Ferritic stainless steel sheet causing little orange peel due to working and production method therefor

A technology for processing surface and stainless steel plate, which is applied in the direction of temperature control, etc., can solve the problems that ferritic stainless steel plate has not yet appeared, and the processing surface roughness is small, so as to achieve the effect of reducing the processing surface roughness and stabilizing manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

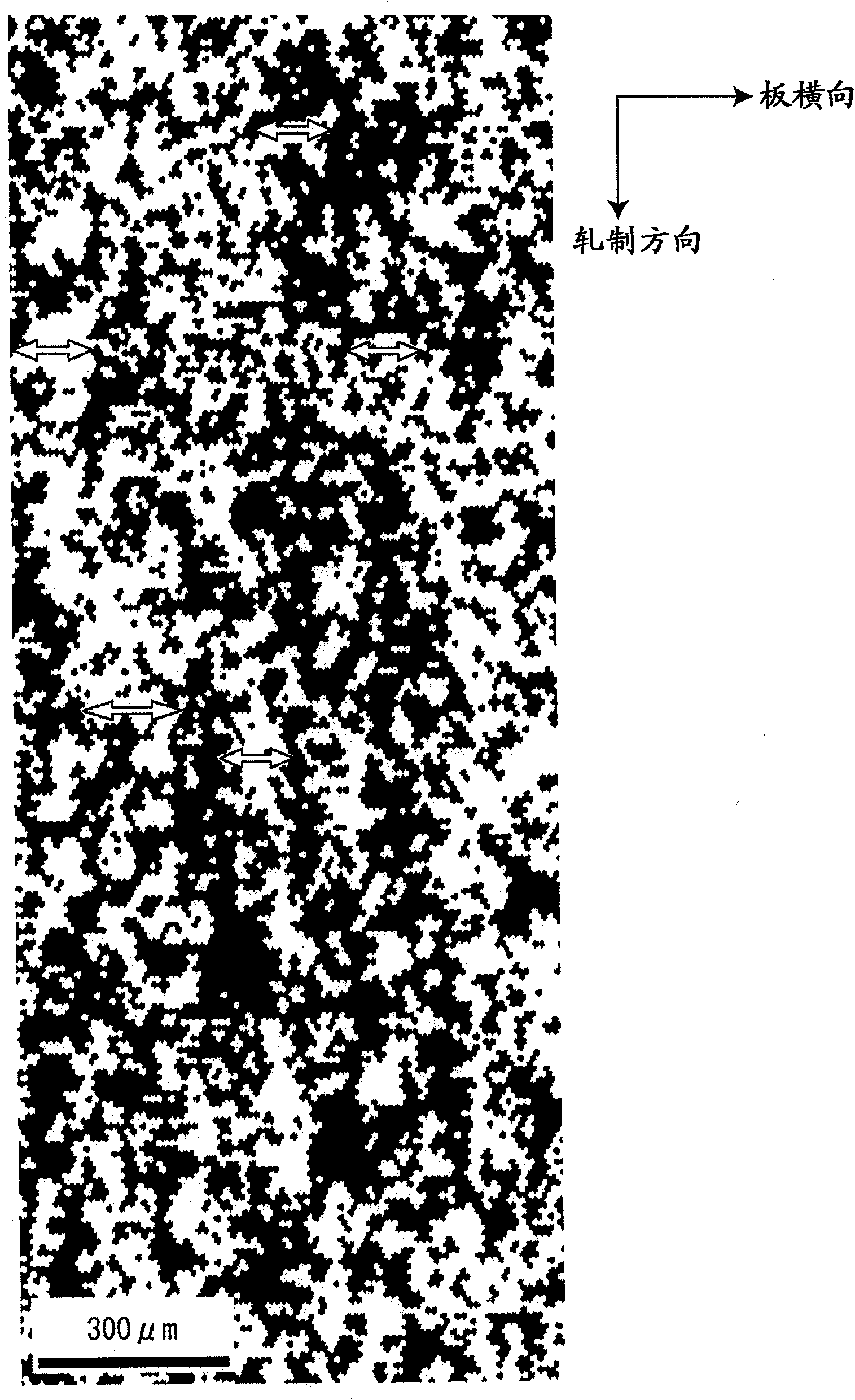

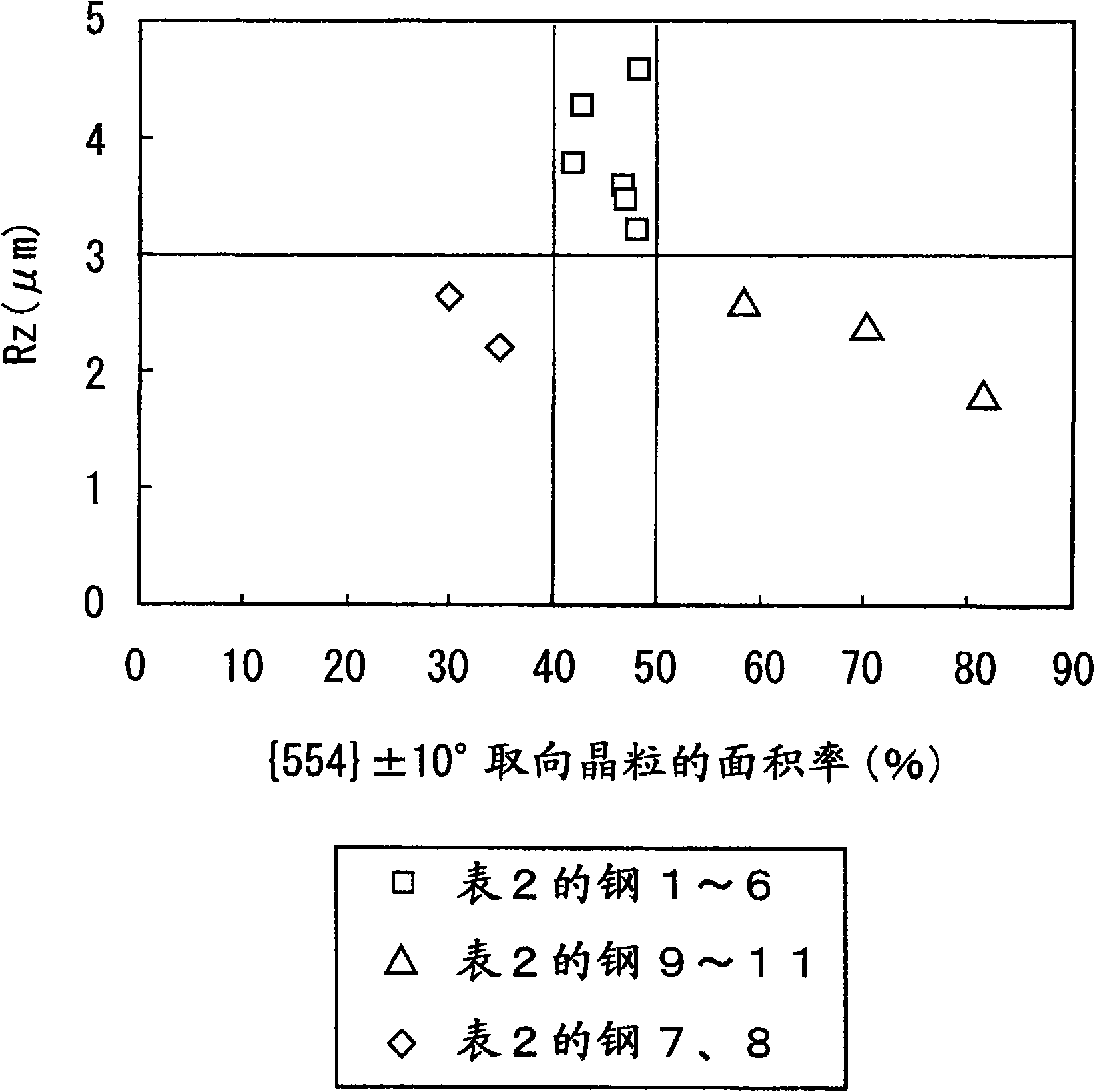

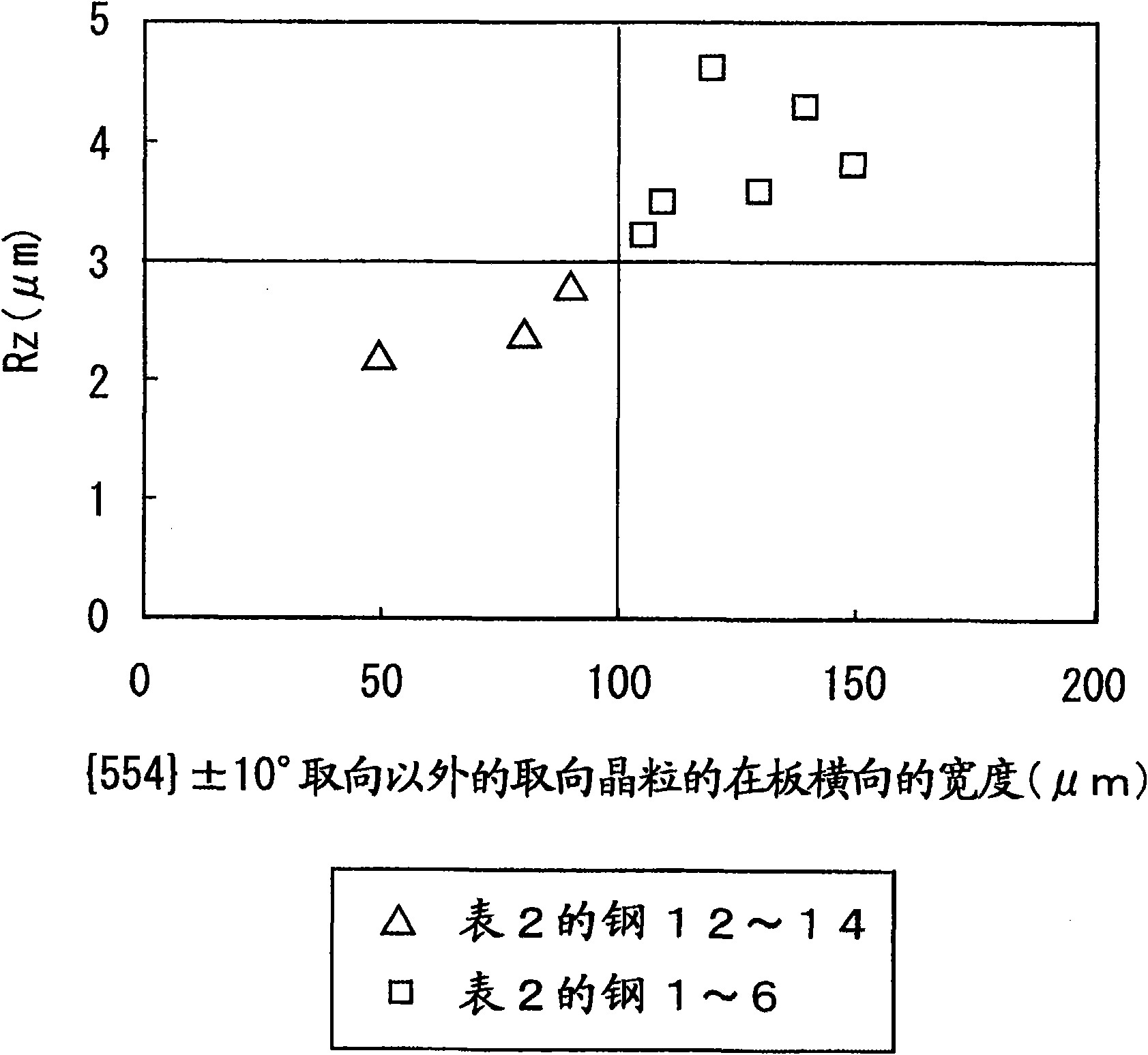

[0087] Examples of a ferritic stainless steel sheet formed into the texture of the present invention by implementing the production method of the present invention will be described below.

