Integrated slab micro heat pipe structure and 3D printing manufacturing method thereof

A flat-plate micro heat pipe and 3D printing technology, applied in the directions of additive manufacturing, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high manufacturing cost, long production cycle, and many processes, so as to reduce production costs and improve performance. and reliability, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below.

[0024] The specific steps of an integrated flat micro heat pipe structure and its 3D printing manufacturing method of the present invention are:

[0025] The first step, the structural area division of the integrated flat micro heat pipe

[0026] The raw material of the flat micro heat pipe structure is metal powder, which is manufactured by laser selective melting 3D printing process.

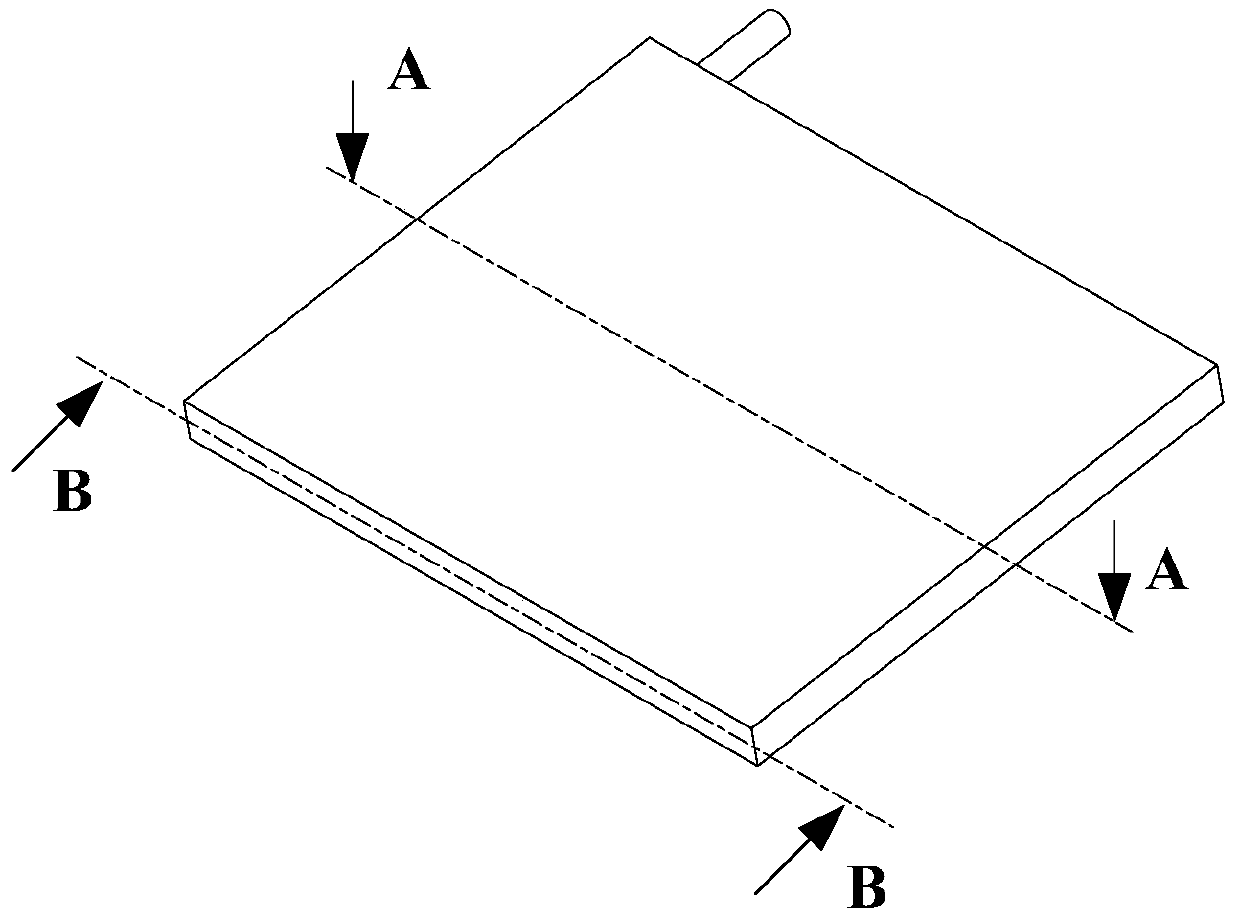

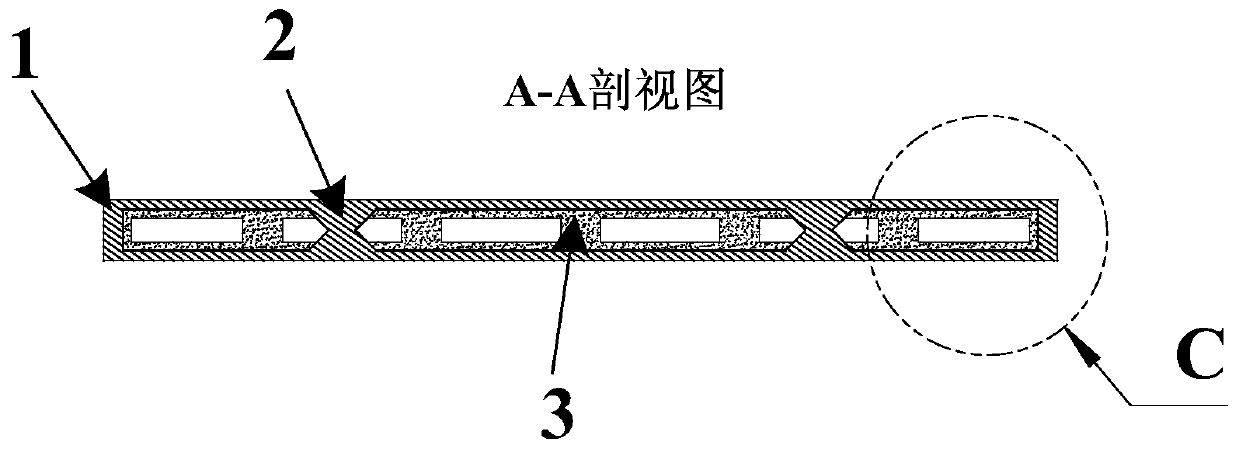

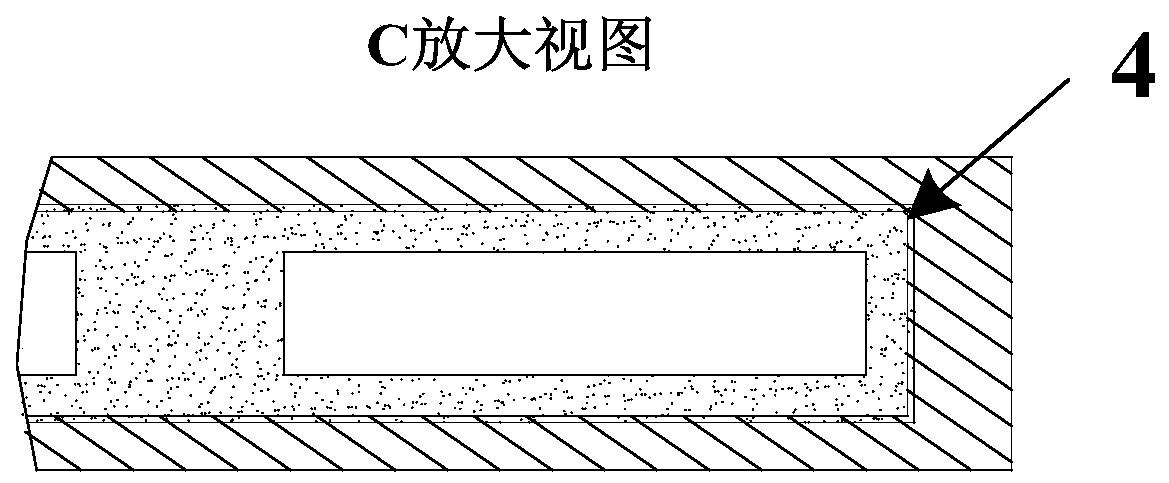

[0027] The integrated flat micro-heat pipe structure is an integral structure, and its material is metal powder, which is divided into four parts: a solid shell 1, a solid support column 2, an internal capillary liquid-absorbing core 3 and an overlapping area 4. Wherein, the inner surface of the solid shell 1 of the integrated flat micro-heat pipe structure is in contact with a plurality of internal capillary liquid-absorbing cores 3, such as Figure 2a shown.

[0028] The material of the shell part 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com