Large-area flexible perovskite solar cell and manufacturing method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency and poor mechanical stability of large-area devices, so as to improve photoelectric conversion efficiency and repeatability, improve Mechanical stability, the effect of improving spectral utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention also provides a preparation method of a large-area flexible perovskite solar cell, comprising the following steps:

[0039] (1) Surface modification of the flexible transparent electrode to improve the hydrophilicity of the electrode surface;

[0040] (2) preparing a polymer template layer on the surface of the flexible transparent electrode after surface treatment;

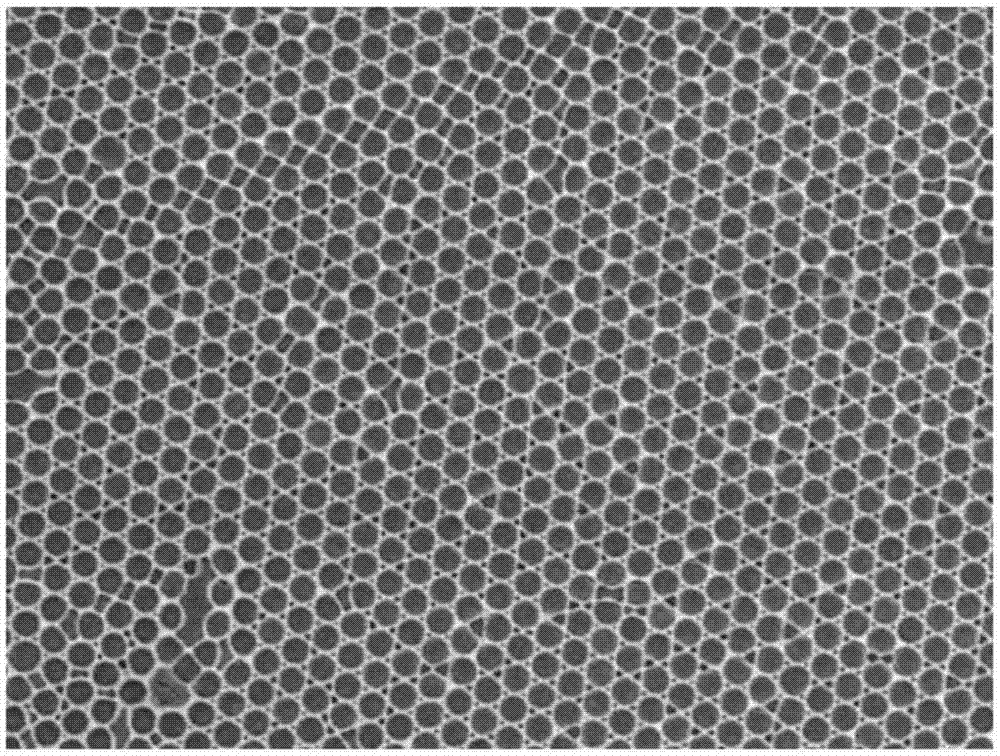

[0041] (3) filling the nano-honeycomb scaffold material on the polymer template layer, and then removing the polymer template layer to obtain a nano-honeycomb scaffold;

[0042] (4) A perovskite layer, an optional interface transport layer, and a metal electrode are sequentially deposited on the upper layer of the nano-honeycomb scaffold to prepare a flexible perovskite solar cell.

[0043] According to the present invention, the surface energy of the flexible transparent electrode substrate is low, and the bonding with the conductive film will directly affect the overall quality of the flex...

Embodiment 1

[0065] A conductive polymer transparent electrode based on PET substrate (surface sheet resistance: 30Ω / □; light transmittance: 85%; 3cm×3cm) was selected, and its surface was treated with air plasma (100w, 2min) for use.

[0066] In a solvent with a volume ratio of deionized water and ethanol of 2:1, after 35min ultrasonic treatment, it was fully dispersed, and prepared into a polystyrene microsphere dispersion liquid with a mass fraction of 2% and a particle size of 200 nm, for use.

[0067] Add 100 μl of polystyrene microsphere dispersion dropwise to the transparent electrode substrate after air plasma treatment, spin-coat at 2000 rpm for 30 s, and place the spin-coated film in an oven at 80 °C for 20 min to complete the polymer template layer. After the film was cooled, 100 μl of nano-honeycomb scaffold material PEDOT:PSS Al 4083 (based on the total mass of the material, doped with isopropanol with a mass fraction of 10%, can improve wettability and ensure film spreading) d...

Embodiment 2

[0072] A conductive polymer transparent electrode based on PET substrate (surface sheet resistance: 30Ω / □; light transmittance: 85%; 3cm×3cm) was selected, and its surface was treated with air plasma (100w, 2min) for use.

[0073] In a solvent with a volume ratio of deionized water and ethanol of 2:1, after 40 minutes of ultrasonic treatment, it was fully dispersed, and prepared into a polystyrene microsphere dispersion liquid with a mass fraction of 2% and a particle size of 500 nm, for use.

[0074] Add 100 μl of polystyrene microsphere dispersion dropwise to the transparent electrode substrate after air plasma treatment, spin-coat at 2000 rpm for 30 s, and place the spin-coated film in an oven at 80 °C for 20 min to complete the polymer template layer. After the film was cooled, 100 μl of nano-honeycomb scaffold material PEDOT:PSS Al 4083 (based on the total mass of the material, doped with isopropanol with a mass fraction of 10%, can improve wettability and ensure film spre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com