Patents

Literature

33results about How to "Reduce the roughness of the machined surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

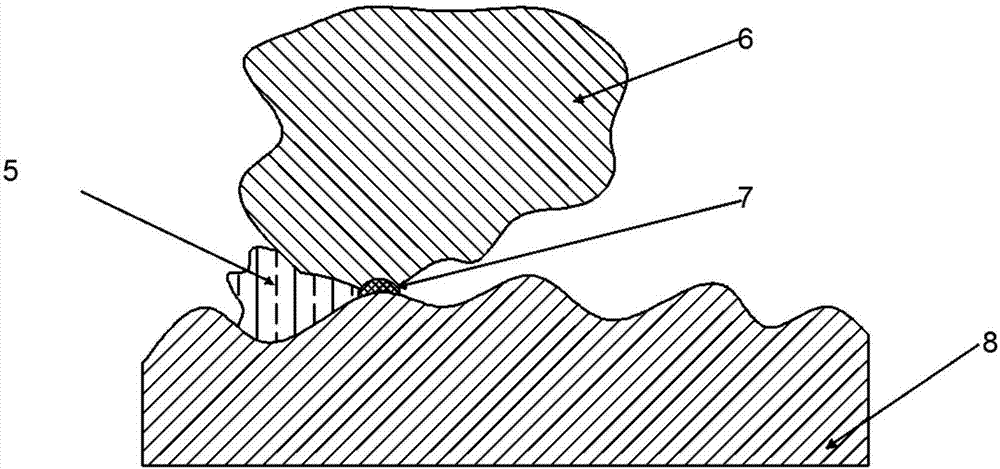

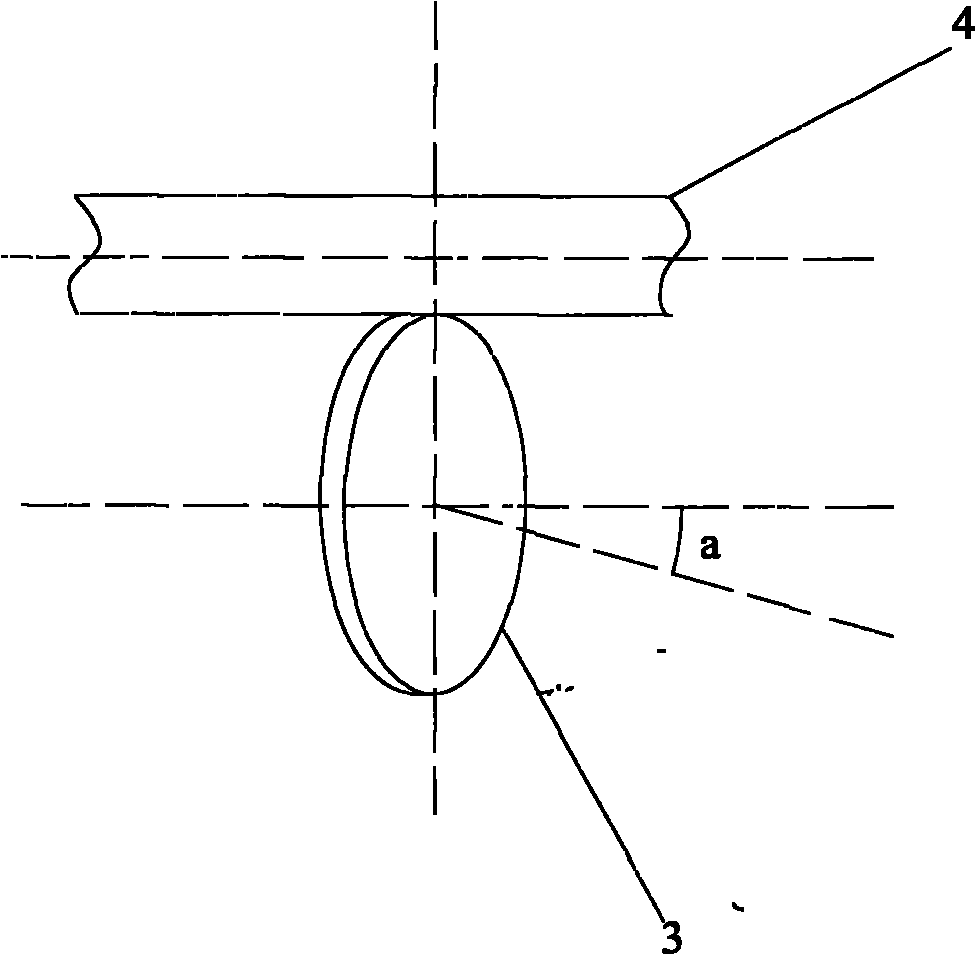

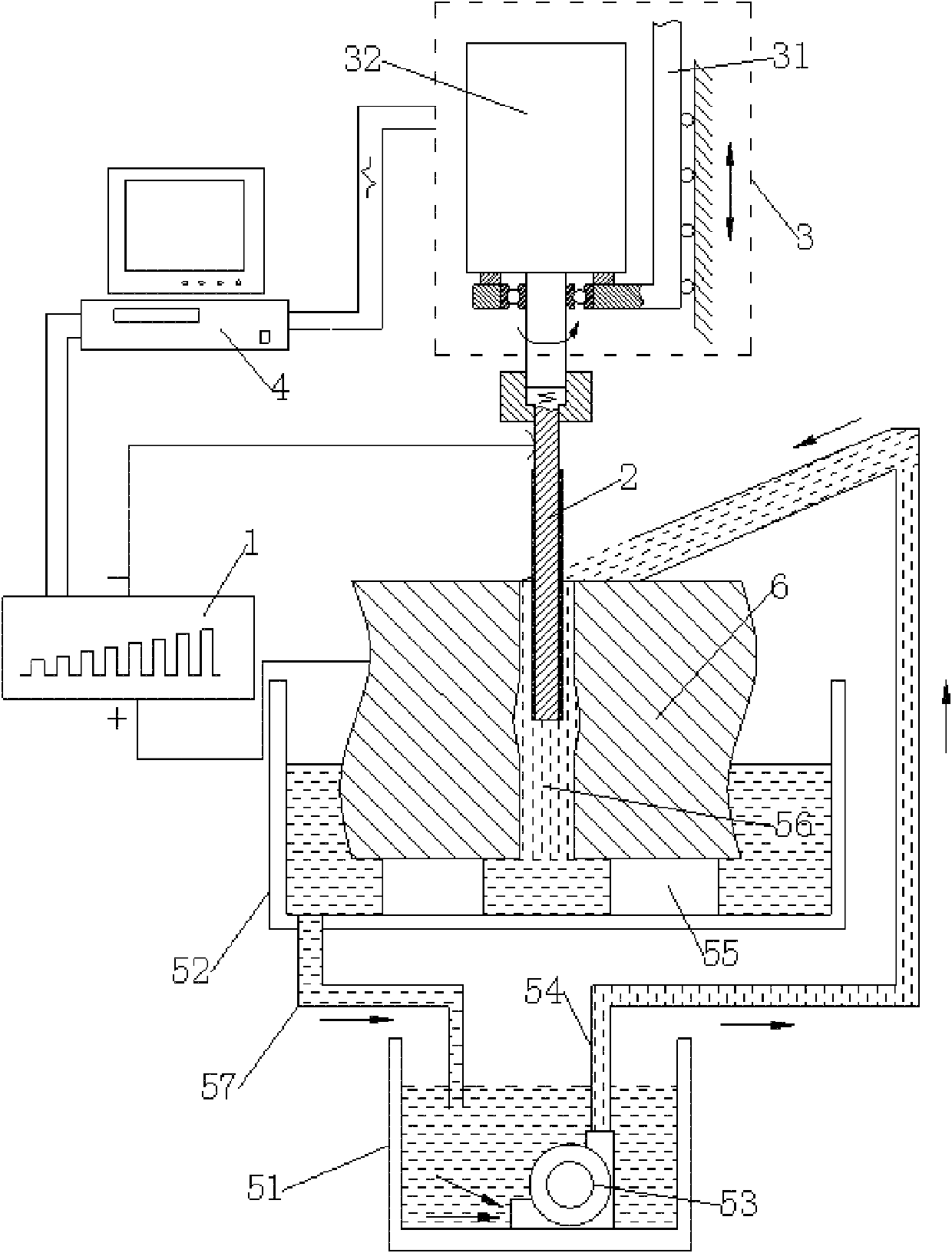

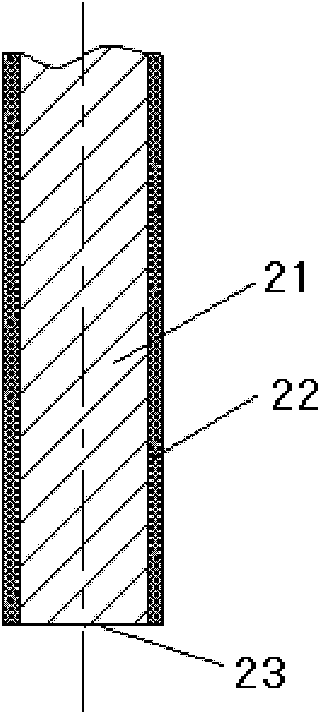

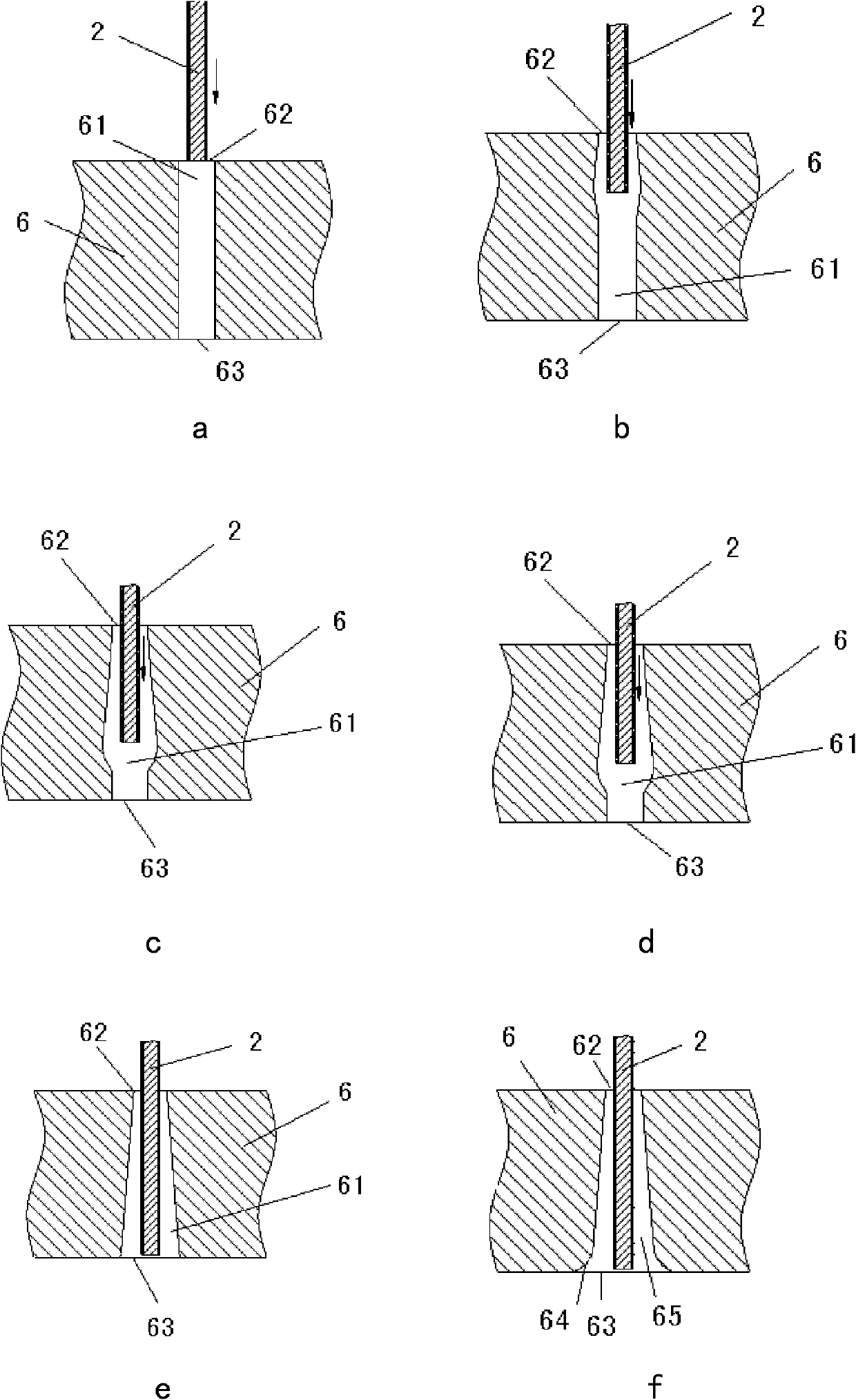

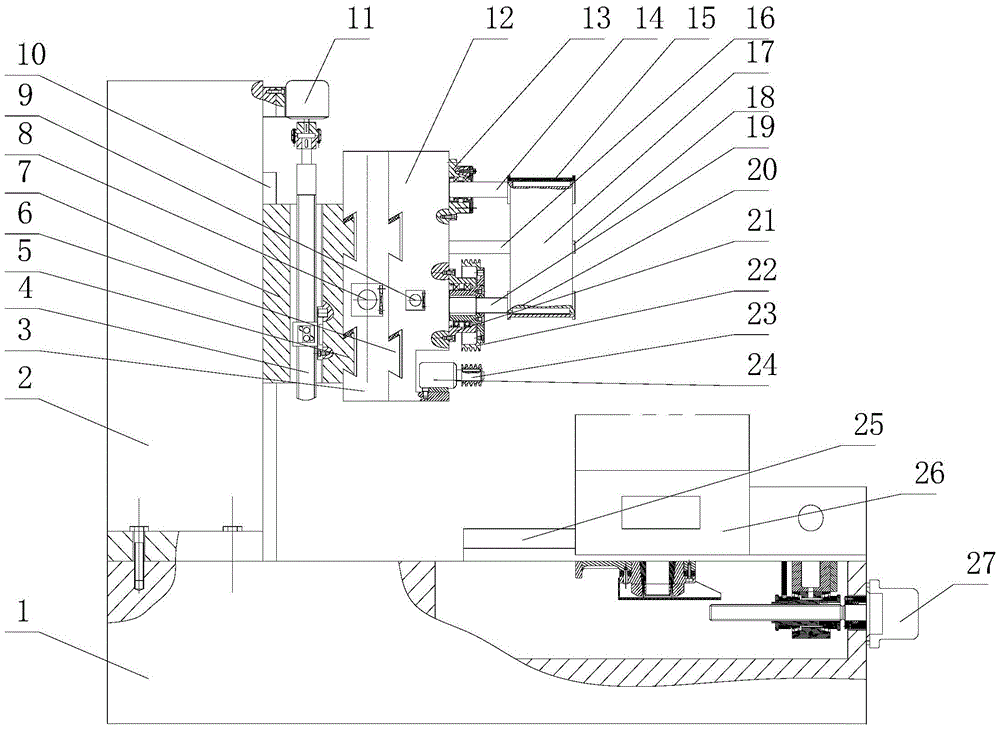

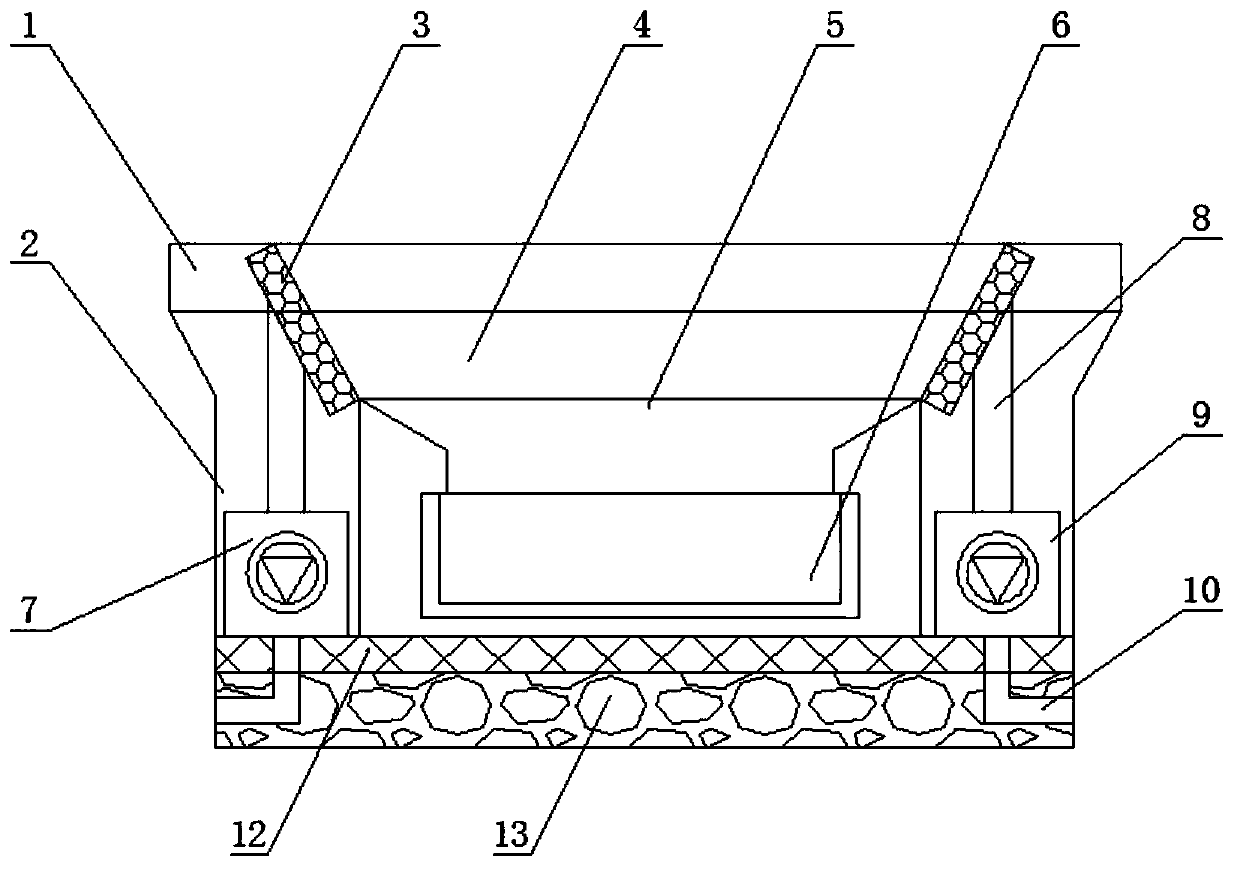

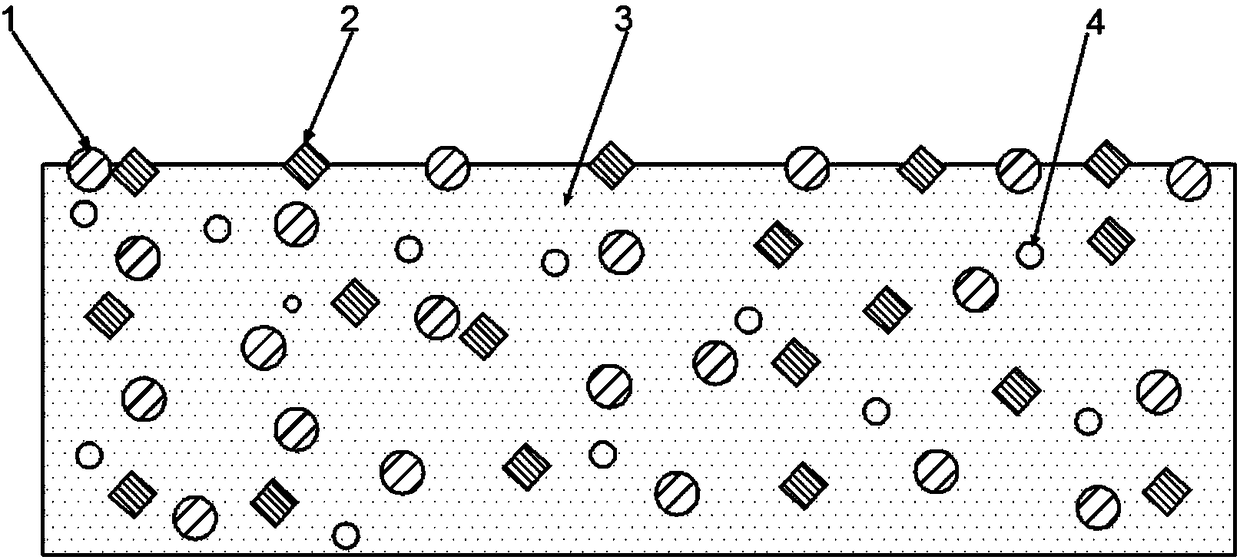

Electrochemical machining method and device for oil nozzle spray orifice of diesel motor

InactiveCN102240835AImprove nozzle flow coefficientImprove spray effectElectrochemical machining apparatusPersonal computerAnode

