A kind of cutting fluid and preparation method thereof

A technology of cutting fluid and ternary polycarboxylate, applied in lubricating compositions, petroleum industry, etc., can solve problems such as water eutrophication, red tide, poor biodegradability of phenol, hazards, etc., achieve wear spot diameter reduction, friction coefficient The effect of reducing and reducing the roughness of the processed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

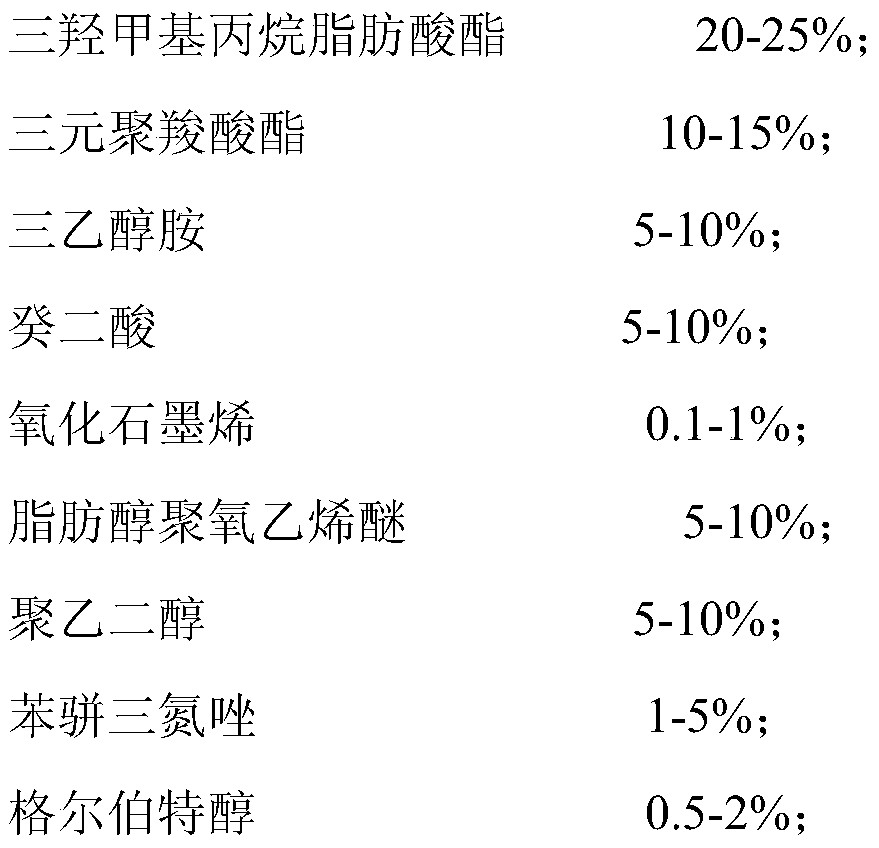

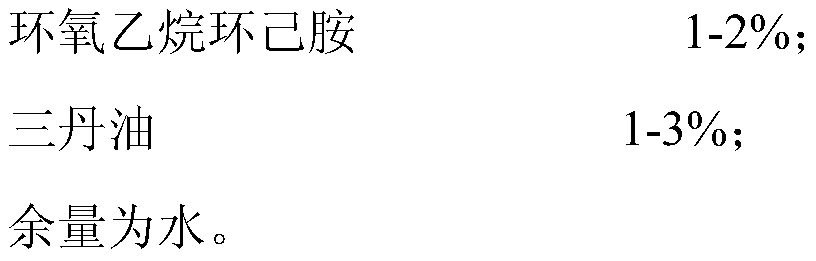

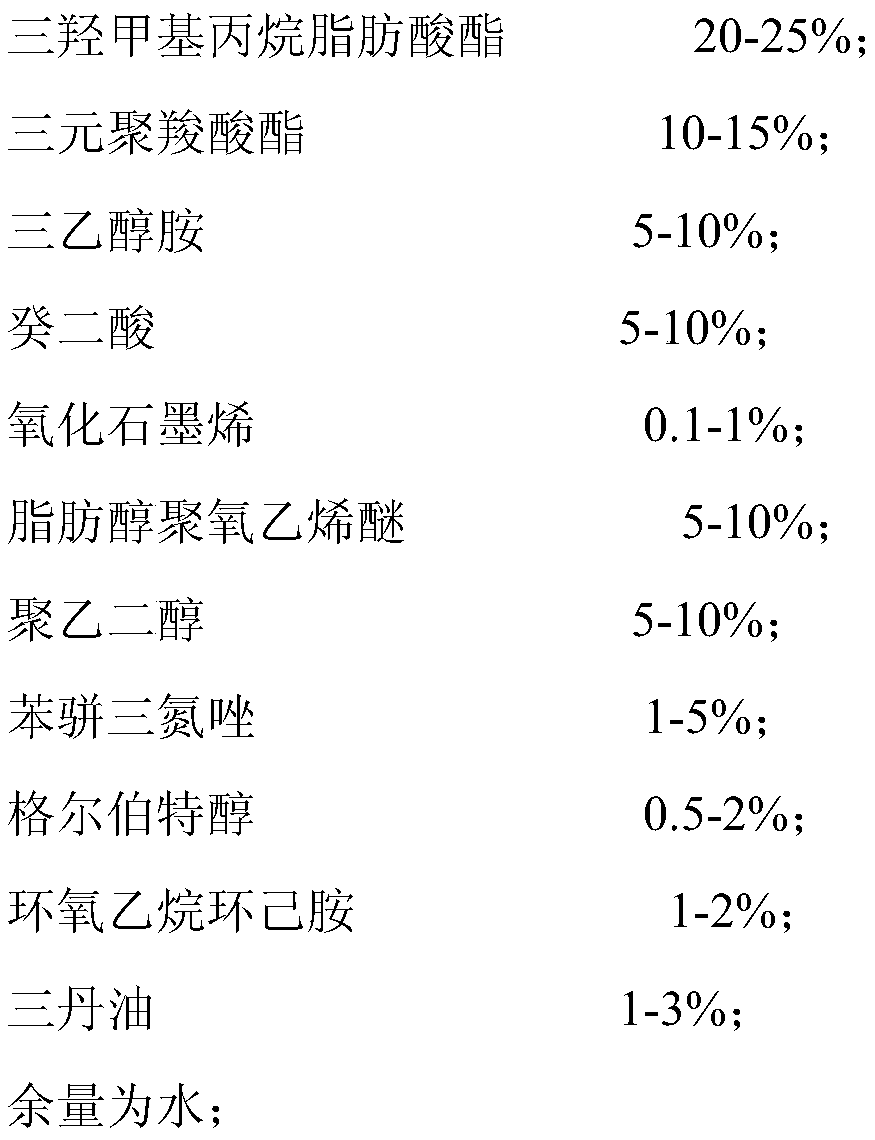

[0020] The components of a cutting fluid and the mass fractions of each component are: 24% of trimethylolpropane fatty acid ester, 15% of ternary polycarboxylate, 10% of triethanolamine, 8% of sebacic acid, 1% of graphene oxide %, Fatty Alcohol Polyoxyethylene Ether 8%, Polyethylene Glycol 8%, Benzotriazole 5%, Guerbet Alcohol 2%, Ethylene Oxide Cyclohexylamine 2%, Sandan Oil 3%, Deionized water 14%.

[0021] Specific implementation method: take each component raw material according to the above-mentioned formula, and trimethylolpropane fatty acid ester, ternary polycarboxylate, sebacic acid, triethanolamine, Guerbet alcohol, ethylene oxide cyclohexane Add amine and benzotriazole to deionized water after mixing, stir at