Patents

Literature

56results about How to "Chip removal is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

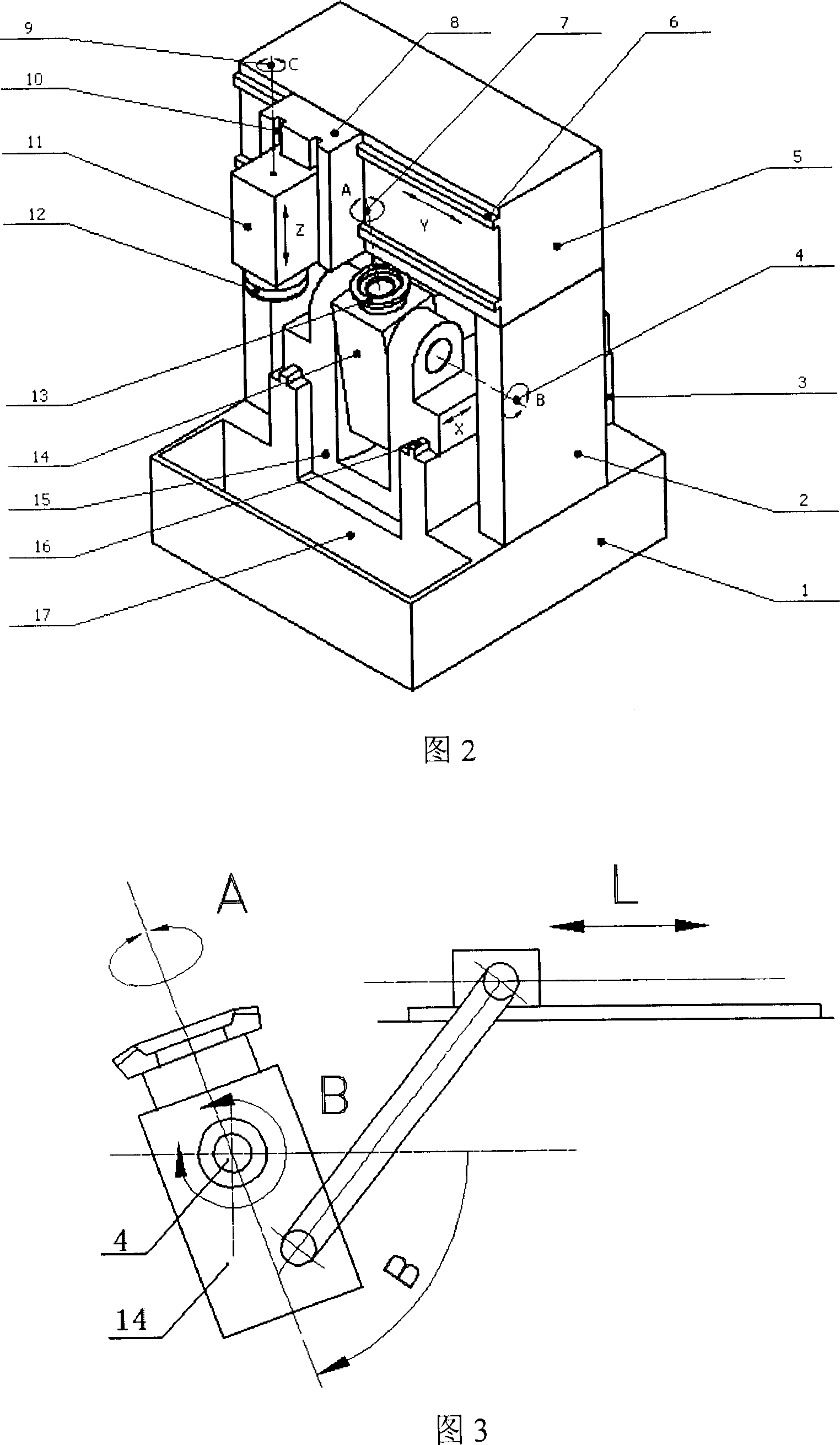

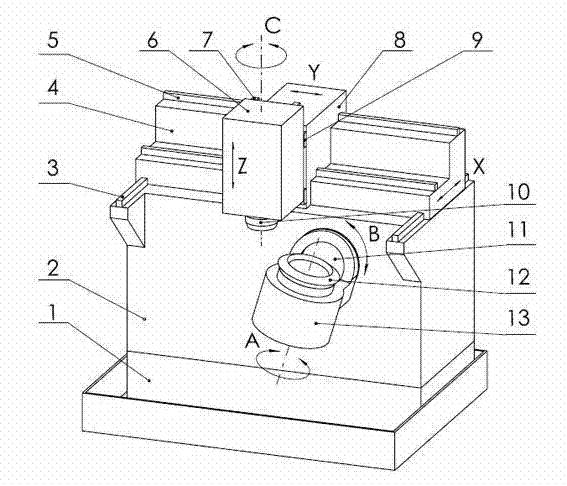

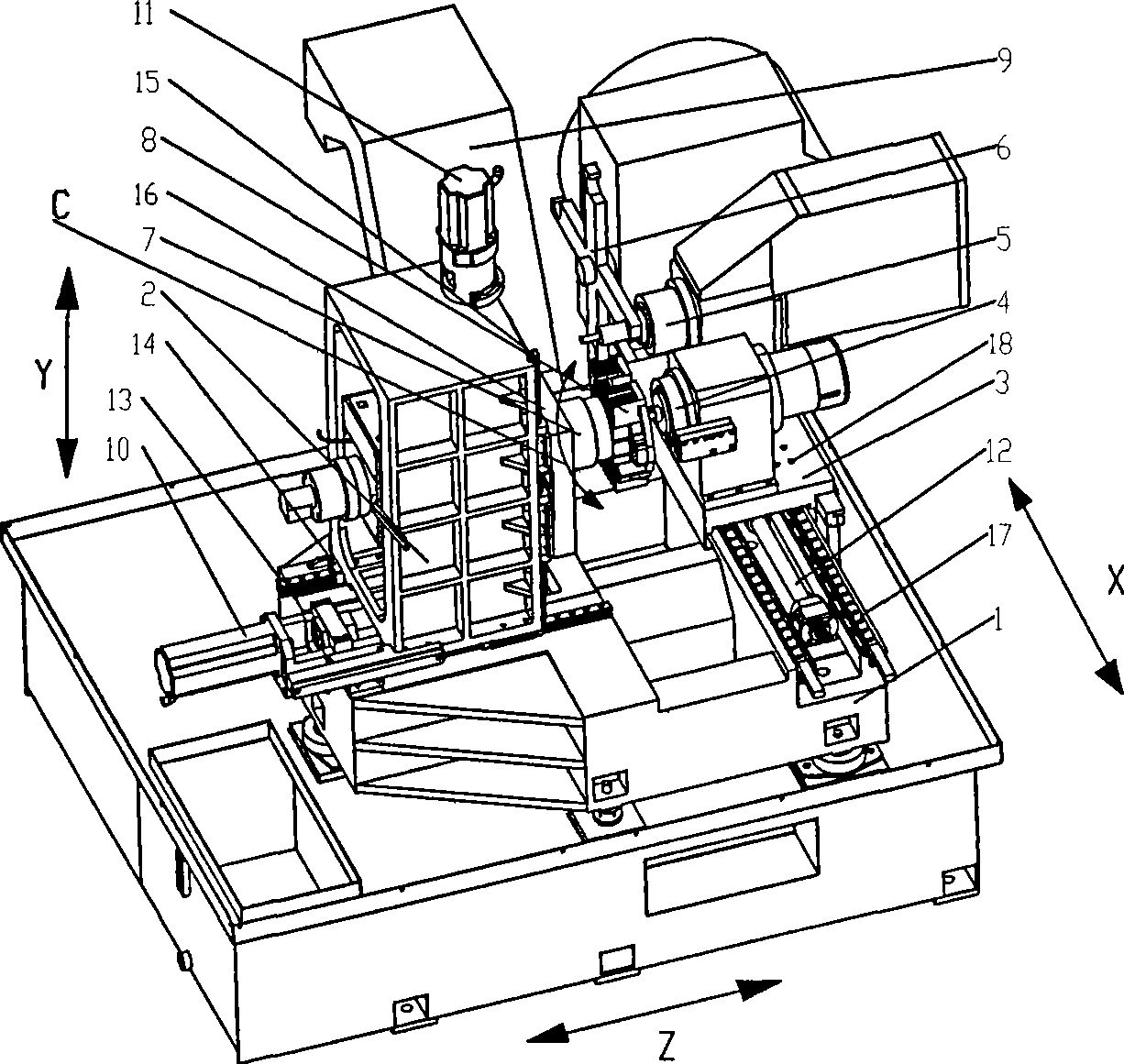

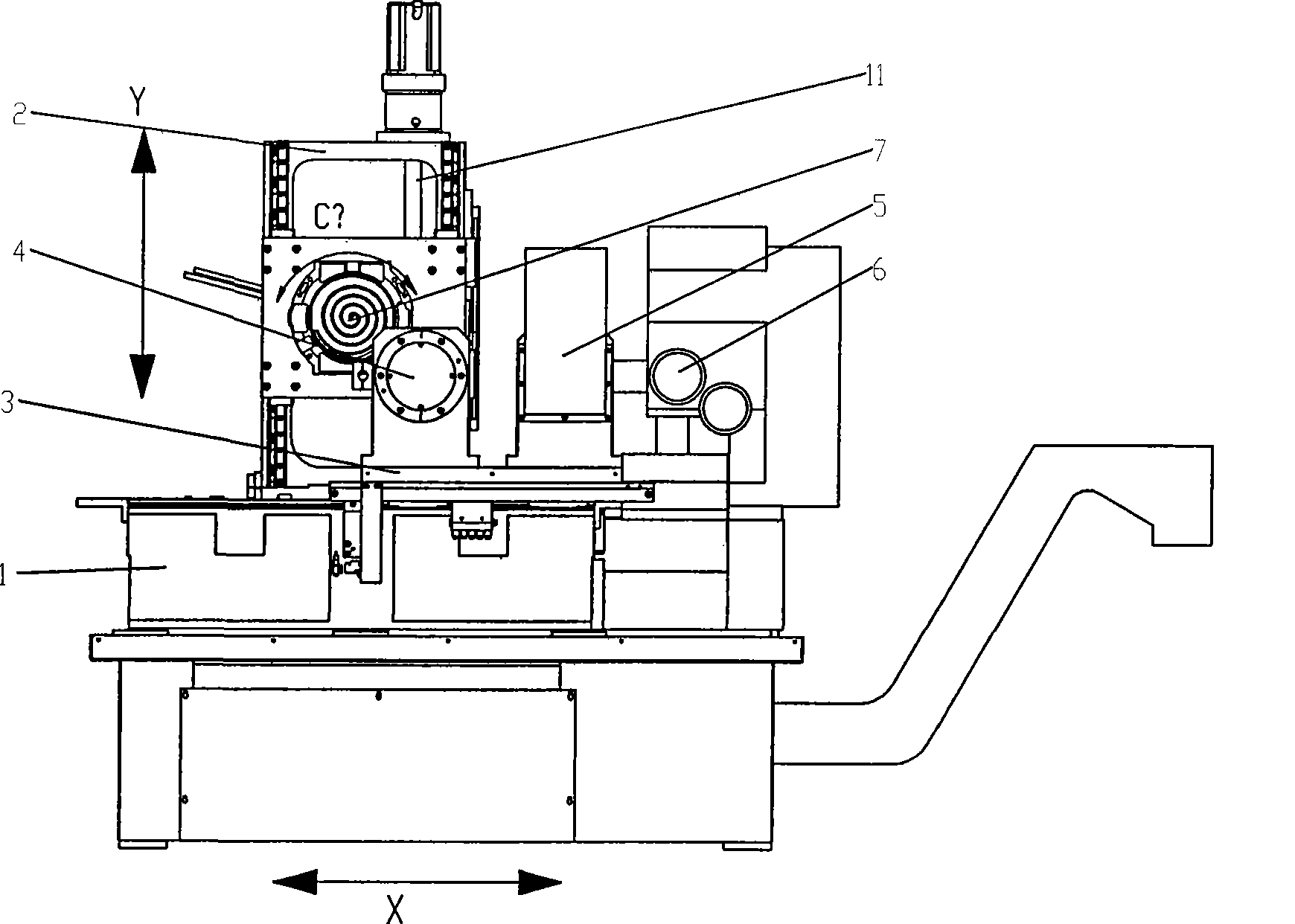

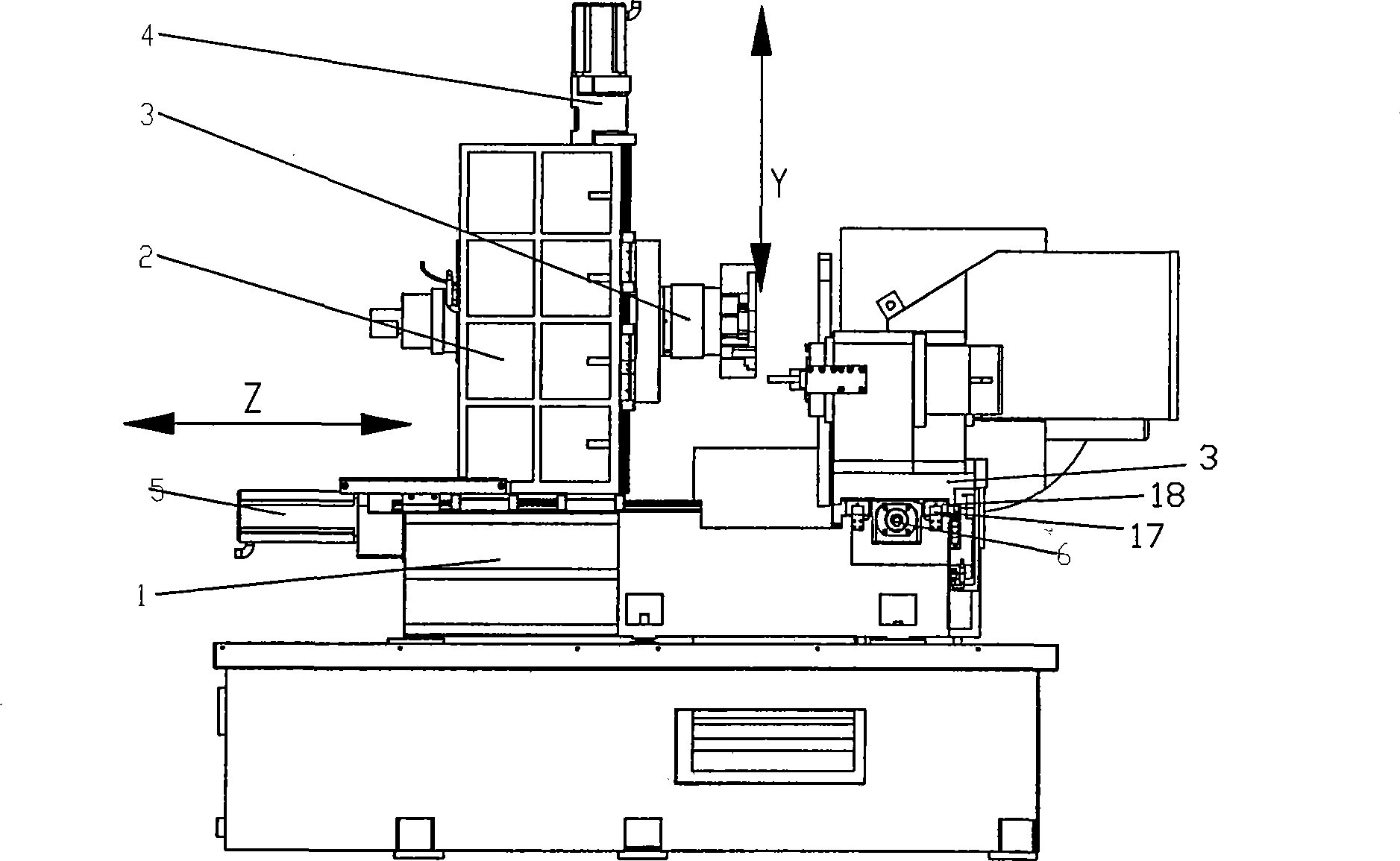

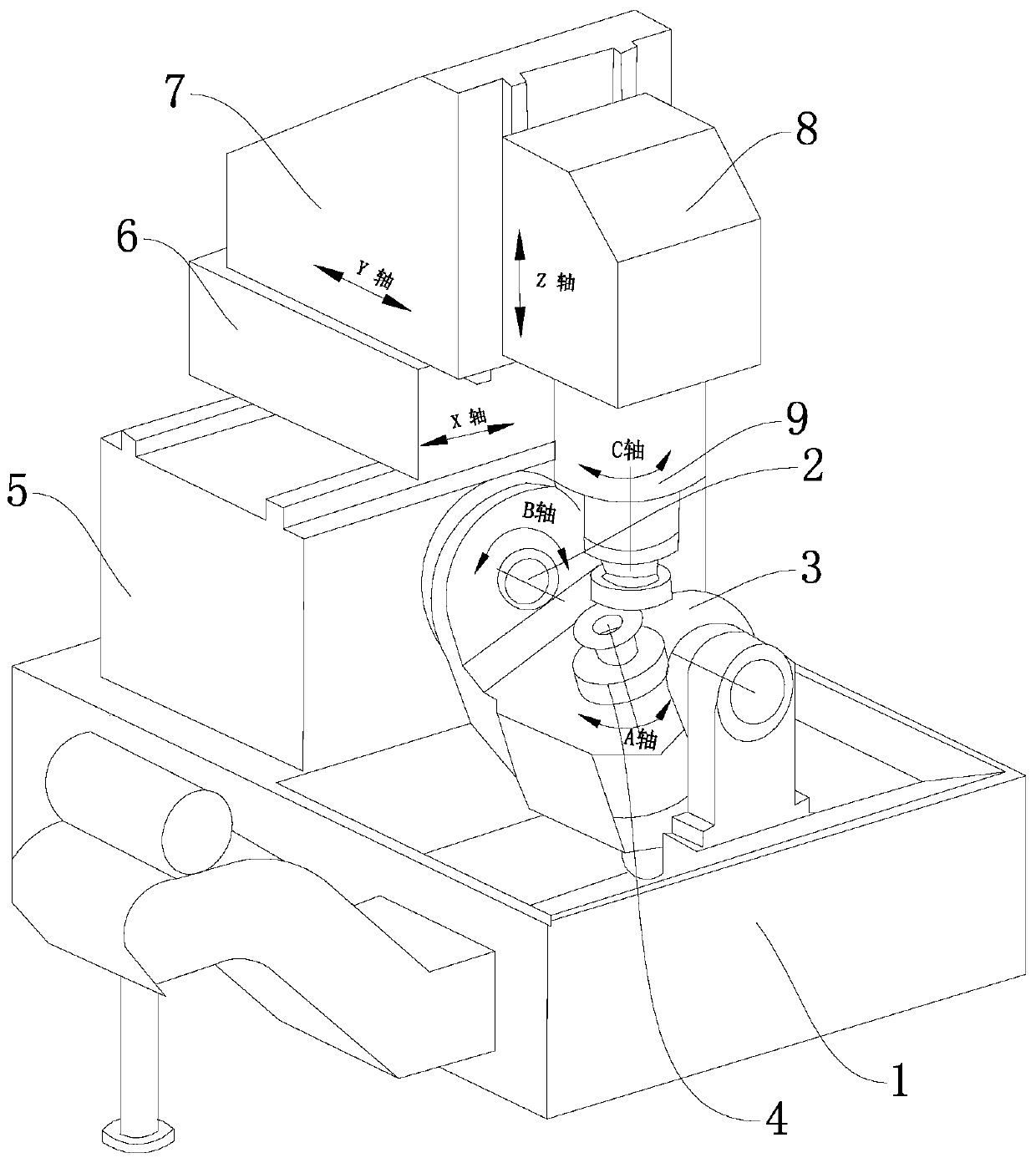

Six-five axis spiral awl gear cutting machine

InactiveCN101015870ACompact structureEasy to assembleLarge fixed membersGear teethEngineeringGear cutting