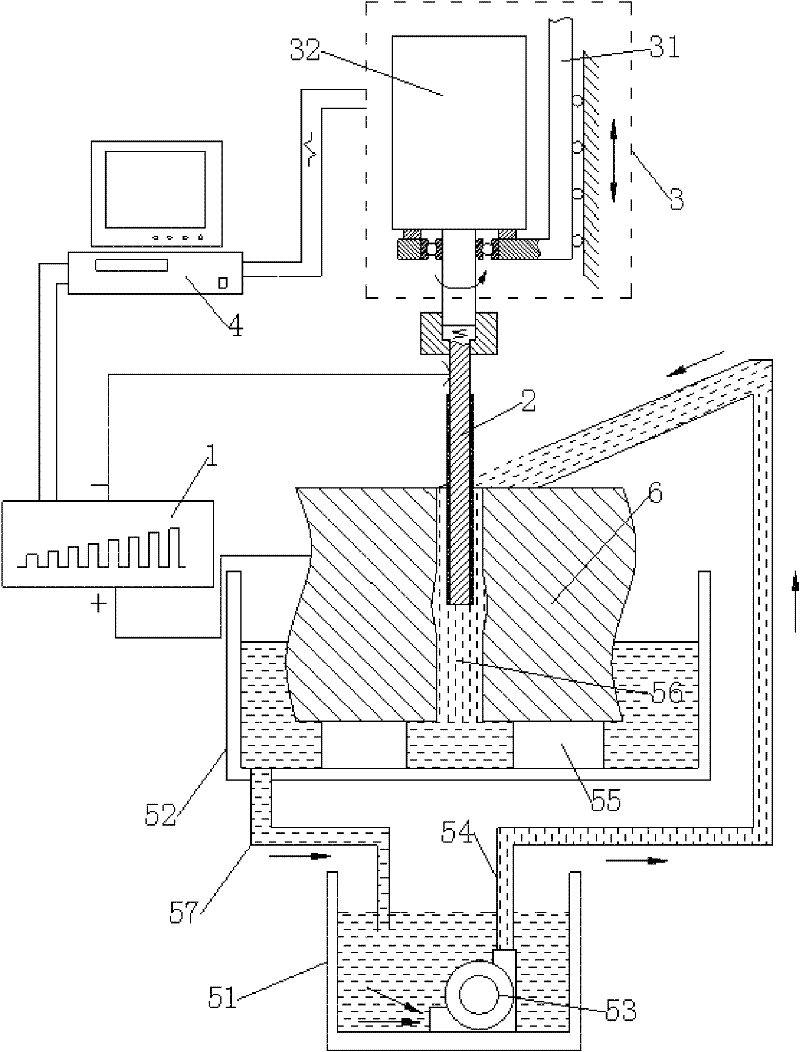

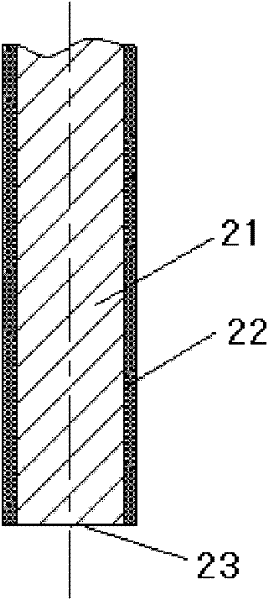

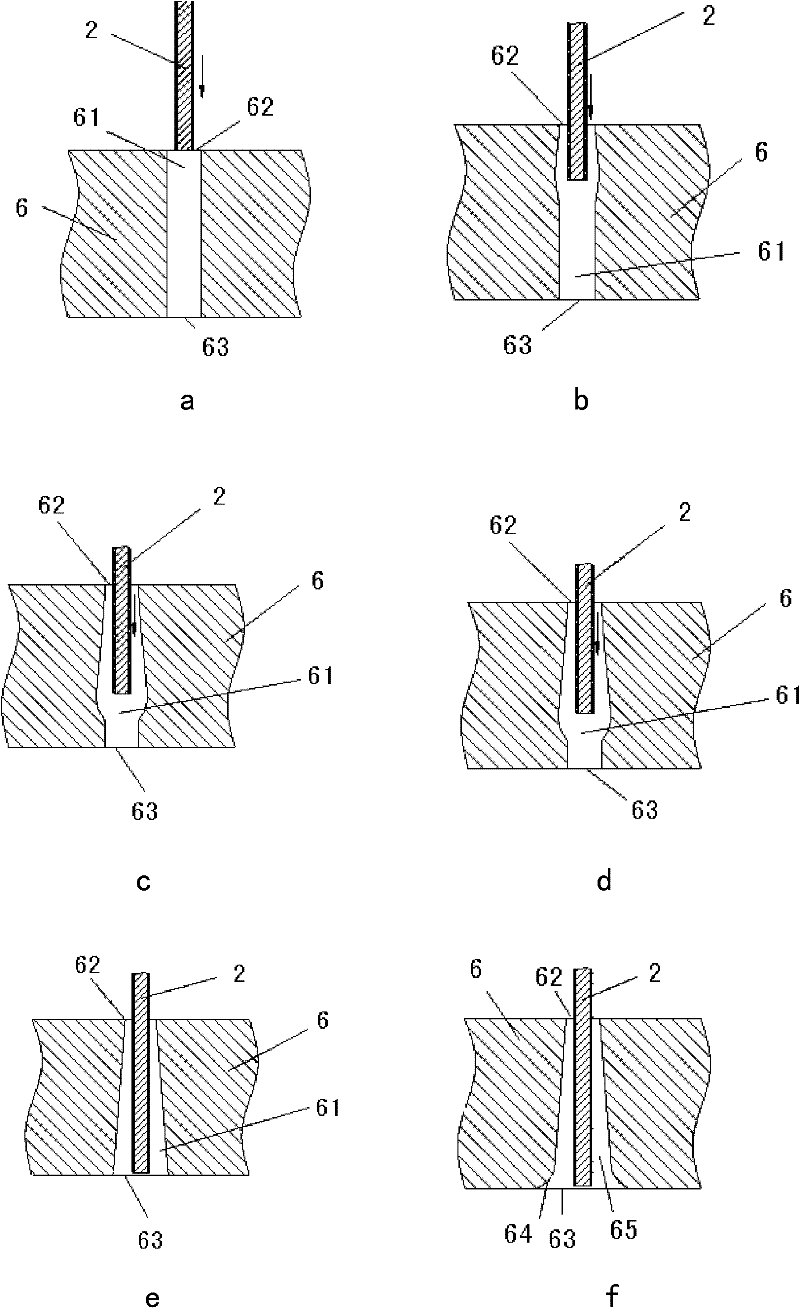

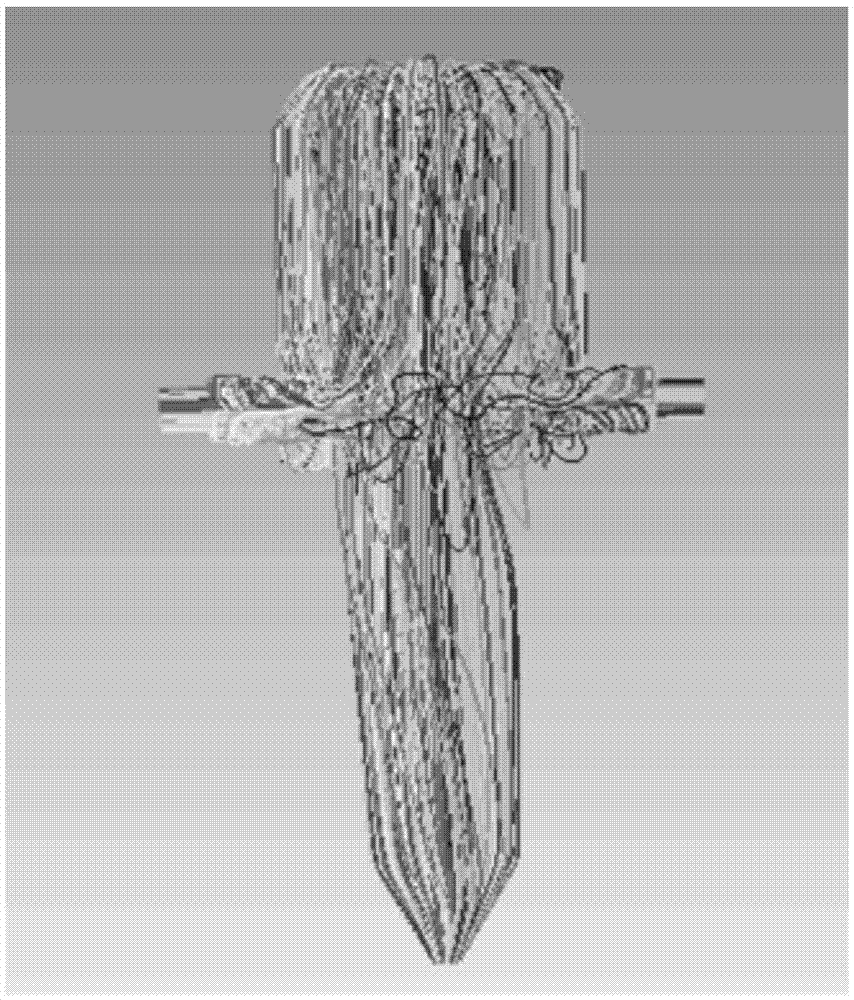

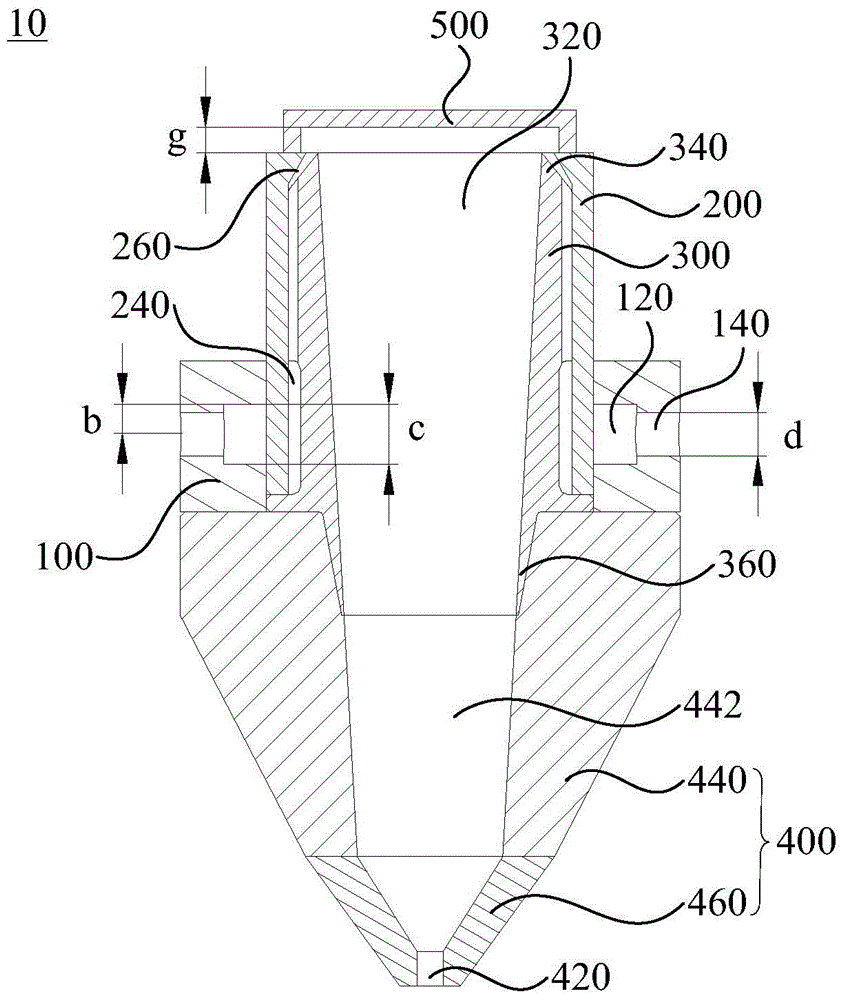

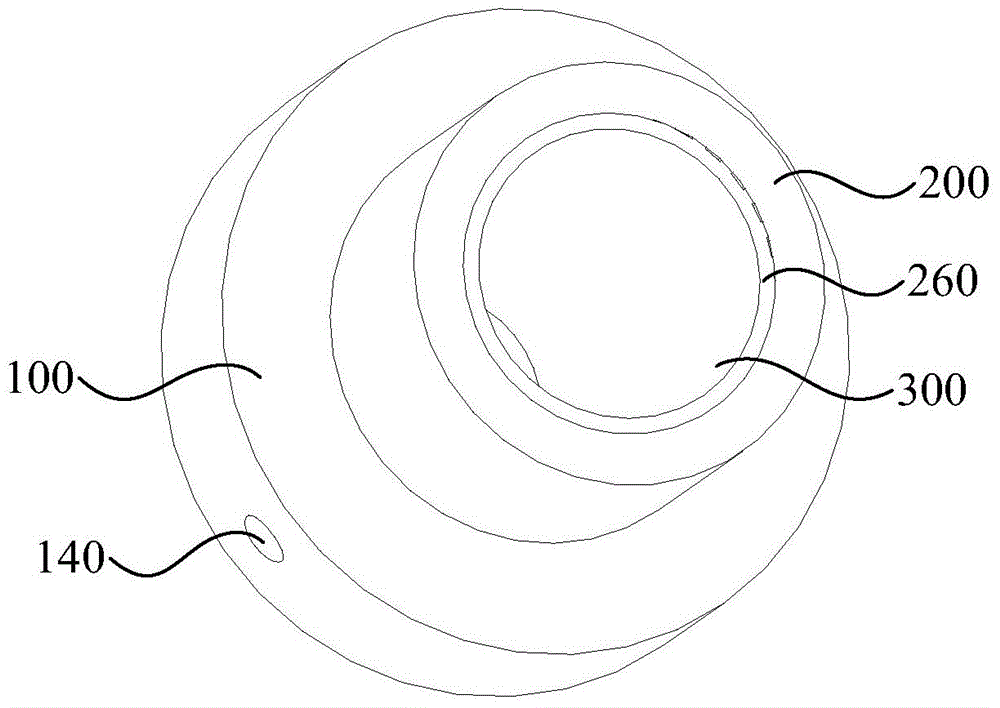

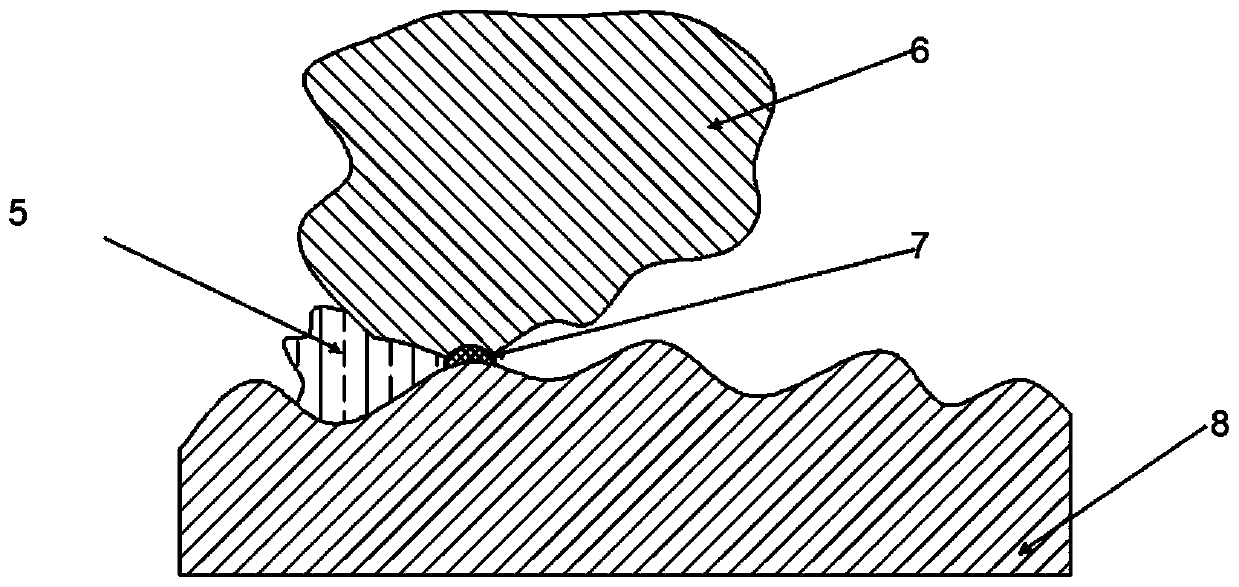

The invention relates to an electrochemical machining method and device for an oil nozzle spray orifice of a diesel motor. The electrochemical machining method comprises the following steps: 1) machining a cylindrical or right conical through hole on an oil nozzle workpiece in advance; 2) placing the oil nozzle workpiece in an electrolyte circulating device, clamping a tool electrode on an electrode feeding mechanism, connecting the anode of an electrochemical machining power supply to the oil nozzle workpiece, connecting the cathode of the electrochemical machining power supply to the tool electrode, and then connecting the electrochemical machining power supply, the electrode feeding mechanism and the liquid pump of the electrolyte circulating device to an industrial personal computer through a driving circuit; 3) starting the liquid pump to inject an electrolyte into the through hole of the oil nozzle workpiece, and guiding the electrolyte to flow back to an electrolyte container from a liquid groove, thereby forming electrolyte circulation; 4) starting the electrochemical machining power supply, using the industrial personal computer to control the electrode feeding mechanism to drive the tool electrode to perform feed motion and meanwhile control the electric signal parameter of the power supply, and electrochemically machining the through hole until the through hole is processed into an inverted conical spray orifice with an arc transition area; and 5) turning off the electrochemical machining power supply and the liquid pump and resetting the tool electrode. The electrochemical machining method provided by the invention can be widely applied to machining the spray orifices in various shapes.

Owner:TSINGHUA UNIV

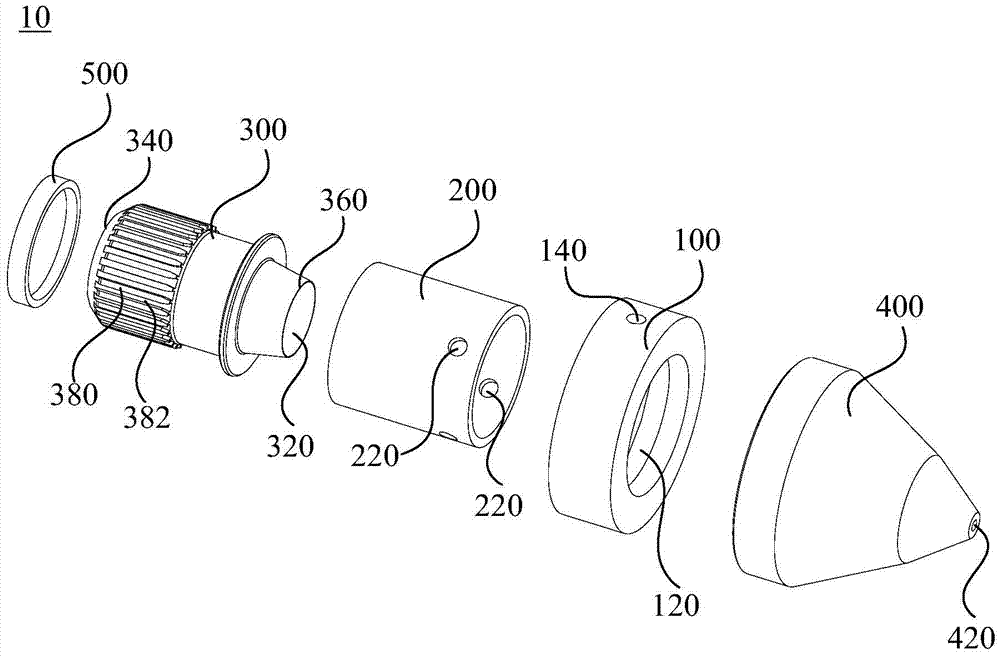

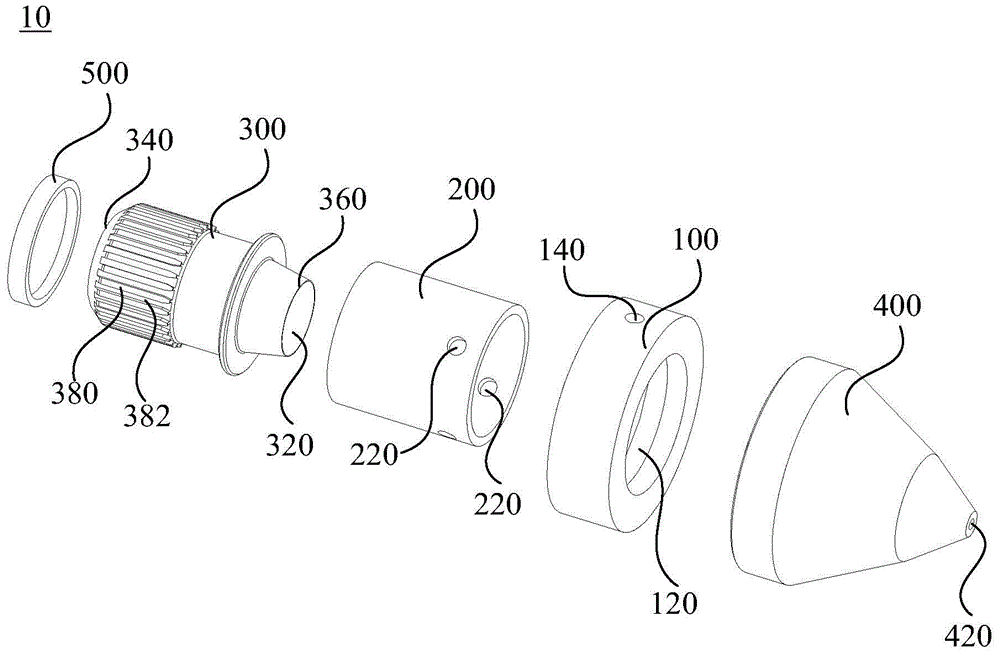

Laser cutting device and laser head thereof

ActiveCN105436720AReduce the impactImprove verticalityLaser beam welding apparatusMachined surfaceEngineering

The invention relates to a laser cutting device and a laser head thereof. The laser head comprises an air inlet ring, a first rectifier tube, a second rectifier tube and an air nozzle. An annular groove is formed in the inner side of the air inlet ring, and air inlet holes communicated to the groove are formed in the outer side of the air inlet ring; ventilation holes are formed in the side wall of the first rectifier tube, the first rectifier tube is sleeved with the air inlet ring, and the ventilation holes are communicated with the groove; an air flow passage is formed inside the second rectifier tube, and the second rectifier tube comprises a first end and a second end which are opposite; the second rectifier tube is sleeved with the first rectifier tube, and a rectifying passage is formed between the first rectifier tube and the second rectifier tube; and an air outlet gap is formed between the first rectifier tube and the first end, and the air flow passage and the rectifying passage are communicated through the air outlet gap. Due to two times of rectifying, the airflow distribution evenness of cutting air can be improved, and the intensity of turbulence can be reduced, so that the influence of the pneumatic optical effect on a laser path is reduced, the stability of the quality of laser beams is guaranteed, the roughness of the machined surface is reduced, and the perpendicularity of cut lines is improved.

