Three-dimensional woven hollow structure preform based on digital guide template and forming method of preform

A technology of three-dimensional weaving and prefabrication, which is applied in the direction of textiles, papermaking, and woven fabrics, and can solve problems such as the limitation of overall mechanical properties and the poor bonding ability of bonded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

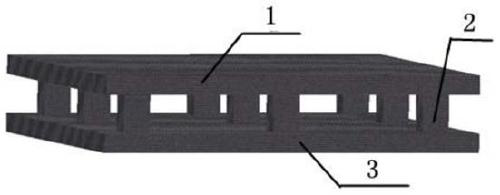

[0027] The three-dimensional woven hollow prefabricated body and its forming method based on the digital guide template proposed by the present invention are as follows: Figure 1-8 as shown in figure 1 As shown in , the forming of the three-dimensional hollow preform includes three parts, the upper panel 1, the middle support core 2, and the lower panel 3.

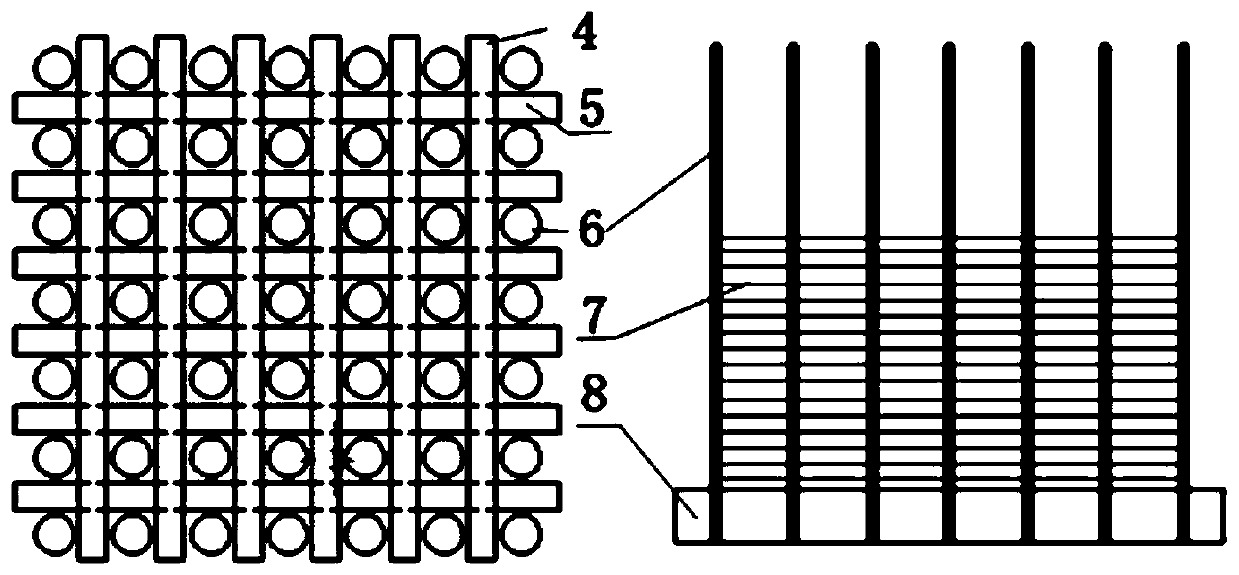

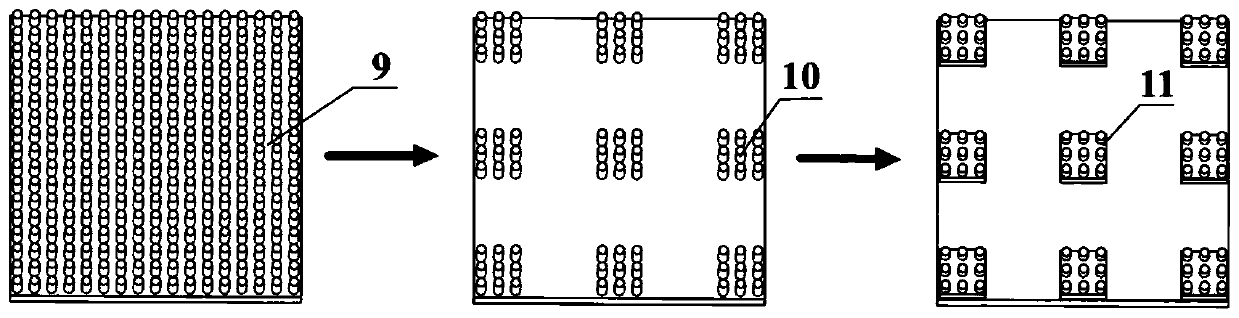

[0028] First, according to the design requirements of the hollow prefabricated body, the upper panel and the lower panel are woven layer by layer using the guide rod array, as shown in figure 2 As shown, the horizontal fibers 4 and the longitudinal fibers 5 are laid and formed along the array formed by the guide rods 6. The guide rods 6 are positioned by the guide rod fixing plate 8, and the laid fibers are stacked and formed layer by layer to obtain the upper panel and the lower panel. The weaving structure of the lower panel and the middle support core can adopt a single woven structure or a mixed structure, and can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com