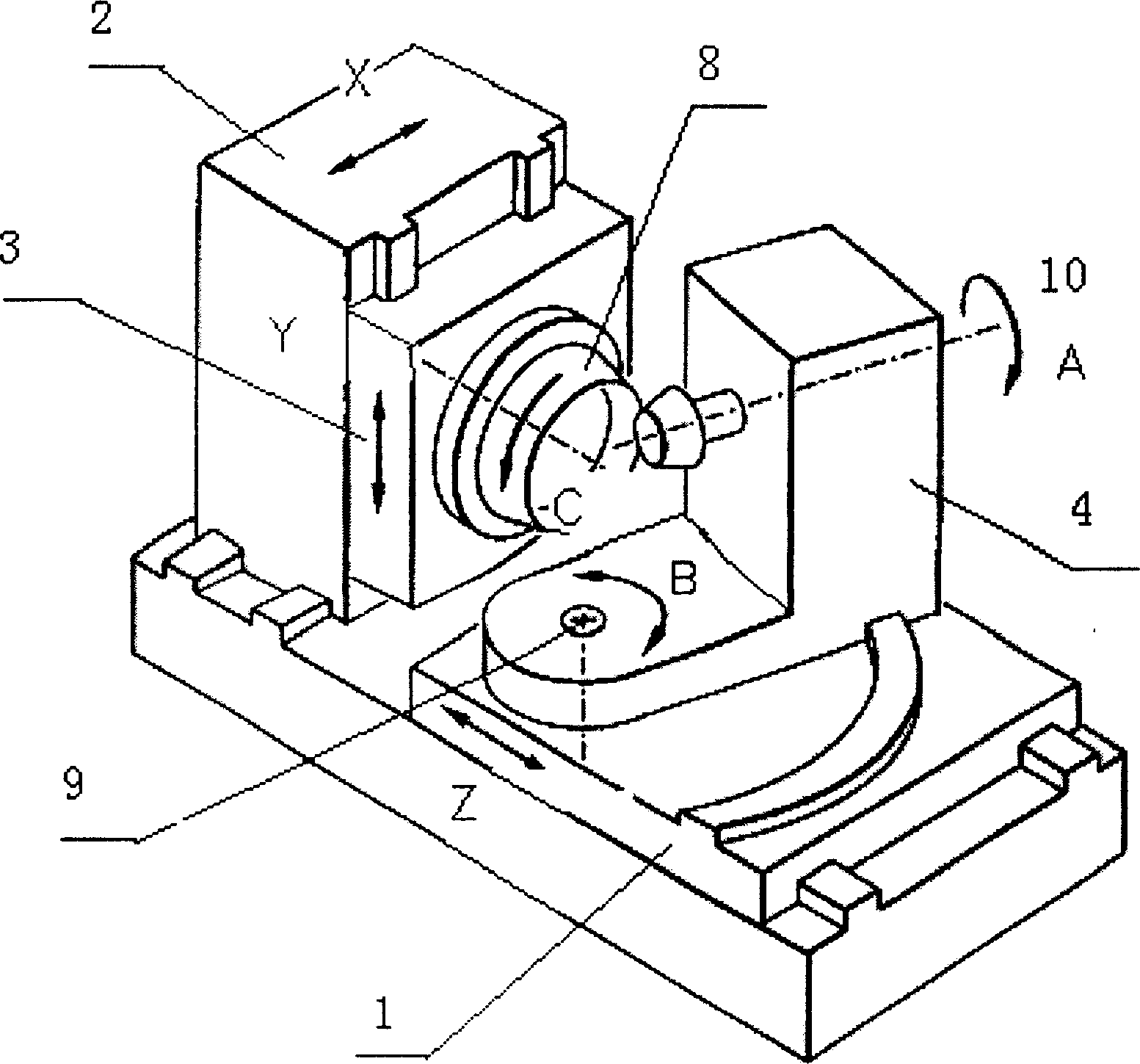

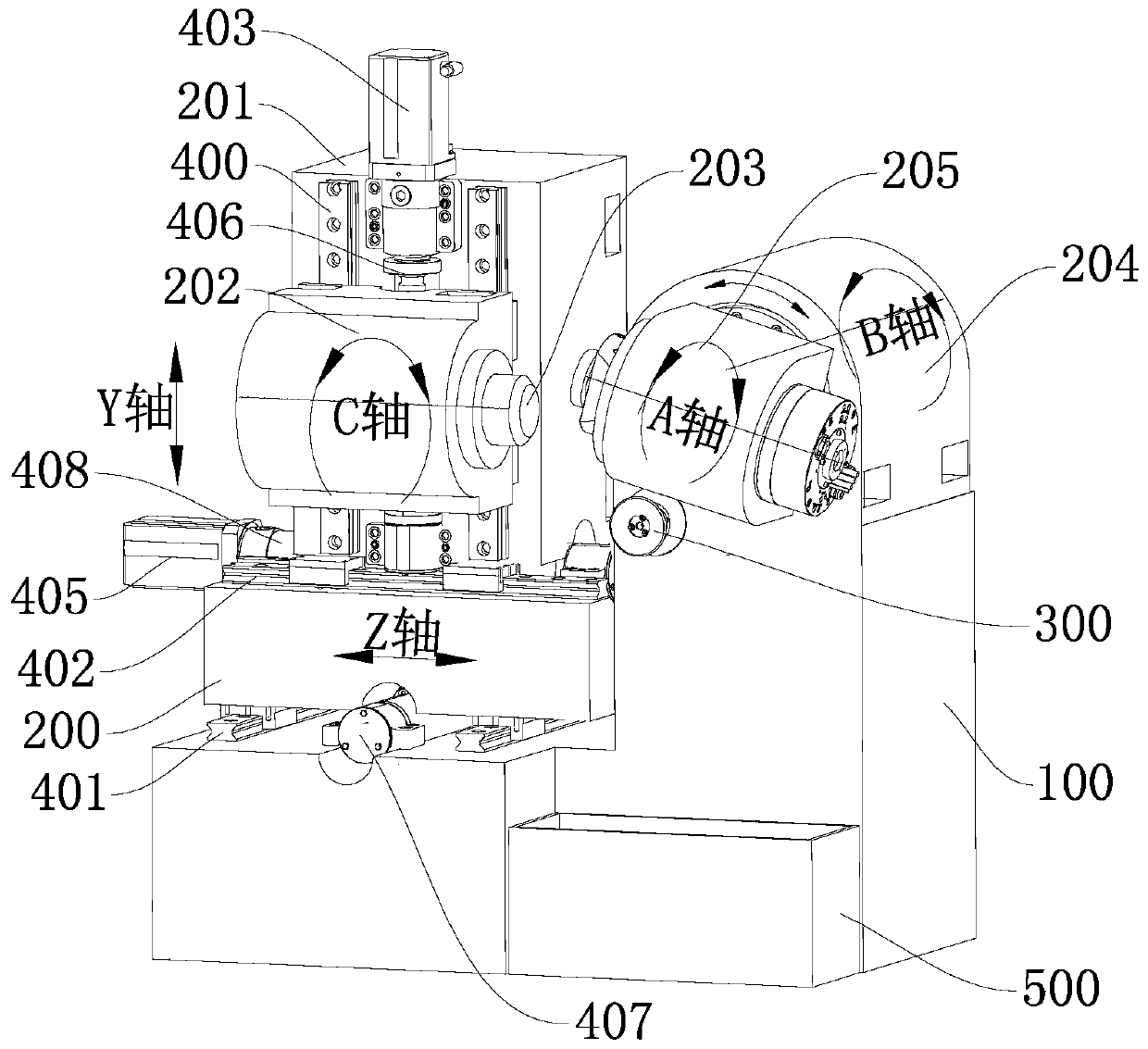

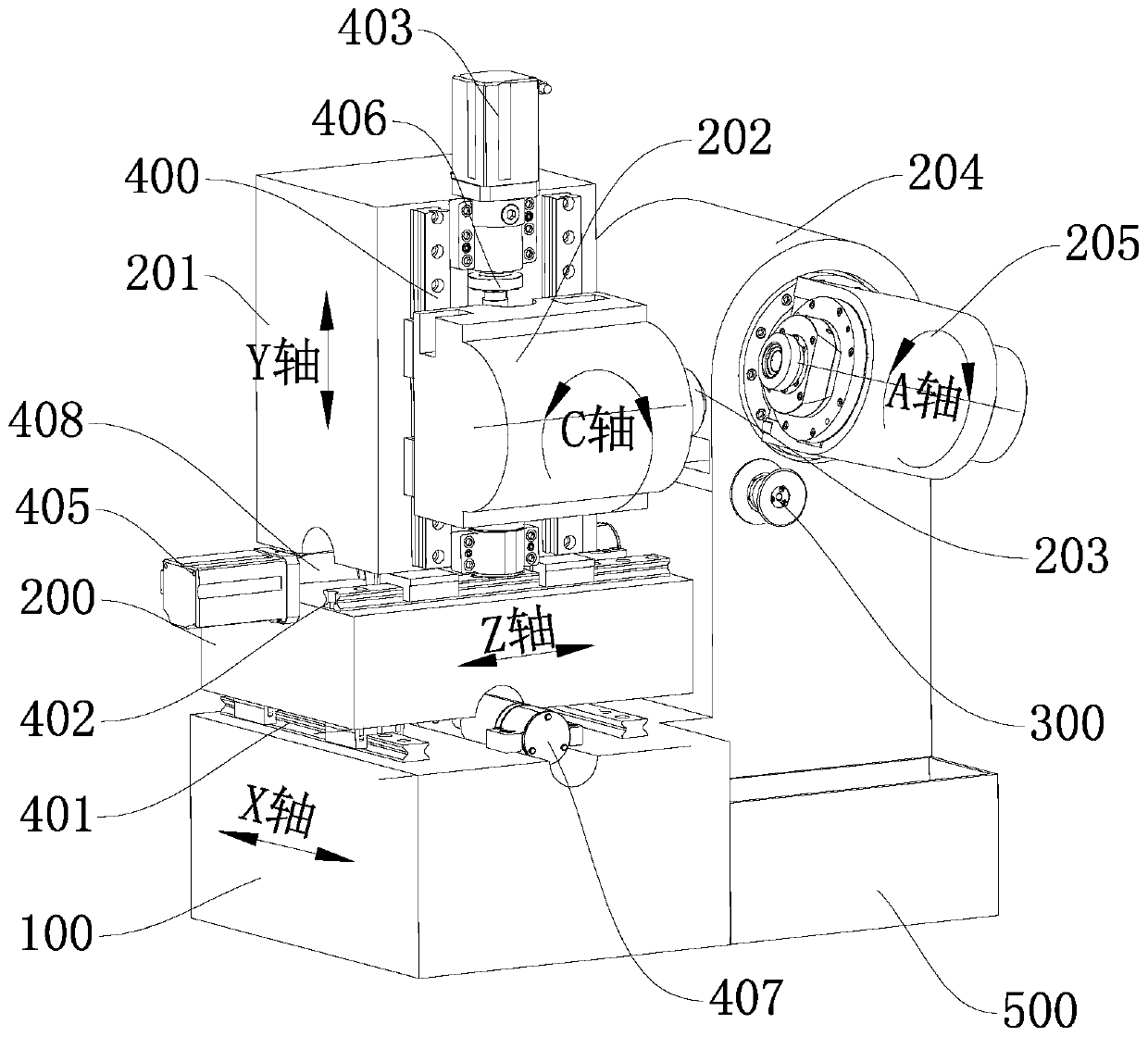

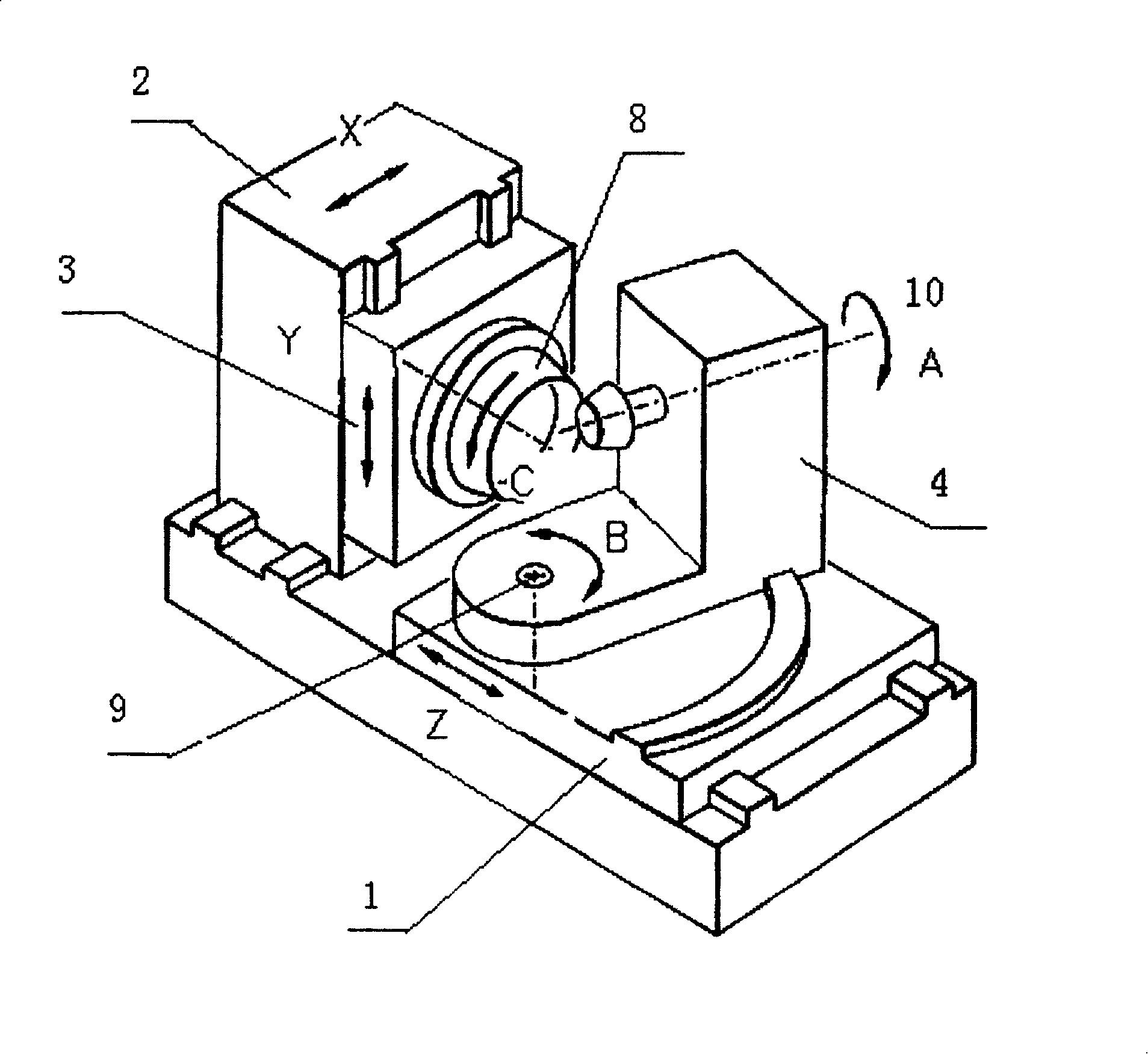

The invention relates to a six-axle five-linkage screw taper gear turning machine, wherein two sides of the machine are arranged with posts, a beam is mounted at the top of the posts, the middle of the machine is disposed with a X-track engaged with a movable X-axle block, one side of the beam is arranged with a Y-track with a movable Y-axle block, the Y-axle block is arranged with a Z-track with a movable Z-axle block mounted with a tool box, the tool box rotates driven by a driver and is mounted with a C axle with blades, the X-axle block is mounted with a work-piece box arranged with A axle for rotating and mounting work-piece driven by the driver, the work-piece box via B axle is hinged on the X-axle block and rotates around B axle. The invention has simple structure, high stability and efficiency.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

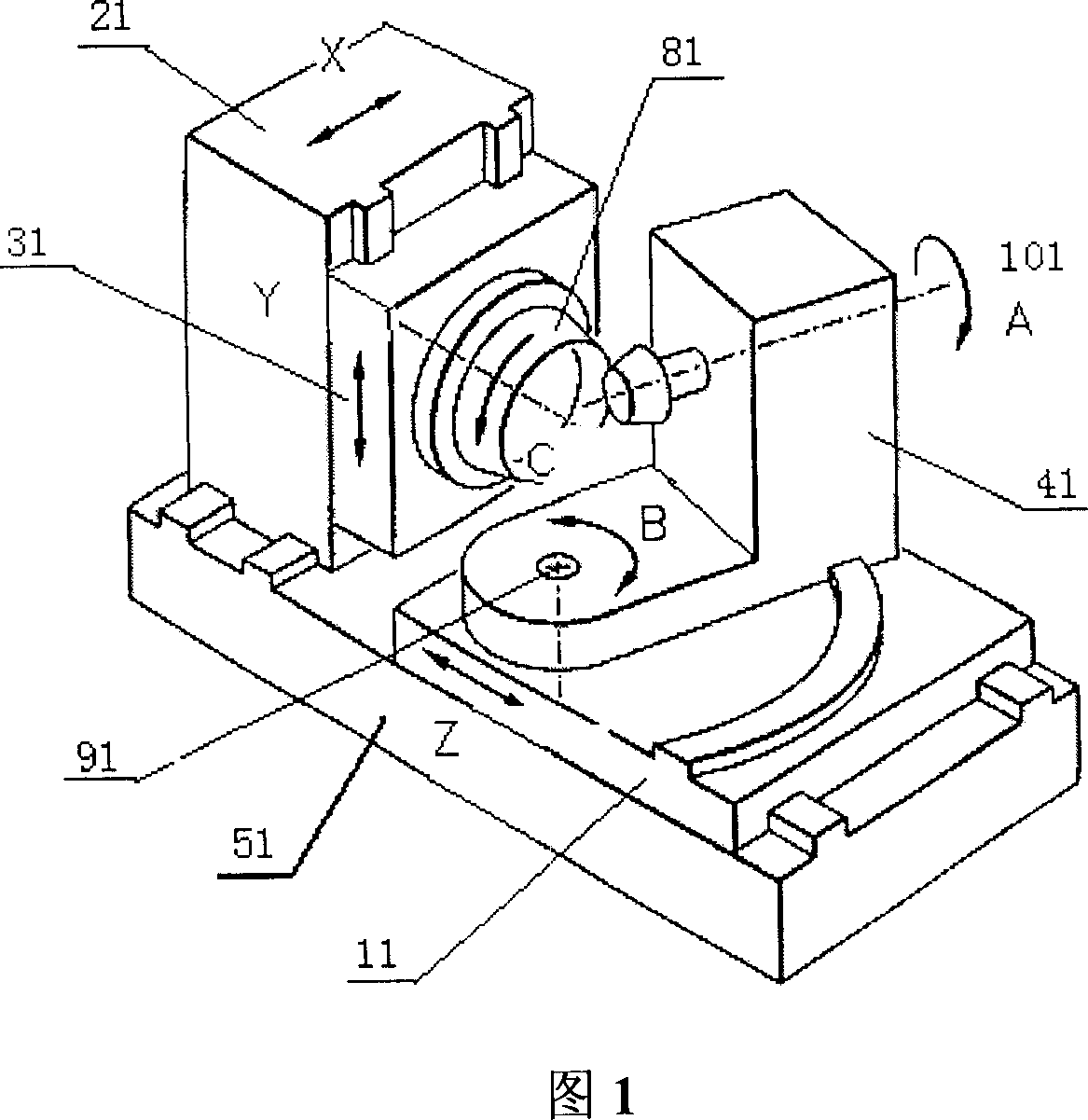

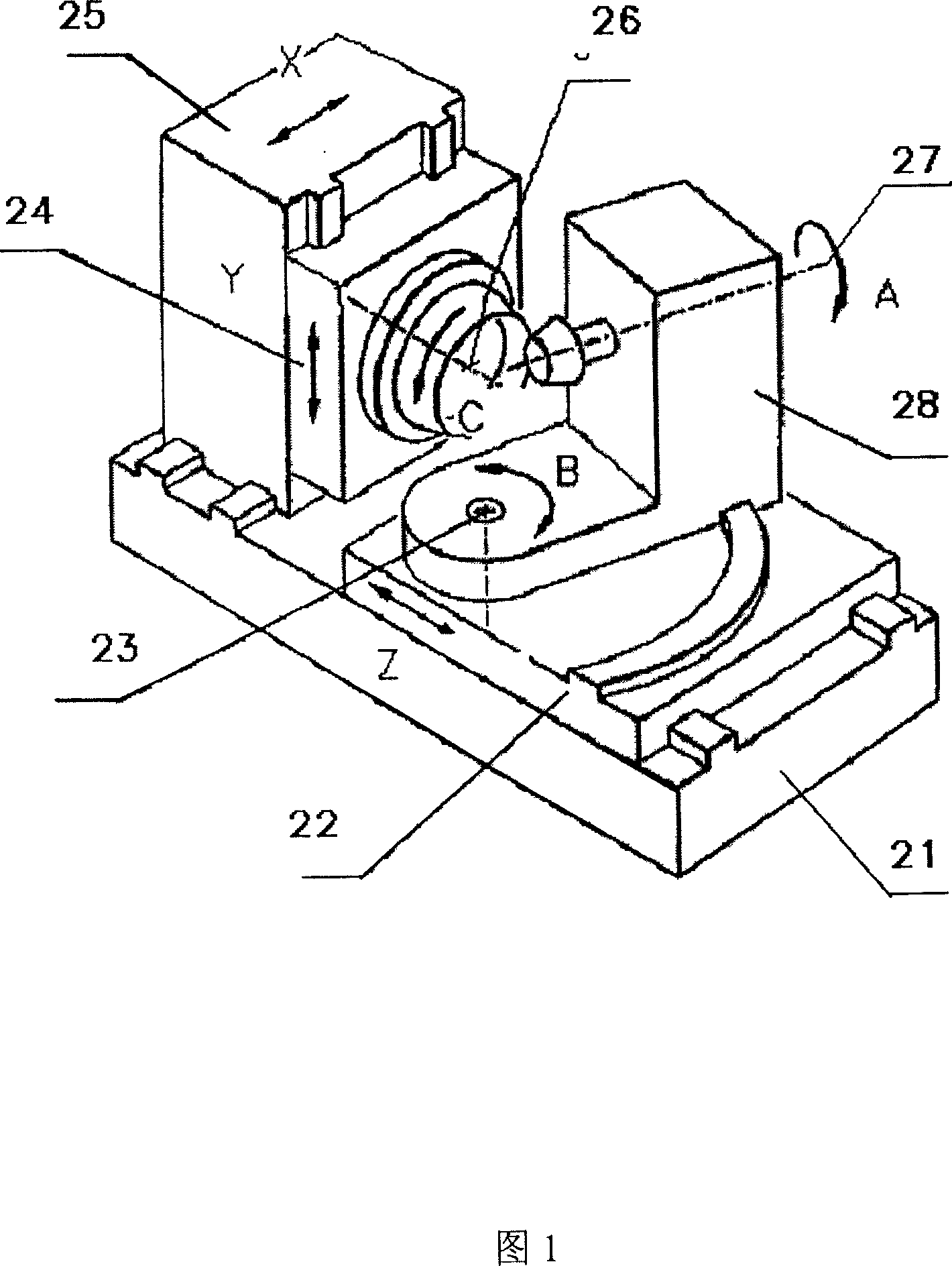

Machine tool for processing spiral taper gear with six axes, five linkage axes

InactiveCN1958226AEasy loading and unloadingEasy to realize automatic loading and unloadingLarge fixed membersMetal working apparatusGear wheelMachine tool