Owner:HANS LASER TECH IND GRP CO LTD

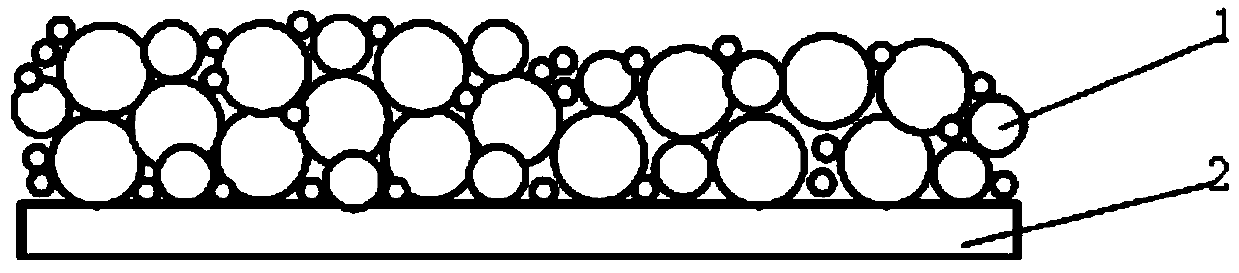

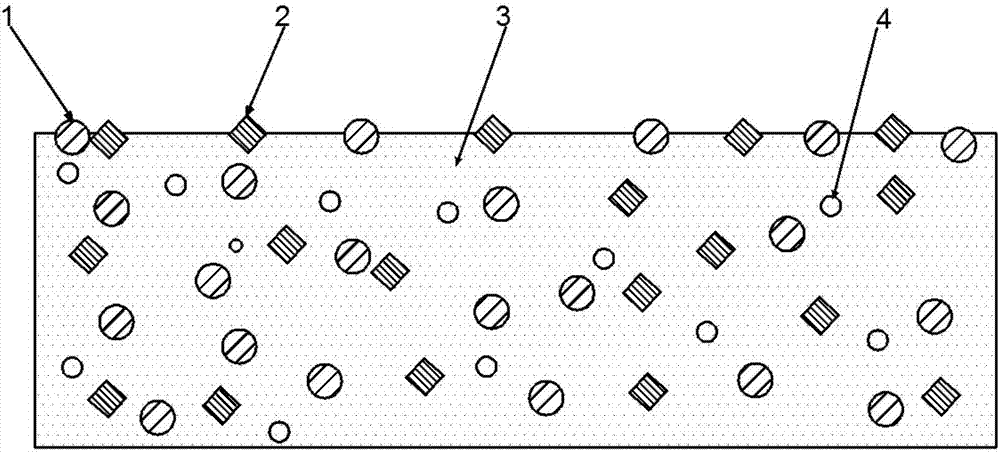

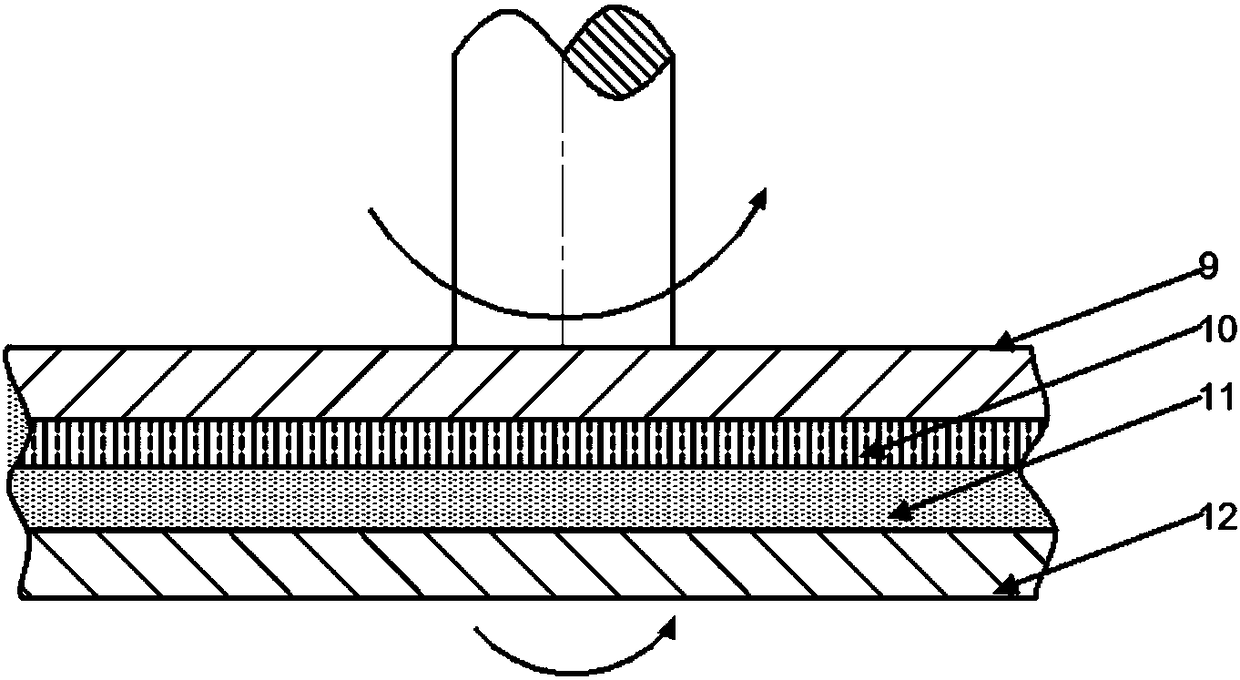

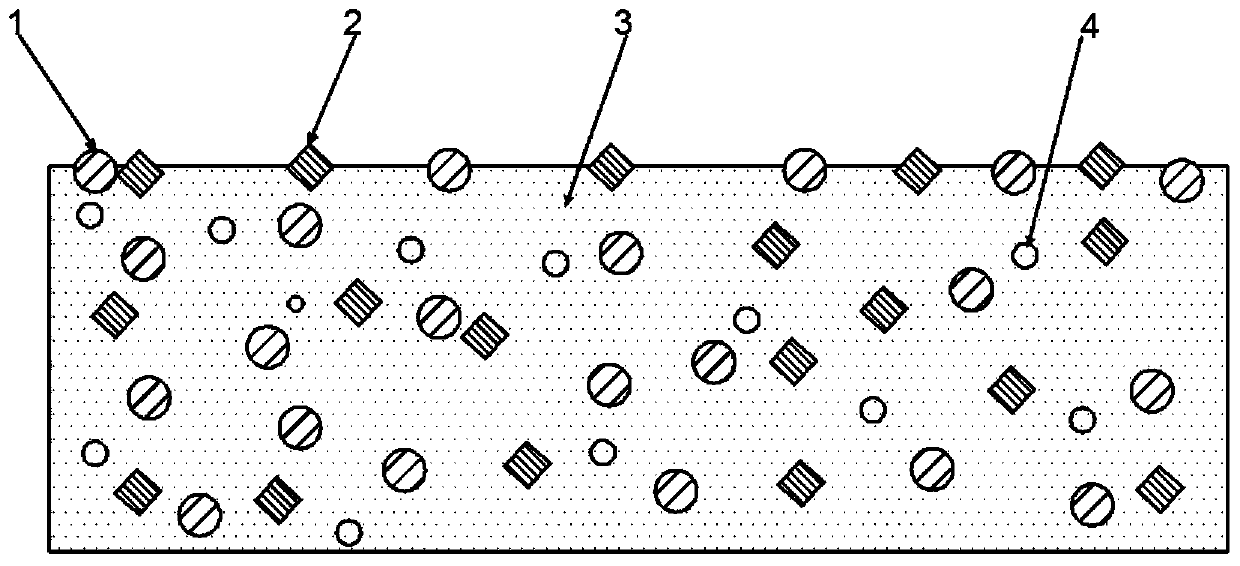

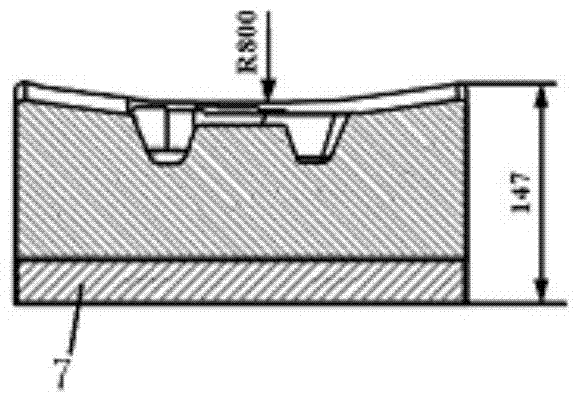

Method for manufacturing soluble fixed soft abrasive-polishing film

InactiveCN104209879AReduce resin binder contentDurable Polishing PerformanceAbrasion apparatusGrinding devicesSolventElastic substrate

The invention relates to a soluble fixed soft abrasive-polishing film, which comprises an abrasive layer and a substrate layer and has the thickness of 0.3 to 5mm. A soluble high-molecular material is used as a bonding agent of the abrasive layer, and a certain proportion of multilayer particle-diameter soft microfine abrasives are distributed and coated on the elastic substrate according to a certain rule. Small-particle-diameter abrasive particles not only can directly participate in a polishing process, but also can be used as a filling material and achieves the effect of supporting large particles, so that the content of a resin bonding agent in the polishing film is decreased, and the problems of film surface cracking and breakage are effectively solved. A specific nonpoisonous and harmless aqueous solvent is adopted in the machining process to solve the bonding agent on the surface layer of the polishing film, so that the holding force of he bonding agent for the abrasive particles is decreased to enable the bonding agent to fall off; on one hand, the passivated abrasive particles on the surface layer can be removed, so that the polishing film has more lasting polishing performance; on the other hand, the abrasive particles which are fixed on the surface of the polishing film and the abrasive particles which fall off and are dispersed into a polishing solution jointly act on a workpiece, so that the ultra-smooth high-efficiency surface polishing of the workpiece can be realized.

Owner:QUZHOU UNIV

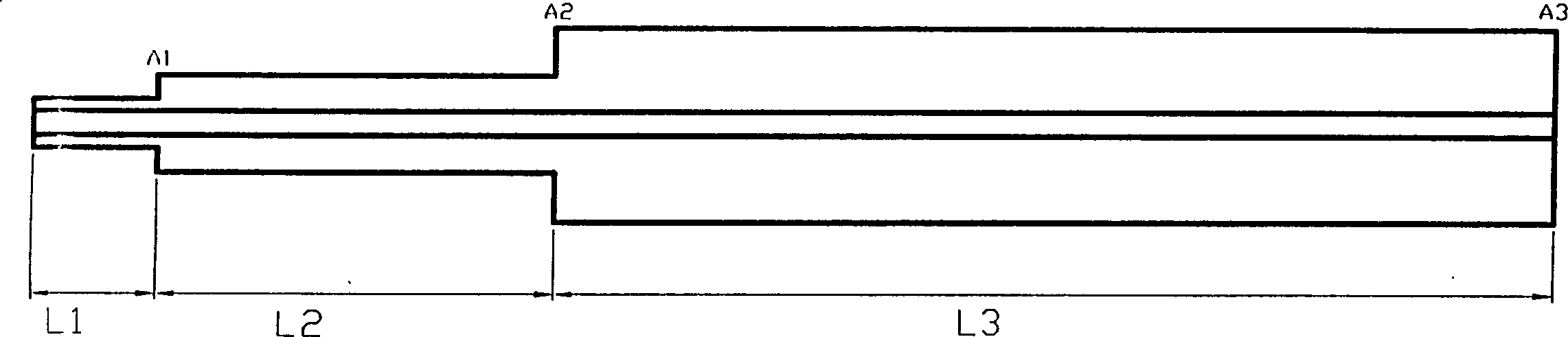

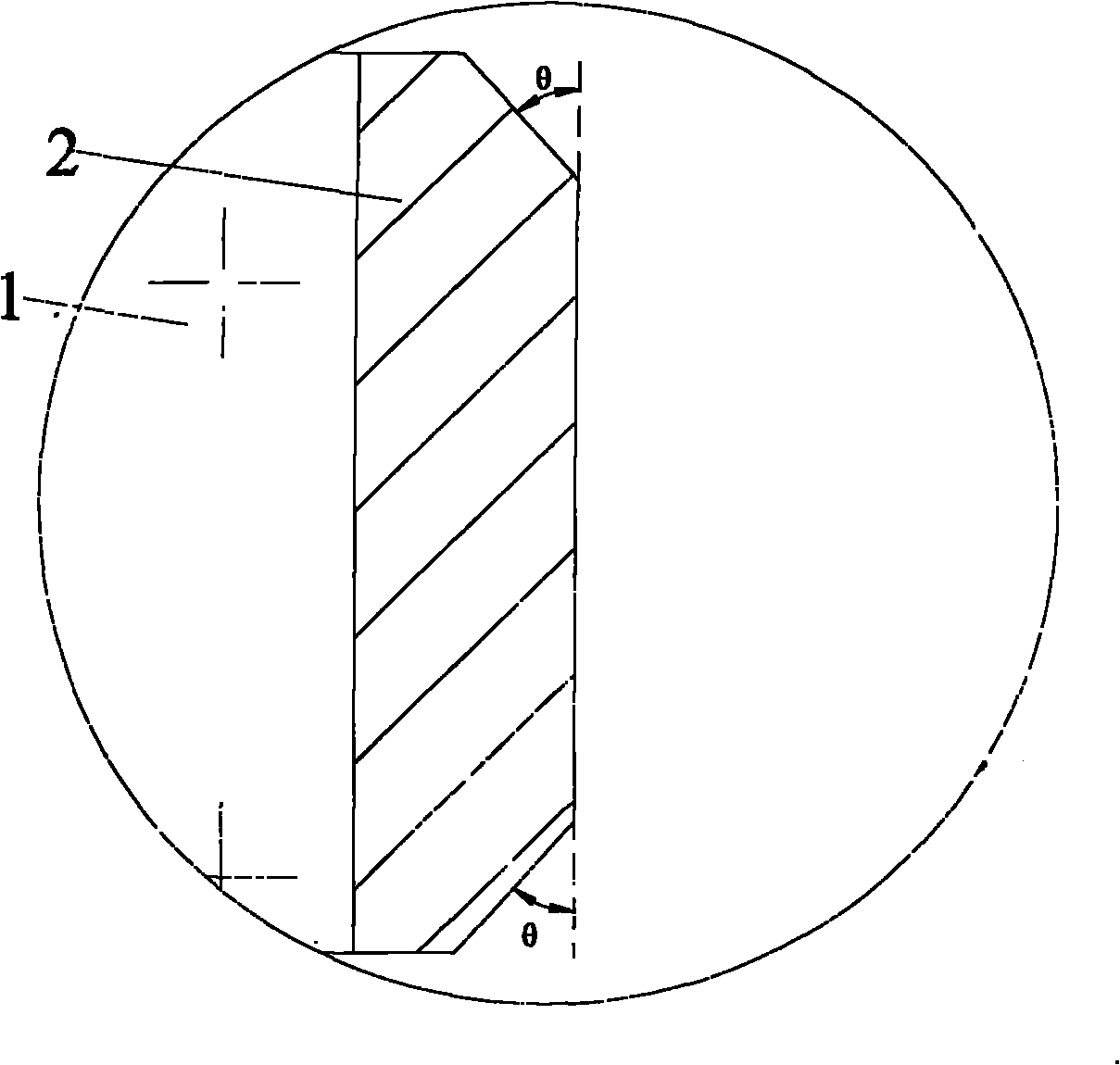

Miniature total pressure probe and its manufacturing method

InactiveCN1693897ADoes not affect stiffnessLow costFluid speed measurement using pressure differenceFluid pressure measurementElectricityElectrolysis

The invention is a miniature total press probe and its making method. The probe is made up of a 3-rated outside circles, terraced tube whose head outside diameter is 0.2 mms. The ratio of these three circles' diameters is 1:2:5 while the ratio of the lengths is 1:(3-5):.(8-12).The producing method is to adopt the tiny electrical spark and the tiny electrolysis compound process to pack the parts once. The positioning accuracy can attain to 2 ums. The detailed craft is as follows:1 tiny electrical sparks processing craft;2 tiny electrolysis of pure water processing craft;3 tiny operation craft. Here are the advantages: provide the valid measure means for tiny fluid mechanics experiments; the special design of the probe guarantees that the valid measure dimension stays between millimeters and centimeters of total press distribution, and makes sure that the probe's rigidity can bear the strength of the tiny dimension-low Renault current of air without being impacted. The advantages are low cost and conveniently use.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

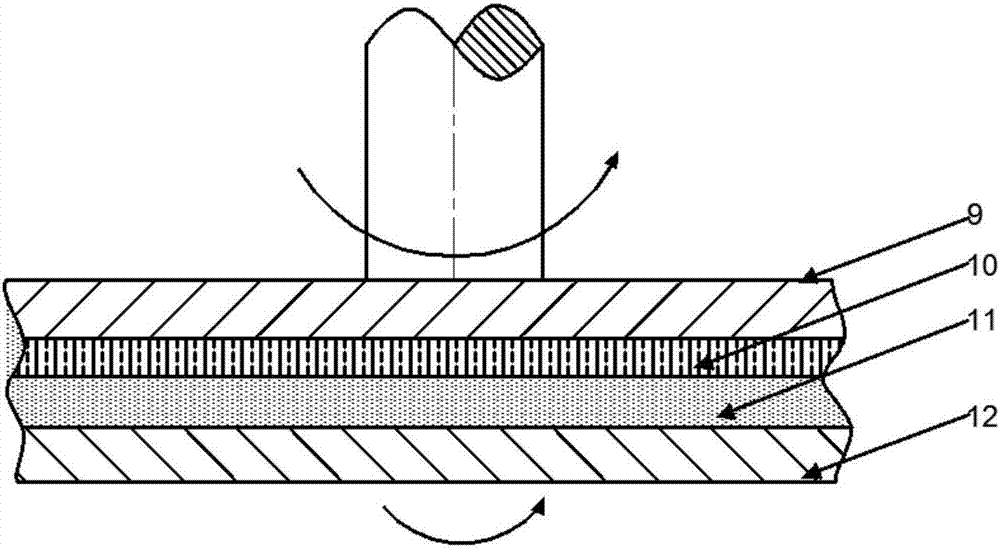

Sapphire wafer polishing method based on fixed abrasive tool containing neodymium compound and soft abrasive materials

InactiveCN107953148AThe reaction is easy to carry outLow processing roughnessGrinding devicesGrinding/polishing safety devicesHot pressingNeodymium

The invention discloses a sapphire wafer polishing method based on fixed abrasive tool containing neodymium compounds and soft abrasive materials. The method comprises the steps that 1), the fixed abrasive tool containing the neodymium compounds and the soft abrasive materials is prepared by comprising, 40%-60% of nano silicon dioxide, 20%-40% of a binding agent, 10%-15% of a curing agent, 5%-10%of a neodymium compound, and the balance deionized water; 2), the prepared raw materials undergo hot-press forming in a mould, heat curing is completed after demolding is carried out, and the upper end surface and the lower end surface of the formed abrasive tool are trimmed; 3), the abrasive tool is arranged on a polishing machine upper disc, a sapphire wafer to be machined is placed on a polishing machine lower disc capable of rotating and is fixed by a clamp, then a polishing machine is started, a water-based cooling liquid is injected between the upper disc and the lower disc, the neodymium compounds and the silicon dioxide abrasive particles on the abrasive tool scratch the sapphire surface and the solid-phase reaction is carried out, so that the sapphire wafer is polished. Accordingto the method, the removal rate of the sapphire wafer can be improved, the roughness can be reduced, the machining efficiency can be improved, and the production cost can be reduced.

