Aluminum material with high formability

a technology of aluminum alloy and formability, applied in the field of aluminum materials, can solve the problems of poor hem-bendability of aluminum alloy plates that have been subjected to solution treatment at a high temperature for enhancing bake-hardenability, poor hem-bendability of aluminum alloy plates, and inferiority of aluminum alloys to conventional steel sheets and 5000-series aluminum alloy sheets in press formability. achieve the effect of high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

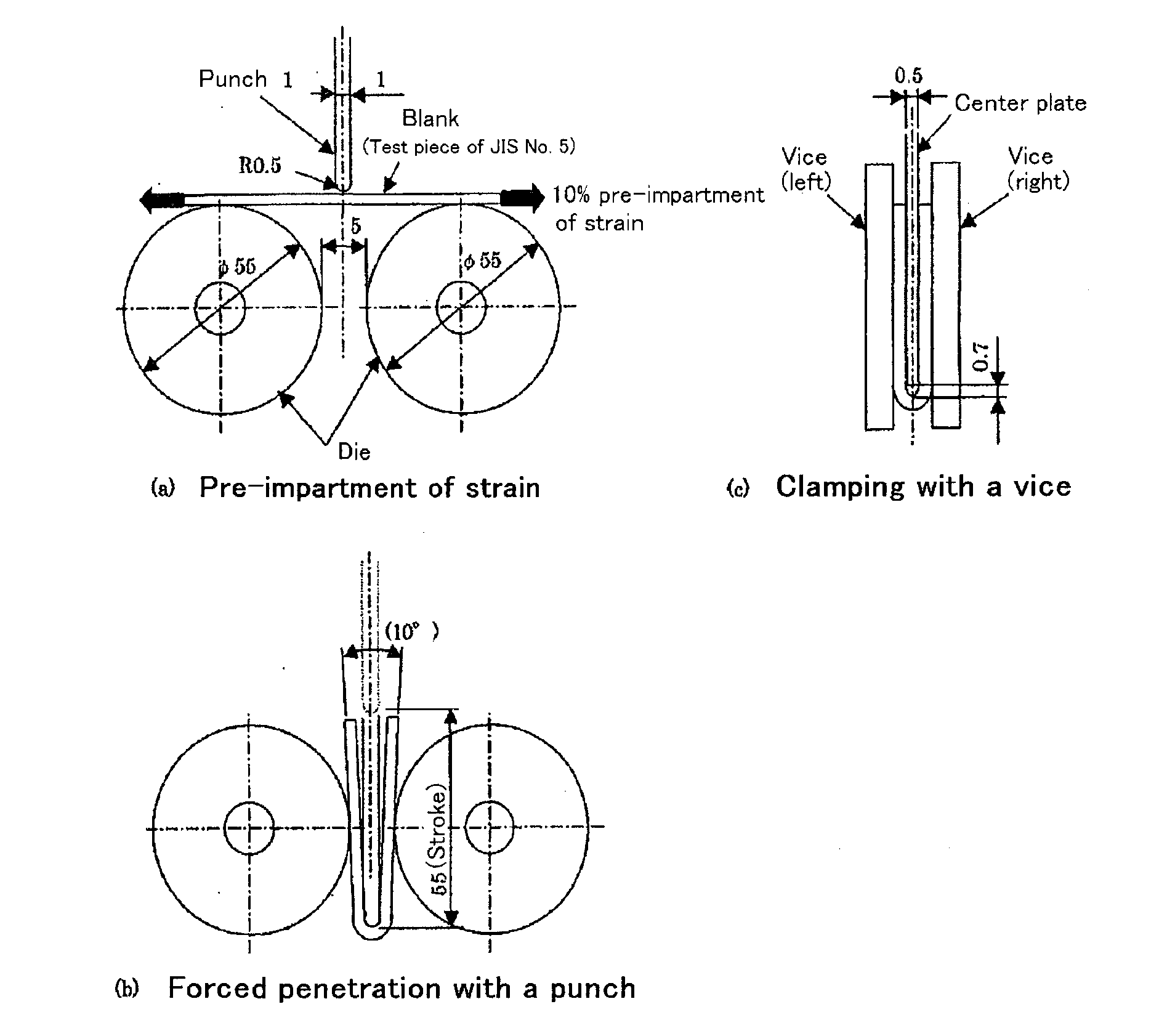

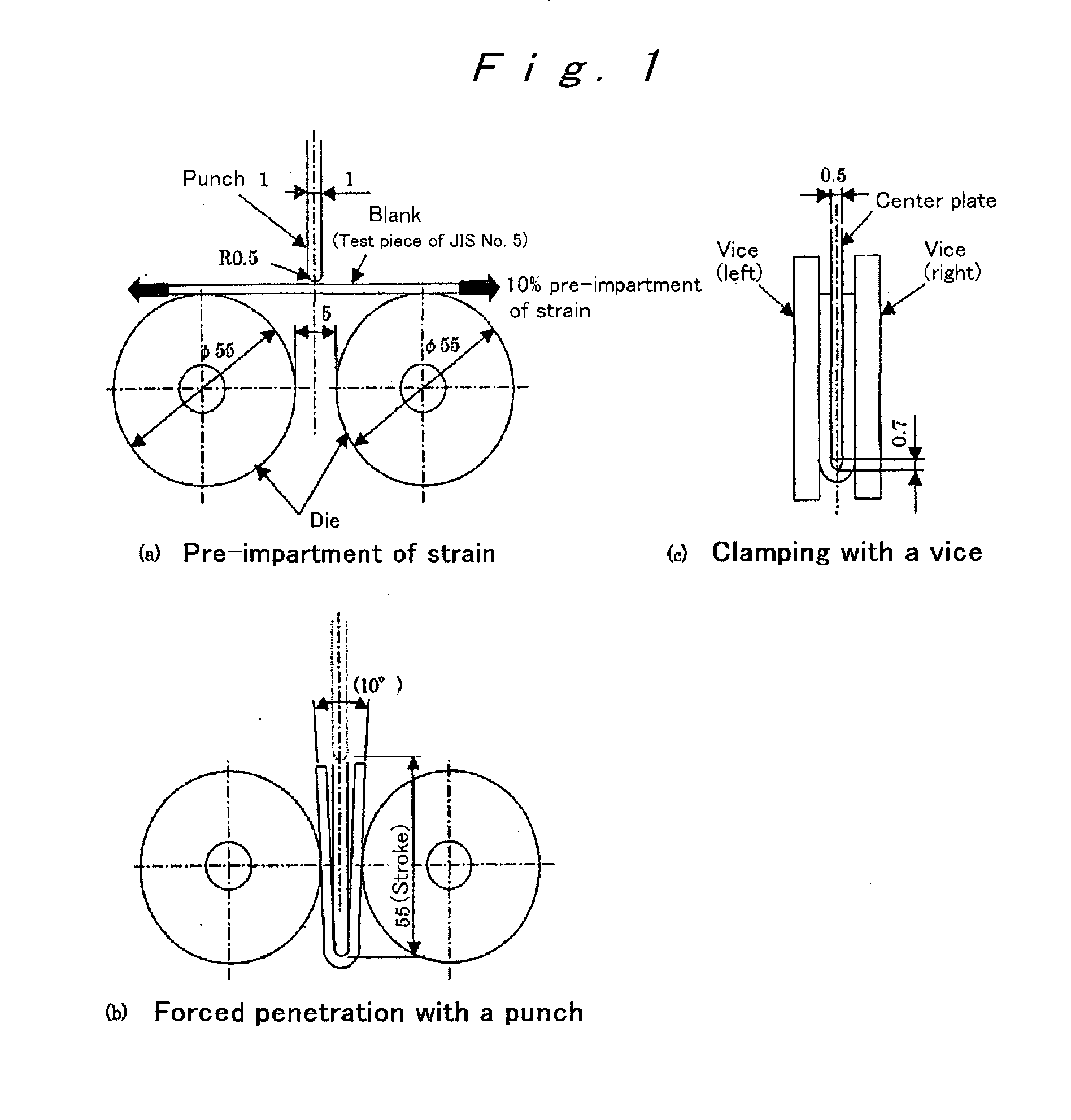

Image

Examples

example 1

[0050]An Al alloy comprising 0.5 mass % of Mg, 0.9 mass % of Si, 0.06 mass % of Mn, 0.07 mass % of Fe, 0.10 mass % of Cu and 0.005 mass % or less each of Zn, Ti and Cr with a balance of Al were melted and cast into an ingot with a thickness of 500 mm by a conventional method. After homogenizing the ingot at 540° C. for 6 hours, it was hot-rolled under conditions of an initiation temperature of 500° C. and termination temperature of 200° C. to obtain a hot-rolled plate with a thickness of 10 mm. Then, the hot-rolled plate was cold-rolled to a predetermined thickness so that a raw finish sheet with a thickness of 1 mm would be obtained by finish cold roll reduction ratio of 20%, 30%, 50%, 70% or 90%. A raw finish sheet with a thickness of 1 mm was directly obtained from the hot-roll plate with a thickness of 10 mm with respect to a sample having the finish cold roll reduction ratio of 90%.

[0051]The cold-rolled sheet with a predetermined thickness was then annealed at 325° C. for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com