Patents

Literature

140 results about "Oriented crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

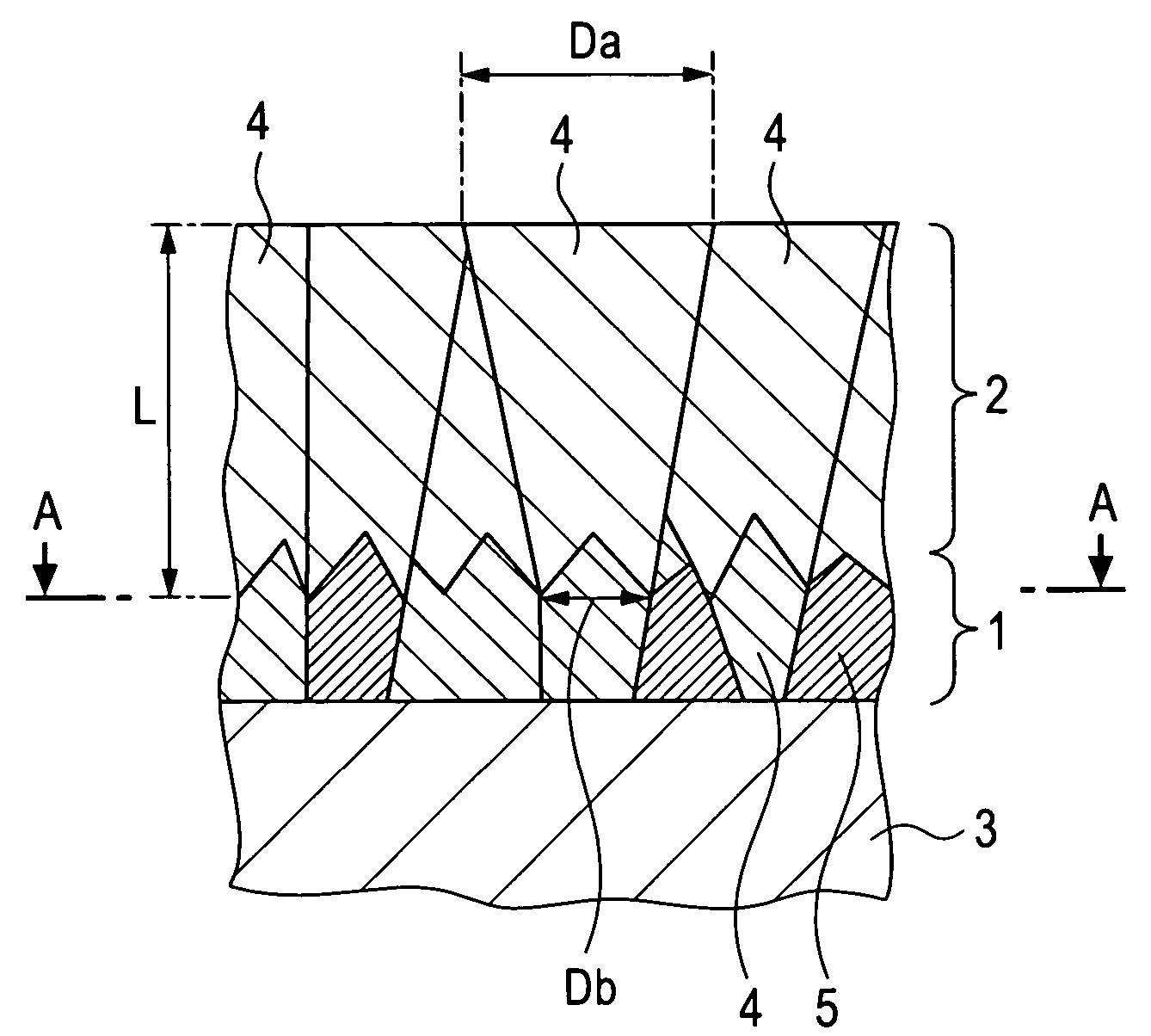

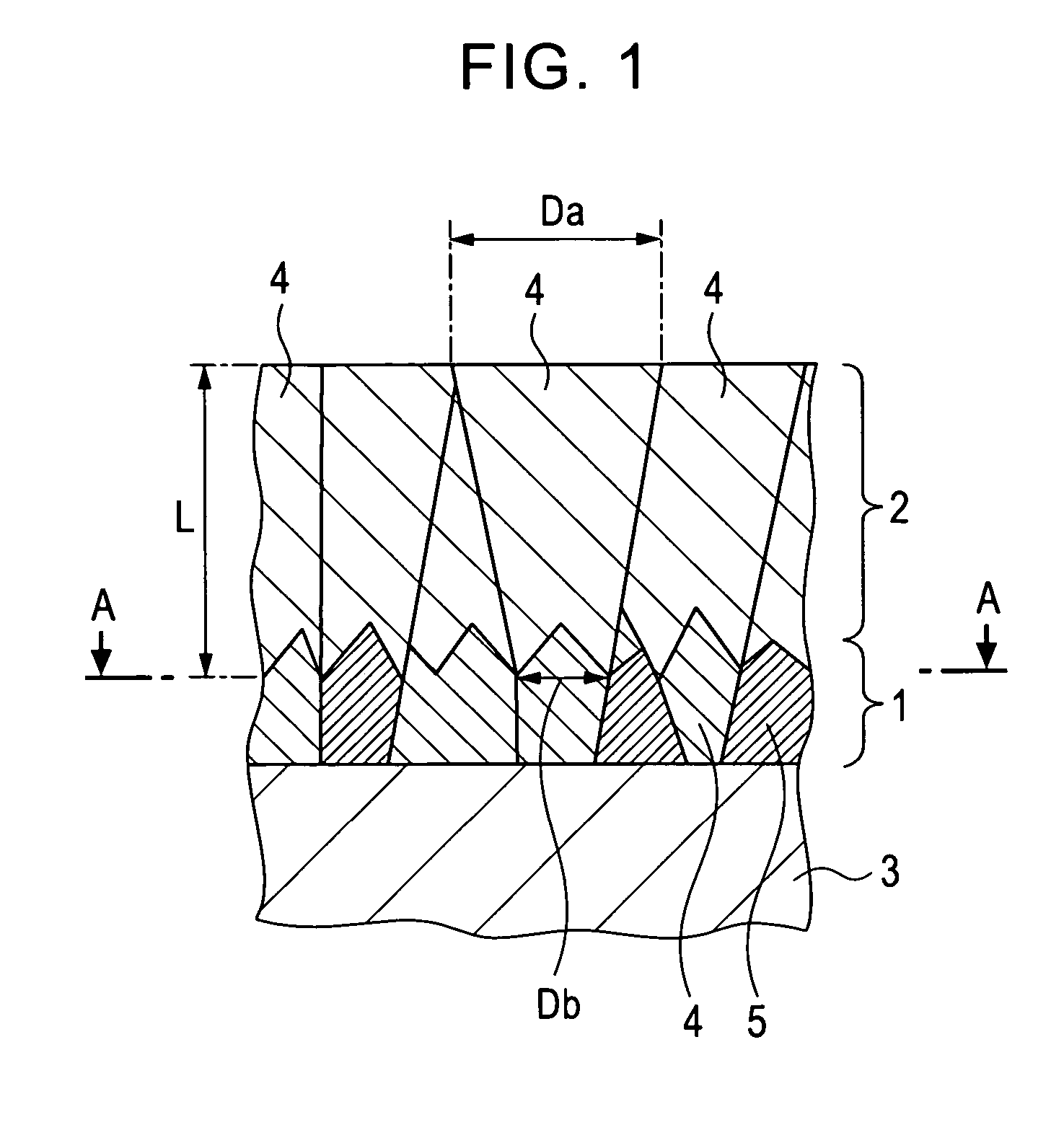

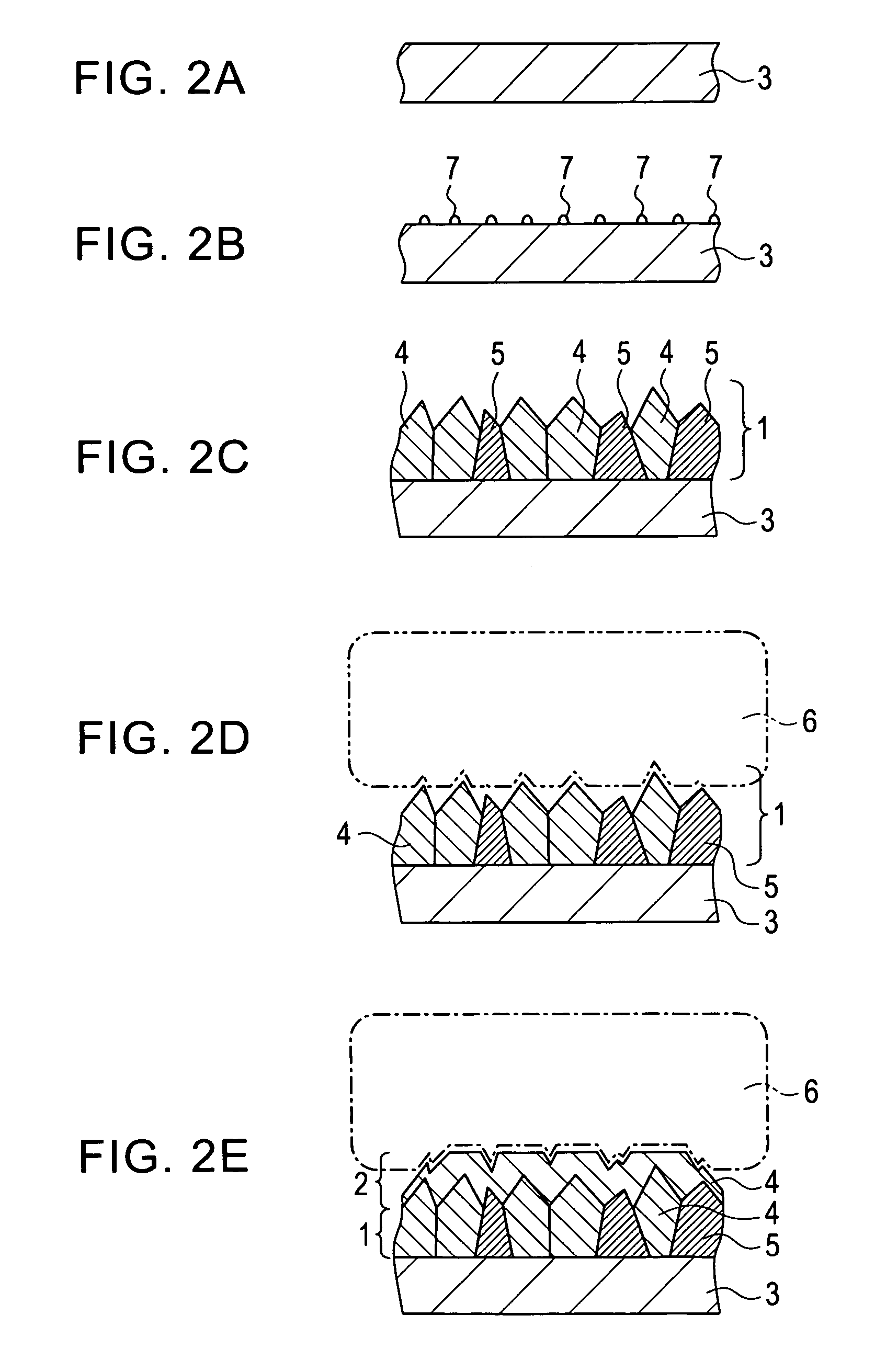

Highly-oriented diamond film, method for manufacturing the same, and electronic device having highly-oriented diamond film

InactiveUS7311977B2Lower performance requirementsImprove performancePolycrystalline material growthFrom chemically reactive gasesHydrogenDiamond crystal

A highly-oriented diamond film which has a flat surface but does not have non-oriented crystals in the surface can be provided by depositing a first diamond layer on a substrate by {111} sector growth of diamond crystals by a CVD method using a gaseous mixture of methane and hydrogen as material gas, and then depositing a second diamond layer on the first diamond layer by {100} sector growth of diamond crystals by a plasma CVD method using a gaseous mixture of methane, hydrogen, and oxygen as material gas under the conditions that the pressure of the material gas is 133 hPa or more; the material gas composition is determined such that ([C]−[O]) / [CH3+H2+O2] is −0.2×10−2 or more and [O] / [C] is 1.2 or less; and the substrate temperature is between 750° C. and 1000° C.

Owner:KOBE STEEL LTD

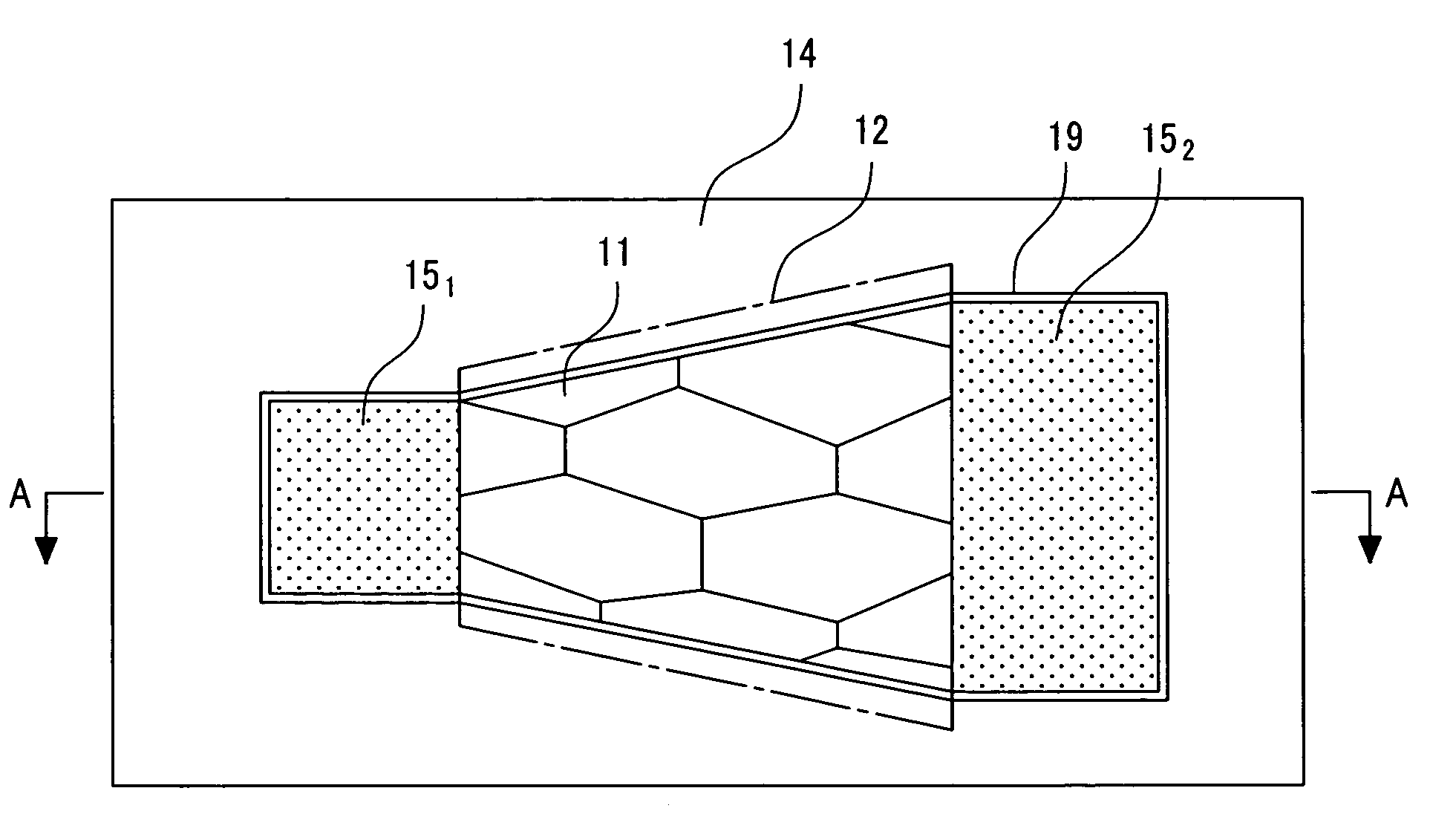

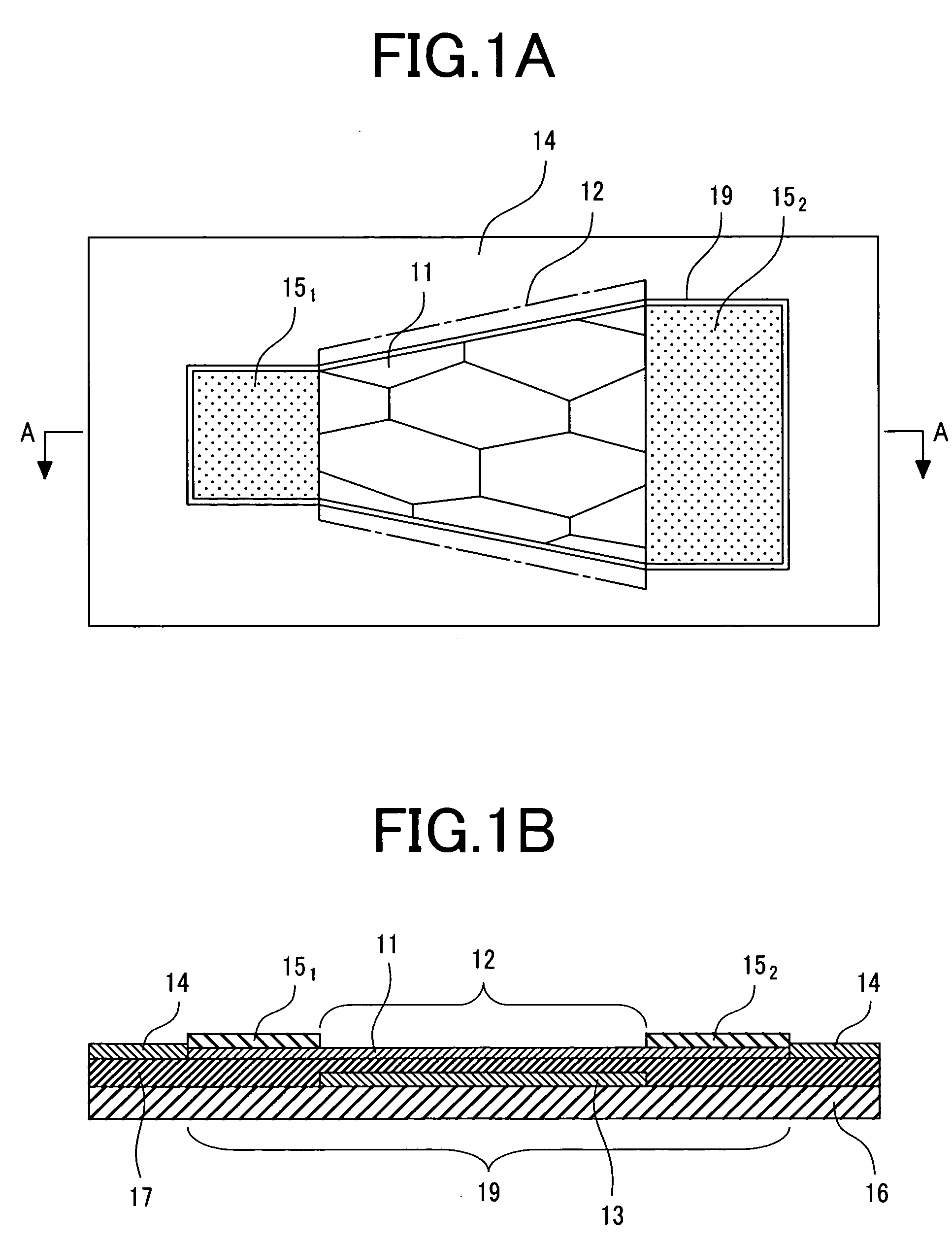

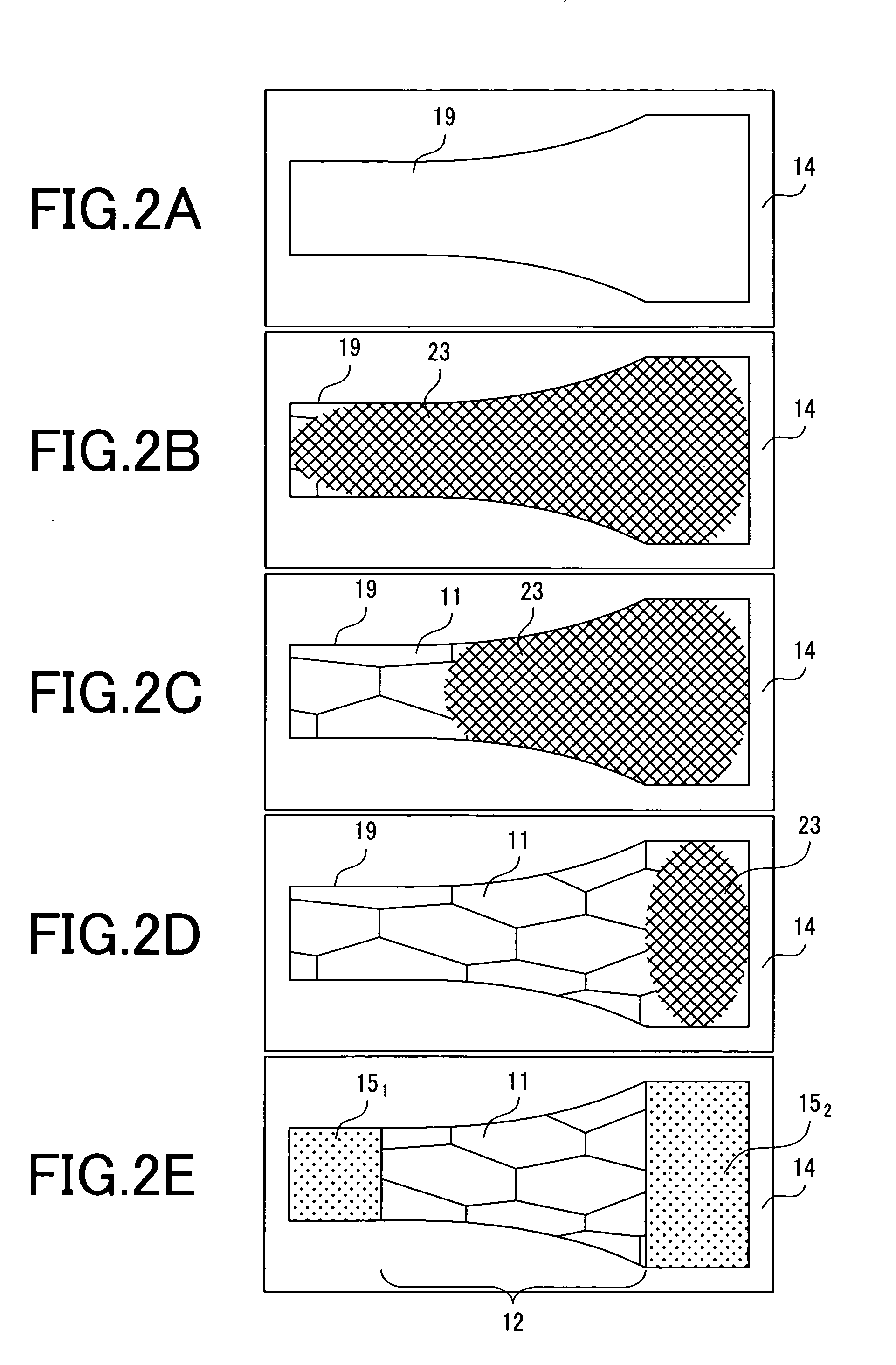

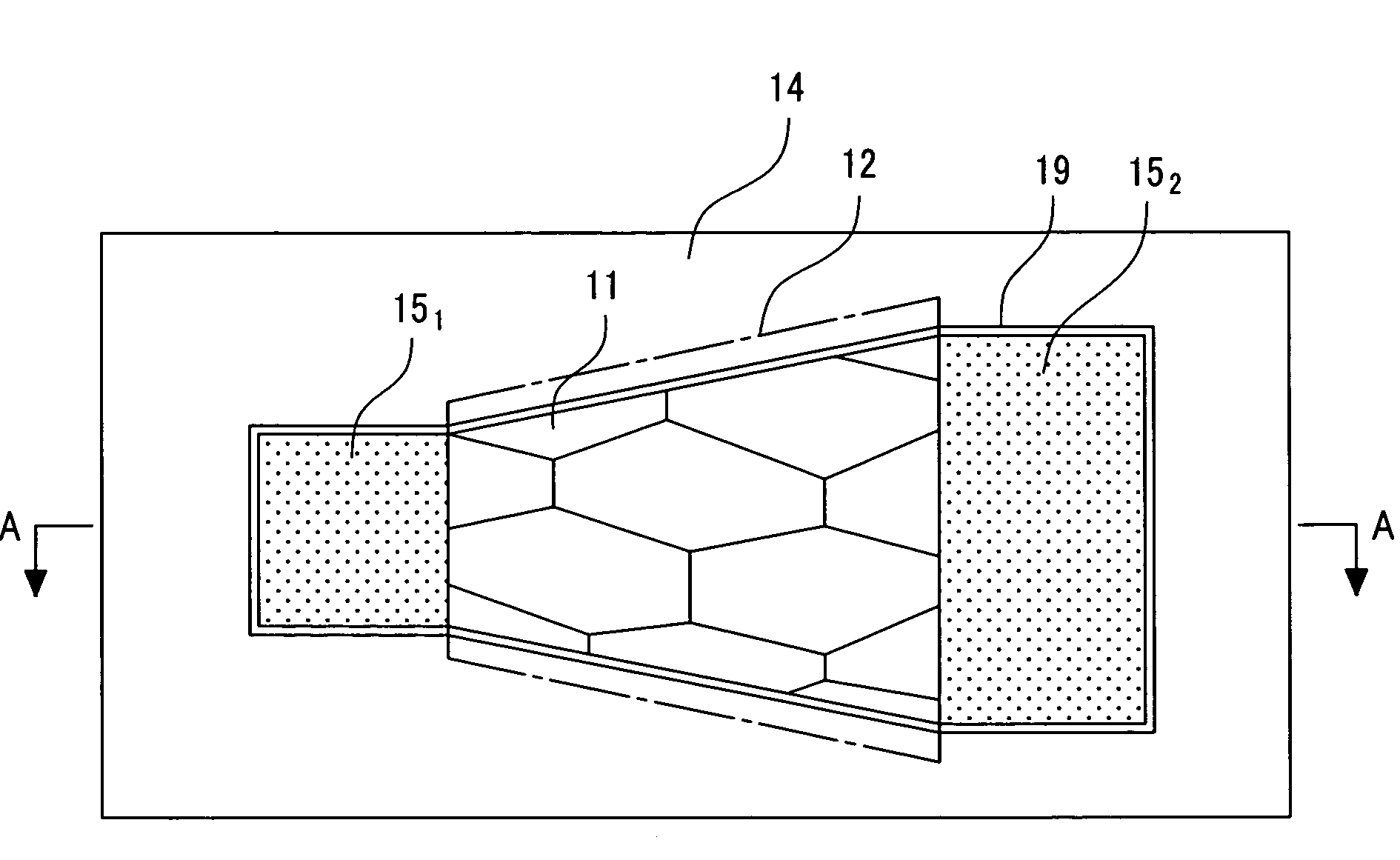

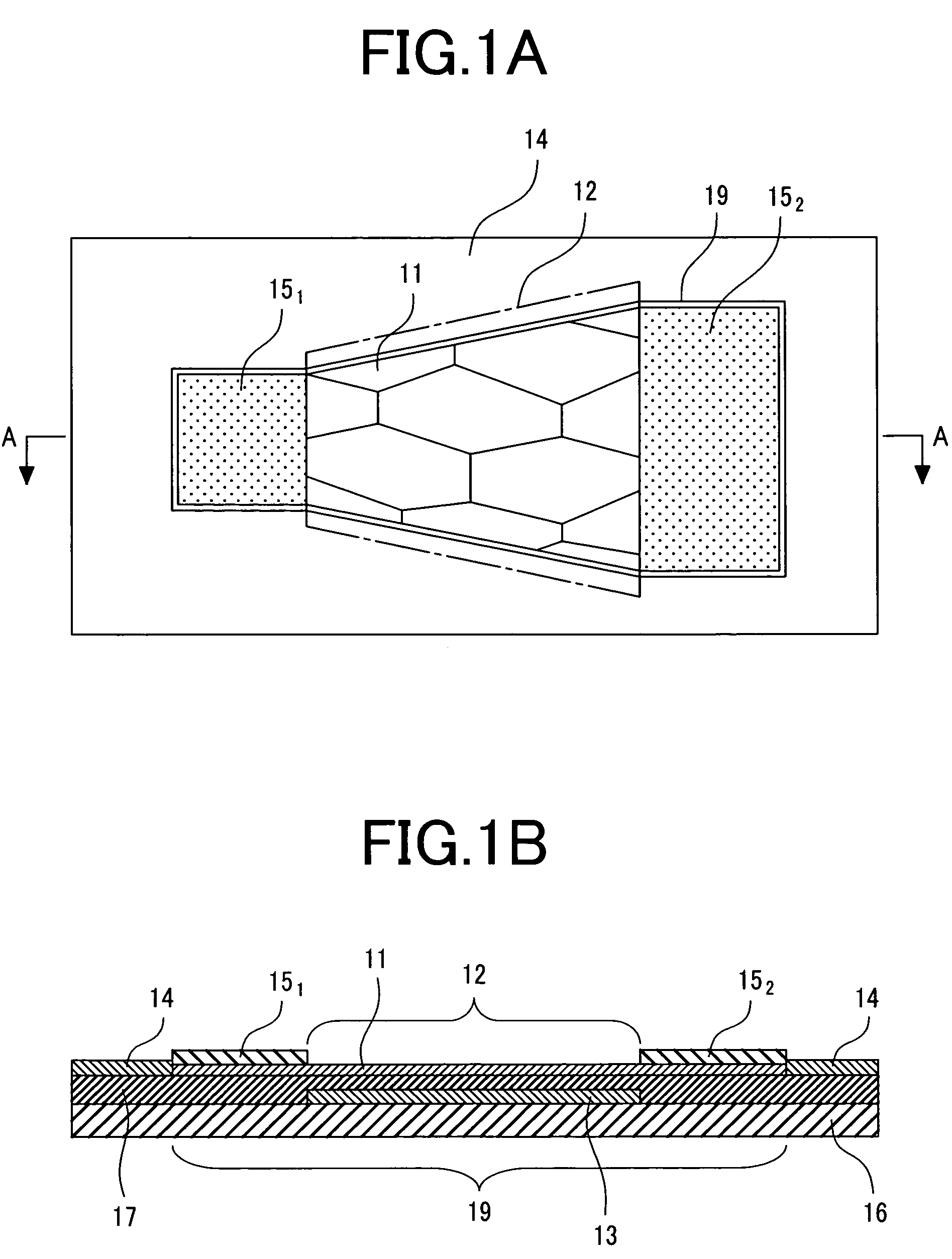

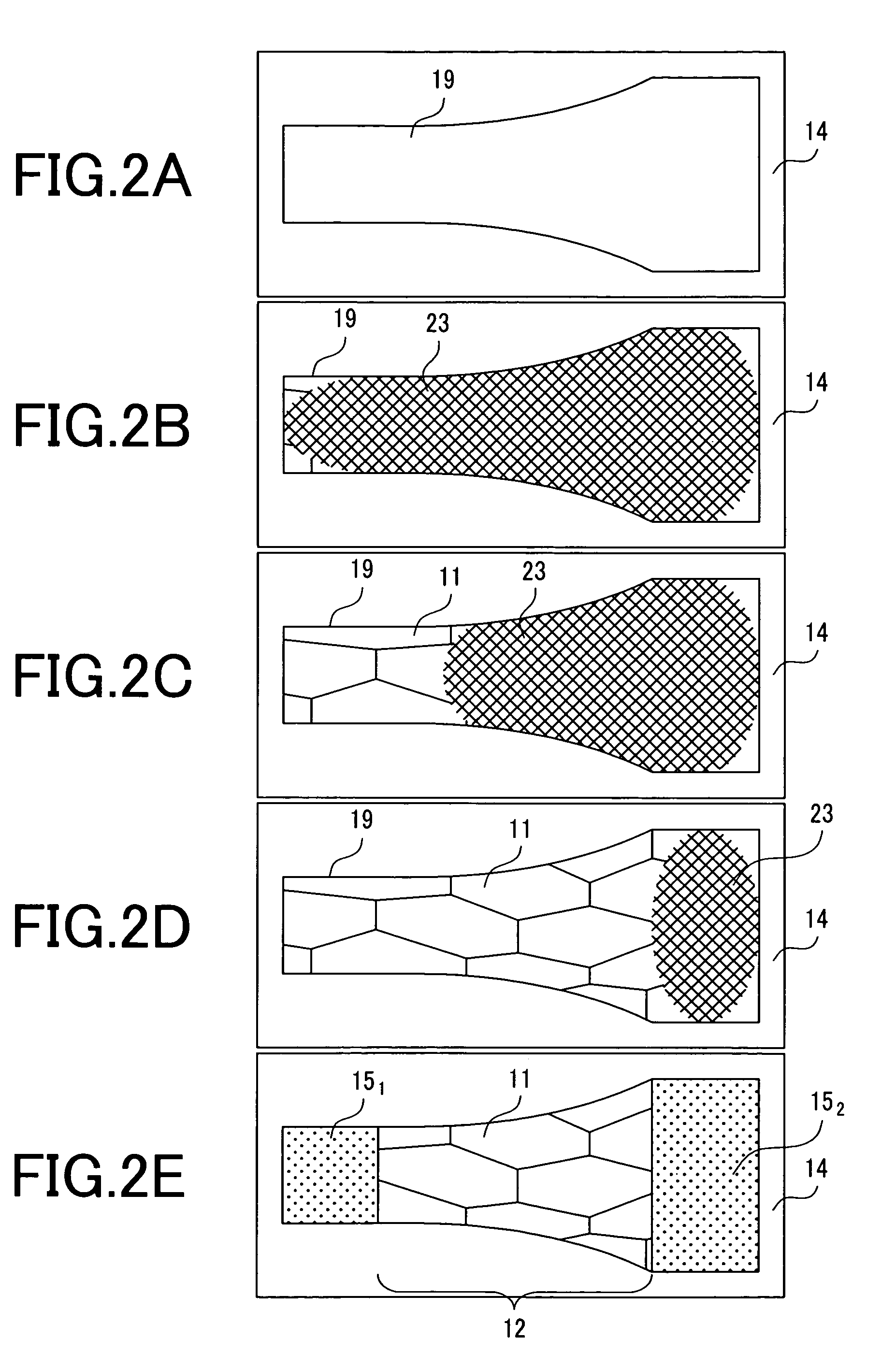

Field effect transistor and method of manufacturing the same

InactiveUS20070117298A1Improve mobilityInexpensively and readily formSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

A TFT having a large mobility of carriers that are conducted through a channel as compared with a conventional organic TFT, and a method of manufacturing the TFT inexpensively and easily are provided. The channel is formed of a semiconductor organic molecular crystal thin film which is highly oriented, and a TFT that is large in the mobility of the carriers that are conducted through the channel, and a lyophilic TFT pattern that is surrounded by a lyophobic region on a substrate are formed, and the configuration of the pattern is featured, whereby a solution of the semiconductor organic molecules which is supplied to an appropriate region of a substrate surface including the channel is spontaneously dried in an anisotropic fashion, and highly oriented crystal is grown in the drying process.