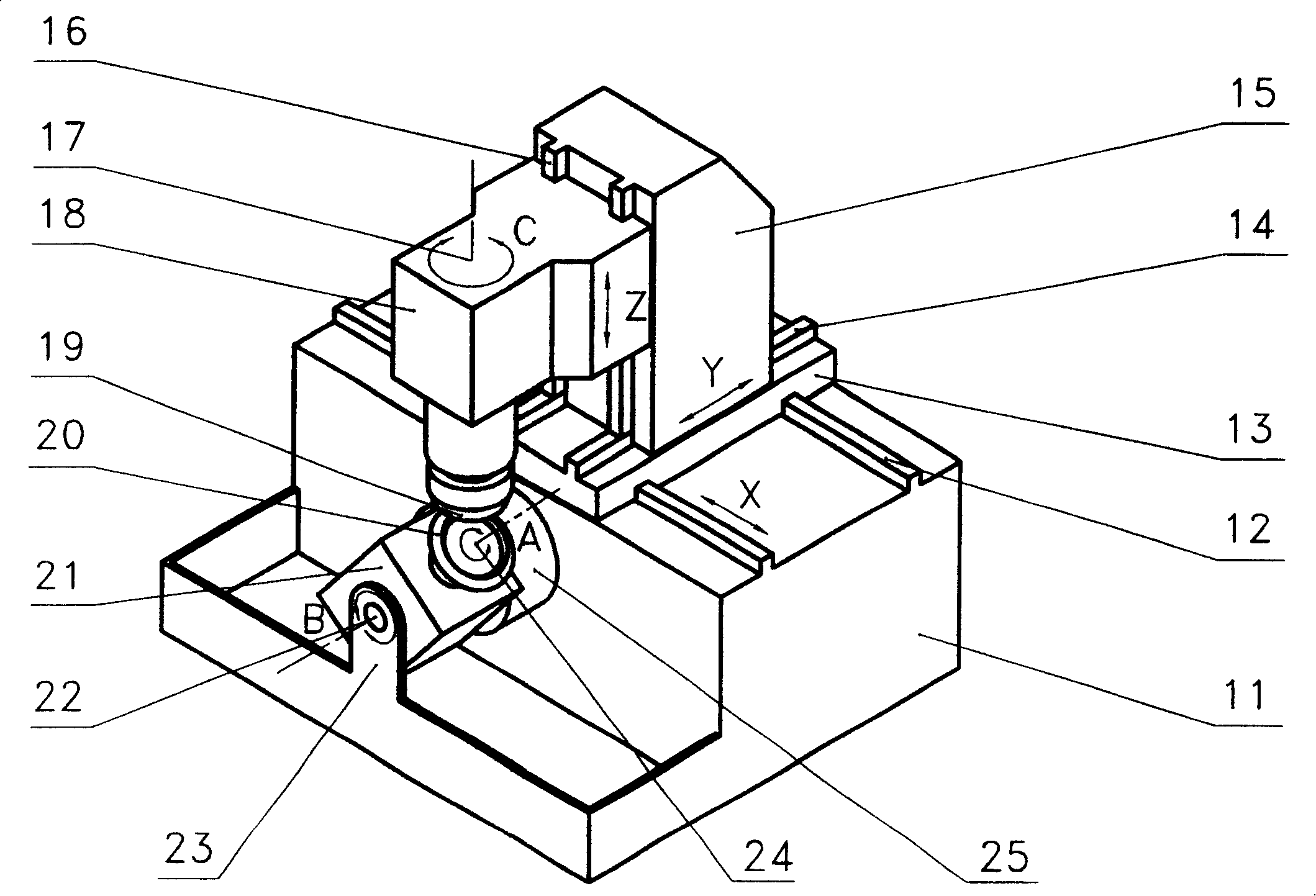

A 6-axle 5-linkage machine-tool for manufacturing spiral bevel gear is composed of machine body, vertical post, linear X-tracks on said machine body, slide X-carrier sliding on said X-tracks, linear Y-tracks on said slide X-carrier, workpiece box sliding on said Y-tracks, rotary axle A on said workpiece box, linear Z-tracks on the lateral surface of said vertical post, Slide Z-carrier sliding on said Z-tracks, drive unit, tool box on said Z-carrier and revolving around axle B and its driver, and rotary axle C installed to said tool box.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Six-shaft and five-linked machine tool for spiral conical gears

A six-axle five-leakage machine-tool for machining spiral bevel gear is composed of a main body, X-axis straight guide track on said main body, X-axis slide table on said X-axis track, Y-axis straight guide track on said X-axis slide table, a slide vertical post on said Y-axis track, a Z-axis guide track on one lateral surface of said vertical post, a cutting tool box moving on said Z-axis track, a C axle on said cutting tool box for installing cutter head or abrasive disc, a B axle for driving cutting tool box to rotate, and an A axle on said cutting tool box for installing the spiral bevel gear to be machined.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

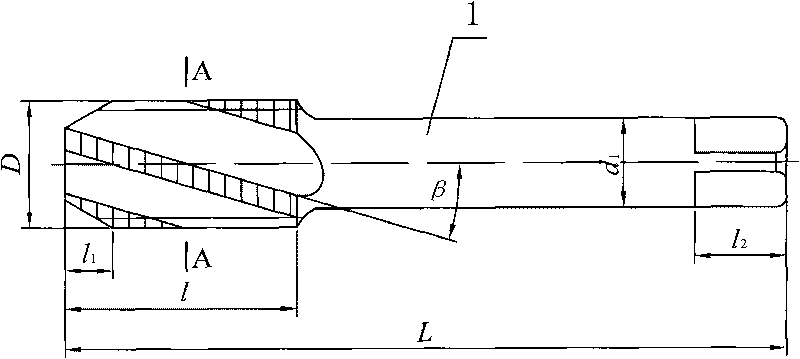

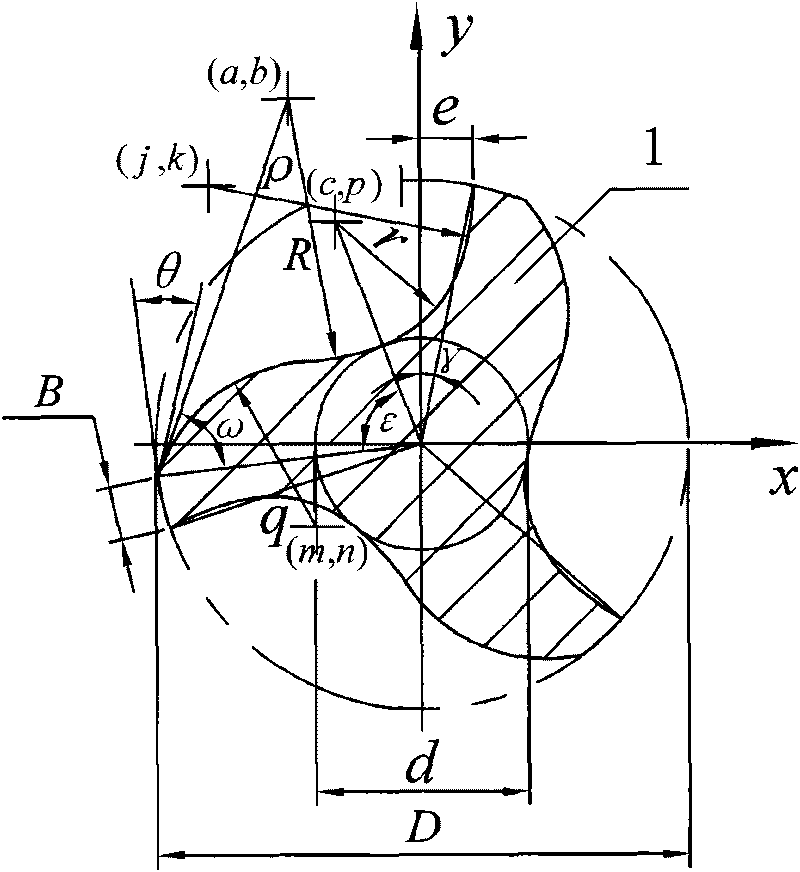

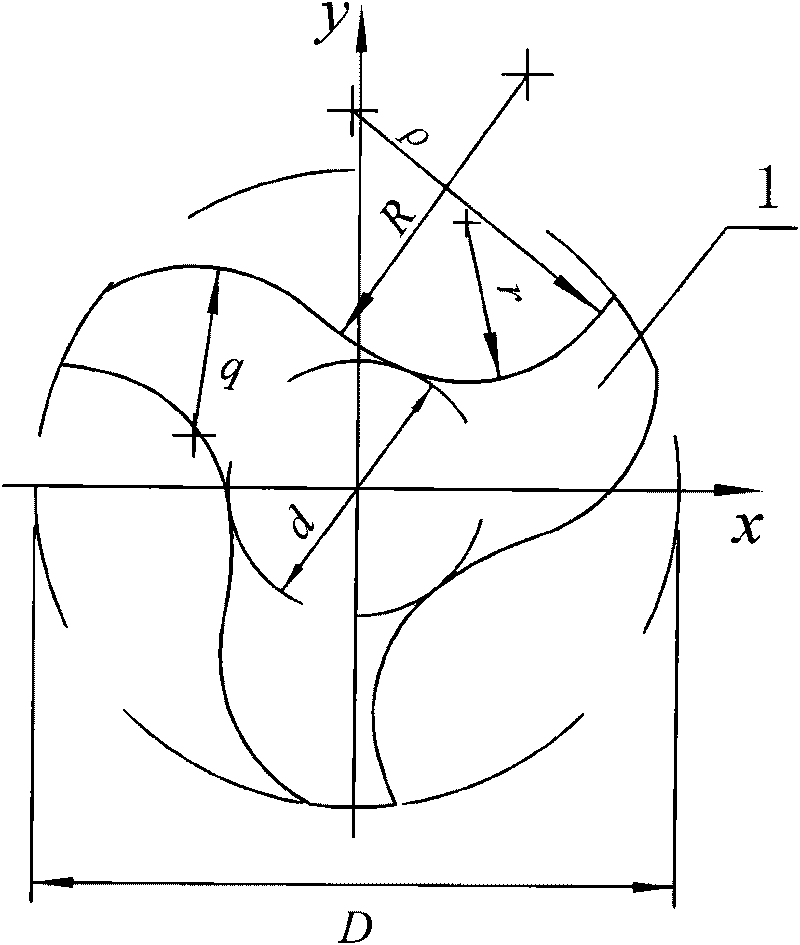

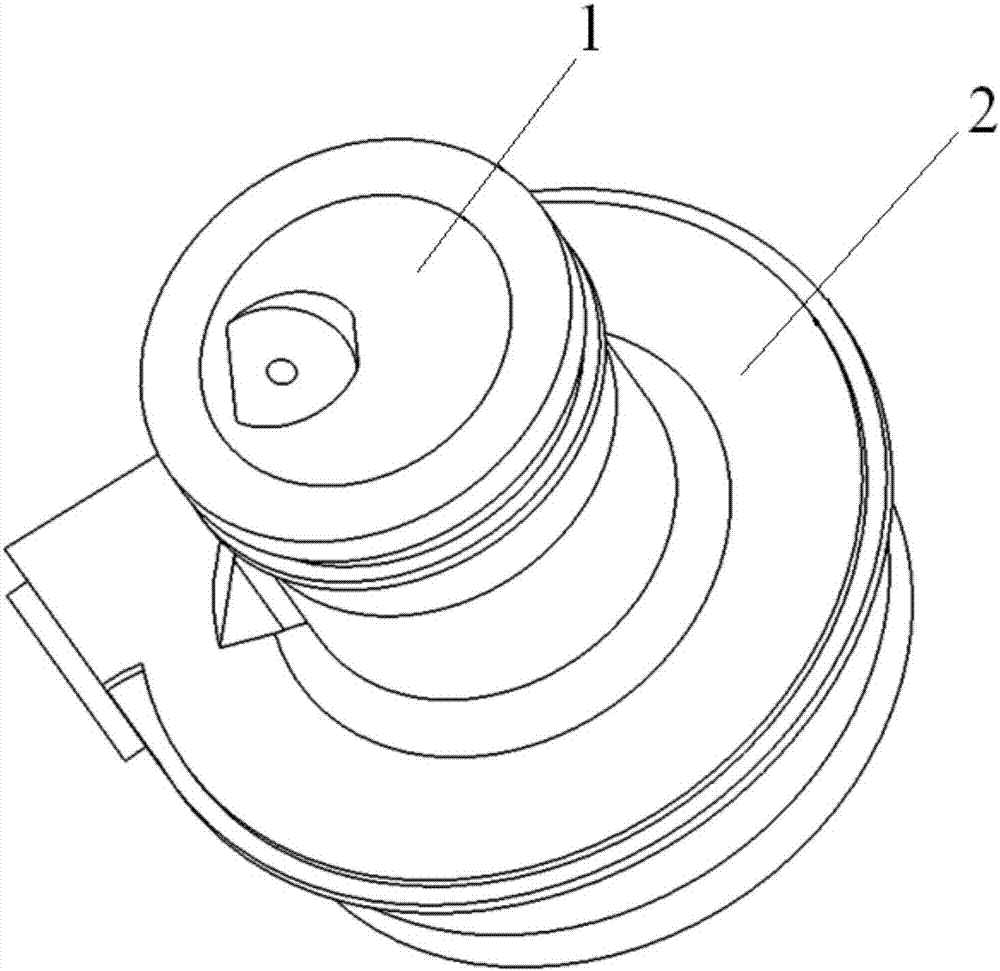

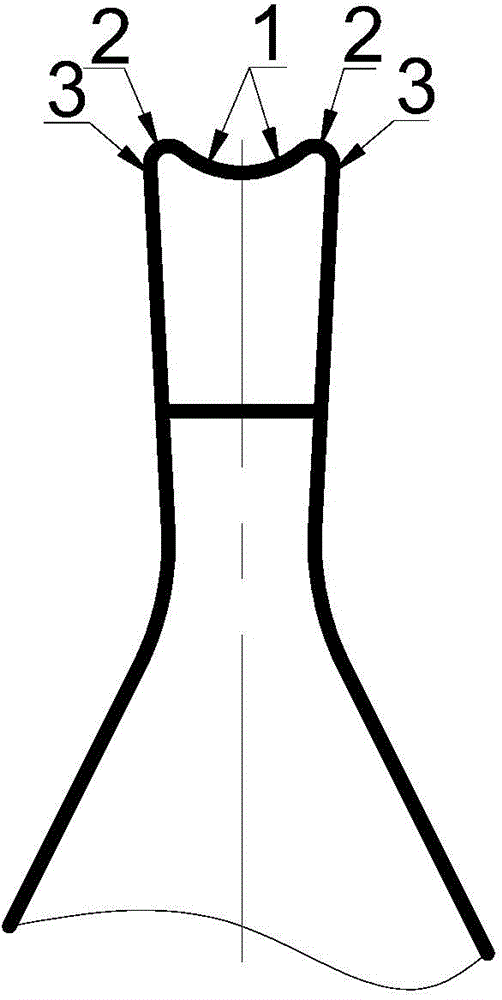

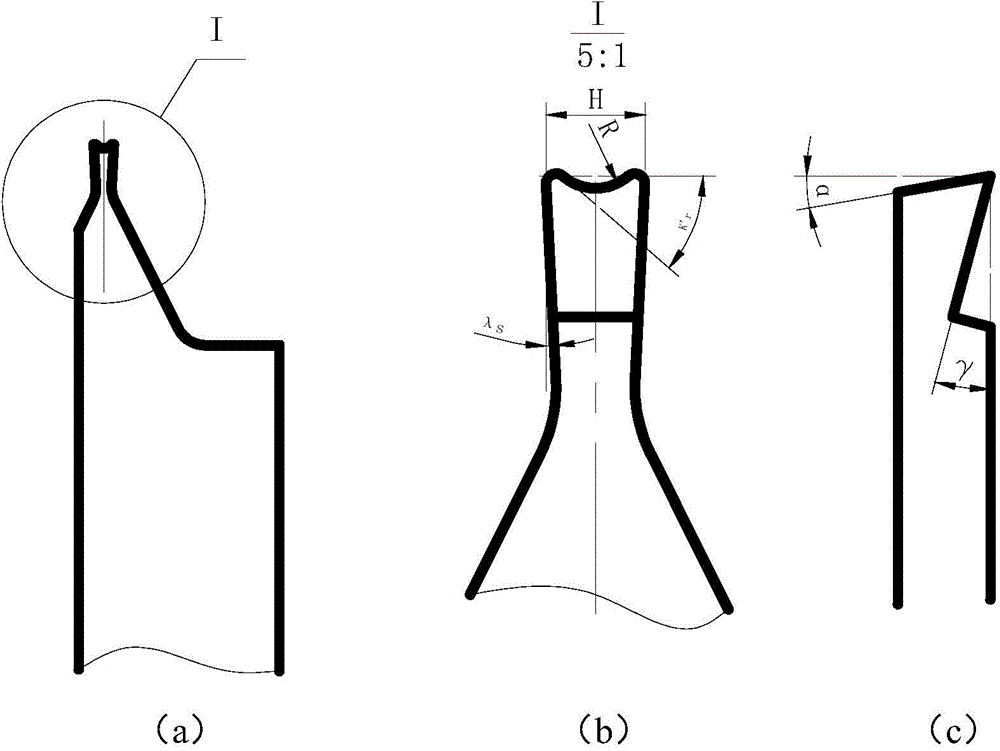

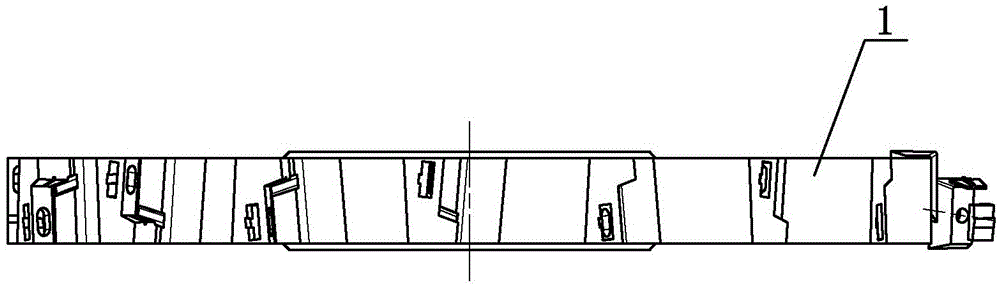

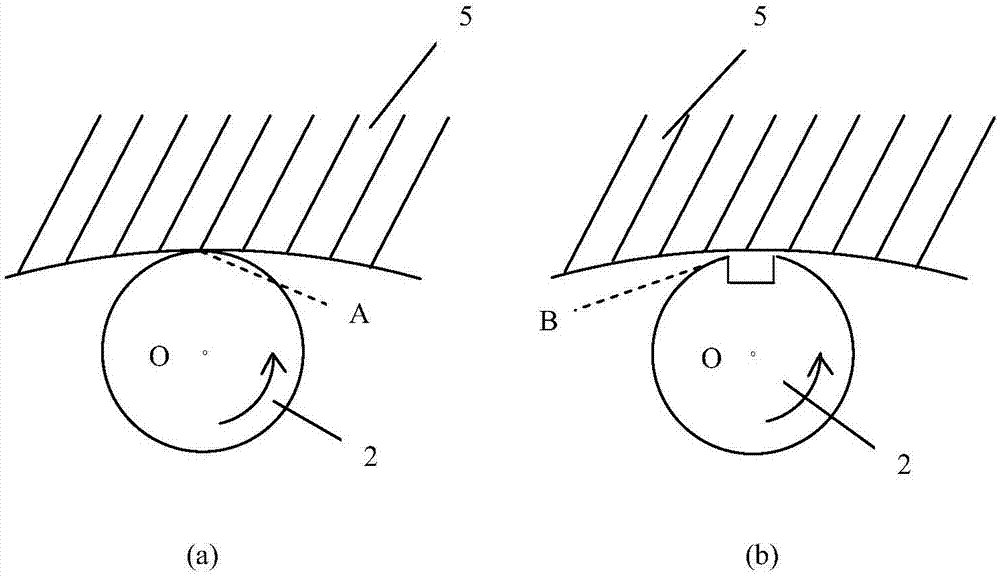

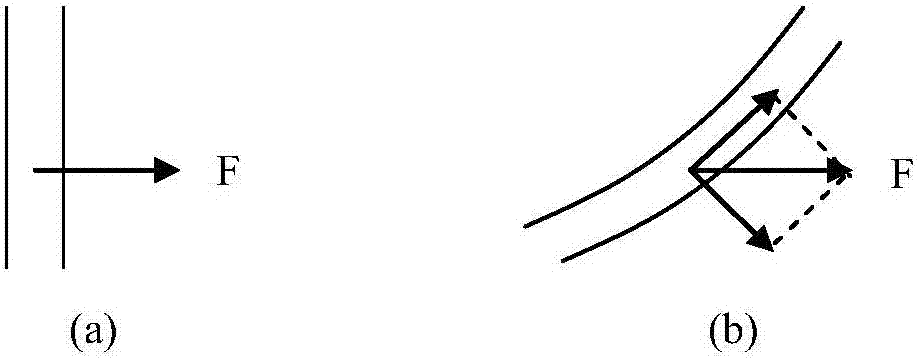

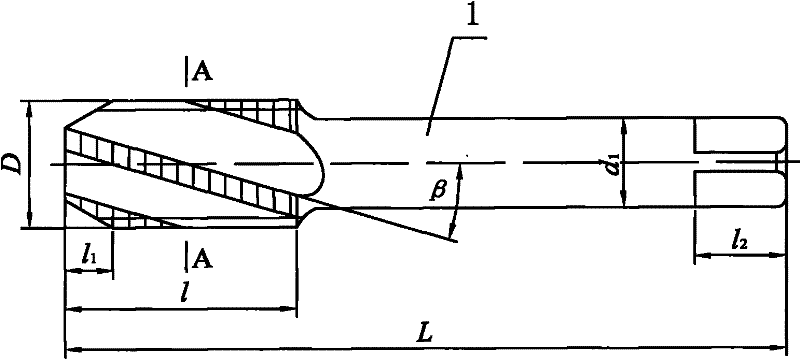

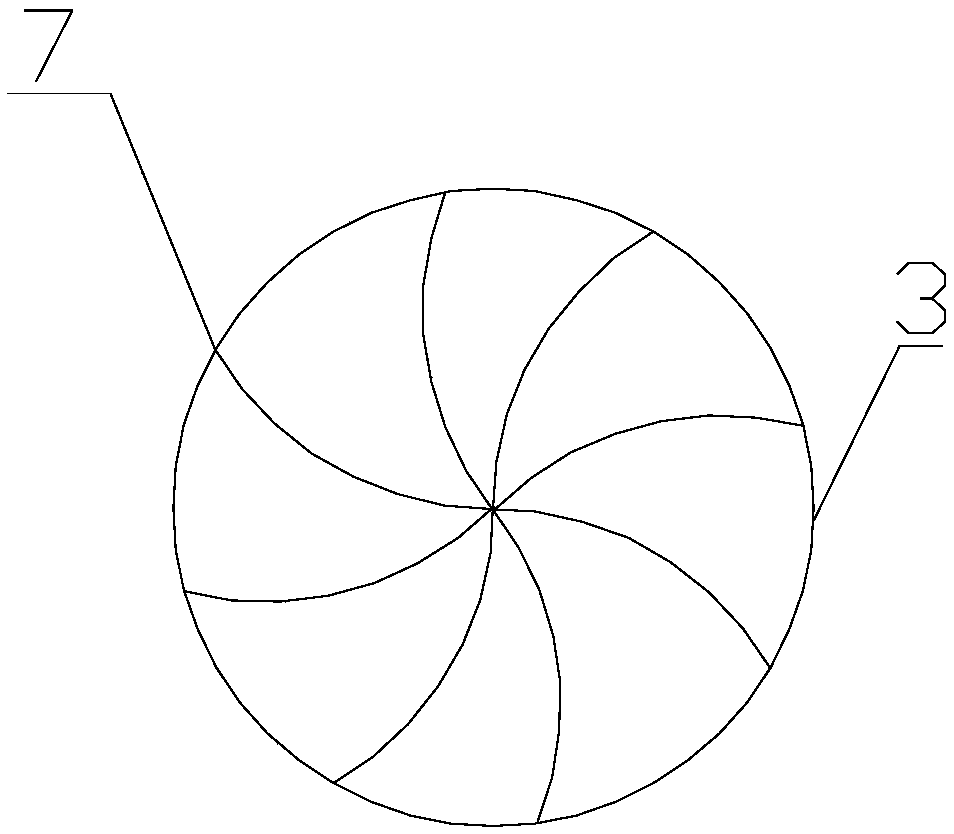

Spiral fluted tap and method for processing same

The invention discloses a spiral fluted tap and a method for processing the same. The spiral fluted tap comprises a tap body provided with a plurality of uniformly distributed spiral flutes on a front cut part, wherein the spiral flute is an S-shaped smooth curved groove formed by sequentially connecting four sections of tangential circular arcs end to end; and the four sections of tangential circular arcs are a cutting circular arc, a chip curling circular arc, a chip accommodating circular arc and a blade back circular arc respectively. The method for processing the spiral fluted tap comprises the following steps of: (1) preparing before processing; (2) processing the spiral flute by a special tool: fitting a blade shape of a cutter by a computer, and then manufacturing the cutter according to the fitted cutter blade shape so as to process the spiral flute; and (3) carrying out subsequent treatment by using a machining process so as to obtain a finished product of the tap body. The spiral fluted tap processed by the method has simple structure and can be molded in one step. Moreover, the processing method is suitable for different processing materials, particularly for processing fluted taps made of light alloys, such as an aluminum alloy and the like.

