High-oxygen barrier property high-strength polyolefin heat conduction pipe and preparation method thereof

A technology of polyolefin and heat pipes, which is applied to tubular objects, other household appliances, applications, etc., can solve the problems of high cost and complex processing technology of oxygen-barrier polyolefin heat pipes, and achieve excellent environmental performance, oxygen barrier performance and heat conduction Improved performance, noticeable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

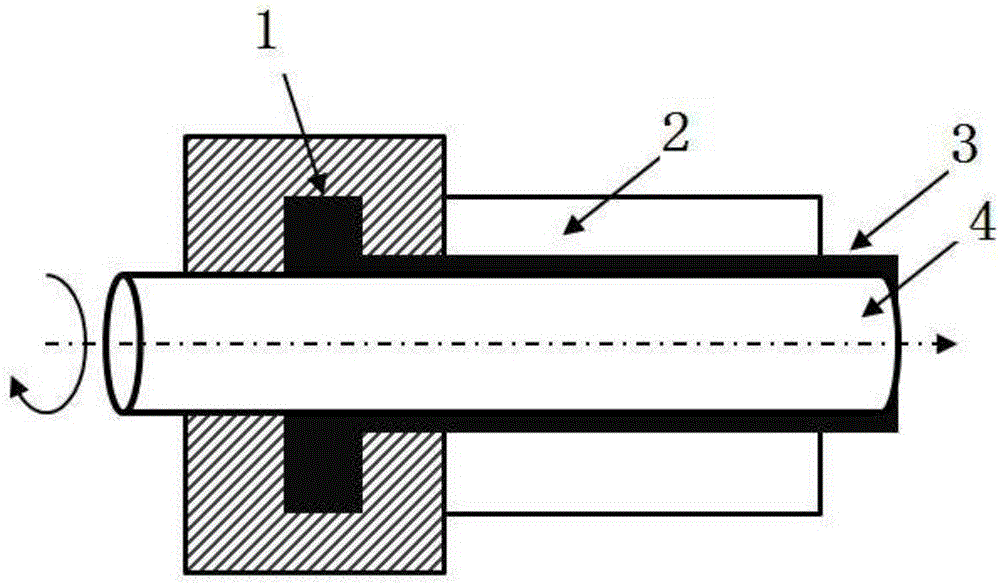

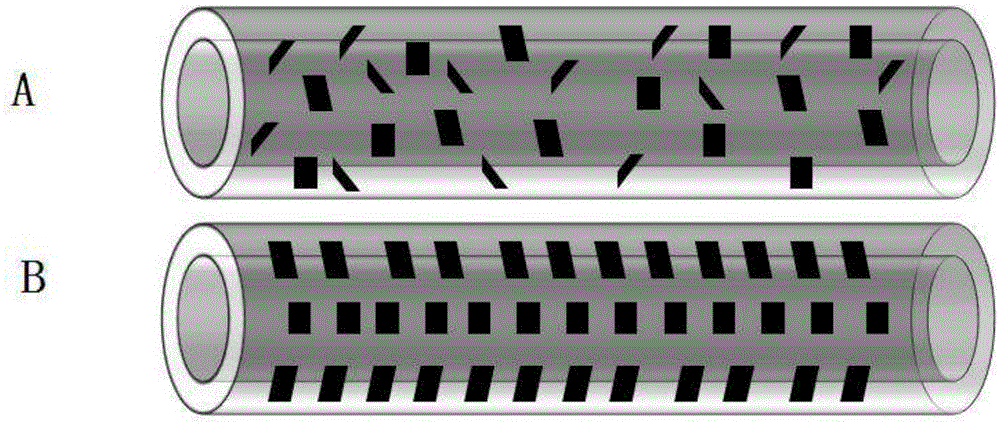

[0037] The present embodiment 1 comprises the following components in parts by weight: the polyolefin resin is 100 parts of high-density polyethylene HDPE, the graphene sheet is 0.5 parts of graphene oxide, and the compatibilizer is 1.5 parts of polyethylene glue Maleic anhydride, antioxidant 1010 of 0.1 parts, graphene oxide sheets are evenly distributed in the polyolefin resin in a circular shape with the central axis of the pipe as the center.

[0038] The preparation method steps are as follows:

[0039] S01, drying: 100 parts of HDPE, 0.5 parts of graphene oxide, 1.5 parts of polyethylene grafted maleic anhydride, 0.1 part of antioxidant 1010 were vacuum-dried at 80°C for 45 minutes;

[0040] S02, mixing: uniformly disperse and mix the dried HDPE, graphene oxide, polyethylene grafted maleic anhydride and antioxidant 1010 for 3 minutes at a speed of 500 rpm in a high mixer to obtain a mixture;

[0041] S03, granulation: put the mixture into a screw extruder to melt and pl...

Embodiment 2

[0046] The present embodiment 2 comprises the following components by weight: polyolefin resin is 100 parts of random copolymerized polypropylene PPR, graphene sheet is 0.1 part of thermally reduced graphene, compatibilizer is 0.3 part of poly Propylene is grafted with maleic anhydride, the antioxidant is 0.2 parts of antioxidant 1010, and the heat-reduced graphene sheets are evenly distributed in the polyolefin resin in a ring shape centered on the central axis of the pipe.

[0047] The preparation method steps are as follows:

[0048] S01, drying: 100 parts of PPR, 0.1 part of thermally reduced graphene, 0.3 part of polypropylene grafted maleic anhydride, and 0.2 part of antioxidant 1010 were vacuum-dried at 80° C. for 45 minutes;

[0049] S02, mixing: uniformly disperse and mix the dried HDPE, graphene oxide, polyethylene grafted maleic anhydride and antioxidant 1010 for 3 minutes at a speed of 500 rpm in a high mixer to obtain a mixture;

[0050] S03, granulation: put the...

Embodiment 3

[0055] The present embodiment 3 comprises the following components in parts by weight: the polyolefin resin is 100 parts of high-density polyethylene HDPE, the graphene sheet is 5 parts of graphene oxide, and the compatibilizer is 15 parts of polyethylene binder. Branch maleic anhydride, antioxidant are the antioxidant 1010 of 0.01 part;

[0056] The preparation method of Example 3 is the same as that of Example 1. The thermal conductivity of the prepared pipe is 0.87W / m·K, the hoop tensile strength is 69.5MPa, and the oxygen permeability coefficient is 0.096g·mm at 25°C 2 / (L·MPa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com