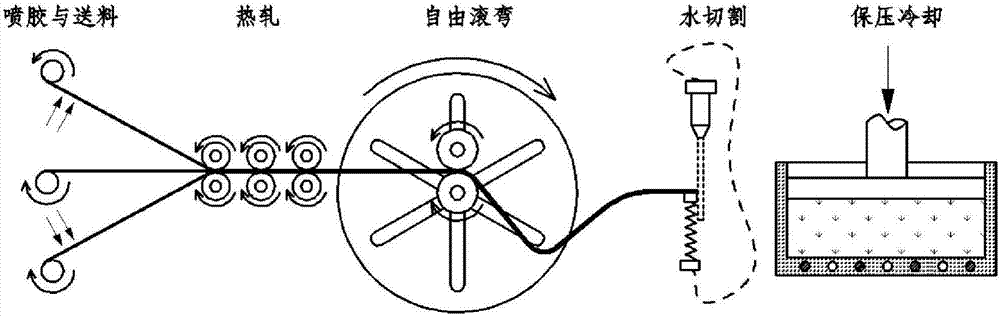

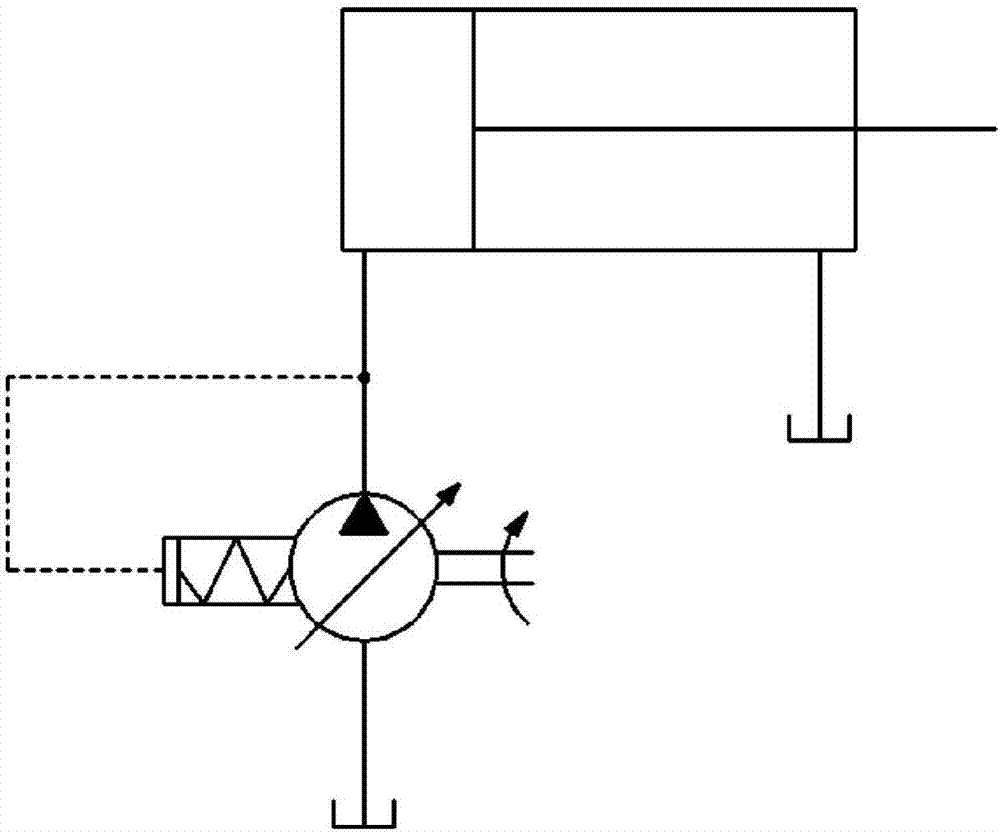

Free roll bending equipment for super-hybrid composite layer plates and forming method

ActiveCN107379572AReduce manufacturing costShorten production timeMetal working apparatusRoom temperatureResin-Based Composite

The invention discloses a free roll bending equipment for super-hybrid composite layer plates and a forming method. The super-hybrid composite layer plates are of lamination structures of metal layers and fiber reinforced resin base composites, and the forming method comprises six procedures, namely spraying glue and feeding, hot rolling, free roll bending, water cutting and pressure maintaining cooling; the free roll bending operation is achieved by rotating of a bending roll shaft and revolving around an fixing roll shaft of the bending roll shaft, the bending curvature is determined by the radius of the fixing roll shaft, and the bending angle is determined by the revolution angle of the bending roll shaft; and after an bending component is subjected to free roll bending, the bending component is placed in a closed container with a constant pressure to conduct heat insulation and is cooled to a room temperature. According to the free roll bending equipment for the super-hybrid composite layer plates and the forming method, preparation and bending formation of the super-hybrid composite layer plates are integrated, manufacturing cost and time is reduced by a large margin, and the free roll bending equipment for the super-hybrid composite layer plates and the forming method have the advantages of being high in interlayer combination strength, high in forming precision, high in degree of automation and high in designability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

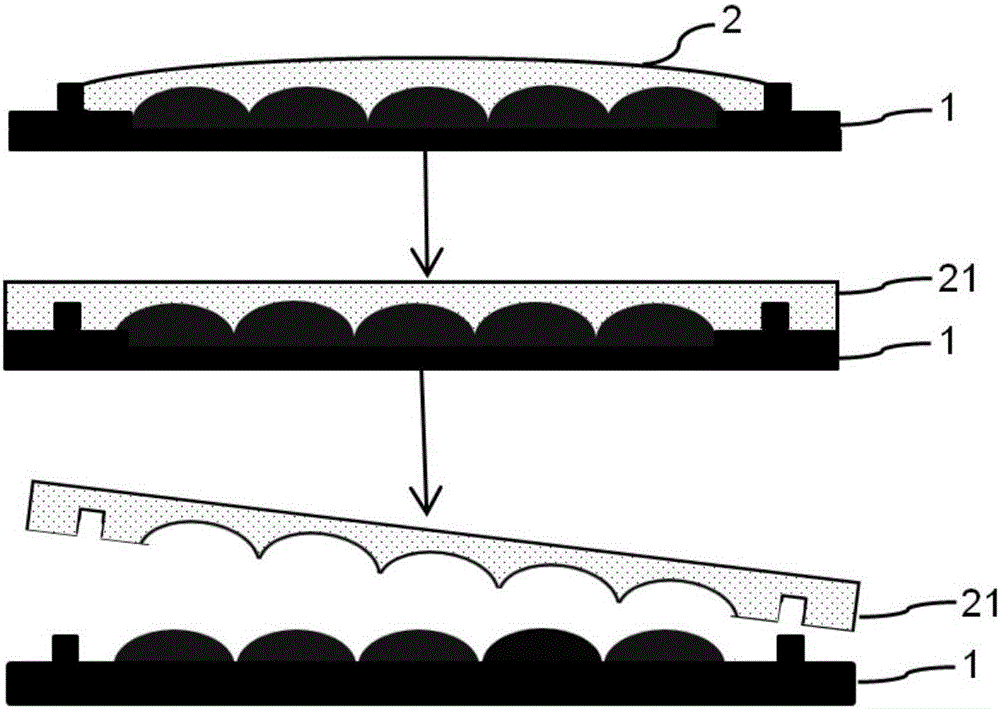

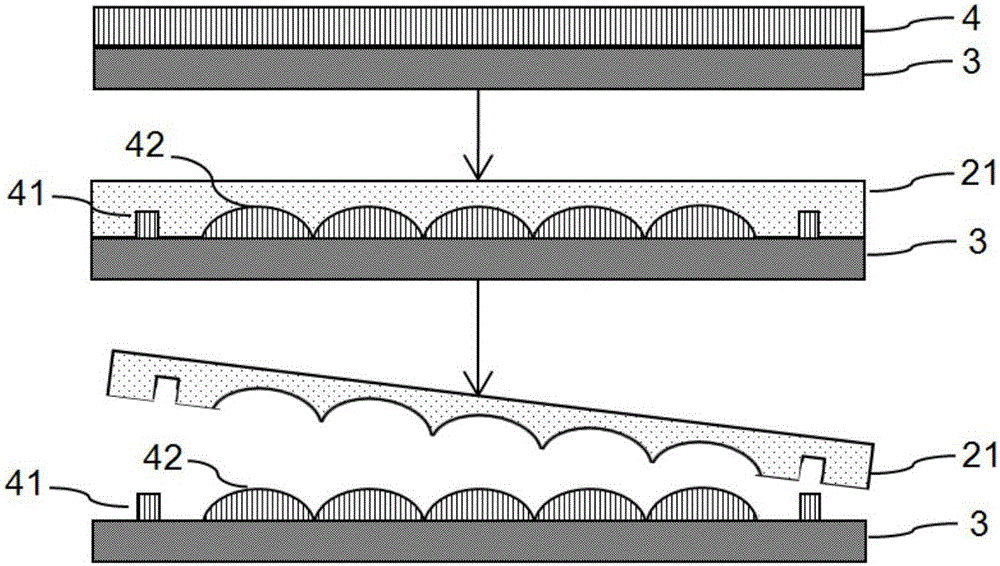

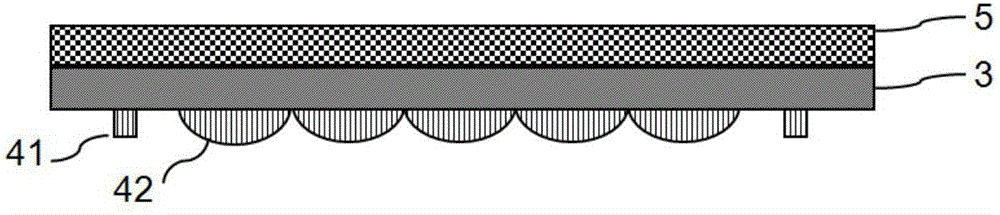

Method for forming naked eye three-dimensional display film device through double-sided alignment

InactiveCN106842815ARealize integrated formingImprove alignment accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusComputer sciencePhotoresist

The invention discloses a method for forming a naked eye three-dimensional display film device through double-sided alignment and relates to the fields of micro machining and image display. The method comprises the following main steps: (1) realizing the preparation for a flexible pressing template with an imaging structure; (2) selecting a base material according to the requirement for a three-dimensional display film device; (3) coating a layer of pressing glue on the surface of the base material, and transferring the structure information on the pressing template to the pressing glue; (4) preparing a layer of colorful material on the other side of the base material; (5) coating a photoresist on the colorful material, performing double-sided alignment exposure on an aligning mark on a mask plate with image information and a mark on a pressing glue structure, utilizing the mask plate to expose the photoresist, and acquiring a photoresist pattern layer through developing and hardening processes; and (6) finally, by adopting an etching mode, etching the pattern layer on the photoresist and transferring to the colorful material layer, thereby forming an integrated three-dimensional display film device.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