Owner:HITACHI LTD

Method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum

The invention provides a method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum, comprising the technological steps of purification, crystal transforming reaction, oriented crystallization, washing and separation, and drying and pulverization. The method concretely comprises the following steps of: enhancing the taste of calcium sulfate dlhy in the desulfurized gypsum to be greater than 95% through a purification treatment; dissolving and recrystallizing the desulfurized gypsum at 70 to 98 DEG C under the normal pressure through adding prepared habit modifiers, transforming into the alpha semi-hydrated gypsum and then carrying out oriented crystallization on the alpha semi-hydrated gypsum to form a short column-shaped alpha semi-hydrated gypsum crystal under the function of an oriented crystal type stabilizer, wherein the length-diameter ratio of the short column-shaped alpha semi-hydrated gypsum crystal is less than 1:3, the 2h breaking strength is greater than 6.5 MPa, the compression strength is greater than 23 MPa, the dry breaking strength is greater than 25 MPa, and the dry compression strength is greater than 53 MPa. The method can be widely used in the fields of ceramics, automobiles, precise casting, heterogenic casting and the like.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Perovskite type oxide material, piezoelectric element, liquid discharge head and liquid discharge apparatus using the same, and method of producing perovskite type oxide material

ActiveUS20070060467A1Improve featuresIncrease stickinessVacuum evaporation coatingSputtering coatingTetragonal crystal systemCubic crystal system

A perovskite type oxide of a single crystal structure or a uniaxial-oriented crystal structure represented by ABO3 where site A includes Pb as a main component and site B includes a plurality of elements, wherein the perovskite type oxide includes a plurality of crystal phases selected from the group consisting of tetragonal, rhombohedral, orthorhombic, cubic, pseudo-cubic and monoclinic systems and the plurality of crystal phases are oriented in the direction of <100>.

Owner:CANON KK

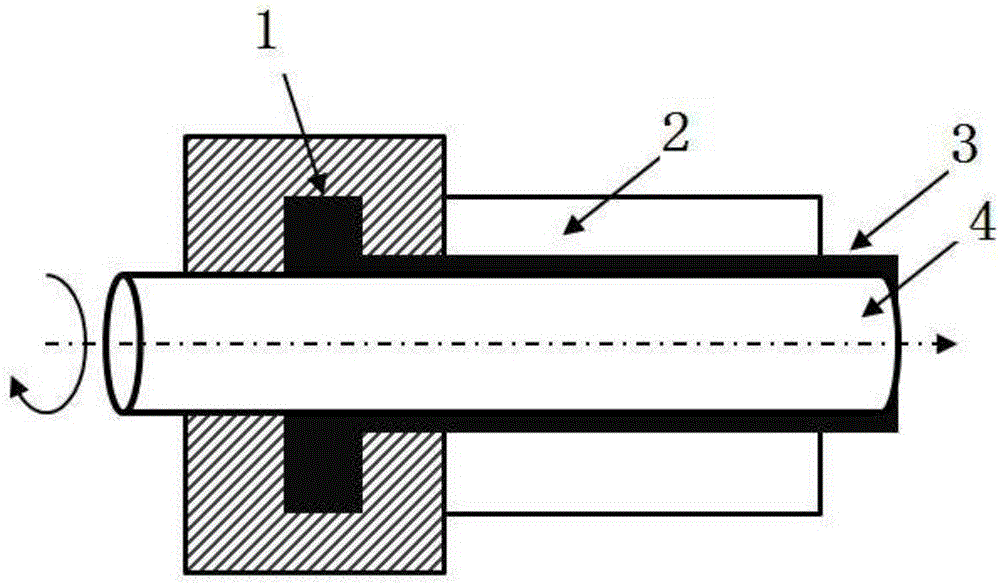

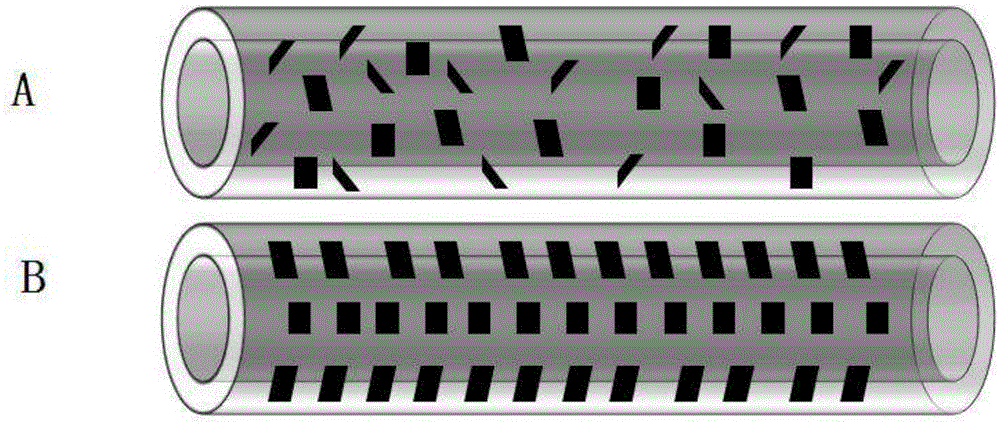

High-oxygen barrier property high-strength polyolefin heat conduction pipe and preparation method thereof

The invention provides a high-oxygen barrier property high-strength polyolefin heat conduction pipe and a preparation method thereof. The high-oxygen resistance high-strength polyolefin heat conduction pipe comprises, by weight, 100 parts of polyolefin resin, 0.1-5 parts of graphene slice layers, 0.1-15 parts of a compatilizer and 0.01-0.2 parts of an anti-oxidant. The graphene slice layers are uniformly distributed in the polyolefin resin in a ring way around a pipe central axis as a center. Through use of the graphene slice layers and a rotary core rod mouth mold, a polyolefin crystallization degree is high, a lot of oriented crystals are formed and pipe mechanical properties, heat conduction and heatproof performances are obviously improved. The graphene slice layers are uniformly distributed in the pipe in a ring way so that graphene slice layer obstruction performances are greatly improved and thus the good oxygen barrier property is kept under the condition of a very small amount of an anti-oxidant.

Owner:TIANJIN KINGFA NEW MATERIAL

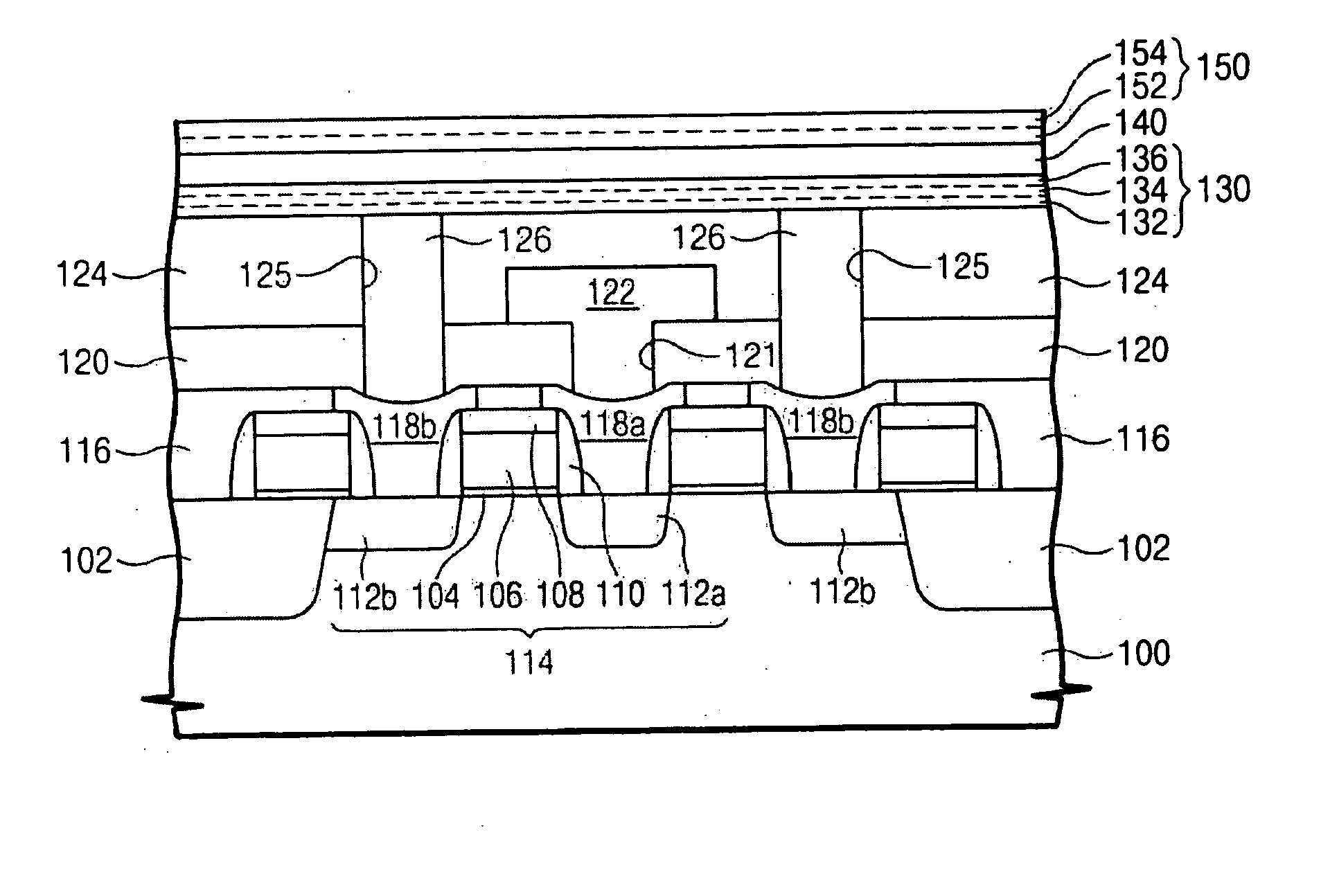

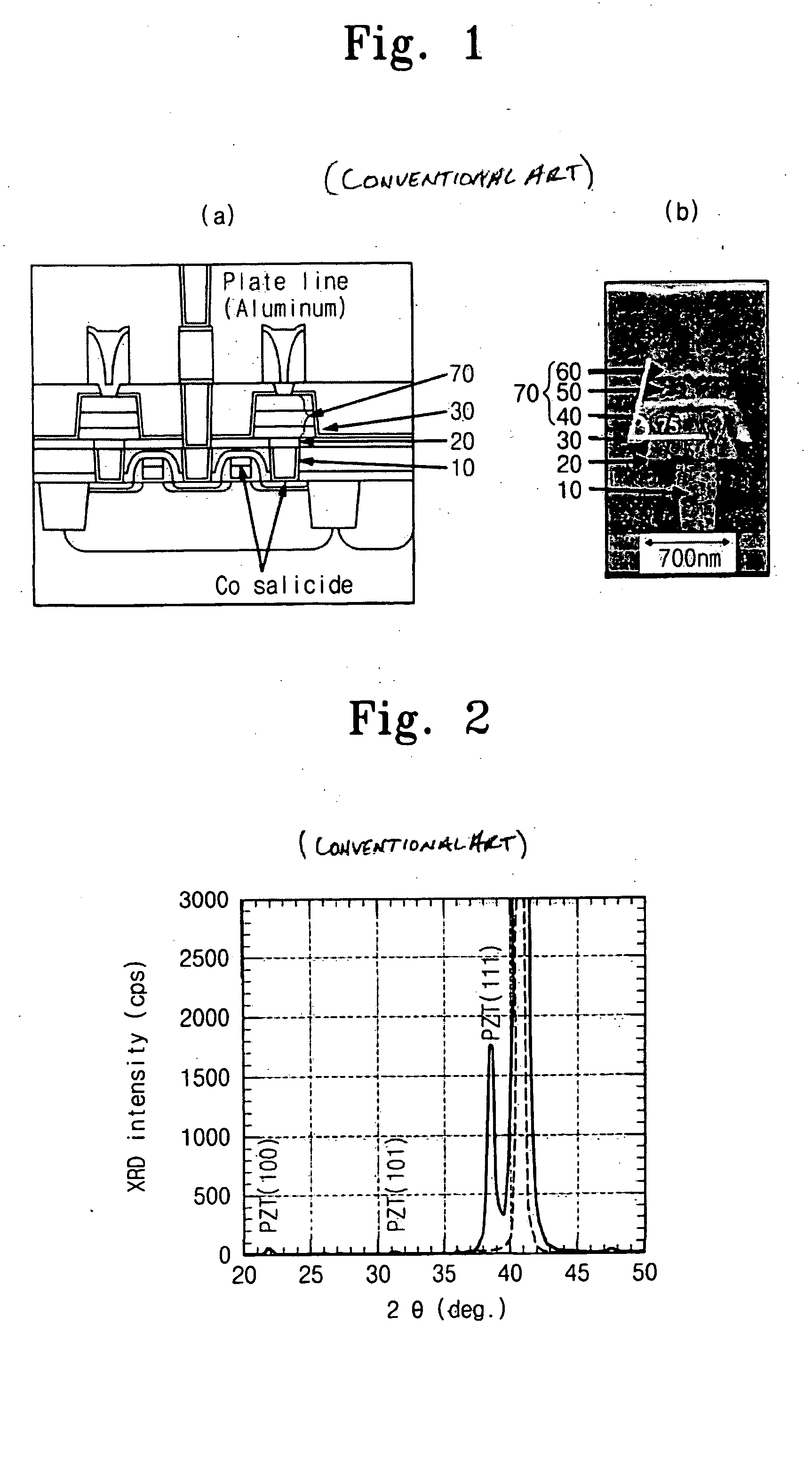

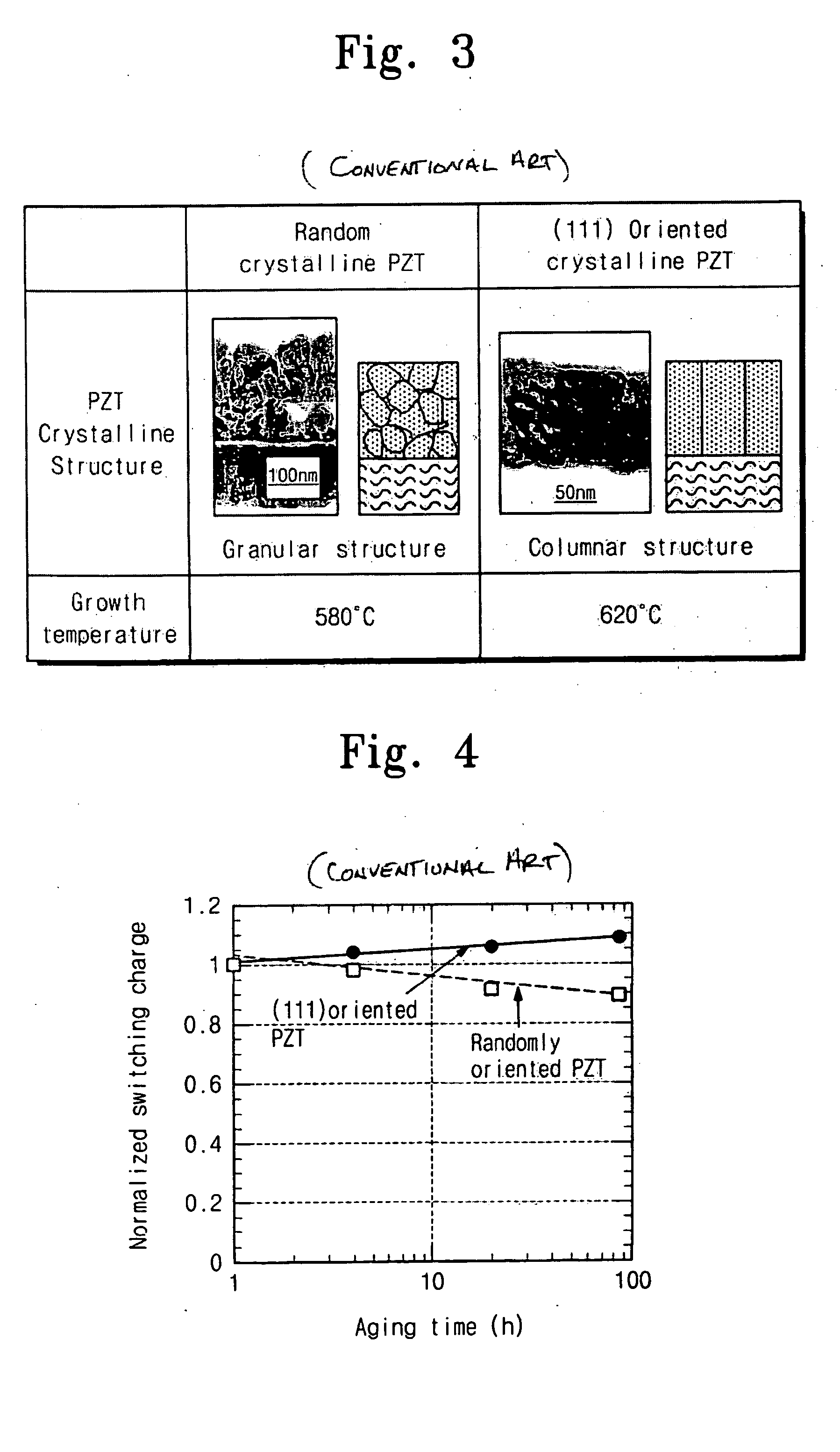

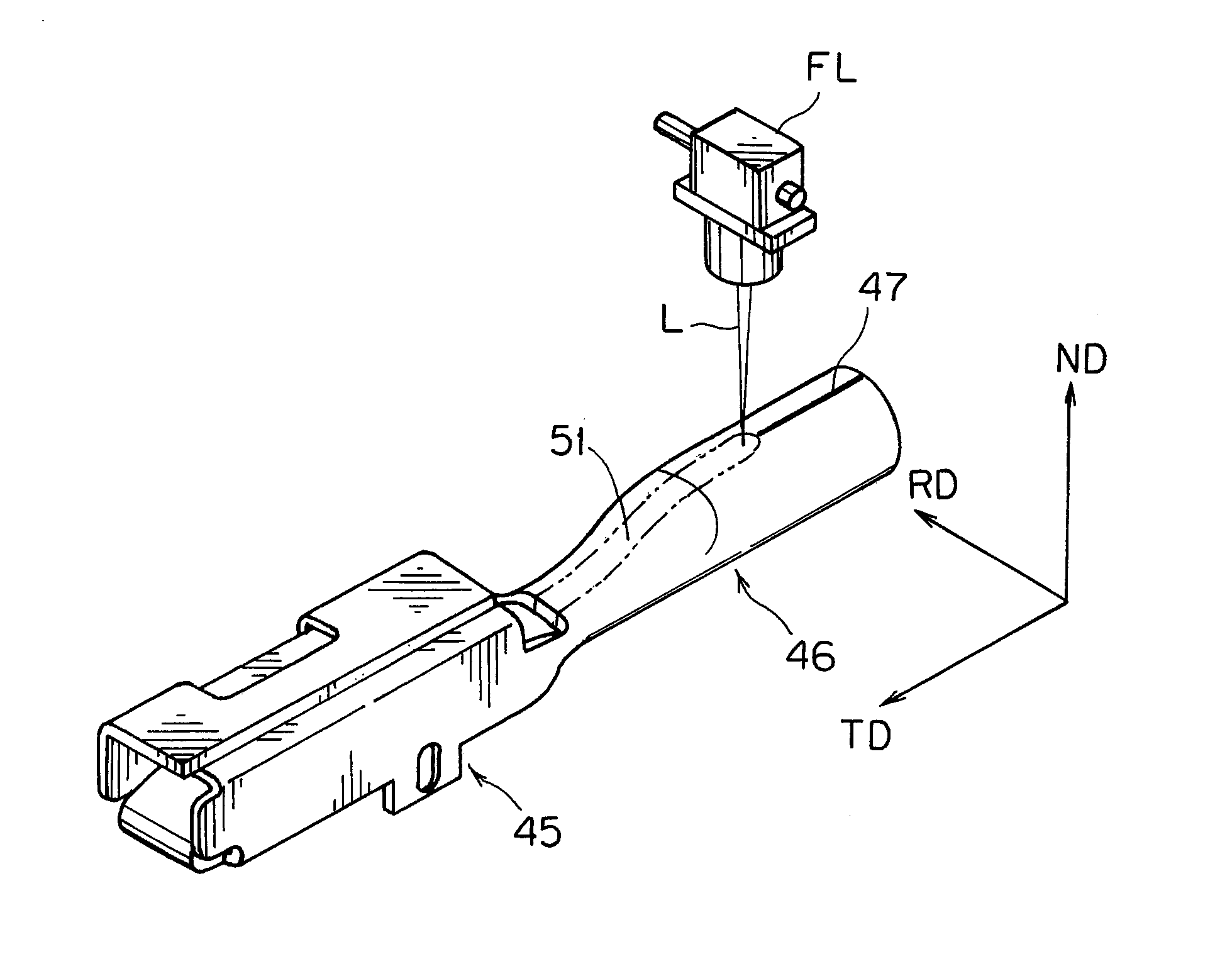

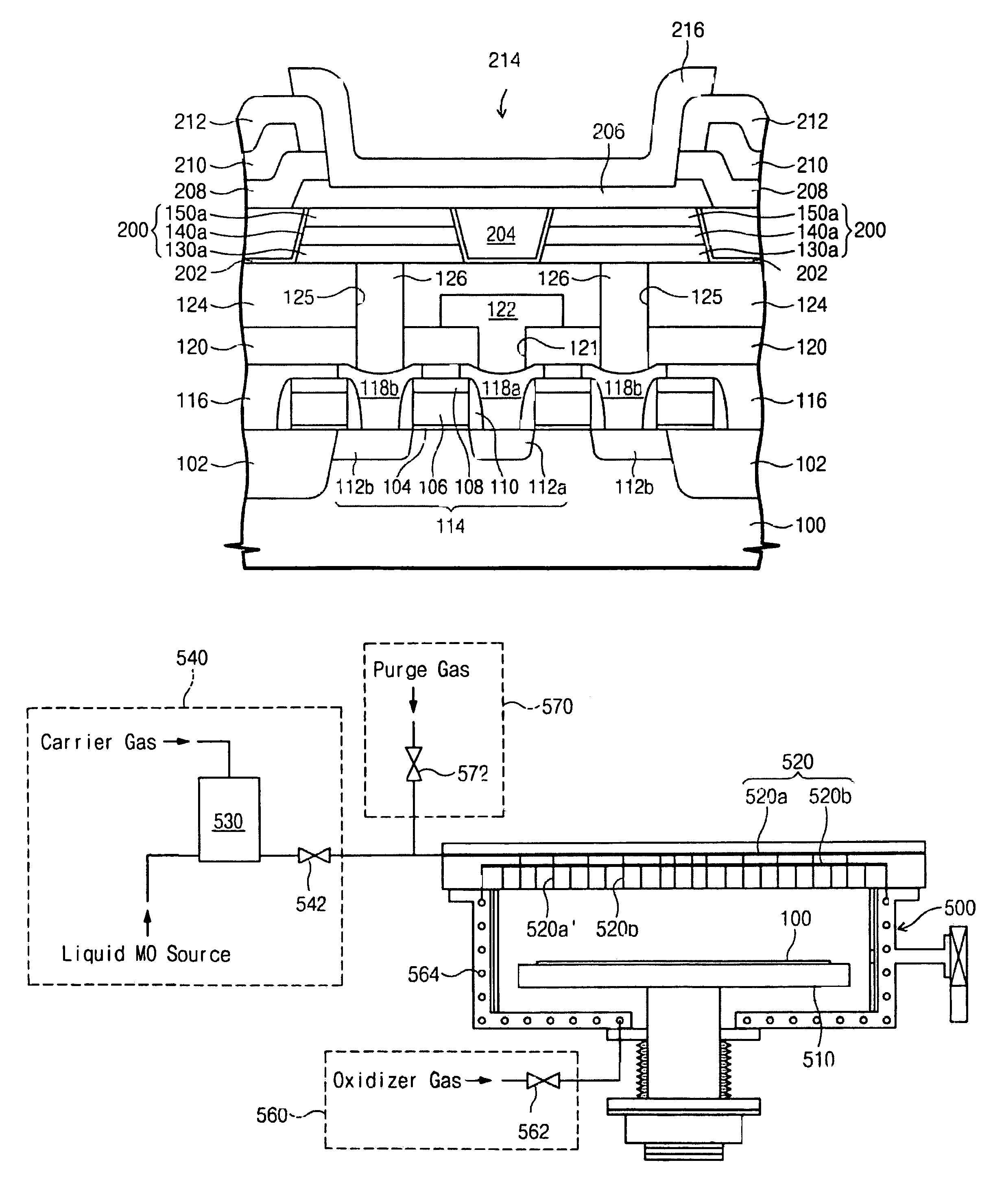

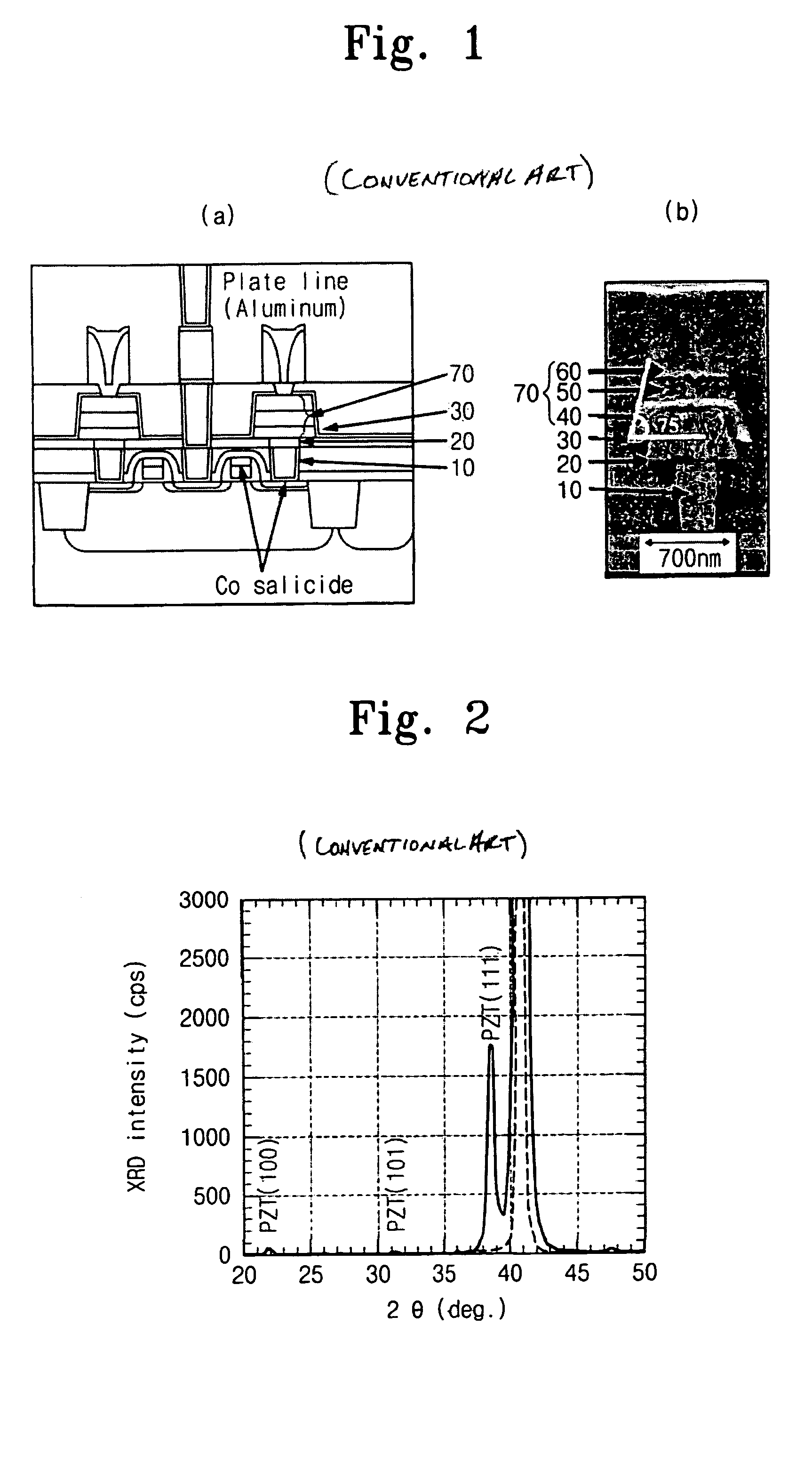

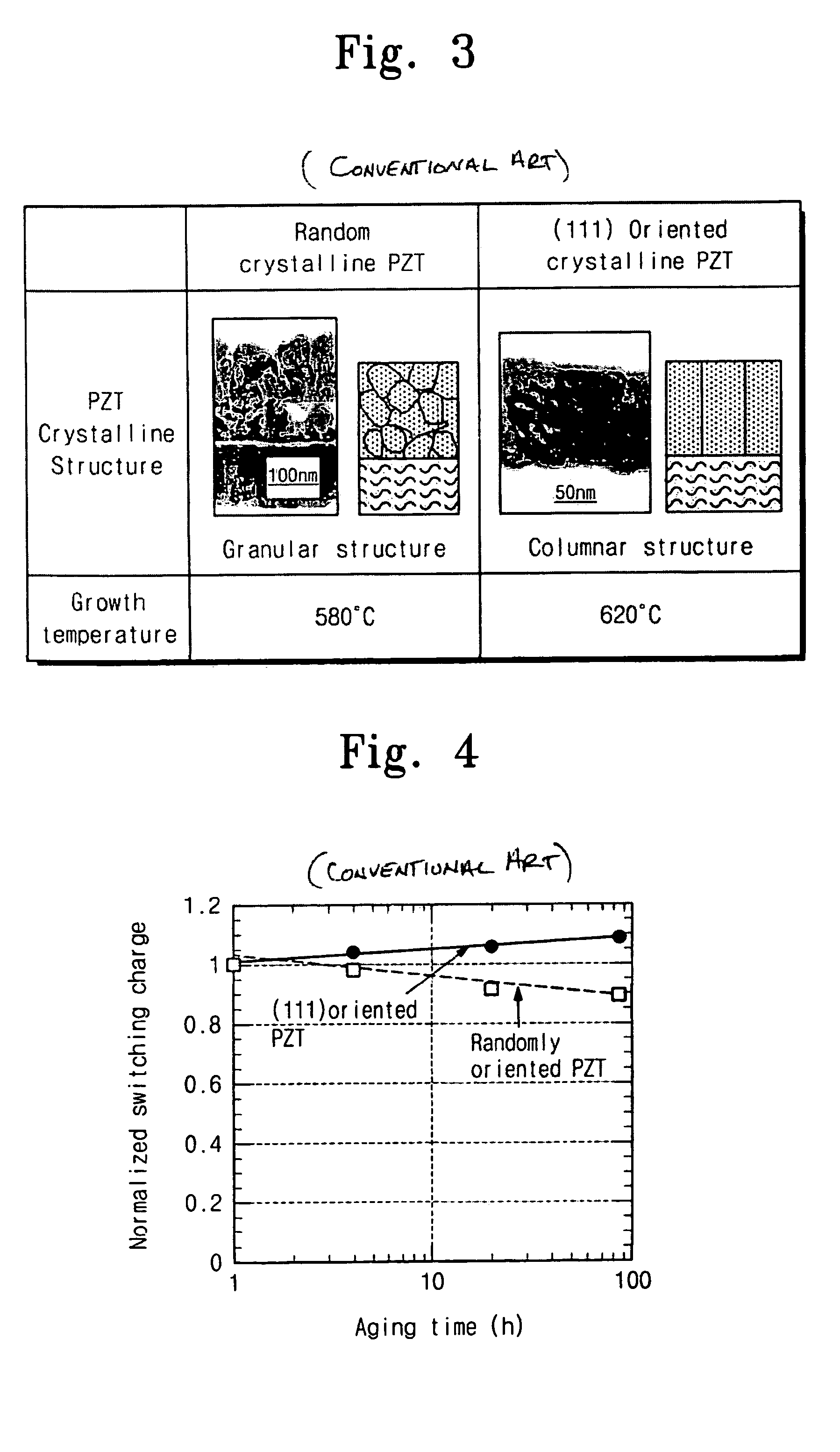

Methods for forming a ferroelectric layer and capacitor and FRAM using the same

ActiveUS20050064605A1Improve uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionCrystal growth

Metal organic chemical vapor deposition (MOCVD) may be utilized in methods of forming an (111) oriented PZT ferroelectric layer at a lower temperature, a ferroelectric capacitor and methods of fabricating, and a ferroelectric memory device using the same may be provided. Using the metal organic chemical vapor deposition, ferroelectric layers, capacitors, and memory devices, which may be fabricated and may have (111) preferred oriented crystal growth.