Owner:XIAN TECHNOLOGICAL UNIV

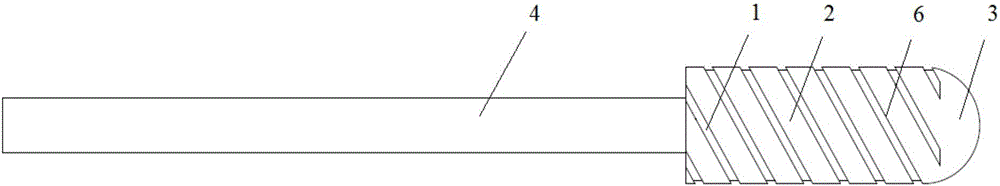

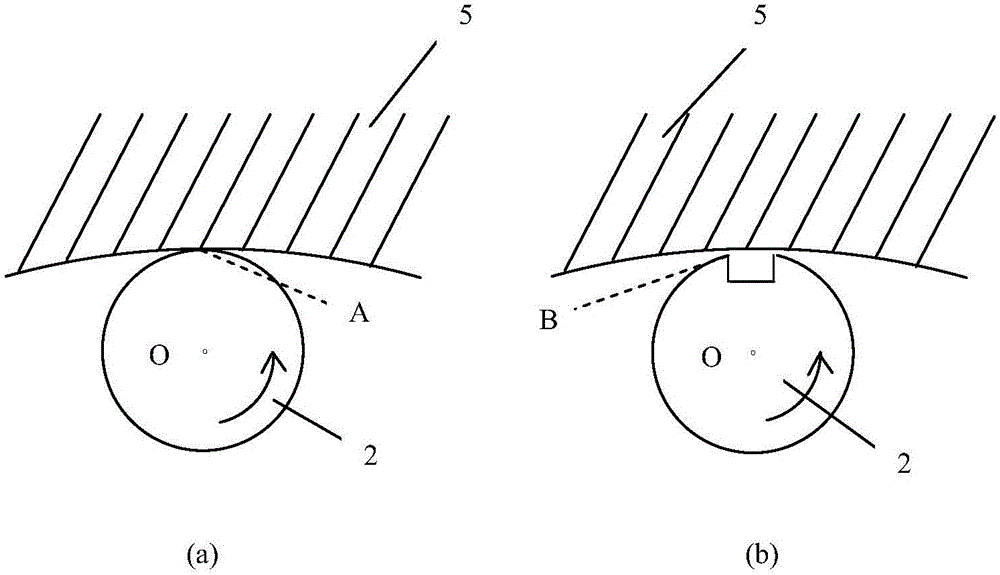

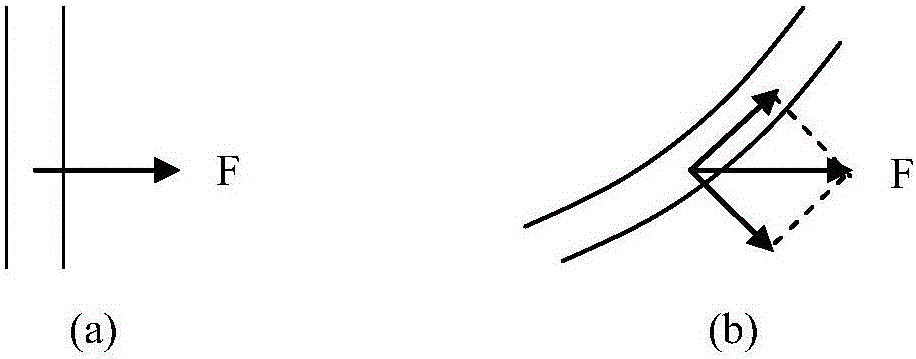

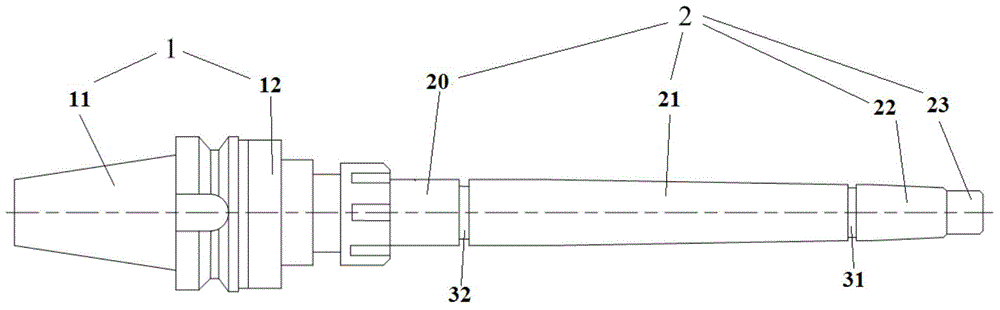

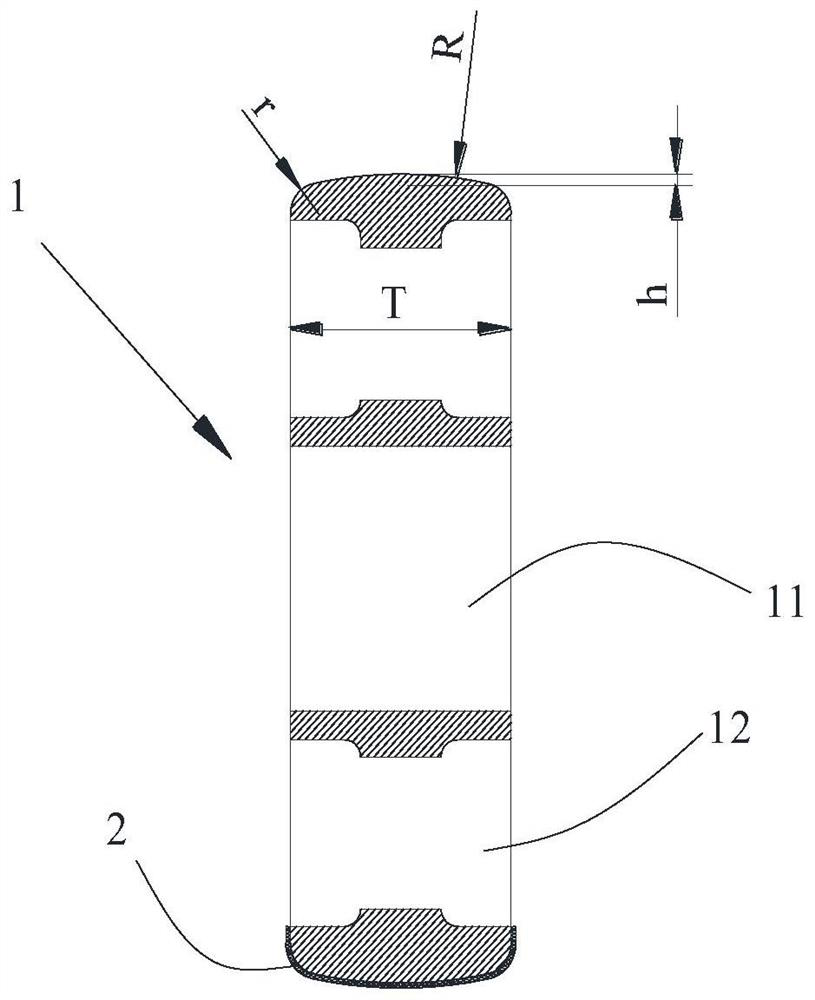

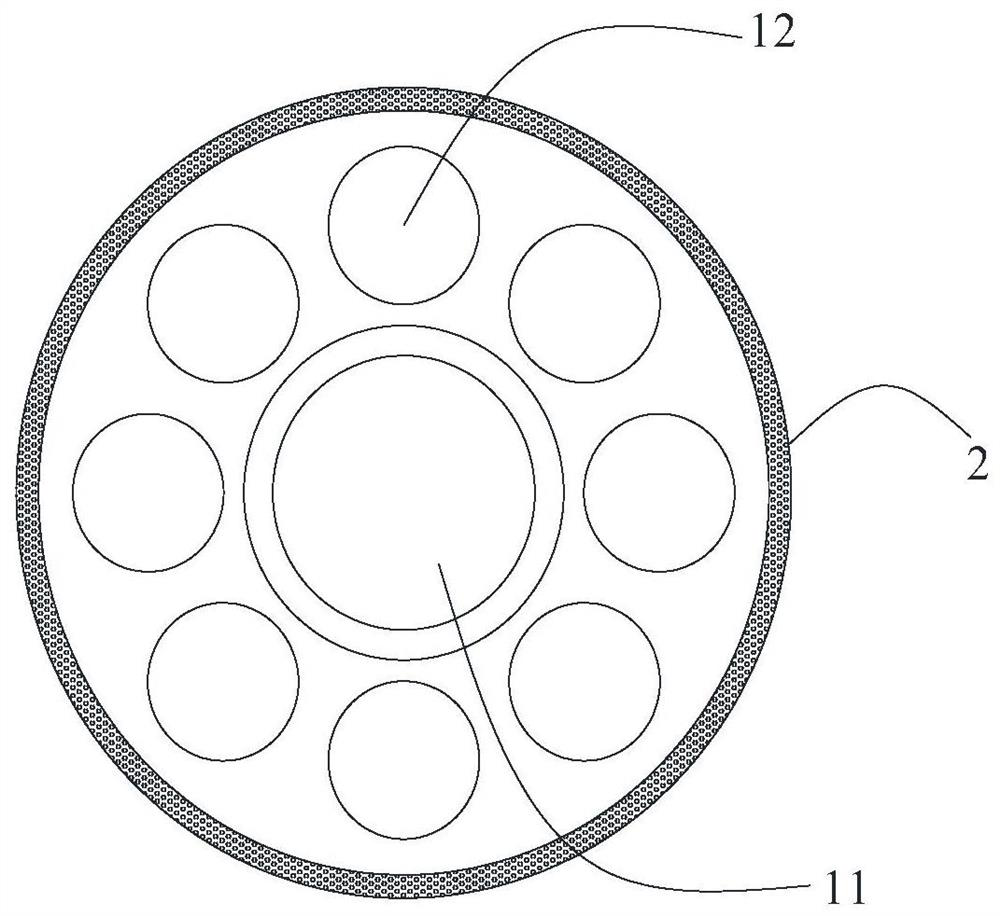

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

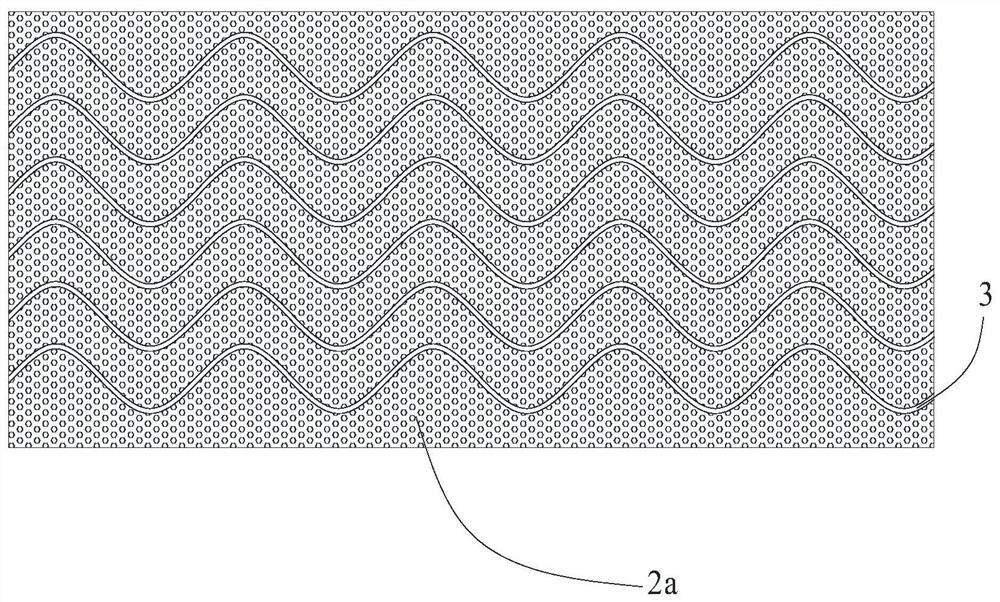

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

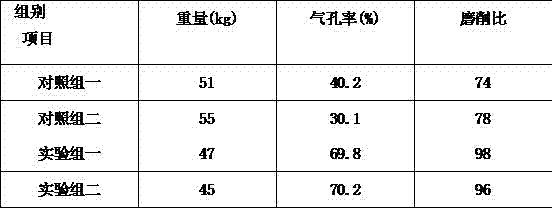

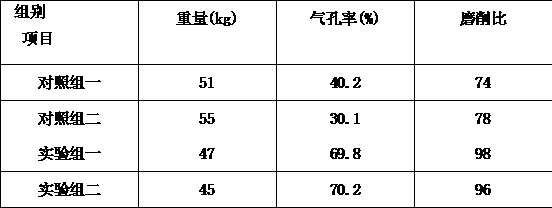

Method for manufacturing foaming-type grinding wheel with big air pores

InactiveCN107116485AAdequate stomataLow densityAbrasion apparatusGrinding devicesSurface-active agentsPolyresin

The invention discloses a foaming-type grinding wheel with big air pores which is made of resin adhesive, an abrasive material, a thinner, a surface active agent, secondary reinforced resin, dextrin, a foaming agent, a defoaming agent, filler and starch. A manufacturing method of the foaming-type grinding wheel with big air pores includes the steps that the resin adhesive and the thinner are added into a container to be evenly stirred under the water bath condition of 60 DEG C; then the abrasive material and the surface active agent are added to be evenly stirred; afterwards, the secondary reinforced resin, the dextrin, the starch, the filler, the foaming agent and the defoaming agent are added in sequence, and slurry is injected into a mold of 45-60 DEG C when the reaction temperature of the slurry reaches 50 DEG C; and finally the mold is put into an oven to be roasted, demolding is conducted after the slurry in the mold is completely cured, and accordingly the foaming-type grinding wheel with big air pores can be obtained. The foaming-type grinding wheel with big air pores has the characteristics that the grinding wheel is low in weight and nontoxic, and air pores are uniform; the grinding wheel is far superior to a common resin grinding wheel on the aspects of water resistance, abrasion resistance, heat-conducting property and the like; and especially when the grinding wheel is used for grinding long-axis metal parts, no vibration ripple can be caused, and the grinding effect is better.

Owner:广州捷骏电子科技有限公司

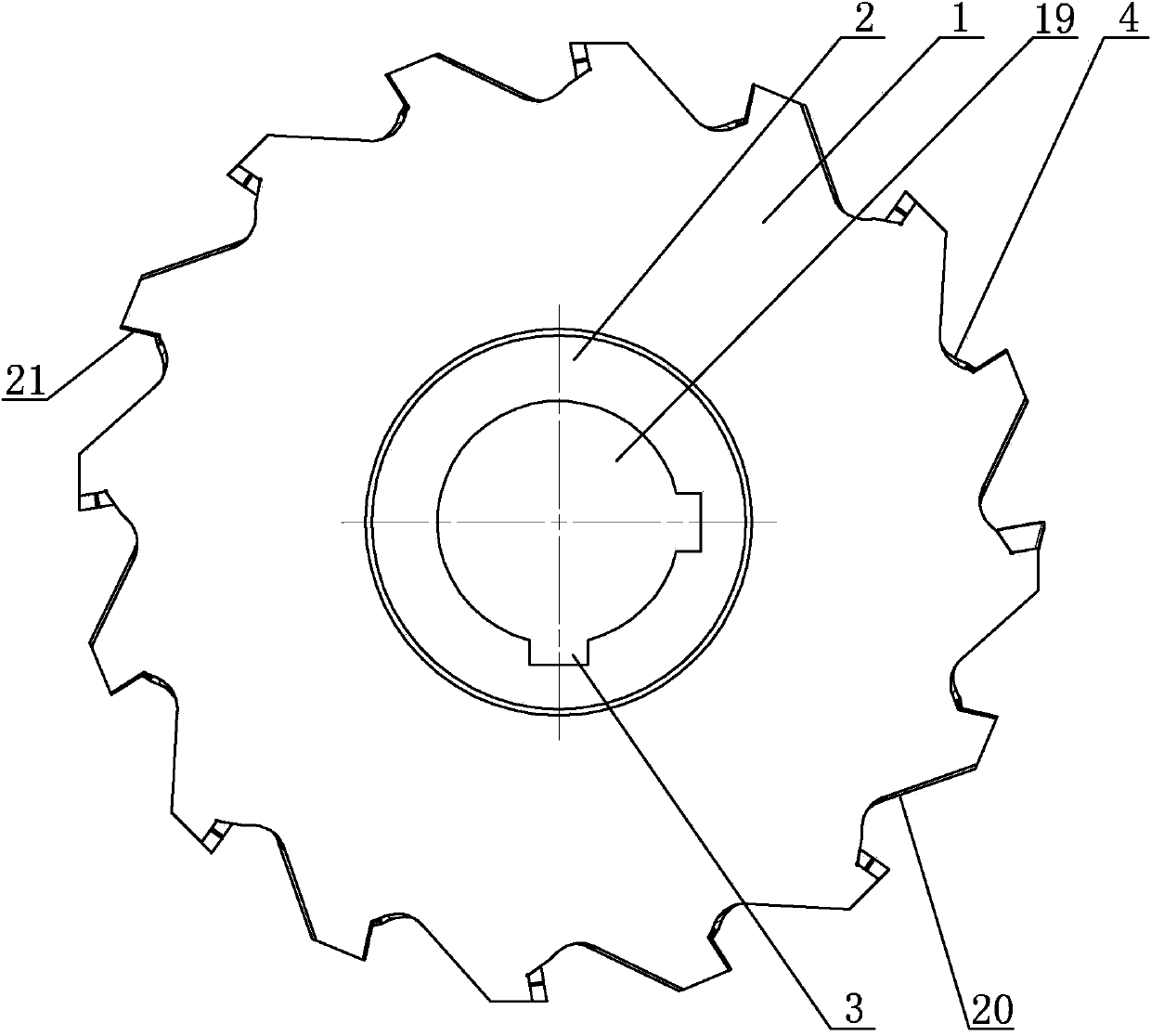

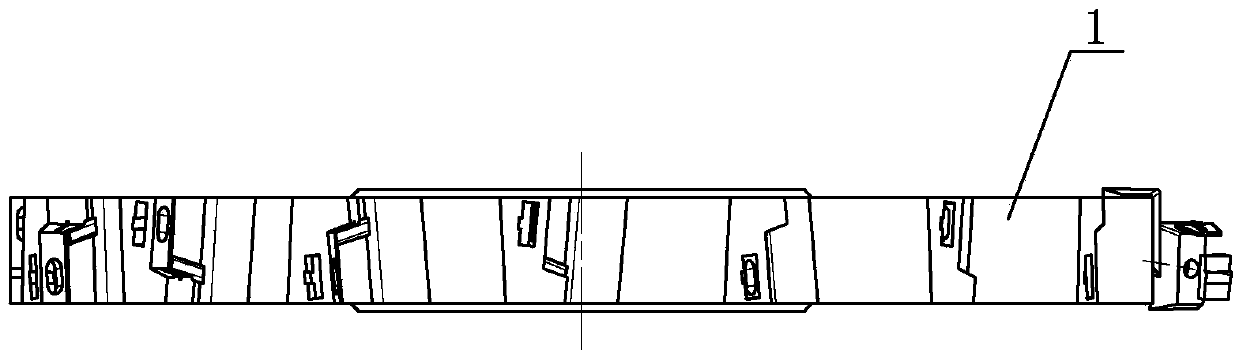

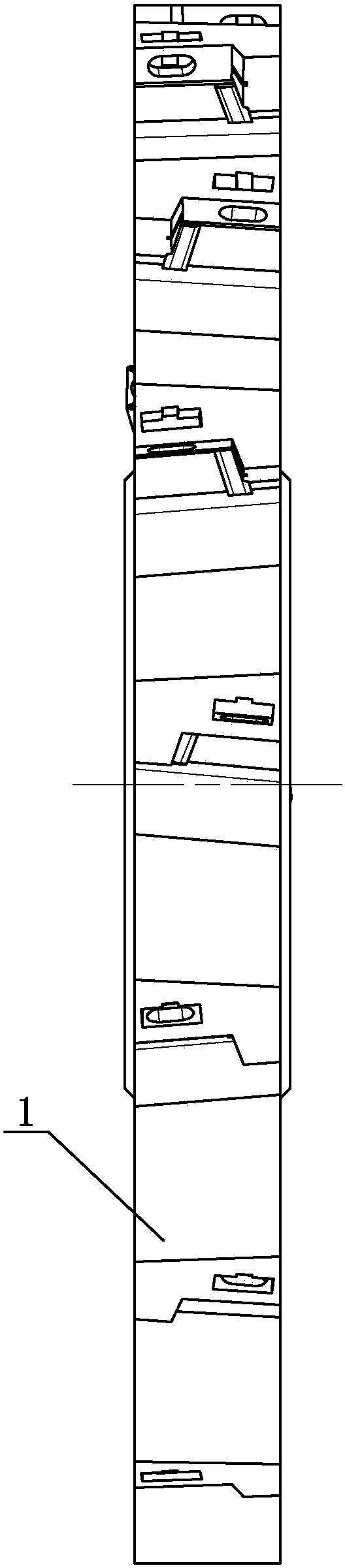

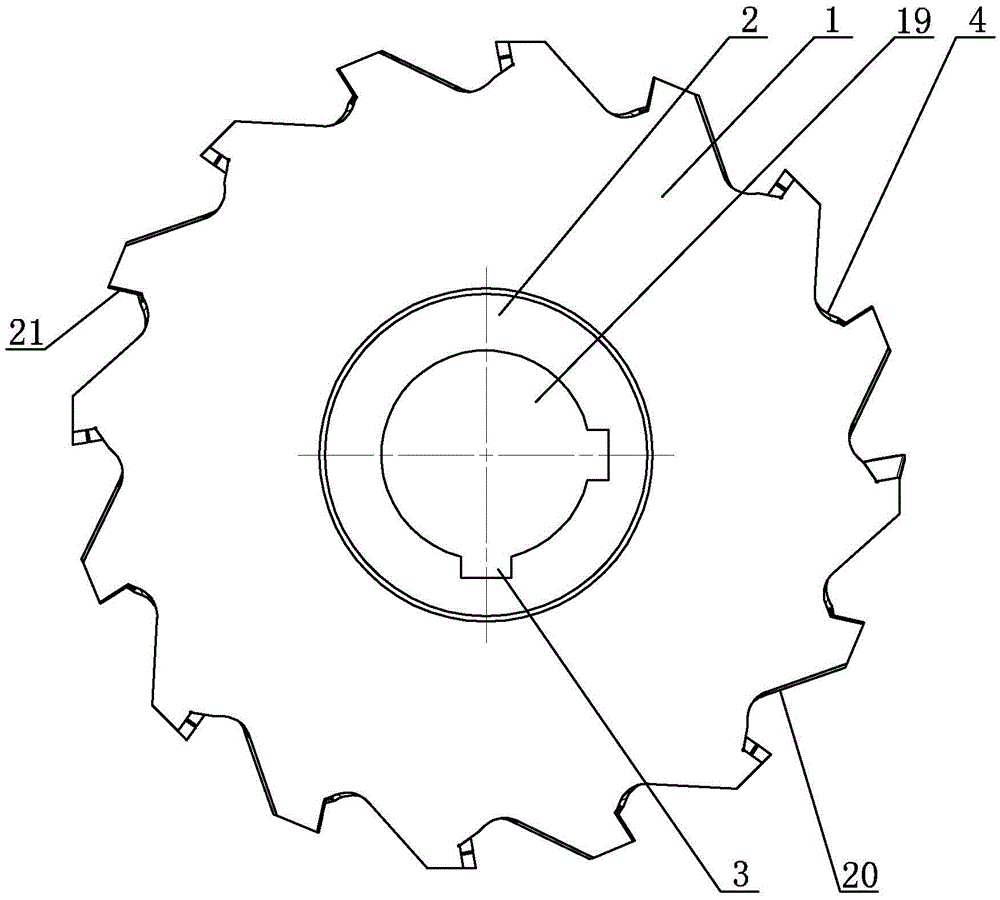

Special cutting-width-variable three-edge milling cutter for grooving overall blade disk