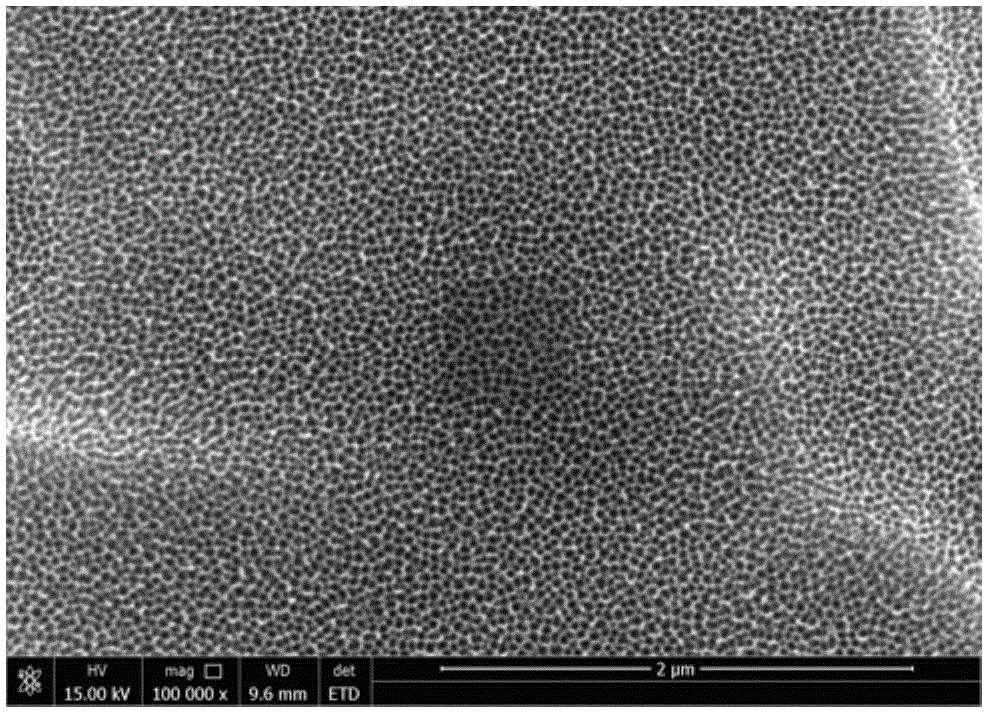

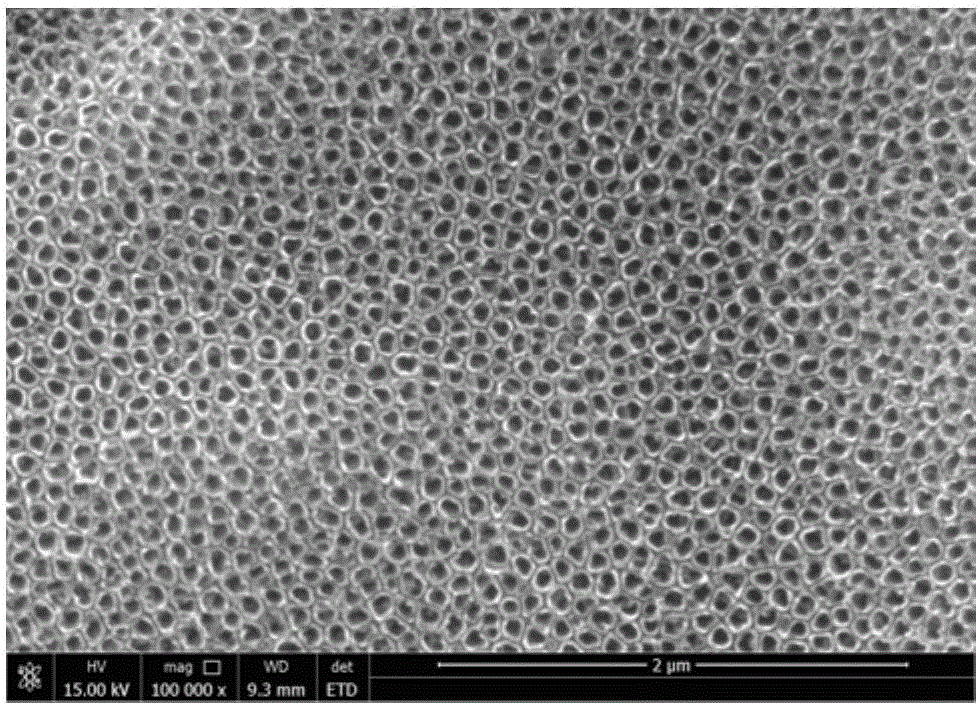

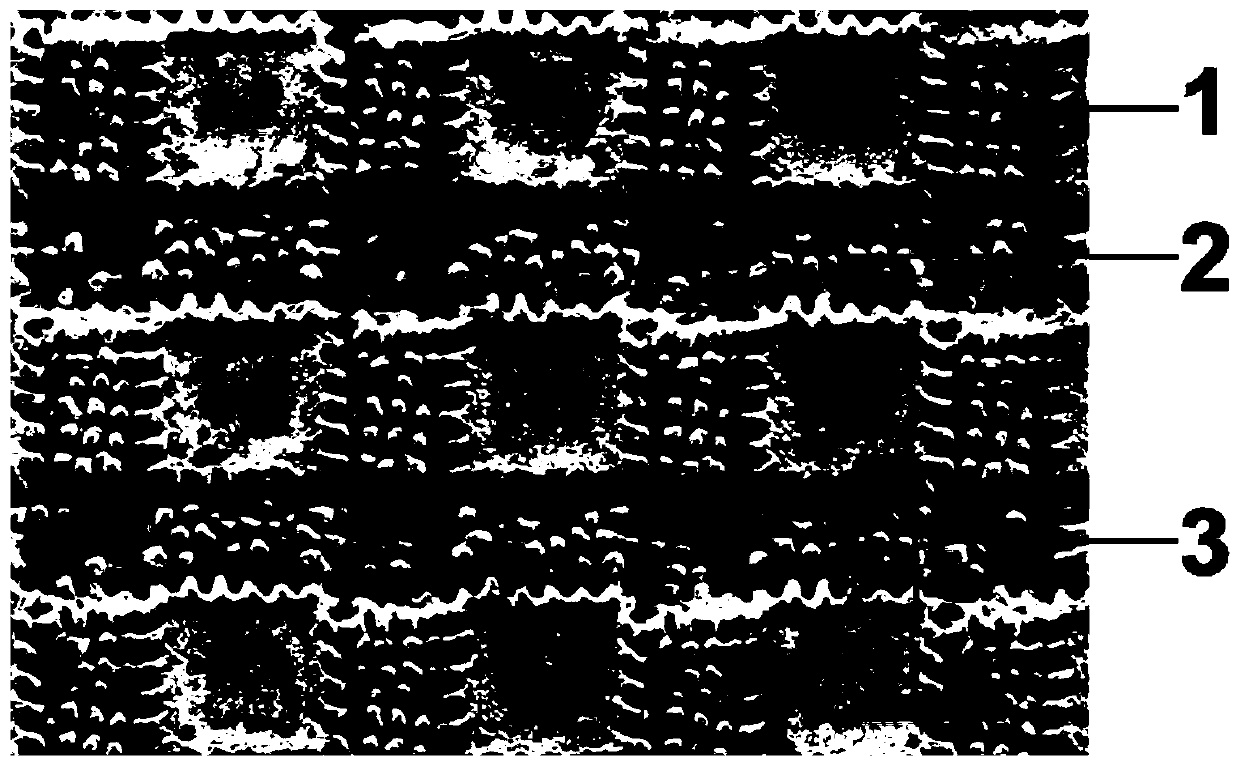

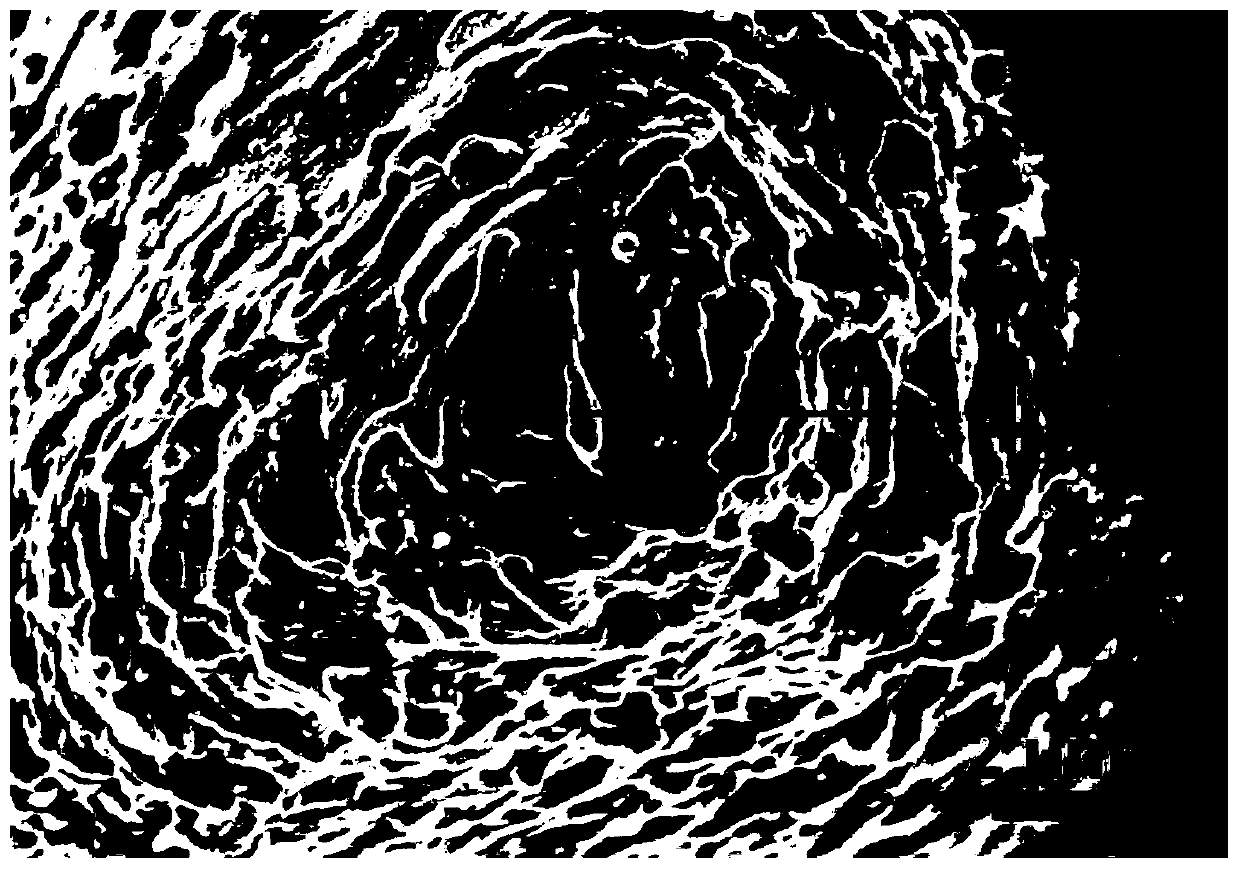

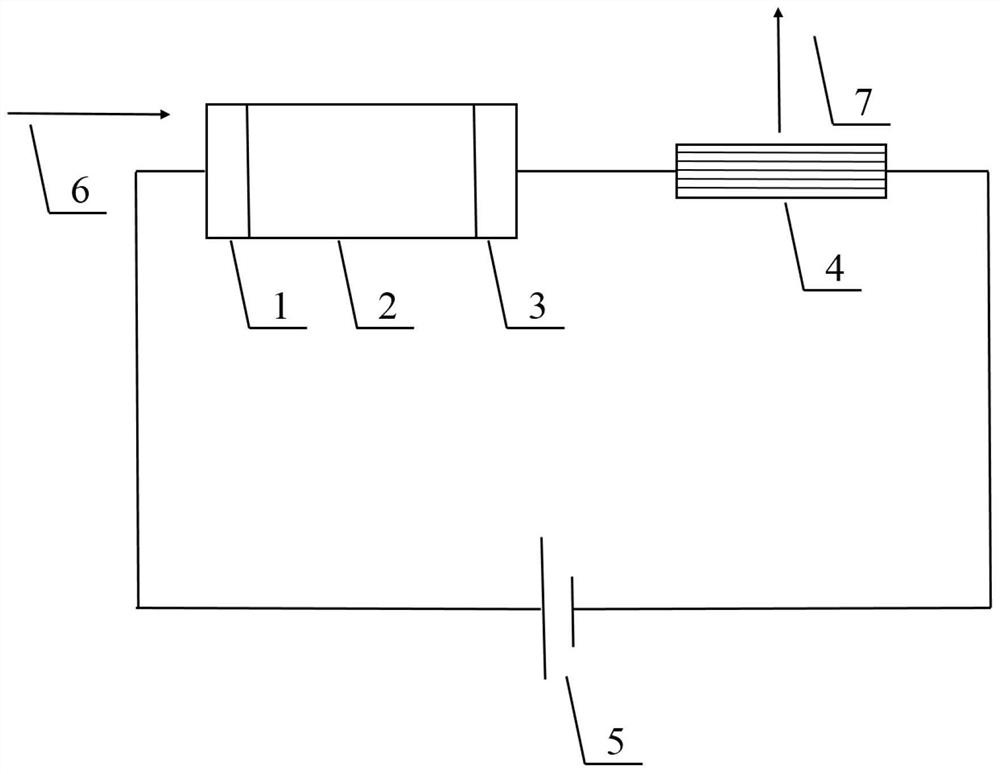

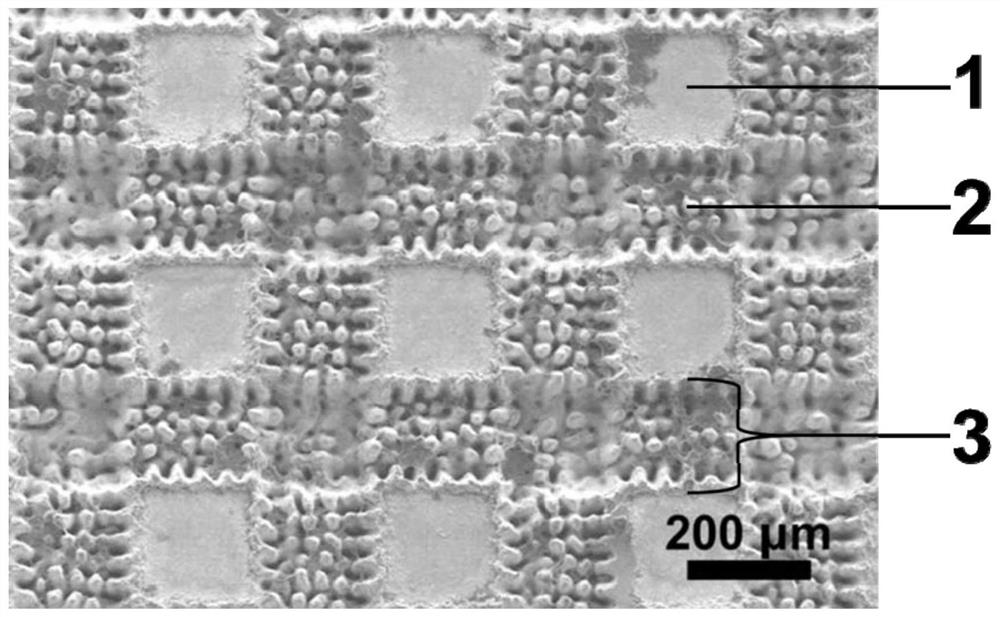

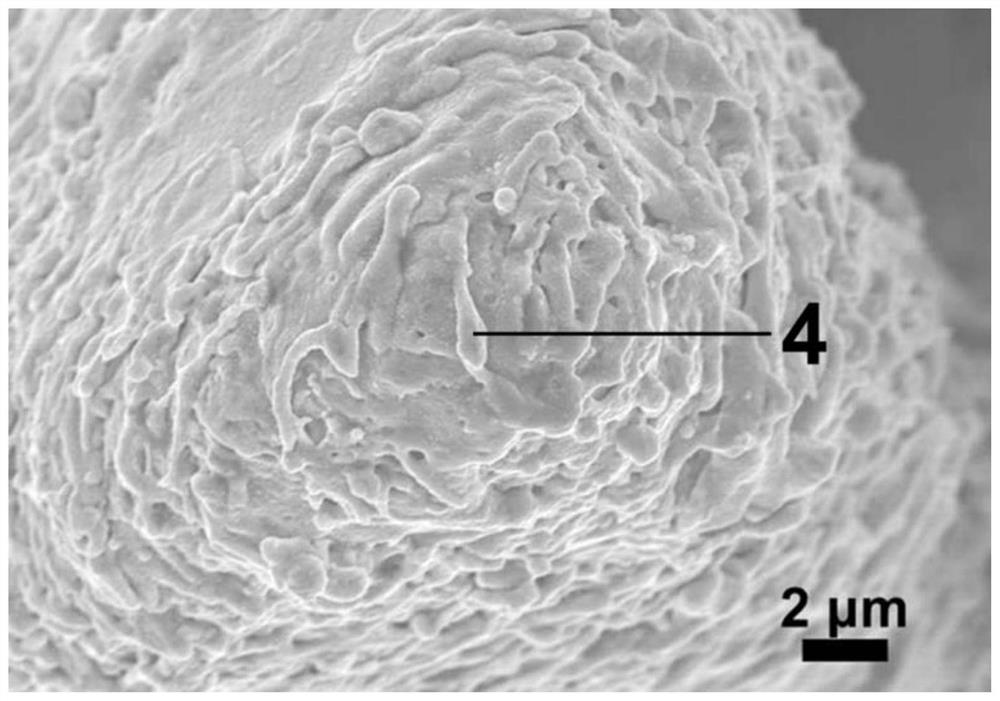

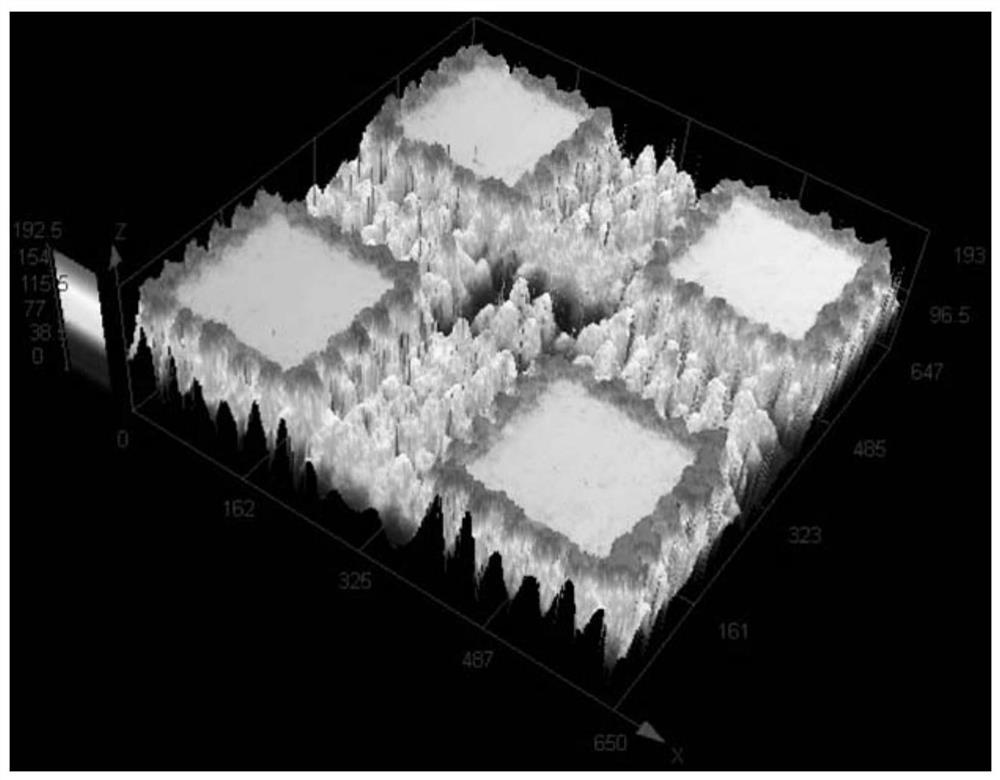

Material surface micro-nano composite strengthening boiling structure as well as preparation method and application thereof

ActiveCN109974512ALittle motor blockMultiple Vaporization CoresHeat transfer modificationLaser beam welding apparatusMicro nanoNanometre

The invention discloses a material surface micro-nano composite strengthening boiling structure as well as a preparation method and application of the material surface micro-nano composite strengthening boiling structure. The material surface micro-nano composite strengthening boiling structure comprises a base material and a micro-nano composite structure formed on the surface of the base material. The micro-nano composite structure comprises micro mastoids, communication-type grooves and nano-folds, wherein the micro mastoids are formed in the communication-type grooves, and the surfaces ofthe micro mastoids are provided with nano-fold shapes. The preparation method of the material surface micro-nano composite strengthening boiling structure comprises the following step of forming a micro-nano composite strengthening boiling structure on the base material through a laser integrated etching method. The material surface micro-nano composite strengthening boiling structure has multi-scale micron and nanometer characteristics in different levels.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