Owner:SAMSUNG ELECTRONICS CO LTD

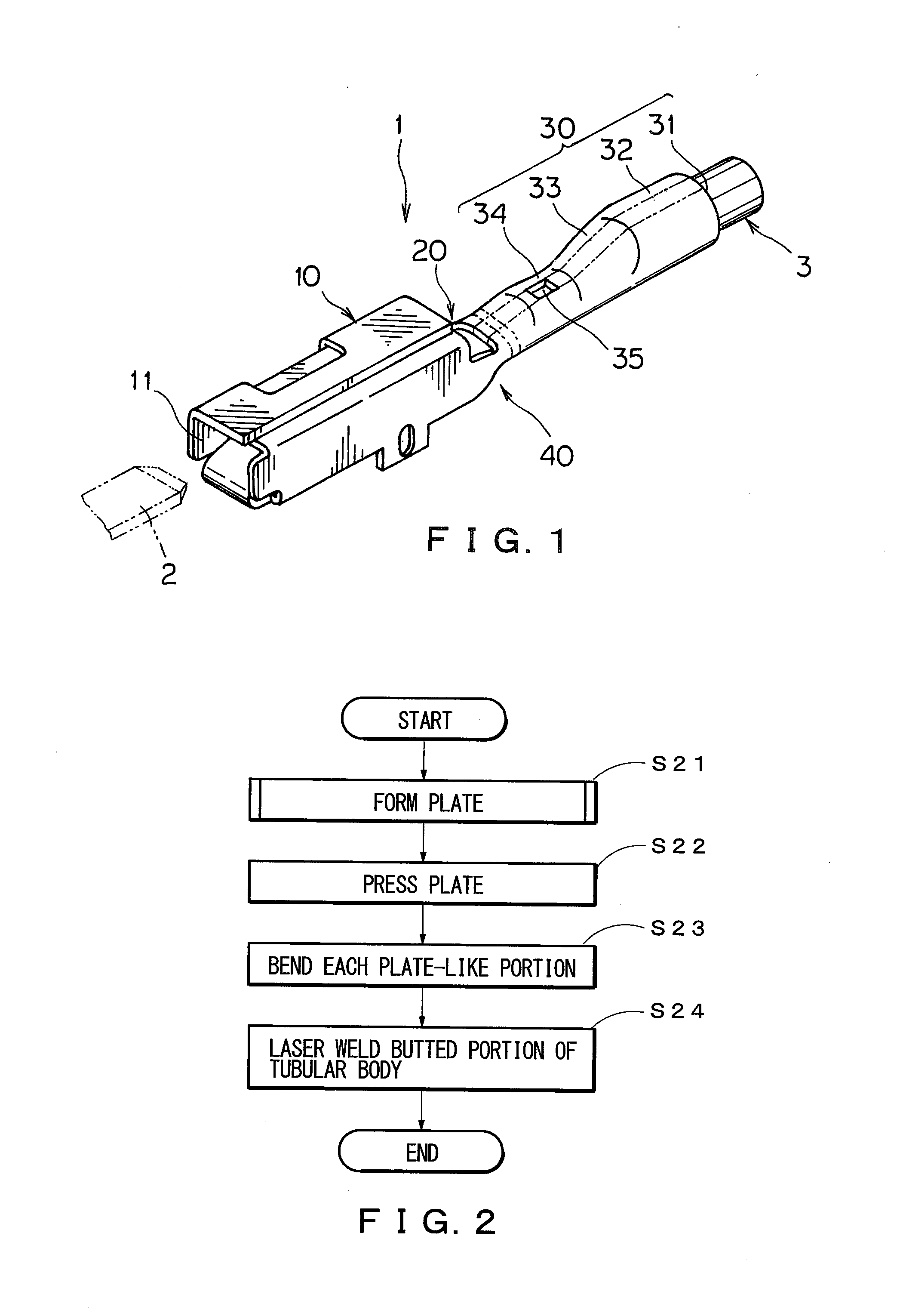

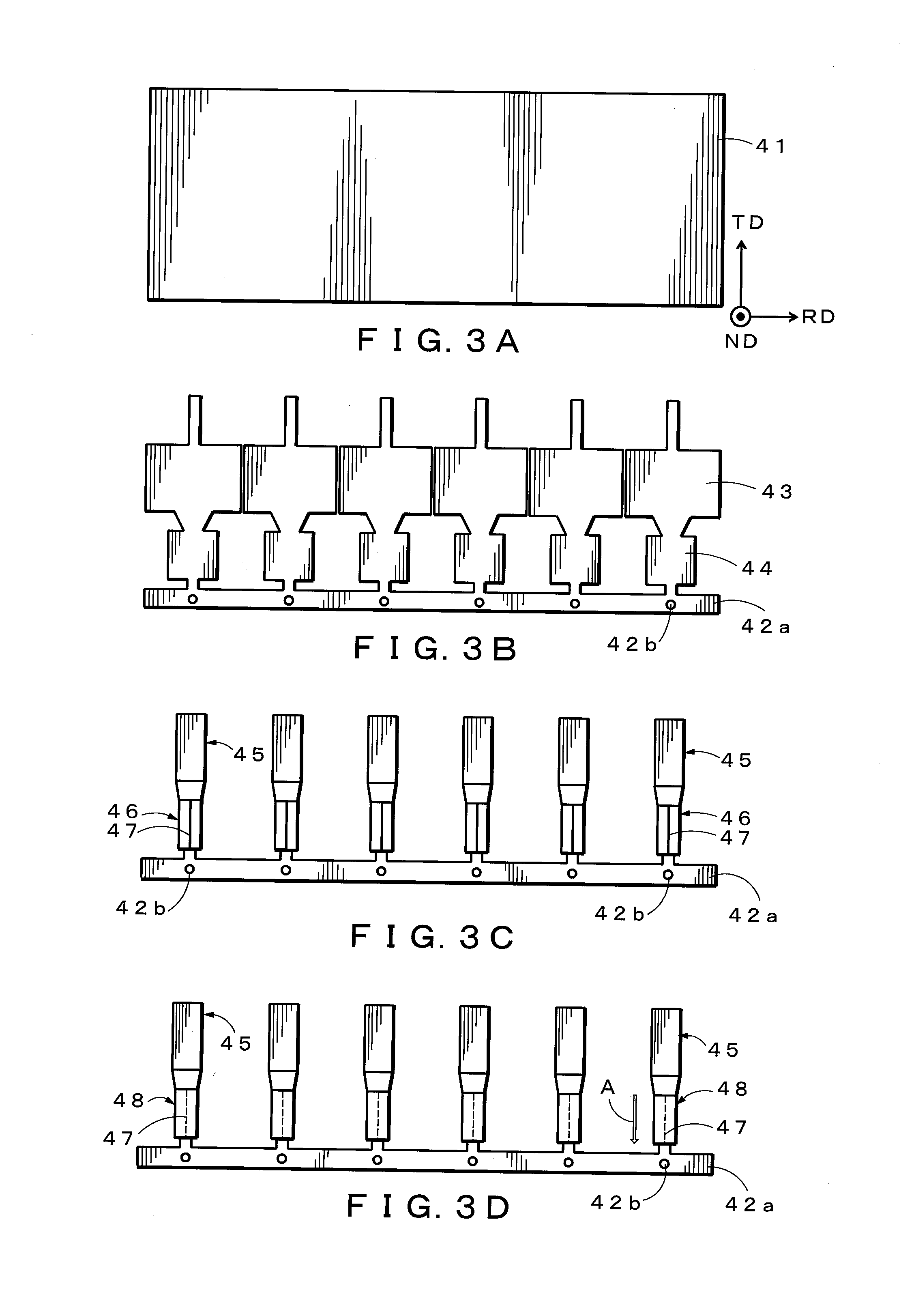

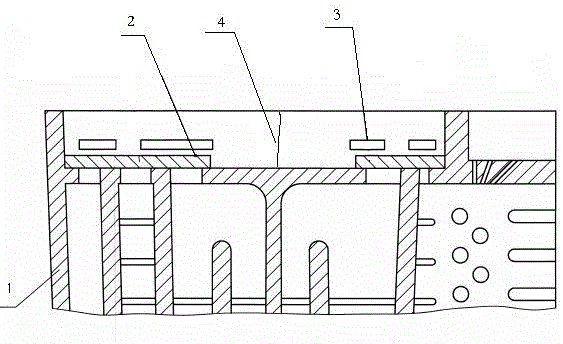

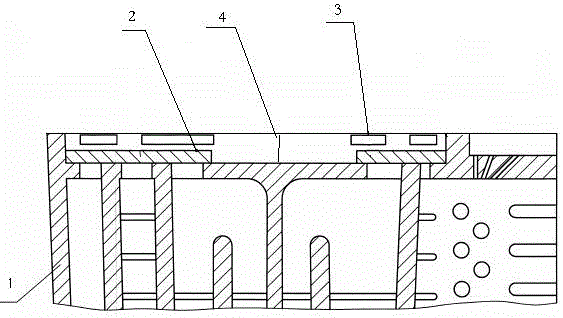

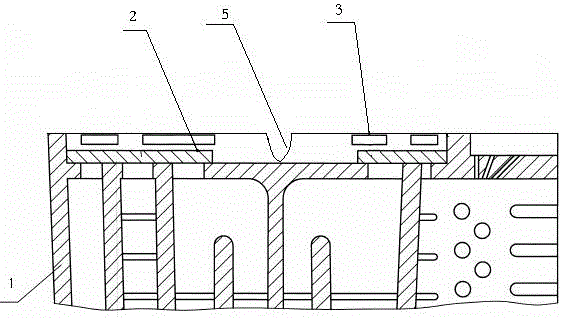

Terminal, Wire Connecting Structure and Method of Manufacturing A Terminal

ActiveUS20150357725A1Reduce widthContact member manufacturingCoupling contact membersElectrical conductorElectric wire

A terminal includes a connector portion electrically connectable to an external terminal, a tubular crimp portion formed integrally or separate from the connector portion and crimps with a wire, and a transition portion coupling the two. The tubular crimp portion of a copper or copper alloy metal base material or a metal member having the same is a tubular member closed on transition portion side and reduces in diameter towards the transition portion side such that a conductor-end portion of the electric wire is un-exposed. The tubular crimp portion has a belt-shaped weld portion along a longitudinal direction of the tubular crimp portion. A circumferential direction of the tubular crimp portion matches the RD-direction of the base material. A sum of area ratios R1, R2 and R3 in a rolling plane of the base material, of Cube-, RDW-, and Goss-oriented crystal grains, respectively, is greater than or equal to 15%.

Owner:FURUKAWA ELECTRIC CO LTD +1

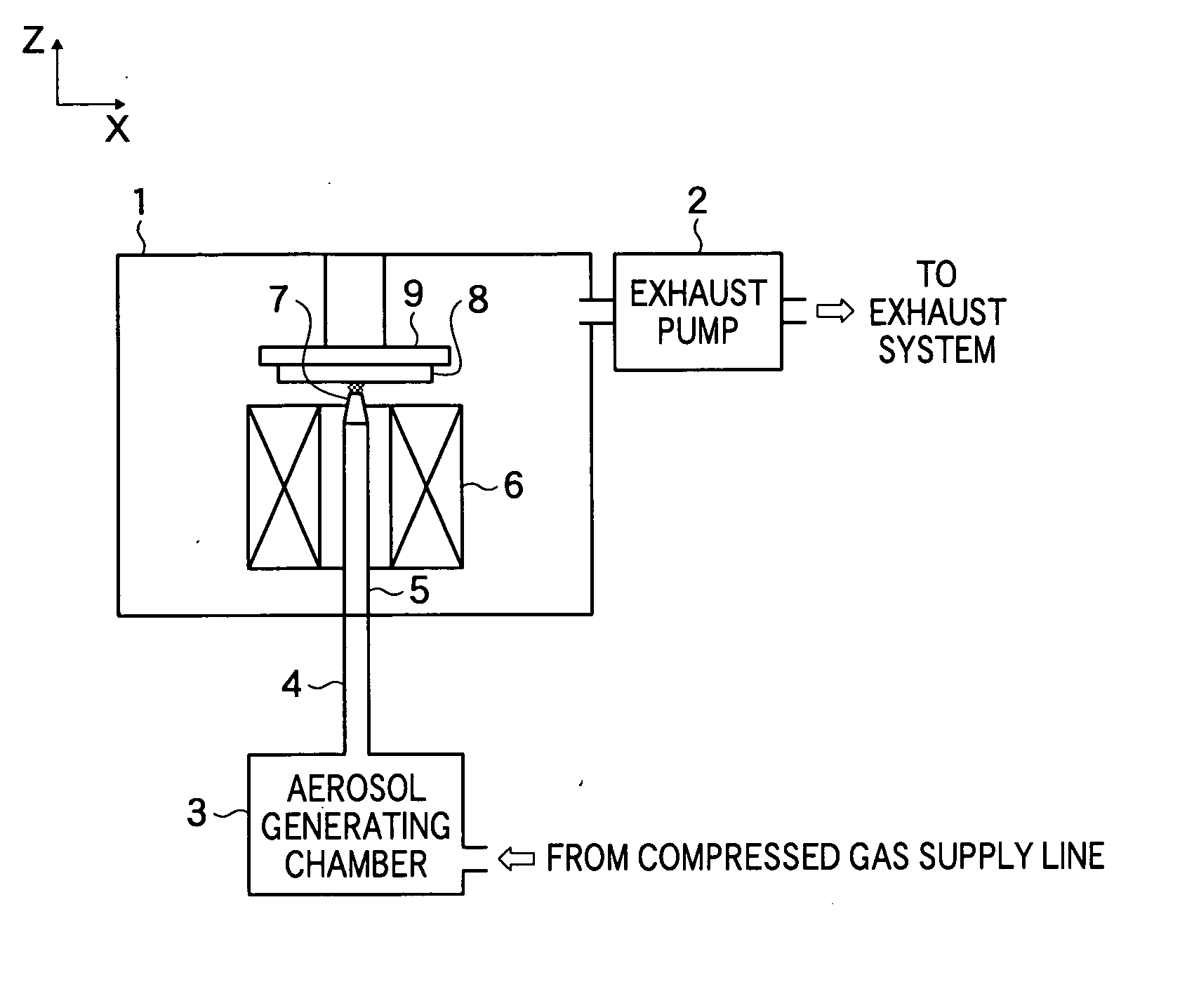

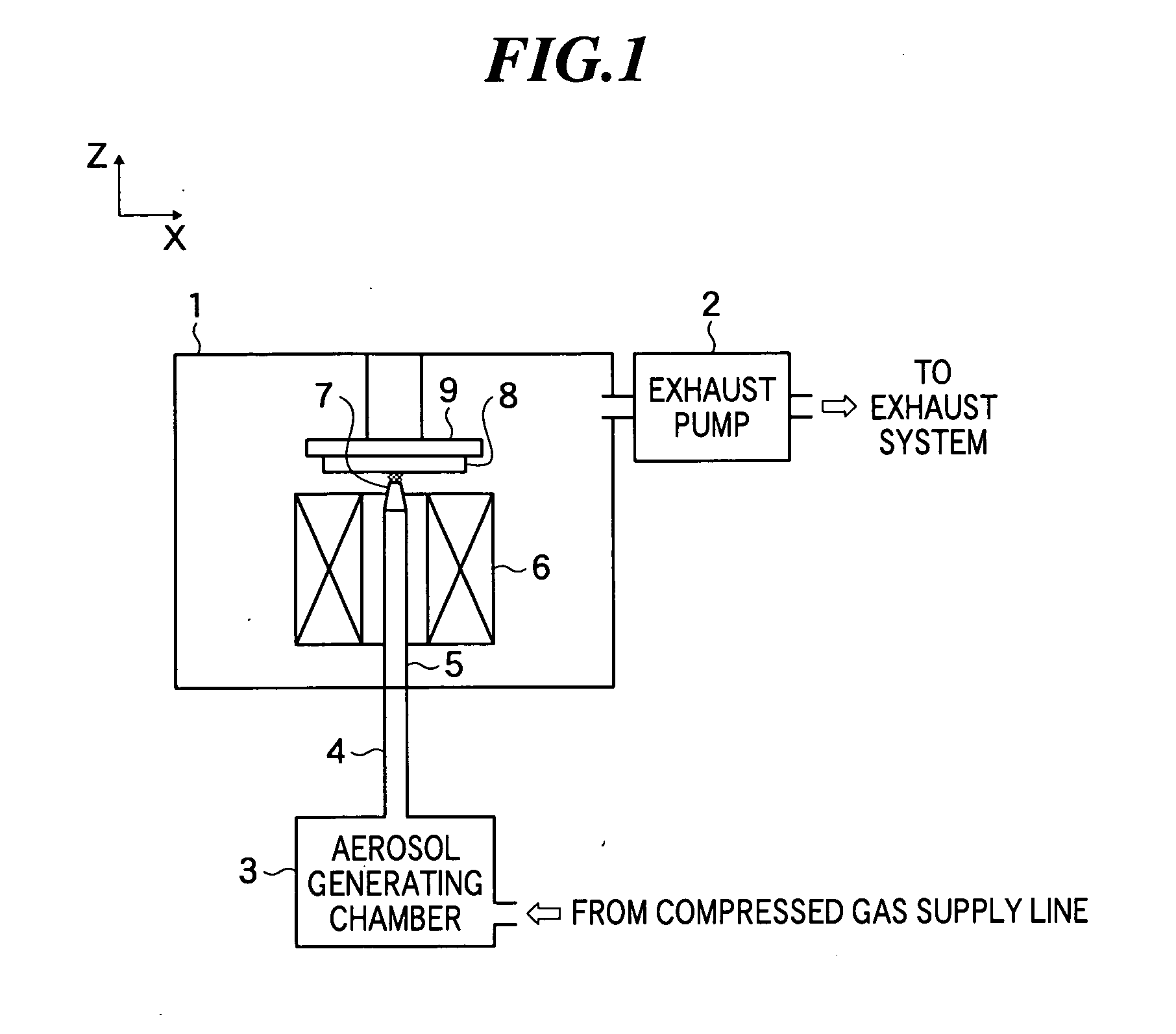

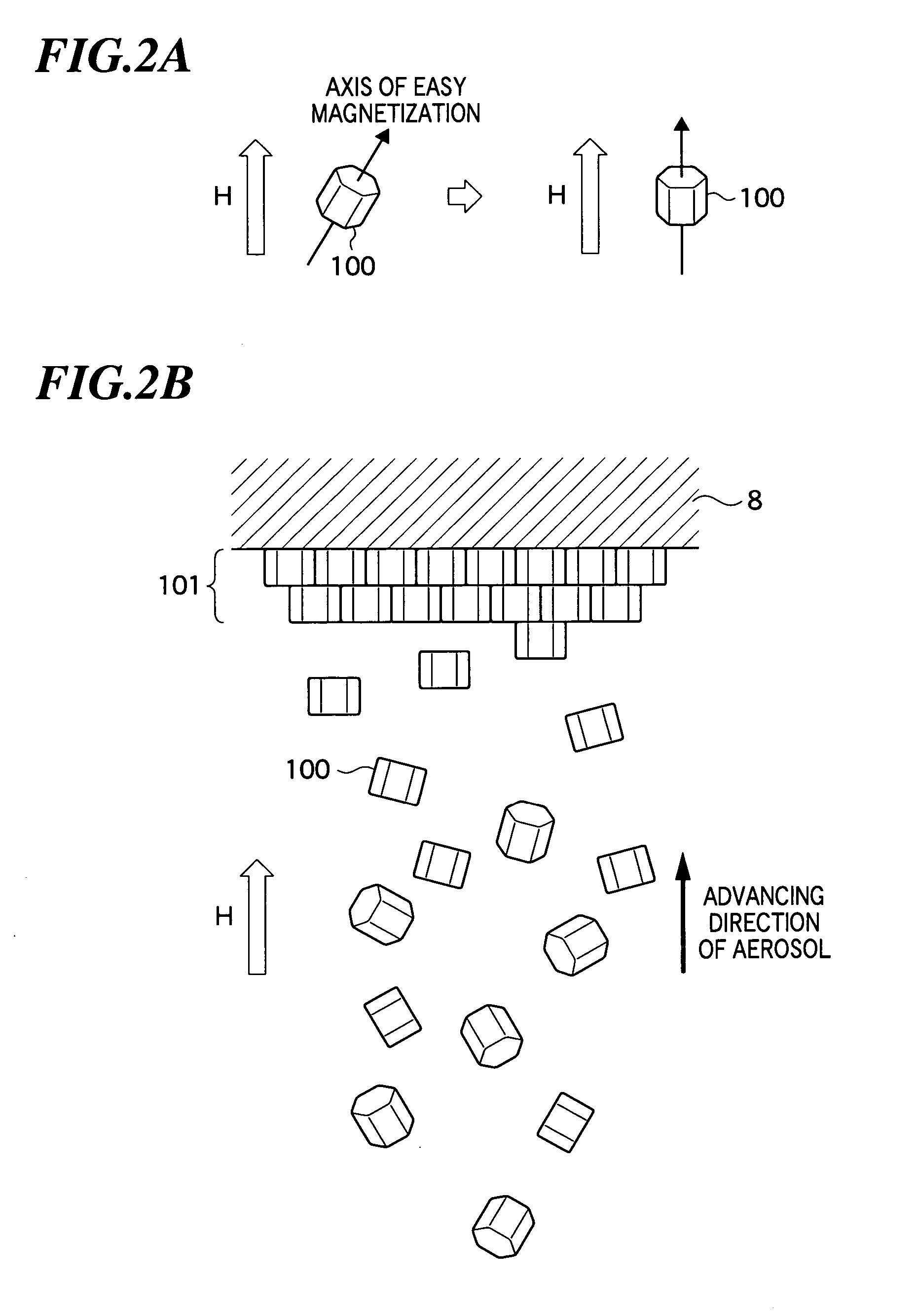

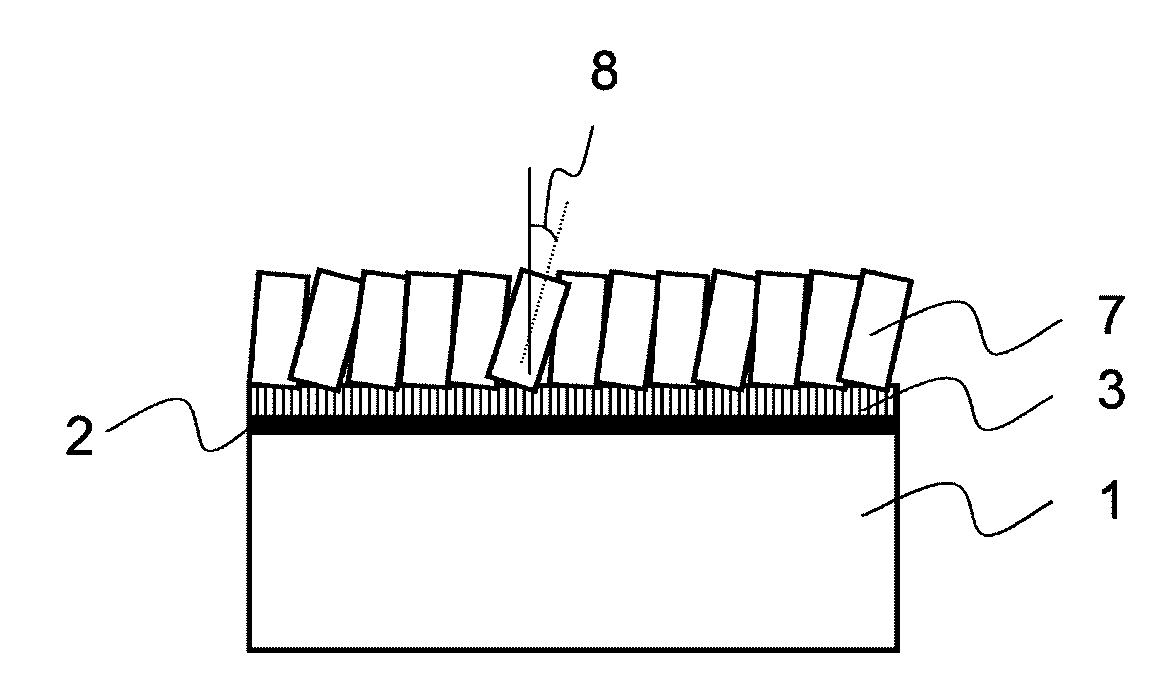

Film forming method and film forming apparatus

InactiveUS20060068105A1Improve propertiesIncrease valuePretreated surfacesMagnetic film to substrate applicationProperty valueCrystal orientation

A film forming apparatus by which property values in a film formed by the AD method can be improved. The film forming apparatus includes: a chamber having a substrate stage for holding a substrate on which a film is to be formed; an aerosol generating unit for generating an aerosol by dispersing a raw material powder into a gas; a magnetic field applying device for applying a magnetic field to a flow path of the aerosol generated by the aerosol generating unit so as to orient crystal orientation in the raw material powder in an aerosol state; and an injection nozzle for spraying the aerosol applied with the magnetic field by the magnetic field applying device to the substrate so as to deposit the raw material powder, in which the crystal orientation is oriented, on the substrate.