InactiveCN103769663AReduce processing costsIncrease productivityMilling cuttersMilling cutterEngineering

The invention discloses a special cutting-width-variable three-edge milling cutter for grooving an overall blade disk, belongs to the technical field of machining tools, and aims to solve the problems of tool abrasion, poor chip removal effect, poor machining quality, non-adjustable blade position, low machining efficiency, high production cost, large tool manufacturing difficulty and inconvenience in tool installation when the overall blade disk is grooved and machined by an existing three-edge milling cutter. A central bushing is fixedly arranged in a cutter body; N chip removal grooves are uniformly formed in the outer circumferential surface of the cutter body; two groove inner side surfaces of each chip removal groove are a large inclined surface and a small inclined surface; a cutter groove is formed in the small inclined surface of each chip removal groove; two adjacent cutter grooves are staggered; a threaded block groove is formed in the outer circumferential end surface of the cutter body; an elongated guide groove is formed in the side surface of each cutter groove; a blade is arranged in each cutter groove and is in fastened connection with a threaded hole of a threaded block through a fastening screw which penetrates into a fastening screw hole and each elongated guide groove; when each blade shifts for 0.5mm, 1.0mm or 1.5mm, a cushion block is arranged between each blade and the end surface of the corresponding cutter groove. The special cutting-width-variable three-edge milling cutter is used for grooving the overall blade disk.

Owner:HARBIN UNIV OF SCI & TECH

Machine tool for machining large gear in spiral bevel gear pair

The invention relates to a machine tool for machining a large gear in a spiral bevel gear pair and further relates to the machine tool of the large gear of the spiral bevel gear pair used for an automobile drive axle. Three sets of an X-axis guide rail, a Y-axis guide rail and a Z-axis guide rail which are vertical to each other are arranged on the top face of the machine tool body, and an X-axis slide table, a Y-axis slide table and a Z-axis slide table which move along corresponding guide rails under the action of a driving mechanism are arranged on the X-axis guide rail, the Y-axis guide rail and the Z-axis guide rail. A cutter plate or a grinding wheel is arranged at the bottom of the Z-axis slide table, and a shaft C capable of driving a machined workpiece to rotate is arranged in the Z-axis slide table. The machine tool further comprises a shaft B which penetrates through the front end face and the rear end face of the machine tool body. The front end of the shaft B is connected with a workpiece box, and the rear end of the shaft B is provided with a rotating mechanism driving the shaft to rotate B. A shaft A driving the machined workpiece to rotate is arranged in the workpiece box, and the shaft A is vertical to the shaft B. Compared with an existing device, the machine tool for machining the large gear in the spiral bevel gear pair has the advantages of being simple in structure, economic in cost, convenient to install and detach, capable of easily discharging chips and the like, and is particularly suitable for dry cutting and high-efficiency machining.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

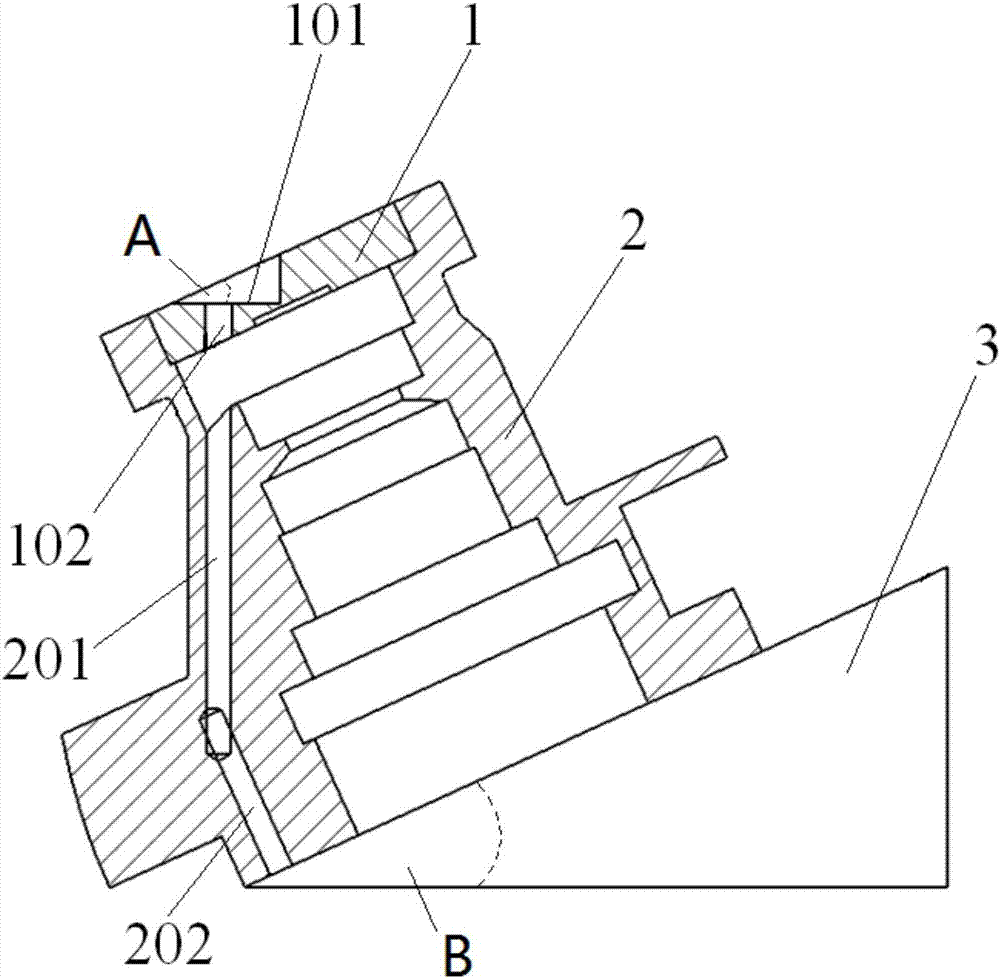

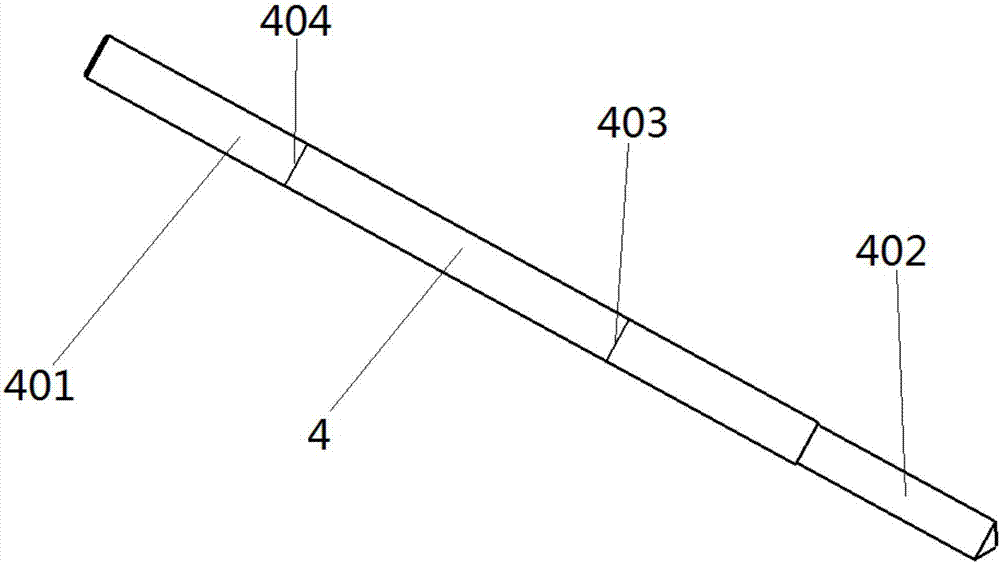

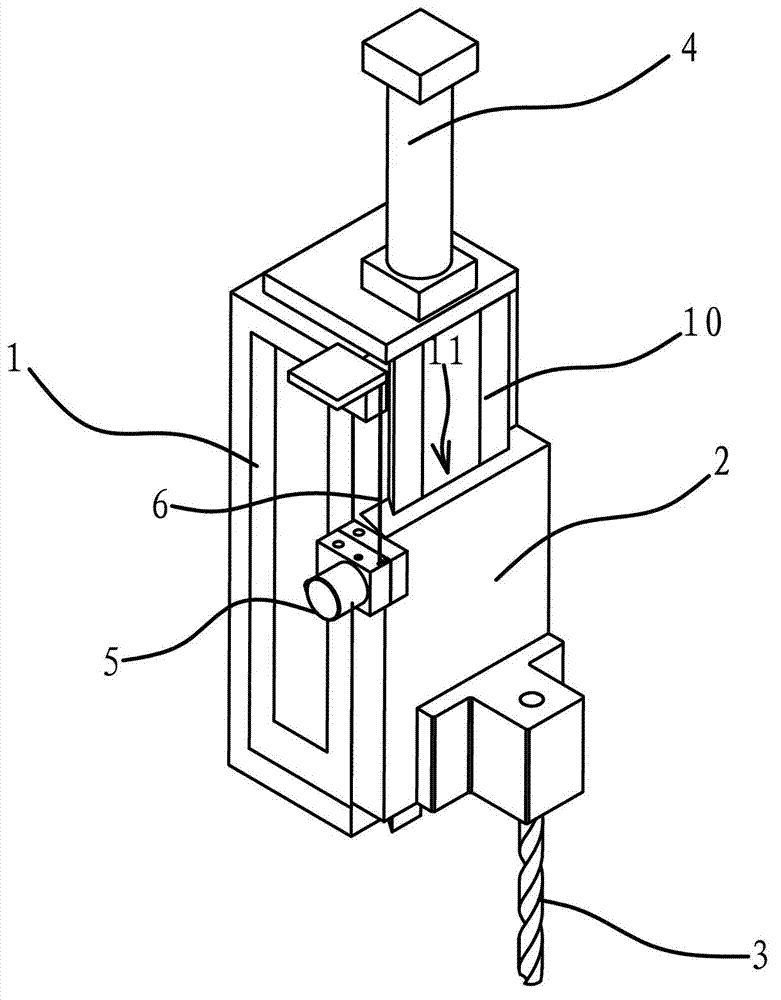

Auxiliary device for machining of oil supply crossed hole of turbine pump and machining and detecting method

ActiveCN107999823ASave machine timeReduce processing costsMechanical measuring arrangementsDrill jigsEngineeringTurbopump

The invention relates to an auxiliary device for machining of an oil supply crossed hole of a turbine pump and a machining and detecting method and belongs to the technical field of machining. The auxiliary device for machining of the oil supply crossed hole of the turbine pump and the machining and detecting method are used for solving the problems that as for existing oil supply crossed holes ofturbine pumps, machining is difficult, cost is high, and detecting is difficult. A machining limiting block is installed in a stepped hole in the upper end of a turbine pump shell, and the turbine pump shell is placed on the inclined end face of an angle positioning cushion block. A machining groove is formed in the upper end face of the machining limiting block, a machining platform is arrangedon the bottom end face of the machining groove, and a through limiting hole is formed in the machining platform. The included angle A formed by the machining platform and the upper end face of the machining limiting block is equal to the included angle B formed between the inclined end face of the angle positioning cushion block and the horizontal direction. By means of the auxiliary device for machining of the oil supply crossed hole of the turbine pump and the machining and detecting method, the machining mode of the oil supply crossed hole of the turbine pump can be simplified, and machining difficulty is reduced.

