Package with strap handle

a strap handle and packaging technology, applied in the direction of packaging, packaging preventing decay, sealing, etc., can solve the problems of affecting the integrity of the package, affecting the quality of the package, so as to achieve stable and pressure-distributing, easy handling, and easy pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

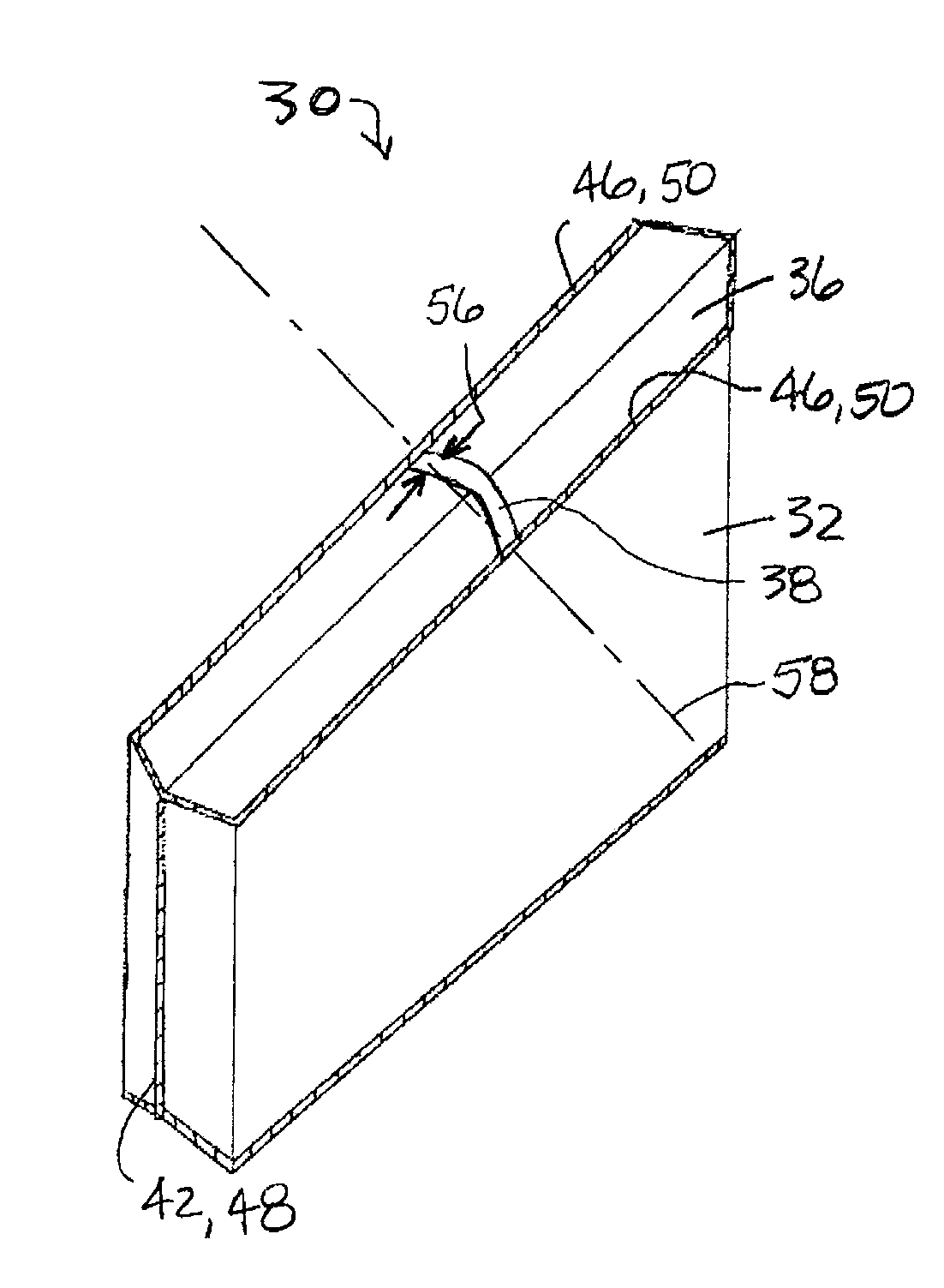

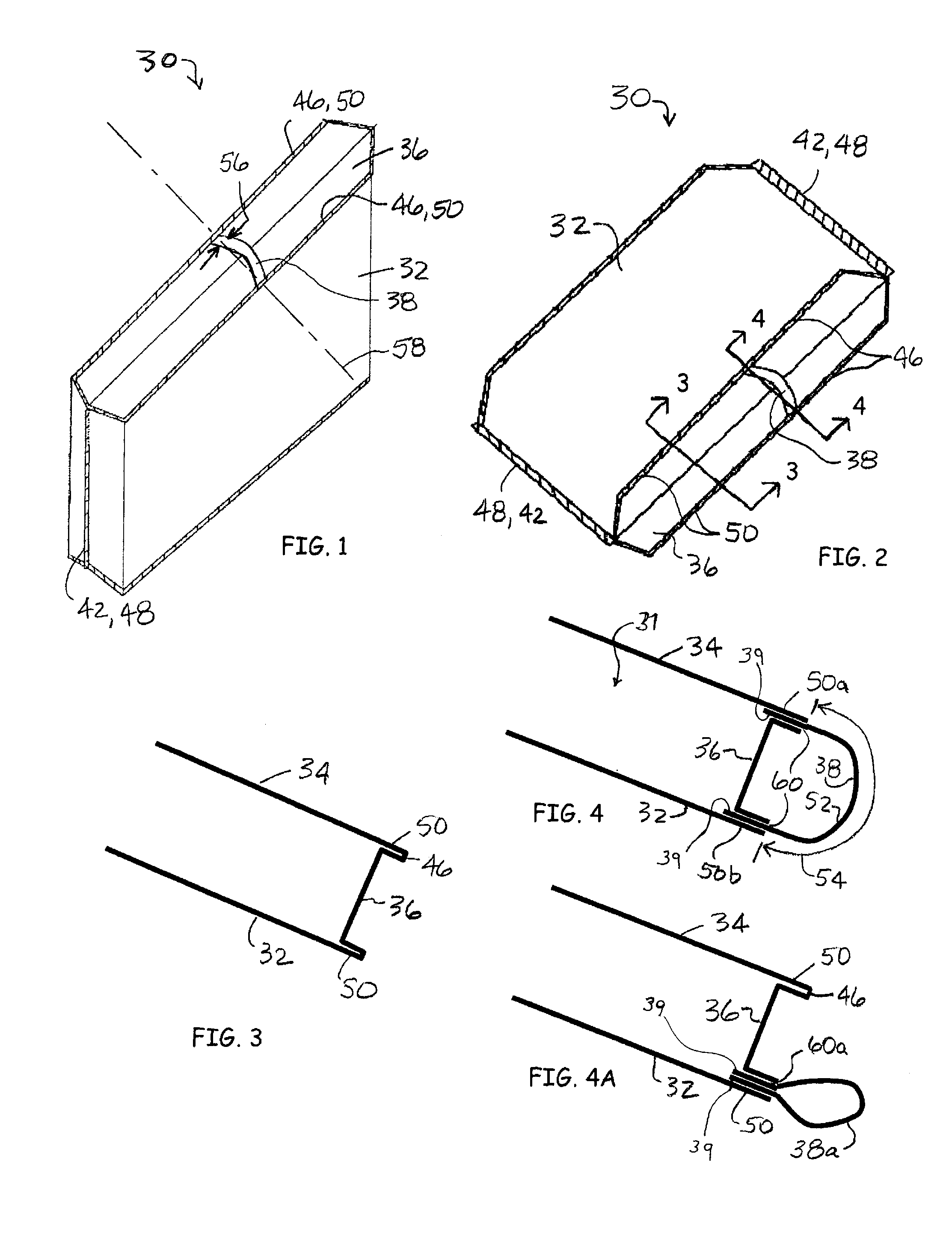

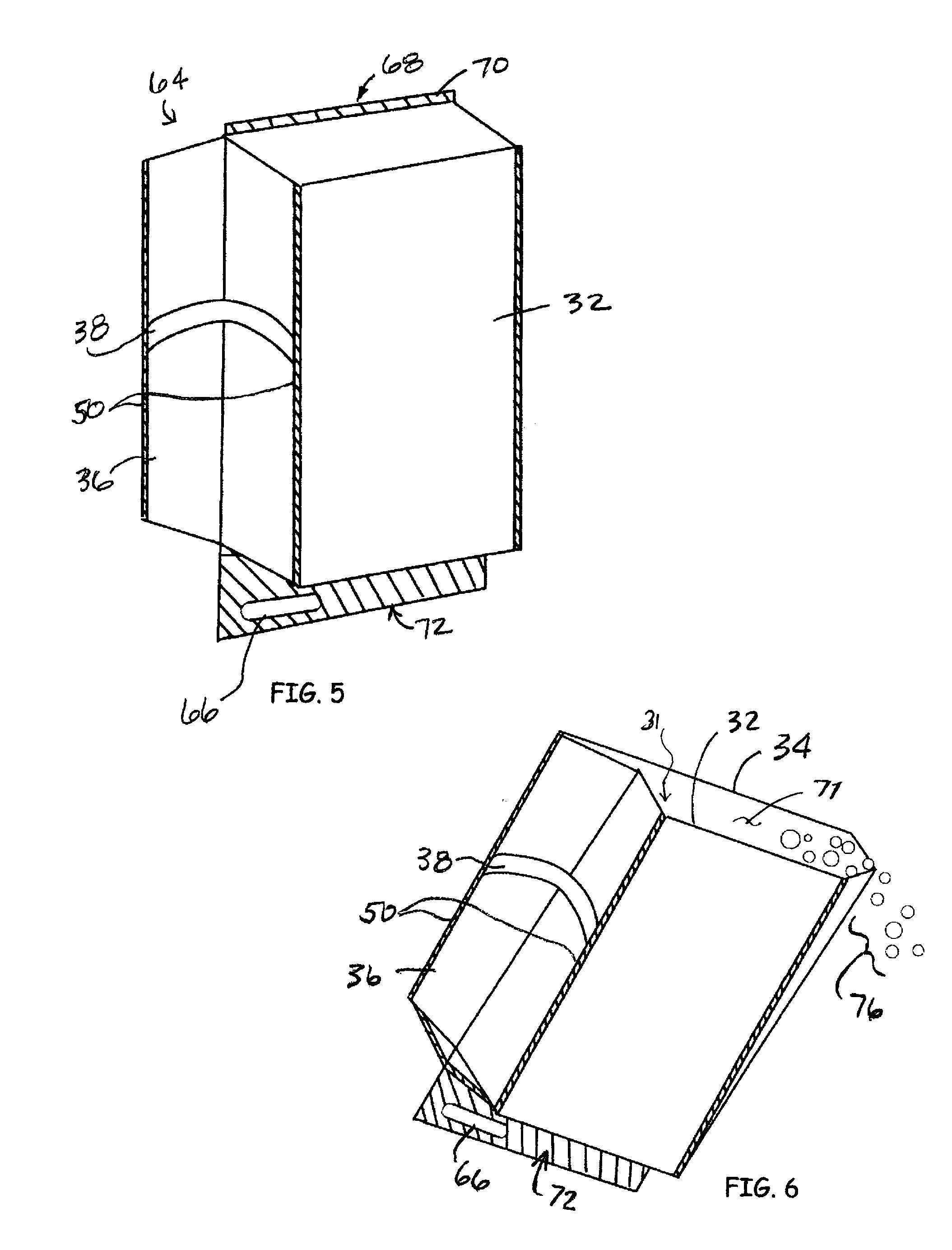

[0021]Referring to FIGS. 1 through 4, a strap handled package 30 is depicted in an embodiment of the invention. The strap handled package 30 may include a first panel portion 32 and a second panel portion 34 with a gusset panel portion 36 disposed therebetween. Various embodiments can further include additional panels, such as sides, bottom, top, etc., gusseted or non-gusseted. The package panel portions can be formed of a single web material and folded or formed to define the distinct panel portions, or one or more film materials or webs can be separately joined to define the various structures of the package. The cross-hatching in the figures is used generally to denote sealing and / or panel edges or seams.

[0022]In one embodiment, a portion of a handle 38 extends between the first and second panels 32 and 34 external to the gusset portion 36. The first and second panels 32 and 34 may be further characterized as having end edges 42 and longitudinal edges 46. In one embodiment, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length dimension | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com