Heterogeneous multilayer heat prevention-heat insulation composite material prefabricating body structure and molding process thereof

A composite material and forming process technology, applied in the directions of lamination, layered products, lamination devices, etc., can solve the problem of poor thermal performance stability, affecting the reliability of the thermal protection system of hypersonic aircraft, and the weight of the thermal protection system being too large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

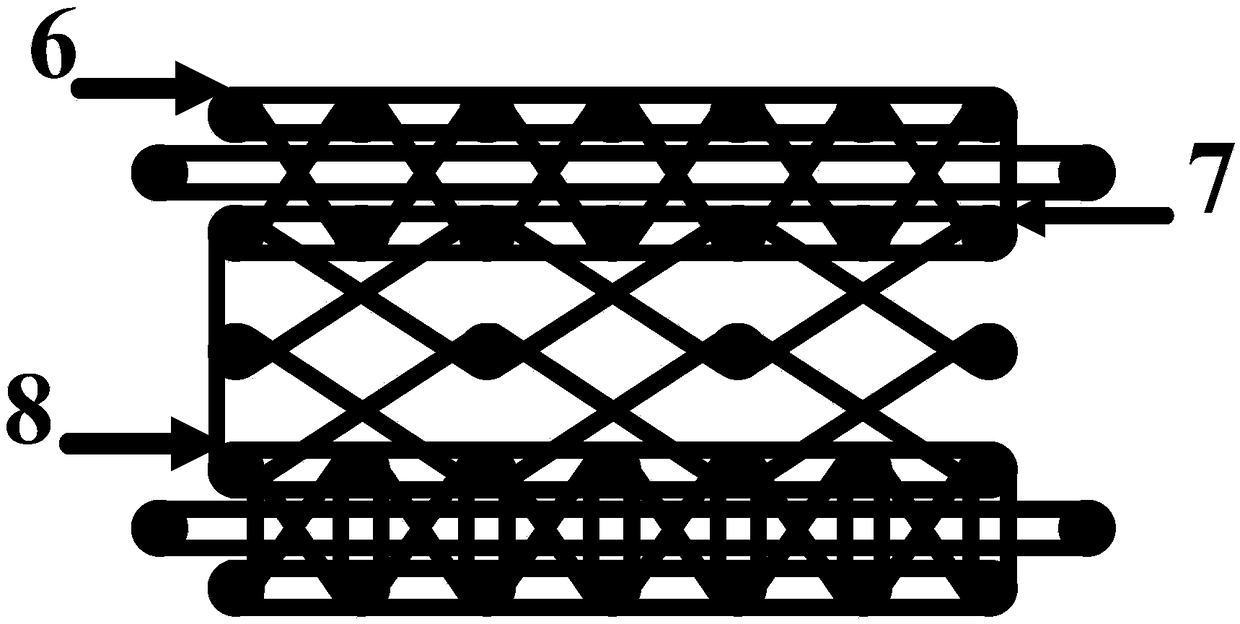

[0033] Prepare the positioning plate 5 and the guide rod 4, the diameter of the guide rod is 1.2mm, punch a hole on the positioning plate 5, the hole diameter is 1.2mm, fix the guide rod 4 on the positioning plate 5, as figure 2 shown.

[0034] image 3 It is a top view of the guide rod 4 distribution, the center distance of the guide sleeves in the y direction is 2 mm, the center distance of the first, second, fourth and fifth rows of guide sleeves in the x direction is 2 mm, and the center distance of the third row of guide sleeves in the x direction is 4 mm.