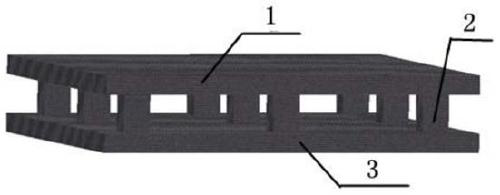

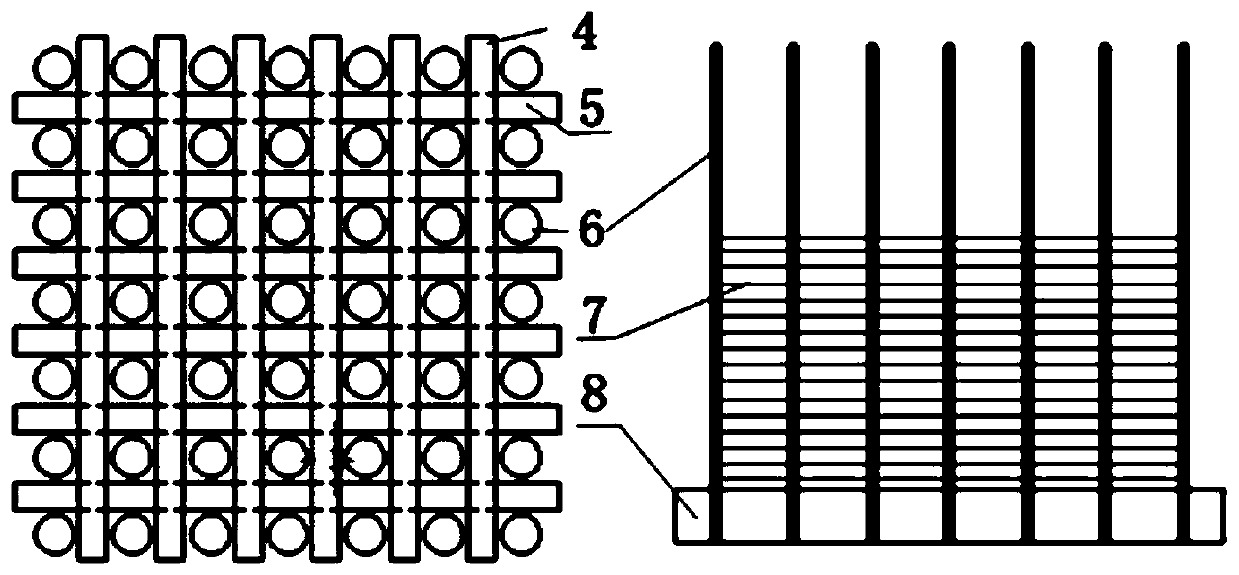

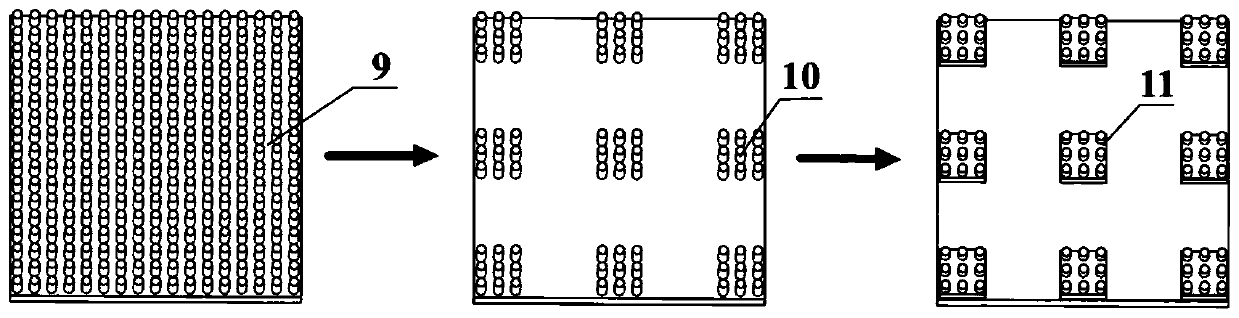

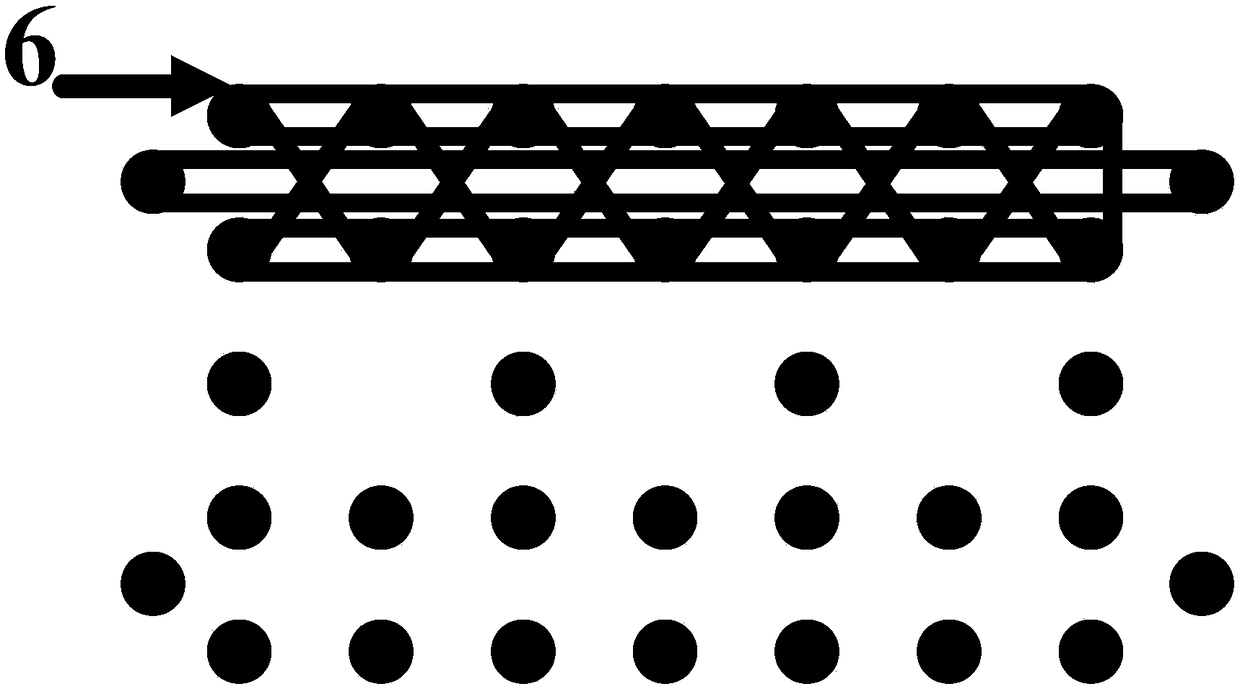

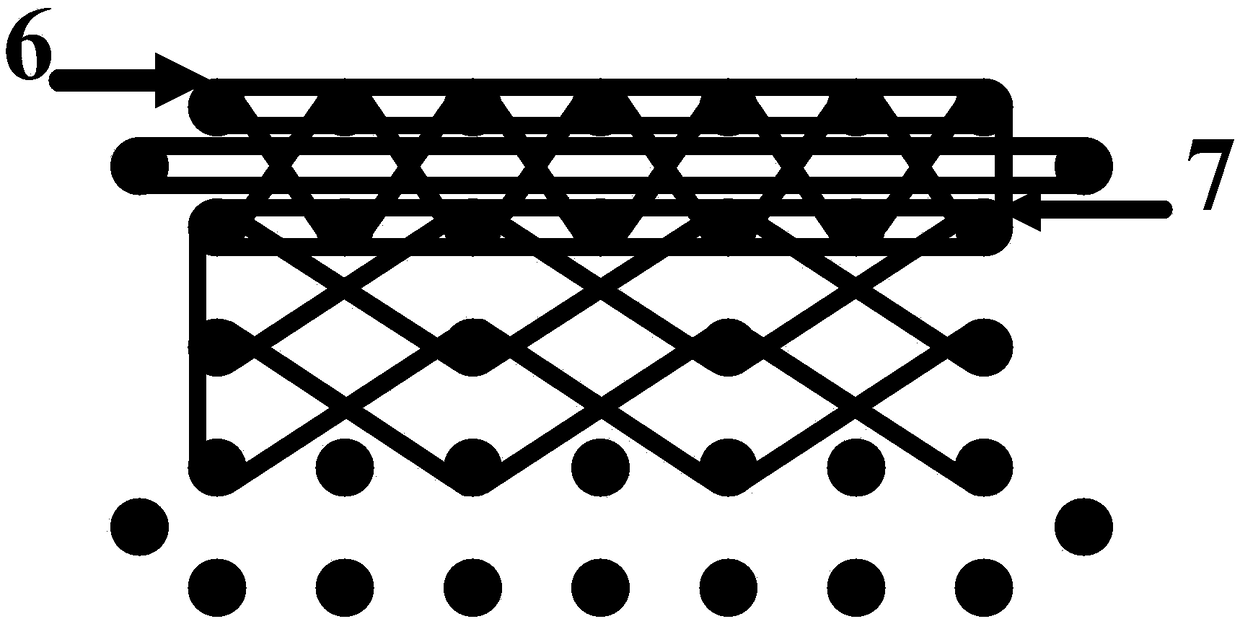

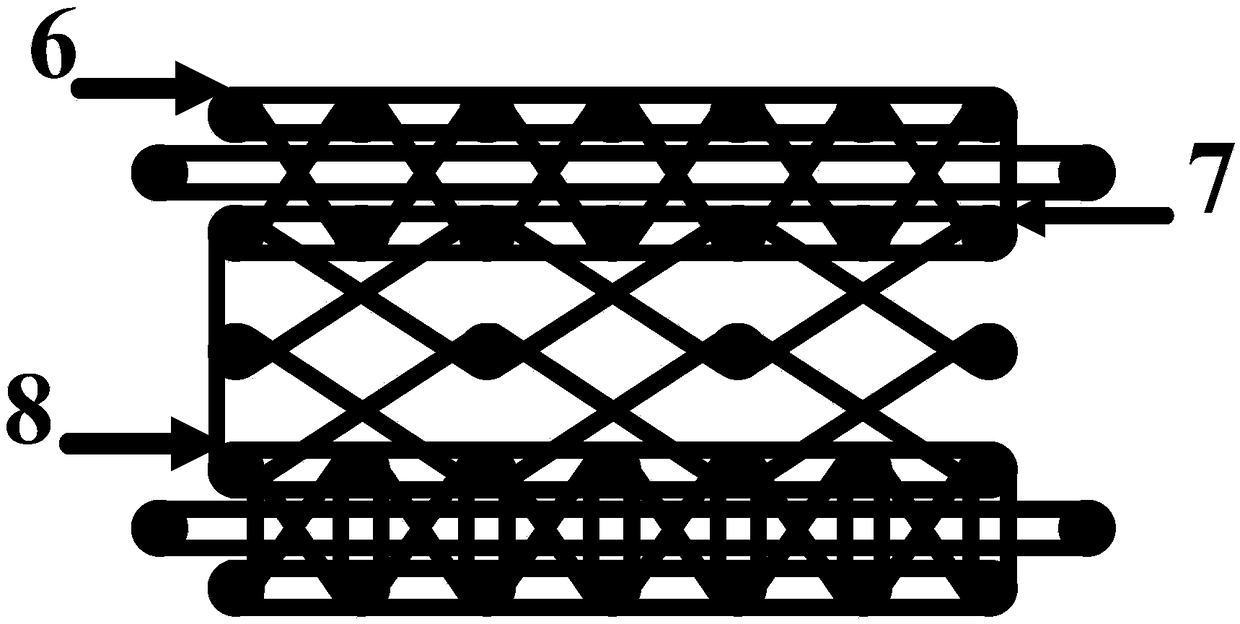

Three-dimensional woven hollow structure preform based on digital guide template and forming method of preform

ActiveCN111501195ARealize flexible weavingRealize integrated formingBraidMechanical propertyFiber reinforcement

The invention relates to a three-dimensional hollow structure preform and a forming method thereof, and can realize the integrated flexible weaving of the hollow structure preform. The hollow preformcomprises an upper panel, a middle connecting core and a lower panel; the preform can further be composed into a matrix, the matrix comprises a resin base, a metal base, a carbon-ceramic base and thelike; and after the composition of the matrix, a filling core is added to the hollow part, and an integrated hollow composite material can be obtained. According to the three-dimensional hollow structure preform, the upper panel, the connecting core and the lower panel are reinforced by three-dimensional structural fibers, and compared with a traditional hollow structure, the mechanical or adhesive connection is reduced, and the overall structural mechanical property is more excellent; the design is more flexible, shaped preform fibers may be one or more, fiber space structure of the preform may be one or more combinations, and the shaped hollow structure may be dot-matrix type, rib type, ring type, or a combination of several structures; and when used for weaving the integrated hollow structure preform, the method has the advantages of being simple in forming principle and flexible in design.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

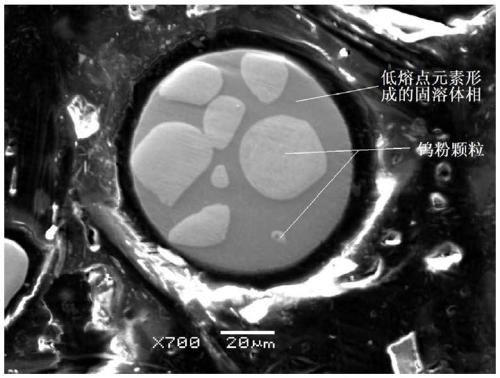

High-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder

ActiveCN110315076APromote meltingNot easy to melt and formAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formSolid solution

The invention discloses a high-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder. The high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder comprises the steps that firstly, according to the designed ingredients and proportion of the high-specific-gravity tungsten-based alloy, material mixing, pressing, vacuum sintering and forging machining are sequentially conducted, then a tungsten-based alloy rod is obtained, and pre-alloyed powder is obtained through a plasma-rotating electrode powder manufacturing method; secondly, athree-dimensional model of the high-specific-gravity tungsten-based alloy is established, slicing and designing are conducted, and then slice layers and scanning data are obtained; thirdly, with the pre-alloyed powder as the raw material, according to the slice layers and the scanning data, a powder bed type electron beam additive manufacturing forming device is adopted to form the high-specific-gravity tungsten-based alloy. According to the high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder, by utilizing the different melting points between tungsten and other elements in the high-specific-gravity tungsten-based alloy, the pre-alloyed powder with tungsten powder particles being wrapped inside low-melting-point element solid solution is prepared, sothat the shells of the pre-alloyed powder are easy to melt and adhere to one another for formation, and therefore the formation difficulty of the pre-alloyed powder is lowered; and with the pre-alloyed powder as the raw material, preparation of the high-specific-gravity tungsten-based alloy is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

