Technique for integrally and quickly forming special shaped rudder shaft of aircraft

A process method and aircraft technology, applied to the improvement of process efficiency, additive processing, metal processing equipment, etc., can solve the problems of complex manufacturing process, low pass rate, and difficult forming of rudder shaft segments, and meet the requirements of research and development. Effects of reduced processing costs and improved material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

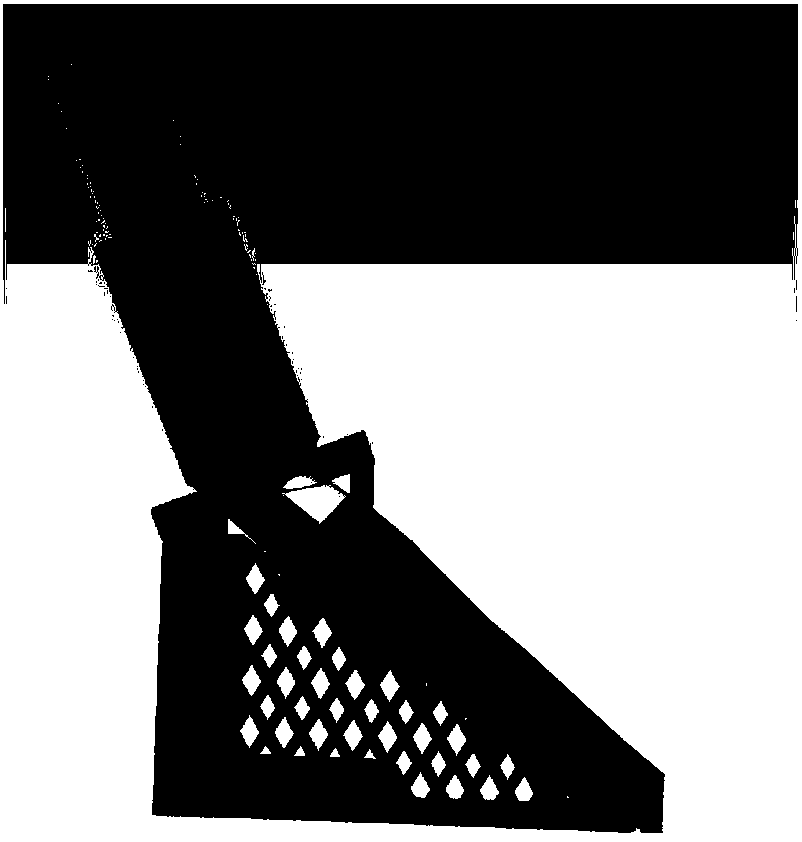

[0049] The material used in this embodiment is GH4169 alloy. Such as Figure 5 shown in the following steps:

[0050] The first step, model preparation

[0051] The three-dimensional model of the rudder shaft is processed, and the three segments are summed as a whole, and a margin of 2 mm is added to the outer surface of the long end and short end of the rudder shaft, and a margin of 0.5 mm is added to all inner profiles. Add a 0.1mm deep "U"-shaped reference line around the surface of the rudder shaft as a line drawing reference for finishing. According to the structural characteristics and forming direction of the rudder shaft, a solid process support is added at the bottom of the long end of the rudder shaft. The thickness of the solid body is 20mm. Multiple diamond-shaped hollow supports are added to the solid body to improve the forming efficiency and powder utilization rate.

[0052] The second step, slice file preparation

[0053] Import the processed part model int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com