Photoelectrical semiconductor component with 3-familty Ni compound semiconductor buffer layer and its making method

An optoelectronic semiconductor and manufacturing method technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of high hardness of the accumulated stress buffer layer, deterioration of epitaxial structure quality, lattice mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

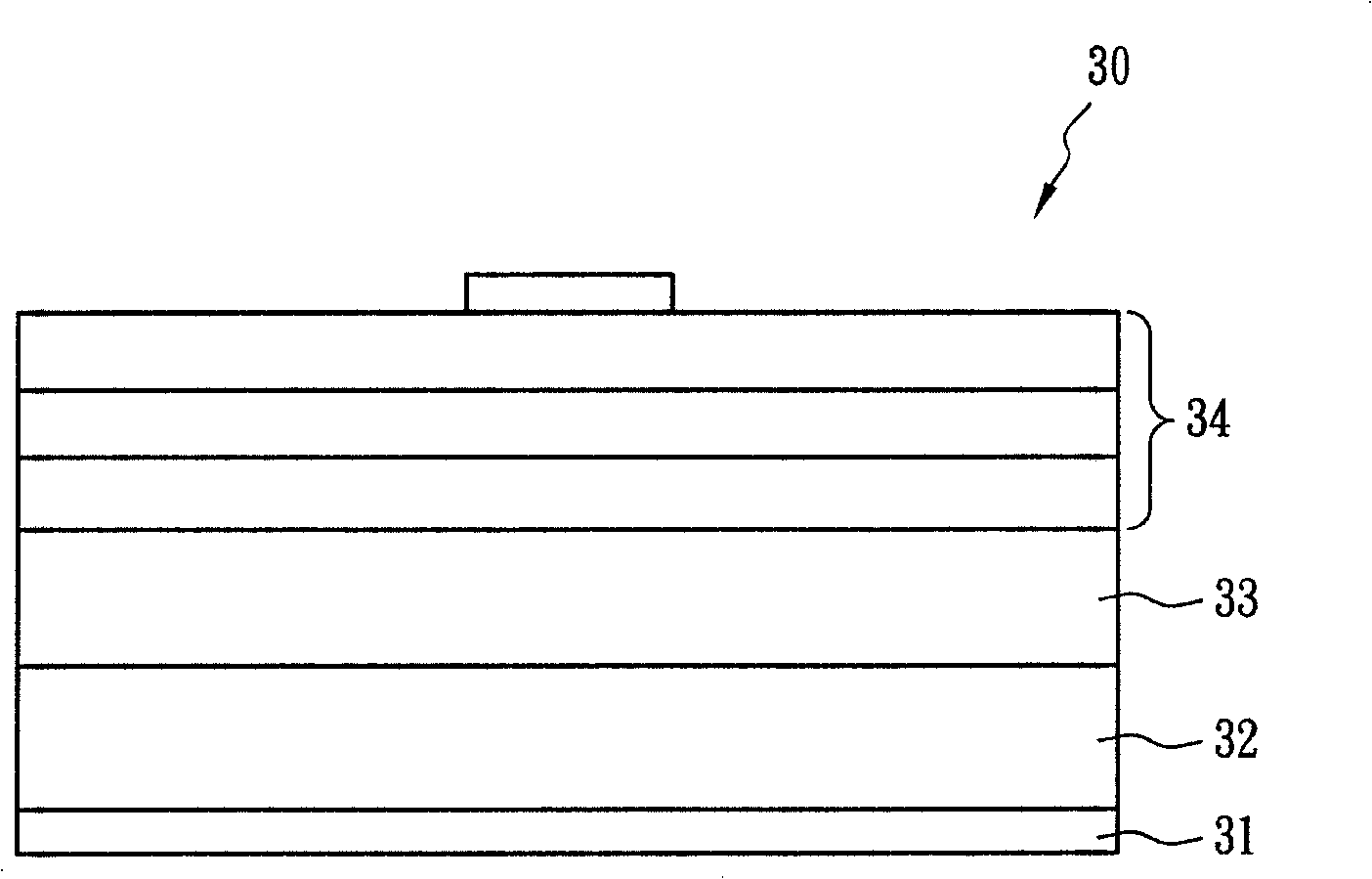

[0026] Figure 5 It is a structural diagram of the optoelectronic semiconductor component with P-type III nitrogen compound semiconductor of the present invention. Generally speaking, to make this optoelectronic semiconductor component 50 is to first provide a substrate 51, such as: sapphire (that is, aluminum oxide compound Al 2 o 3 ), silicon carbide (SiC), silicon, zinc oxide (ZnO), magnesium oxide (MgO), gallium arsenide (GaAs), etc., and different material layers are formed on the substrate 51 . Because the substrate 51 does not match the lattice constant of the III-group nitrogen compound, it is necessary to form at least two In on the substrate 51. x Ga 1-x N layer 521 and at least two In y Ga 1-yThe N layers 522 overlap a buffer layer 52 . Then grow an N-type semiconductor material layer 53 on the buffer layer 52 , which can be used as the N-type semiconductor material layer 53 to produce an N-type GaN-doped silicon thin film by epitaxy. Then grow an active laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com