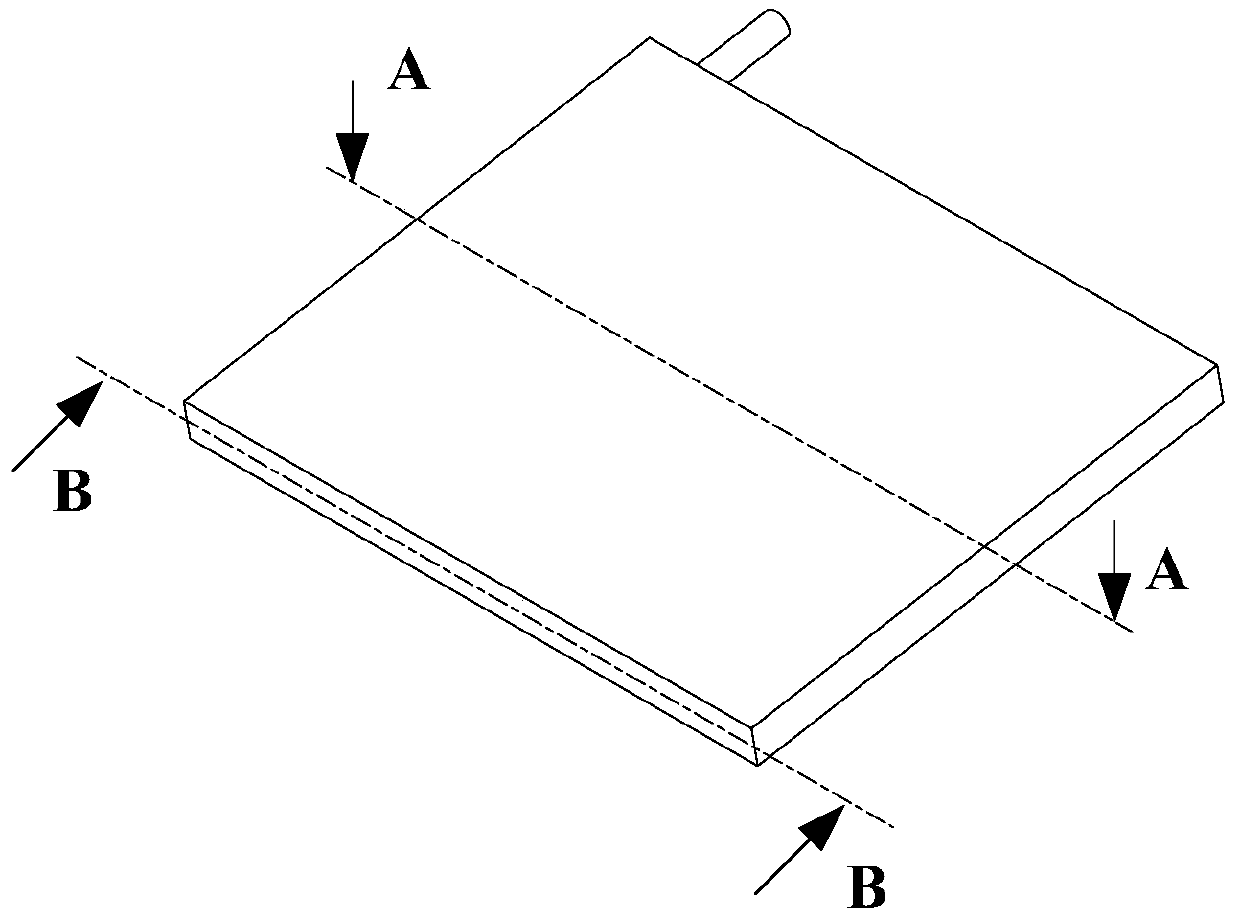

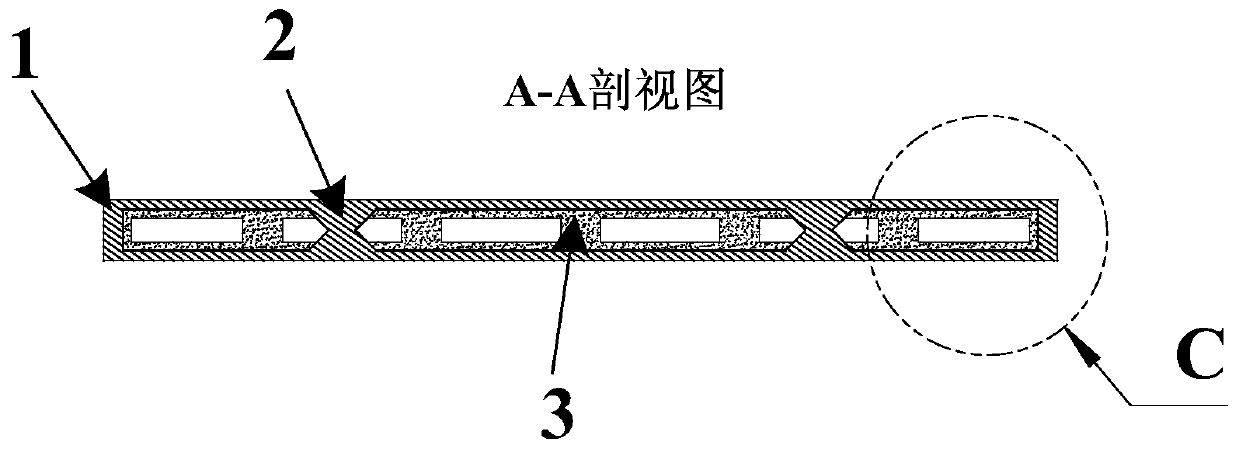

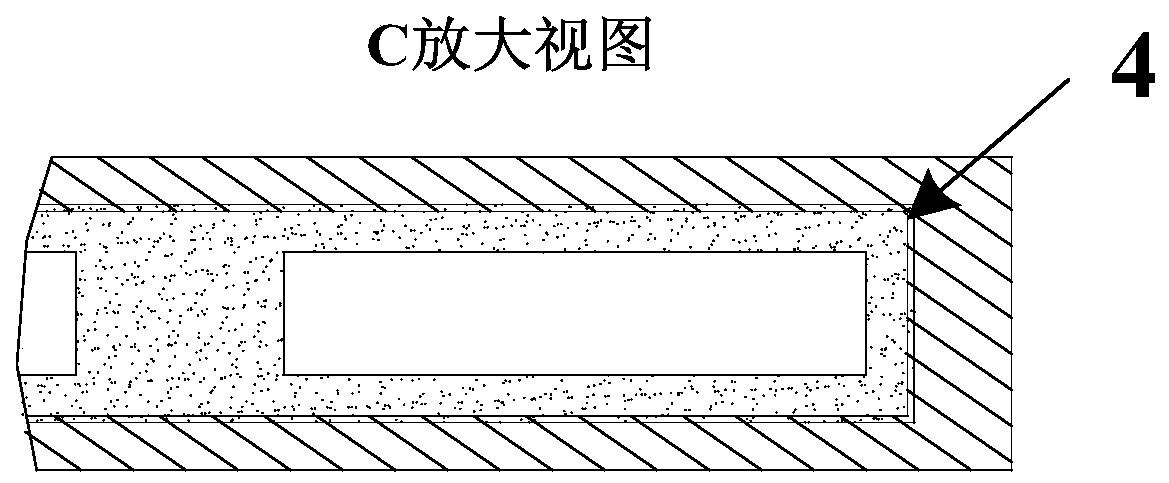

Integrated slab micro heat pipe structure and 3D printing manufacturing method thereof

InactiveCN111590073ASolve many processesResolution cycleAdditive manufacturing apparatusIncreasing energy efficiency3d printProcess engineering

The invention relates to an integrated slab micro heat pipe structure and a 3D printing manufacturing method thereof. The method comprises the steps that the first step, area division of the integrated slab micro heat pipe structure is carried out; the second step, 3D printing model processing of the integrated slab micro heat pipe structure is carried out; the third step, the slab micro heat pipestructure is integrally formed through 3D printing; and the fourth step, the 3D-printed integrated slab micro heat pipe structural part is post-processed, so that the manufacturing of an integrated slab micro heat pipe is completed. According to the method, the problems of multiple procedures, long production cycle and high manufacturing cost of a manufacturing method of a traditional slab microheat pipe split structure are solved. The area division, model processing, forming process parameter confirmation and post-processing of the 3D printing integrated slab micro heat pipe structure ensure that the integration of the slab micro heat pipe structure is synchronized formed, so that the production cycle of the slab micro heat pipe is significantly shortened, production costs are reduced,and performance and reliability of the slab micro heat pipe are improved.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

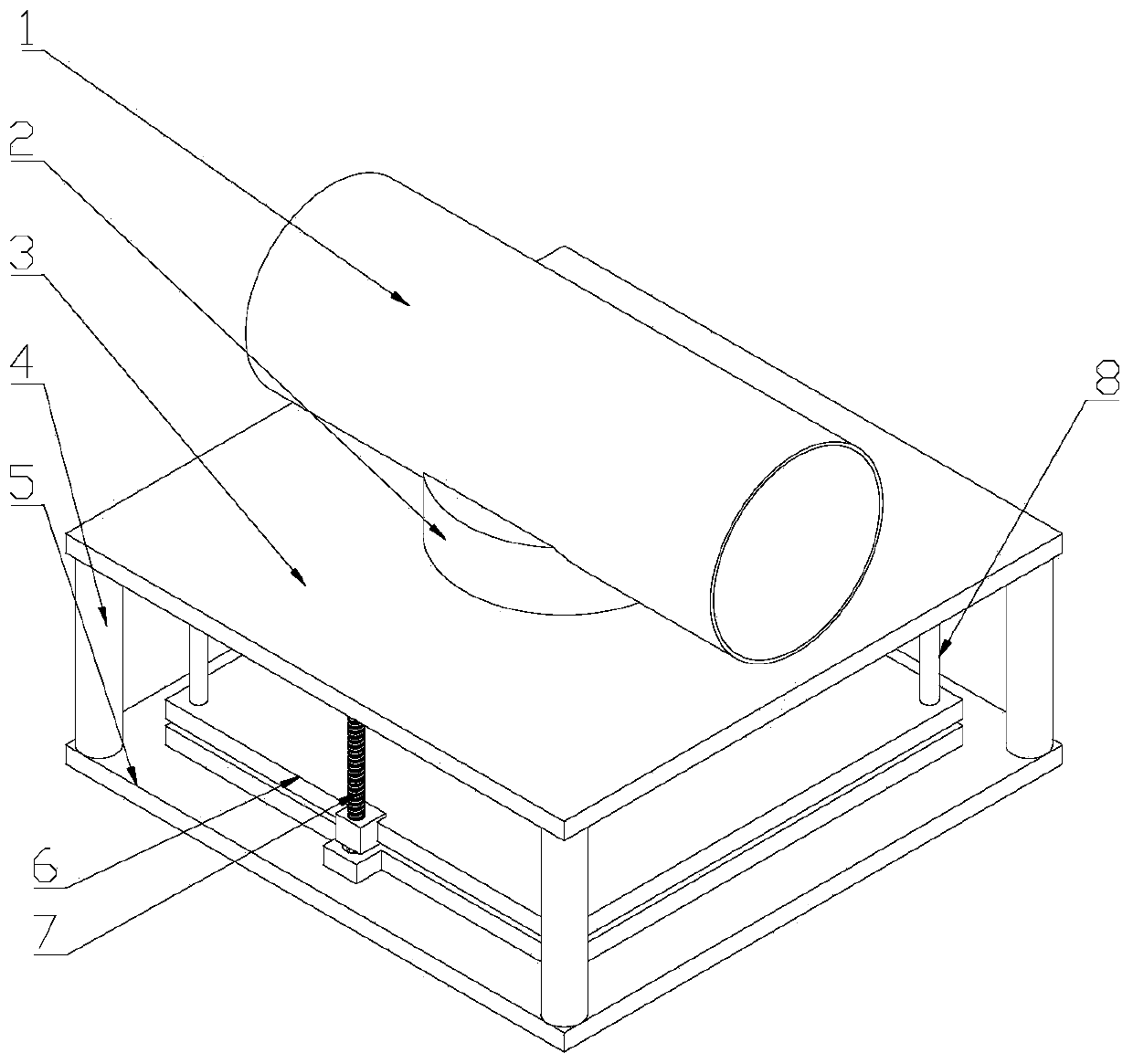

Heterogeneous multilayer heat prevention-heat insulation composite material prefabricating body structure and molding process thereof

ActiveCN109263160AImprove performanceDifferent areal densitiesSynthetic resin layered productsLaminationMulti materialTransition layer

The invention discloses a heterogeneous multilayer heat prevention-heat insulation composite material prefabricating body structure and a molding process thereof, wherein the structure comprises a heat prevention structure layer, a heat insulation transition layer and a bearing structure layer. According to the molding process, a guiding rod is pre-arranged, different combinations of different kinds of fibers are used, the sequences in fiber winding processes are controlled, the center distance of a guiding sleeve is changed, and the guiding sleeve is replaced with fibers, such that the multi-material multilayer prefabricating body with density gradient is prepared; fibers with excellent heat prevention performance are wound and spread along the guiding sleeve to prepare the heat prevention structure layer; fibers with excellent heat insulation performance are wound along the guiding sleeve to prepare the heat insulation transition layer; continuous fibers are wound and spread along the guiding sleeve to prepare the bearing structure layer; and density gradient structure is achieved by controlling the center distance of the guiding sleeve and the fiber spreading and winding combination mode. According to the present invention, the composite material prepared from the prefabricating body structure and the matrix through impregnating can achieve the heat prevention / heat insulation / bearing integrated function.