Owner:FUJIFILM CORP +1

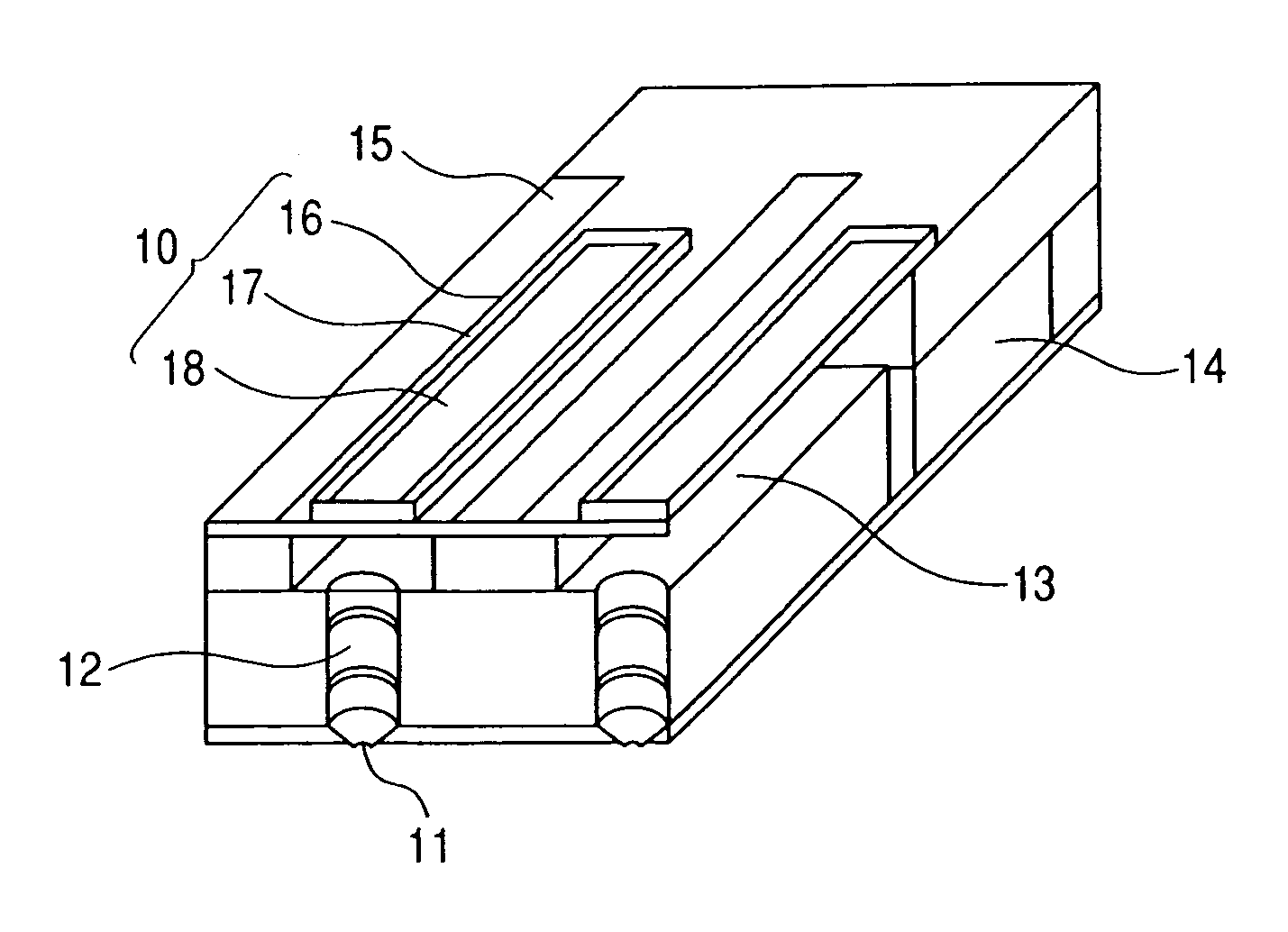

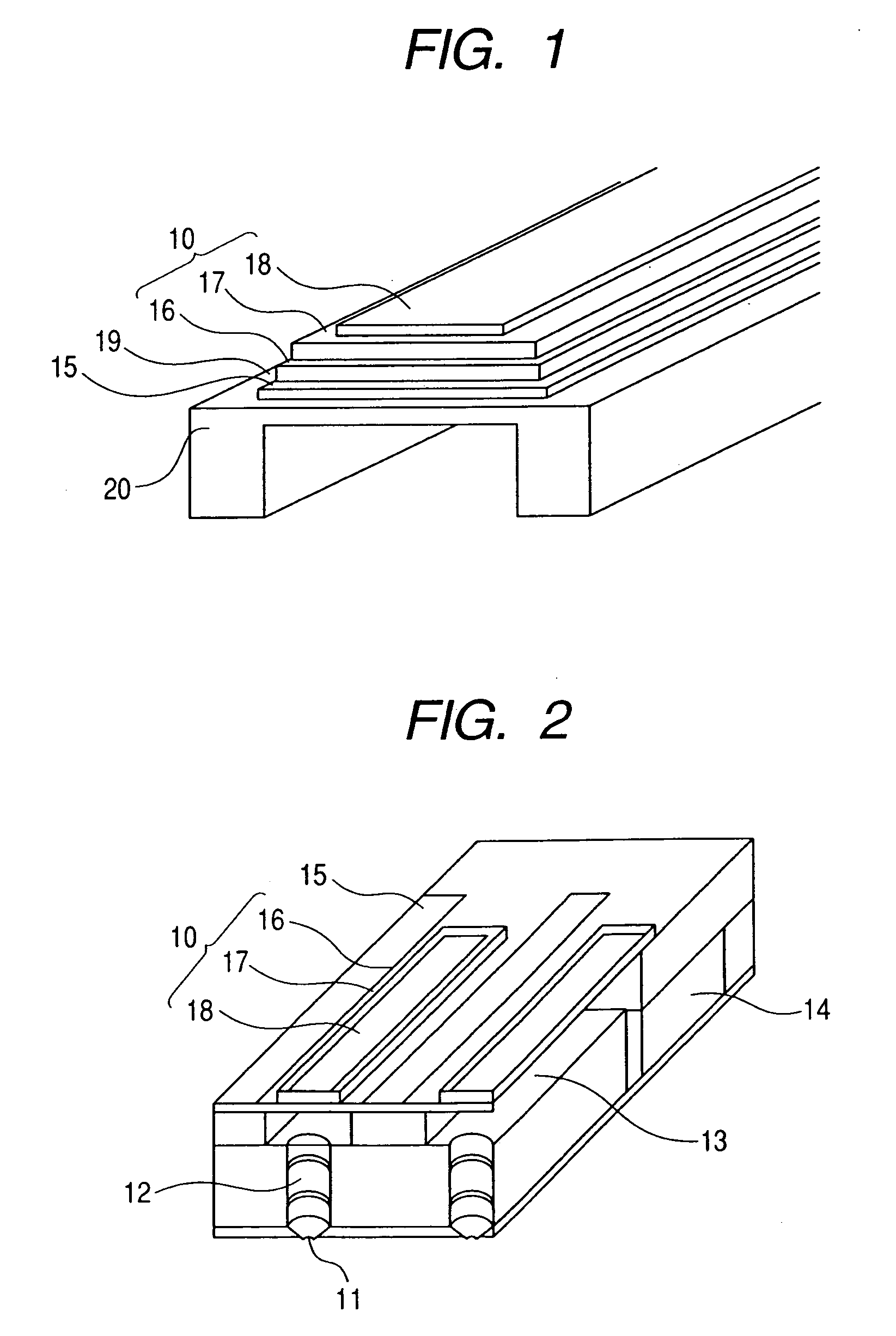

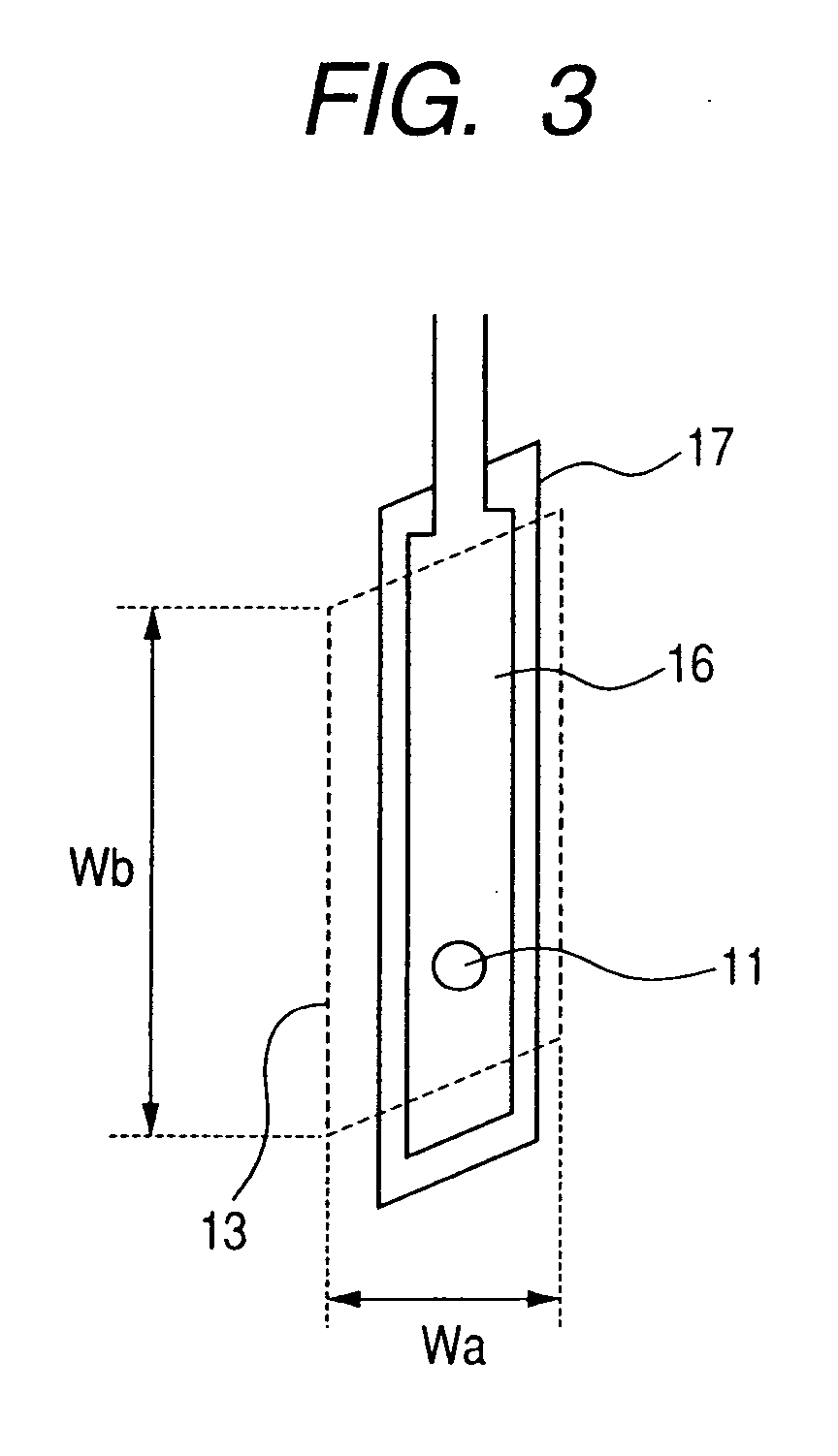

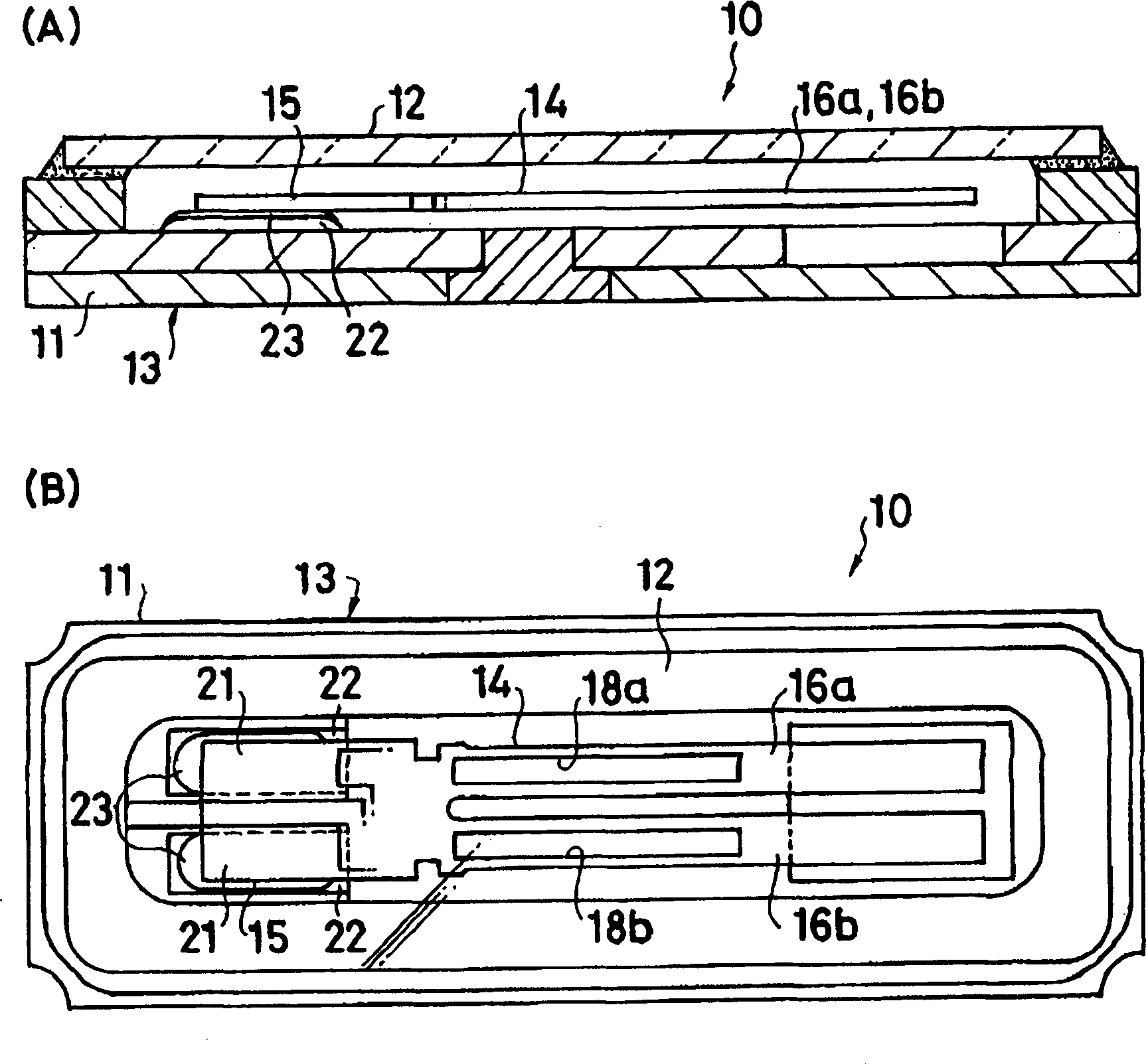

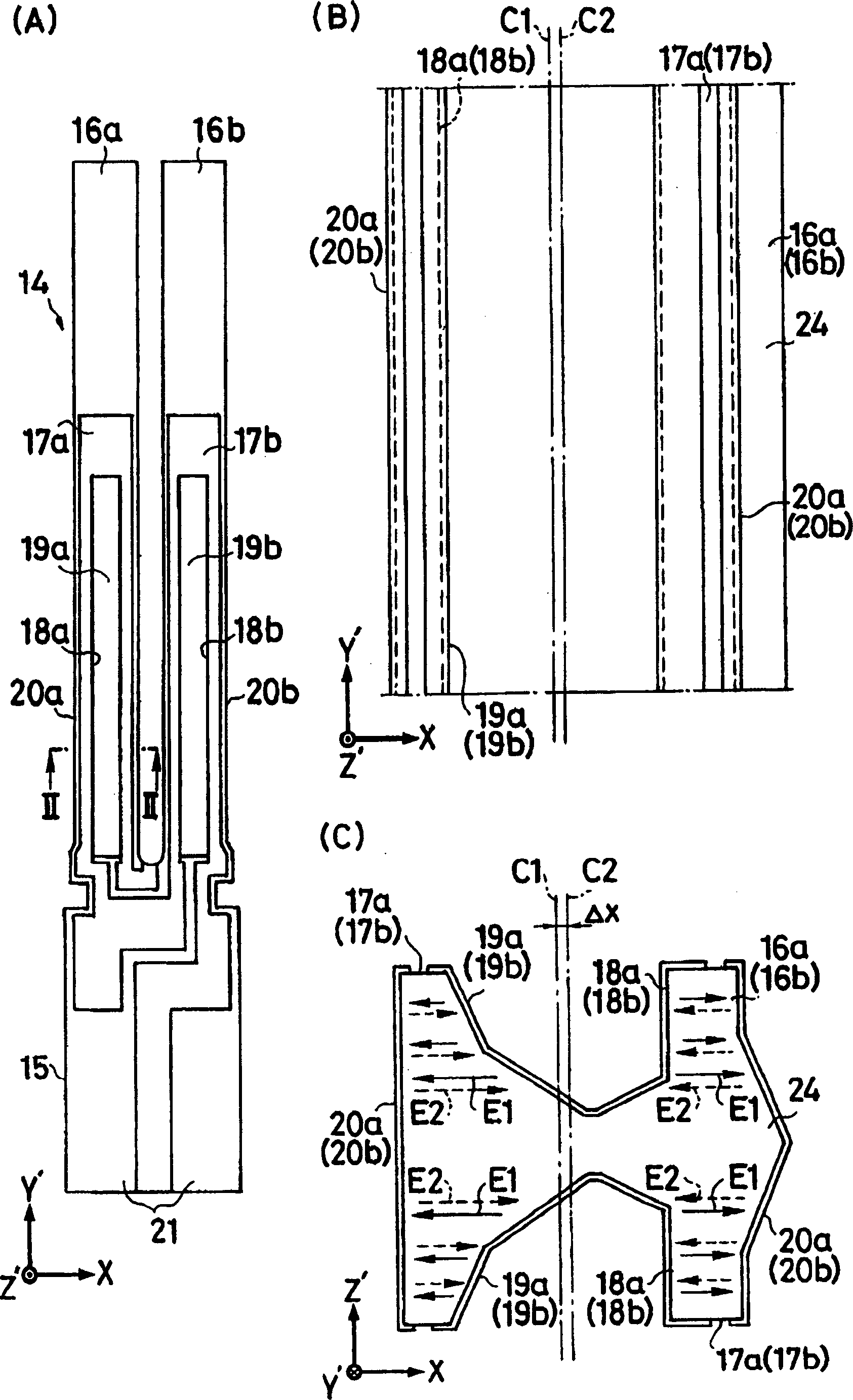

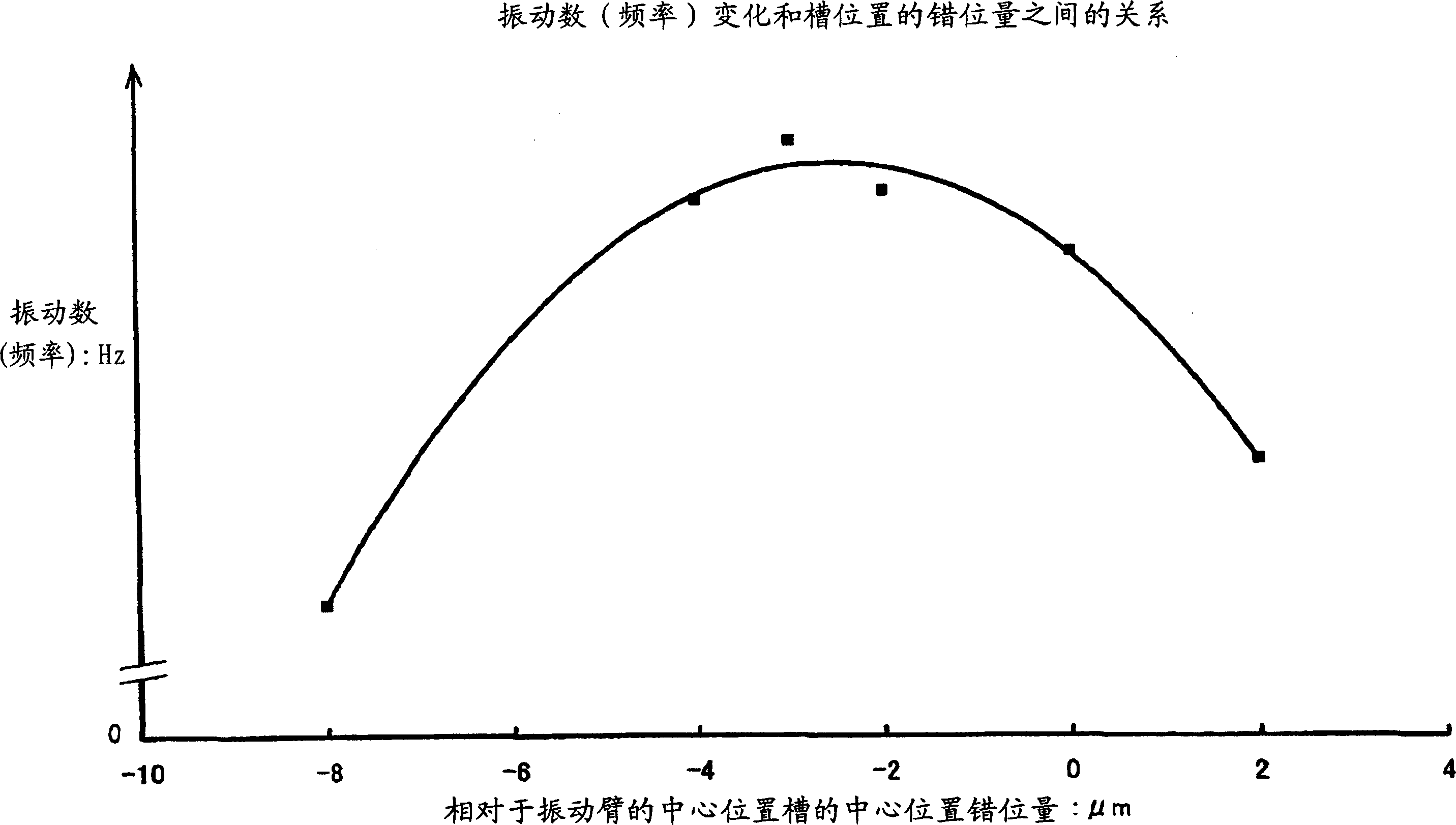

Tuning fork type piezoelectic oscillatory sheet, its mfg. method and piezoelectric device

InactiveCN1447454APiezoelectric/electrostrictive device manufacture/assemblyImpedence networksTuning forkEtching

The tuning fork type crystal vibrating piece (14) is constituted like this, by wet etching the Y axis of its crystal axis, the X axis and the Z axis correspond to the length direction, the width direction and the thickness direction of the vibrating arms (16a), (16b) For the oriented crystal substrate, grooves (18a) and (18b) in the longitudinal direction are arranged on the main plane of the vibrating arm. , the left and right stiffnesses in the width direction of the vibrating arm are balanced, and the bending motion of the vibrating arm is stabilized. In the manufacturing process of the tuning fork type piezoelectric vibrating plate, the dislocation of the position in the width direction of the upper and lower main planes (17a) and (17b) of the vibrating arm caused by the misalignment of the photomask, on the cross section in the width direction of the vibrating arm, in the thickness direction The centers of gravity M1 and M2 of the upper and lower parts divided into two equal parts are adjusted on the same straight line perpendicular to the main plane. By adjusting the relative positions of the grooves (18a) and (18b) in the width direction, vibration due to vibration Displacement in the thickness direction of the arm is eliminated and suppressed, and distortion energy loss due to vibration leakage is prevented. High stability is achieved by suppressing the CI value to improve its performance.

Owner:SEIKO EPSON CORP

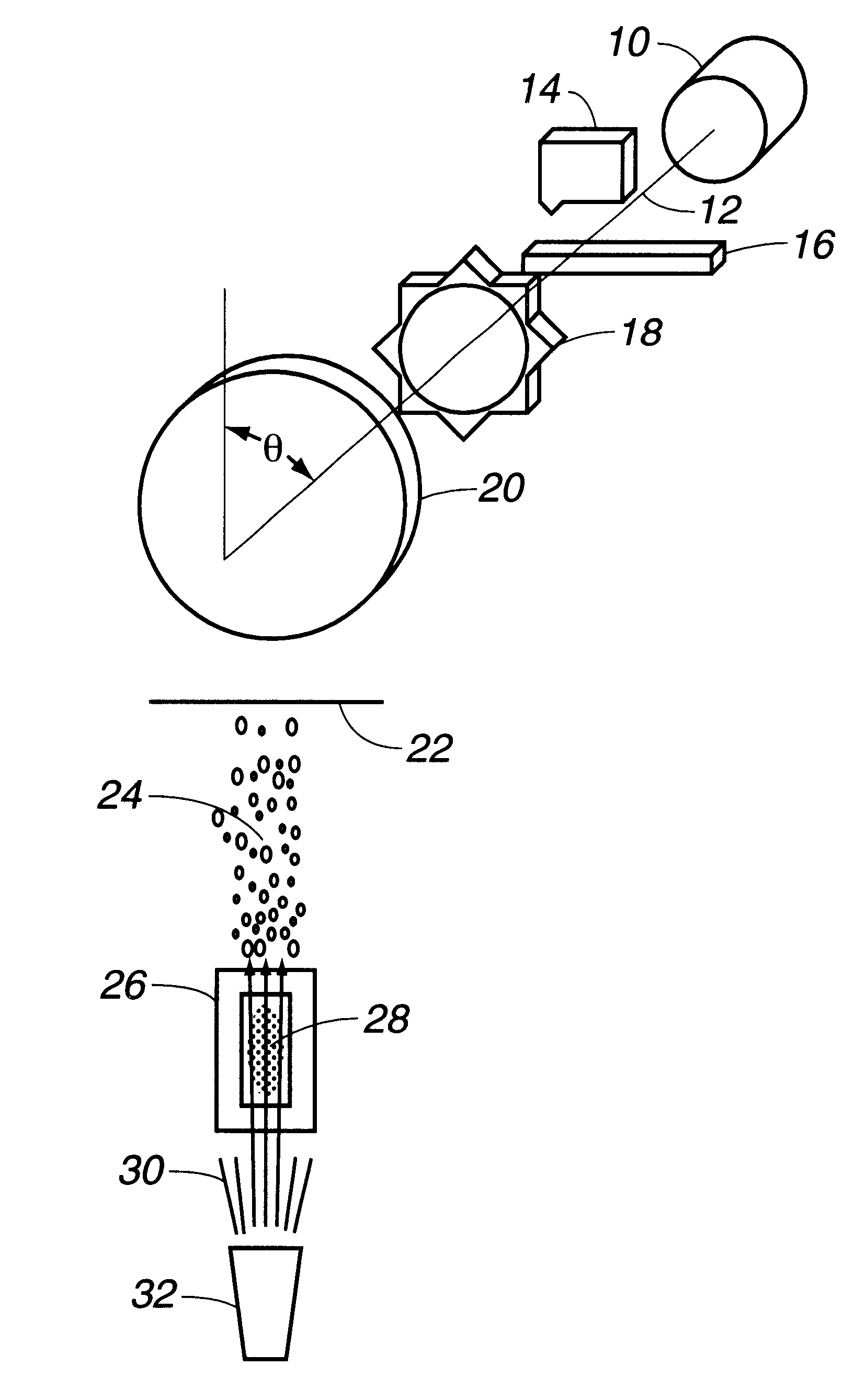

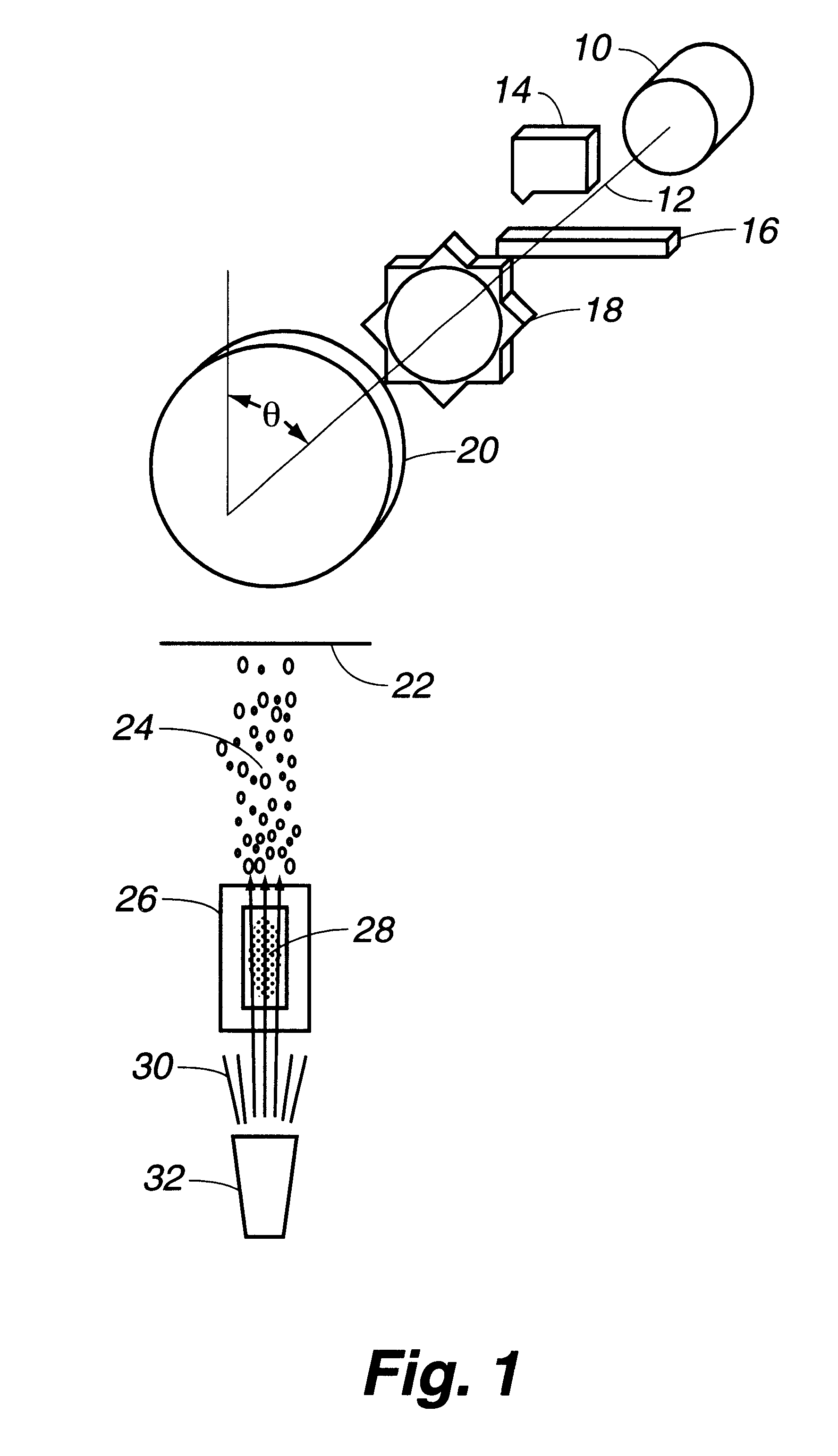

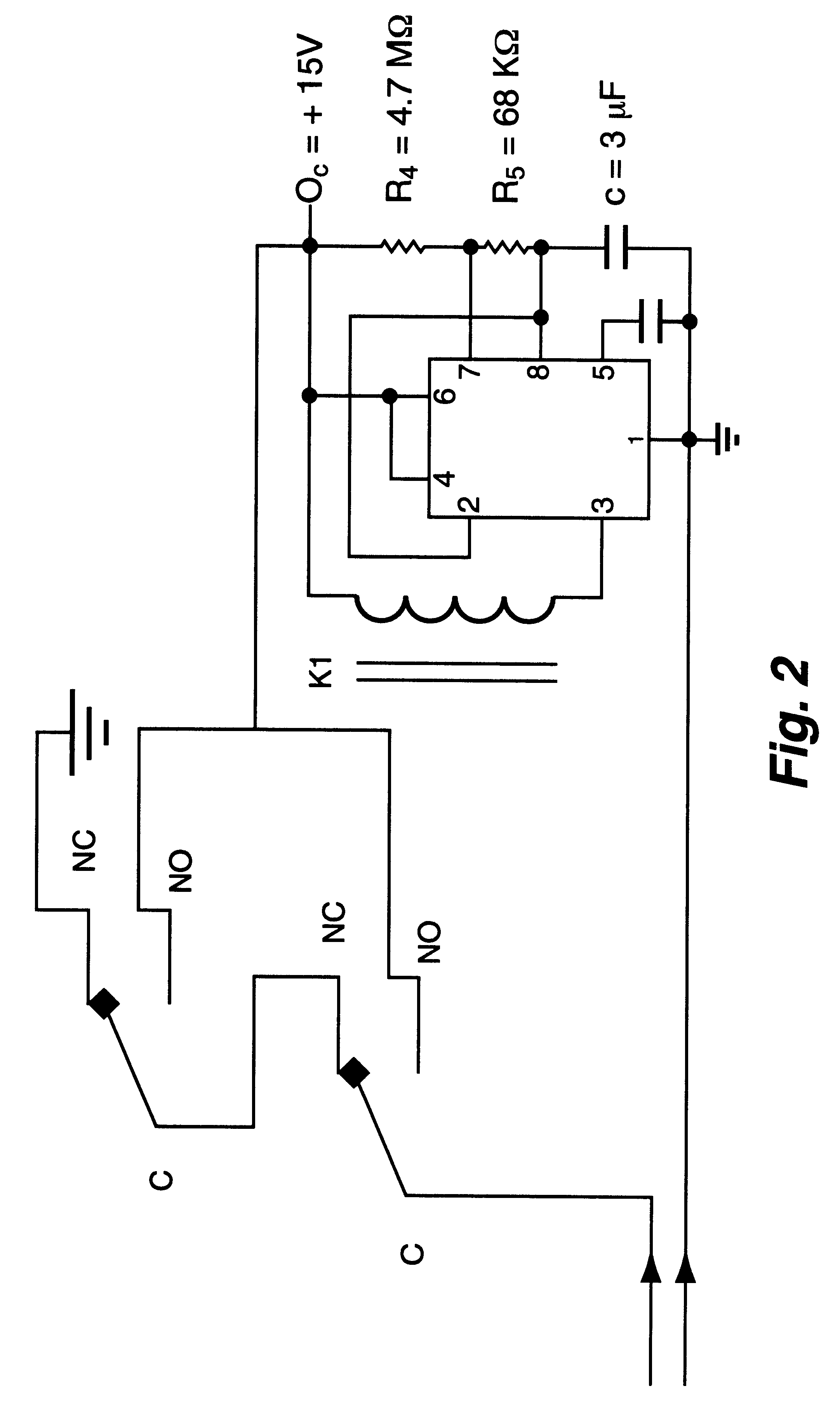

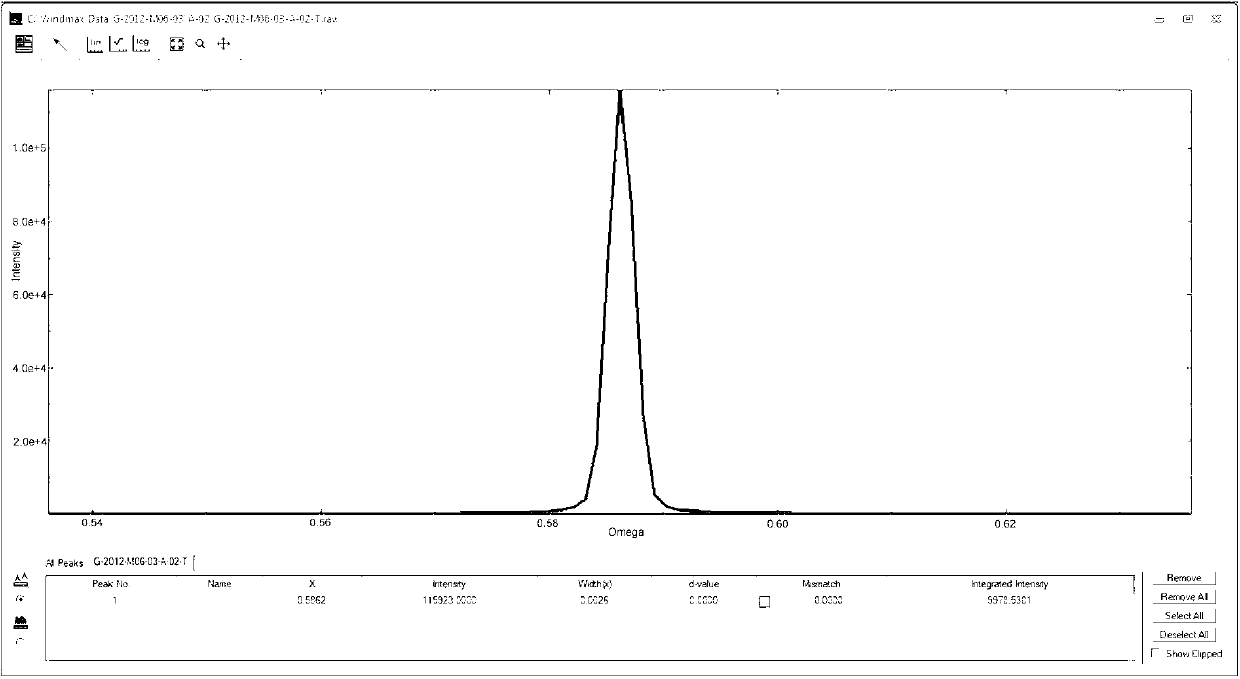

Process and apparatus for making oriented crystal layers

Thin films of single crystal-like materials are made by using flow-through ion beam deposition during specific substrate rotation around an axis in a clocking action. The substrate is quickly rotated to a selected deposition position, paused in the deposition position for ionized material to be deposited, then quickly rotated to the next selected deposition position. The clocking motion can be achieved by use of a lobed cam on the spindle with which the substrate is rotated or by stopping and starting a stepper motor at long and short intervals. Other symmetries can be programmed into the process, allowing virtually any oriented inorganic crystal to be grown on the substrate surface.

Owner:LOS ALAMOS NATIONAL SECURITY

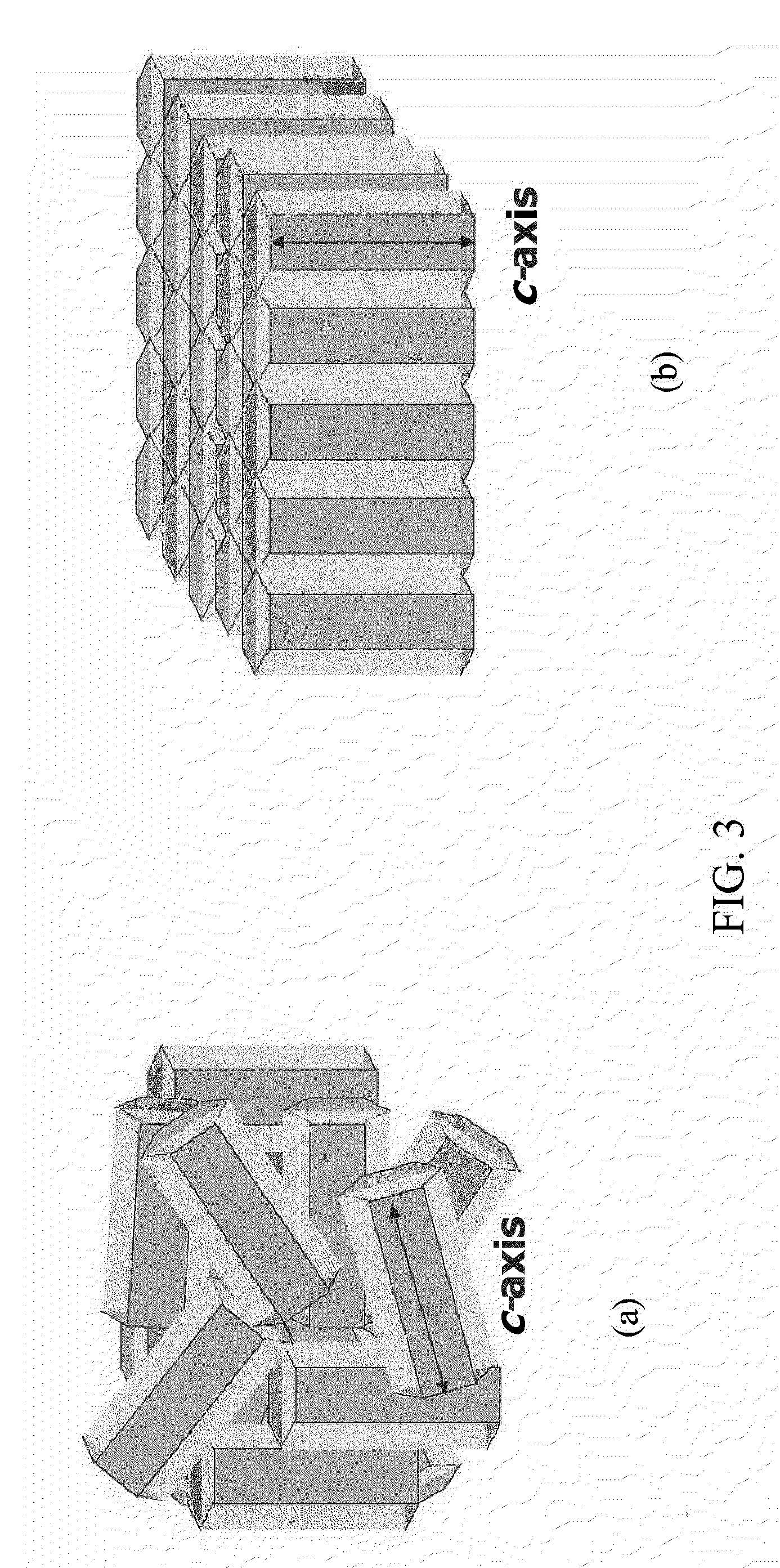

Manufacturing method of large-size C-oriented sapphire crystals

ActiveCN103103604AImprove temperature distributionAvoid or reduce air bubblesPolycrystalline material growthBy pulling from meltCrucibleSeed crystal

The invention relates to a manufacturing method of large-size C-oriented sapphire crystals. According to the method, an alumina raw material with the high purity of 99.999 wt% is adopted and is heated to be molten and subjected to crystal seeding and crystal growing. A main heater and an assistant heater are adopted, wherein a tungsten rod cylinder-shaped heating body is arranged around a crucible and is used as the main heater; another tungsten disc-shaped heating body is arranged at the bottom of the crucible and is be used as the assistant heater; the power ratio of the main heater to the assistant heater is (20 to 80 KW): (10 to 60 KW). In addition, a tungsten tube is mounted at the top of the crucible, and argon is introduced into the tungsten tube to regulate the temperature of the seed crystal and a liquid surface. As the method is used, the temperature distribution of a longitudinal temperature field in the crucible is improved, so that air bubbles, cracks and other defects are avoided or reduced, i.e., the seed crystal is prevented from being molten at overhigh temperature during the crystal seeding process. Therefore, the generation of a C-oriented long crystal boundary with a small angle is controlled effectively. As a result, the growing C-oriented crystals with the diameter of 14 inches are good in position staggering density and single crystal performance. Consequently, the method provided by the invention reaches the international advanced level.