Owner:ZHEJIANG UNIV OF TECH

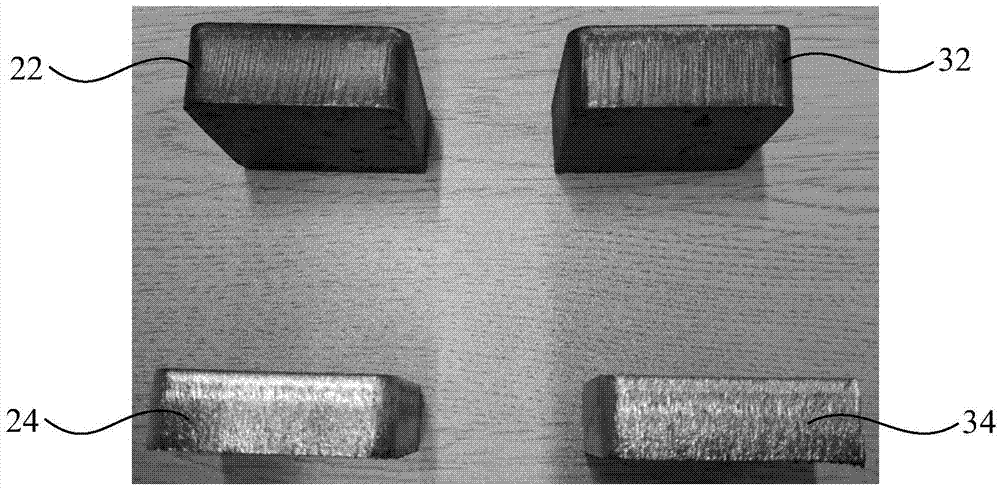

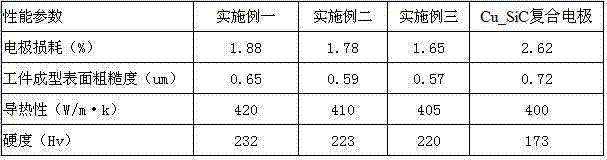

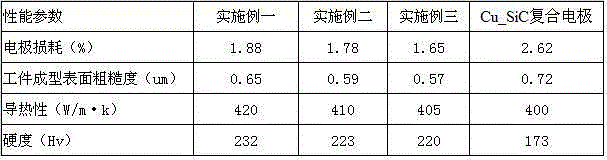

Composite material tool electrode for electrolytic deposition and electric spark and preparation method thereof

ActiveCN103878455AHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceHardness

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

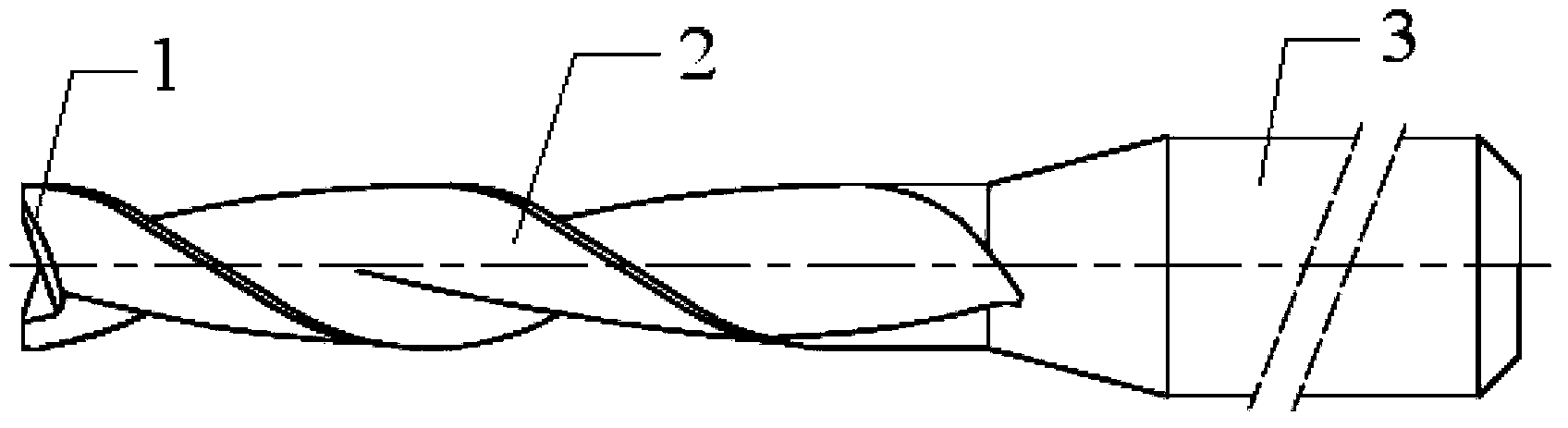

Blind groove diamond coating milling cutter

InactiveCN103567520AImprove high temperature resistanceImprove wear resistanceMilling cuttersChemical vapor deposition coatingMilling cutterEngineering

The invention relates to a blind groove diamond coating milling cutter. The milling cutter has a fishtail-shaped structure, and comprises a milling cutter head, a scrap discharging groove and a handle, wherein the head cutting edge of the milling cutter head is inclined to the center; the scrap discharging groove is integrally formed in the back cutter surface of the milling cutter; a helical angle is formed outside the scrap discharging groove; the handle is arranged on the back part of the scrap discharging groove and is connected with the main shaft of a PCB (printed circuit board) drilling and milling machine; an HFCVD (hot filament chemical vapor deposition) diamond coating is deposed on the surface of the milling cutter. Compared with the prior art, the blind groove diamond coating milling cutter has the advantages of wide machining range, high production efficiency, long service life and the like.

Owner:SHANGHAI UNIV OF ENG SCI +1

Bismuth-containing free-cutting pre-hardened plastic die steel and preparation method thereof

ActiveCN112030073AShorten the production cycleReduce processing costsMetal-working apparatusChemical compositionIngot

The invention discloses bismuth-containing free-cutting pre-hardened plastic die steel and a preparation method thereof. The die steel comprises the following chemical components of, in percentage bymass, 0.32%-0.40% of C, 0.15%-0.30% of Si, 1.50%-1.70% of Mn, 1.70%-2.00% of Cr, 0.85%-1.15% of Ni, 0.25%-0.40% of Mo, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.05%-0.10%of V, 0.05%-0.15% of Bi, and the balance Fe. The preparation method comprises the following steps that smelting and casting are performed into a cast ingot according to set chemical components, the cast ingot is subjected to high-temperature homogenization treatment into a forging stock, normalizing treatment is performed offline after forging to refine grains, and finally, quenched-tempered heattreatment is performed to obtain a uniform structure with the hardness of 32-48HRC. According to the bismuth-containing free-cutting pre-hardened plastic die steel, through reasonable chemical component design, the bismuth element is added to replace traditional free-cutting elements including sulfur and lead, and due to the fact that a sulfur content is controlled, reasonable forging and heat treatment processes are matched, the hot brittleness phenomenon and anisotropy caused by the sulfur element are avoided, meanwhile, the problems that the lead is harmful to human bodies and pollutes anenvironment are solved.

Owner:NORTHEASTERN UNIV

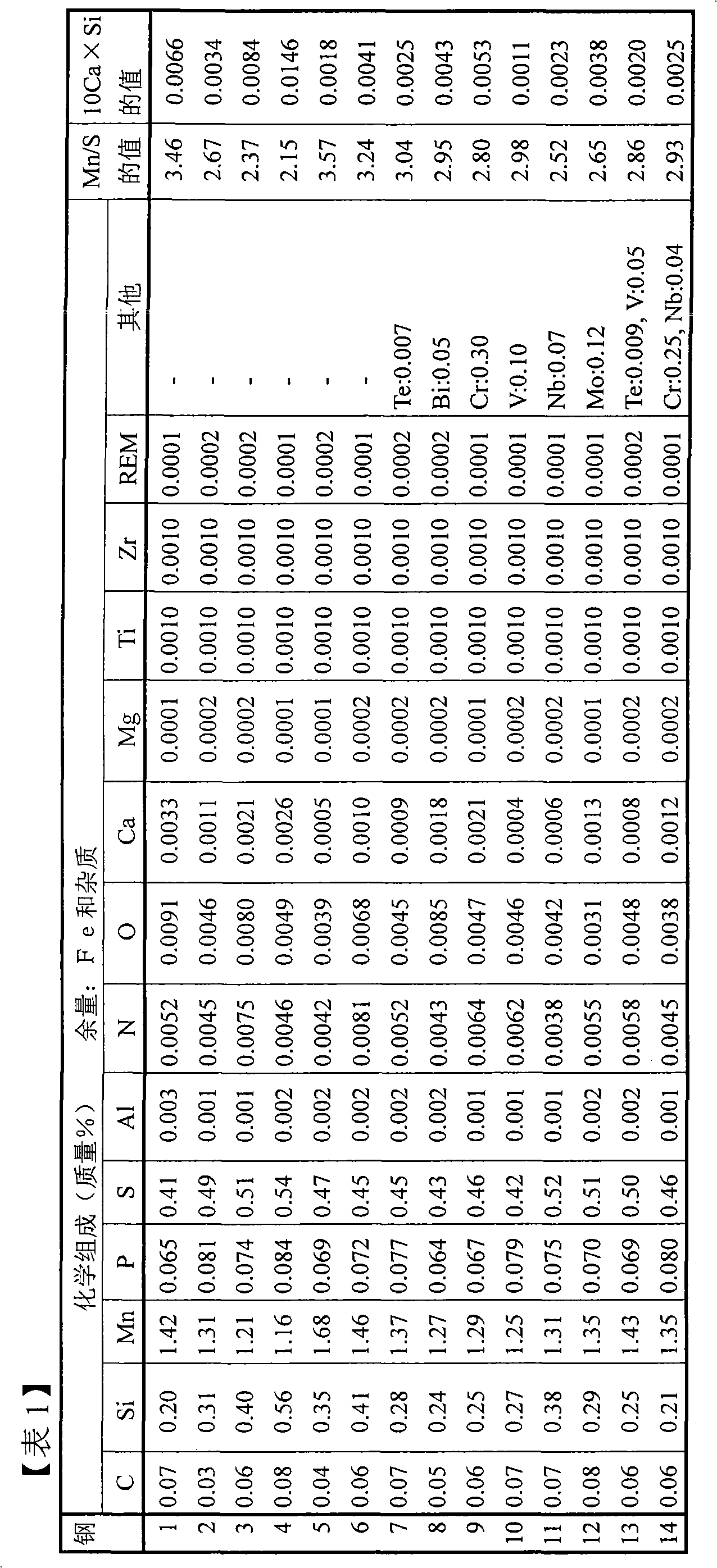

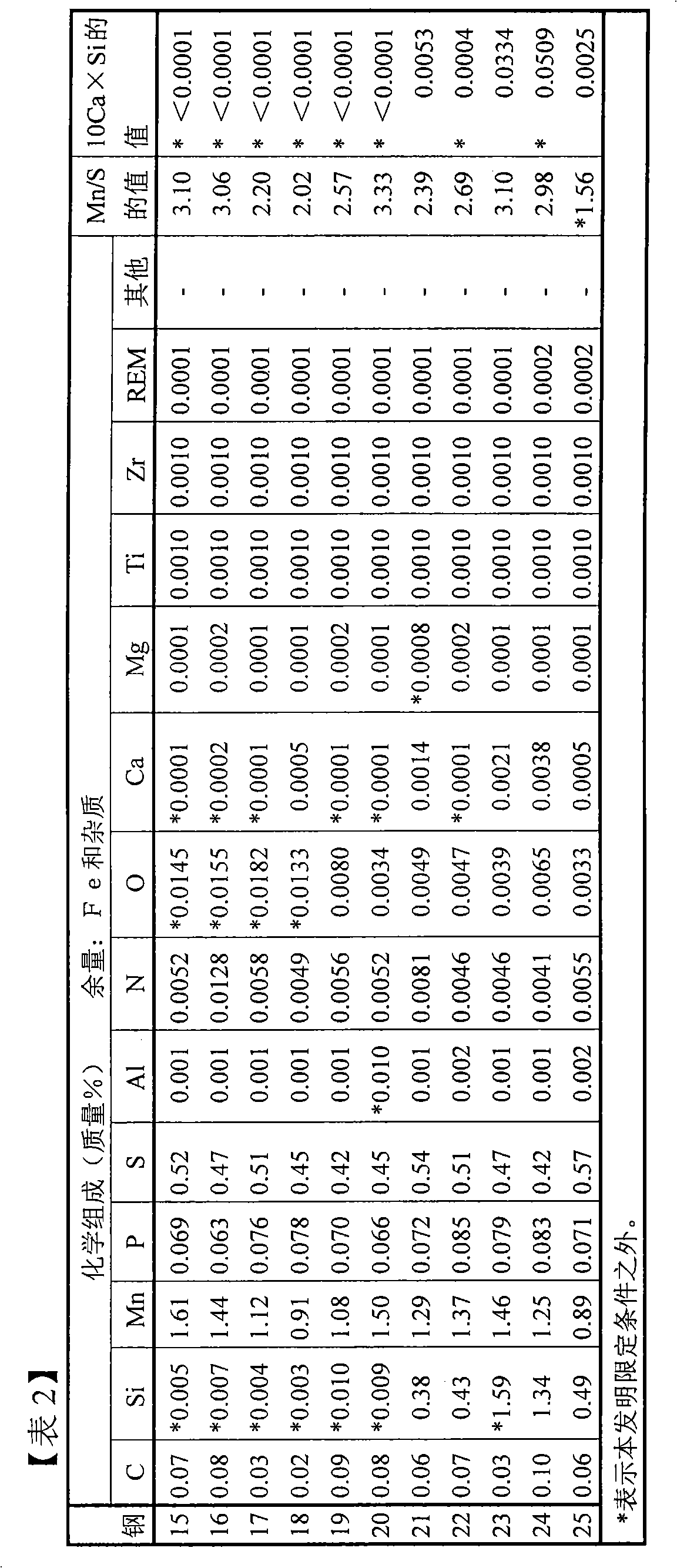

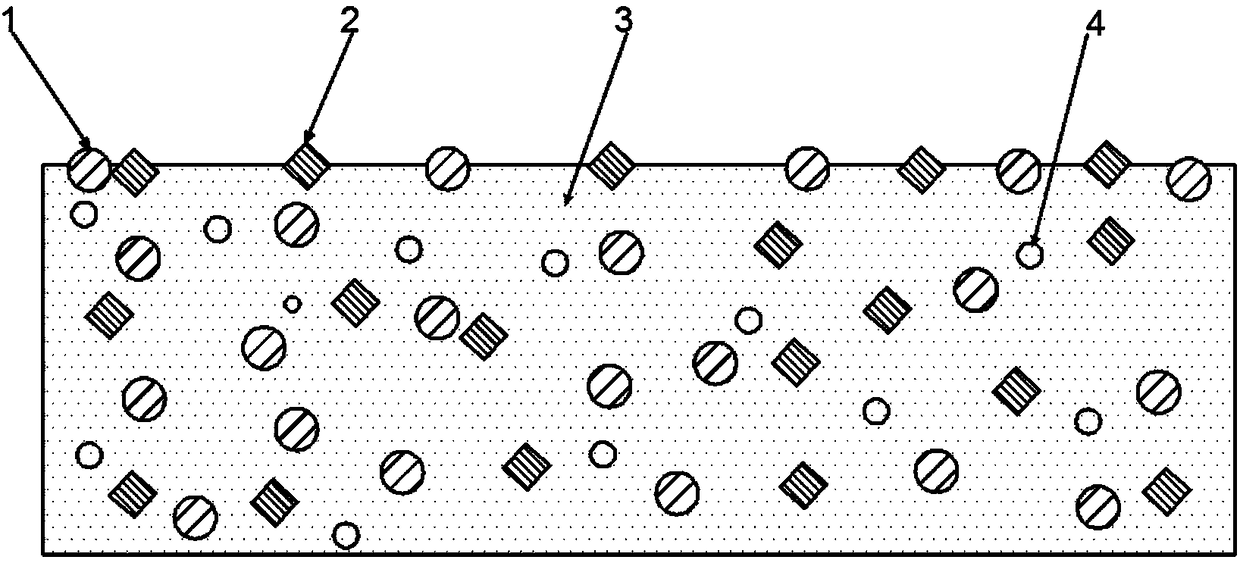

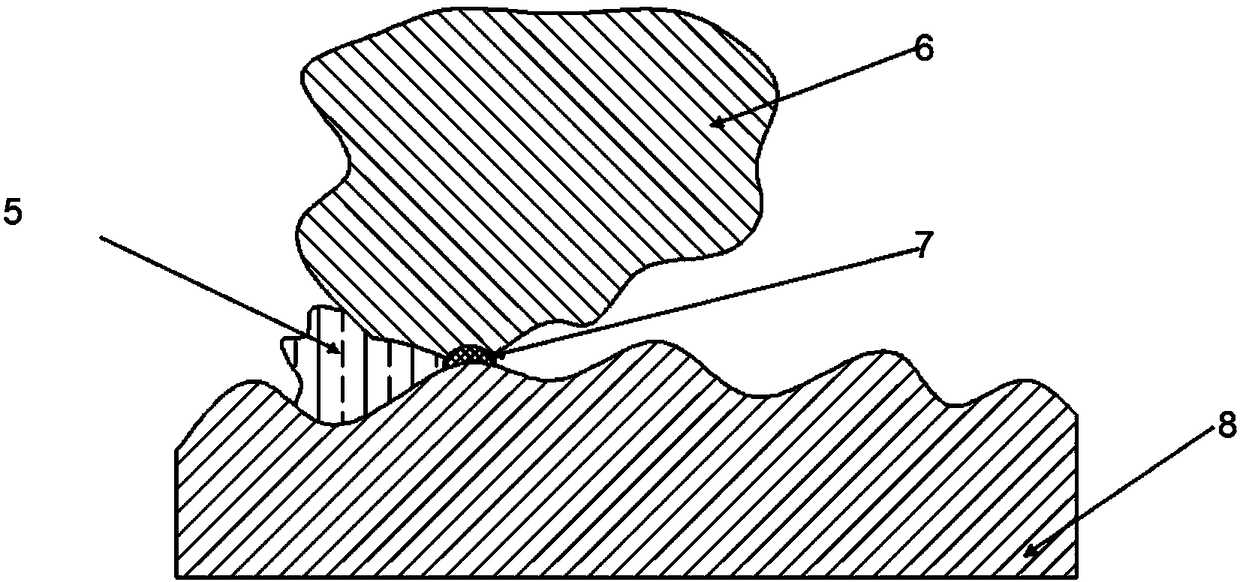

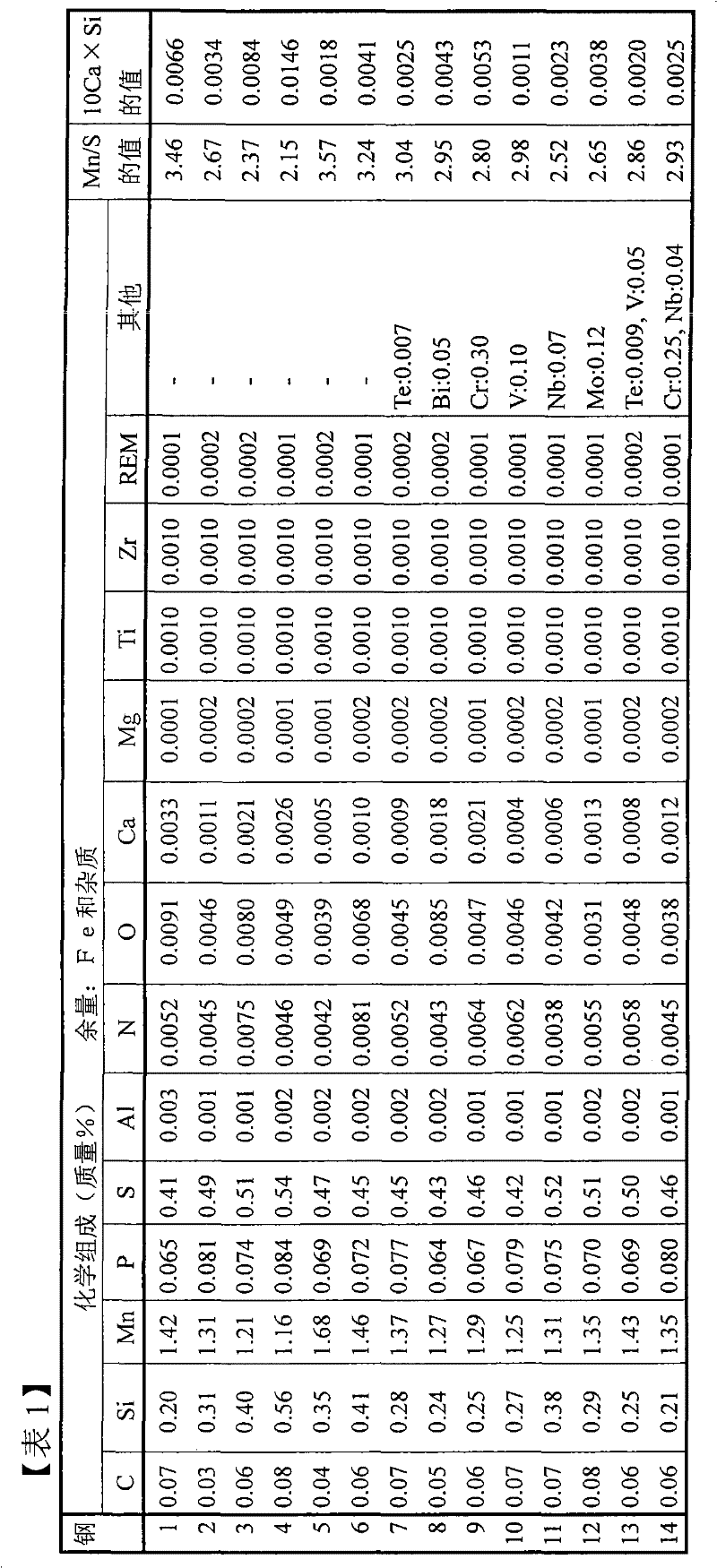

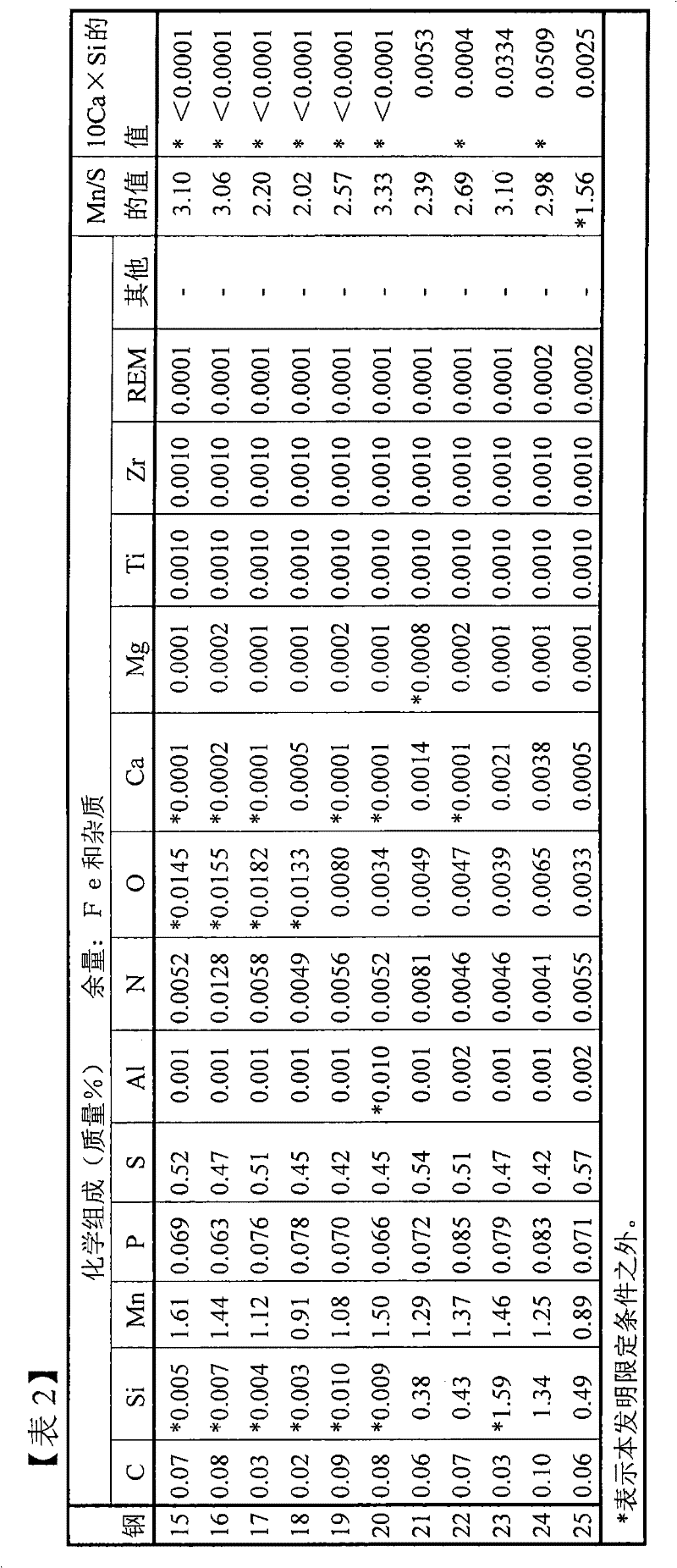

Low-carbon sulphur free-cutting steel

A low-carbon sulphur free-cutting steel which contains C: 0.02% to less than 0.20%, Si: more than 0.10% to 1.5%, Mn: 0.8 to 2.2%, P: 0.005 to 0.25%, S: more than 0.40% to 0.8%, O: <0.010%, N:<= 0.025%, and Ca: 0.0003 to 0.005% with the balance consisting of Fe and impurities and in which the impurities contain Al < 0.005%, Mg < 0.0003%, Ti <= 0.002%, Zr <= 0.002%, and REM < 0.0003% and the relationships: 2.0 < Mn / S < 4.0, and 0.0005 <= 10Ca x Si <= 0.050 are satisfied attains a smaller finished-surface roughness than that of conventional non-Pb low-carbon free -cutting steel and excellent chipdisposability in the finish cutting process by turning with a carbide tool. The low-carbon sulphur free-cutting steel may contain one or more of Te<=0.05%, Bi<=0.15%, and Sn<=0.5% and / or one or moreof Cr<=2.0%, Mo<=0.5%, V<=0.3%, and Nb<=0.3%.