Owner:航天科工哈尔滨风华有限公司

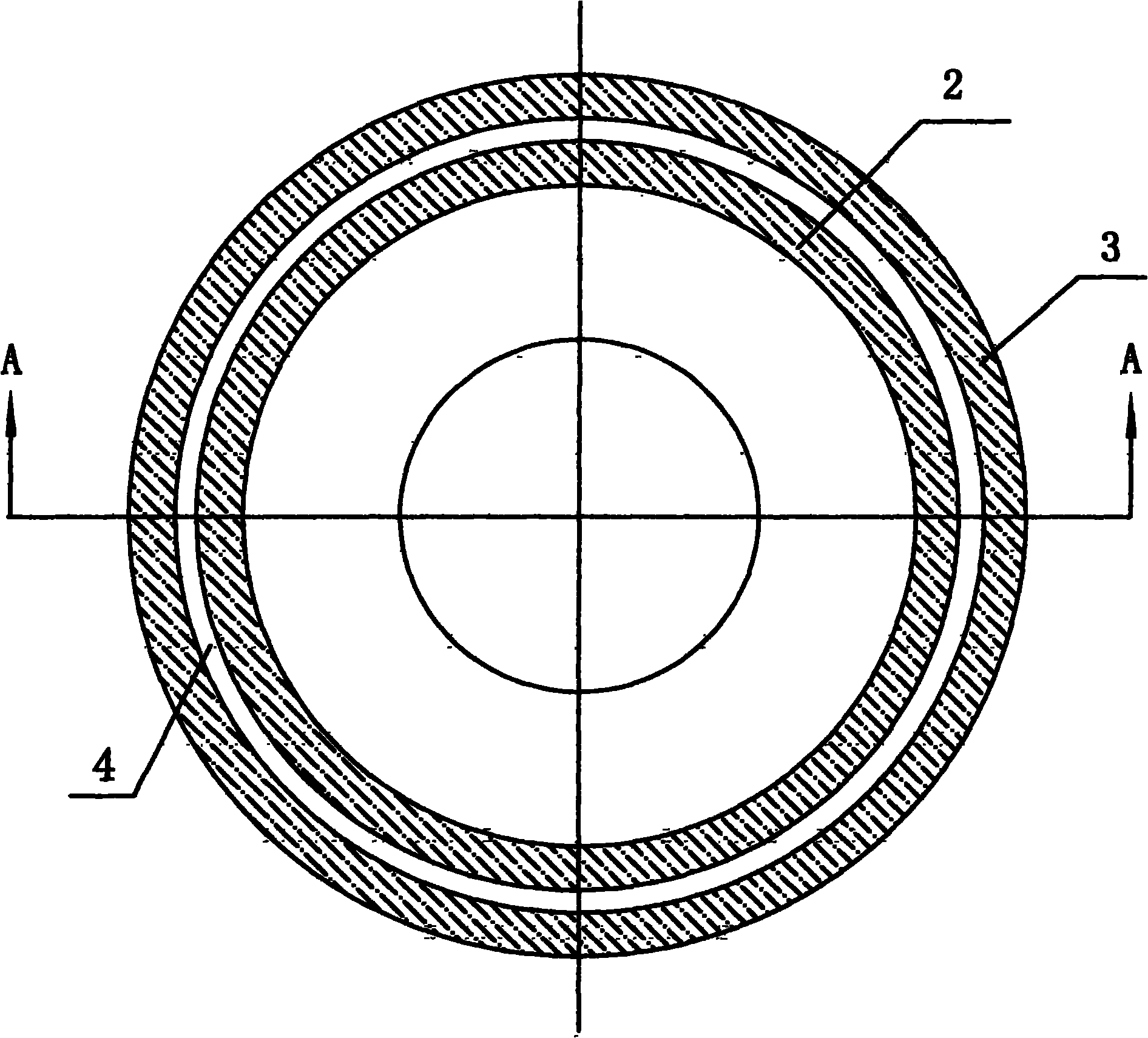

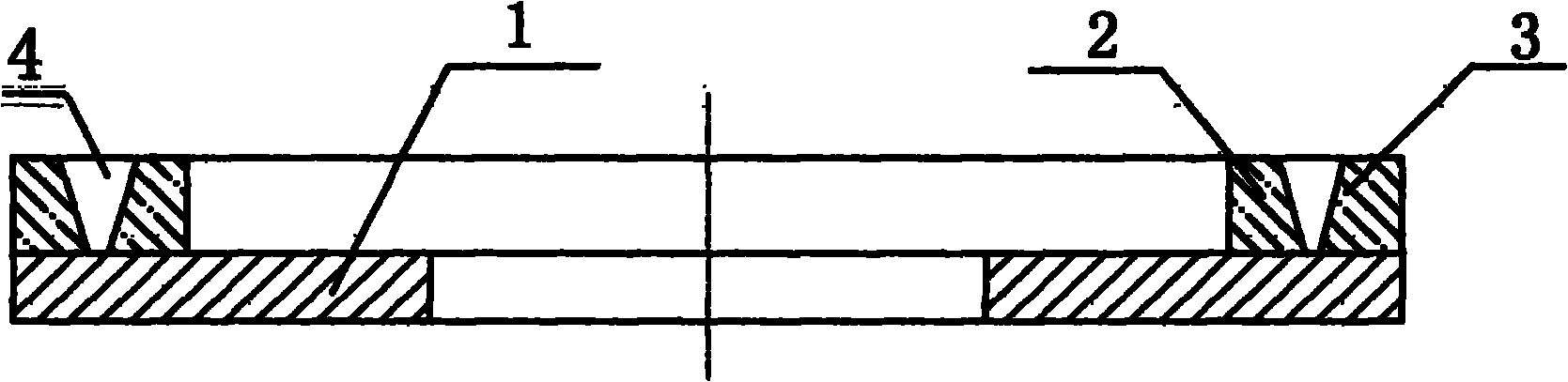

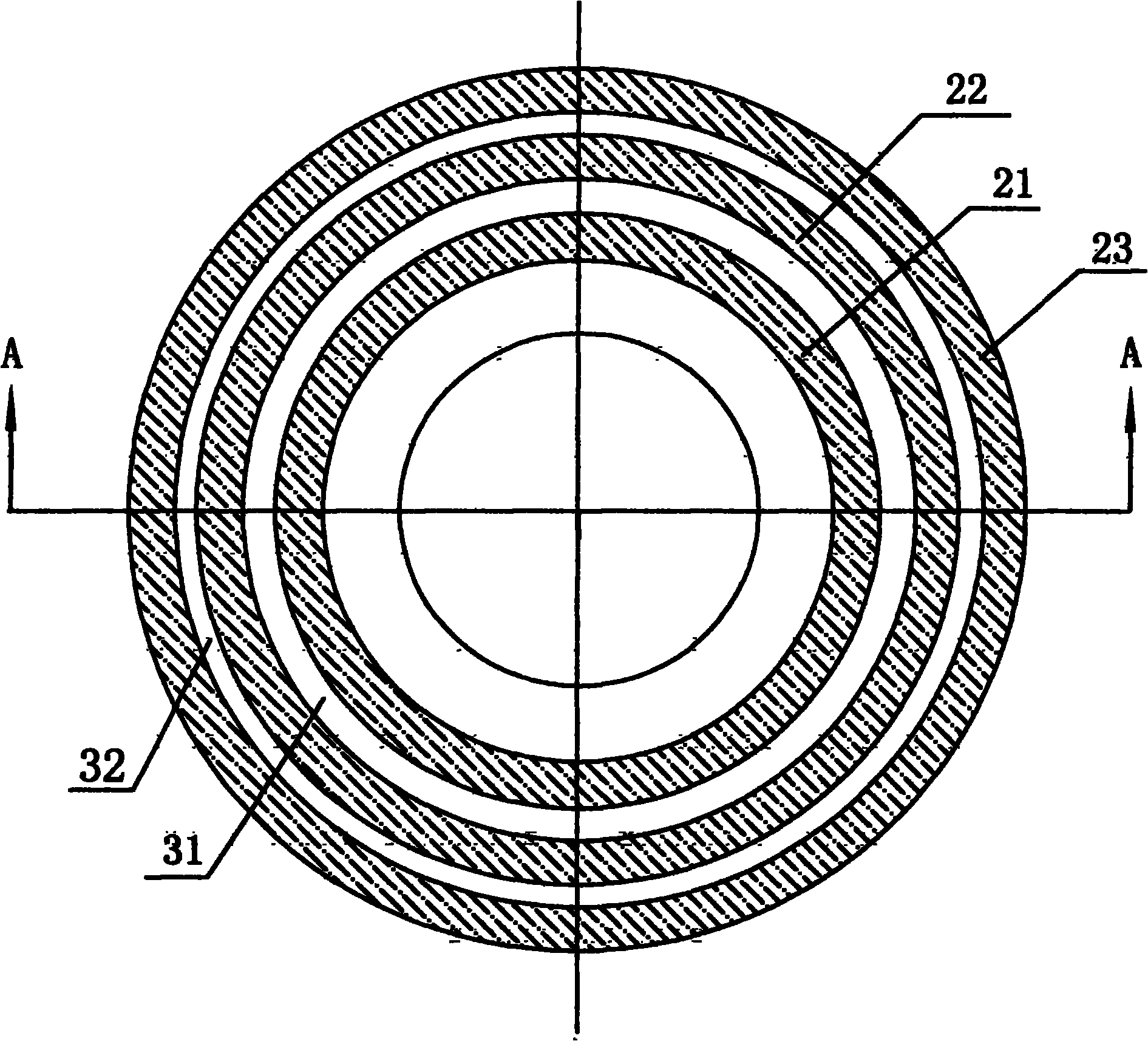

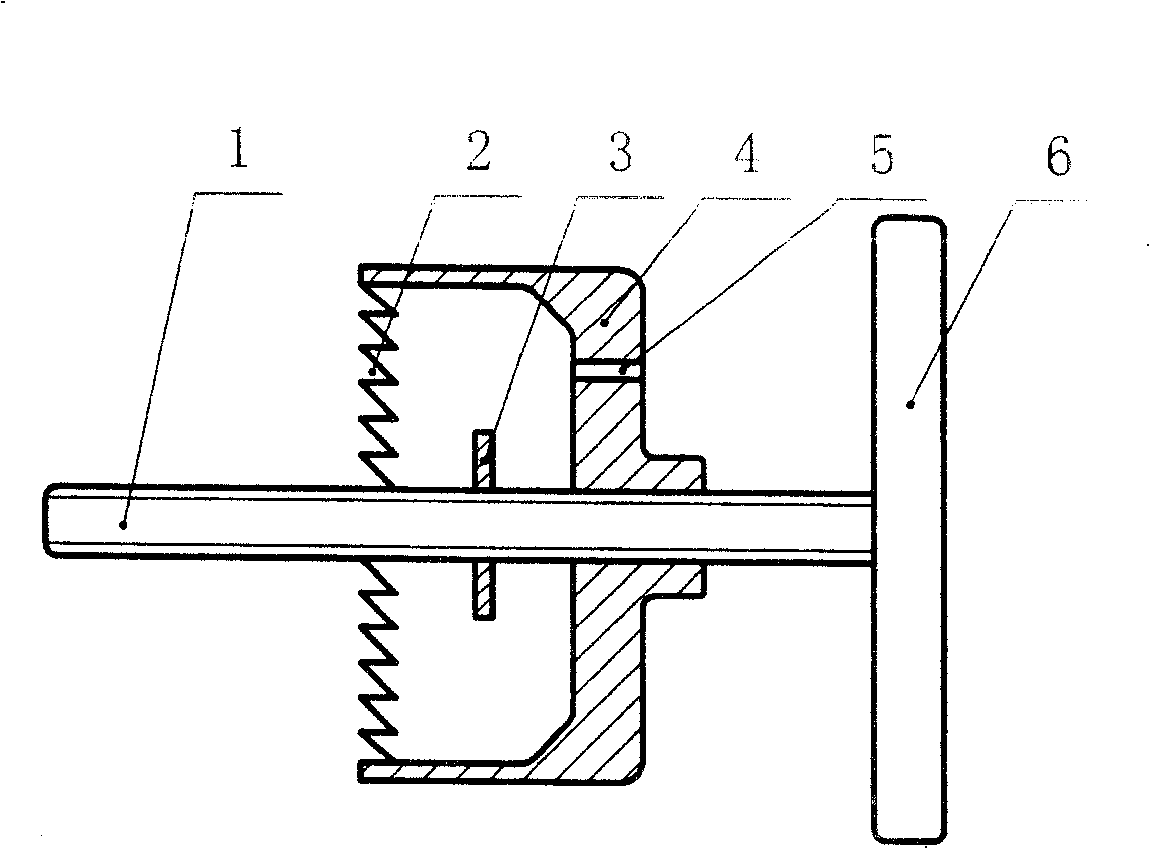

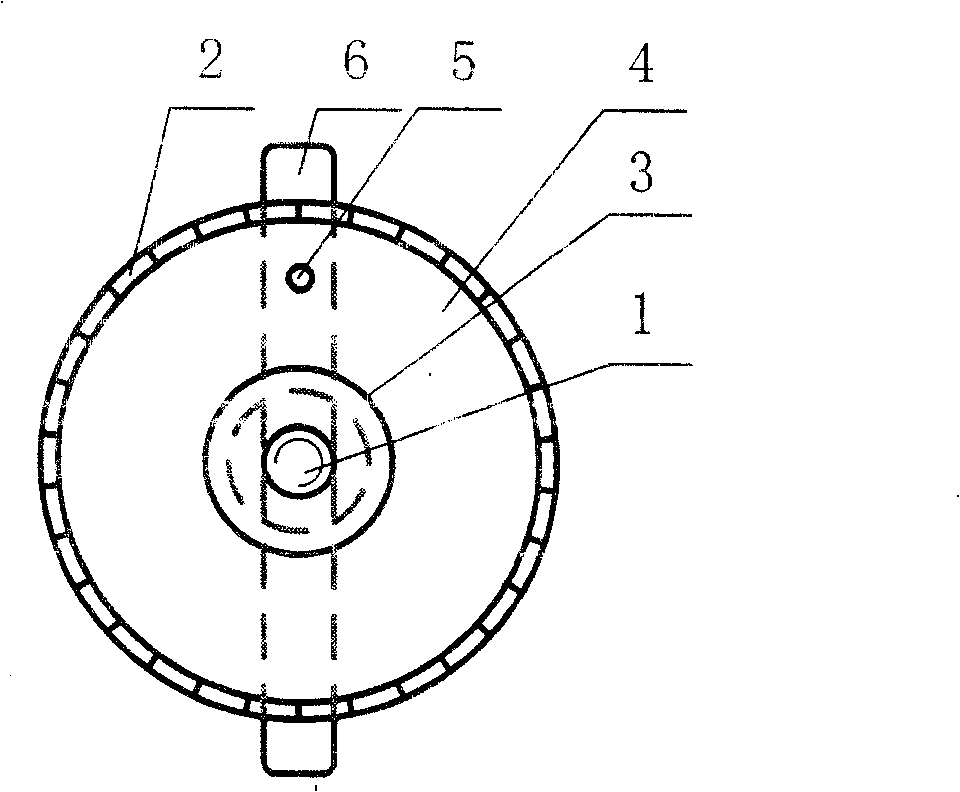

Multi-ring dry grinding wheel for tiles

ActiveCN102059661AEasy to use quantityReduce usageBonded abrasive wheelsEngineeringMachining process

The invention relates to a tool for grinding, in particular to a multi-ring dry grinding wheel applied to ceramic walls and floor tiles. The multi-ring dry grinding wheel comprises a substrate, a plurality of grinding rings and a plurality of circular ring grooves formed between any two adjacent grinding rings of the plurality of grinding rings; the plurality of grinding rings are fixed on the substrate; and the plurality of grinding rings and the plurality of circular ring grooves are concentric circular rings. The multi-ring dry grinding wheel has the advantages of large amount of feed, easiness of heat dissipation, cooling and chip removal and no blocking, can meet requirements of different machining processes, and has the high grinding efficiency and grinding effect.

Owner:珠海市世创金刚石工具制造有限公司

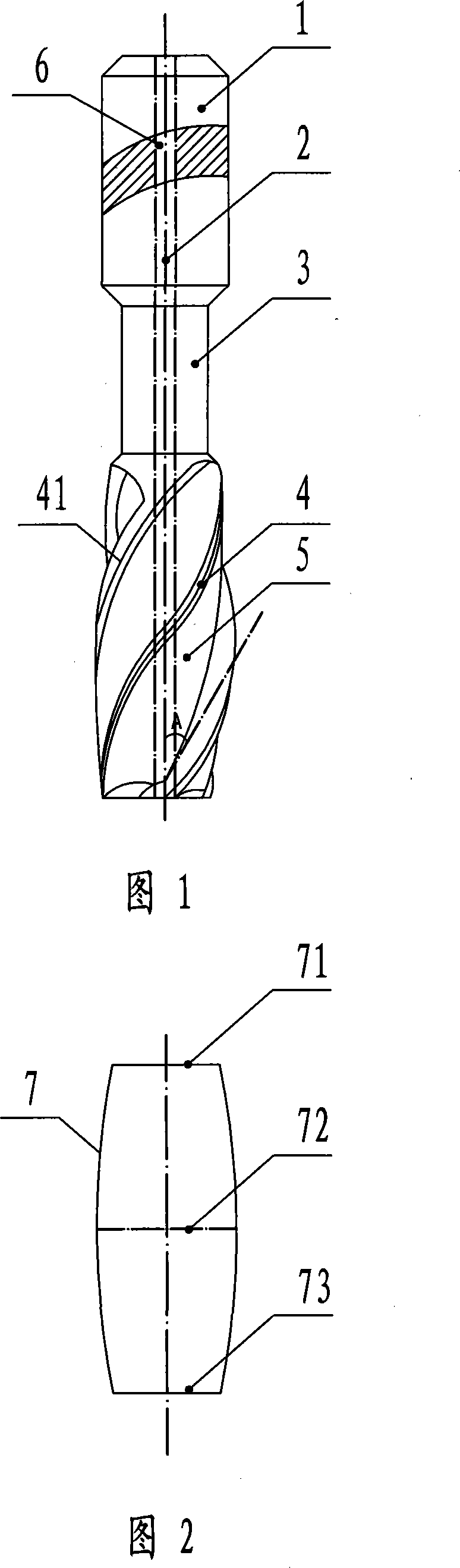

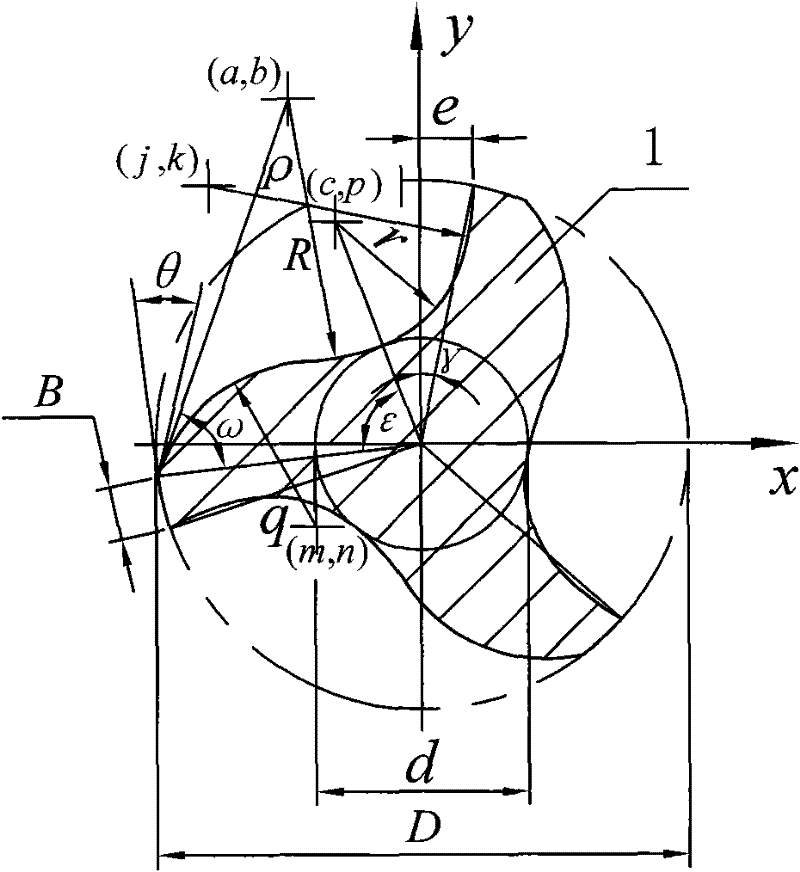

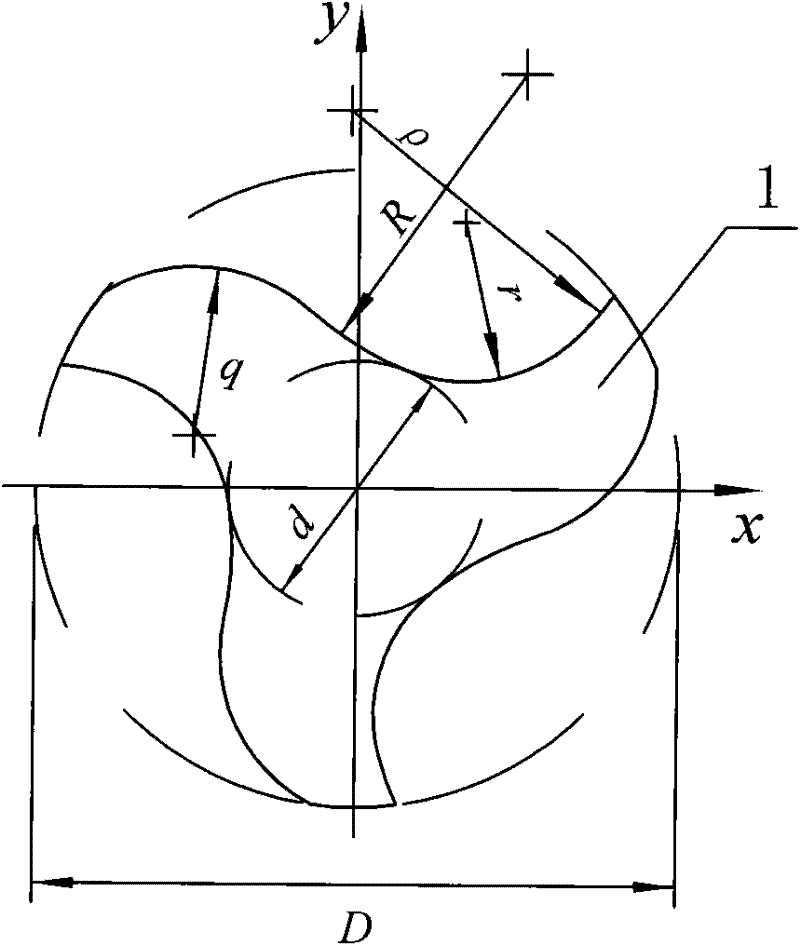

Milling tool for processing inter cavity of level bubble

The present invention relates to milling cutter, and is especially one kind of milling cutter for machining the cavity of level gauge. The milling cutter includes one cutter shank, one edge zone and one connecting zone in between. The edge zone includes 2-12 cutting edges and chip pockets in the same quantity, with the cutting edges being drum shaped. The milling cutter has the features of easy chip removal, long service life and capacity of machining surface in special shape.

Owner:吴东明

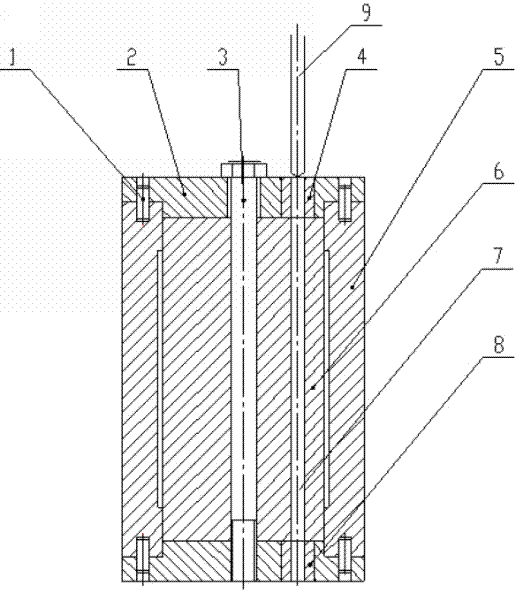

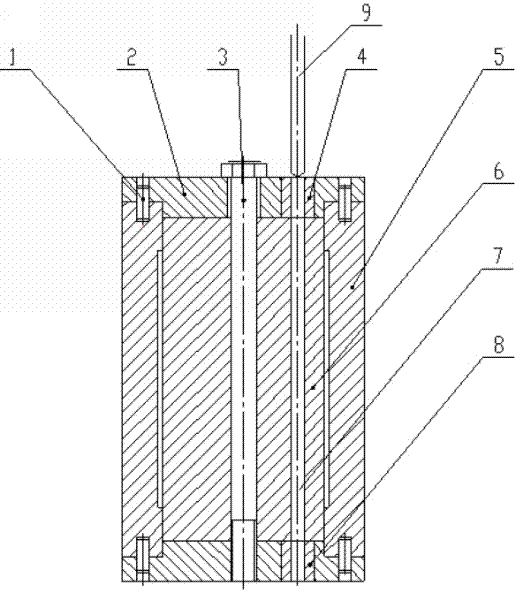

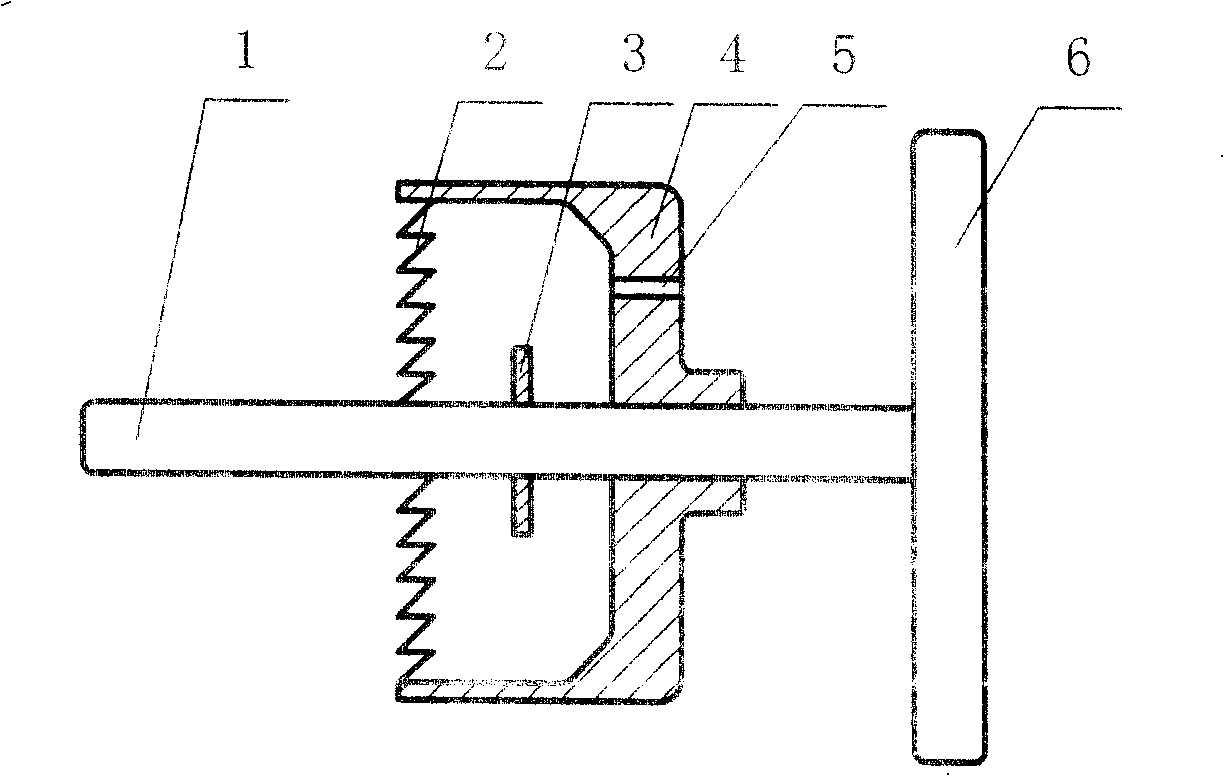

Deep-hole drilling jig

The invention discloses a deep-hole drilling jig for processing deep holes. Two drilling jig plates and a drilling jig body are positioned by positioning pins; a workpiece is arranged in the drilling jig body and between the two drilling jig plates and is pressed by a pressing screw; and the two drilling jig plates are internally and respectively provided with a drilling sleeve I and a drilling sleeve II which are concentric. The deep-hole drilling jig adopts a method of oppositely drilling at two ends to process the deep holes, and since holes concentrically drilled by the two drilling sleeves are not easy to deviate, are high in concentricity are not subjected to limitation of equipment, and the processing of the deep holes can be realized on any drilling machine; the drilling jig can be designed and manufactured according to the shape of the workpiece, and is simple in structure and low in cost; and a lengthened twist drill can not be adopted, chip removal is easy, the fracture of a drilling bit is effectively prevented, the processing cost is reduced and the hole drilling efficiency is high.