Owner:TDG HLDG CO LTD

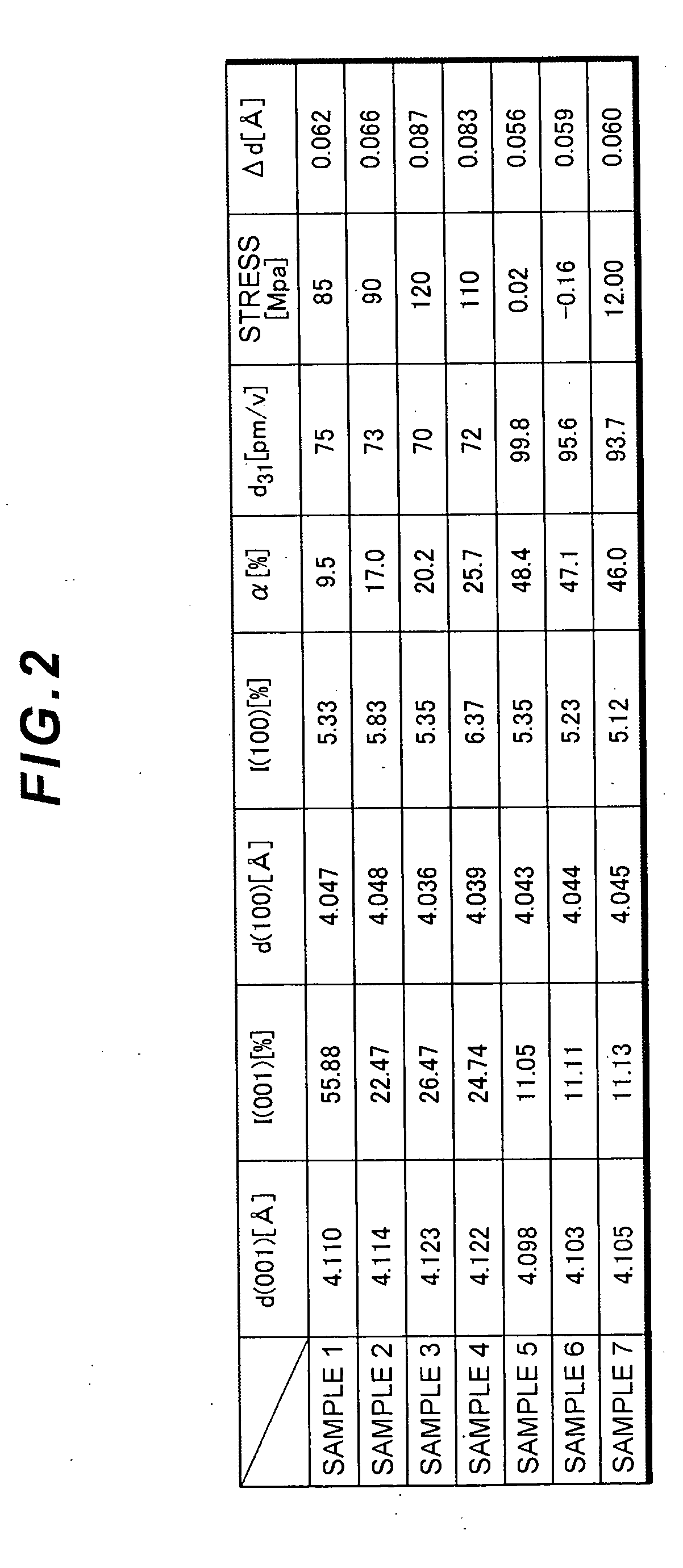

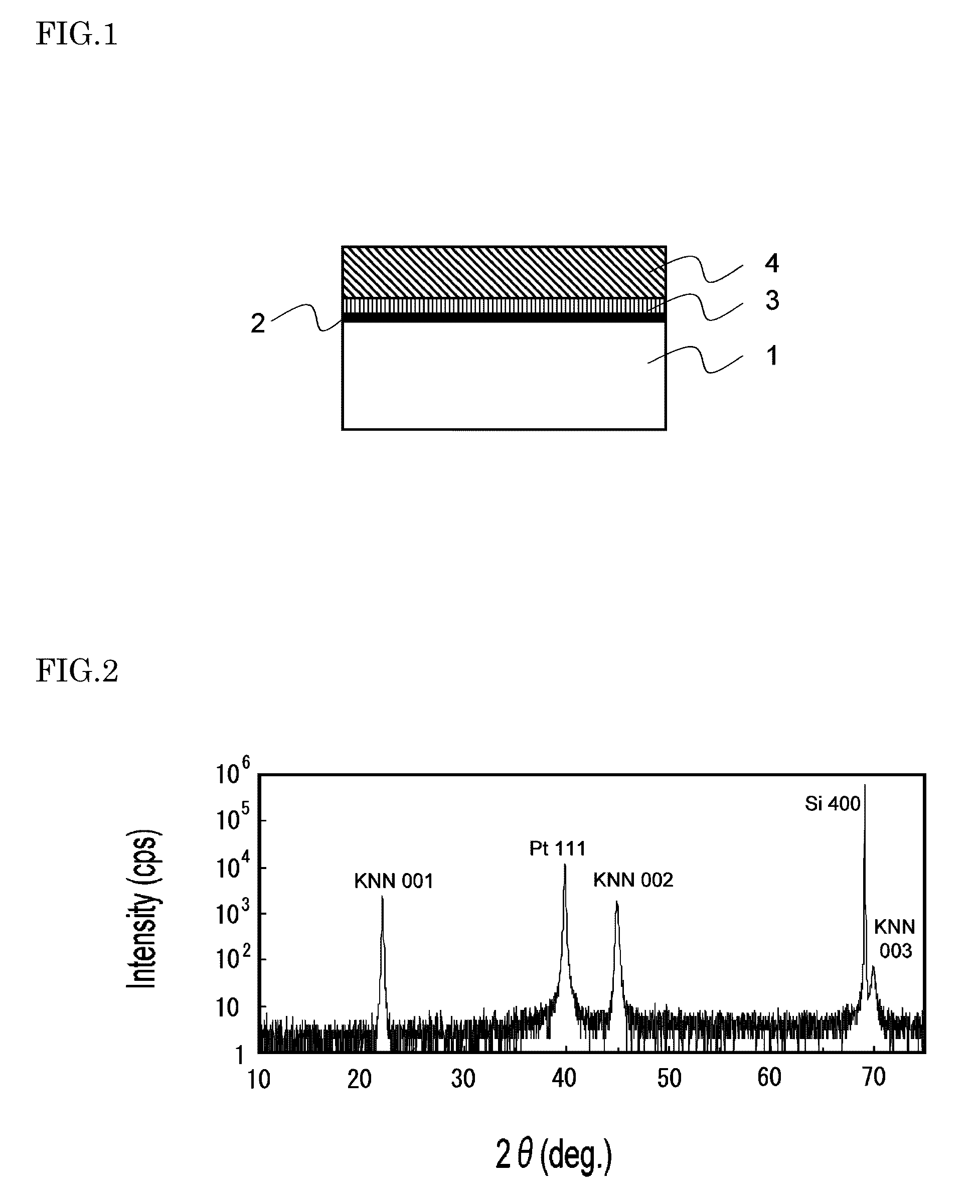

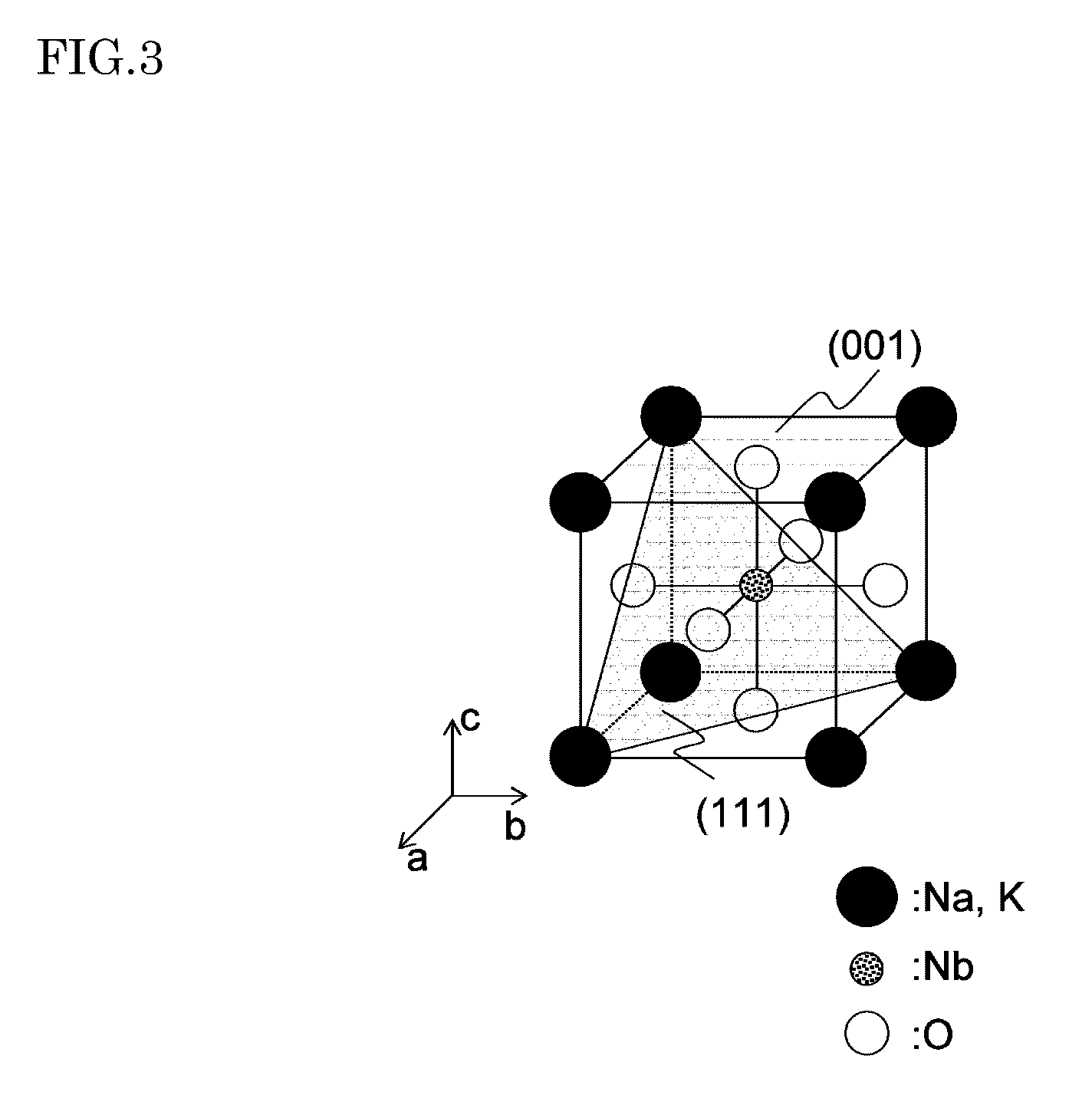

Piezoelectric element and gyroscope

ActiveUS20100244632A1Excellent piezoelectric propertiesHigh detection sensitivityPiezoelectric/electrostriction/magnetostriction machinesSpeed measurement using gyroscopic effectsGyroscopeCrystal structure

A piezoelectric element having a crystal structure that enables a piezoelectric film to be formed in an unstressed state is provided. The piezoelectric film contains an a-axis oriented crystal and a c-axis oriented crystal, where a difference in lattice constant between the a-axis oriented crystal and the c-axis oriented crystal is not more than 0.06 Å. The present inventors have newly found that a stress accumulated in the piezoelectric film can be reduced while maintaining favorable piezoelectric properties when a condition that the difference in lattice constant between the a-axis oriented crystal and the c-axis oriented crystal is not more than 0.06 Å is satisfied. When the condition is satisfied, the c-axis oriented crystal and the a-axis oriented crystal are properly balanced and as a result crystal particles of the piezoelectric film are closest-packed on its base in an ideal state, which contributes to a reduced stress.

Owner:TDK CORPARATION

Method for detecting orientation of large-sized crystal grains

ActiveCN102103093ARapid Batch DetectionMaterial analysis using radiation diffractionMetallic materialsPolycrystalline material

The invention discloses a method for detecting orientation of large-sized crystal grains. The method mainly comprises the following steps of: establishing and storing a database; combining the colors of the crystal grains and crystallographic data by an electron backscatter diffraction pattern (EBSP) technology; establishing the correspondence between the colors and the crystallographic data; recording corrosion conditions of different metal materials and differently-oriented crystal grains; quickly retrieving the database to search a corrosion state after a large number of samples to be detected are obtained; corroding according to the same corrosion mode; and recording the colors of the crystal grains corresponding to the orientation, which accords with the conditions, of the database under the conditions of the same light source and the same viewing angle to finally realize quick and batch orientation detection of the crystal grains. In the method, the specific color of the differently-oriented crystal grains is obtained through observation under fixed conditions by quantitatively calculating the surface energy of the crystal grain orientation and proper corrosion time, and quick and batch orientation detection of a large-sized polycrystalline material is realized corresponding to the scanning of the database so as to determine the performance of the material.

Owner:ANGANG STEEL CO LTD

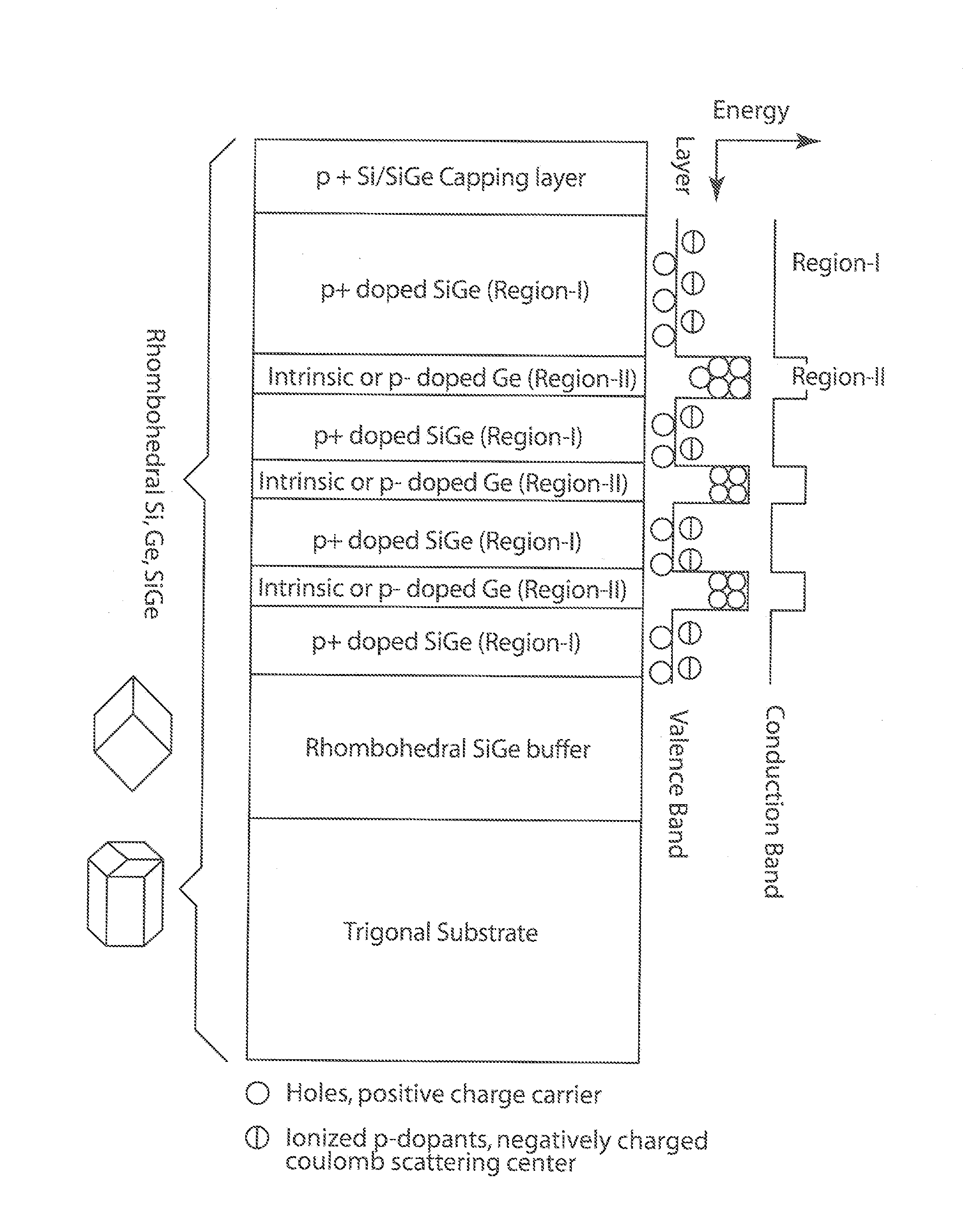

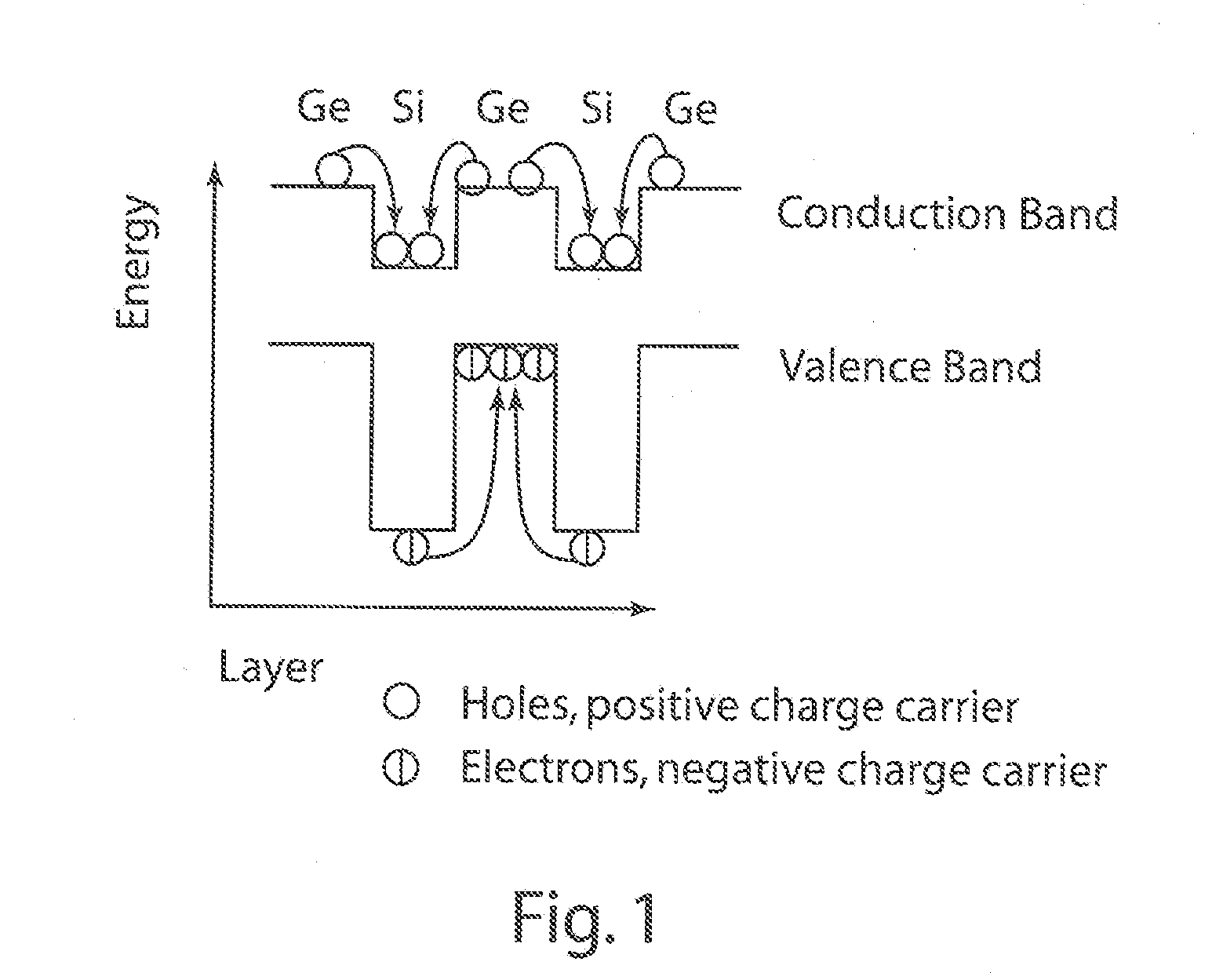

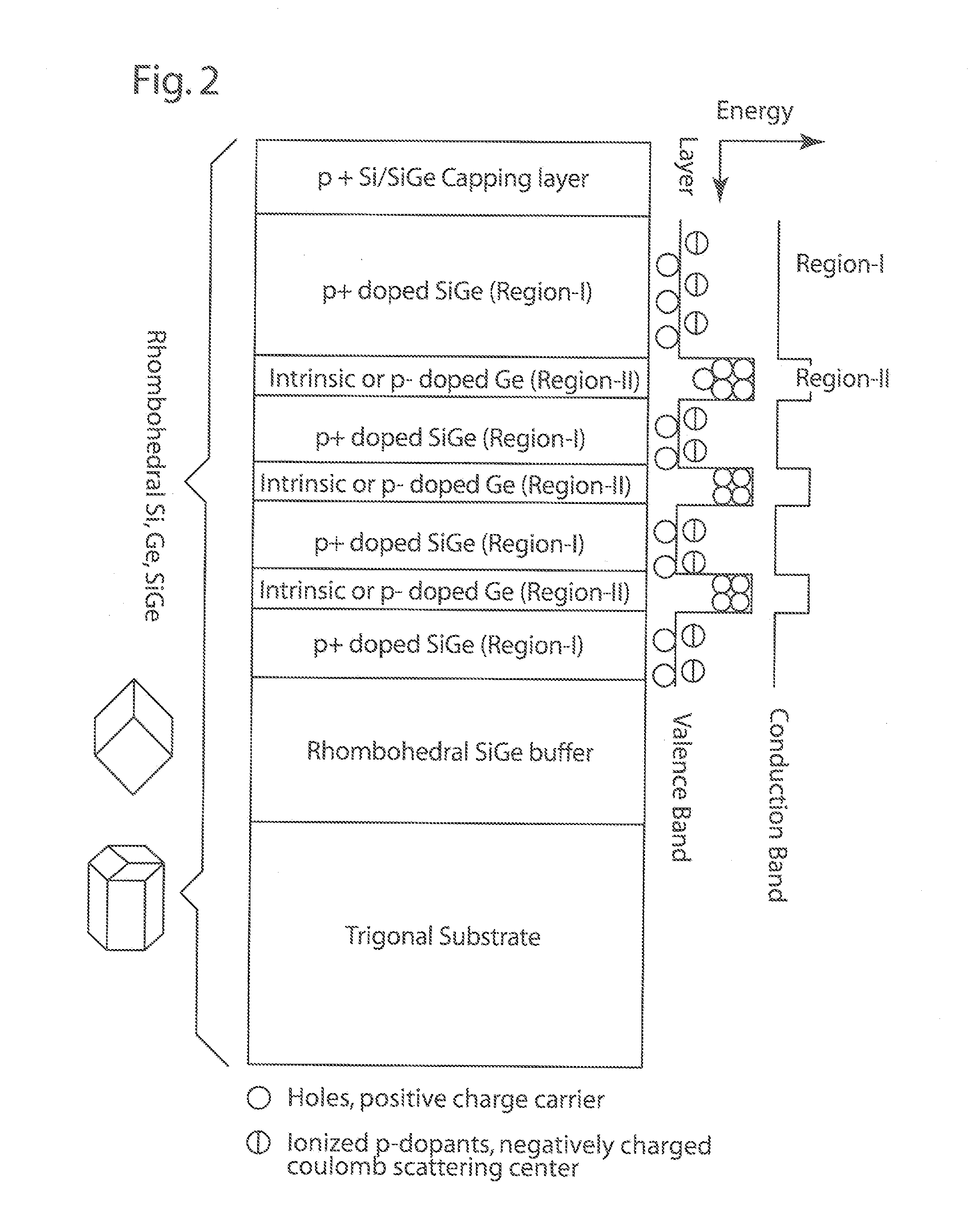

High Mobility Transport Layer Structures for Rhombohedral Si/Ge/SiGe Devices

ActiveUS20140264459A1Promote growthFacilitates of materialSemiconductor/solid-state device manufacturingPhotovoltaic energy generationTransport layerElectron

An electronic device includes a trigonal crystal substrate defining a (0001) C-plane. The substrate may comprise Sapphire or other suitable material. A plurality of rhomhohedrally aligned SiGe (111)-oriented crystals are disposed on the (0001) C-plane of the crystal substrate. A first region of material is disposed on the rhombohedrally aligned SiGe layer. The first region comprises an intrinsic or doped Si, Ge, or SiGe layer. The first region can be layered between two secondary regions comprising n+doped SiGe or n+doped Ge, whereby the first region collects electrons from the two secondary regions.