Owner:NIPPON STEEL CORP

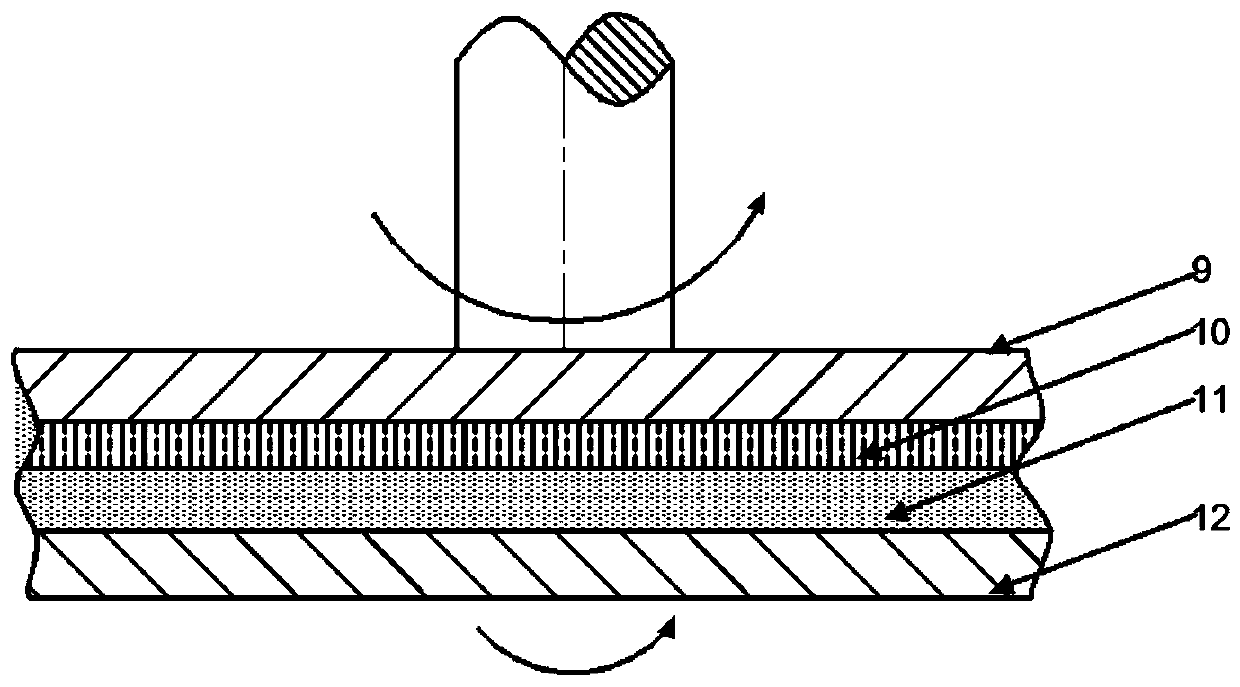

Neodymium compound containing soft grinding material fixing grinding tool for polishing sapphire wafer and manufacturing method of neodymium compound containing soft grinding material fixing grinding tool

ActiveCN108098569AMeet the requirements of polishingReduce the roughness of the machined surfaceGrinding devicesLapping toolsSapphire waferSilicon dioxide

The invention relates to a neodymium compound containing soft grinding material fixing grinding tool for polishing a sapphire wafer. Preparation raw materials of the neodymium compound containing softgrinding material fixing grinding tool comprise, by mass percent, 40%-60% of nanosilicon dioxide, 20%-40% of a binder, 10%-15% of a curing agent, 5%-10% of a neodymium compound and the balance deionized water. The invention provides a manufacturing method of the neodymium compound containing soft grinding material fixing grinding tool for polishing the sapphire wafer. The curing agent is added into the deionized water and is stirred to be dissolved, and then the binder, nanosilicon dioxide, the neodymium compound and the like are added and stirred uniformly; and the prepared materials are subjected to hot press forming in a mold, after demolding, thermocuring is completed, the upper end face and the lower end face are subjected to finishing, the flatness and parallelism of the upper end face and the lower end face of the grinding tool are guaranteed, and the neodymium compound containing soft grinding material fixing grinding tool is obtained. The removal rate of the sapphire wafer can be improved, roughness can be reduced, the processing efficiency can be improved, and the production cost can be reduced.

Owner:ZHEJIANG UNIV OF TECH

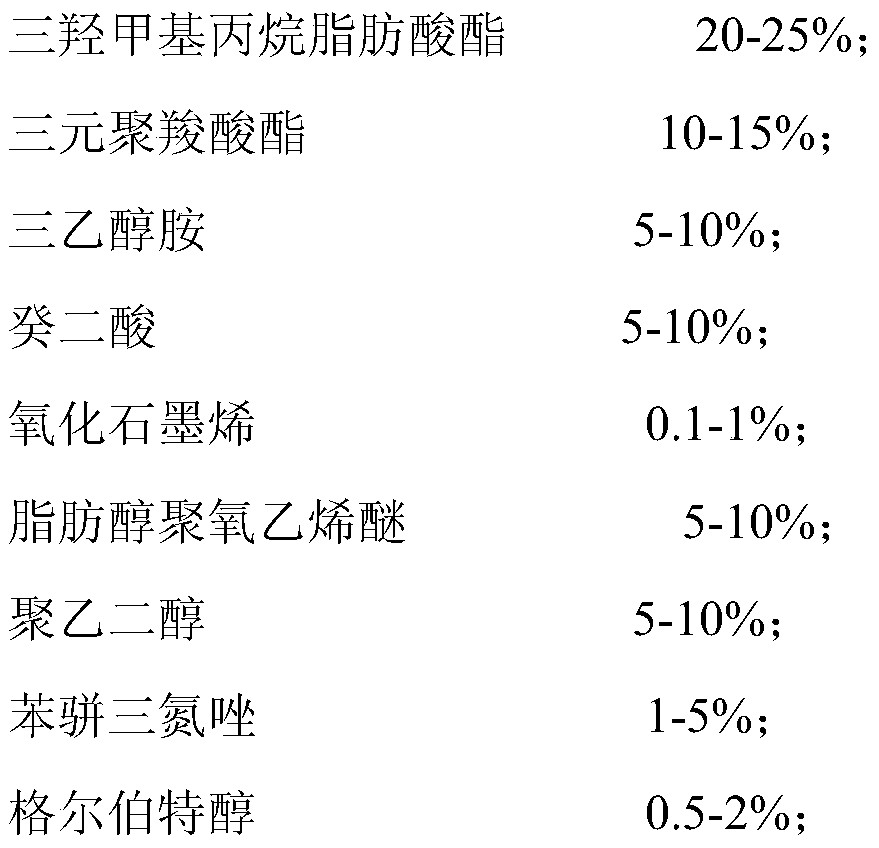

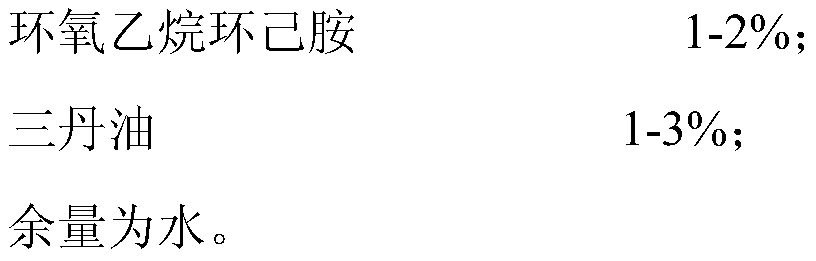

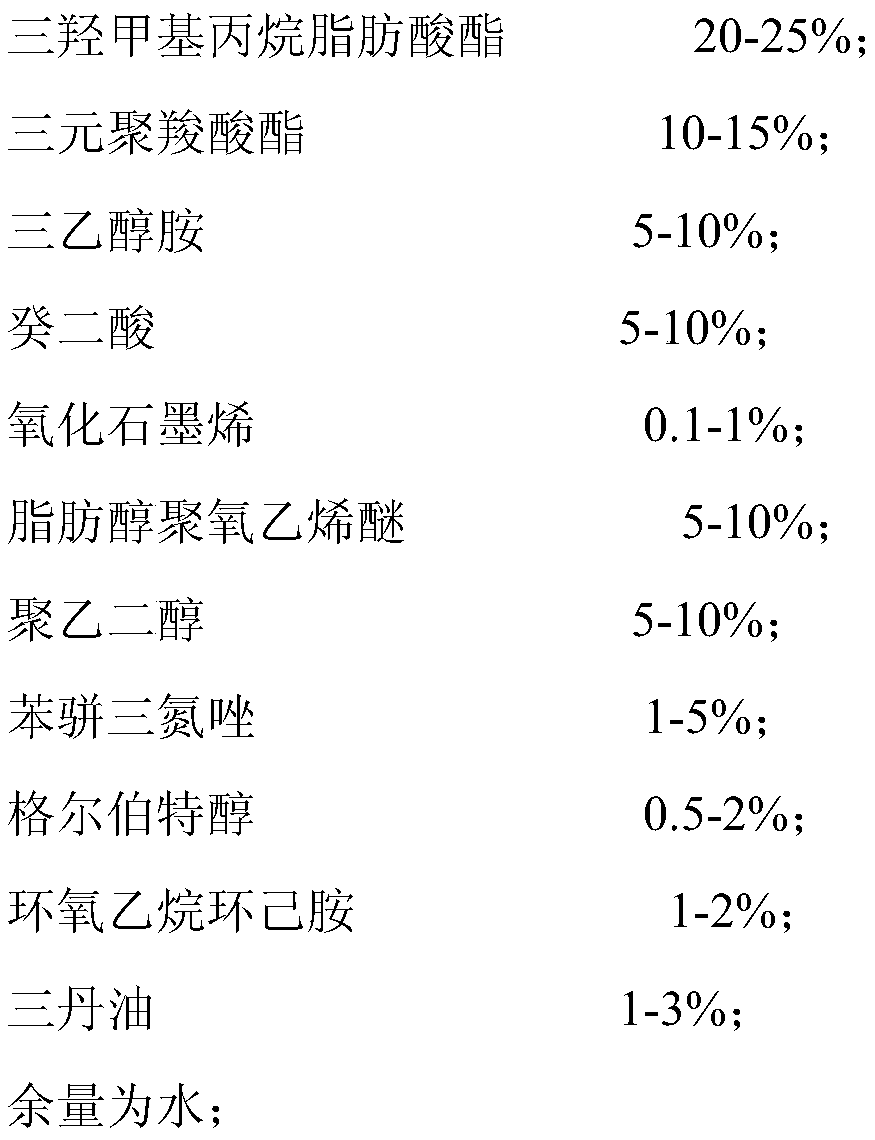

Cutting fluid and preparation method thereof

ActiveCN107011977AImprove lubrication performanceReduce the roughness of the machined surfaceLubricant compositionContrast mediumWater soluble

The invention discloses a cutting fluid and a preparation method thereof. The preparation method comprises the steps of mixing trimethylolpropane fatty acid ester, ternary polycarboxylate, sebacic acid, triethanolamine, guerbet alcohol, ethylene oxide cyclohexylamine and benzotriazole at the ratio, adding to water, stirring evenly, heating, reacting for a certain period of time to form a transparent solution and a solid without particles and preparing a water-soluble cutting fluid complex agent; and adding fatty alcohol-polyoxyethylene ether and starcide BK into the water-soluble cutting fluid complex agent, stirring at a uniform sped at room temperature for a certain period of time until the solution is transparent, adding graphene oxide, further stirring at a uniform sped at the room temperature till the solution is semitransparent, thus obtaining the cutting fluid containing the graphene oxide. The cutting fluid is green, environment-friendly and pollution-free in components and good in lubricating property.

Owner:UNIV OF JINAN

High temperature alloy chemical milling fluid and using method thereof

InactiveCN107723709AImprove processing efficiencyReduce the roughness of the machined surfaceEtchingMachined surface

The invention relates to the field of thermal machining, in particular to a machining method of chemical milling of a high temperature alloy. The machining method is characterized in that, the components and contents of high temperature alloy chemical milling fluid comprise, by mass, 65% of concentrated nitric acid with the concentration being 100-500 ml / L, 98% of concentrated sulfuric acid with the concentration being 100-300 ml / L, ferric sulfate with the concentration being 100-300 g / L, hexamethylene tetramine with the concentration being 2-20 g / L and the balance water. By adopting the method, chemical milling can be rapidly and stably conducted on a high temperature alloy part, and it is ensured that the machined surface of the high temperature alloy part is bright and clean, and the defects of over etching, filament line pits and the like do not exist.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

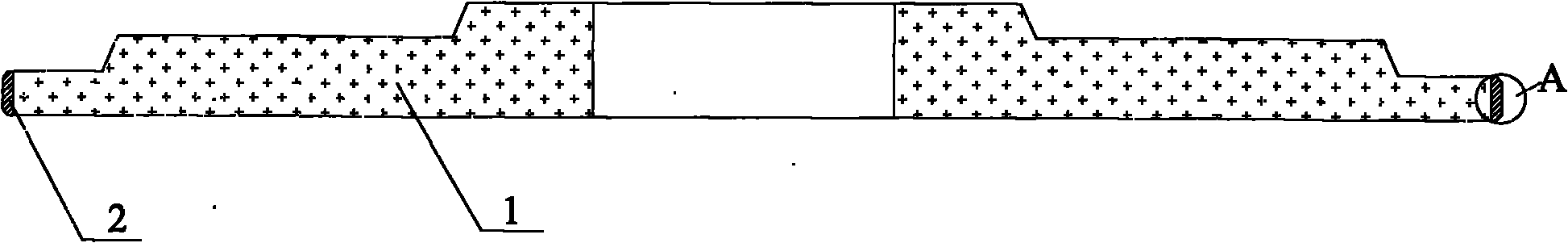

Novel superspeed point grinding wheel and grinding method thereof

The invention discloses a novel superspeed point grinding wheel and a grinding method thereof, wherein for the superspeed point grinding wheel, an inclination angle theta is arranged on a grinding wheel rough-grinding area so as to lead the contact form of the grinding wheel and a workpiece to have a change and be capable of saving the overall cost of the grinding wheel, and as grinding liquid is easier to enter a grinding plane, the abrasion of the grinding wheel is reduced, and the repair cost and difficulty can be decreased; the existence of the inclination angle theta more easily discharges cuttings out of the grinding area, the axis of the grinding wheel and the axis of the workpiece are in parallel in vertical direction when the grinding wheel is ground, the variable angle alpha belonging to (minus 0.5 degree to plus 0.5 degree) of the axis of the grinding wheel and the axis of the workpiece in horizontal direction can lead the cuttings when the grinding wheel is ground to have certain angles, thus reducing the grinding cuttings accumulation phenomenon.

Owner:巩亚东 +3

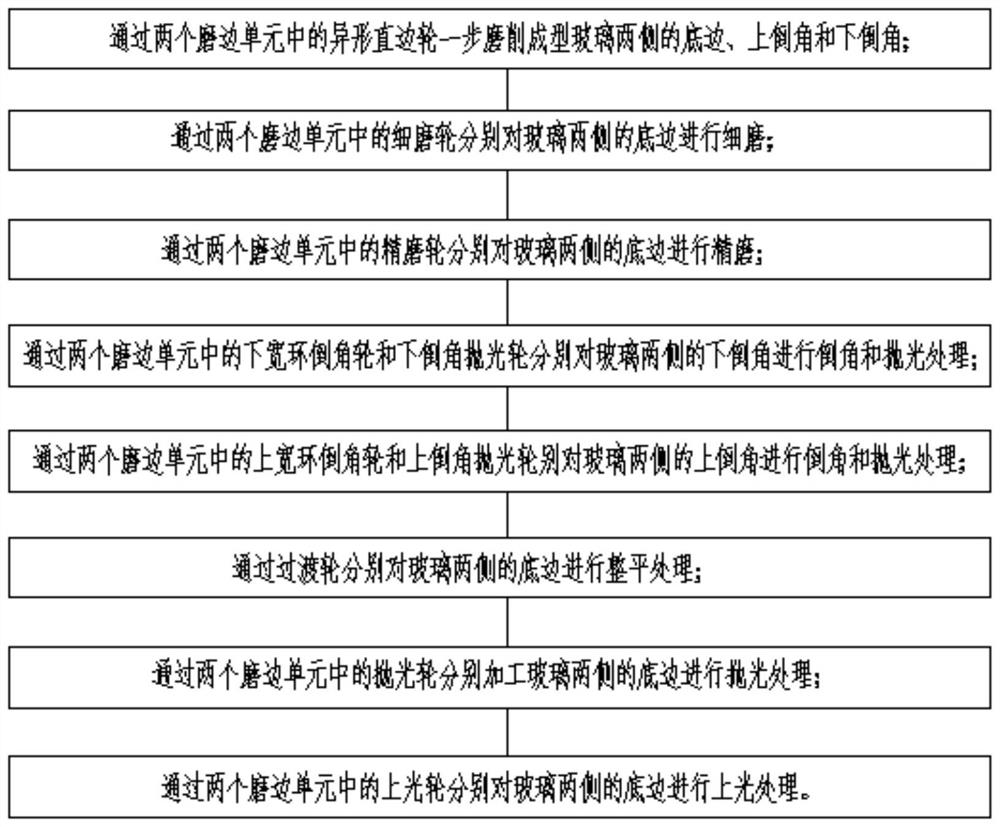

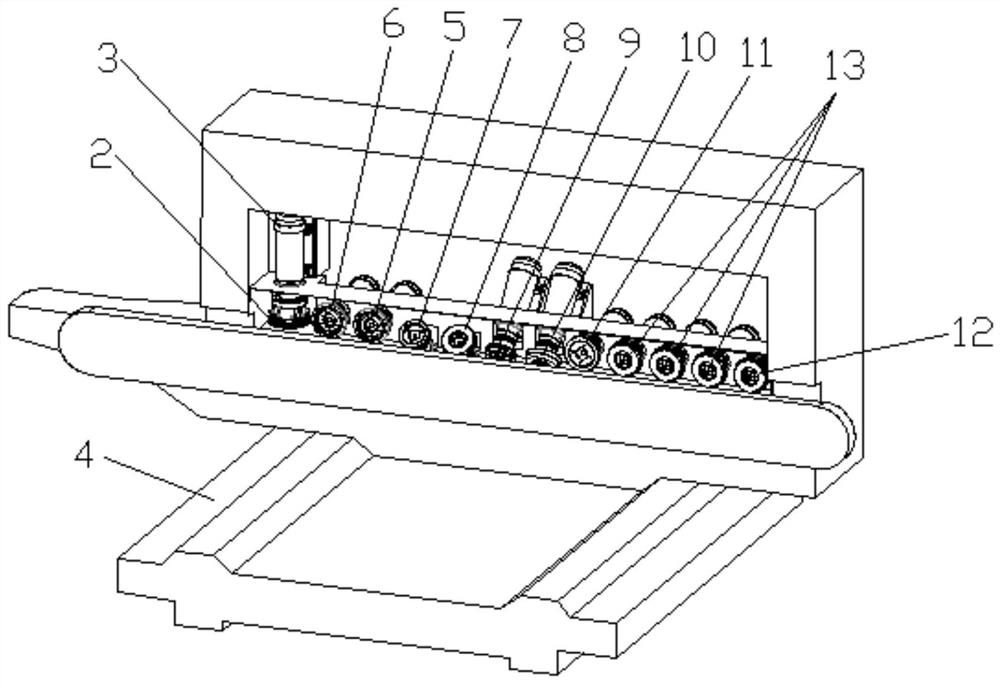

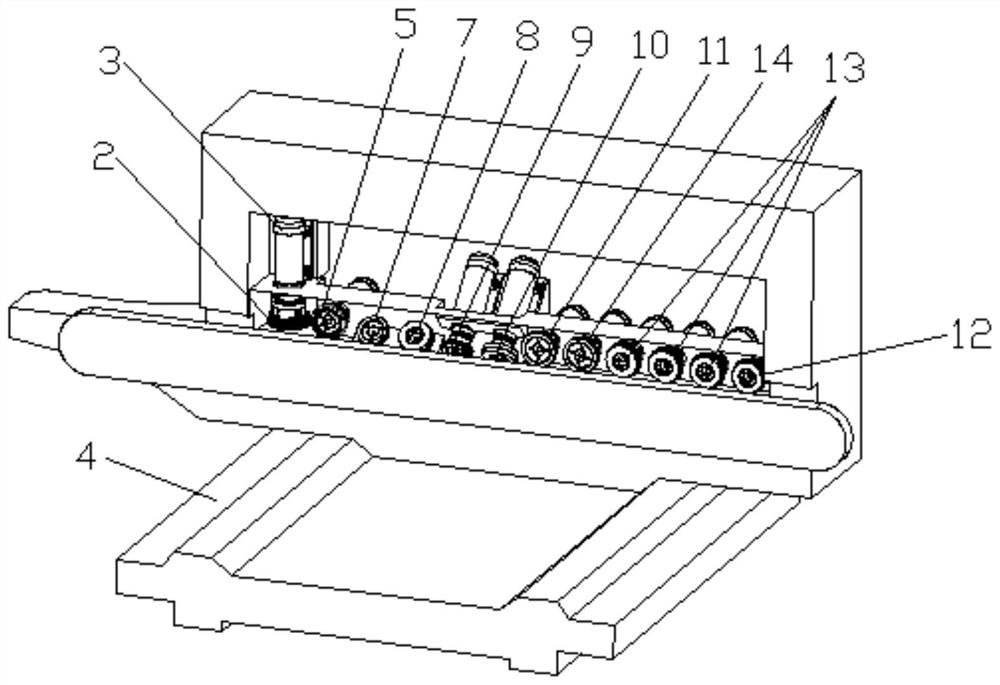

Efficient straight edge grinding method for glass and round and straight edge double-edge machine system

