Method for forming naked eye three-dimensional display film device through double-sided alignment

A thin-film device and naked-eye three-dimensional technology, which is applied in the field of double-sided alignment forming naked-eye three-dimensional display thin film devices, can solve the problems of lightness, softness, and portability, and achieve the effects of being easy to bend, easy to carry, and improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But the following examples are limited to explain the present invention, and the protection scope of the present invention should include the entire content of the claims, and through the following examples, those skilled in the art can realize the entire contents of the claims of the present invention.

[0031] In a specific embodiment, a method for forming a naked-eye three-dimensional display film device by double-side alignment is as follows:

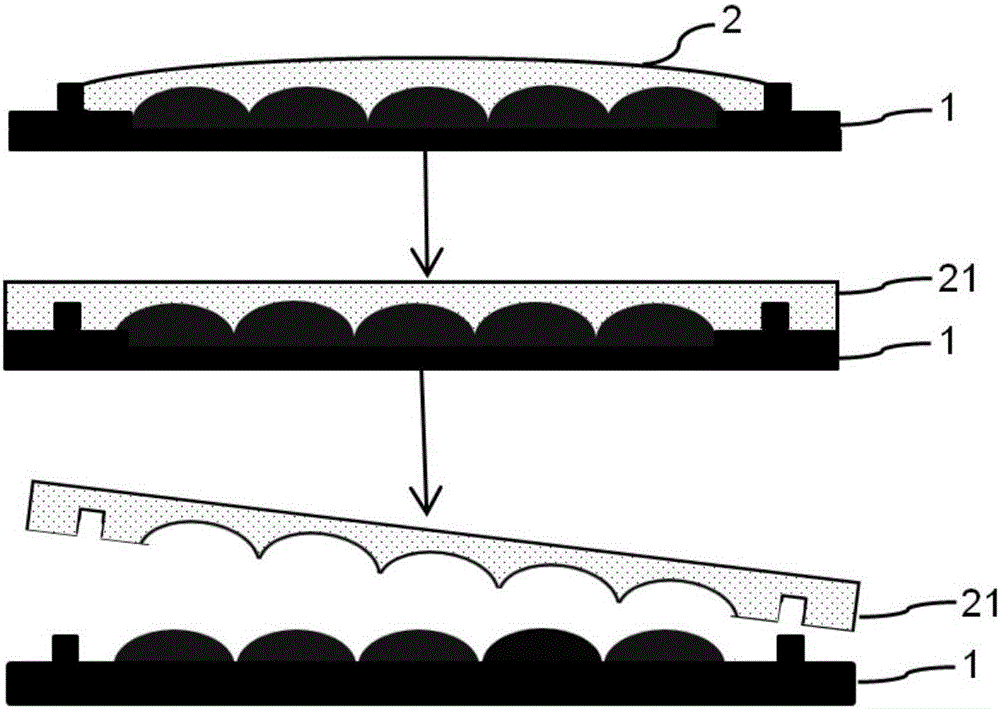

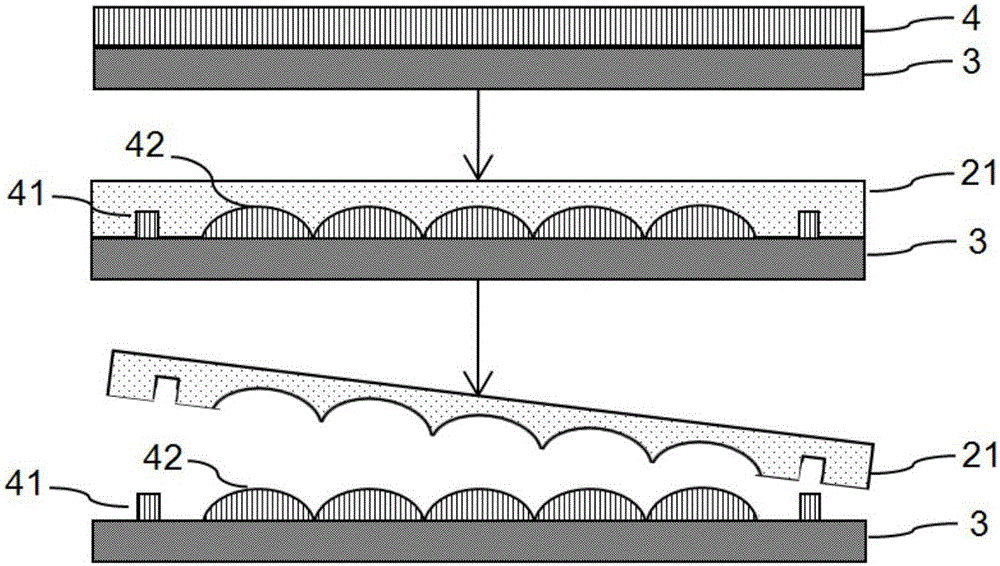

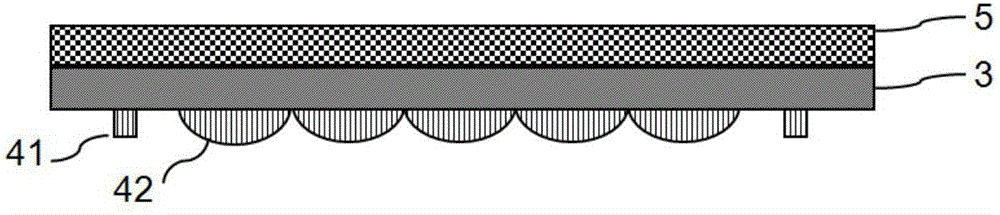

[0032] figure 1 Schematic illustration of the preparation of flexible imprint templates for imaging structures. The master plate 1 of the imaging structure is prepared by using a conventional method for preparing microlenses. The master plate is made of quartz material and carries both imaging structure information and alignment mark information. The imaging structure is a microlens array with an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com