Nitrogen-containing stainless steel, preparation method and use of parts

A technology for stainless steel and components, applied in the field of nitrogen-containing stainless steel and component preparation, can solve the problem that nitrogen-containing stainless steel is not suitable for additive manufacturing, and achieve the effect of improving process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In a second aspect, an embodiment of the present invention provides a method for preparing a nitrogen-containing stainless steel component, including:

[0053] The nitrogen-containing stainless steel is prepared into an ingot by induction furnace melting.

[0054] Further, the preparation method also includes:

[0055] The ingot is prepared into powder by nitrogen atomization;

[0056] The powder is machined into shape using an additive manufacturing process.

[0057] The above ingot was prepared into powder by nitrogen atomization. And carry out the qualification inspection on the powder composition, the qualified powder composition should meet the mass percentage range requirements of each composition in the above-mentioned nitrogen-containing stainless steel.

[0058] The nitrogen-containing stainless steel powder is processed into shape by an additive manufacturing process using nitrogen as a protective atmosphere. Unlike 316L and other stainless steels that use...

Embodiment 1

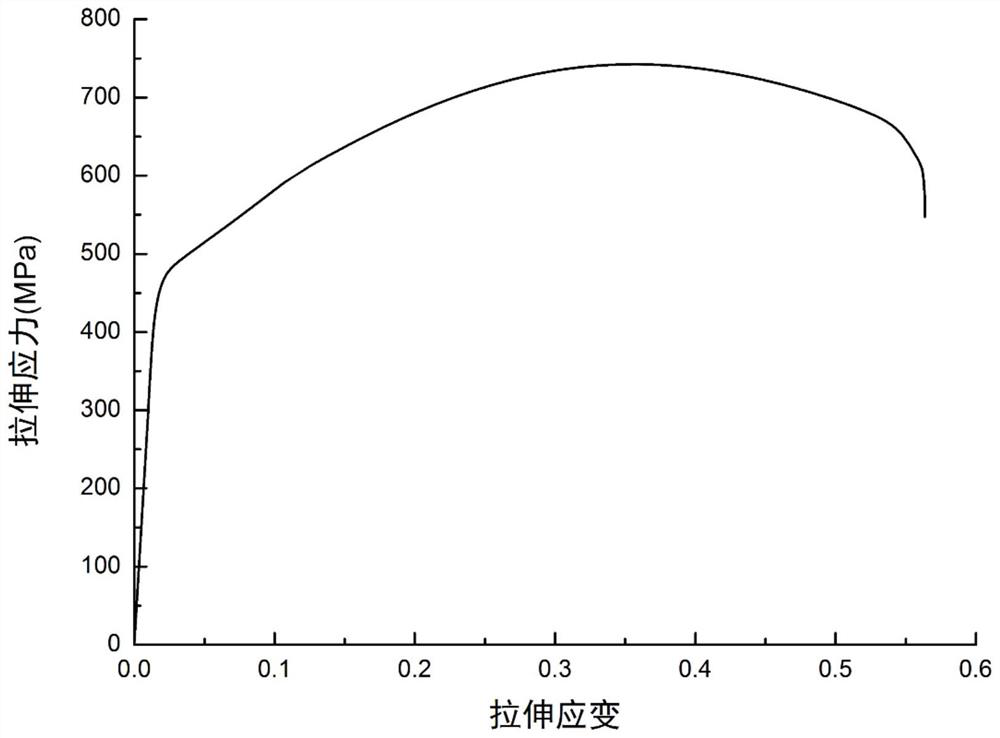

[0067] The nitrogen-containing stainless steel ingot is prepared by induction furnace melting, and the cross-sectional area perpendicular to the length direction of the ingot is about 80 square centimeters. The induction furnace smelting method is vacuum smelting, and the ingot is cooled and shaped by a metal mold. The surface of the above-mentioned ingot is cleaned, and the cleaning method includes grinding and lathe processing. The above ingot was prepared into powder by nitrogen atomization. And conduct qualification inspection on the powder components, wherein, the mass fraction of each component in the powder is C 0.04%, Si0.4%, Mn 6.8%, Ni 10.3%, Cr 18.7%, Mo 1.4%, N 0.09%, V 0.29 %, Nb 0.32%, and the balance is Fe; the powder composition meets the technical requirements of the nitrogen-containing stainless steel powder of the present invention. The nitrogen-containing stainless steel powder is processed into shape by an additive manufacturing process using nitrogen as...

Embodiment 2

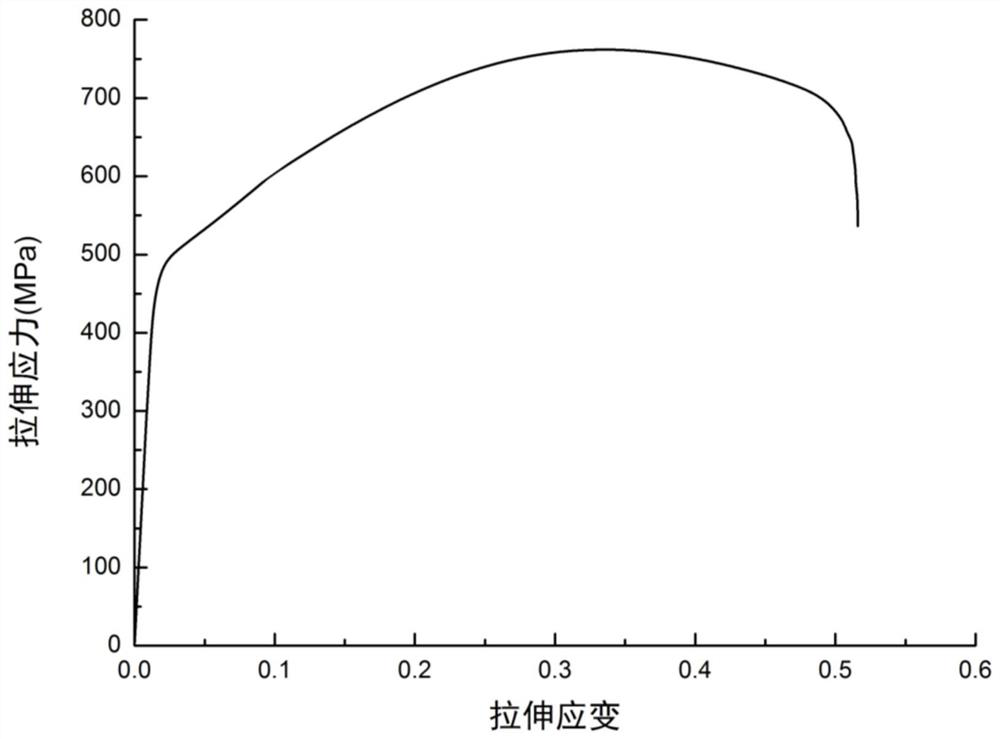

[0069] The main difference between this example and Example 1 is that the mass fraction of each component in the powder is C 0.08%, Si0.2%, Mn6.9%, Ni 10.8%, Cr 18.2%, Mo 1.0%, N 0.17%, V 0.26%, Nb 0.34% and the balance of Fe, the powder components meet the technical requirements of the nitrogen-containing stainless steel powder of the present invention. Tensile stress-strain curve reference for additively manufactured specimens figure 2 As shown, the alloy has excellent tensile strength and plasticity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com