Screw dowel for fastening rails

a technology of screw dowels and fastening rails, which is applied in the direction of track superstructure, roads, construction, etc., can solve the problems of cracks and fissures, different mechanical and physical properties of screw anchors made of plastic from the surrounding material, and widening of cracks, so as to prevent the expansion of plastic materials, prevent the effect of pressure stress between the anchor and the surrounding concrete, and high strength of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

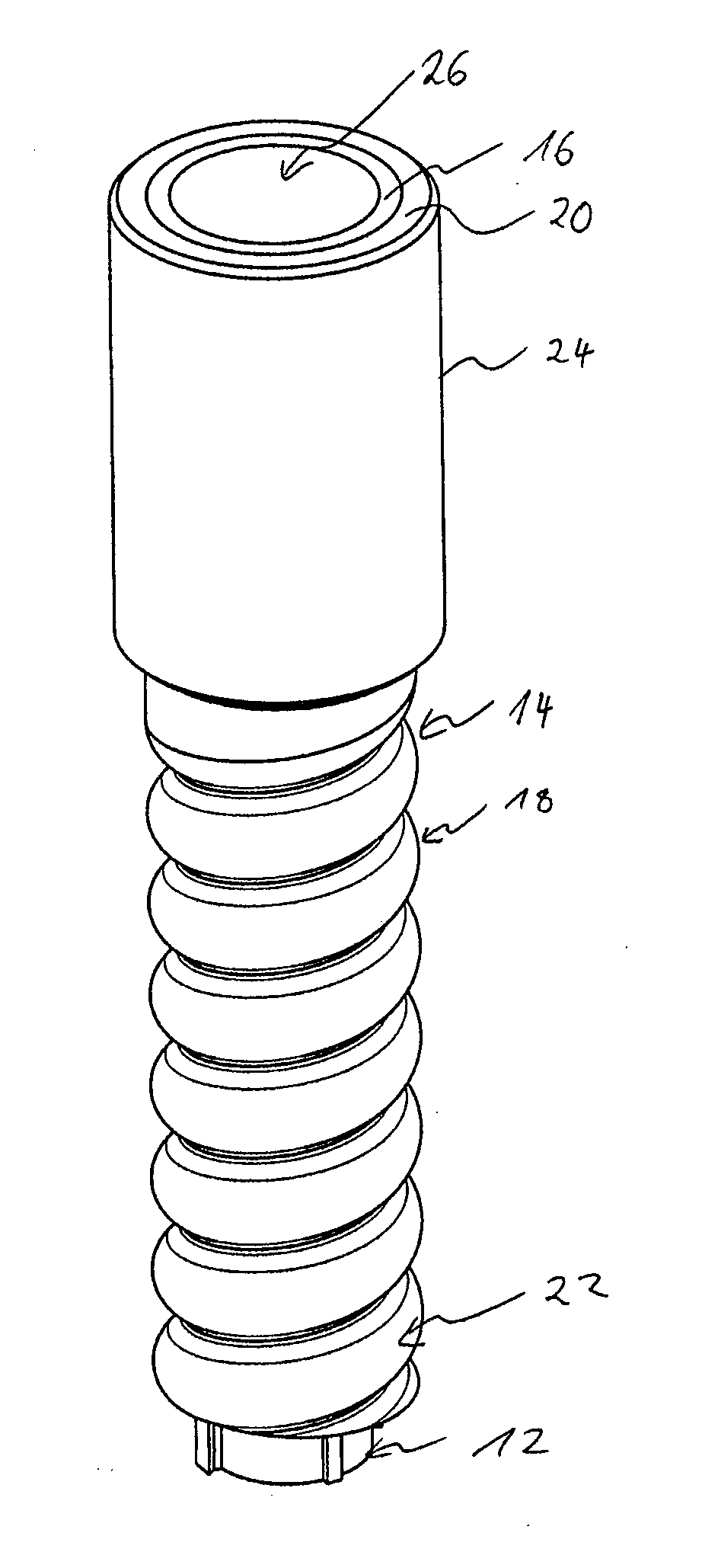

[0020]FIG. 1 shows a cross-section of a screw anchor according to the invention; and