Owner:NASA +1

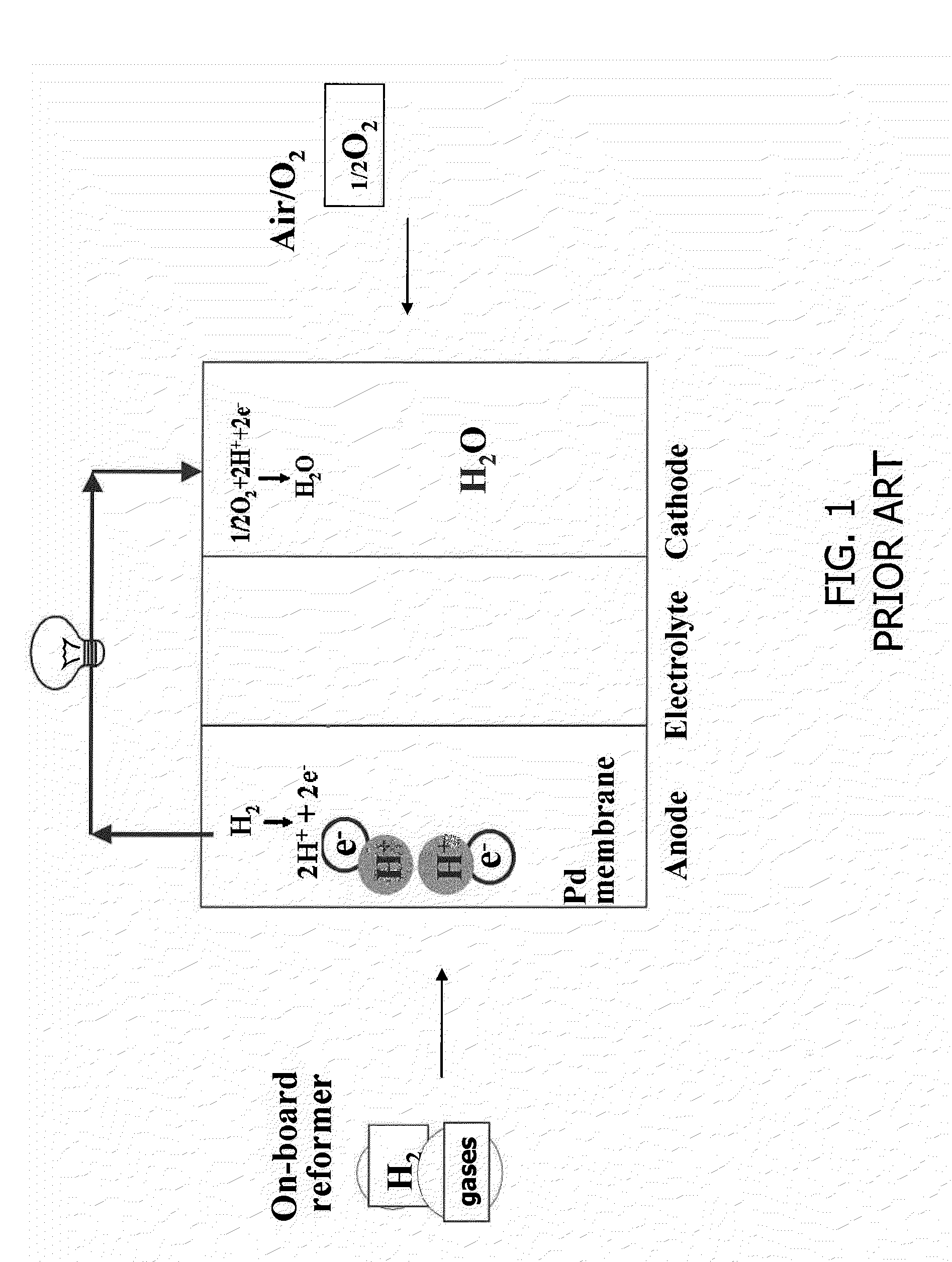

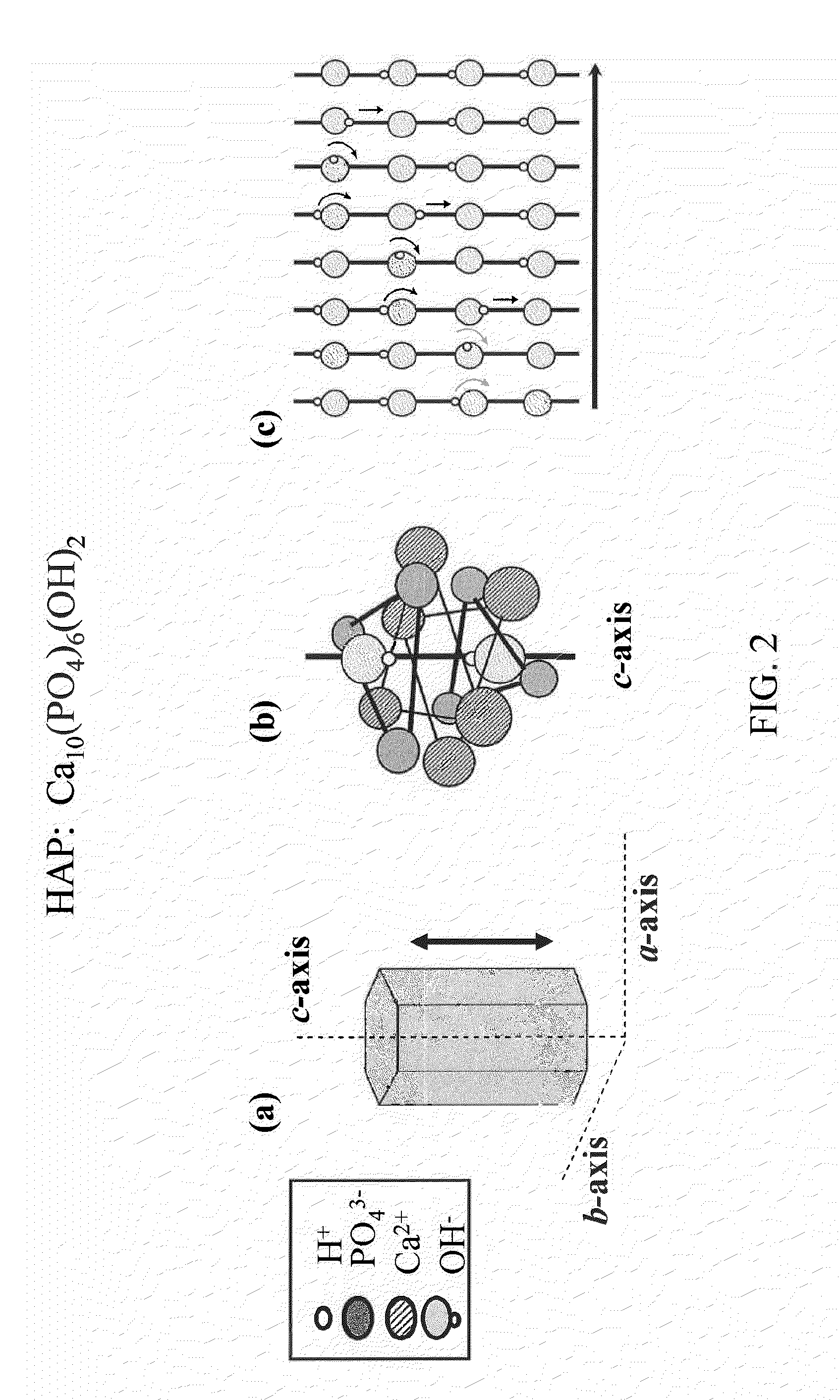

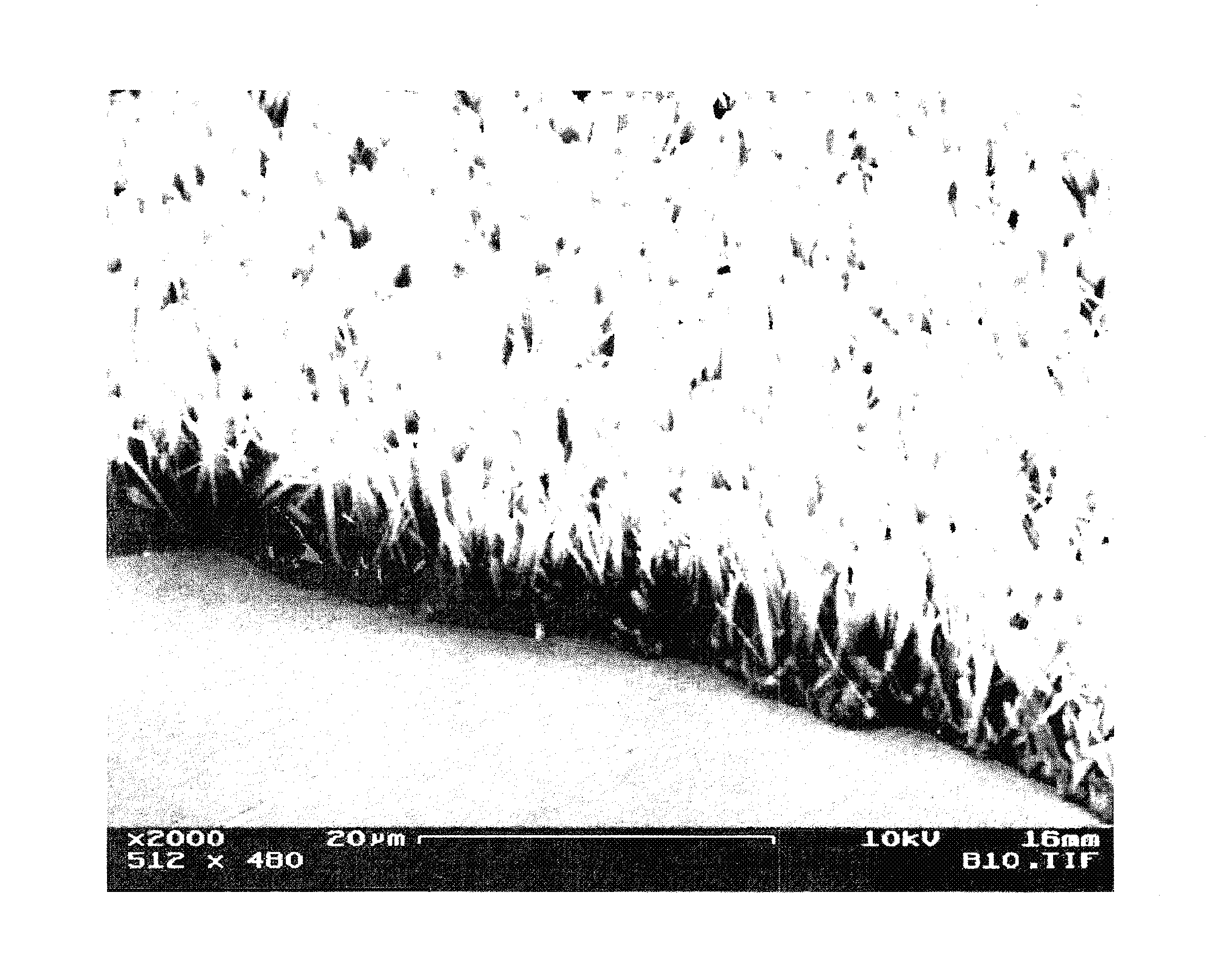

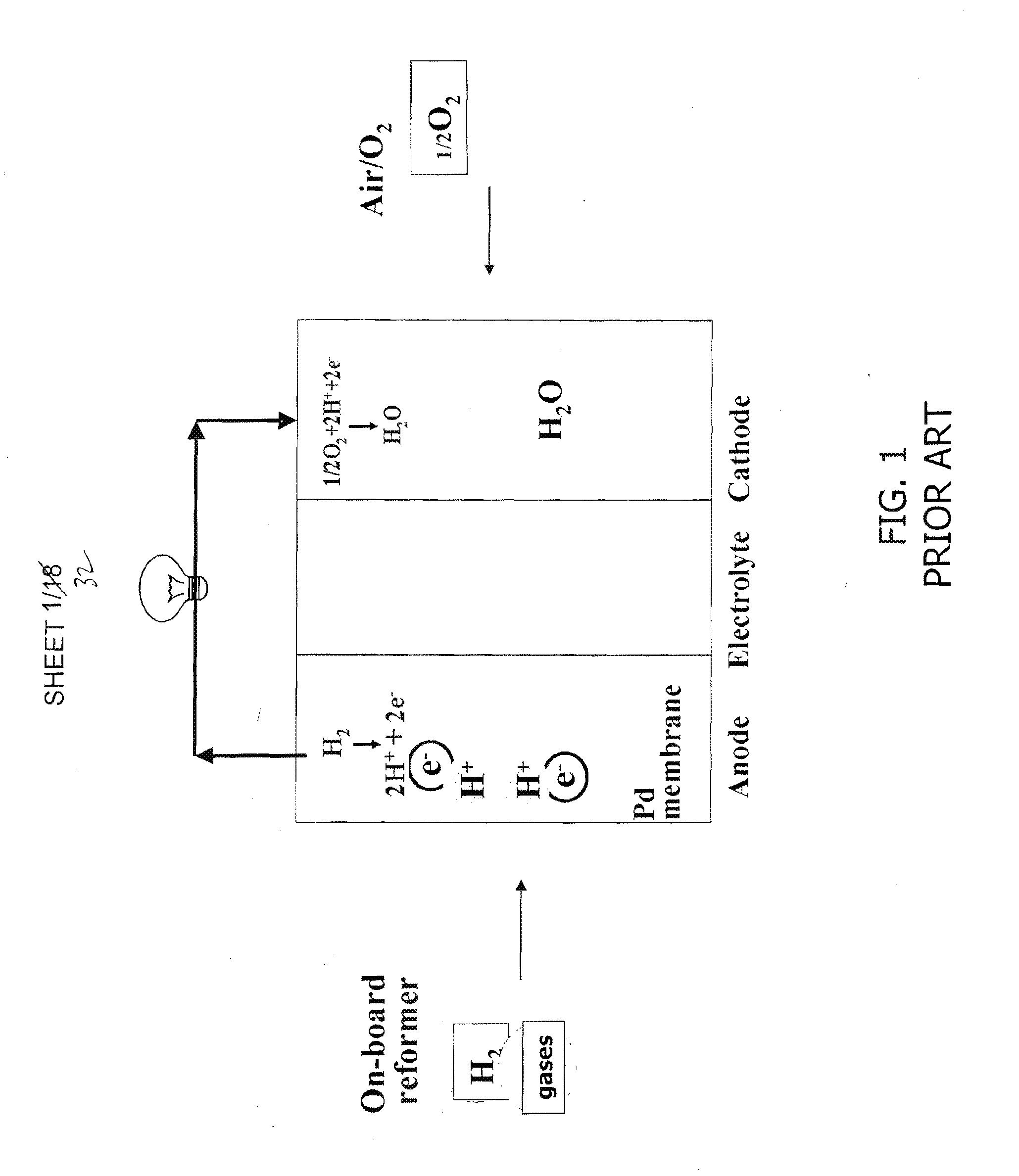

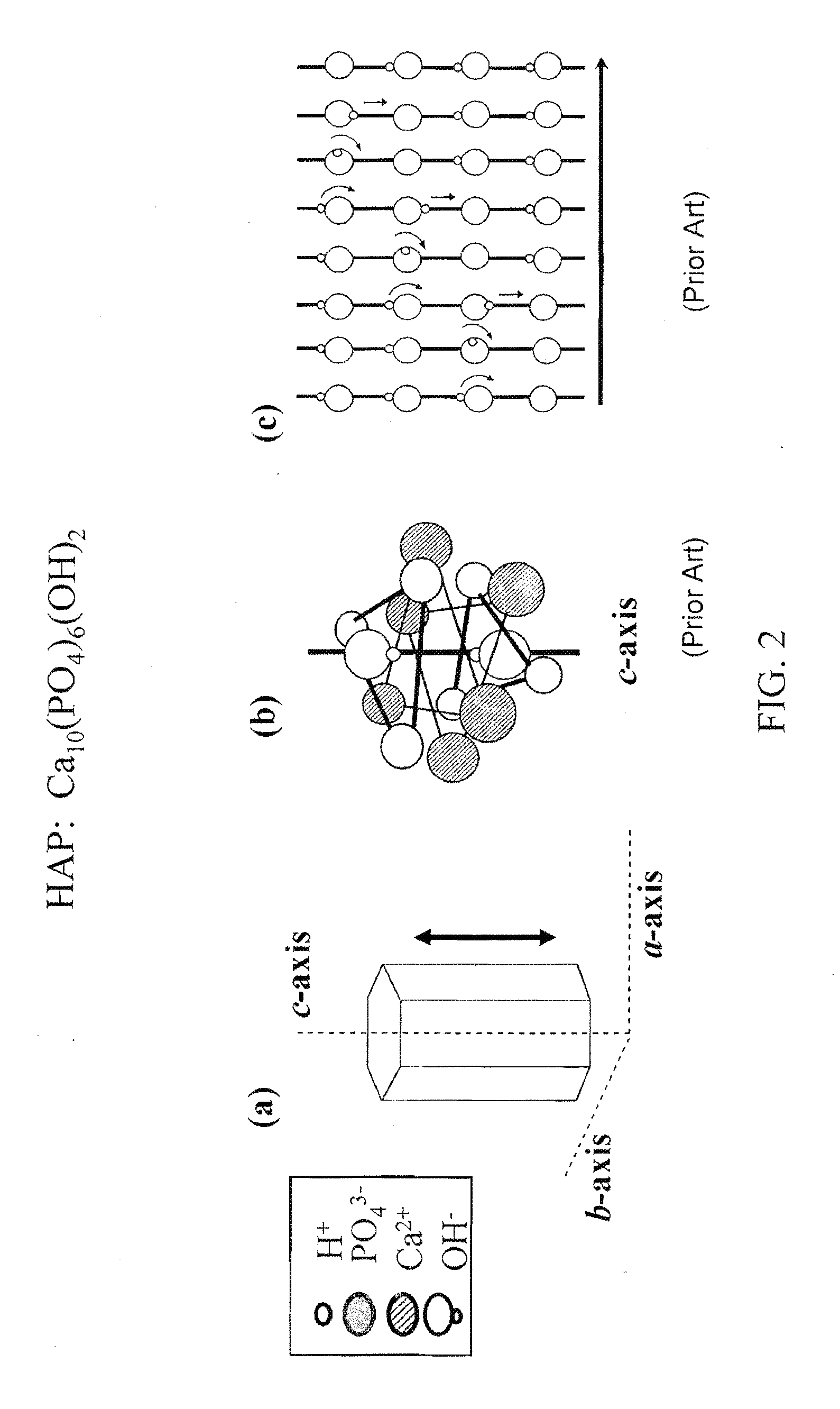

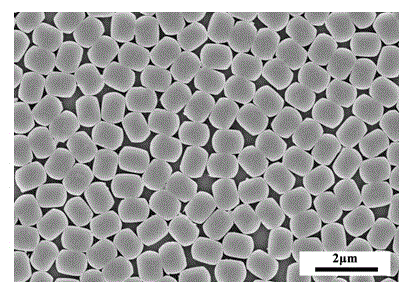

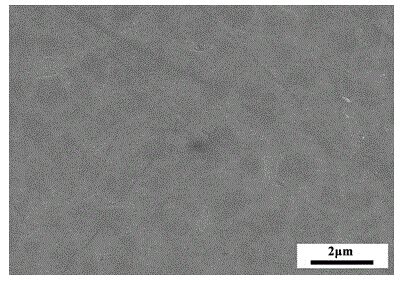

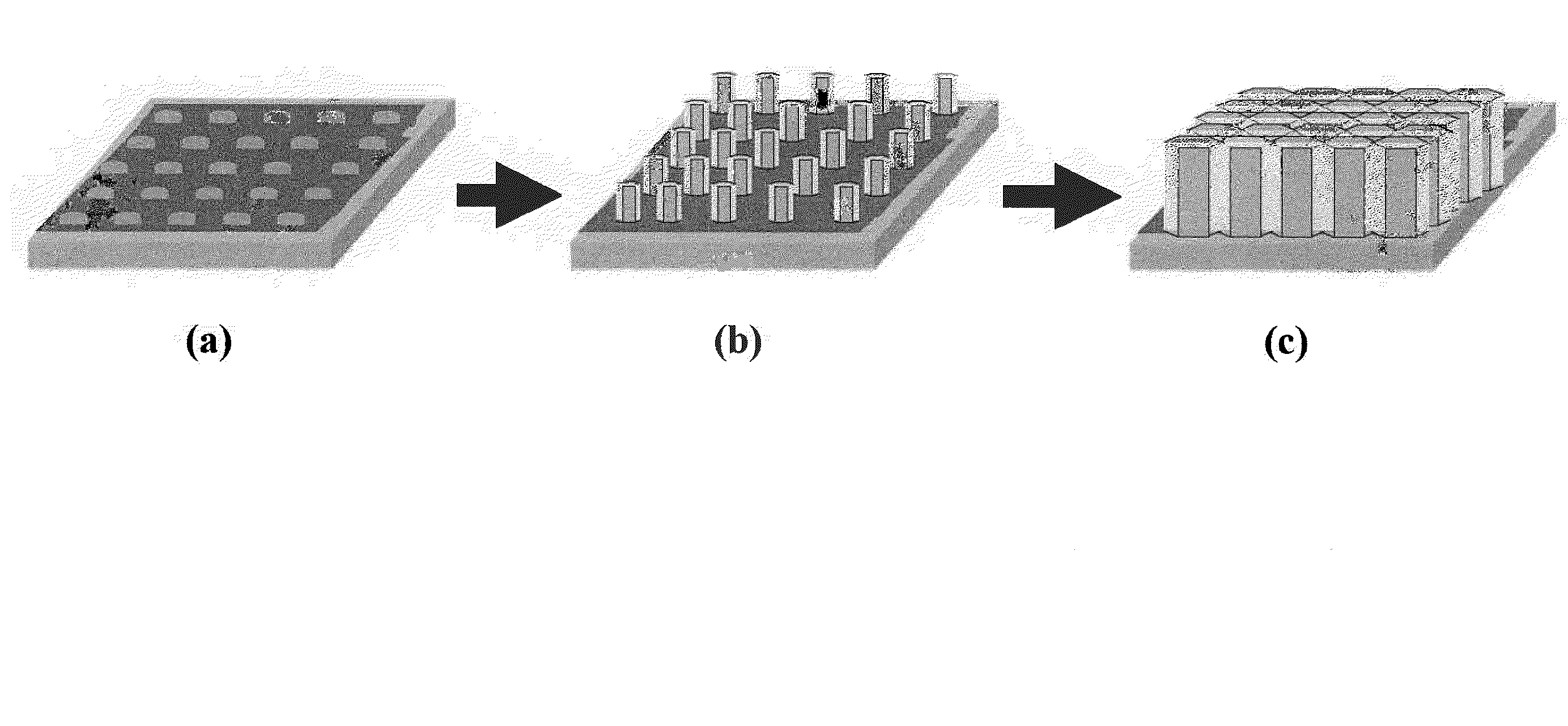

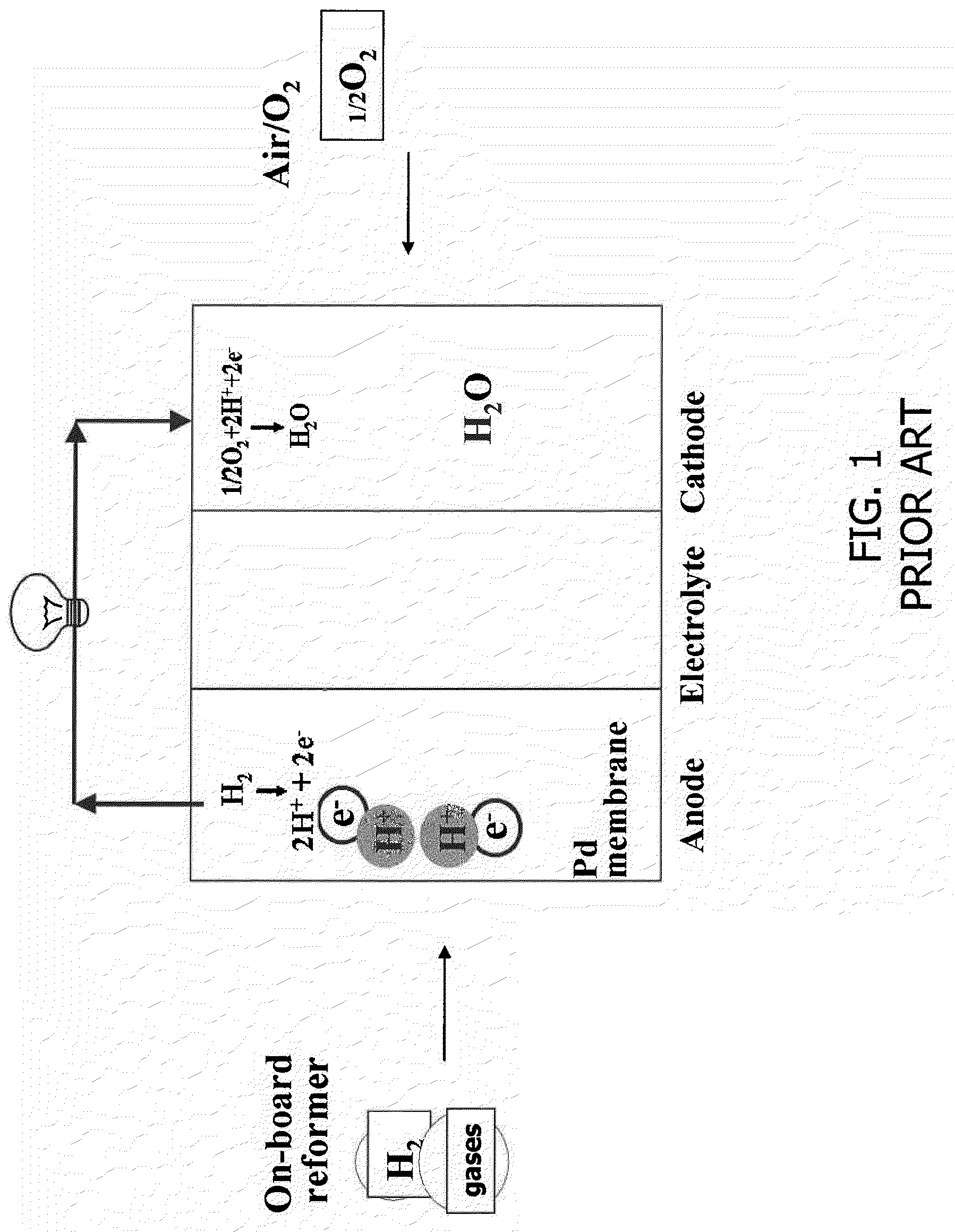

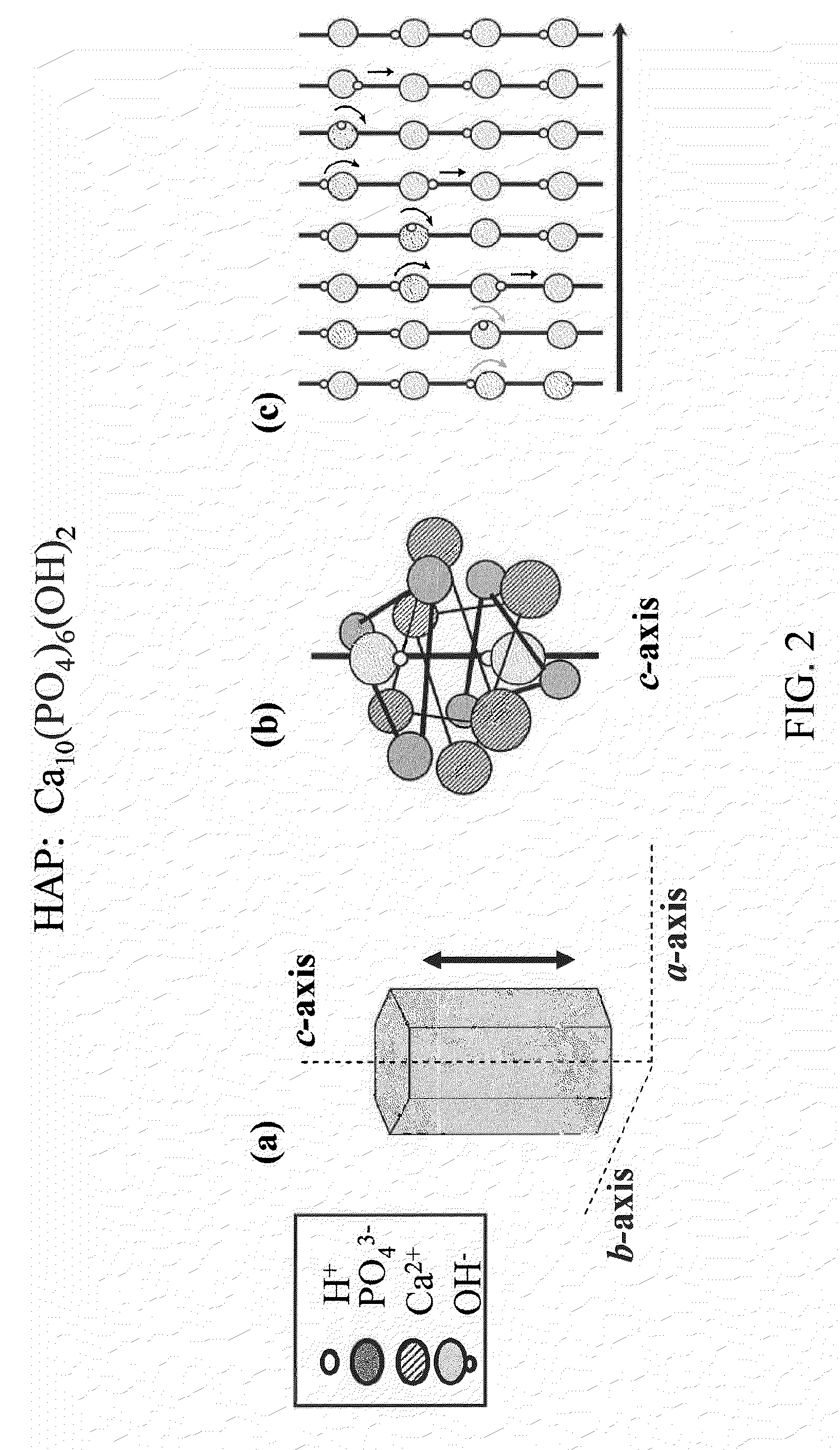

Ion-Conducting Ceramic Apparatus, Method, Fabrication, and Applications

InactiveUS20100015494A1Easy to transportReduce the temperaturePolycrystalline material growthPhosphatesHydrogen atmosphereSynthesis methods

A c-axis-oriented HAP thin film synthesized by seeded growth on a palladium hydrogen membrane substrate. An exemplary synthetic process includes electrochemical seeding on the substrate, and secondary and tertiary hydrothermal treatments under conditions that favor growth along c-axes and a-axes in sequence. By adjusting corresponding synthetic conditions, an HAP this film can be grown to a controllable thickness with a dense coverage on the underlying substrate. The thin films have relatively high proton conductivity under hydrogen atmosphere and high temperature conditions. The c-axis oriented films may be integrated into fuel cells for application in the intermediate temperature range of 200-600° C. The electrochemical-hydrothermal deposition technique may be applied to create other oriented crystal materials having optimized properties, useful for separations and catalysis as well as electronic and electrochemical applications, electrochemical membrane reactors, and in chemical sensors.

Owner:UNIVERSITY OF ROCHESTER

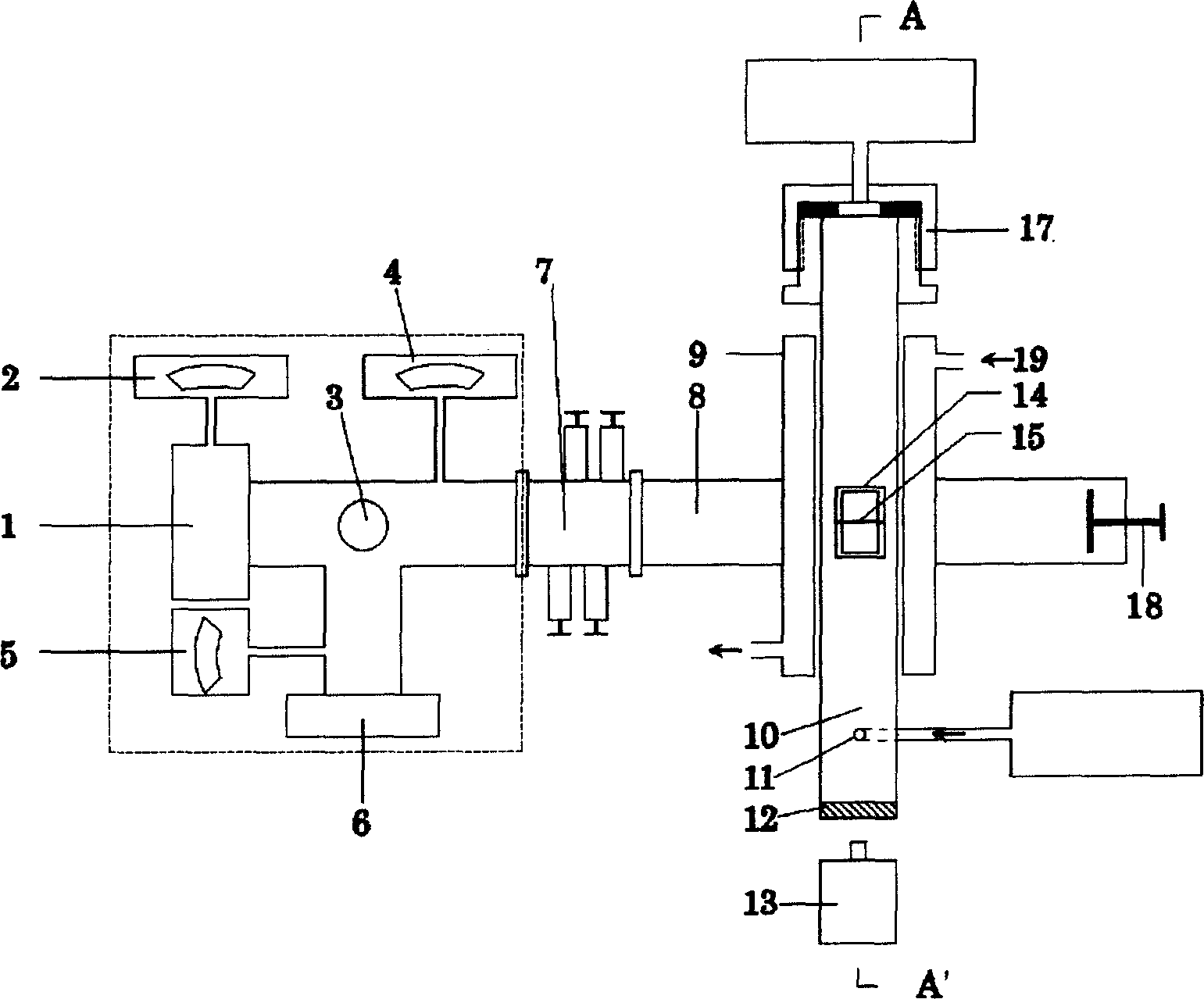

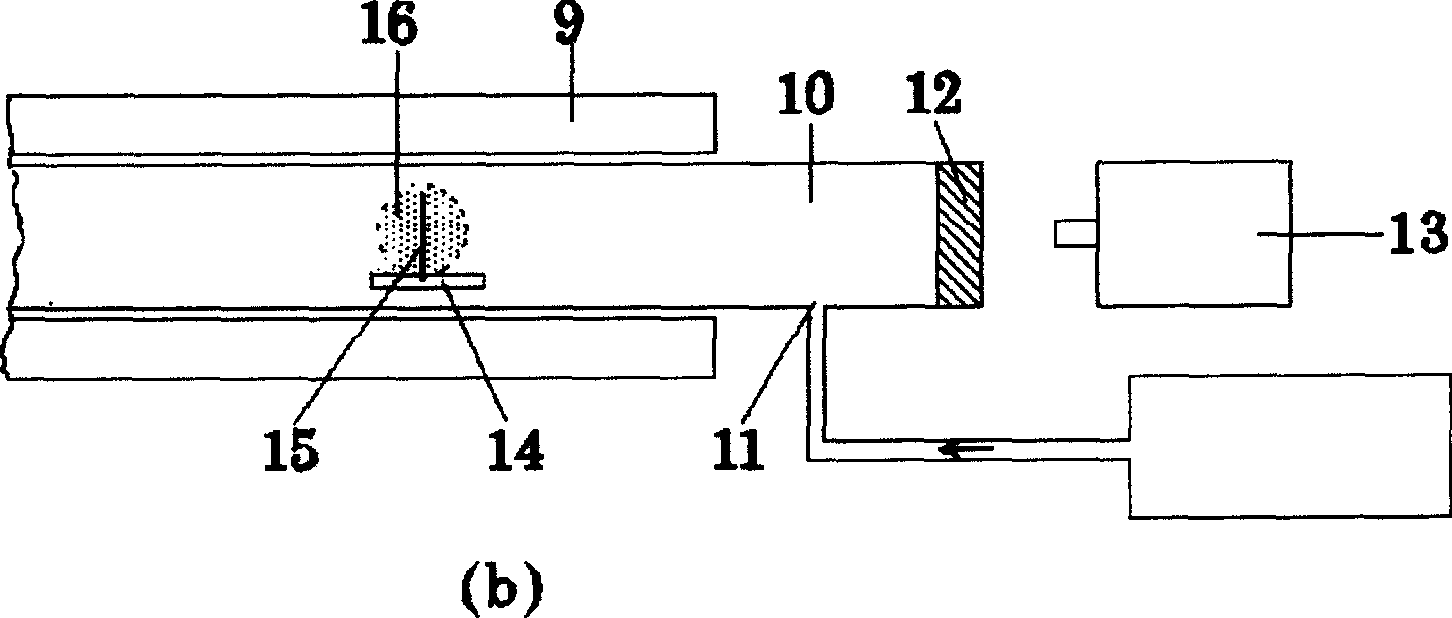

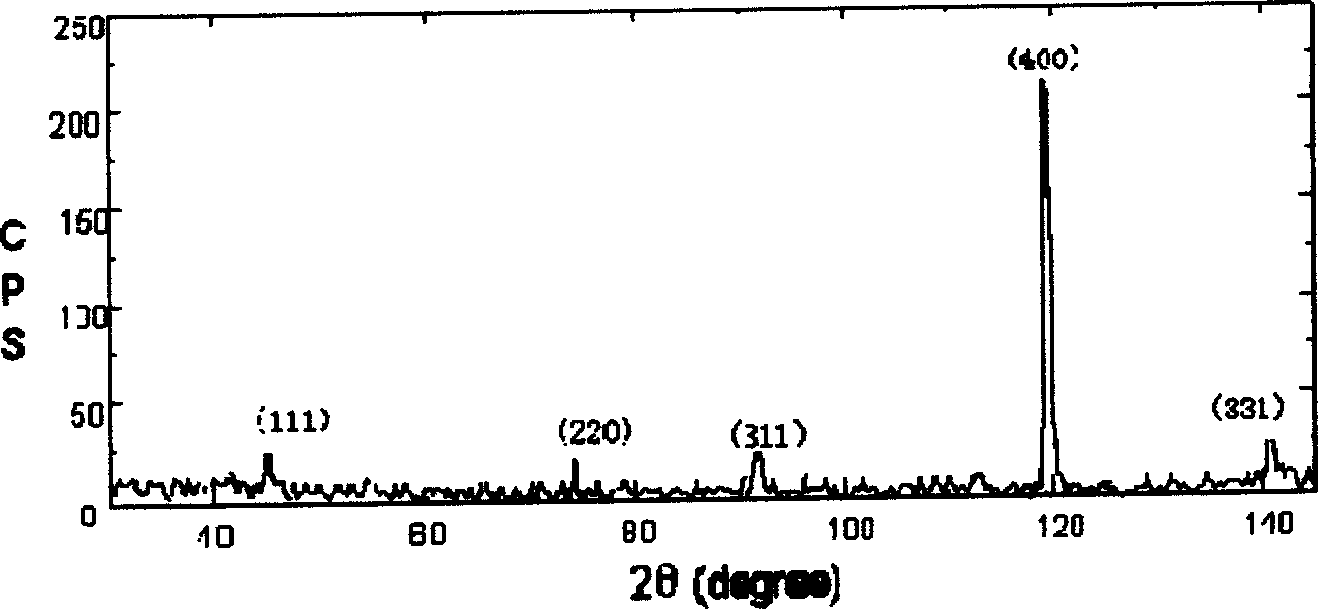

Method for oriented growth of diamond film on aluminium oxide ceramic

The present invention relates to microwave plasma chemical vapor deposition process of oriented diamond film on alumina ceramic. The technological process includes the following steps: implanting carbon ion to alumina ceramic before deposition; microwave plasma high-temperature annealing of the alumina ceramic under mixed nitrogen and hydrogen atmosphere; and the oriented deposition of diamond film on the alumina ceramic. During the oriented deposition, the alumina ceramic is set inside the quartz tube reactor with microwave plasma radiation, the reactor is vacuum pumped, inflated with mixed gas of hydrogen and methane, and diamond film of oriented crystal grains is formed through vapor deposition under specific technological condition.

