Selective laser melting and forming method of titanium alloy asymmetric protection shield

A technology of laser selective melting and protective cover, which is applied in the coating process and coating of metal materials, can solve the problems of improper control, complex stress, warping and deformation, etc., and achieve the elimination of residual stress, ensure the quality of forming, and reduce the temperature gradient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

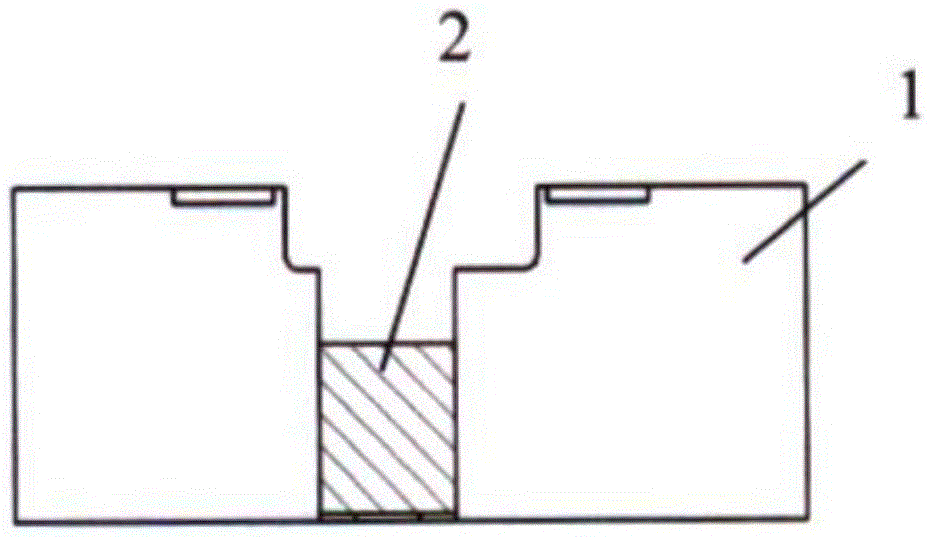

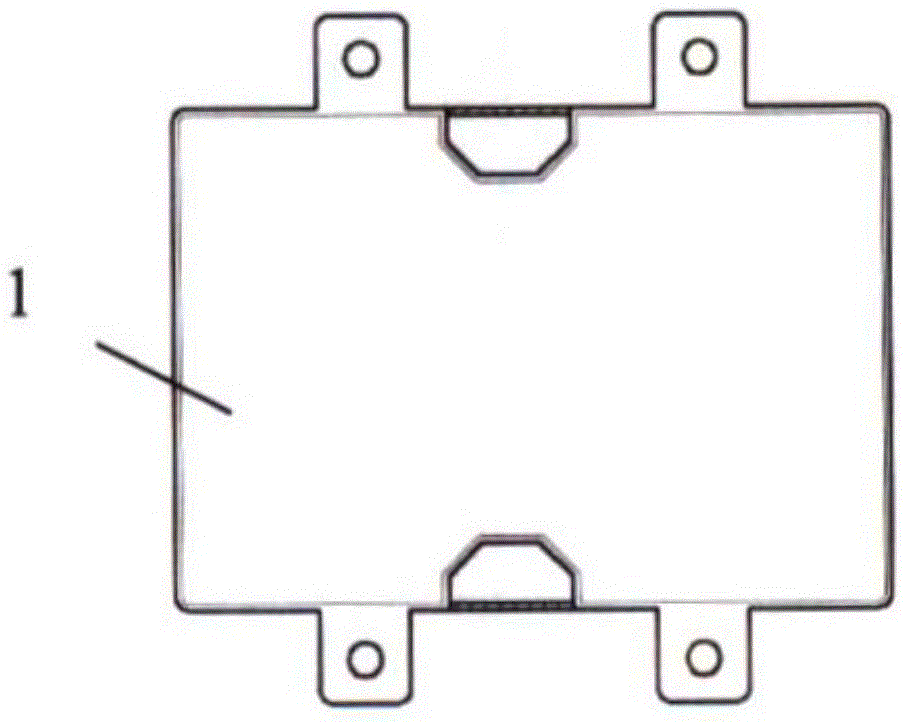

[0026] A method for laser selective melting and forming of a titanium alloy asymmetric protective cover according to the present invention, the titanium alloy asymmetric protective cover is a semi-open thin-walled flexible structure with a wall thickness of 2 mm, and the method includes the following steps:

[0027] (a) Design of external restraint structure

[0028] Design an additional restraint structure 2 at the opening of the protective cover 1 by three-dimensional solid modeling software to ensure that the protective cover 1 has sufficient rigidity, and the wall thickness of the additional restraint structure is 0.9 mm;

[0029] (b) Preparation of titanium alloy powder

[0030] Sieve the titanium alloy powder through a powder sieving machine to ensure that the powder particle size is -400 mesh;

[0031] Put the sieved titanium alloy powder into a drying box to remove the moisture absorbed in the powder, set the powder baking temperature to 90°C, and the powder baking ti...

Embodiment 2

[0041] A laser selective melting forming method for an asymmetric titanium alloy protective cover according to the present invention, wherein the asymmetric titanium alloy protective cover has a semi-open thin-walled flexible structure with a wall thickness of 1 mm, and the method includes the following steps:

[0042] (a) Design of external restraint structure

[0043] Design the additional restraint structure 2 at the opening of the protective cover 1 by three-dimensional solid modeling software to ensure that the protective cover 1 has sufficient rigidity, and the wall thickness of the additional restraint structure is 0.8mm;

[0044] (b) Preparation of titanium alloy powder

[0045] Sieve the titanium alloy powder through a powder sieving machine to ensure that the powder particle size is -400 mesh;

[0046] Put the sieved titanium alloy powder into a drying box to remove the moisture absorbed in the powder, set the powder baking temperature to 80°C, and the powder baking...

Embodiment 3

[0055] A method for laser selective melting and forming of a titanium alloy asymmetric protective cover according to the present invention, the titanium alloy asymmetric protective cover is a semi-open thin-walled flexible structure with a wall thickness of 2 mm, and the method includes the following steps:

[0056] (a) Design of external restraint structure

[0057] Design an additional restraint structure 2 at the opening of the protective cover 1 by three-dimensional solid modeling software to ensure that the protective cover 1 has sufficient rigidity, and the wall thickness of the additional restraint structure is 1 mm;

[0058] (b) Preparation of titanium alloy powder

[0059] Sieve the titanium alloy powder through a powder sieving machine to ensure that the powder particle size is -400 mesh;

[0060] Put the sieved titanium alloy powder into a drying box to remove the moisture absorbed in the powder, set the powder baking temperature to 100°C, and the powder baking tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com