Owner:CRRC LUOYANG CO LTD

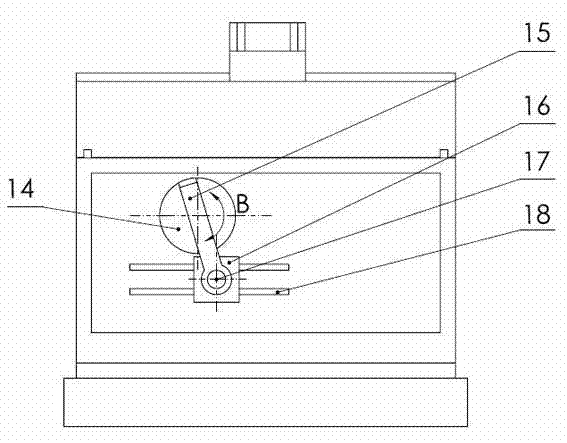

Horizontal type swirl machining center

InactiveCN101434038AGuaranteed accuracyGuaranteed position control accuracyLarge fixed membersMetal working apparatusNumerical controlEngineering

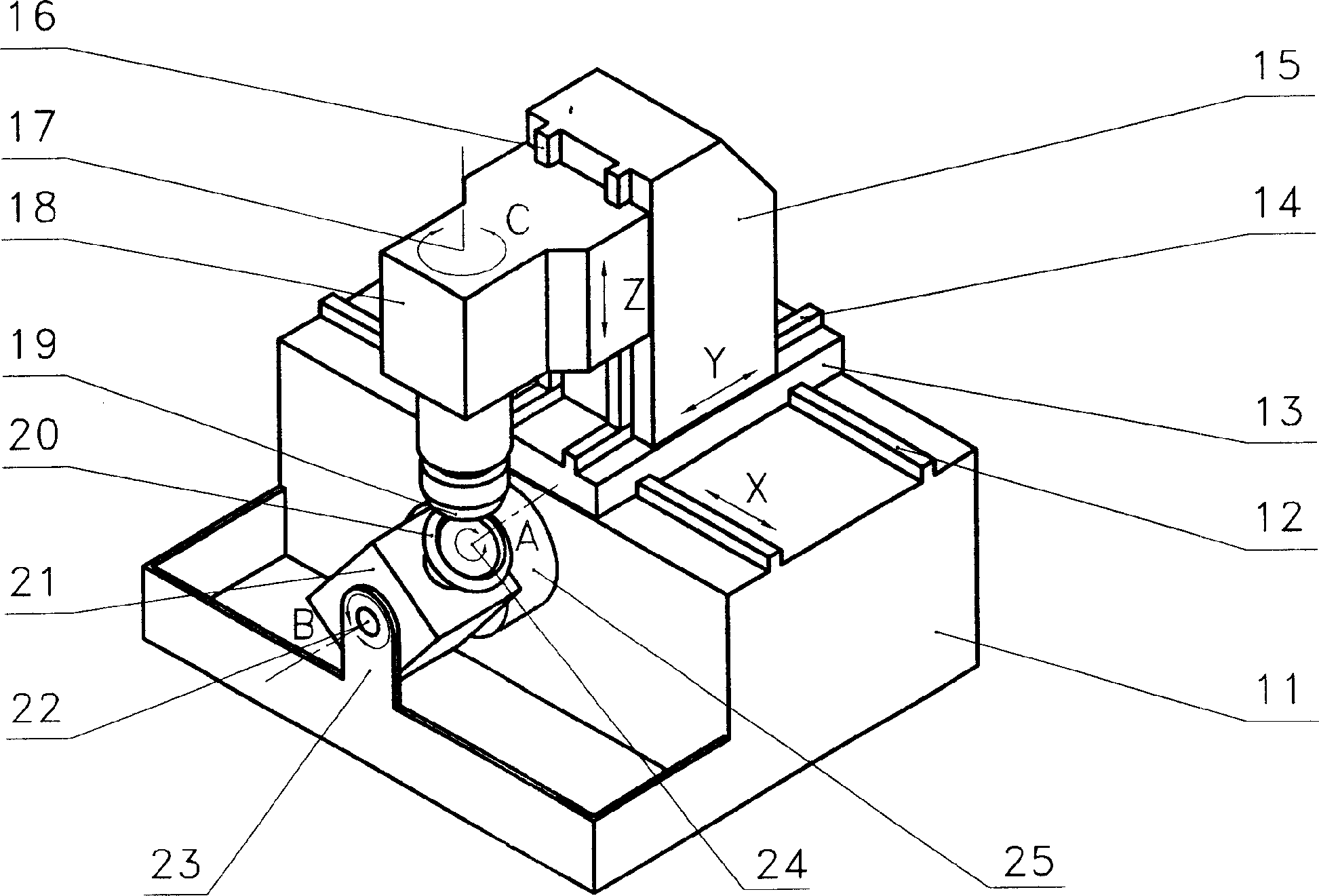

The invention relates to a horizontal vortex machining center, which relates to a high-grade digital control machine tool product for processing a key component of a vortex compressor. The horizontal vortex machining center consists of a lathe bed, an upright post, a precise milling electrical main shaft, a machining center main shaft, a machining center tool magazine, a workpiece moment motor main shaft, a Z-axis guide rail, a Z-axis slider, a Y-axis guide rail, a Y-axis slider, an X-axis guide rail, an X-axis slider, etc., wherein the X-axis guide rail is arranged on the lathe bed; the precise milling electrical main shaft is arranged on the X-axis slider; the Z-axis guide rail is arranged on the lathe bed; the upright post is arranged on the Z-axis slider; the Y-axis guide rail is arranged on the upright post; the workpiece moment motor main shaft is arranged on the Y-axis slider; the machining center main shaft is arranged on the X-axis slider; the workpiece moment motor main shaft is a C gyro shaft and horizontally arranged on the Y-axis slider. The horizontal vortex machining center guarantees the precision requirement of workpieces, is easy to remove scrap iron, and avoids influence on the surface quality of the workpieces due to accumulation of the scrap iron.

Owner:GUANGZHOU CITY AGILE MFG

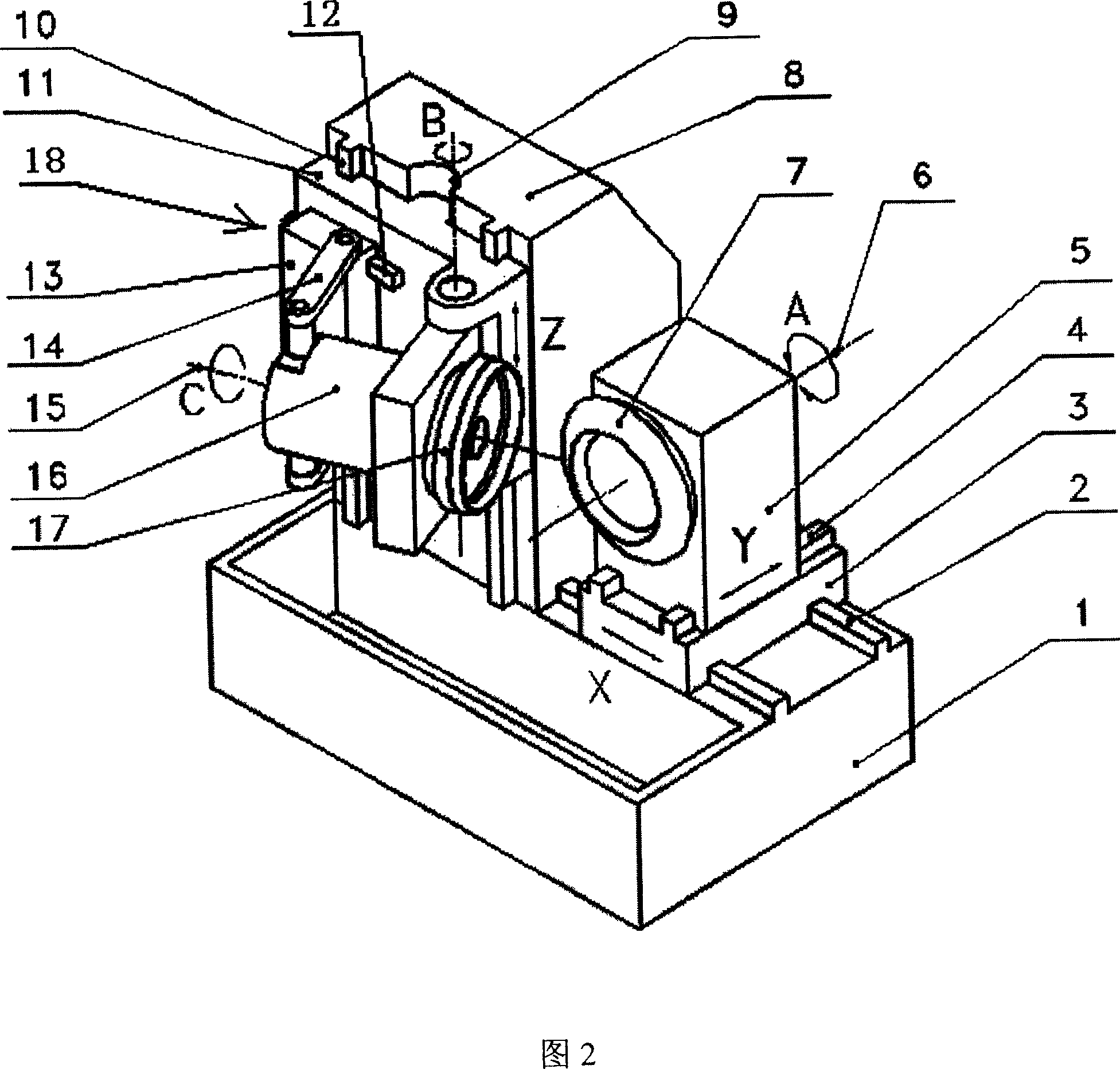

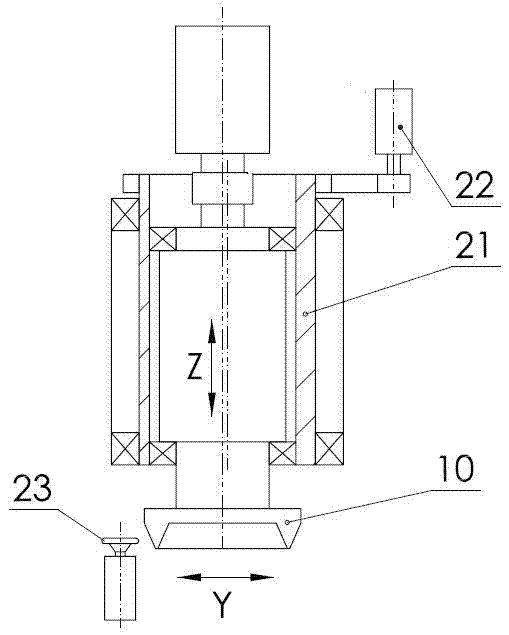

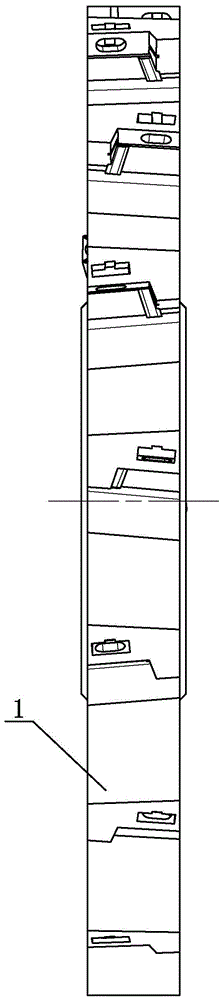

Numerical control gear grinding machine

PendingCN110340450AReduce jitterCompact structureGear-cutting machinesGear teethGear grindingNumerical control

The invention discloses a numerical control gear grinding machine. The numerical control gear grinding machine comprises a machine bed, and a sliding table is movably arranged on the machine bed alongthe axis X. A stand column is movably arranged on the sliding table along the axis Z. a grinding wheel box is movably arranged on the side wall of the stand column along the axis Y. A grinding wheelspindle C is rotationally arranged in the grinding wheel box, and a grinding wheel is mounted at one end of the grinding wheel spindle C. A rotary shaft box is mounted on the machine bed, and a rotaryshaft B is rotationally arranged in the rotary shaft box. A workpiece box is arranged at the end, out of the rotary shaft box, of the rotary shaft B. The workpiece box rotates along with the rotary shaft B, and a workpiece spindle A is rotationally arranged in the workpiece box. The workpiece spindle A is perpendicular to the rotary shaft B, and a workpiece is mounted at the end, close to the grinding wheel spindle C, of the workpiece spindle A. A grinding wheel dresser is arranged on the machine bed. The numerical control gear grinding machine has the advantages of being compact in structure, small in occupied area, high in stability, convenient to operate, high in machining precision and convenient for grinding wheel dressing.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

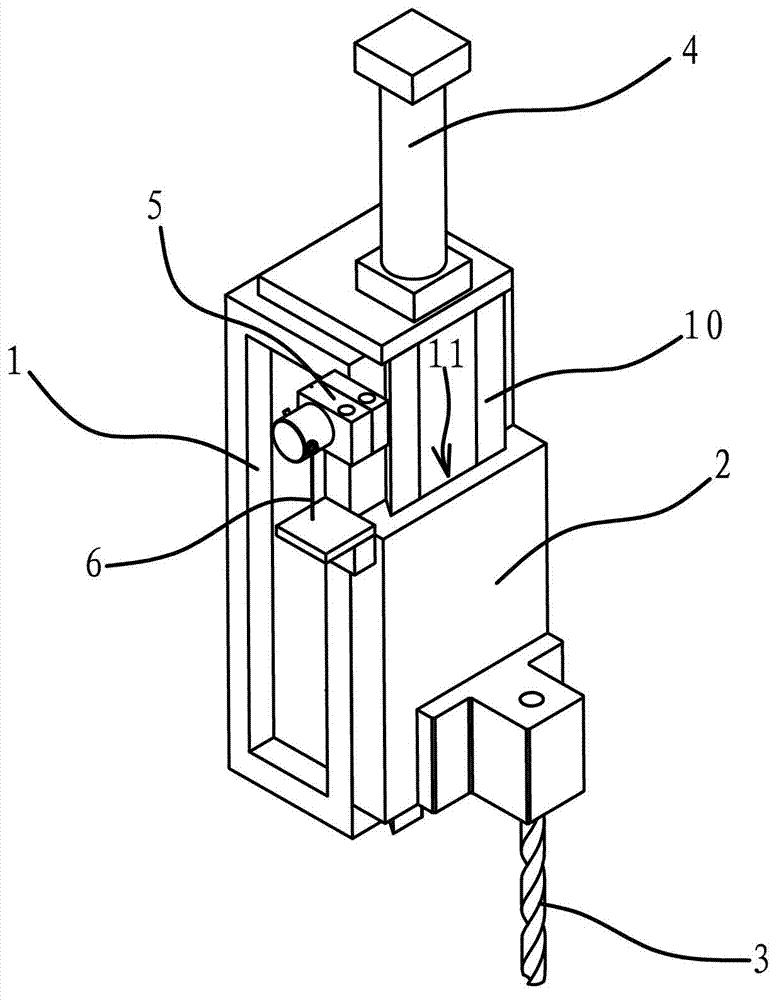

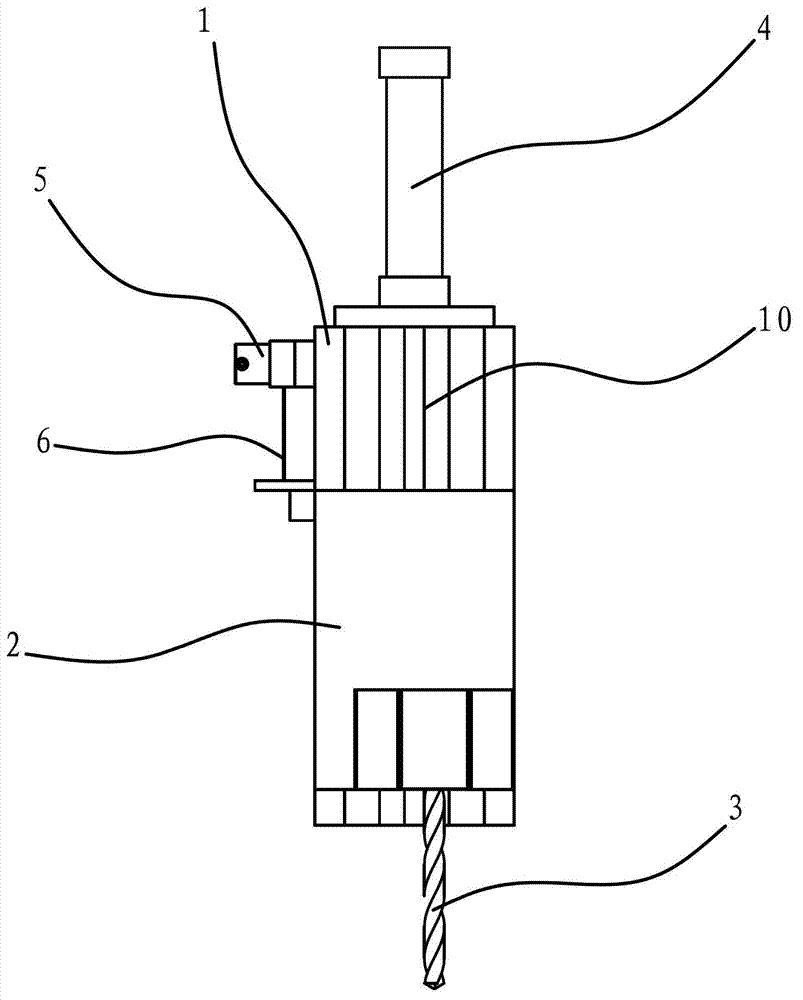

Feed device for processing deep holes

InactiveCN102764908ASafe and stable useReduce tool damageAutomatic control devicesFeeding apparatusLow speedMachine tool

The invention provides a feed device for processing deep holes and belongs to the technical field of machine tool components. The device solves the problems that prior feed devices for processing deep holes are complex in structure and poor in processing stability. The feed device comprises a rack and a control device, wherein a moving sliding block is arranged on the rack, one end of the moving sliding block is connected with a first driving member, the other end of the moving sliding block is connected with a cutter, the first driving member can drive the moving sliding block to make a translational motion, the control device can control the first driving member to drive the moving sliding block to make a multiple reciprocating translational motion, and when the first driving member drives the moving sliding block to translate to a prior translation exit position, the control device enables the first driving member to drive the moving sliding block, so that the high-speed feed motion is changed to a low-speed feed motion. The feed device has the advantages of being simple in structure and good in processing stability.

Owner:TAIZHOU LIPENG AUTOMATION CONTROL EQUIP

Machining method for deep and narrow annular groove

Provided is a machining method for a deep and narrow annular groove. The method comprises the following steps that firstly, a dedicated fixture and dedicated tools are designed and manufactured, design and positioning are carried out according to the shape of the deep and narrow annular groove, the fixture is fixed, the tools are designed, and manufacturing is carried out; secondly, the two tools used for rough machining and fine machining are prepared, and the rough machining tool is 2.8 + / - 0.1 mm, the fine machining tool is 3.4 + / -0.1 mm; thirdly, the tools are installed on a tool rest of a machine tool, and the height of the tools is slightly larger than the center line of a product by 0.2 mm to 0.5 mm; fourthly, a mandrel prepared for adjusting the position of the tools; fifthly, the amount of tool feeding is selected to range from 0.05 m to 0.15 m per minute, and the cutting speed ranges from 80 m to 100 m per minute; sixthly, kerosene emulsion cooling liquid is selected to serve as cutting liquid. According to the machining method, the quality is favorable to guarantee, the yield can reach 99%, the production efficiency is greatly improved, and the operation is convenient and safe.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Turning tool for improving quality of surface of flange end face sealing groove

PendingCN104607673AIncrease the secondary declinationReduce cutting forceCutting insertsTurning toolsMachining deformationEngineering

The invention provides a turning tool for improving the quality of the surface of a flange end face sealing groove. A grooving tool is provided with a main cutting edge, tool nose smoothing edges and auxiliary cutting edges. The main cutting edge, the tool nose smoothers and the auxiliary cutting edges are integrally formed in a grinding mode. According to the main cutting edge of the grooving tool, an original linear common end face grooving turning tool main cutting edge is improved into a concave circular-arc-shaped main cutting edge. According to the two tool nose smoothers, original common end face grooving turning tool nose circular arc radiuses are improved into tool noses with smoothing edges, the surface quality is improved by one time while the same feeding can be ensured. According to the auxiliary cutting edges on the two sides of the grooving tool, the width of an original common end face grooving turning tool is improved to be half of the width of a sealing groove, chip removing is easy, and gear marks are reduced. The turning tool has certain universality and is suitable for machining flange type parts, the machining deformation is small, the surface quality is high, the production period is greatly shortened, the production cost is reduced, and therefore the turning tool can be applied and popularized.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

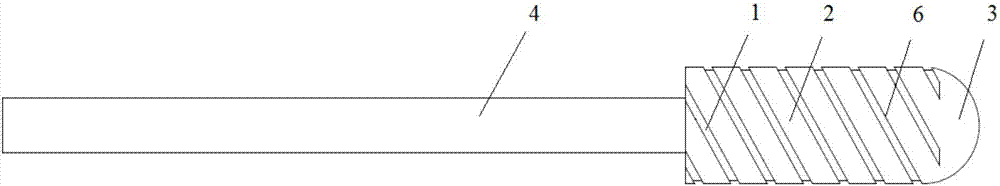

Honing cutter and machining center

InactiveCN106312787ANot easy to go off trackImprove machining accuracyHoning toolsEngineeringFriction force

The invention discloses a honing cutter and a machining center, and relates to the technical field of engineering machines. The technical problem that in the prior art, the hole machining precision is low is solved. The honing cutter comprises a cutter handle and a stepped honing head which are in driving connection, and the cutter handle is a self-centering cutter handle. In the process of driving the cutter handle to rotate through friction force, the cutter handle can provide centering force for the stepped honing head, wherein the centering force can make the center line of the stepped honing head get close to the center line of a machined hole. The stepped honing head at least comprises a micro honing part, a half micro honing part and a rough honing and guiding part in the direction away from the cutter handle, wherein the micro honing part, the half micro honing part and the rough honing and guiding part are sequentially connected. The machining center comprises a rotating shaft and the provided honing cutter. The honing cutter and the machining center are used for improving the hole machining precision and the hole machining efficiency.

Owner:XCMG CONSTR MACHINERY

Six-shaft and five-linked machine tool for spiral conical gears

A six-axle five-leakage machine-tool for machining spiral bevel gear is composed of a main body, X-axis straight guide track on said main body, X-axis slide table on said X-axis track, Y-axis straight guide track on said X-axis slide table, a slide vertical post on said Y-axis track, a Z-axis guide track on one lateral surface of said vertical post, a cutting tool box moving on said Z-axis track, a C axle on said cutting tool box for installing cutter head or abrasive disc, a B axle for driving cutting tool box to rotate, and an A axle on said cutting tool box for installing the spiral bevel gear to be machined.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Integral blisk grooving special variable cutting width three-sided milling cutter

InactiveCN103769663BReduce processing costsIncrease productivityMilling cuttersMilling cutterEngineering

The invention discloses a special cutting-width-variable three-edge milling cutter for grooving an overall blade disk, belongs to the technical field of machining tools, and aims to solve the problems of tool abrasion, poor chip removal effect, poor machining quality, non-adjustable blade position, low machining efficiency, high production cost, large tool manufacturing difficulty and inconvenience in tool installation when the overall blade disk is grooved and machined by an existing three-edge milling cutter. A central bushing is fixedly arranged in a cutter body; N chip removal grooves are uniformly formed in the outer circumferential surface of the cutter body; two groove inner side surfaces of each chip removal groove are a large inclined surface and a small inclined surface; a cutter groove is formed in the small inclined surface of each chip removal groove; two adjacent cutter grooves are staggered; a threaded block groove is formed in the outer circumferential end surface of the cutter body; an elongated guide groove is formed in the side surface of each cutter groove; a blade is arranged in each cutter groove and is in fastened connection with a threaded hole of a threaded block through a fastening screw which penetrates into a fastening screw hole and each elongated guide groove; when each blade shifts for 0.5mm, 1.0mm or 1.5mm, a cushion block is arranged between each blade and the end surface of the corresponding cutter groove. The special cutting-width-variable three-edge milling cutter is used for grooving the overall blade disk.