Owner:CHINA ACADEMY OF MACHINERY SCIENCE & TECHNOLOGY +1

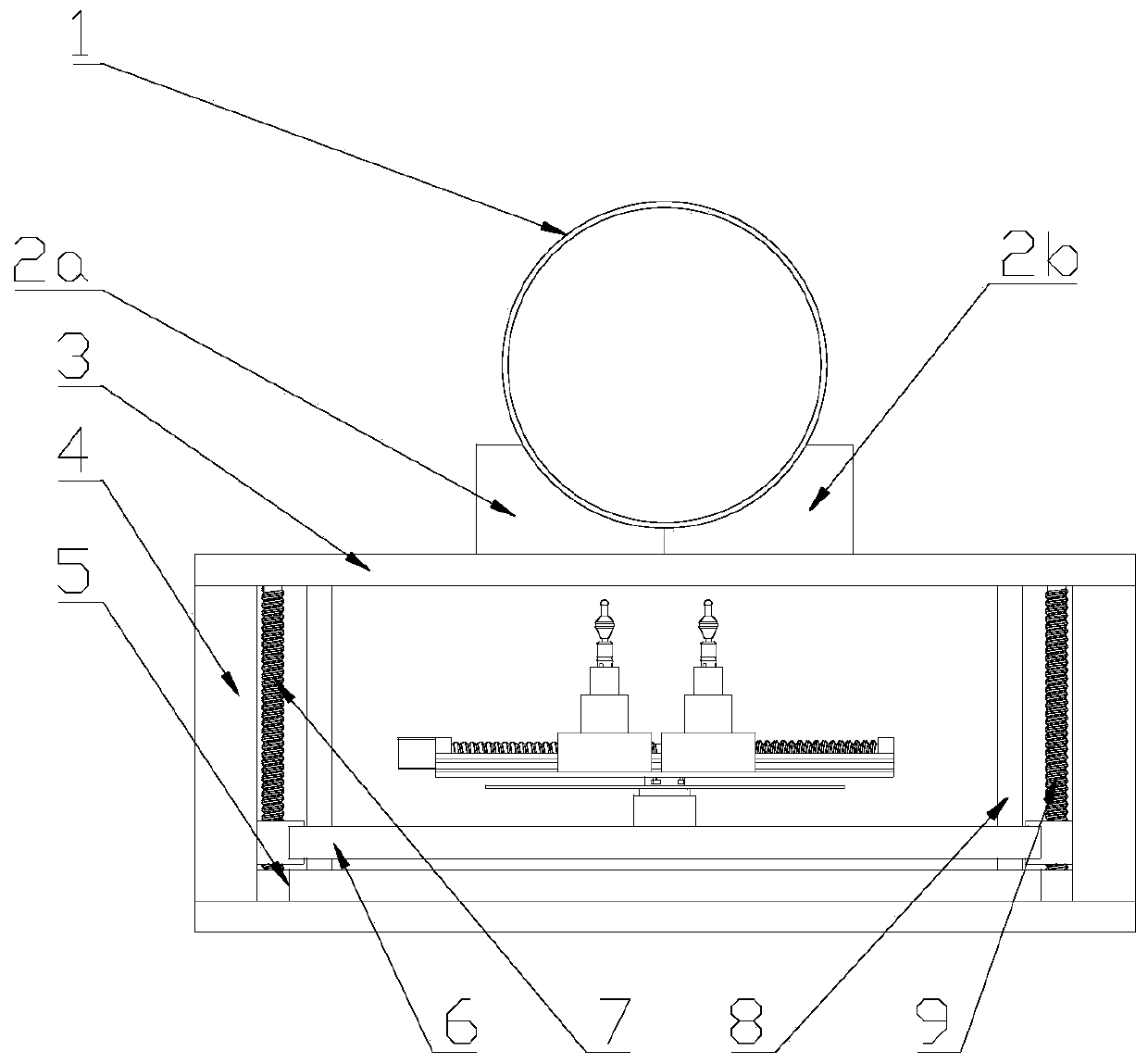

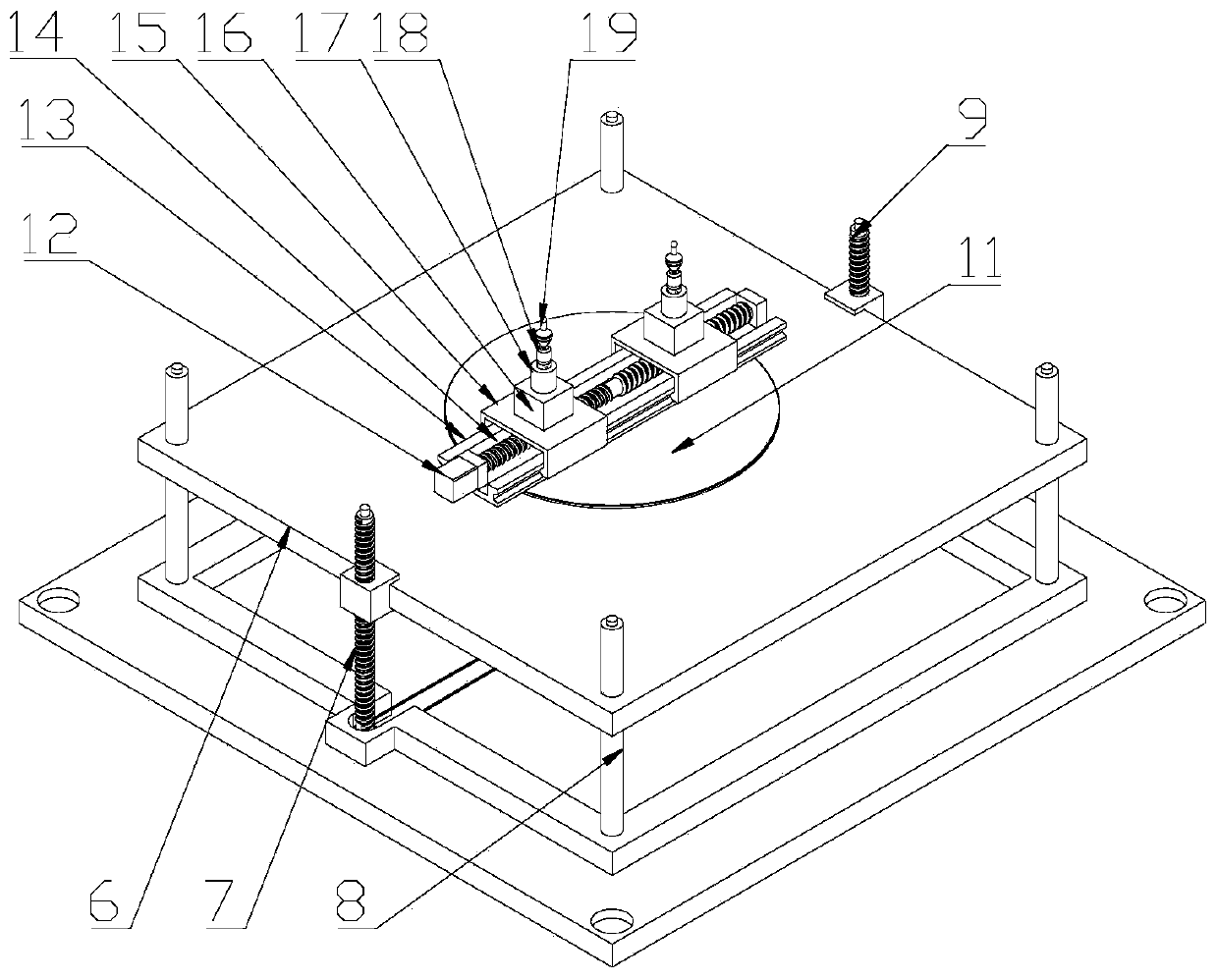

Integrated composite progressive forming device and process of large shell branch pipe flange

The invention discloses an integrated composite progressive forming device and process of a large shell branch pipe flange. The integrated composite progressive forming device comprises a rack, a workbench and a symmetrical tool head system, wherein the workbench is arranged on the rack, and the symmetrical tool head system is connected to the workbench. According to the process, the synchronous movement of a plurality of pairs of tool heads is realized through the symmetrical tool head system, and the integrated forming of a cylindrical part branch pipe flange is realized. The forming processis high in flexibility, suitable for the integrated forming of thick-wall cylindrical part branch pipes with different sizes, and good in universality. Stamping dies and auxiliary feeding mechanismsdo not need to be manufactured, so that the cost is saved. The clamping process is simpler. The forming efficiency can be effectively improved through a multi-point symmetric structure. The stress ofa cylindrical part in the forming process is better balanced. The forming quality is high. Meanwhile, the forming efficiency is effectively improved by the plurality of pairs of tool heads.

Owner:XI AN JIAOTONG UNIV

Method for punching and spinning integrated formation of filter flange

The invention provides a method for punching and spinning integrated formation of a filter flange. The method for punching and spinning integrated formation of the filter flange comprises the steps that firstly, a central hole and small holes around the central hole are punched by means of a round plate, and the edge of the central hole is chamfered, so that a blank is obtained; then punching and spinning integrated formation is conducted, the blank is installed on the conical surface of a lower die of punching and spinning integrated equipment, an upper die moves towards the lower die till the upper die and the lower die are completely attached to the blank, and inner hole flanging of the blank is achieved, so that a primary workpiece is obtained; the die assembly position of the upper die and the lower die is not changed, the primary workpiece is clamped, the upper die also serves as a mandrel for spinning formation, the lower die also serves as a spinning tailstock, and multi-pass spinning of the primary workpiece is achieved by means of a spinning wheel, so that a secondary workpiece is obtained; then shape righting is conducted on the secondary workpiece, so that a final workpiece is obtained; and finally, edge cutting is conducted on the final workpiece, so that the filter flange is obtained. By the adoption of the method for punching and spinning integrated formation of the filter flange, the number of sets of dies can be effectively reduced, the formation time is shortened, and production cost is reduced.

Owner:XI AN JIAOTONG UNIV

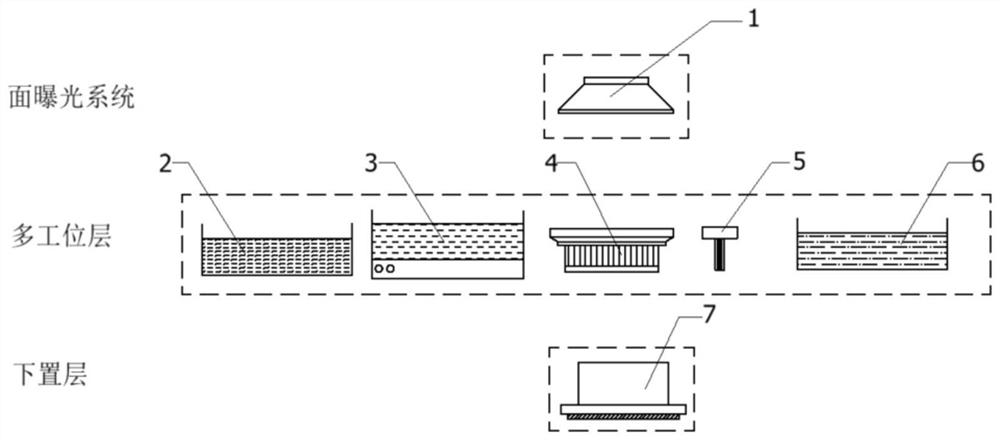

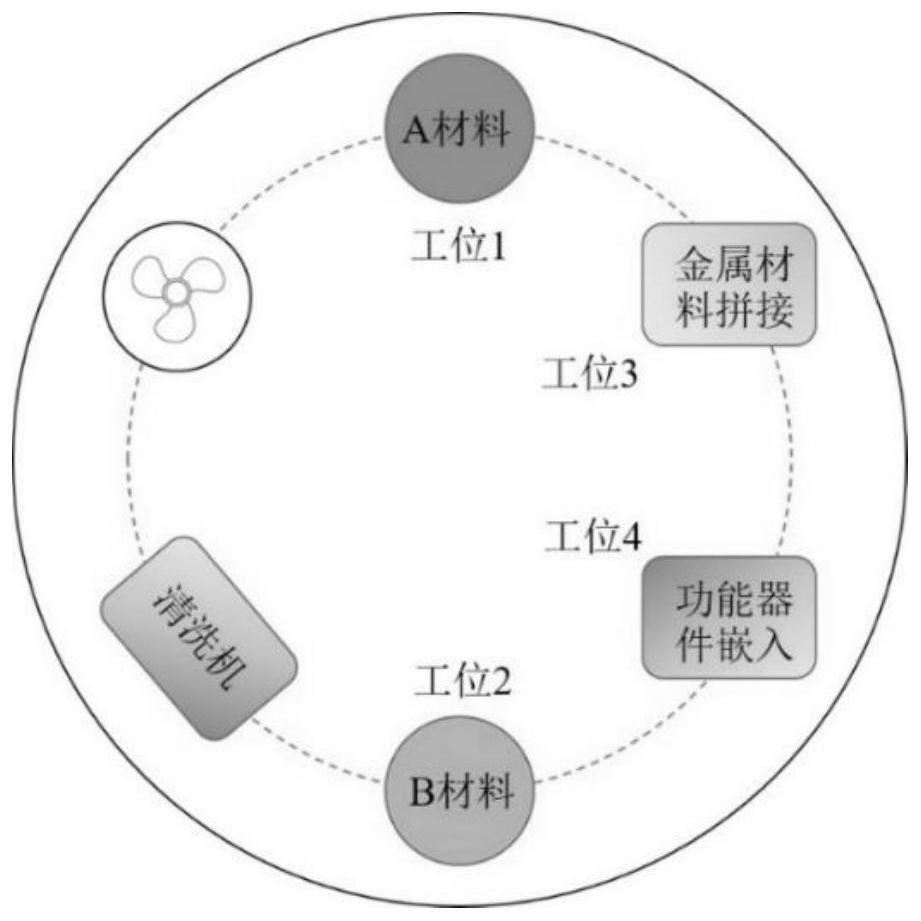

Composite multi-material energy field constraint part additive manufacturing device based on surface exposure and composite multi-material energy field constraint part additive manufacturing method

ActiveCN112590201AImprove developmentSolve processabilityManufacturing platforms/substratesManufacturing enclosuresComplex fieldAdditive layer manufacturing

The invention discloses a composite multi-material energy field constraint part additive manufacturing device based on surface exposure and a composite multi-material energy field constraint part additive manufacturing method. The energy field constraint part additive manufacturing device adopts surface exposure, and forming of a composite material and embedding of a functional part are achieved through switching of internal stations of the device. After one type of liquid composite material is formed, the material can be formed according to actual requirements, or another station can be switched to form other composite materials, before liquid tanks are switched, a formed part needs to be cleaned and dried, mutual influence between the materials is avoided, the operation is repeated in this way, and finally, additive manufacturing of a composite material energy field constraint part is achieved. According to the energy field constraint part additive manufacturing device using surfaceexposure, by adopting a rotating station with a simple structure, the equipment space is effectively saved, the actions among procedures are coherent, the forming time is saved, the cost is reduced, and the additive manufacturing device has a good application prospect in the energy field constraint part such as a marine sensor and a complex field antenna.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

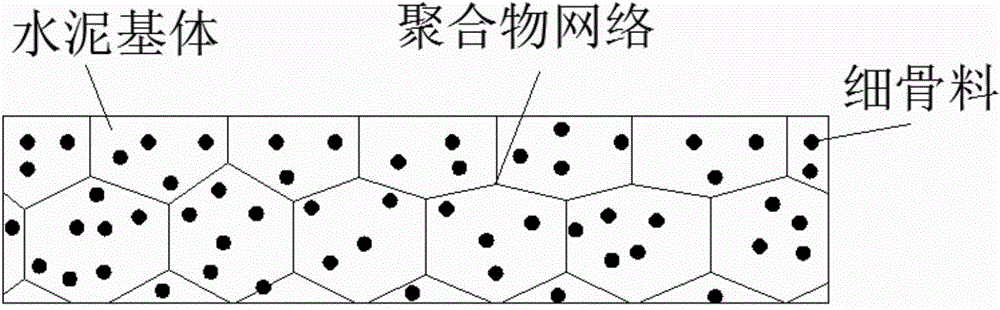

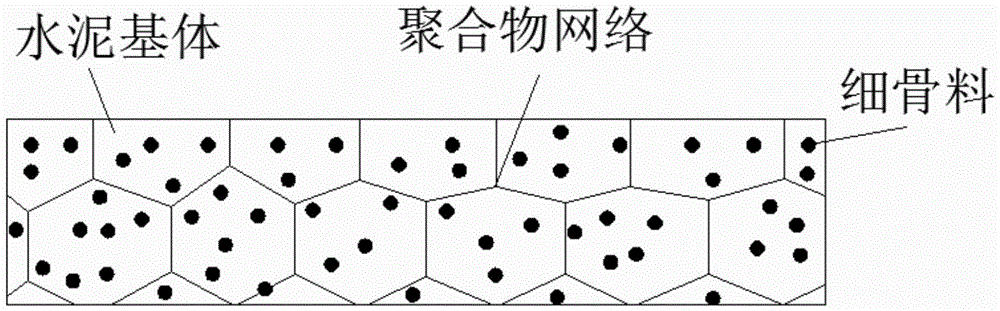

Preparation method of special-shaped polymer structure reinforcing composite light-weight cement

InactiveCN104016642AIncrease usage intensityRealize integrated formingCement compositesCement slurry

The invention relates to a preparation method of special-shaped polymer structure reinforcing composite light-weight cement, relating to a preparation method of composite light-weight cement and aiming at obtaining a light-weight high-strength cement building material. The preparation method comprises the following steps of 1, preparing a special-shaped polymer structure; 2, preparing cement slurry; 3, forming a light-weight cement composite material. The preparation method disclosed by the invention improves the reinforcing mechanism of the cement-based composite material from the independent reinforcement of a discontinuous reinforcement phase into the synergetic enhancement of a continuous reinforcement phase by substituting a continuous polymer special-shaped structure network for a discontinuous polymer fiber, thereby effectively enhancing the usage property of the cement-based composite material. The preparation method disclosed by the invention effectively reduces the weight of the material by 40%-50%, does not change the flowing property of the cement slurry, can be used for freely designing the structure of the reinforcement phases and integrally forming the composite material and a prefabricated structure, has the advantages of simple preparation process, low cost, high designability of a technical process, abundance in used raw material and the like and can effectively reduce the weight of the cement building material.