Owner:SHANGHAI UNIV

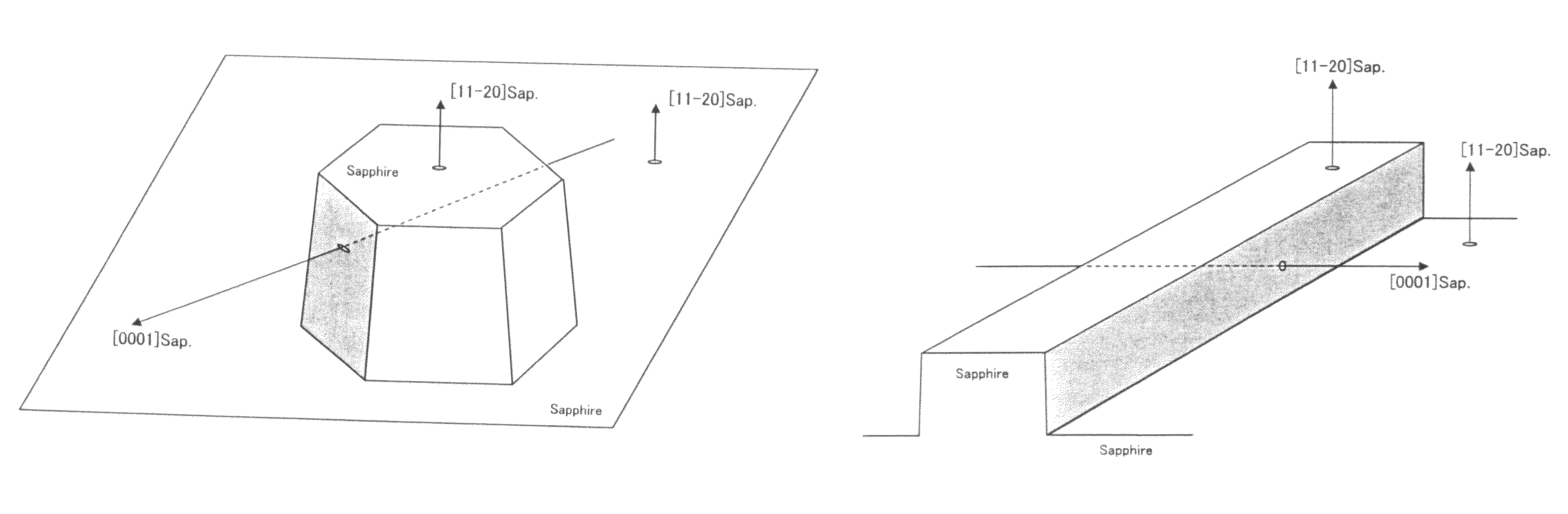

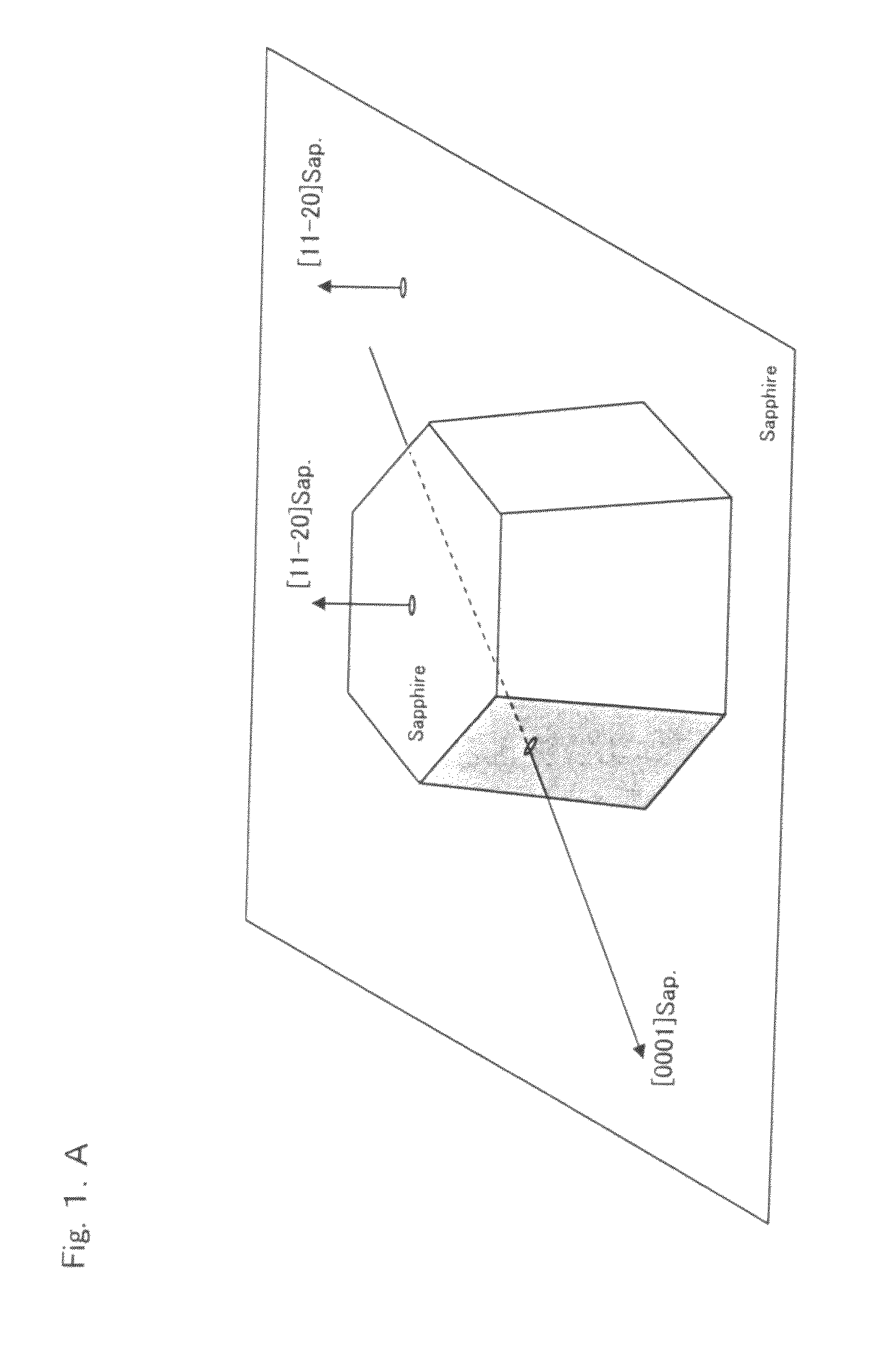

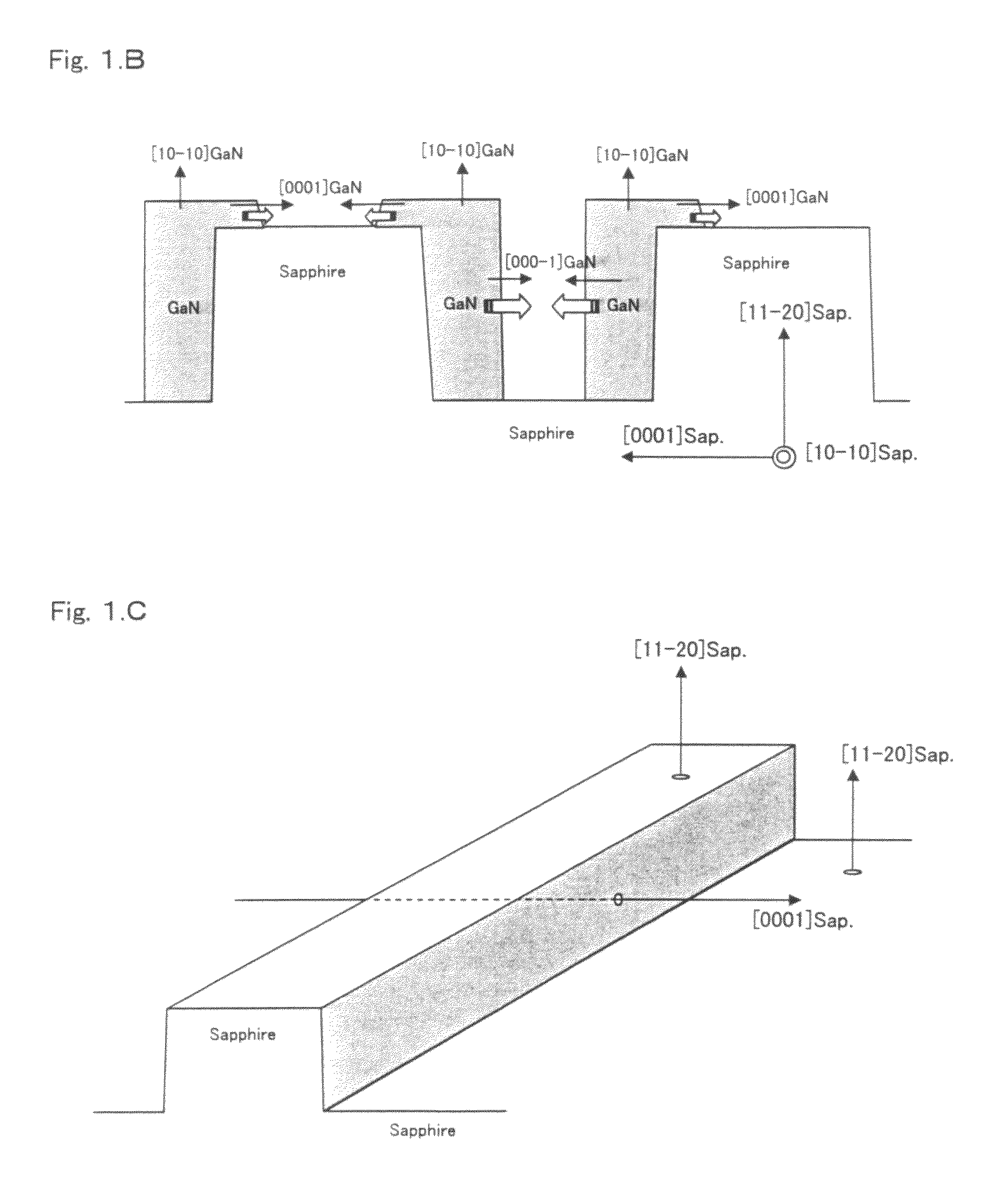

Method for producing group III nitride-based compound semiconductor, wafer including group III nitride-based compound semiconductor, and group III nitrided-based compound semiconductor device

ActiveUS8518806B2Polycrystalline material growthSemiconductor/solid-state device manufacturingNitrideSemiconductor device

To produce a Group III nitride-based compound semiconductor having a m-plane main surface and uniformly oriented crystal axes.A mesa having a side surface having an off-angle of 45° or less from c-plane is formed in a a-plane main surface of a sapphire substrate. Subsequently, trimethylaluminum is supplied at 300° C. to 420° C., to thereby form an aluminum layer having a thickness of 40 Å or less. The aluminum layer is nitridated to form an aluminum nitride layer. Through the procedure, a Group III nitride-based compound semiconductor is epitaxially grown only from a side surface of the mesa having an off-angle of 45° or less from c-plane in the sapphire substrate having an a-plane main surface. Thus, a Group III nitride-based compound semiconductor having m-plane which is parallel to the main surface of the sapphire substrate can be formed.

Owner:TOYODA GOSEI CO LTD

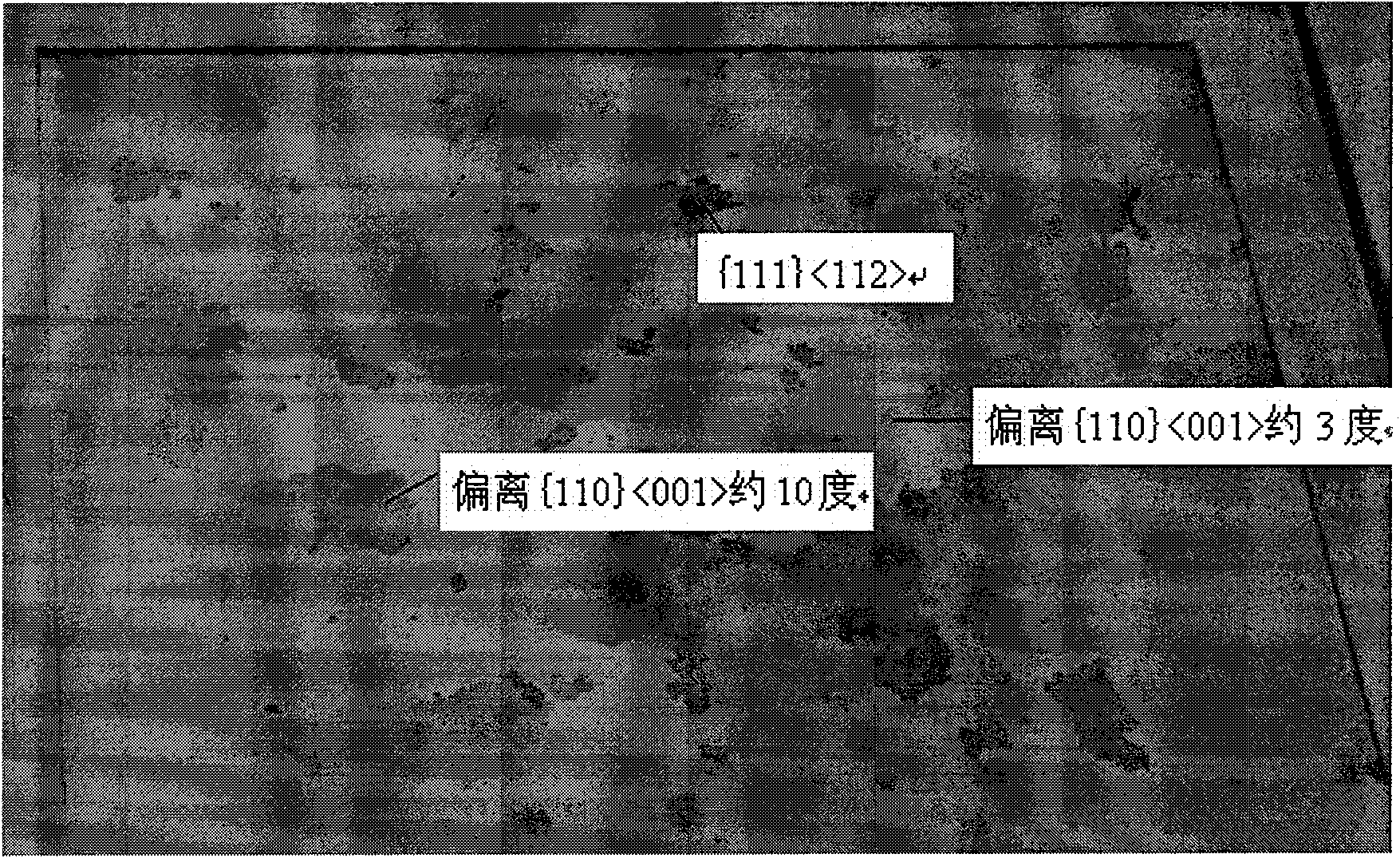

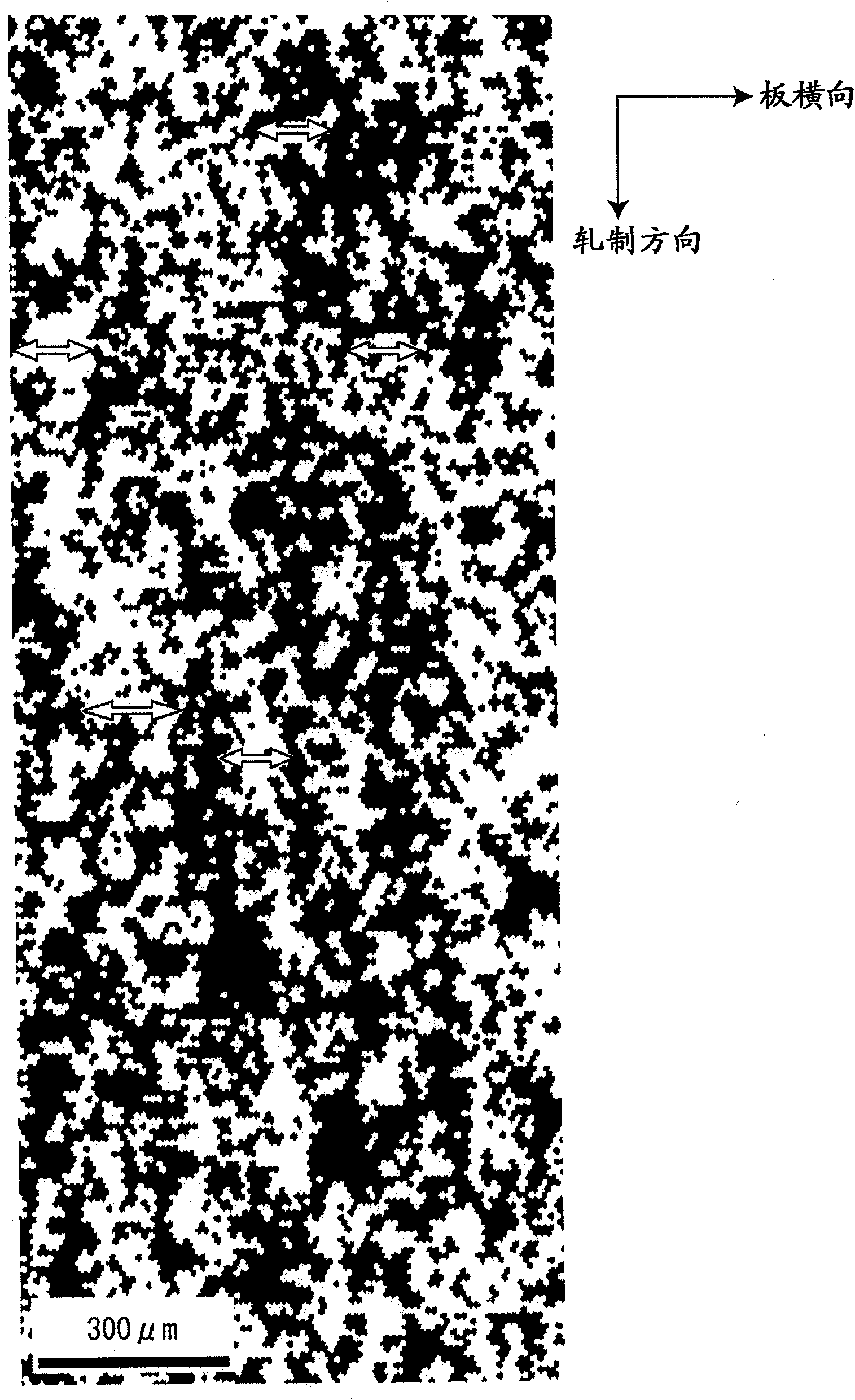

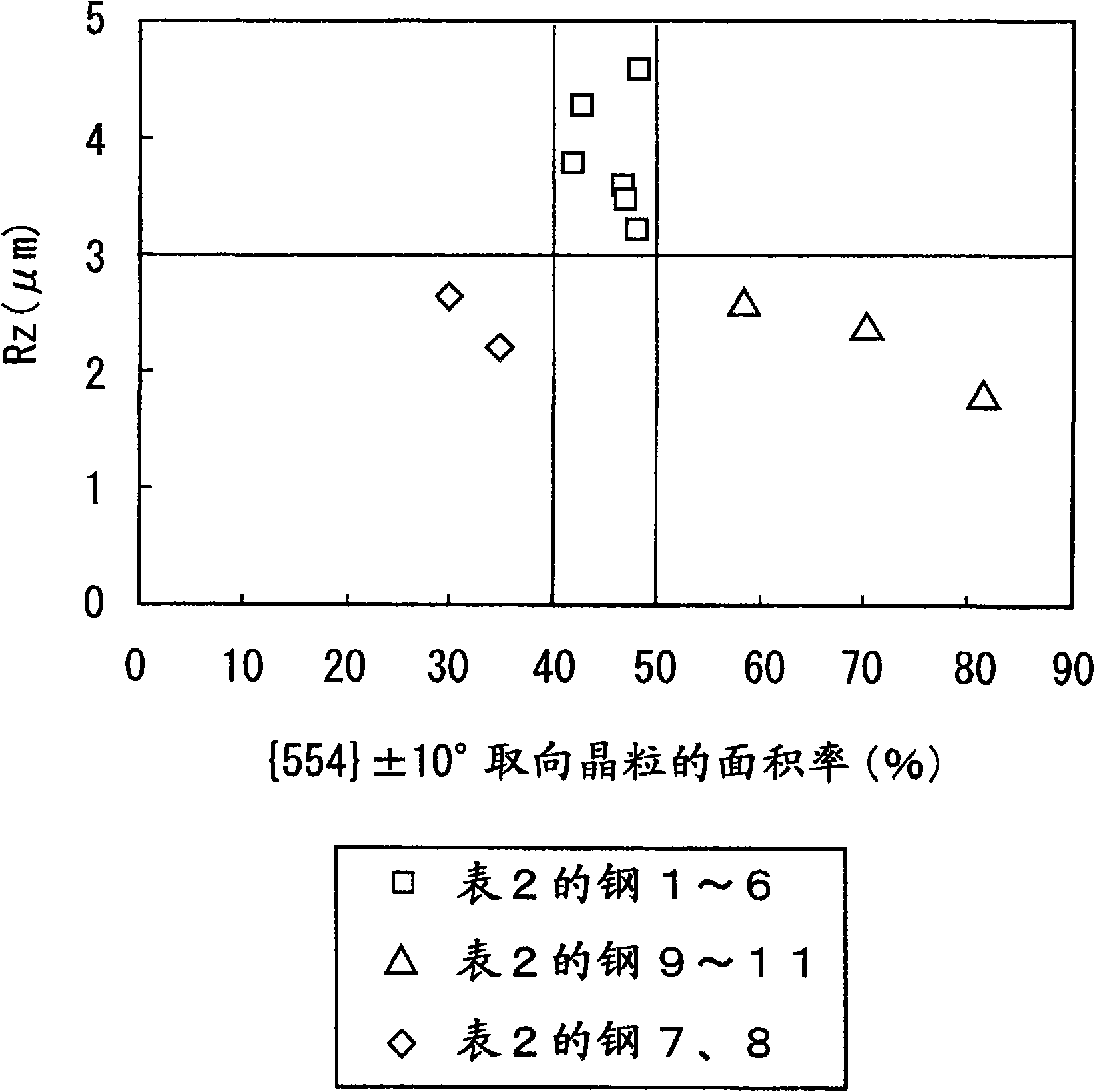

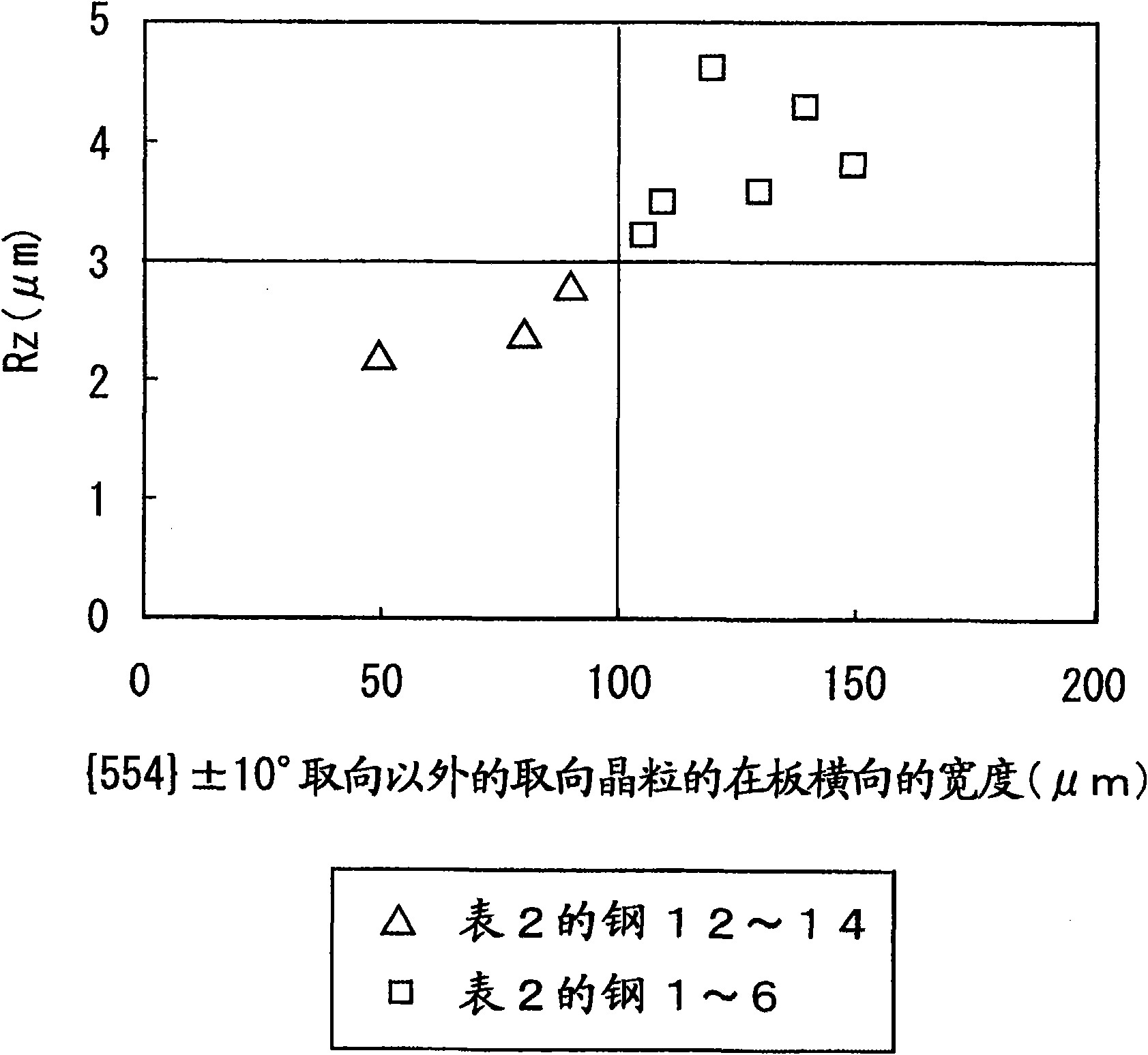

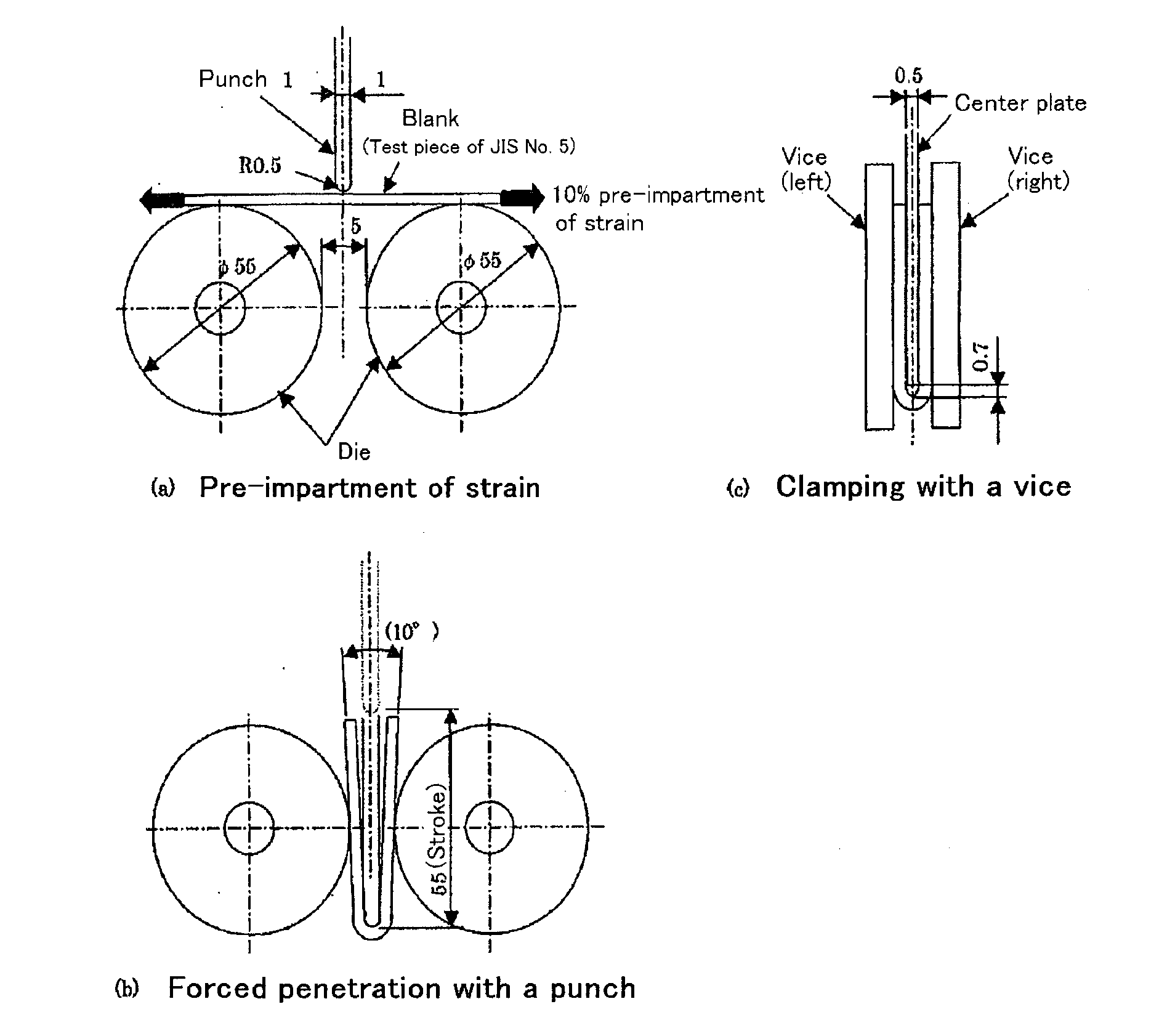

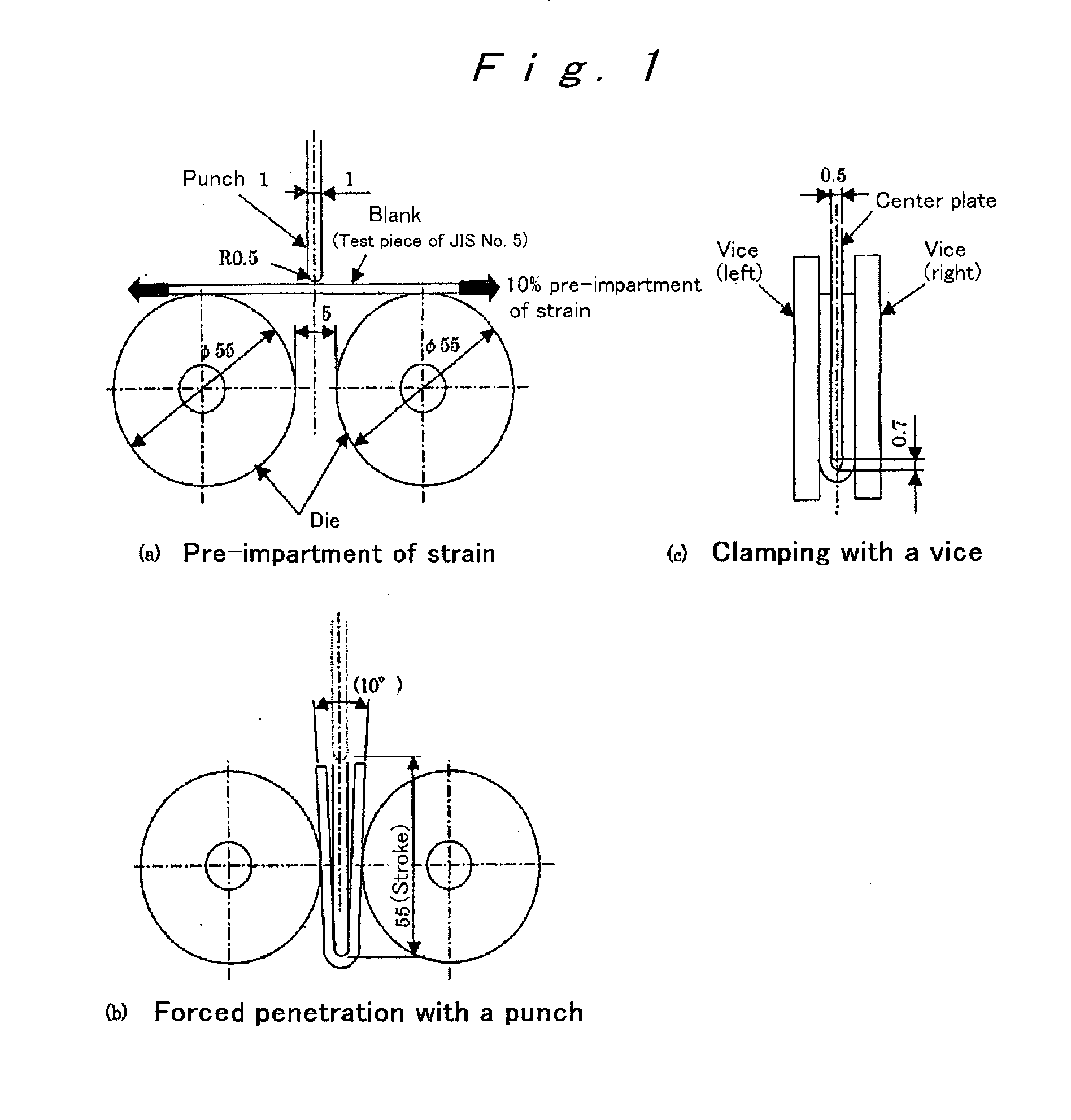

Ferritic stainless steel sheet causing little orange peel due to working and production method therefor

ActiveCN101671796AReduce the roughness of the machined surfaceStable manufacturingTemperature control deviceSurface roughnessSteel casting

The aim of the invention is to obtain a ferrite series stainless steel plate which has small roughness of machining surface and excellent formability. The task is to provide the ferrite series stainless steel plate with small roughness of machining surface through making the component and structure of steel satisfy an approximate range. Thus the annealing of hot rolled plate is saved for the ferrite series stainless steel plate, and a primary cold rolling with a rolling rate higher than 40% is performed. The intermediate annealing at the temperature of 750-900 DEG C is performed, and a final cold rolling with rolling rate high than 60% and a final annealing at the temperature of 750-1000 DEG C are performed. Therefore the area rate of the [554]+ / -10 DEG oriented crystal grain is more than50%. Additionally, the ferrite series stainless steel casting blank is heated to a temperature range of 1050-1200 DEG C. The starting temperature of hot rough rolling is set to 1000-1150 DEG C. A retention for more than five minutes is performed in hot coarse rolling at the temperature of 900-1100 DEG C. Afterwards, after hot fine rolling is performed, cold rolling-annealing is performed without performing annealing. Therefore the widths of the aligned crystal grains except for the alignment of [554]+ / -10 DEG are smaller than 100 mu m.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

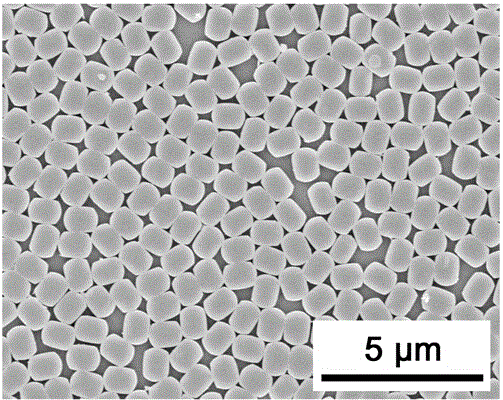

Ion/proton-conducting apparatus and method

InactiveUS20120040269A1Improve performanceReduce the temperatureSolid electrolytesPolycrystalline material growthHydrogen atmosphereSynthesis methods

A c-axis-oriented HAP thin film synthesized by seeded growth on a palladium hydrogen membrane substrate. An exemplary synthetic process includes electrochemical seeding on the substrate, and secondary and tertiary hydrothermal treatments under conditions that favor growth along c-axes and a-axes in sequence. By adjusting corresponding synthetic conditions, an HAP this film can be grown to a controllable thickness with a dense coverage on the underlying substrate. The thin films have relatively high proton conductivity under hydrogen atmosphere and high temperature conditions. The c-axis oriented films may be integrated into fuel cells for application in the intermediate temperature range of 200-600° C. The electrochemical-hydrothermal deposition technique may be applied to create other oriented crystal materials having optimized properties, useful for separations and catalysis as well as electronic and electrochemical applications, electrochemical membrane reactors, and in chemical sensors. Additional high-density and gas-tight HAP film compositions may be deposited using a two-step deposition method that includes an electrochemical deposition method followed by a hydrothermal deposition method. The two-step method uses a single hydrothermal deposition solution composition. The method may be used to deposit HAP films including but not limited to at least doped HAP films, and more particularly including carbonated HAP films. In addition, the high-density and gas-tight HAP films may be used in proton exchange membrane fuel cells.