a constant speed and heat to 80°C, react for 60 minutes, a transparent solution without granular solids is formed, and a water-soluble cutting fluid compound is prepared, and the temperature is lowered to below 40°C for later use ;

[0022] Weigh fatty alcoho...

Embodiment 2

[0024] The components of a cutting fluid and the mass fractions of each component are: 20% of trimethylolpropane fatty acid ester, 15% of ternary polycarboxylate, 10% of triethanolamine, 10% of sebacic acid, 1% of graphene oxide %, Fatty Alcohol Polyoxyethylene Ether 10%, Polyethylene Glycol 8%, Benzotriazole 5%, Guerbet Alcohol 2%, Ethylene Oxide Cyclohexylamine 2%, Sandan Oil 3%, Deionized water 14%.

[0025] Specific implementation method: take each component raw material according to the above-mentioned formula, and trimethylolpropane fatty acid ester, ternary polycarboxylate, sebacic acid, triethanolamine, Guerbet alcohol, ethylene oxide cyclohexane Add amine and benzotriazole to deionized water after mixing, stir at a constant speed and heat to 75°C, react for 55 minutes, a transparent solution without granular solids is formed, and a water-soluble cutting fluid compound is prepared, and the temperature is lowered to below 32°C for later use ;

[0026] Weigh fatty alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com