PDC drill bit for coal mine high-position directional drilling

A directional drilling and high-position technology, which is applied in the direction of drill bits, drilling equipment, and earthwork drilling, can solve the problems of drill bit wear, cutting tooth wear, and low drilling efficiency, so as to suppress lateral unbalanced swing and improve drilling efficiency. The ability of rock and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

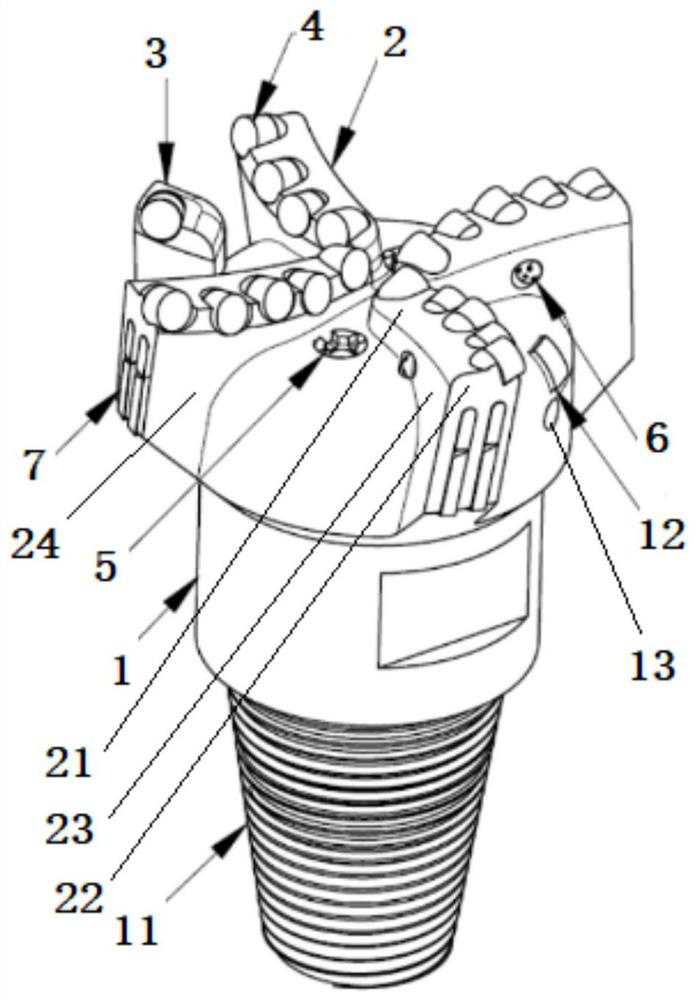

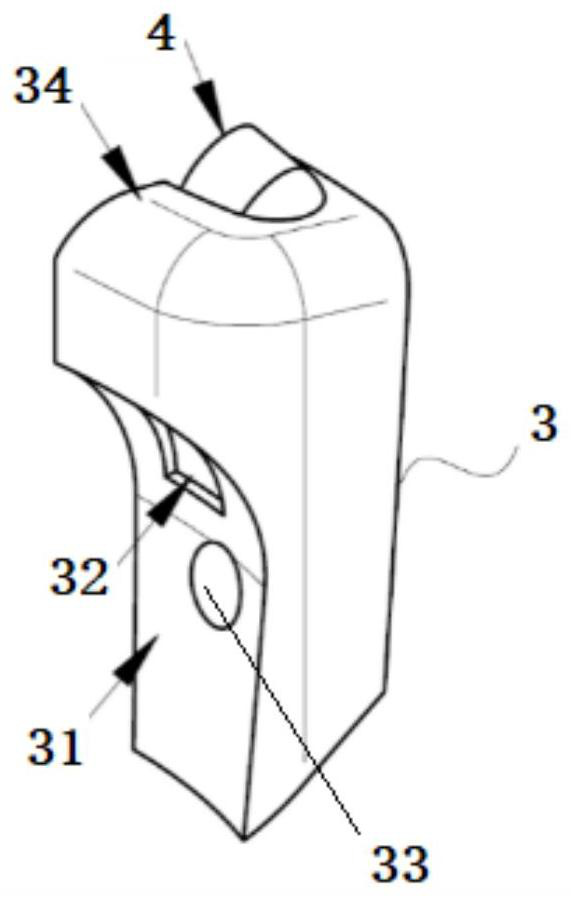

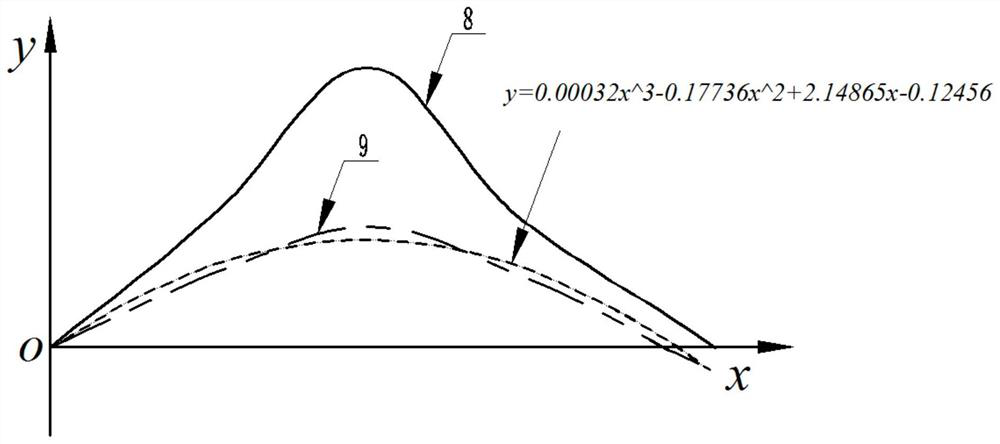

[0052] like Figure 1 to Figure 8 As shown, this embodiment provides a PDC drill bit for high-position directional drilling in coal mines, including an integrally formed drill body 1 and a plurality of fixed blades 2, movable blades 3 detachably mounted on the drill body 1, and respectively The PDC cutting teeth 4 welded on the fixed blade 2 and the movable blade 3; in this embodiment, the drill body is made of steel material, the front end of the drill body 1 is provided with the fixed blade 2, and the rear end is a tapered male thread 11, Used to connect with downhole power drilling tools; trapezoidal protrusions 12 and first screw holes 13 are provided on the drill bit body 1 between adjacent fixed blades 2; fixed blades 2, trapezoidal bosses 12 and drill body 1 adopt Five-axis CNC machining is integrally formed.

[0053] A plurality of fixed blades 2 are evenly distributed along the circumference of the front end of the drill body 1, and each fixed blade 2 includes a toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com