Owner:UNIVERSITY OF ROCHESTER

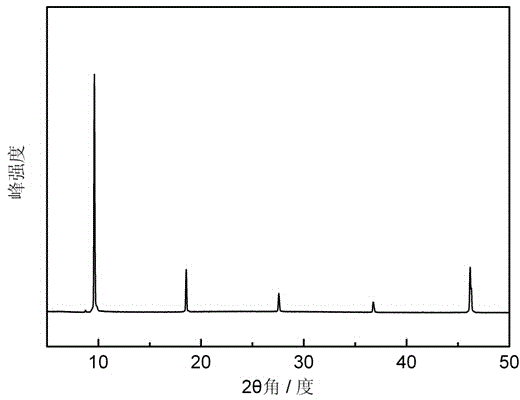

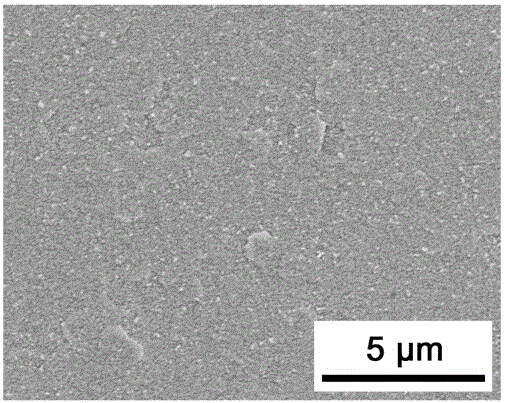

Method for preparing highly-oriented MFI-type molecular sieve membrane by secondary growth process

InactiveCN104891519ASuppress generationGood orientationCrystalline aluminosilicate zeolitesMolecular sieveSilicic acid

The invention discloses a method for preparing a highly-oriented MFI-type molecular sieve membrane by a secondary growth process, which comprises the following steps: 1) preparation of a secondary growth synthesis liquid: mixing certain amounts of ethyl orthosilicate, tetrapropyl ammonium hydroxide and water, stirring at room temperature for 3-5 hours, adding an ammonium salt water solution with a certain concentration into the clear synthesis liquid, and continuing stirring for 1-3 hours to obtain the final synthesis liquid, wherein the synthesis liquid is composed of the following components in parts by mole: 1 part of ethyl orthosilicate, 0.1-0.4 part of tetrapropyl ammonium hydroxide, 100-500 parts of water and 0.075-0.3 part of water; 2) putting a carrier coated with a b-axis-oriented crystal seed layer into a high-pressure synthesis kettle, pouring the synthesis liquid, and sealing; crystallizing at 120-180 DEG C for 3-12 hours; and 3) cooling the synthesis kettle, taking out the carrier, washing and drying to obtain the oriented MFI-type molecular sieve membrane on the carrier. The ammonium salt added into the traditional synthesis liquid can effectively inhibit the twin crystal from generation in the secondary growth process. The method is simple to operate, and has the advantages of wide application range, no special requirements for the carrier and low preparation cost.

Owner:ZHEJIANG UNIV

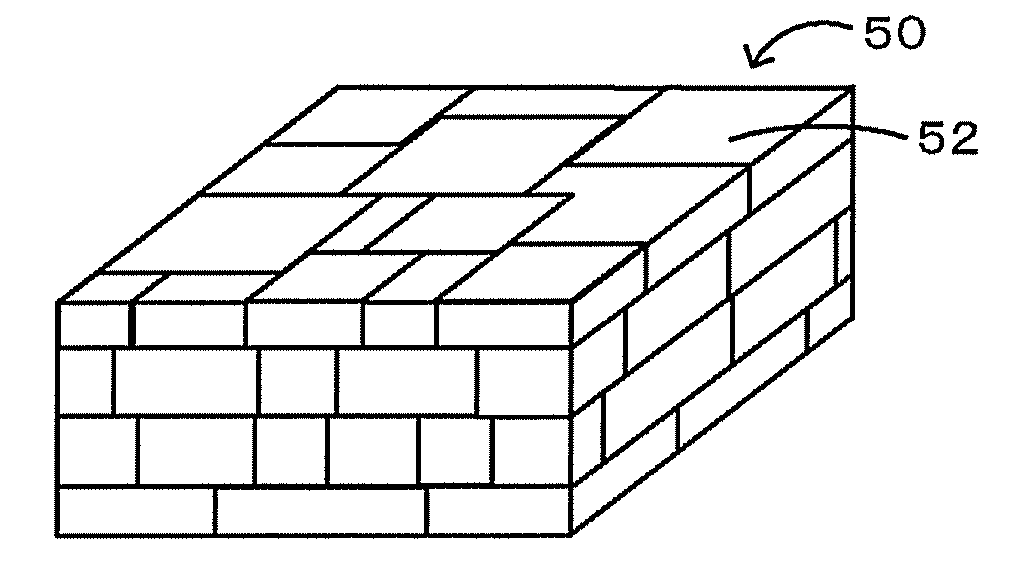

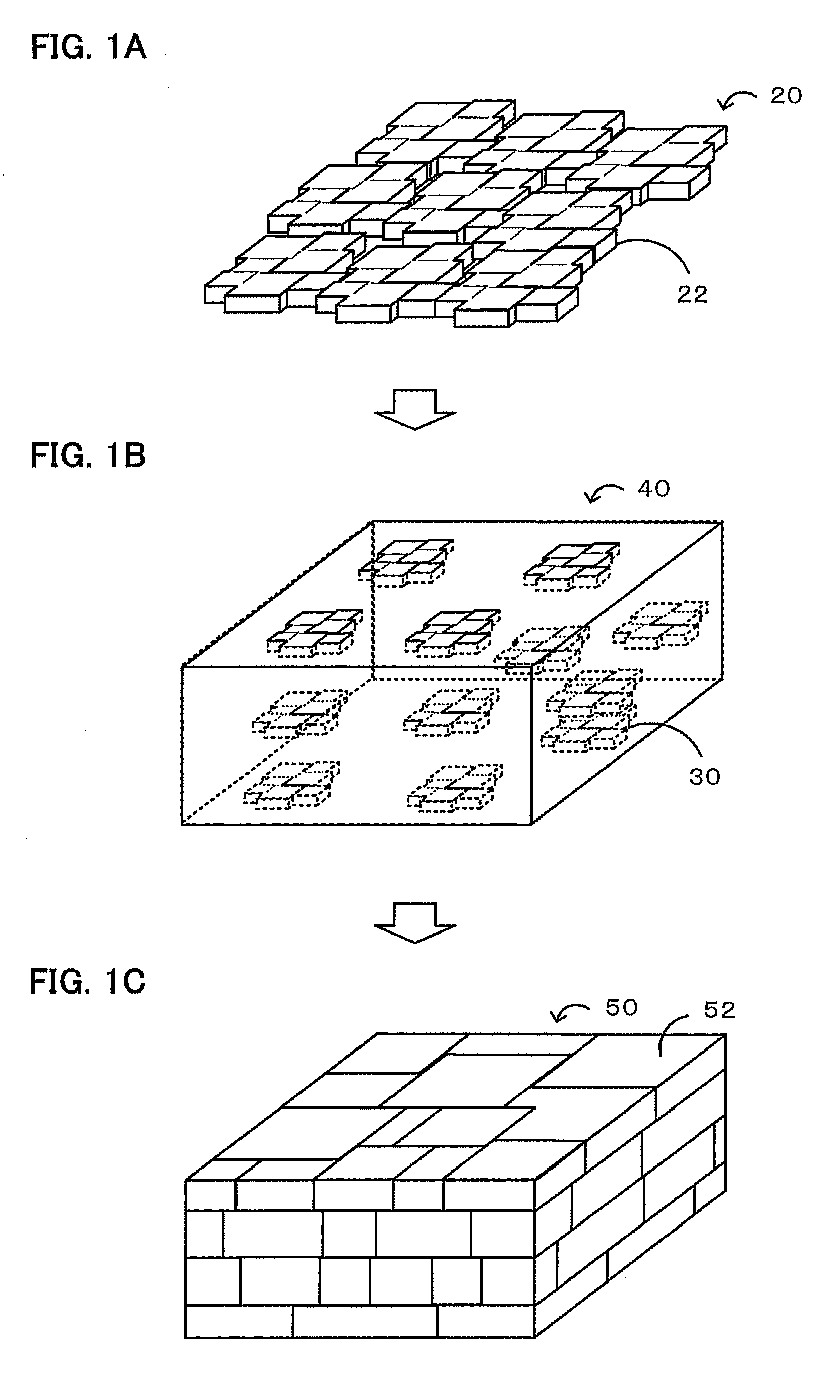

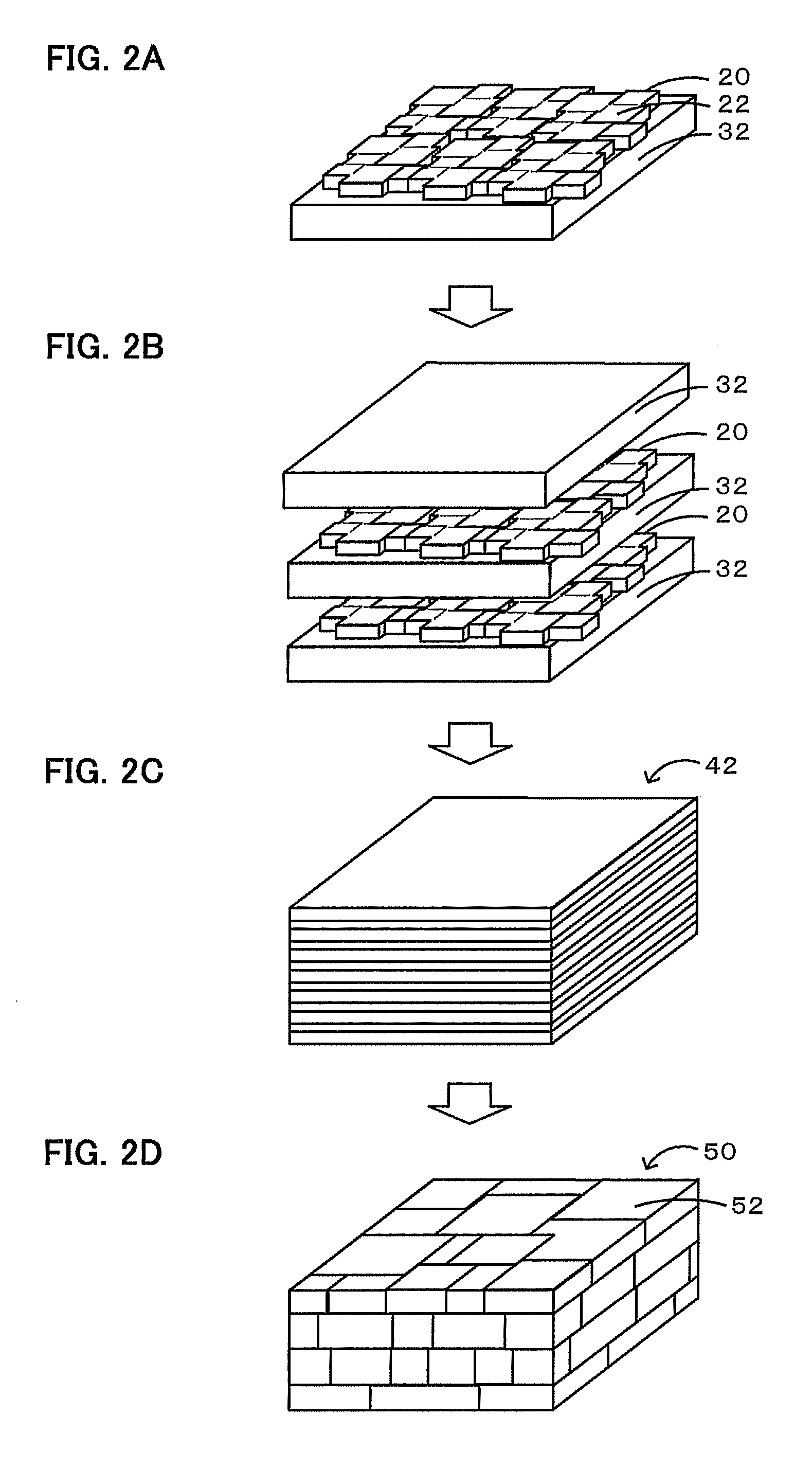

Crystallographically-oriented ceramic

InactiveUS20090170686A1Low efficiencyEfficiently fulfillPiezoelectric/electrostrictive device manufacture/assemblyZirconium compoundsCrystal planeGrain growth

A crystallographically-oriented ceramic containing Pb and in which piezoelectric / electrostrictive properties can be enhanced. Using a raw material having Pb(Zr1-xTiX)O3 as a main component, a ceramic sheet was formed with a thickness of 15 μm or less. In this material, grains were allowed to grow into an anisotropic shape, and crystal grains with specific crystal planes being aligned were produced. A non-oriented raw material having Pb(Zr1-xTiX)O3 as a main component and the crystal grains were mixed, and shaping was performed so that crystal grains were oriented in a predetermined direction. The shaped body was fired. In the resulting ceramic, the degree of orientation was high at 50% or more. It is possible to enhance the degree of orientation using, as crystal nuclei, a ceramic sheet which can have the same composition as that of the crystallographically-oriented ceramic. Therefore, production can be performed without adding an unnecessary element, for example, for orienting crystals.

Owner:NGK INSULATORS LTD

Method of preparing high-oriented MFI type zeolite membrane by virtue of secondary growth under neutral condition

InactiveCN104556107AReduce manufacturing costLess destructiveCrystalline aluminosilicate zeolitesRoom temperatureSecondary growth

The invention discloses a method of preparing a high-oriented MFI type zeolite membrane by virtue of secondary growth under the neutral condition. The method comprises the following steps: 1) preparing a neutral synthetic fluid, wherein the synthetic fluid is prepared from the following components including a silica source, tetrapropylammonium bromide and water, and the molar ratio of the silica source to tetrapropylammonium bromide to water is 1 to (0.1-5) to (10-2000); and 2) stirring the synthetic fluid for 10-60 minutes at room temperature, charging into a reaction kettle, putting a supporting body coated with a b axis oriented crystal seed layer into the reaction kettle, immersing the supporting body with the synthetic fluid, sealing the reaction kettle, carrying out heating synthesis, washing, and drying to obtain the oriented MFI type zeolite membrane on the supporting body, wherein the synthesis temperature is 120-200 DEG C, and the synthesis time is 12-72h. According to the method disclosed by the invention, the synthesized MFI type zeolite membrane has high b axis orientation, the used synthetic fluid is neutral and is small in damage on the surface of the supporting body and low in raw material cost, and the cost is easily lowered.

Owner:ZHEJIANG UNIV

Field effect transistor having a structure in which an organic semiconductor that forms a channel is made of a single crystal or a polycrystal of organic molecules

InactiveUS7608857B2Improve mobilityInexpensively and readily formSolid-state devicesSemiconductor devicesOrganic field-effect transistorCharge carrier

A TFT having a large mobility of carriers that are conducted through a channel as compared with a conventional organic TFT, and a method of manufacturing the TFT inexpensively and easily are provided. The channel is formed of a semiconductor organic molecular crystal thin film which is highly oriented, and a TFT that is large in the mobility of the carriers that are conducted through the channel, and a lyophilic TFT pattern that is surrounded by a lyophobic region on a substrate are formed, and the configuration of the pattern is featured, whereby a solution of the semiconductor organic molecules which is supplied to an appropriate region of a substrate surface including the channel is spontaneously dried in an anisotropic fashion, and highly oriented crystal is grown in the drying process.

Owner:HITACHI LTD

Repair material for repairing turbine blade tip cracks and repair method thereof

The invention relates to the technical field of maintenance of aviation engines, in particular to a repair material for repairing turbine blade tip cracks and a repair method thereof. The repair material is high-strength oxidation resisting nickel base high-temperature alloy powder; an inert atmosphere induction preheating laser cladding technology is adopted to repair deep crack parts at blade tips of high-pressure turbine working blades; the high-pressure turbine working blades adopt the materials of directional solidification nickel base high-temperature alloys DZ125; and the repair process comprises coating layer removal-polishing of blade tip deep cracks-repair path planning-inert atmosphere induction preheating-laser cladding-shape finishing by manual polishing-coating layer recovery. The repair material realizes repair of directional solidification high-pressure turbine working blades with cracks extending to a cover plate; the cracks are not discovered by the X-ray and fluorescent penetrant inspection after repair; a repair interface has an oriented crystal structure; the life of the repaired high-pressure turbine working blades can reach above 380 hours; and the repair material has important significance on acceleration of application and development of the aviation technology.

Owner:成都天翔动力技术研究院有限公司

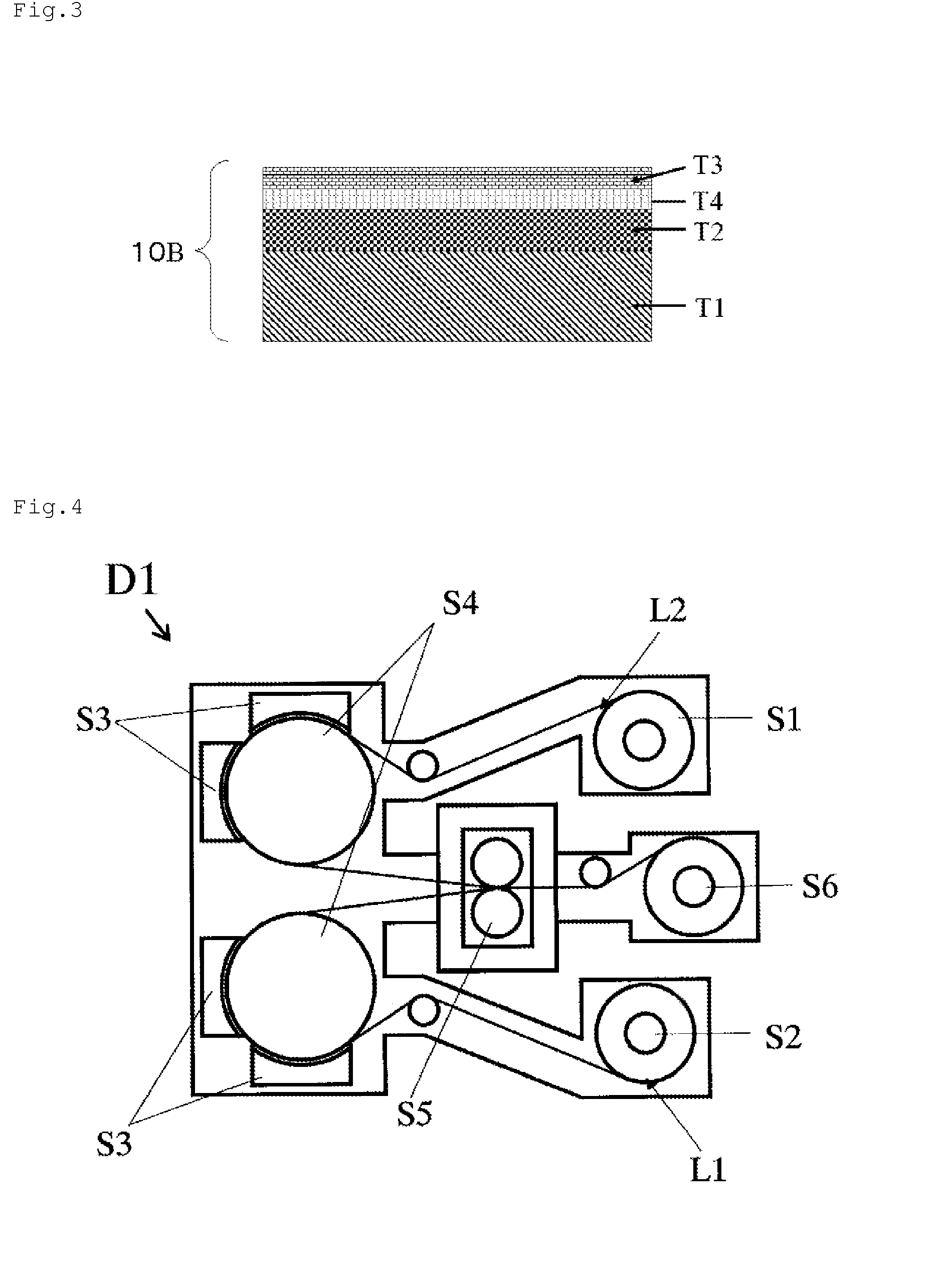

Piezoelectric thin film element and piezoelectric thin film device including the same

ActiveUS8310135B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCrystal structureSubstrate surface

Owner:SUMITOMO CHEM CO LTD

Method for growing cerium-doped lanthanum bromide scintillation crystal by using out-of-phase seed crystal

ActiveCN102534775AControlled growthReduce usagePolycrystalline material growthFrom frozen solutionsChemical reactionScintillation crystals

The invention relates to a method for growing a cerium-doped lanthanum bromide scintillation crystal by using an out-of-phase seed crystal. The seed crystal made of a crystal material of which the structural parameters and symmetry are similar to those of a lanthanum bromide crystal is placed in a nucleation area at the bottom of a quartz crucible, the seed crystal material and lanthanum bromide are not subjected to chemical reaction, and the melting point of the seed crystal material is higher than that of the lanthanum bromide crystal. The crystal is grown by a crucible descending method, two-section temperature control is performed at the melting stage of a raw material to ensure that the upper part is cold and the lower part is hot, the convection effect of a melt is improved, the lanthanum bromide is nucleated on the surface of the seed crystal preferentially in the crucible descending process, the growth direction of the lanthanum bromide is consistent with the crystallographic direction of the seed crystal, and the lanthanum bromide crystal in the required direction is obtained by continuous growth. The method has the advantages that: a stable crystal material in air can be selected as the seed crystal, and the phenomenon that processing and anhydrous operation are difficult to perform when the lanthanum bromide crystal is taken as the seed crystal is avoided; and compared with a seed-crystal-free spontaneous nucleation growth method, the method has the advantage that: the success rate of oriented crystal growth is greatly improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Aluminum material with high formability

An aluminum material, which is composed of crystal grains having different crystal orientations, in which the crystal grains comprise Cube-oriented crystal grains, Brass-oriented crystal grains and Copper-oriented crystal grains with a balance of crystal grains of other orientations, and in which the proportion of the Cube-oriented crystal grains is from 0.3 to 0.7, the proportion of the Brass-oriented crystal grains is from 0.1 to 0.5, the proportion of the Copper-oriented crystal grains is 0.2 or less, and the total proportion of these orientations is from 0.4 to 1.0; and a car component using the same.

Owner:FURUKAWA ELECTRIC CO LTD

Ion-/proton-conducting apparatus and method

InactiveUS7943269B2Polycrystalline material growthPhosphatesHydrogen atmosphereHydrothermal deposition

A c-axis-oriented HAP thin film synthesized by seeded growth on a palladium hydrogen membrane substrate. An exemplary synthetic process includes electrochemical seeding on the substrate, and secondary and tertiary hydrothermal treatments under conditions that favor growth along c-axes and a-axes in sequence. By adjusting corresponding synthetic conditions, an HAP this film can be grown to a controllable thickness with a dense coverage on the underlying substrate. The thin films have relatively high proton conductivity under hydrogen atmosphere and high temperature conditions. The c-axis oriented films may be integrated into fuel cells for application in the intermediate temperature range of 200-600° C. The electrochemical-hydrothermal deposition technique may be applied to create other oriented crystal materials having optimized properties, useful for separations and catalysis as well as electronic and electrochemical applications, electrochemical membrane reactors, and in chemical sensors.

Owner:UNIVERSITY OF ROCHESTER

Methods for forming a ferroelectric layer and capacitor and FRAM using the same

ActiveUS7312091B2Improve uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionCrystal growth

Metal organic chemical vapor deposition (MOCVD) may be utilized in methods of forming an (111) oriented PZT ferroelectric layer at a lower temperature, a ferroelectric capacitor and methods of fabricating, and a ferroelectric memory device using the same may be provided. Using the metal organic chemical vapor deposition, ferroelectric layers, capacitors, and memory devices, which may be fabricated and may have (111) preferred oriented crystal growth.

Owner:SAMSUNG ELECTRONICS CO LTD

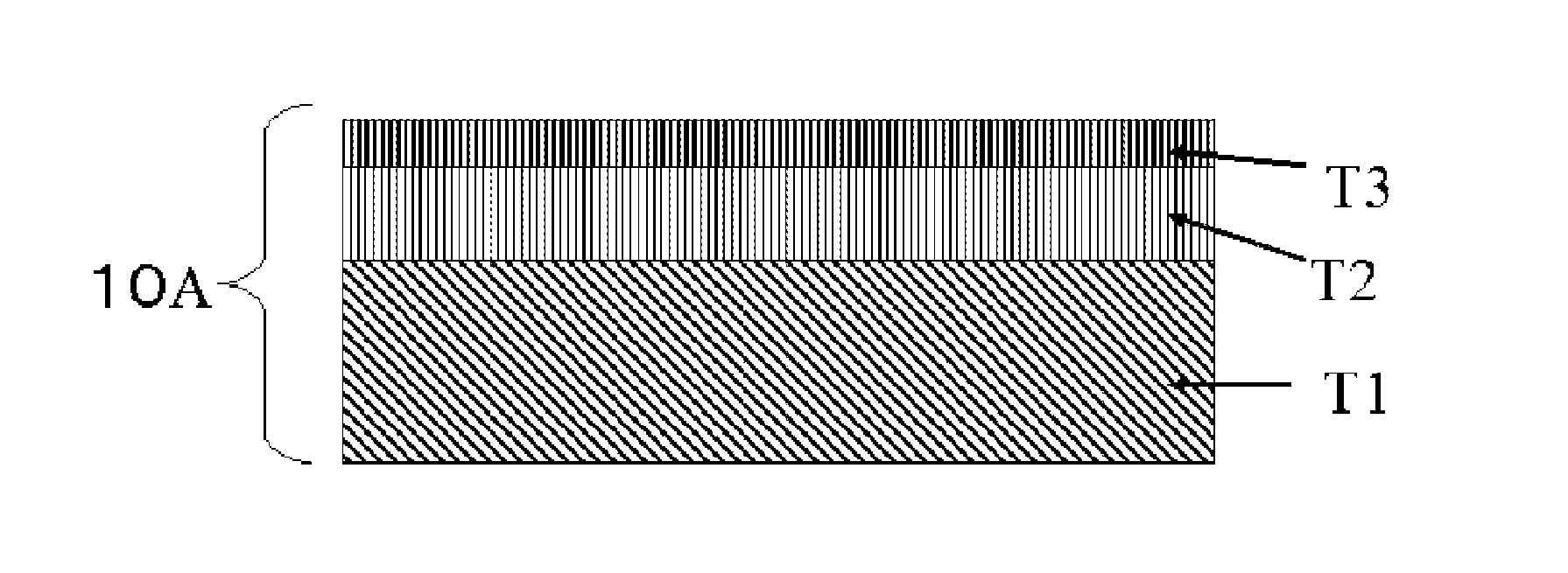

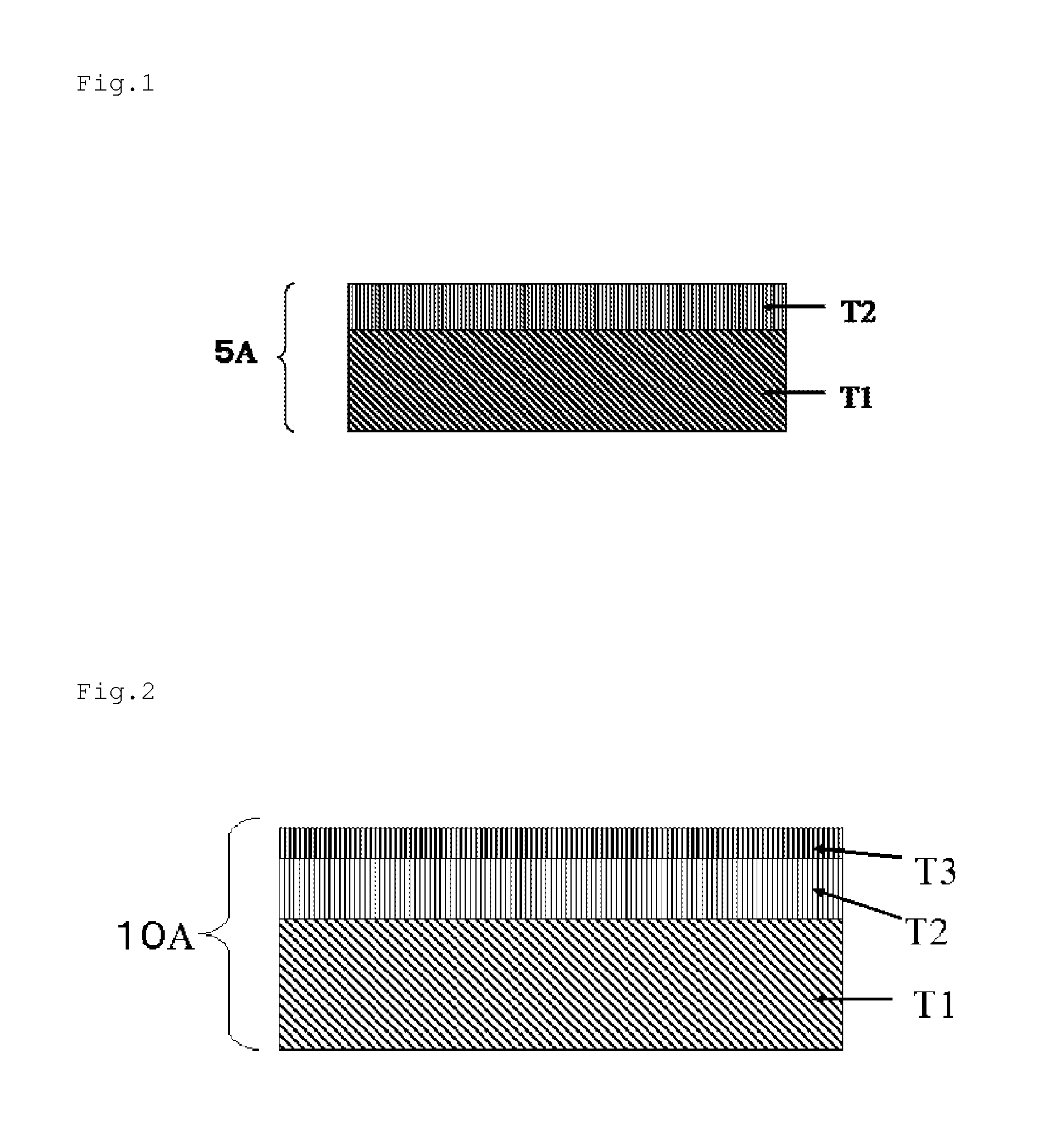

Method for manufacturing metal laminated substrate for semiconductor element formation and metal laminated substrate for semiconductor element formation

InactiveUS20110290380A1Low rolling reductionSmooth interfaceDecorative surface effectsSemiconductor/solid-state device detailsEtchingMetal foil

Disclosed is a metal laminated substrate for forming an epitaxial growth film for forming a semiconductor element having high biaxial crystal orientation on a surface of a metal substrate and a method of manufacturing the metal laminated substrate. The manufacturing method includes the steps of activating at least one surface of a metal plate T1 by sputter etching or the like; activating at least one surface of a metal foil T2 made of Cu or a Cu alloy which is cold-rolled at a rolling reduction of 90% or more; laminating the metal plate and the metal foil such that an activated surface of the metal plate and an activated surface of the metal foil face each other in an opposed manner and applying cold rolling to the metal plate and the metal foil which are laminated to each other at a rolling reduction of 10% or less, for example; and biaxially orienting crystals of the metal foil by heat treatment at a temperature of not lower than 150° C. and not higher than 1000° C.

Owner:TOYO KOHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com