[0088] Using ferritic stainless steel having the composition shown in Table 1, the cast slab was heated and hot-rolled by the production method shown in Table 2 to produce a hot-rolled steel sheet having a thickness of 3 to 6 mm. After pickling, the hot-rolled steel plate is subjected to one cold rolling, intermediate annealing, final cold rolling, and final annealing to produce a product with a plate thickness of 0.5-0.8 mm. The surface specification of the product is 2B. Hot rolling and manufacturing of products from hot-rolled steel sheets are carried out within the scope specified in the present invention and other conditions. In Table 2, "-" means omission of a process.

[0089] According to the production method described in Table 2, steels 1 to 8 were subjected to hot-rolled sheet...

Embodiment 2

[0095] Examples of a ferritic stainless steel sheet formed into the texture of the present invention by carrying out the production method of the present invention will be described below.

[0096] Using ferritic stainless steel having the composition shown in Table 3, the cast slab was heated and hot-rolled by the production method shown in Table 4 to produce a hot-rolled steel sheet having a thickness of 3 to 6 mm. After pickling, the hot-rolled steel plate is subjected to one cold rolling, intermediate annealing, final cold rolling, and final annealing to produce a product with a plate thickness of 0.5-0.8 mm. The surface specification of the product is 2B. The chemical composition, hot rolling, and the manufacture of products from hot-rolled steel sheets were carried out within the range specified in the present invention and other conditions. In Table 3 and Table 4, the underline means outside the scope of the present invention. In addition, in Table 4, "-" means omissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com