A kind of material surface micro-nano composite enhanced boiling structure and preparation method and application thereof

A technology of enhanced boiling and composite structure, applied in the direction of manufacturing tools, welding equipment, heat exchange equipment, etc., can solve the problems of inability to provide multi-scale structure enhanced boiling heat transfer, electrochemical processing cycle is slow, not suitable for mass production, etc. , to achieve the effect of large operation area, short processing cycle and adjustable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention provides a method for preparing a micro-nano composite enhanced boiling structure on the surface of a material, which specifically includes the following steps:

[0064] 1) Pretreatment of base material:

[0065] The surface of the material is ultrasonically cleaned with water and ethanol, and vacuum-dried; the time of the ultrasonic cleaning is 0.25h to 2.0h, and the frequency of the ultrasonic cleaning is 60Hz to 120Hz; the temperature of the vacuum drying is 20°C to 100°C, The time of the vacuum drying is 2h~24h;

[0066] 2) Form the micro-nano composite enhanced boiling structure by laser integrated etching method, wherein the laser used is a pulsed laser with a pulse width of at least nanosecond level (10 -9 s); further, the pulse width of the pulsed laser can also be picosecond level (10 -12 s) or femtosecond level (10 -15 s); the output power of the laser is 3W-30W, the pulse frequency of the laser is 20Hz-200kHz, the moving speed of the laser is...

Embodiment 1

[0073] The micro-nano composite enhanced boiling structure on the surface of the copper sheet is prepared by using an ultraviolet semiconductor nanosecond pulsed laser with a wavelength of 355nm, including the following steps:

[0074] 1) Place a copper sheet with a thickness of 1mm in water and ethanol in order to ultrasonically clean it for 0.5h at a frequency of 100Hz, and dry it in vacuum at 20°C for 12h;

[0075] 2) The micro-nano composite enhanced boiling structure is formed by laser integrated etching method. The laser used is an ultraviolet semiconductor nanosecond pulse laser with a wavelength of 355nm and a pulse width of 10 -9 s; the laser output power is 5W, the laser pulse frequency is 20Hz, and the laser moving speed is 1000mm / s; the laser integrated etching method specifically includes the following steps:

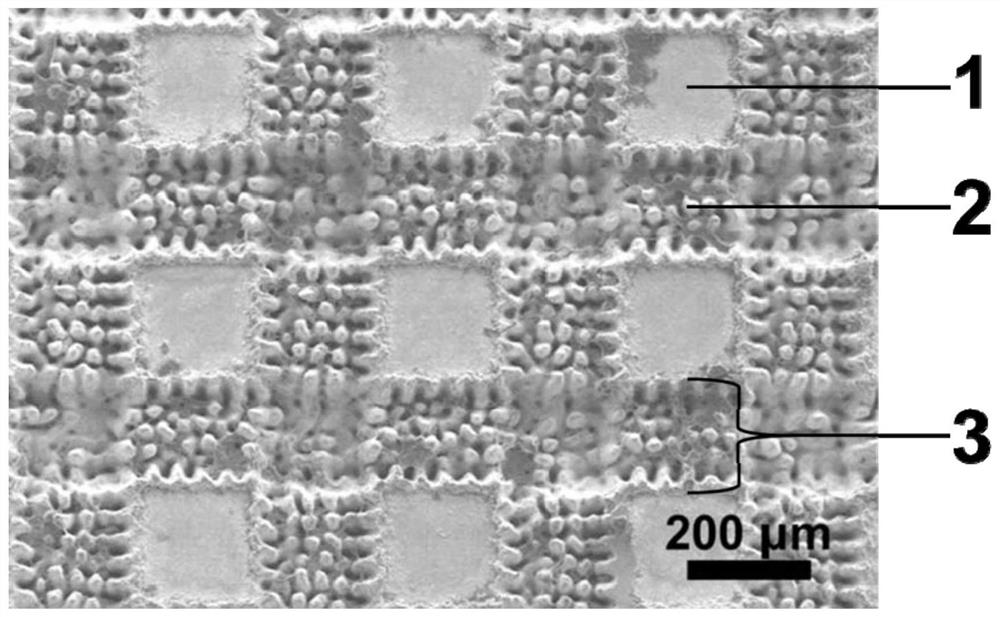

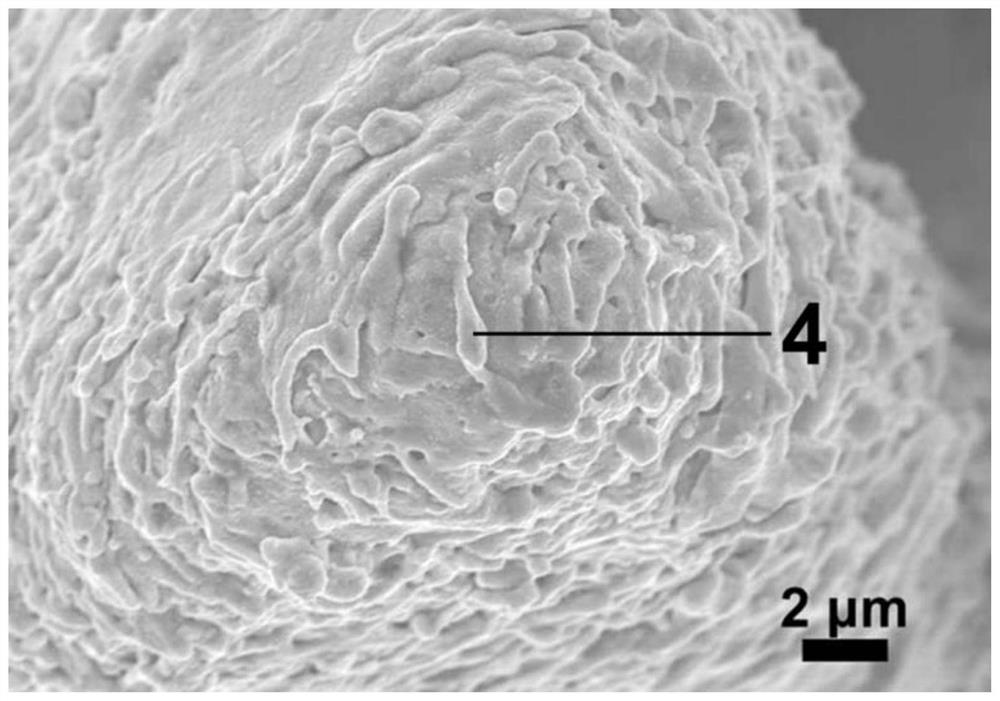

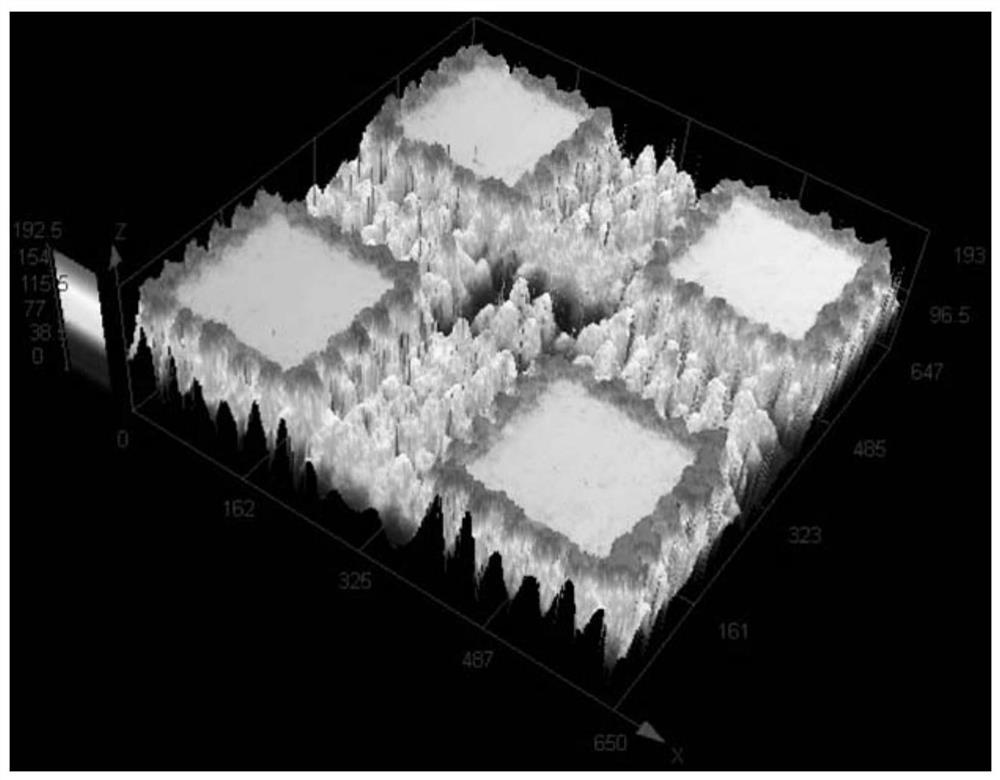

[0076] Place the pretreated copper sheet on the laser micromachining platform, pre-design the laser moving path, use the equal-spaced criss-cross grooves t...

Embodiment 2

[0086] The micro-nano composite enhanced boiling structure on the surface of the copper plate is prepared by using an ultraviolet semiconductor nanosecond pulsed laser with a wavelength of 355nm, including the following steps:

[0087] 1) Place a copper plate with a thickness of 3mm in water and ethanol in sequence for 0.5h, ultrasonic cleaning at a frequency of 100Hz, and vacuum-dry at 20°C for 12h;

[0088] 2) The micro-nano composite enhanced boiling structure is formed by laser integrated etching method. The laser used is an ultraviolet semiconductor nanosecond pulse laser with a wavelength of 355nm and a pulse width of 10 -9 s; the laser output power is 3W, the laser pulse frequency is 40Hz, and the laser moving speed is 1000mm / s; the laser integrated etching method specifically includes the following steps:

[0089] Place the pretreated copper plate on the laser micromachining platform, pre-design the laser moving path, use the equal-spaced criss-cross grooves to form co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com