Owner:HARBIN INST OF TECH

Method for preparing silicon carbide particle-reinforced silicon nitride composite ceramic parts

The invention discloses a method for preparing silicon carbide particle-reinforced silicon nitride composite ceramic parts, and belongs to the technical field of ceramic part preparation. The method comprises the following steps of: mixing SiC powder, Si3N4 powder, a sintering acid and a paraffin base multicomponent binder into a uniform feed; and performing solvent-thermal debinding and presintering at the temperature of between 1,150 and 1,200 DEG C on a preformed blank obtained by injection molding of the feed, and sintering in a vacuum carbon tube furnace at the temperature of between 1,800 and 1,900 DEG C and at the normal pressure in the Ar atmosphere to prepare SiCp / Si3N4 composite ceramic parts. The method for preparing the silicon carbide particle-reinforced silicon nitride composite ceramic parts has the advantages of direct preparation of SiCp / Si3N4 composite ceramic products with complicated geometry, uniform texture, high dimensional accuracy and no need of subsequent processing, achievement of integrated molding of the SiCp / Si3N4 materials and the parts, and establishment of low-cost preparation technology for the SiCp / Si3N4 composite ceramic parts with complicated shapes and high dimensional accuracy.

Owner:UNIV OF SCI & TECH BEIJING

A composite integrated manufacturing method of arc addition and subtraction materials for a thruster model

ActiveCN110000381BGood lookingRealize printingAdditive manufacturing apparatusElectrode supporting devicesManufactured materialWaste product

The invention belongs to the field of arc additive manufacturing, and discloses an arc additive and subtractive composite integrated manufacturing method for a thruster model. The method includes: (a) Dividing the propeller model into three parts, performing slice layering on the three parts and planning the filling trajectory of each slice layer, and the direction of the rotor and stator slices is along the outer direction of the core axis. In the direction, each slice layer forms a slice contour on the mandrel, and the filling trajectory is planned in the slice contour to obtain the filling trajectory of each slice layer; (b) forming the mandrel; (c) forming the rotor and stator. In the project of layer-by-layer processing of the slice layer, the real-time inspection of the slice layer is carried out by using infrared thermal imaging defect detection and line laser shape detection, thereby realizing the integrated manufacturing of additive and subtractive composites. The invention avoids the irreversible loss caused by the detection of waste products after parts are printed, reduces the consumption of energy and raw materials, and shortens the manufacturing period.

Owner:HUAZHONG UNIV OF SCI & TECH

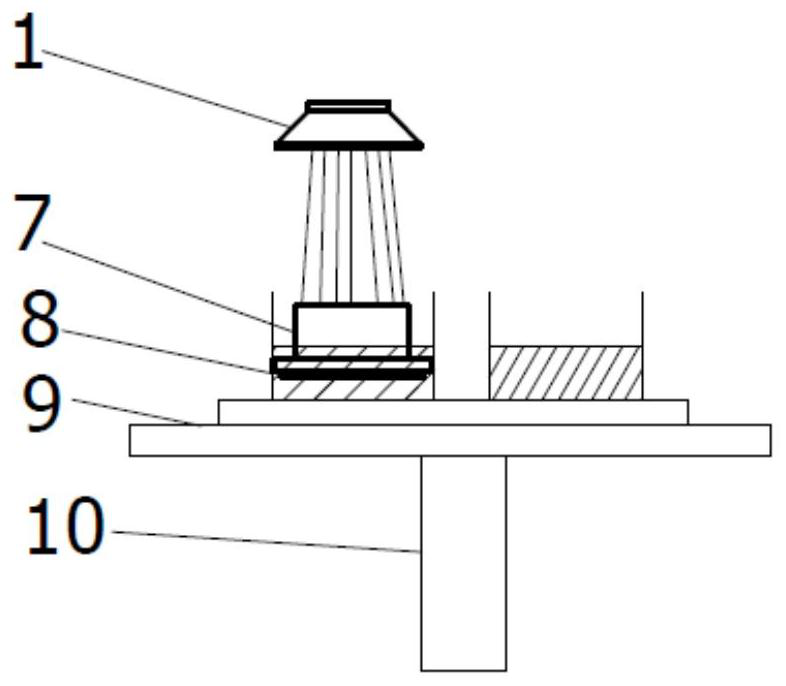

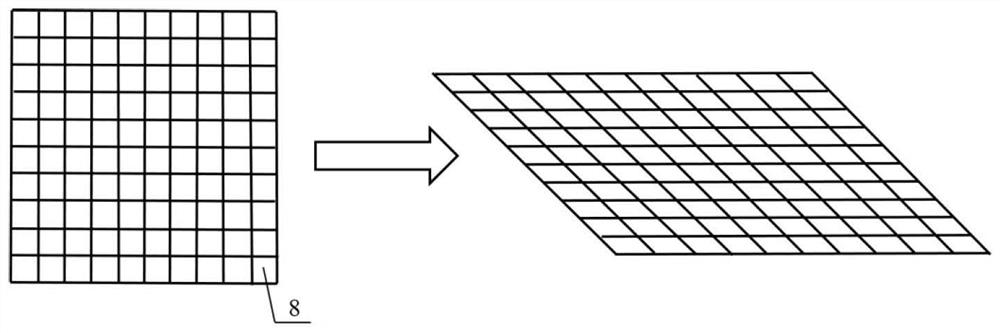

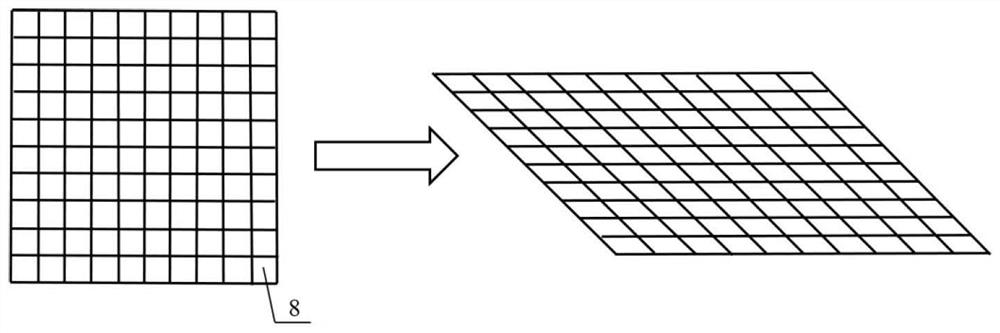

Nerve-imitating tactile sensor formed based on 4D printing

ActiveCN112477112ARealize integrated formingAdditive manufacturing apparatus3D object support structuresAutomatic controlMedicine

The invention belongs to the field of tactile sensors, and more particularly relates to a nerve-imitating tactile sensor formed based on 4D printing. The nerve-imitating tactile sensor comprises a plurality of sensor units (8), wherein the sensor units (8) are formed through 4D printing; each sensor unit (8) comprises a pressure-sensitive assembly, an electro-shape memory polymer (4) and an energysupply assembly (5); the pressure-sensitive assembly is electrically connected with the electro-shape memory polymer (4) through a wire; and the pressure-sensitive assembly and the electro-shape memory polymer (4) are electrically connected with the energy supply assembly (5) through wires. The sensor is manufactured based on a 4D printing technology, and the unique manufacturing mode of layer-by-layer superposition forming is adopted. Compared with a traditional manufacturing method, the method has the unique advantage in forming any part with a complex structure, can be better applied to the fields of automatic control, soft robots and the like, and has a wide market prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

Integral Spinning Forming Method of Thin-wall Shell with Circumferential Rib Curved Busbar

The invention provides an integral spinning forming method for a curved generatrix thin-walled shell with annular reinforcing ribs. A tube blank is machined into the shell through the forming method.The shell comprises a curved generatrix tube section and a straight tube section. The curved generatrix tube section is provided with the annular reinforcing ribs. The forming method comprises the following steps that (1) the tube blank is prepared; (2) stress relief treatment is conducted; (3) power spinning is conducted, specifically, (3.1) the initial spinning position and the final spinning position of the tube blank are determined, (3.2) the number of times of power spinning is determined, and design of a power spinning track is completed, (3.3) the tube blank is mounted, (3.4) a power spinning program based on the power spinning track is designed, and the power spinning program is started for power spinning until the pass of power spinning is completed, and (3.5) the step 3.4 if repeated, after several times of power spinning, the power spinning forming process is completed, and a semi-finished tube blank with stagewise thicknesses is obtained; and (4) closing and spinning are conducted. Through the technical scheme, costs such as mold input and maintenance are greatly reduced, and the production cost is lowered.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

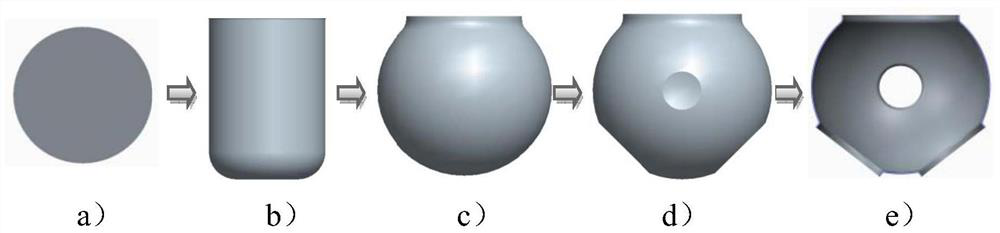

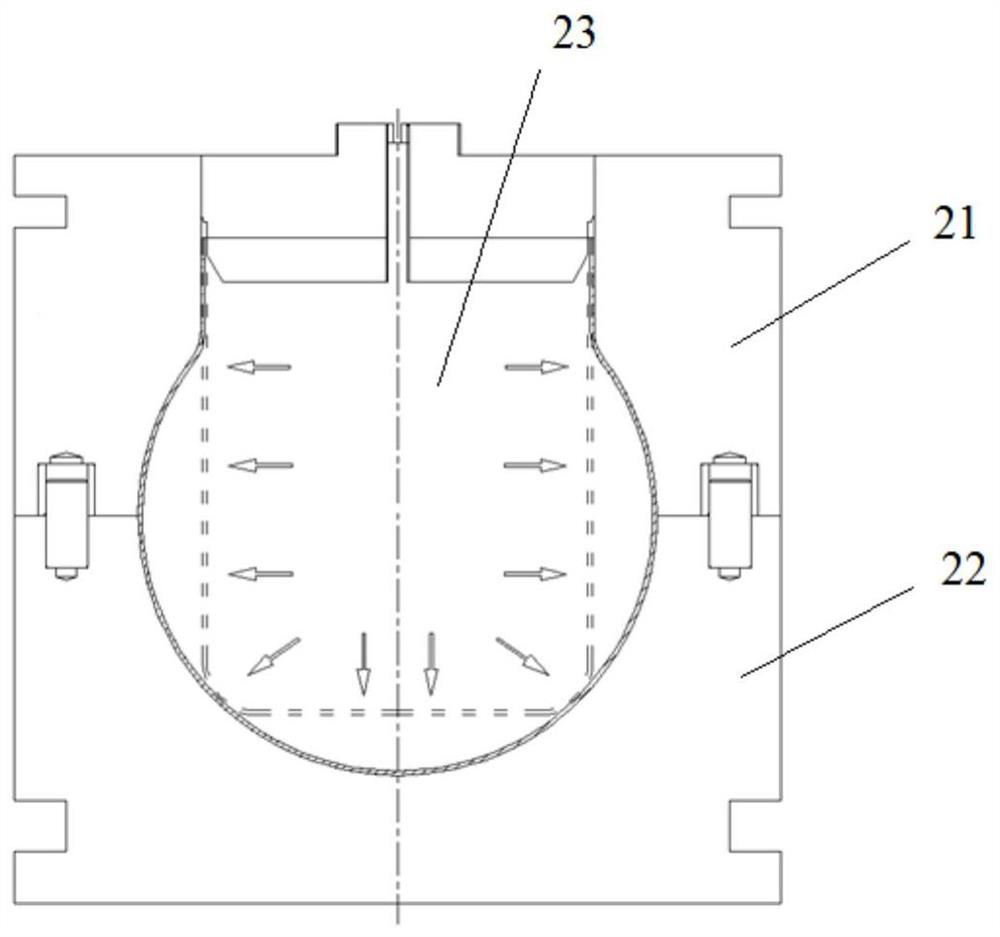

Spherical multi-way part multi-process combined integral forming method and spherical multi-way part

