Preparation method of special-shaped polymer structure reinforcing composite light-weight cement

A technology of structural reinforcement and polymer, which is applied in the field of preparation of composite lightweight cement, can solve problems such as confounding concrete research ideas, and achieve the effect of abundant raw materials, simple manufacturing process, and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

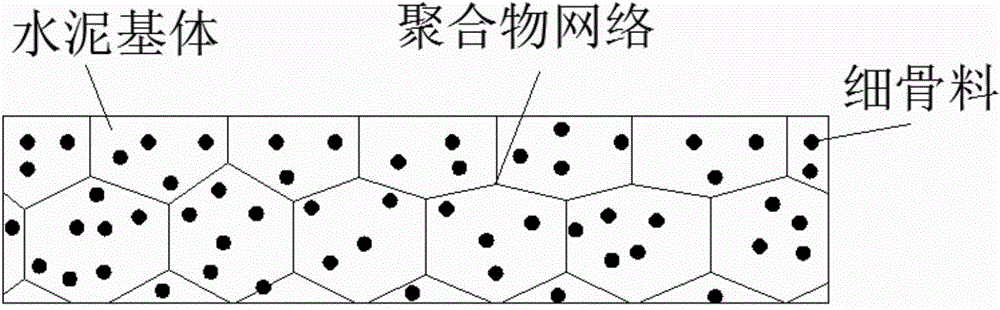

[0012] Specific implementation mode 1: The preparation method of the composite lightweight cement reinforced by the special-shaped polymer structure in this implementation mode is realized according to the following steps:

[0013] 1. Fabrication of polymer special-shaped structures: The thermoplastic material is processed into a highly stable spatial structure by fusion deposition forming method; the thermoplastic material is polyethylene, polypropylene, polyvinyl chloride, nylon or polyurethane;

[0014] 2. Production of cement slurry: Stir ordinary portland cement, fine aggregate and water evenly according to the volume ratio 1:(1~4):(1~1.5);

[0015] 3. Forming of lightweight cement composite materials: fix the special-shaped polymer structure in the mold, and the special-shaped polymer structure accounts for 0.1% to 30% of the inner volume of the mold, and then pour cement slurry under vibration conditions, and dry it naturally after pouring. After opening the mold, clean...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the space structure with high stability in Step 1 is a diamond three-dimensional network structure or a graphite crystal hexagonal three-dimensional network structure. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that Portland cement and fine aggregate are evenly stirred according to the volume ratio of 1:2:1 in step 2. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com