Owner:HARBIN UNIV OF SCI & TECH

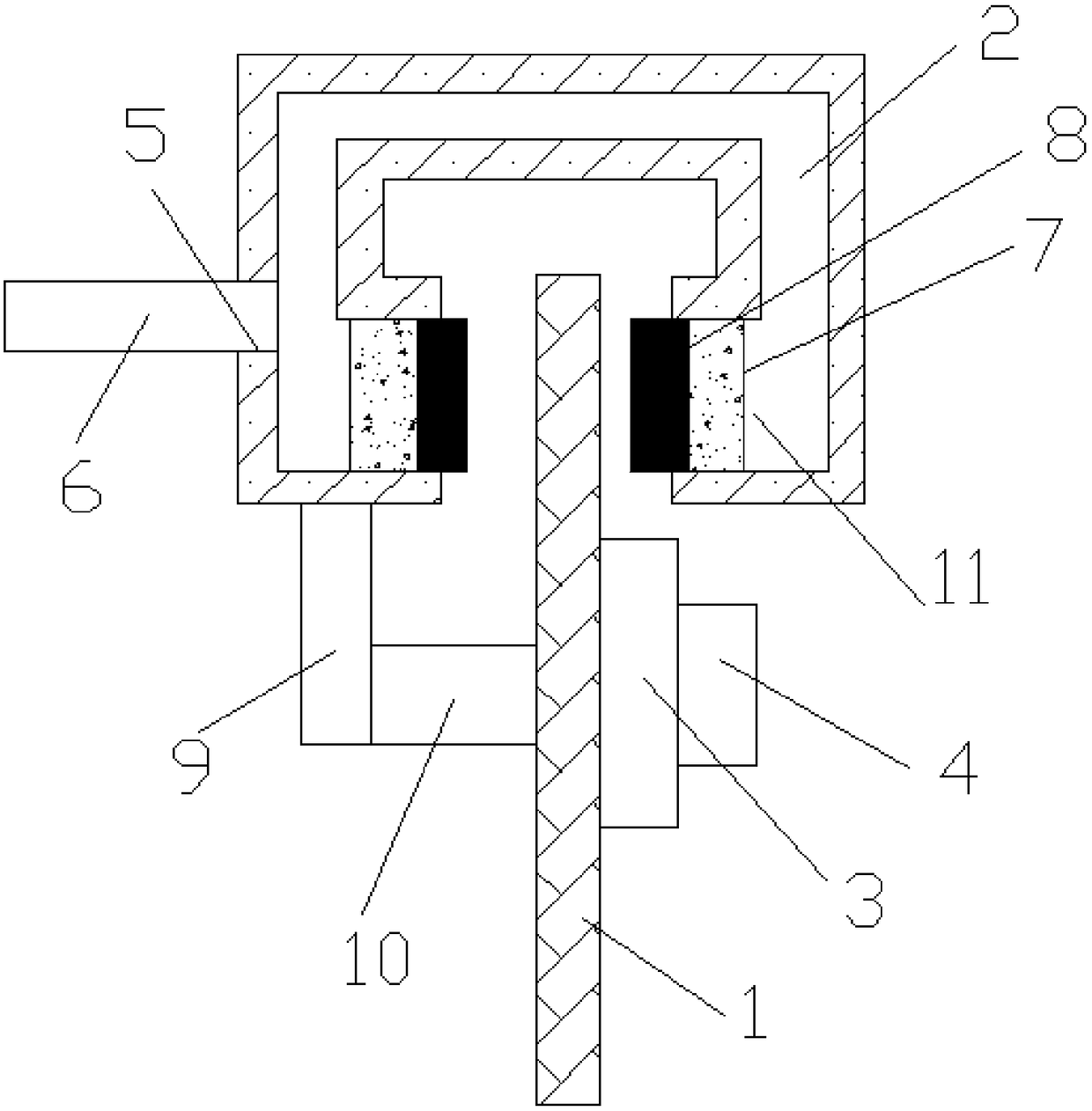

Gasket device of disc brake

PendingCN108317196ASolution to short lifeChip removal is easyBrake actuating mechanismsFriction liningEngineeringPiston

The invention relates to the technical field of brakes, in particular to gasket device of a disc brake. The gasket device of the disc brake comprises a brake disc and a hydraulic inlay, wherein the cardinal plane, located at the geometrical center, of the brake disc is fixedly connected to a fixed disc; the end, far from the brake disc is fixedly connected to a connecting piece; an oil hole is formed in the side wall of the hydraulic inlay; a hydraulic oil pipe is connected to the oil hole in a sleeving manner; two driving cylinders are symmetrically arranged on the side walls corresponding tothe hydraulic inlay; two pistons are arranged on the inner walls of the two driving cylinders; two brake gaskets are fixedly connected to one sides, close to the port parts of the two driving cylinders, of the two pistons; the side wall of one of the driving cylinders is fixedly connected to a fixed bar; and the end, far from the driving cylinder, of the fixed bar is vertically and fixedly connected to a supporting rod. As the two pistons are arranged on the inner walls of the two driving cylinders, the two brake gaskets are fixedly connected to one sides, close to the port parts of the two driving cylinders, of the two pistons, and the two brake gaskets are hydraulically driven to move forward and are attached to the brake disc so as to brake.

Owner:DEQING COUNTY HAICHANG AUTO PARTS CO LTD

A method for processing narrow-groove impellers, a grinding head and a preparation method thereof

Owner:NORTHEASTERN UNIV LIAONING

A high-speed groove milling method for knitting needles

The invention relates to the technical field of mechanical processing, in particular to a high-speed groove milling method for knitting needles. The circular machine needle is fixed on the fixture, and the groove template is fixed on the fixture. After the groove template is fixed, the groove milling tool is installed. , fix the milling tool on the tool driving device, adjust the position of the milling tool so that the milling tool faces the direction of the fixture, fix the tool driving device on the direction adjustment device, start the controller, and control the driving device to drive the milling tool Rotate, the controller controls the direction adjusting device to adjust the position of the milling cutter so that the milling cutter is above the groove template, and then slowly adjust the milling cutter so that the milling cutter is located in the groove hole on the groove template, the direction adjusting device Drive the tool driving device to move, mill the circular machine needle, after the slot milling, the controller controls the direction adjustment device to restore the milling tool to the initial position.

Owner:福建省精新科技制针有限公司

Ring-cutting knife

InactiveCN100411785CSimple structureEasy to useTransportation and packagingTrepanning drillsEngineeringWrench

The invention discloses a paring circle knife, comprising location bearing and cylindrical hollow cutting knife which is nested on the location bearing through center hole. The cylindrical hollow cutting knife can move up and down. On the back of cylindrical hollow cutting knife there is breather, the head of it there are hackly cutting edges, and on the knife there are arrises. The invention has the advantages of simple structure, easy operation, and wide application. The invention is especially used to maintain the mine equipments.

Owner:王中华

Spiral fluted tap and method for processing same

The invention discloses a spiral fluted tap and a method for processing the same. The spiral fluted tap comprises a tap body provided with a plurality of uniformly distributed spiral flutes on a front cut part, wherein the spiral flute is an S-shaped smooth curved groove formed by sequentially connecting four sections of tangential circular arcs end to end; and the four sections of tangential circular arcs are a cutting circular arc, a chip curling circular arc, a chip accommodating circular arc and a blade back circular arc respectively. The method for processing the spiral fluted tap comprises the following steps of: (1) preparing before processing; (2) processing the spiral flute by a special tool: fitting a blade shape of a cutter by a computer, and then manufacturing the cutter according to the fitted cutter blade shape so as to process the spiral flute; and (3) carrying out subsequent treatment by using a machining process so as to obtain a finished product of the tap body. The spiral fluted tap processed by the method has simple structure and can be molded in one step. Moreover, the processing method is suitable for different processing materials, particularly for processing fluted taps made of light alloys, such as an aluminum alloy and the like.

Owner:XIAN TECH UNIV

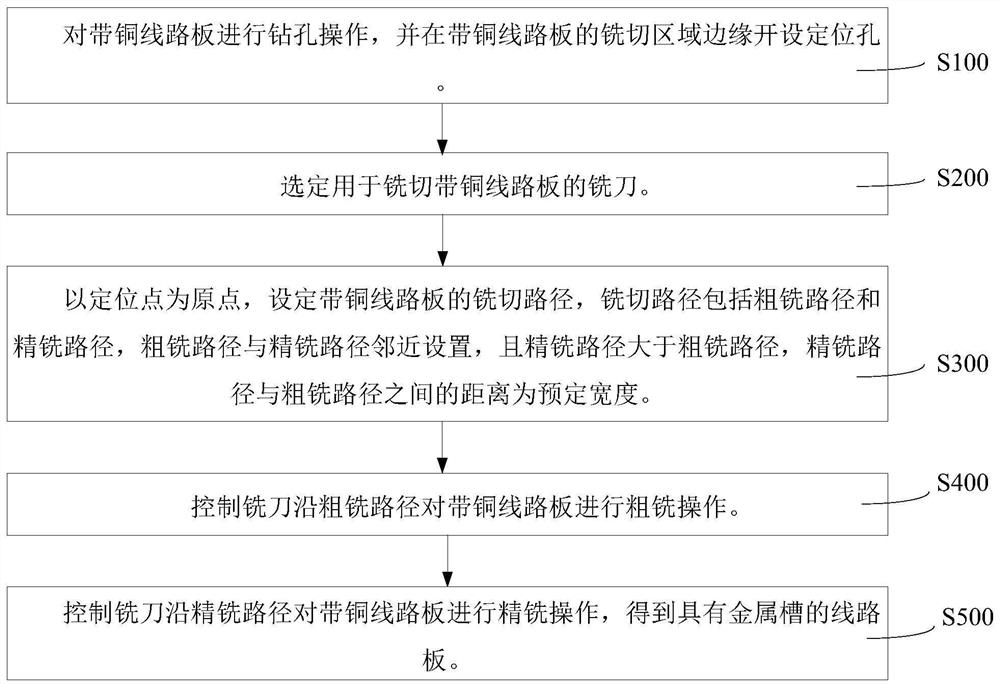

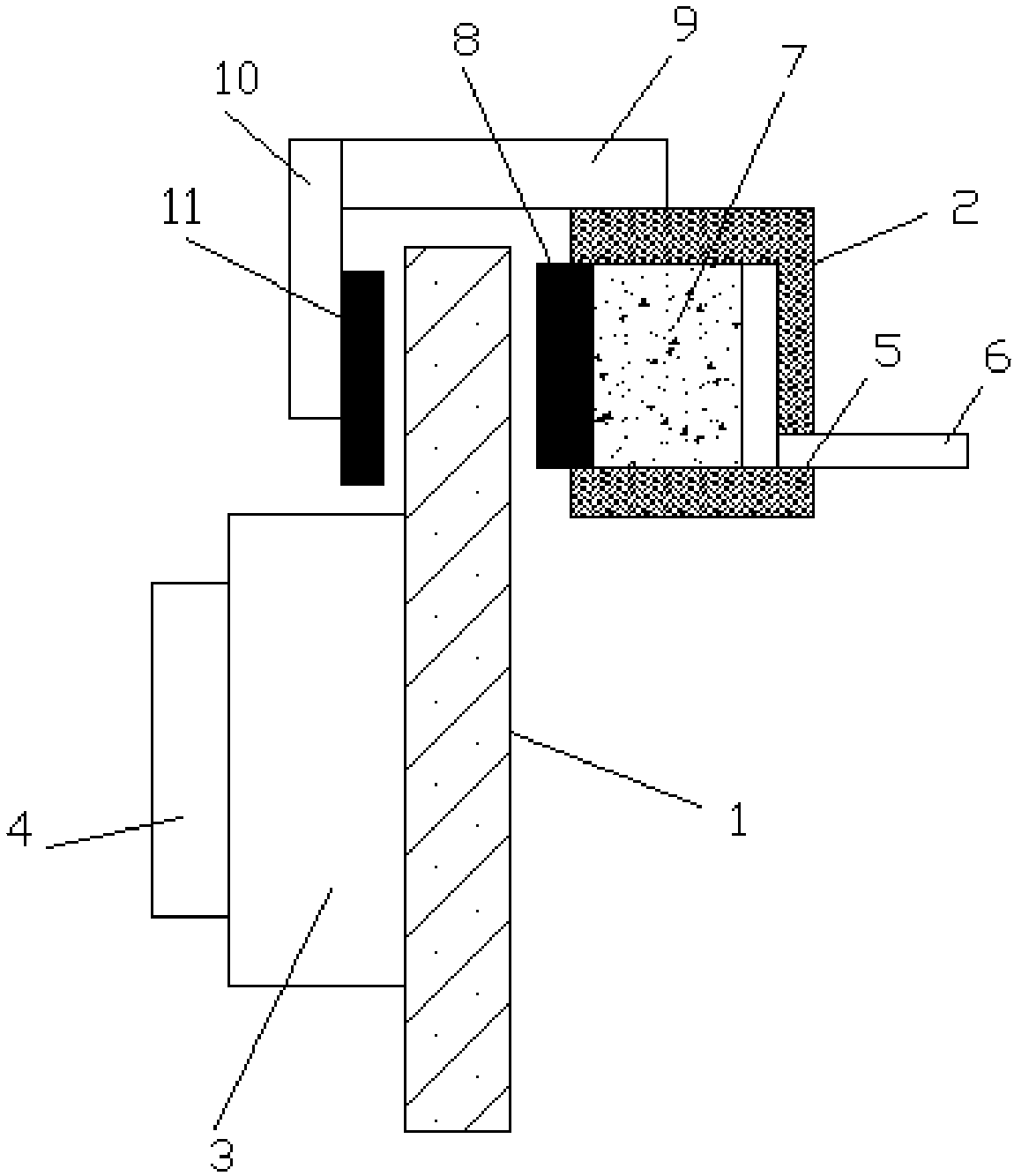

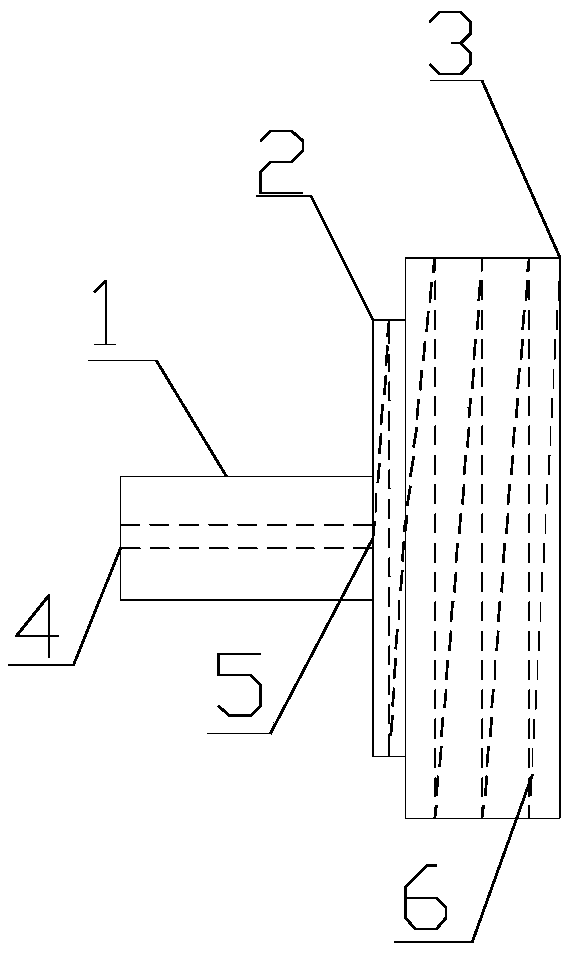

Circuit board processing method

InactiveCN112235954AAvoid prone toReduce volumePrinted circuit manufactureMilling cutterStructural engineering

Owner:HUIZHOU TECHUANG ELECTRONIC TECH CO LTD

Brake with braking pad linings

InactiveCN108278285AChip removal is easyImprove cooling effectAxially engaging brakesBraking discsHydraulic cylinderPulp and paper industry

The invention relates to the technical field of brakes, in particular to a brake with braking pad linings. The brake with the braking pad linings comprises a braking disk and a hydraulic cylinder; thebasal plane, at the geometric center, of the braking disk is fixedly connected with a fixing disk; the end, away from the braking disk, of the fixing disk is fixedly connected with a connection piece; the bottom of the hydraulic cylinder is provided with an oil hole in which a hydraulic oil pipe is connected in a sleeved manner; the inner wall of the hydraulic cylinder is provided with a piston,and the side, close to the port portion of the hydraulic cylinder, of the piston is fixedly connected with the first braking pad lining; the side wall of the hydraulic cylinder is fixedly connected with a fixing rod; the end, away from the hydraulic cylinder, of the fixing rod is perpendicularly and fixedly connected with a supporting rod; and the side wall of the supporting rod is fixedly connected with the second braking pad lining. According to the brake with the braking pad linings, the inner wall of the hydraulic cylinder is provided with the piston, the side, close to the port portion ofthe hydraulic cylinder, of the piston is fixedly connected with the first braking pad lining, the first braking pad lining is hydraulically driven to move forwards to be attached to the braking disk,and in cooperation with attaching of the second braking pad lining to the braking disk, braking is achieved and is stable.

Owner:DEQING COUNTY HAICHANG AUTO PARTS CO LTD

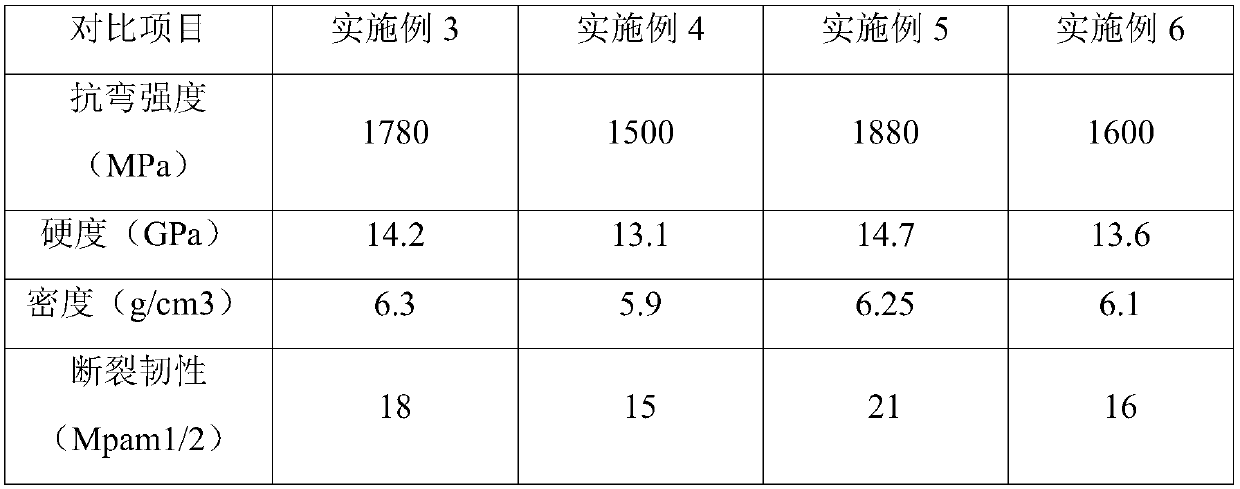

Grinding tool for hard alloy cutter grinding and preparation method thereof

ActiveCN109514359AReduce crackingReduced end face crushingGrinding machine componentsBonded abrasive wheelsWear resistantAlloy

The invention discloses a grinding tool for hard alloy cutter grinding and a preparation method thereof. The grinding tool comprises a fixing end, a substrate and a grinding head. The fixing end is used for being fixed to a grinding machine tool main shaft and is of a hollow structure; one end of the substrate is connected with the fixing end, and the substrate is internally provided with at leastone substrate cooling flow passage; and the grinding head is connected with the other end of the substrate and internally provided with at least one grinding head cooling flow passage, and a surfacechip discharging flow passage is arranged on the grinding part, being in contact with the surface of a workpiece, of the front surface of the grinding head. The hollow structure, the substrate coolingflow passages, the grinding head cooling flow passages and the surface chip discharging flow passage communicate with one another, gas flow or liquid flow can be realized, the grinding tool for hardalloy cutter grinding has good radiating, chip discharging, intensity and wear-resistant properties.

Owner:江西天仙精藏设备有限公司

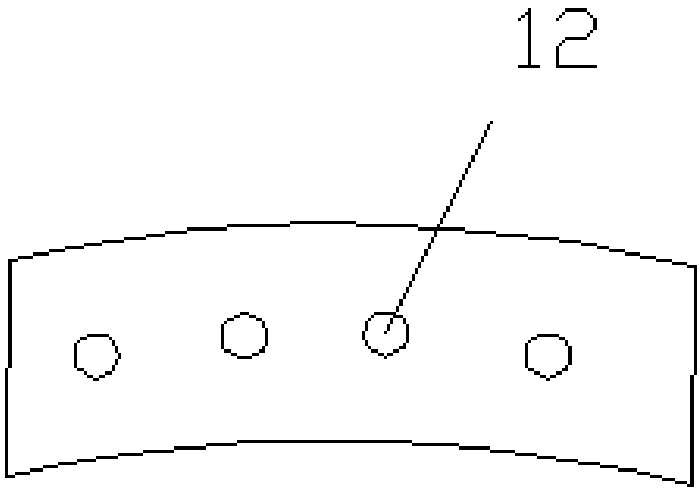

Diamond grinding wheel applied to grinding of inner wall of cast pipe

ActiveCN112959229AExposed highEasy chip removalBonded abrasive wheelsDiamond grindingAutomotive engineering

The invention belongs to the technical field of superhard abrasive tools, and particularly discloses a diamond grinding wheel applied to grinding of the inner wall of a cast pipe. A diamond is brazed on the wheel face of a grinding wheel base body to serve as the grinding face, the exposure is high, chip removal is easy, and the grinding efficiency is high. Compared with a resin grinding wheel in the prior art, the comprehensive grinding efficiency can be improved by 20% or above, dust and peculiar smell are basically not volatilized in the grinding process, and the working environment is greatly improved. The wheel face of the grinding wheel base body is of a designed novel structure, the grinding wheel base body is matched with the movement working condition of inner wall grinding equipment, continuous grinding is achieved, the stable and long-service-life effect is achieved, the consumable cost can be saved by more than 20% compared with a traditional resin grinding wheel, and remarkable economic efficiency is achieved. According to the diamond grinding wheel, through the structural design, the overall weight of the diamond grinding wheel is equivalent to that of a resin grinding wheel sold in the market under the same working condition, the diamond grinding wheel can be directly matched with an existing grinding machine for use, the operation difficulty and complexity of existing equipment are greatly reduced, and operation and maintenance are easy.

Owner:江苏韦尔博新材料科技有限公司

A kind of manufacturing method of foam type macroporous grinding wheel

InactiveCN107116485BAdequate stomataLow densityAbrasion apparatusGrinding devicesWater bathsHeat conducting

The invention discloses a foaming-type grinding wheel with big air pores which is made of resin adhesive, an abrasive material, a thinner, a surface active agent, secondary reinforced resin, dextrin, a foaming agent, a defoaming agent, filler and starch. A manufacturing method of the foaming-type grinding wheel with big air pores includes the steps that the resin adhesive and the thinner are added into a container to be evenly stirred under the water bath condition of 60 DEG C; then the abrasive material and the surface active agent are added to be evenly stirred; afterwards, the secondary reinforced resin, the dextrin, the starch, the filler, the foaming agent and the defoaming agent are added in sequence, and slurry is injected into a mold of 45-60 DEG C when the reaction temperature of the slurry reaches 50 DEG C; and finally the mold is put into an oven to be roasted, demolding is conducted after the slurry in the mold is completely cured, and accordingly the foaming-type grinding wheel with big air pores can be obtained. The foaming-type grinding wheel with big air pores has the characteristics that the grinding wheel is low in weight and nontoxic, and air pores are uniform; the grinding wheel is far superior to a common resin grinding wheel on the aspects of water resistance, abrasion resistance, heat-conducting property and the like; and especially when the grinding wheel is used for grinding long-axis metal parts, no vibration ripple can be caused, and the grinding effect is better.

Owner:广州捷骏电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com