PendingCN114178929ALow costImprove efficient processing capabilitiesEdge grinding machinesPolishing machinesGrindingPolishing

The invention relates to an efficient straight edge grinding method for glass and a round and straight edge double-edge machine system. The method comprises the following specific steps that two grinding forming devices are used for machining and forming bottom edges, upper chamfers and lower chamfers on the two sides of the glass in one step; the two chamfering and polishing devices are used for machining an upper chamfer and a lower chamfer on the two sides of the glass correspondingly for chamfering and polishing treatment; and the two bottom edge polishing devices are used for polishing the bottom edges on the two sides of the glass correspondingly. The polishing machine has the beneficial effects that the design is reasonable, the rotating speed of the polishing machine can be properly increased, the grinding and polishing processes are integrated and optimized, the purpose of high-speed and high-efficiency straight edge grinding is achieved, glass edge cracking is avoided, the glass machining quality is guaranteed, and the market requirement is met.

Owner:宋京新 +1

Through silicon via copper film polishing solution

ActiveCN113789127AHigh speedHigh chelation efficiencyPolishing compositions with abrasivesGlycineMembrane surface

The invention relates to a through silicon via copper film polishing solution, which comprises an abrasive material, two or more chelating agents and a dish pit inhibitor, and is characterized in that the abrasive material is composed of large, medium and small particles mixed together according to a ratio, the particle size of the large particles is 70-120nm, the particle size of the medium particles is 50-80nm, the particle size of the small particles is 30-50nm, and the particles of the three grades are selected within the corresponding ranges according to an arithmetic progression mode during selection; and the chelating agent is a mixture of glycine and basic amino acid. In the CMP process, the polishing solution can quickly remove a copper film, and meanwhile, inhibit the step height between concave and convex platforms on the surface of the copper film.

Owner:博力思(天津)电子科技有限公司

Laser cutting equipment and its laser head

ActiveCN105436720BImprove verticalityImprove distribution uniformityLaser beam welding apparatusMachined surfaceLight beam

The invention relates to a laser cutting device and a laser head thereof. The laser head comprises an air inlet ring, a first rectifier tube, a second rectifier tube and an air nozzle. An annular groove is formed in the inner side of the air inlet ring, and air inlet holes communicated to the groove are formed in the outer side of the air inlet ring; ventilation holes are formed in the side wall of the first rectifier tube, the first rectifier tube is sleeved with the air inlet ring, and the ventilation holes are communicated with the groove; an air flow passage is formed inside the second rectifier tube, and the second rectifier tube comprises a first end and a second end which are opposite; the second rectifier tube is sleeved with the first rectifier tube, and a rectifying passage is formed between the first rectifier tube and the second rectifier tube; and an air outlet gap is formed between the first rectifier tube and the first end, and the air flow passage and the rectifying passage are communicated through the air outlet gap. Due to two times of rectifying, the airflow distribution evenness of cutting air can be improved, and the intensity of turbulence can be reduced, so that the influence of the pneumatic optical effect on a laser path is reduced, the stability of the quality of laser beams is guaranteed, the roughness of the machined surface is reduced, and the perpendicularity of cut lines is improved.

Owner:HANS LASER TECH IND GRP CO LTD

Low carbon sulfur free cutting steel

Owner:NIPPON STEEL CORP

Electrochemical machining method and device for oil nozzle spray orifice of diesel motor

InactiveCN102240835BControl processing rangeImprove machining accuracyElectrochemical machining apparatusElectrolytic agentInjector nozzle

The invention relates to an electrolytic machining method and device for the nozzle hole of a fuel injector of a diesel engine, which comprises the following steps: 1) pre-processing a cylindrical or forward tapered through hole on the workpiece of the fuel injector; The nozzle workpiece is set in an electrolyte circulation device, a tool electrode is clamped on an electrode feeding mechanism, the positive pole of an electrolytic machining power supply is connected to the nozzle workpiece, the negative pole is connected to the tool electrode, and the The electrolytic processing power supply, the electrode feeding mechanism and the liquid pump of the electrolyte circulation device are connected to an industrial computer through the drive circuit; 3) Start the liquid pump to inject the electrolyte into the through hole of the nozzle workpiece, and the electrolyte flows back from the liquid tank to the electrolysis 4) Turn on the electrolytic machining power supply, and the industrial computer controls the electrode feeding mechanism to drive the tool electrode to make a feeding movement, and at the same time controls the electrical signal parameters of the power supply, and performs electrolytic machining on the through hole until the through hole is completely closed. Processed into an inverted tapered nozzle hole with a circular arc transition zone; 5) Turn off the electrolytic machining power supply and liquid pump, and reset the tool electrode. The invention can be widely used in the processing of spray holes with various shapes.

Owner:TSINGHUA UNIV

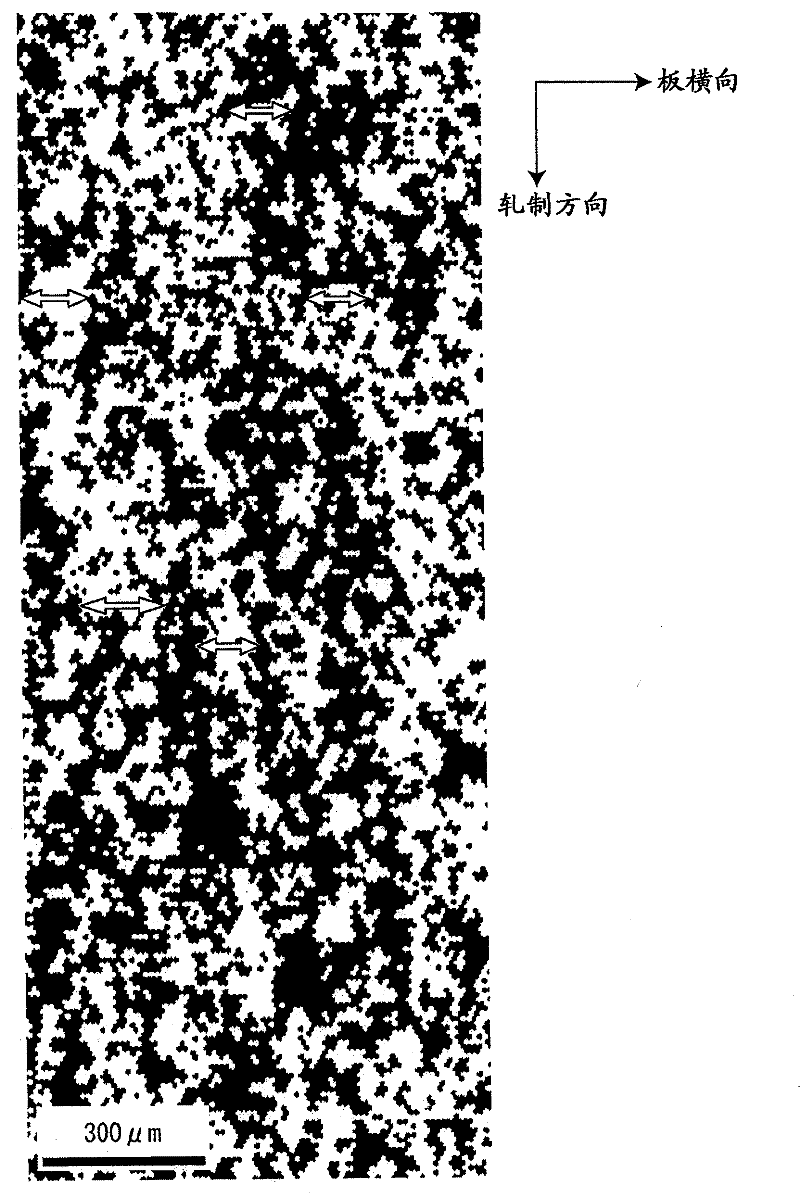

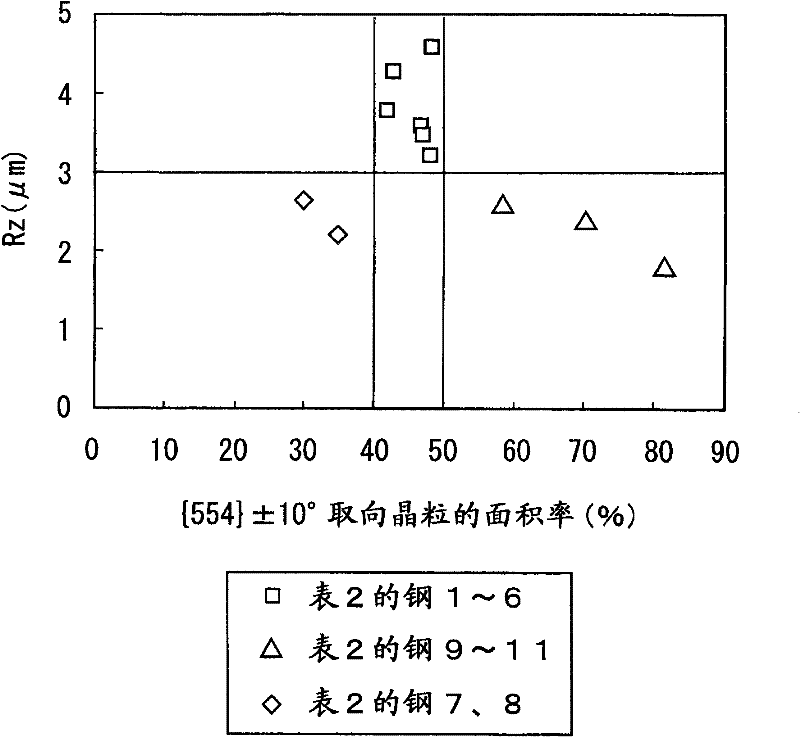

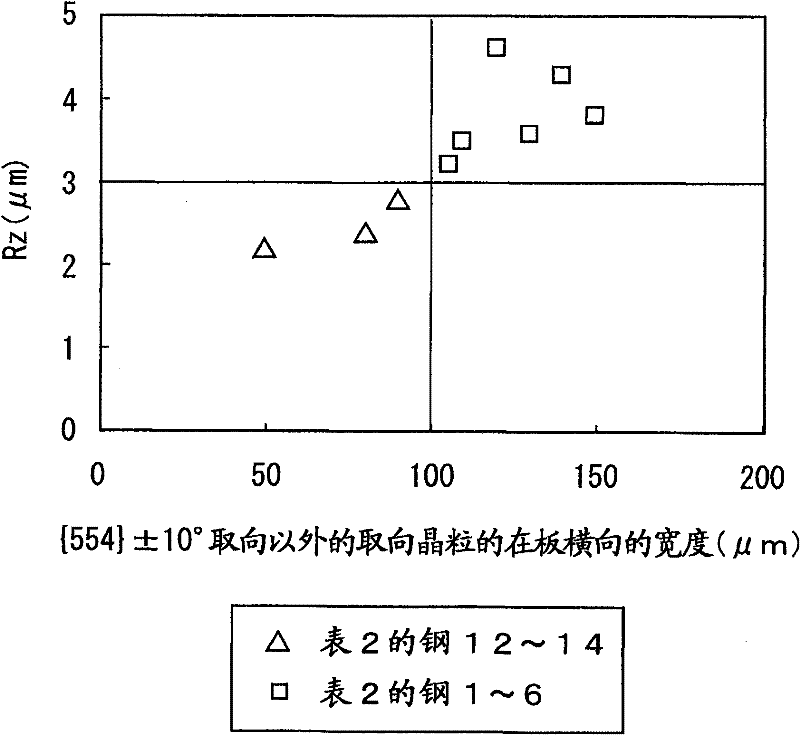

Ferritic stainless steel sheet causing little orange peel due to working and production method therefor

ActiveCN101671796BReduce the roughness of the machined surfaceStable manufacturingTemperature control deviceSurface roughnessSteel casting

The aim of the invention is to obtain a ferrite series stainless steel plate which has small roughness of machining surface and excellent formability. The task is to provide the ferrite series stainless steel plate with small roughness of machining surface through making the component and structure of steel satisfy an approximate range. Thus the annealing of hot rolled plate is saved for the ferrite series stainless steel plate, and a primary cold rolling with a rolling rate higher than 40% is performed. The intermediate annealing at the temperature of 750-900 DEG C is performed, and a final cold rolling with rolling rate high than 60% and a final annealing at the temperature of 750-1000 DEG C are performed. Therefore the area rate of the [554]+ / -10 DEG oriented crystal grain is more than50%. Additionally, the ferrite series stainless steel casting blank is heated to a temperature range of 1050-1200 DEG C. The starting temperature of hot rough rolling is set to 1000-1150 DEG C. A retention for more than five minutes is performed in hot coarse rolling at the temperature of 900-1100 DEG C. Afterwards, after hot fine rolling is performed, cold rolling-annealing is performed without performing annealing. Therefore the widths of the aligned crystal grains except for the alignment of [554]+ / -10 DEG are smaller than 100 mu m.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

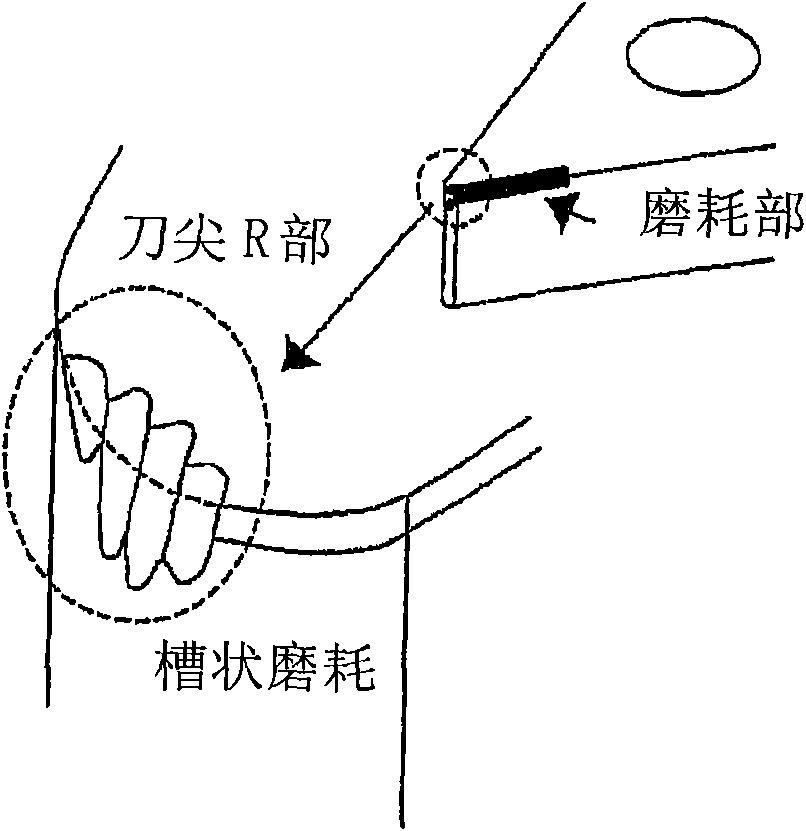

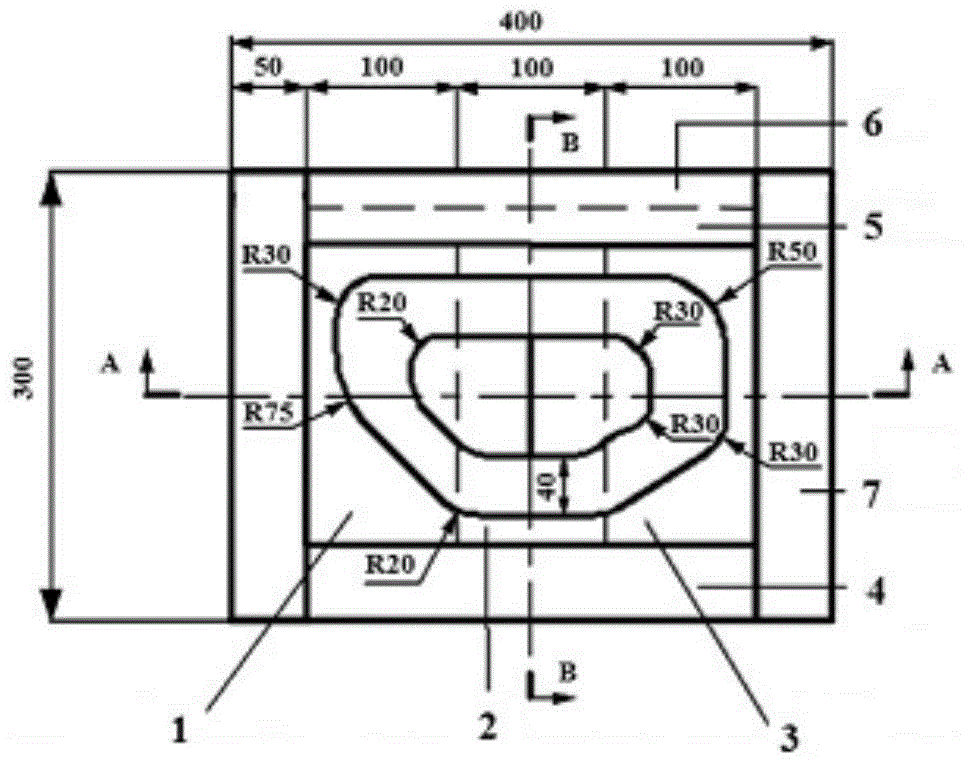

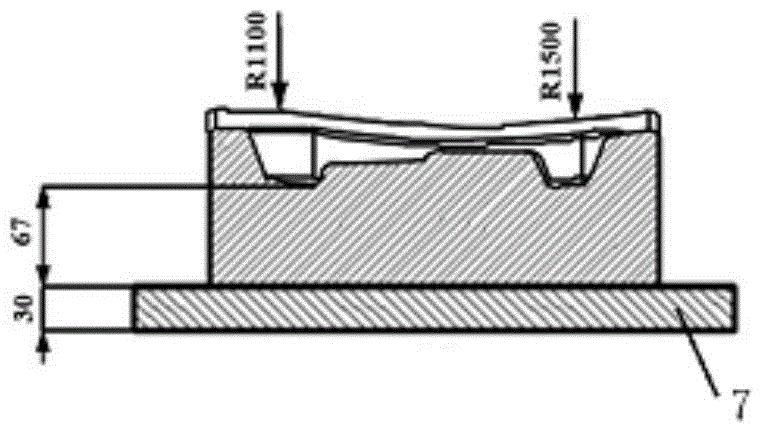

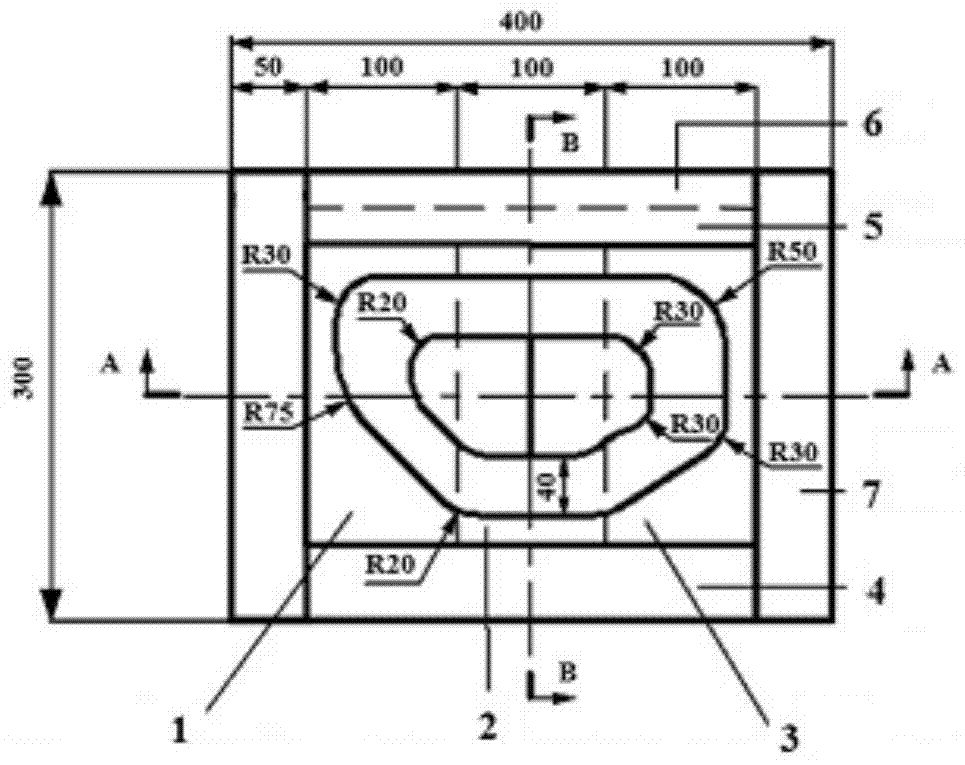

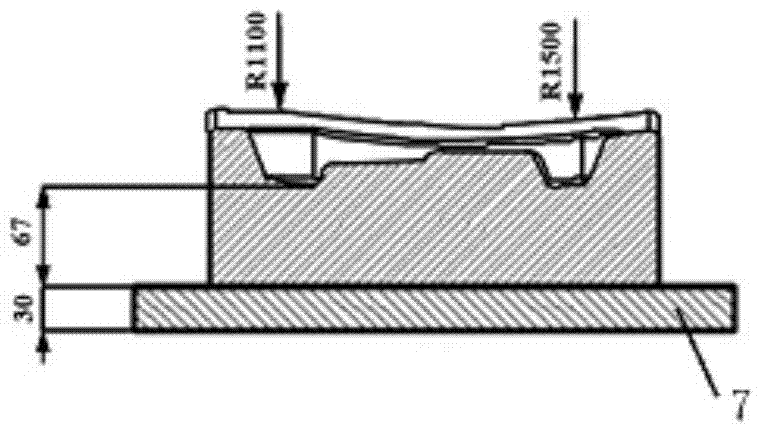

Quenched steel test piece, process detecting method, design method and vehicle door milling method