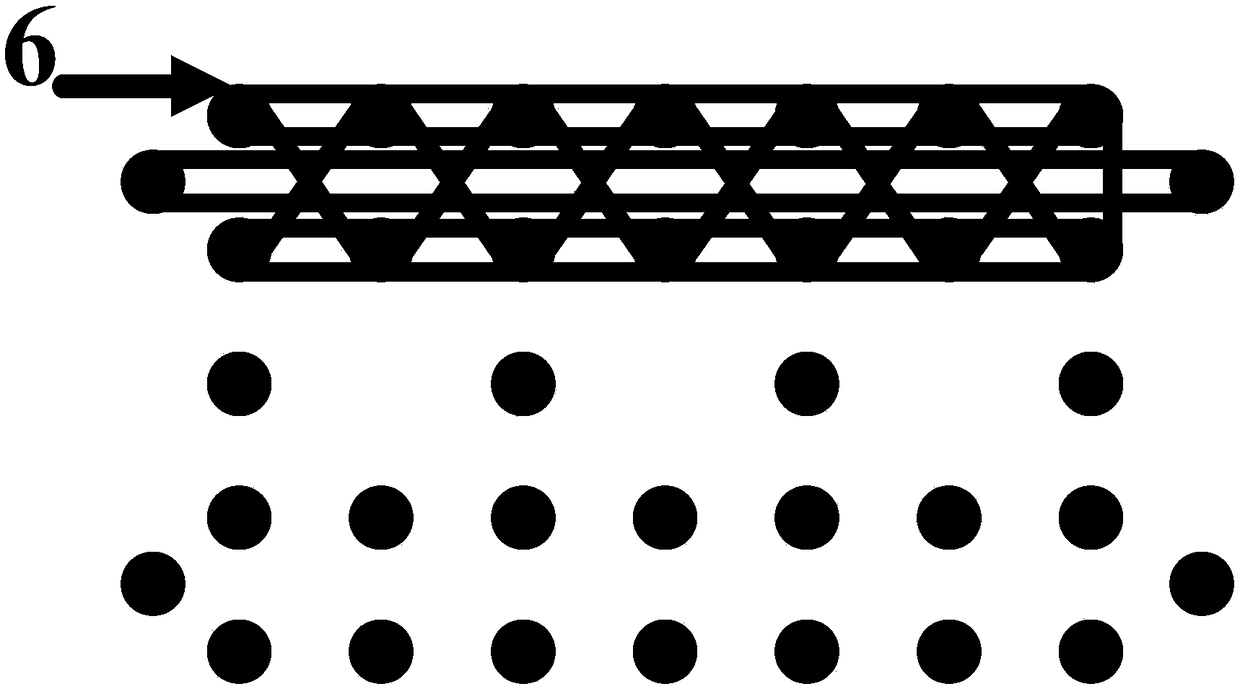

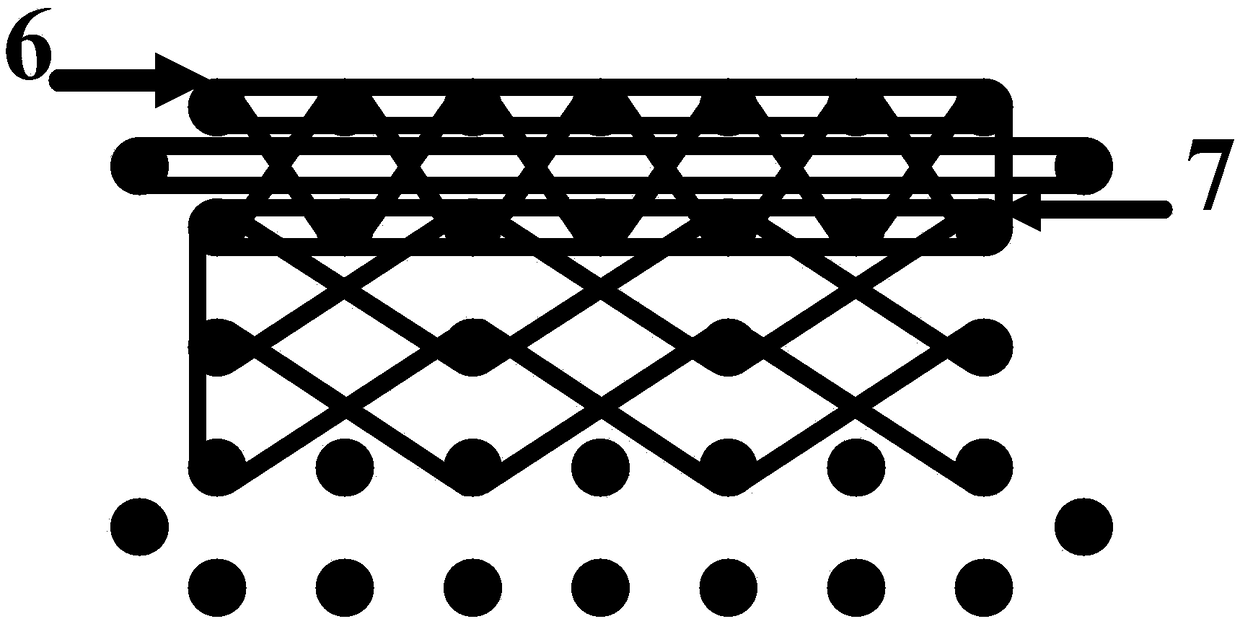

[0035] The heat-proof structure layer 1 is made of 3K SiC fiber with an area density of 1.79g / cm 3 , the center distance of the guide sleeve in the x and y directions is 2mm, and the fibers follow the guide sleeve according to Figure 4 The method of middle 6 is used for cross-winding, and then laid along the horizontal direction of the guide sleeve to prepare a heat-resistant structural layer 1 with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com