A wide-spectrum inorganic perovskite solar cell structure and its preparation method

A technology of solar cells and inorganic calcium, applied in the field of solar cells, can solve the problems of narrow spectral absorption range, low efficiency of inorganic perovskite solar cells, wide band gap, etc., to improve efficiency, increase absorption, improve spectral utilization and light Effect of Raw Carrier Extraction Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

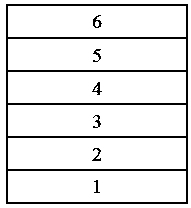

[0024] Such as figure 1 As shown, the structure of a wide-spectrum inorganic perovskite solar cell is conductive glass-1, photoanode layer-2, electron transport layer-3, perovskite light-absorbing layer-4, and photoactivation layer-5 from top to bottom. , Electrode layer-6.

[0025] (1) Conductive glass 1 composed of transparent glass and FTO was ultrasonically cleaned with acetone, isopropanol, and deionized water for 10 to 20 minutes, then dried with nitrogen flow, and then the conductive glass 1 was treated with ultraviolet and ozone for 20 minutes. ~30 minutes.

[0026] (2) Prepare the photoanode layer 2 on the conductive glass 1 . A layer of dense titanium dioxide was coated on conductive glass using the sol-gel method.

[0027] (3) The electron transport layer 3 is prepared on the photoanode layer 2 . A layer of mesoporous titania was prepared on dense titania using a hydrothermal method.

[0028] (4) Prepare the perovskite light absorbing layer 4 on the electron tr...

Embodiment 2

[0032] Such as figure 1 As shown, the structure of a wide-spectrum inorganic perovskite solar cell is conductive glass-1, photoanode layer-2, electron transport layer-3, perovskite light-absorbing layer-4, and photoactivation layer-5 from top to bottom. , electrode layer-6.

[0033] (1) Conductive glass 1 composed of transparent glass and FTO was ultrasonically cleaned with acetone, isopropanol, and deionized water for 10 to 20 minutes, then dried with nitrogen flow, and then the conductive glass 1 was treated with ultraviolet and ozone for 20 minutes. ~30 minutes.

[0034] (2) Prepare the photoanode layer 2 on the conductive glass 1 . A layer of dense titanium dioxide was coated on conductive glass using the sol-gel method.

[0035] (3) The electron transport layer 3 is prepared on the photoanode layer 2 . A layer of mesoporous titania was prepared on dense titania using a hydrothermal method.

[0036] (4) Prepare the perovskite light absorbing layer 4 on the electron tr...

example 3

[0040] Such as figure 1 As shown, the structure of a wide-spectrum inorganic perovskite solar cell is conductive glass-1, photoanode layer-2, electron transport layer-3, perovskite light-absorbing layer-4, and photoactivation layer-5 from top to bottom. , electrode layer-6.

[0041] (1) Conductive glass 1 composed of transparent glass and FTO was ultrasonically cleaned with acetone, isopropanol, and deionized water for 10 to 20 minutes, then dried with nitrogen flow, and then the conductive glass 1 was treated with ultraviolet and ozone for 20 minutes. ~30 minutes.

[0042] (2) Prepare the photoanode layer 2 on the conductive glass 1 . A layer of dense titanium dioxide was coated on conductive glass using the sol-gel method.

[0043] (3) The electron transport layer 3 is prepared on the photoanode layer 2 . A layer of mesoporous titania was prepared on dense titania using a hydrothermal method.

[0044] (4) Prepare the perovskite light absorbing layer 4 on the electron tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com