ActiveCN104942350AReduce processing timeReduce the roughness of the machined surfaceMeasurement/indication equipmentsMilling equipment detailsMachined surfaceMilling cutter

The invention relates to a quenched steel test piece, a process detecting method, a design method and a vehicle door milling method. A process design method for milling a multi-hardness spliced quenched steel mold with high speed solves the problem of process design collision caused by coorelation of multiple evaluation indexes in the prior art through a method of using a test piece for detecting and comprehensively evaluating. The detecting method uses the surface curvature of the test piece and the hardness change feature to detect a milling cutter, and solves the problem of difficult guarantee of the product surface quality. The test piece has the characteristics of multi-curvature change and multi-hardness part combination, and reduces the problem of damage of a mold profile caused by damage of the milling cutter. Through the difference between the rotating speed and the feeding speed, the vehicle door concave mold milling method shortens the machining time, reduces the cutter number, reduces the machined surface roughness, and improves the machining precision.

Owner:HARBIN UNIV OF SCI & TECH

A composite material tool electrode for electrodeposition electric discharge and its preparation method

ActiveCN103878455BHigh specific heat capacityHigh hardnessElectrical-based machining electrodesMachined surfaceThermal expansion

The invention discloses a composite material tool electrode for electrolytic deposition and electric spark and a preparation method of the composite material tool electrode, and belongs to the technical field of electrical discharge machining of electric spark. The composite material tool electrode for electrolytic deposition and electric spark is characterized by comprising, by weight, 16-18% of SiC particles, 14-16% of TiB2 particles, and the balance copper as a base body, and the SiC particles and the TiB2 particles are embedded in the base body. Due to the fact that the SiC particles and the TiB2 particles are added to the copper base body, compared with the method that only the SiC particles are added in the initial research stage, on the premise of not changing the total adding amount, the specific heat capacity of the tool electrode is improved by 10%, the coefficient of thermal expansion is lowered by 3%, the hardness is improved by 5%, and therefore the loss of the electrode under same electrical discharge machining parameters is lowered by 7%, and the roughness of a machined surface is lowered by 2%.

Owner:SHANDONG UNIV OF TECH

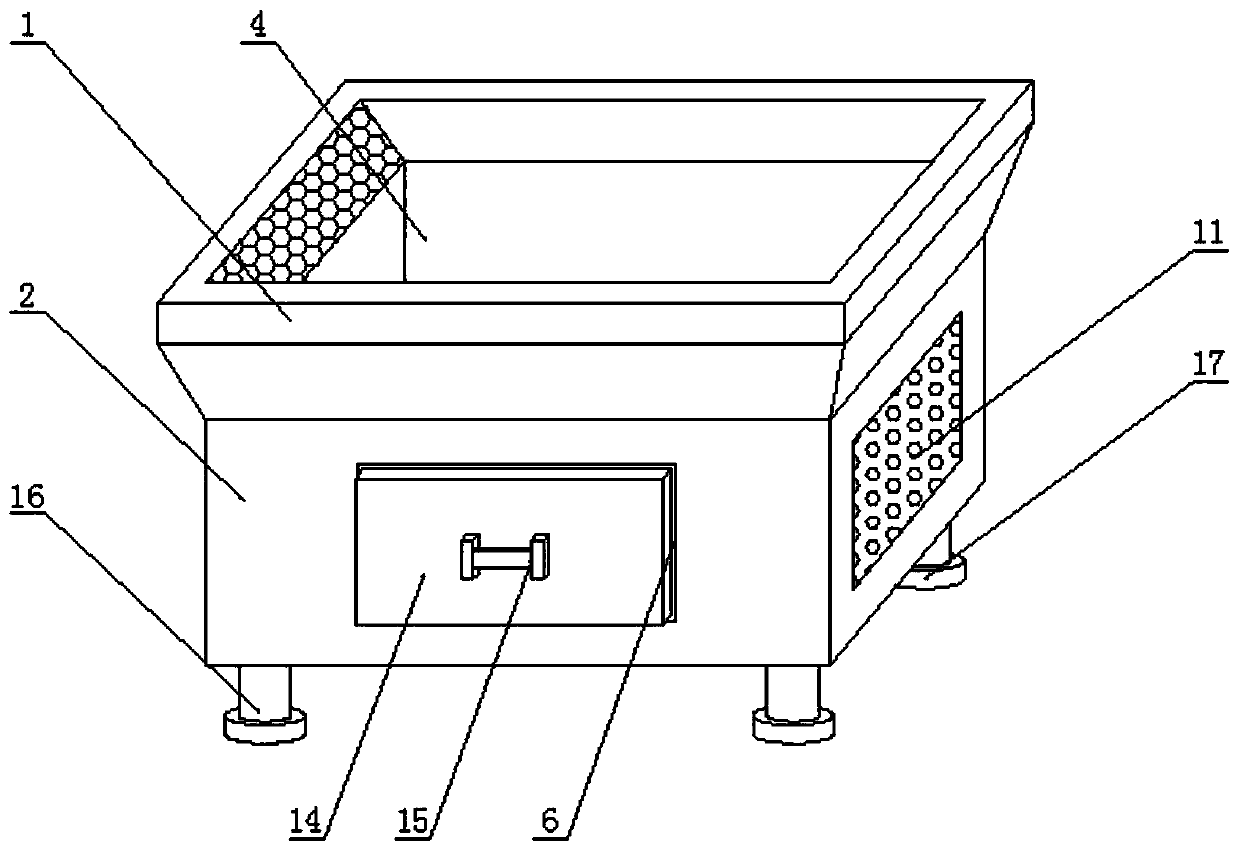

Large gear abrasive belt grinding machine

The invention provides a large gear adhesive belt tooth grinding machine, and relates to a large gear machining device. The large gear adhesive belt tooth grinding machine comprises a machine base, a stand column, a rotating working table, a servo motor, a ball screw I and a power head, and is characterized in that the rotating working table is assembled at one end of the upper portion of the machine base, the stand column is assembled at the other end of the upper portion of the machine base, the power head is assembled on the stand column through a swallow-tail-shaped guide rail I, the servo motor is assembled on the stand column and connected with the ball screw I on the power head so as to drive the power head to move up and down along the swallow-tail-shaped guide rail I, and the rotating working table is assembled on the machine base through the guide rail, connected with a rapid oil cylinder on the machine base and driven by the rapid oil cylinder to move leftward and rightward along the guide rail. The large gear adhesive belt tooth grinding machine has the advantages of being novel in structure, easy and convenient to machine, convenient to use, high in grinding efficiency, high in adaptability, high in machined product quality, short in auxiliary time and the like, and therefore the large gear adhesive belt tooth grinding machine is a novel large gear adhesive belt tooth grinding machine which integrates economical efficiency and practicability.

Owner:DALIAN JIAOTONG UNIVERSITY

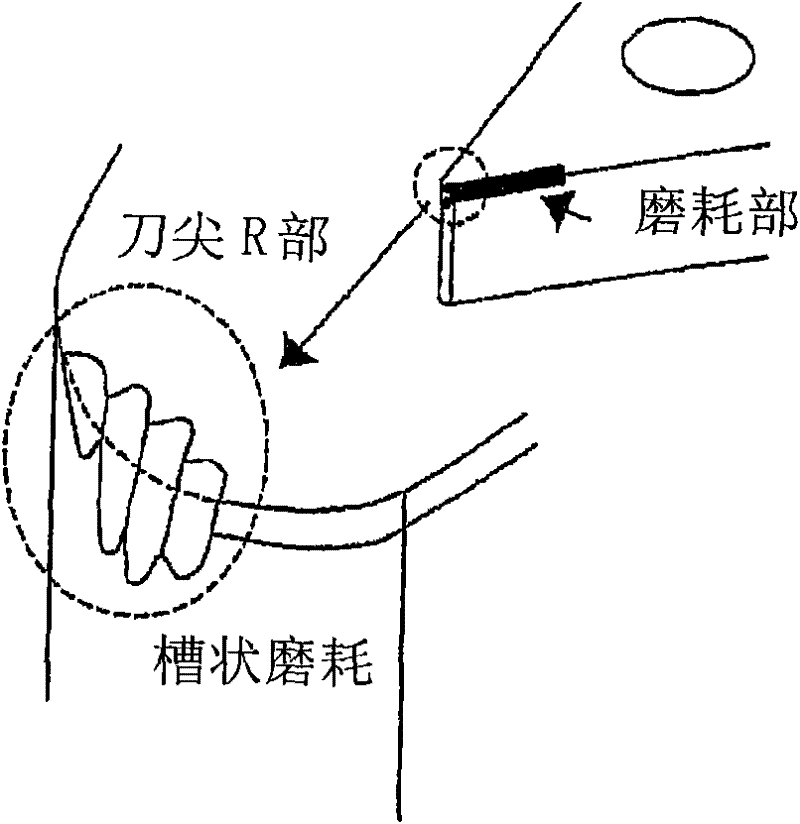

High-speed dry type roll-cutting process

PendingCN110181124AReduce thermal deformationReduce environmental pollutionMaintainance and safety accessoriesGear teethSwarfEngineering

The invention discloses a high-speed dry type roll-cutting process. The high-speed dry type roll-cutting process comprises the following steps: step S1, selecting a proper high-speed numerical-controlgear hobbing machine, selecting a proper cutting tool, checking various working data of the high-speed numerical-control gear hobbing machine in detail before roll-cutting and processing, ensuring ajoint connecting position of a power supply circuit to be free of a loosening condition, and enabling the high-speed numerical-control gear hobbing machine to normally work; and step S2, clamping andfixing a workpiece to be subjected to roll-cutting processing onto a claw disc of the high-speed numerical-control gear hobbing machine through an automatic clamp, determining selected cutting conditions during roll-cutting before dry type cutting, and inputting parameters of high-speed dry type roll-cutting into the high-speed numerical-control gear hobbing machine, wherein a roll-cutting schemeis a high-speed dry-cutting rolling gear, and the gear is a dry-cutting inclined gear. The high-speed dry type roll-cutting process reduces environmental pollution, avoids a condition that cuttings are adhered on a knife, facilitates reducing roughness of a workpiece processing surface, shortens cutting and processing work-hour, improves production efficiency, and reduces processing cost.

Owner:JIANGSUSNGCHI GROUP

A kind of cutting fluid and preparation method thereof

ActiveCN107011977BImprove the lubrication effectImprove practicalityLubricant compositionCyclohexylaminesPolyethylene glycol

The invention discloses a cutting fluid and a preparation method thereof. The preparation method comprises the steps of mixing trimethylolpropane fatty acid ester, ternary polycarboxylate, sebacic acid, triethanolamine, guerbet alcohol, ethylene oxide cyclohexylamine and benzotriazole at the ratio, adding to water, stirring evenly, heating, reacting for a certain period of time to form a transparent solution and a solid without particles and preparing a water-soluble cutting fluid complex agent; and adding fatty alcohol-polyoxyethylene ether and starcide BK into the water-soluble cutting fluid complex agent, stirring at a uniform sped at room temperature for a certain period of time until the solution is transparent, adding graphene oxide, further stirring at a uniform sped at the room temperature till the solution is semitransparent, thus obtaining the cutting fluid containing the graphene oxide. The cutting fluid is green, environment-friendly and pollution-free in components and good in lubricating property.

Owner:UNIV OF JINAN

A fixed abrasive tool containing neodymium compound soft abrasive for polishing sapphire wafer and its manufacturing method

ActiveCN108098569BMeet the requirements of polishingReduce the roughness of the machined surfaceGrinding devicesLapping toolsWaferingSapphire wafer

The invention relates to a neodymium compound containing soft grinding material fixing grinding tool for polishing a sapphire wafer. Preparation raw materials of the neodymium compound containing softgrinding material fixing grinding tool comprise, by mass percent, 40%-60% of nanosilicon dioxide, 20%-40% of a binder, 10%-15% of a curing agent, 5%-10% of a neodymium compound and the balance deionized water. The invention provides a manufacturing method of the neodymium compound containing soft grinding material fixing grinding tool for polishing the sapphire wafer. The curing agent is added into the deionized water and is stirred to be dissolved, and then the binder, nanosilicon dioxide, the neodymium compound and the like are added and stirred uniformly; and the prepared materials are subjected to hot press forming in a mold, after demolding, thermocuring is completed, the upper end face and the lower end face are subjected to finishing, the flatness and parallelism of the upper end face and the lower end face of the grinding tool are guaranteed, and the neodymium compound containing soft grinding material fixing grinding tool is obtained. The removal rate of the sapphire wafer can be improved, roughness can be reduced, the processing efficiency can be improved, and the production cost can be reduced.

Owner:ZHEJIANG UNIV OF TECH

Hardened steel test piece, process testing method, design method, door milling method

ActiveCN104942350BReduce processing timeReduce the roughness of the machined surfaceMeasurement/indication equipmentsMilling equipment detailsMilling cutterMachined surface

Owner:HARBIN UNIV OF SCI & TECH

Soft abrasive fixing mould of polished tantalum-lithium wafer and manufacturing method of soft abrasive fixing mould

InactiveCN108081157ALow processing roughnessImprove processing qualityOther chemical processesAbrasion apparatusNanometreHot pressing

Disclosed is a soft abrasive fixing mould of a polished tantalum-lithium wafer and a manufacturing method of the soft abrasive fixing mould. The soft abrasive fixing mould comprises 40-60% of nano-silica, 20-40% of binder, 10-15% of curing agent, 5-10% of oxidant, 10-15% of deionized water and 5-10% of alkaline PH regulator. The manufacturing method of the soft abrasive fixing mould of the polished tantalum-lithium wafer comprises the steps that the curing agent is added into in the deionized water, stirring is conducted to make the curing agent dissolve, then the binder, nano-silica, the oxidant and the alkaline ph regulator are added, and even stirring is conducted; the prepared ingredients are hot-formed in the mould, and hot curing is completed after demoulding; and the upper and lowerend surfaces of the mould are trimmed, and the smoothness and parallelism of the upper and lower end surfaces of the mould are ensured. The soft abrasive fixing mould is good in processing surface quality, high in processing efficiency and low in production cost.