PendingCN114247802ARealize integrated formingUniform wall thicknessShaping toolsOther manufacturing equipments/toolsNumerical controlSpinning

The invention provides a multi-process combined integral forming method for a spherical multi-way part and the spherical multi-way part. The method comprises the following steps: S1, a spinning step: carrying out a spinning process on an original plate blank material to obtain a flat-bottom deep cylindrical part; s2, stress annealing: adopting a stress relief annealing process to eliminate the internal stress of the spun material; s3, hydraulic bulging is conducted, specifically, the annealed flat-bottom deep cylindrical part is subjected to hydraulic bulging treatment, and a spherical part with an opening is obtained; s4, a numerical control hole control step, wherein a plurality of prefabricated holes are machined in the spherical part with the opening at a time through the multi-degree-of-freedom numerical control hole control technology, and the spherical part with the opening and the prefabricated holes is formed; and S5, hole flanging and forming are conducted, specifically, the prefabricated hole obtained after numerical control machining serves as the positioning reference, and the spherical multi-way part is formed through hole flanging. By means of the multi-process combined forming technology, seamless integral forming of the spherical multi-way part is completed in a combined machining mode, the wall thickness is uniform, the product quality consistency and the size precision are improved, and integrated forming of multi-way parts with flanging holes of different specifications and different positions can be achieved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

A neuromimetic tactile sensor based on 4D printing

ActiveCN112477112BRealize integrated formingAdditive manufacturing apparatus3D object support structuresAutomatic controlPhysical medicine and rehabilitation

The invention belongs to the field of tactile sensors, and more particularly relates to a neuromimetic tactile sensor based on 4D printing. The neuromimetic tactile sensor of the present invention includes several sensor units (8), the sensor units (8) are formed by 4D printing, and the sensor units (8) include pressure sensitive components, electro-induced shape memory polymers (4) and An energy supply component (5), the pressure sensitive component is electrically connected to the electric shape memory polymer (4) through a wire, and both the pressure sensitive component and the electric shape memory polymer (4) are connected to the energy supply component ( 5) Electrically connected by wires. The sensor of the present invention is based on 4D printing technology, and its unique manufacturing method of layer-by-layer superimposition molding has unique advantages in forming any parts with complex structures compared with traditional manufacturing methods, and can be better applied to automatic control , software robots and many other fields, has broad market prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of material surface micro-nano composite enhanced boiling structure and preparation method and application thereof

ActiveCN109974512BLittle motor blockMultiple Vaporization CoresHeat transfer modificationLaser beam welding apparatusMicro nanoComposite structure

The invention discloses a material surface micro-nano composite strengthening boiling structure as well as a preparation method and application of the material surface micro-nano composite strengthening boiling structure. The material surface micro-nano composite strengthening boiling structure comprises a base material and a micro-nano composite structure formed on the surface of the base material. The micro-nano composite structure comprises micro mastoids, communication-type grooves and nano-folds, wherein the micro mastoids are formed in the communication-type grooves, and the surfaces ofthe micro mastoids are provided with nano-fold shapes. The preparation method of the material surface micro-nano composite strengthening boiling structure comprises the following step of forming a micro-nano composite strengthening boiling structure on the base material through a laser integrated etching method. The material surface micro-nano composite strengthening boiling structure has multi-scale micron and nanometer characteristics in different levels.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Nitrogen-containing stainless steel, preparation method and use of parts

ActiveCN113481439BImprove processing stabilityRealize integrated formingAdditive manufacturing apparatusSS - Stainless steelIngot

In order to solve the technical problem in the prior art that the existing nitrogen-containing stainless steel is not suitable for additive manufacturing, the embodiment of the present invention provides a nitrogen-containing stainless steel, a method for preparing parts and its use; nitrogen-containing stainless steel uses iron as a matrix element, including Alloying elements in the following mass fractions: C 0.02‑0.09%, Si 0.2‑0.5%, Mn 6.5‑7.5%, Ni 10‑11%, Cr 18‑19%, Mo 0.9‑1.5%, N 0.08‑0.18%, V 0.25-0.35% and Nb 0.25-0.35%; the component preparation method includes preparing the nitrogen-containing stainless steel into an ingot by means of induction furnace melting. Use of the nitrogen-containing stainless steel or the ingot prepared by the preparation method in additive manufacturing. The embodiments of the present invention improve the process stability of nitrogen-containing stainless steel in the process of additive manufacturing through the reasonable collocation of various elements, and realize the short-process integrated forming of nitrogen-containing stainless steel with high plasticity and toughness.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Preparation method of composite lightweight cement reinforced by special-shaped polymer structure

InactiveCN104016642BIncrease usage intensityRealize integrated formingCement compositesCement slurry

The invention relates to a preparation method of special-shaped polymer structure reinforcing composite light-weight cement, relating to a preparation method of composite light-weight cement and aiming at obtaining a light-weight high-strength cement building material. The preparation method comprises the following steps of 1, preparing a special-shaped polymer structure; 2, preparing cement slurry; 3, forming a light-weight cement composite material. The preparation method disclosed by the invention improves the reinforcing mechanism of the cement-based composite material from the independent reinforcement of a discontinuous reinforcement phase into the synergetic enhancement of a continuous reinforcement phase by substituting a continuous polymer special-shaped structure network for a discontinuous polymer fiber, thereby effectively enhancing the usage property of the cement-based composite material. The preparation method disclosed by the invention effectively reduces the weight of the material by 40%-50%, does not change the flowing property of the cement slurry, can be used for freely designing the structure of the reinforcement phases and integrally forming the composite material and a prefabricated structure, has the advantages of simple preparation process, low cost, high designability of a technical process, abundance in used raw material and the like and can effectively reduce the weight of the cement building material.

Owner:HARBIN INST OF TECH

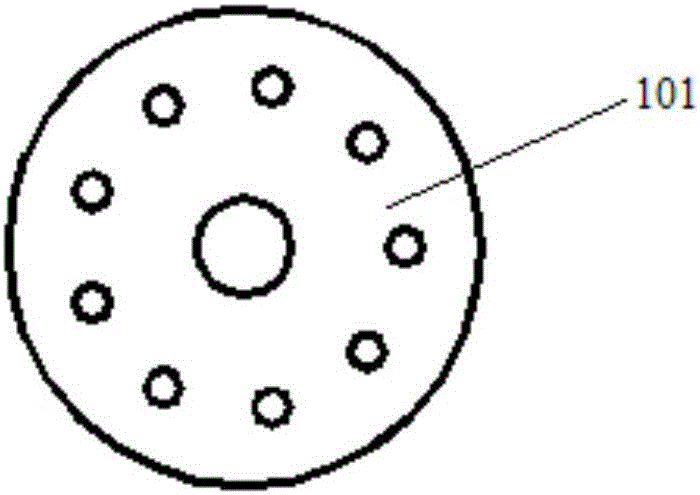

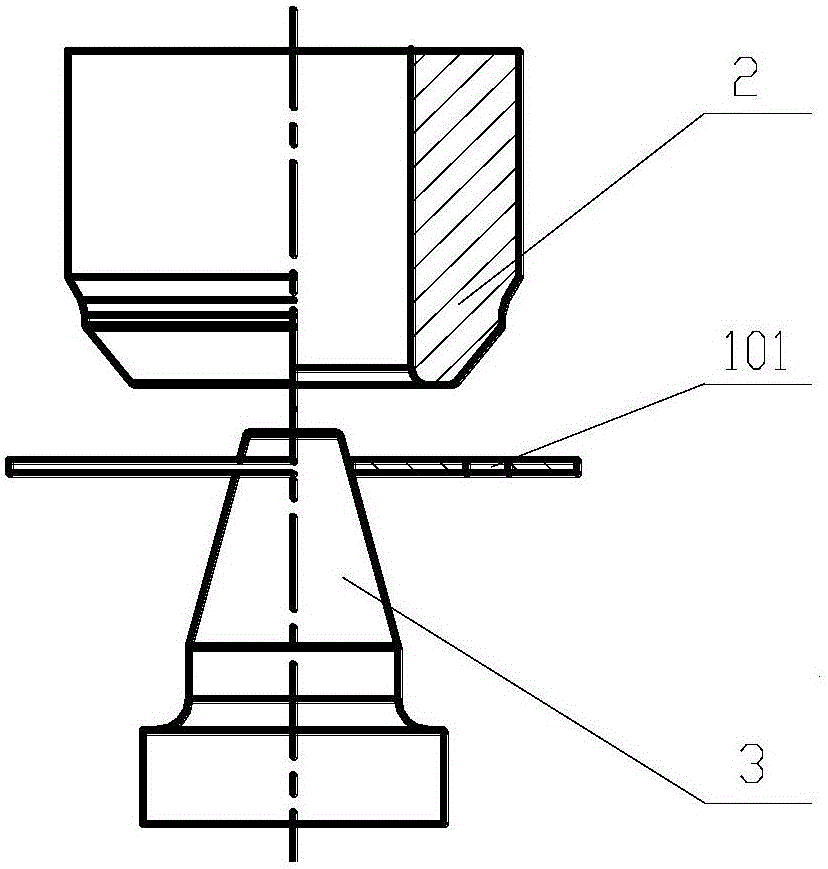

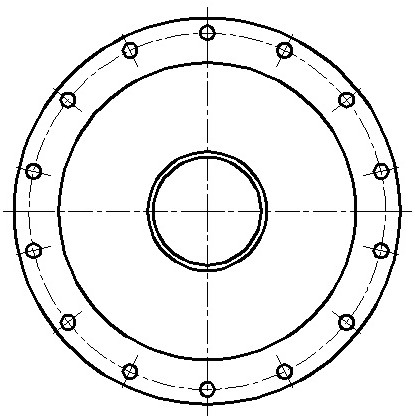

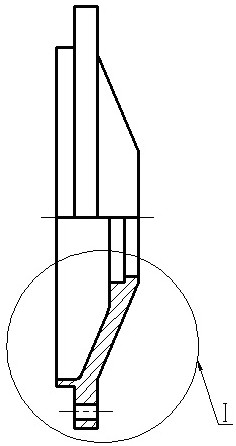

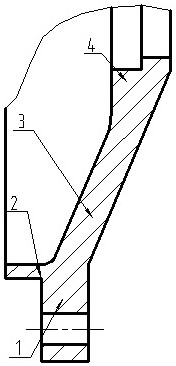

Composite material fixing shell for spray pipe and based on 3D printing

InactiveCN112523902ARealize integrated formingLightweight structureAdditive manufacturing apparatus3D object support structures3d printFiber-reinforced composite

The invention relates to a composite material fixing shell for a spray pipe and based on 3D printing. The composite material fixing shell is divided into a flange section, a convex seam allowance section, a conical section and a step section, the flange section is of a cylinder equal-wall-thickness structure, and a plurality of round holes are evenly distributed in the end face in the circumferential direction; the seam allowance section is of a short cylinder equal-wall-thickness structure and is perpendicular to the flange section; the conical section is of a conical equal-wall-thickness structure and is in smooth transition connection with the convex seam allowance section and the flange section; the step section is a rotary body, the inner surface of the step section is an end surface,and the outer surface of the step section is a short end surface plus a conical surface; one end of the step section is of a one-step structure, and the other end of the step section is in smooth transition connection with the conical section; and the flange section, the convex seam allowance section, the conical section and the step section are all made of continuous fiber reinforced composite materials and are integrally formed through an additive manufacturing process, and all the structures are in smooth transition connection. The 3D printing composite material fixing shell is formed, thestructural mass of the spray pipe is reduced, the mass ratio of an engine is increased, and the 3D printing composite material fixing shell has important significance in supporting future upgrading and generation crossing of missile weapons.

Owner:内蒙动力机械研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com