second embodiment

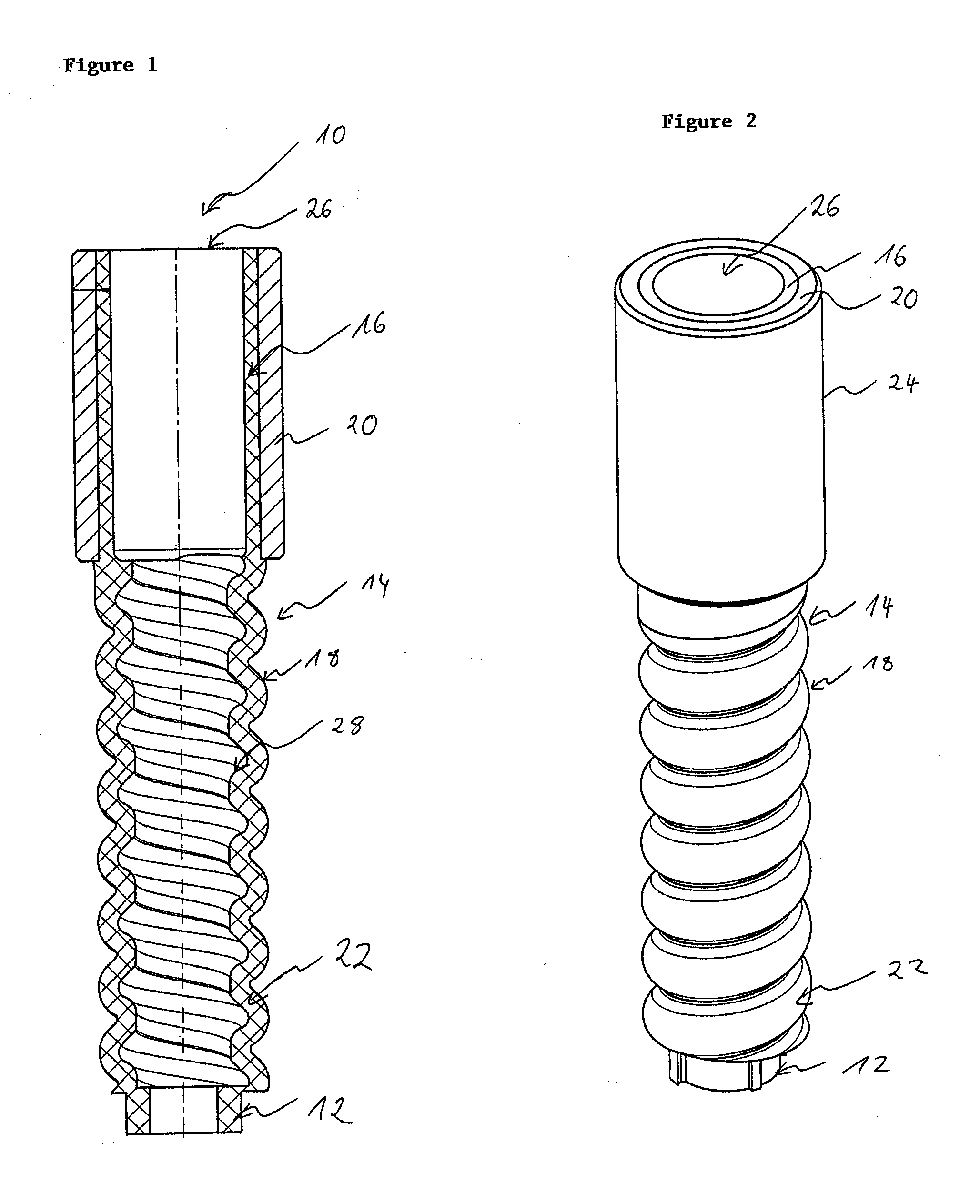

[0021]FIG. 2 is a screw anchor according to the invention.

WAYS OF EXECUTING THE INVENTION

[0022]The screw anchor 10 represented in FIG. 1 consists of the base body 22 made of plastic material and is formed of an upper partial section 16 without external thread, a middle partial section 14 with external threads 18 disposed on the exterior of the screw anchor 10 and internal threads 28 disposed on the interior of the screw anchor and a lower partial section 12. The internal thread can also be executed as a round thread but can differ from the external thread 18 in terms of thread flank and thread pitch.

[0023]The upper partial section 16 is executed essentially in a cylindrical shape and constructed integrally with the thread section 14 as well as the lower partial section 12. Form-fit elements in the shape of ribs extending longitudinally to the screw anchor can be provided on the external circumference of the lower partial section 12, said elements preventing or at least impeding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com