Owner:ZHEJIANG UNIV OF TECH

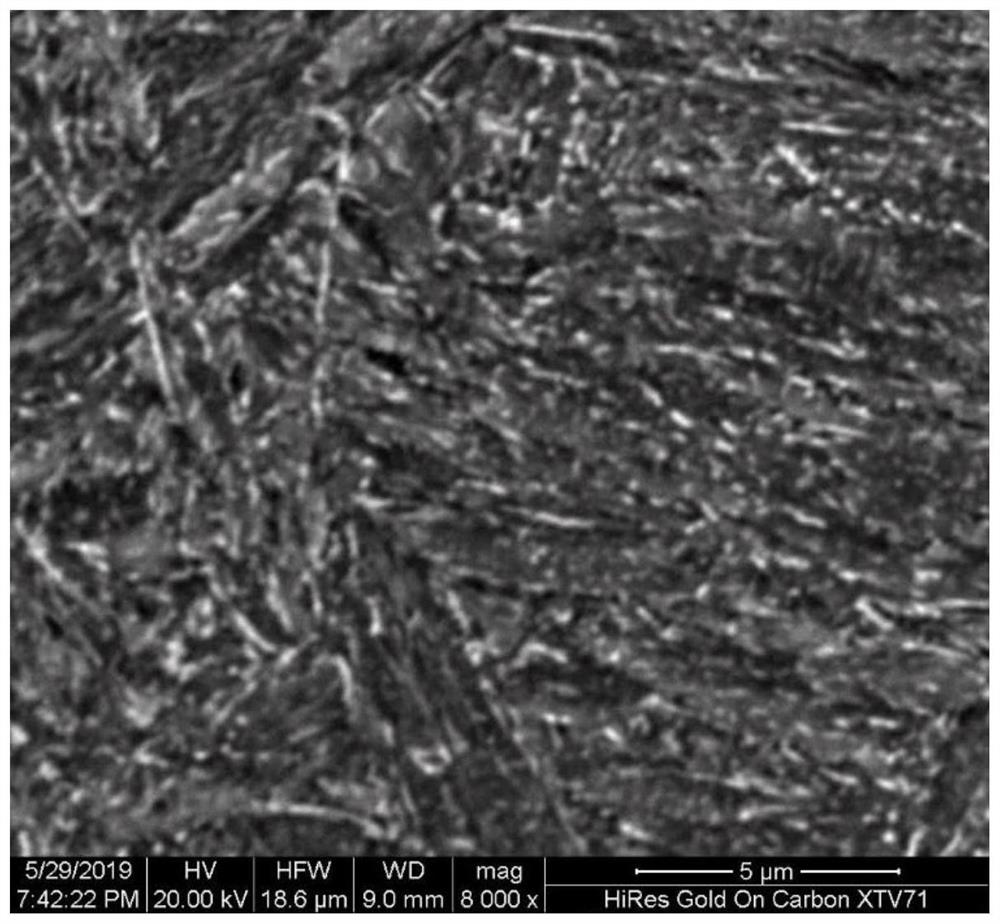

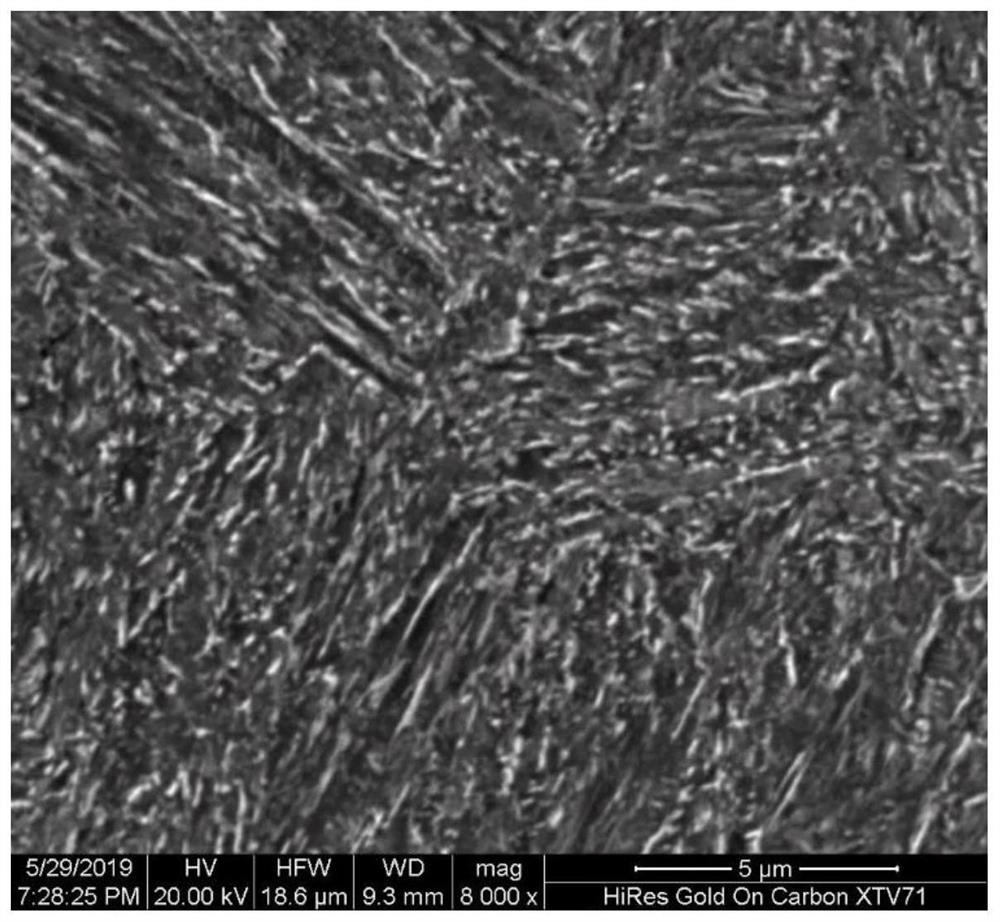

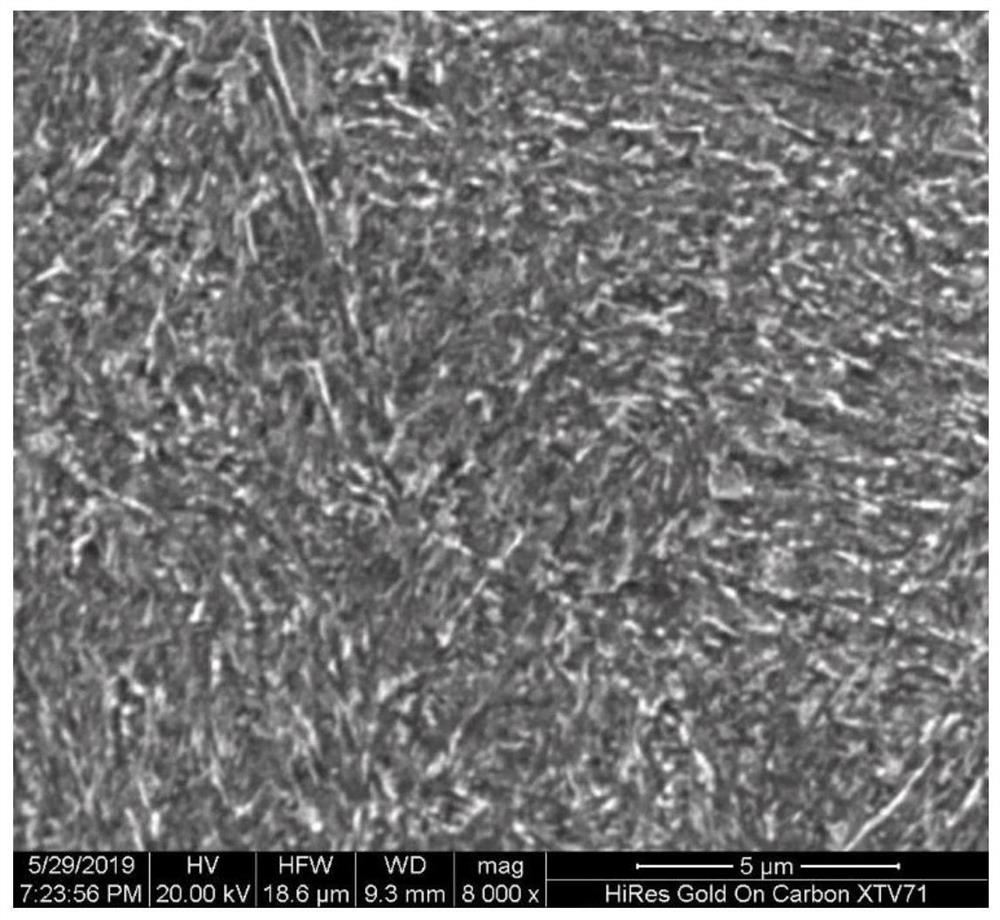

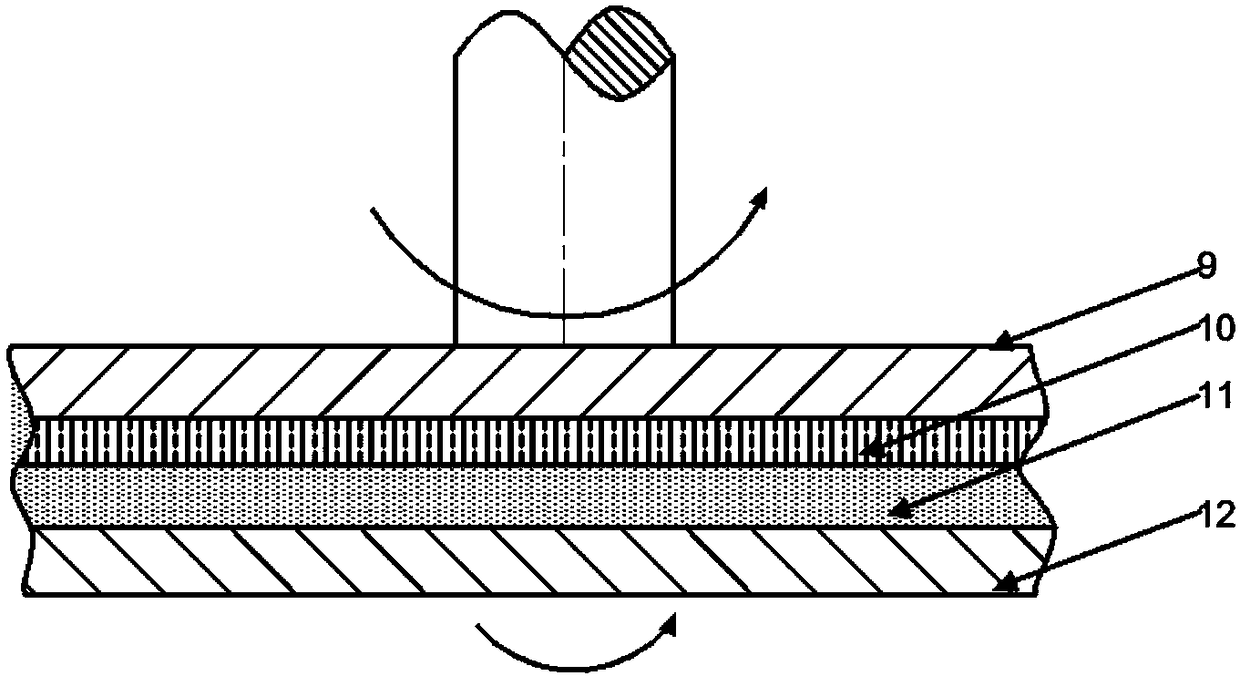

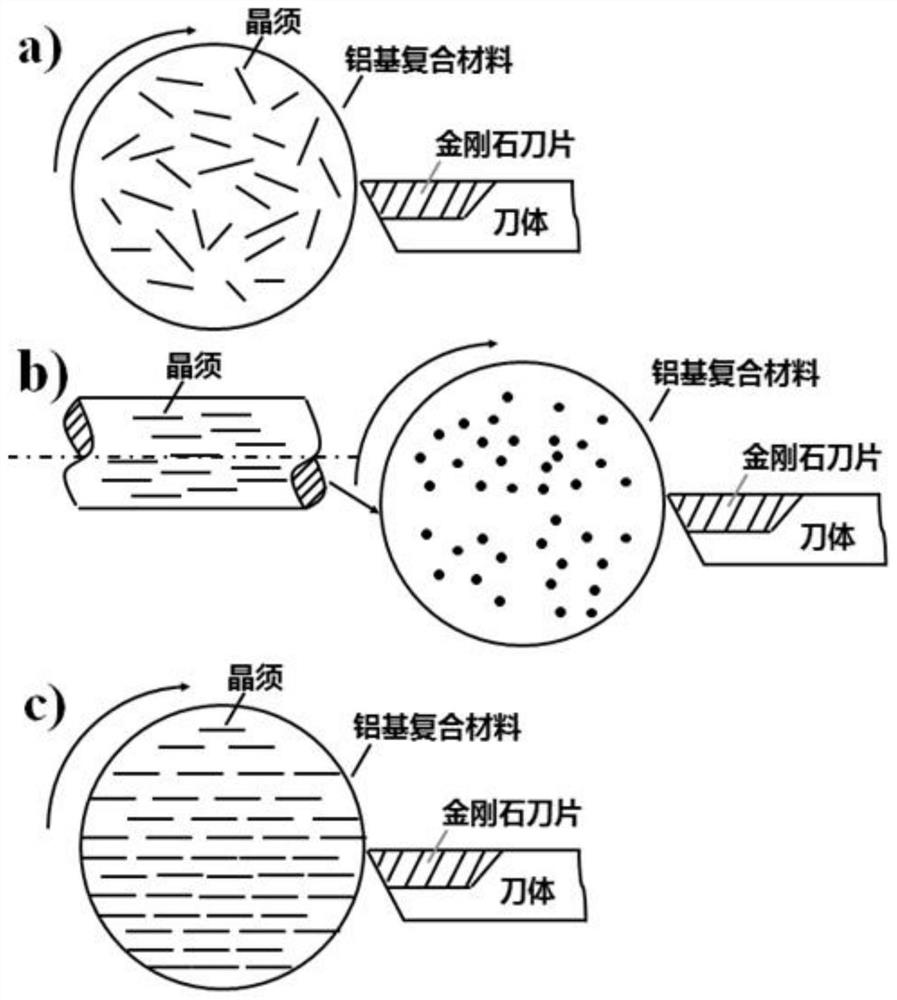

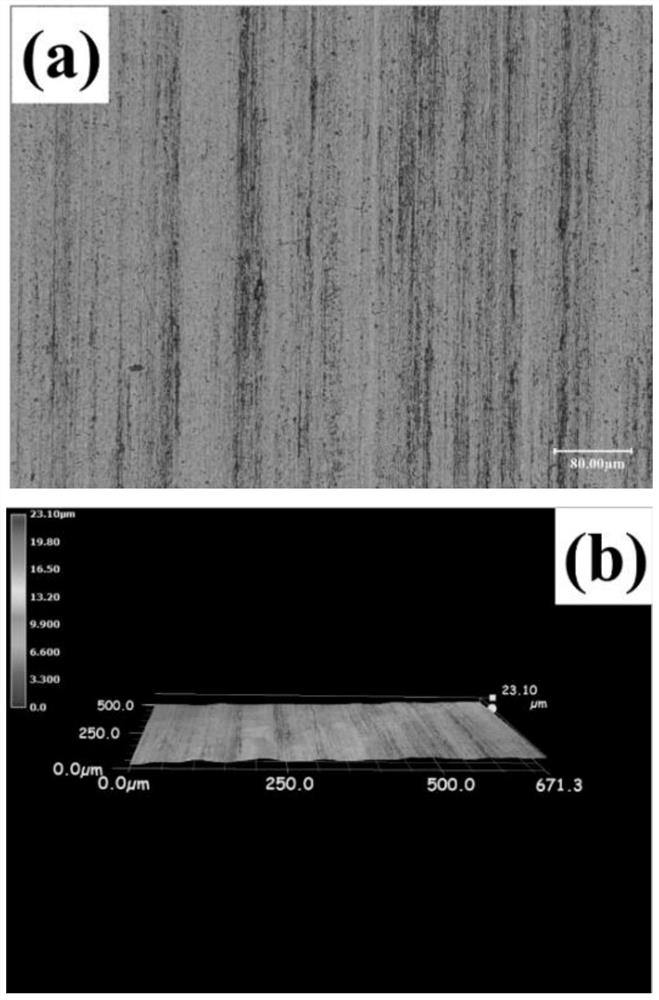

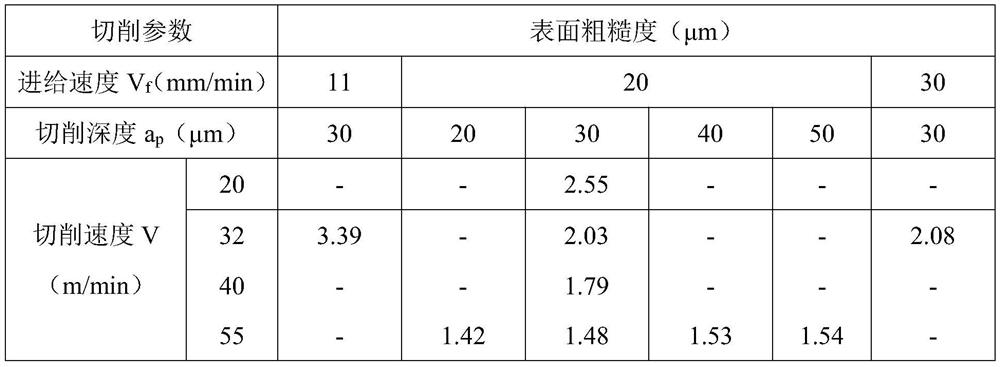

A kind of turning processing method of silicon carbide whisker reinforced aluminum matrix composite material

ActiveCN109676154BReduce formationImprove service performanceMachined surfacePolycrystalline diamond

The invention discloses a turning processing method of silicon carbide whisker-reinforced aluminum-based composite materials, and relates to a turning processing method of composite materials. The invention adopts a single crystal diamond turning tool or a polycrystalline diamond blade. Before turning, the corresponding diamond blade is assembled on the On matching tool holders; turning silicon carbide whisker reinforced aluminum matrix composites under the action of lubricating fluid and coolant. The invention uses kerosene as lubricating and cooling fluid to reduce the formation of scales and reduce the roughness of the machined surface. Through the combination of specific parameters, the cutting residual stress is reduced and the service performance of components is improved.

Owner:HARBIN INST OF TECH

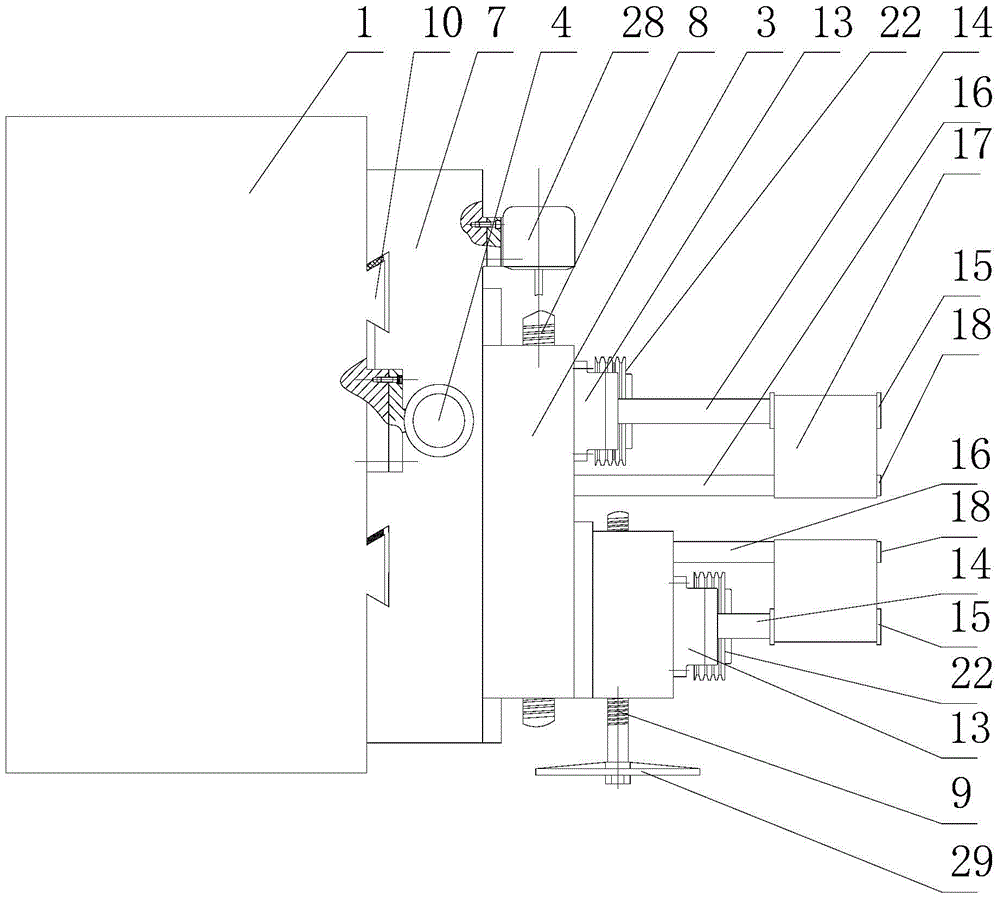

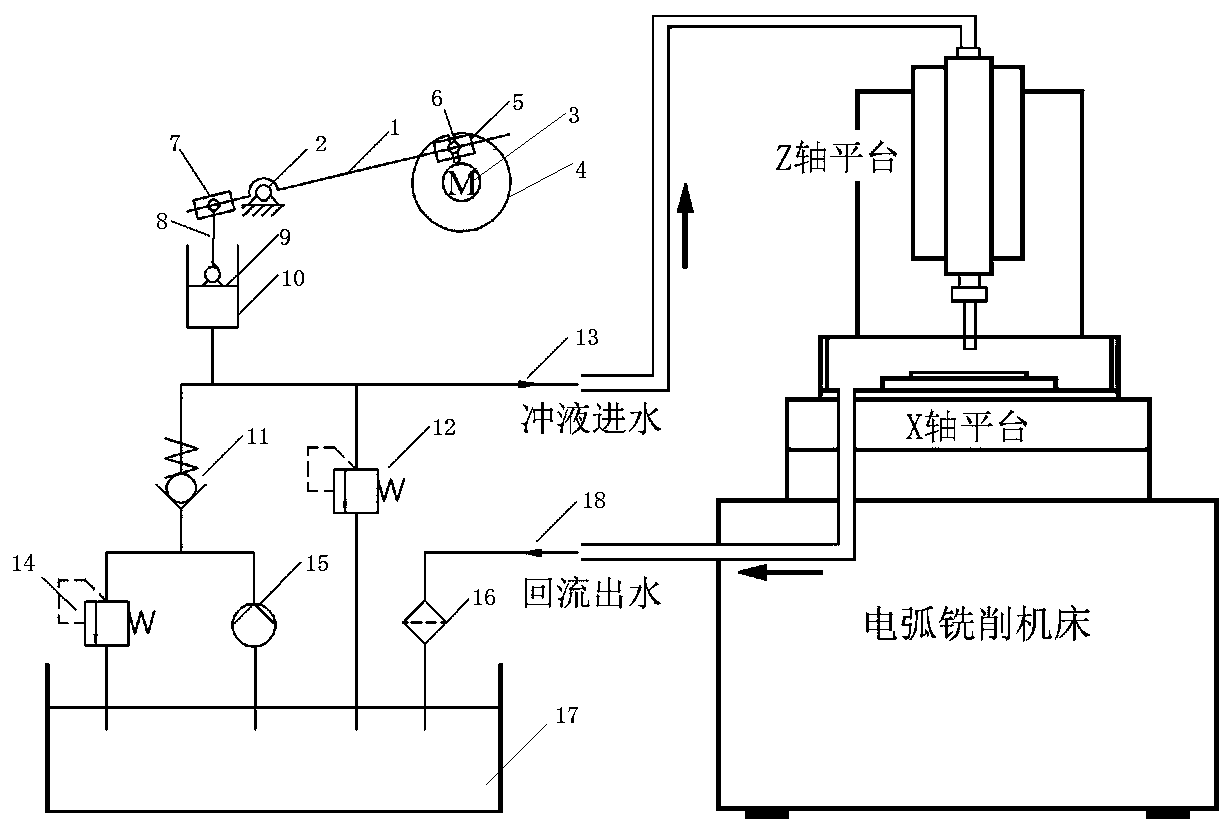

A Fluid Vibration System for Fluid Influx in Auxiliary Arc Milling

ActiveCN106984885BFast processingImprove machined surface qualityServomotorsWelding accessoriesVibration amplitudeEngineering

The invention discloses an internal liquid-flushing fluid vibration system for assisting in electric arc milling. The internal liquid-flushing fluid vibration system for assisting in electric arc milling comprises a vibration system and a liquid-flushing system; the vibration system is connected with the liquid-flushing system; a driving device is fixedly arranged at the one end of a lever; a servo motor is connected with a servo motor wheel; a groove is formed in the servo motor wheel; a hinge on a driving sliding block is fastened on the groove of the servo motor wheel; the driving sliding block is arranged at one end of the lever in a sliding way; a driven sliding block is arranged at the other end of the lever in a sliding way; the driven sliding block is connected with one end of a connecting rod; the other end of the connecting rod is connected with a piston hinge; a piston is arranged in a water jar and moves up and down along the water jar; the bottom of the water communicates an outlet of a parallel pipeline of a one-way valve and a first overflow valve; the outlet of the parallel pipeline of the one-way valve and the first overflow valve communicates with a water inlet pipe; and the other end of the one-way valve communicates with an outlet of a parallel pipeline of a second overflow valve and a water pump. The internal liquid-flushing fluid vibration system for assisting in electric arc milling realizes high-speed and high-surface-quality electric arc processing by adjusting the vibration frequency of the liquid-flushing fluid and adjusting vibration amplitude and pressure intensity.

Owner:宁波科锐电子商务有限公司

A kind of bismuth-containing free-cutting pre-hardened plastic mold steel and its preparation method

ActiveCN112030073BDoes not affect isotropyReduce wearMetal-working apparatusChemical compositionTempering

The invention discloses a bismuth-containing free-cutting pre-hardened plastic mold steel and a preparation method thereof. The chemical composition of the mold steel is as follows according to mass percentage: C: 0.32-0.40%, Si: 0.15-0.30%, Mn: 1.50-1.70 %, Cr: 1.70~2.00%, Ni: 0.85~1.15%, Mo: 0.25~0.40%, P≤0.015%, S≤0.005%, V: 0.05~0.10%, Bi: 0.05~0.15%, and the balance is Fe; its preparation method includes: smelting and casting into ingots according to the set chemical composition, forging the ingots into forging billets after high-temperature homogenization treatment, performing offline normalizing treatment to refine grains after forging, and finally undergoing quenching and tempering heat treatment, A uniform structure with a hardness of 32-48HRC is obtained. The bismuth-containing easy-cutting pre-hardened plastic mold steel of the present invention, through reasonable chemical composition design, adds bismuth element to replace the traditional easy-cutting elements sulfur and lead. It solves the thermal embrittlement phenomenon and the anisotropy caused by sulfur, and at the same time solves the problem that lead is harmful to the human body and pollutes the environment.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com