Machine tool for machining large gear in spiral bevel gear pair

A technology of spiral bevel gears and large gears, applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of cost reduction, waste of resources, etc., and achieve easy chip removal, convenient loading and unloading, and cost-effective Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

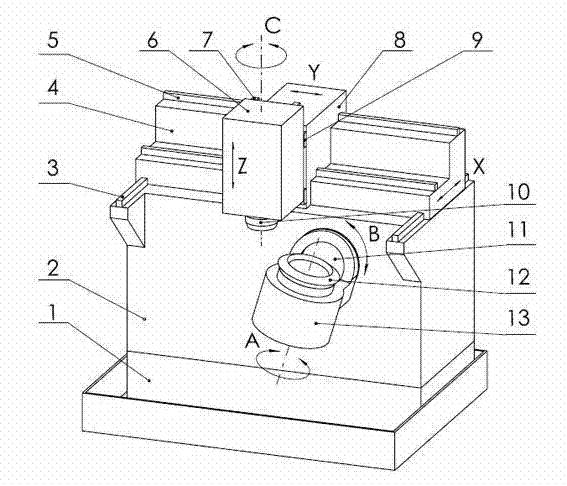

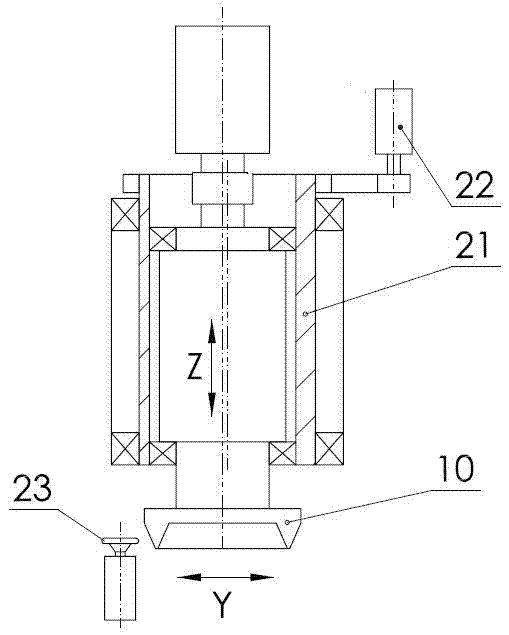

[0024] like figure 1 As shown, a machine tool for processing large gears in a spiral bevel gear pair includes a bed 2, a pallet 1 below the bed 2, a workpiece box 13 for installing a workpiece 12 to be processed, and a front end surface of the bed 2 and The cutter head or grinding wheel 10 for milling and grinding the workpiece 12 is equipped with an X-axis guide rail 3 on the top surface of the bed, and the X-axis guide rail 3 is equipped with a device that can move along the X-axis guide rail 3 under the action of the driving mechanism. The X-axis sliding table 4; the X-axis sliding table 4 is provided with a Y-axis guide rail 5, and the Y-axis guide rail 5 is equipped with a Y-axis sliding table 8 that can move along the Y-axis guide rail 5 under the action of the driving mechanism; the Y-axis slide A slide block 9 is arranged on the table 8, which is combined with the Z-axis guide rail 7 provided on the Z-axis slide table 6 to form a linear motion pair, which can make the ...

Embodiment 2

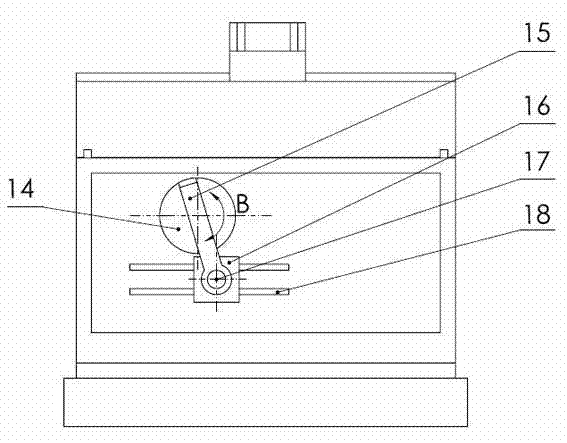

[0029] The machine tool in Example 1 is laid down 90° to the rear, the workpiece box 13 is placed on the top surface of the bed 2, the Y-axis guide rail 5 on one side of the bed 2 is arranged horizontally along the front and rear ends of the bed, and the Y-axis guide rail 5 on the Y-axis guide rail 5 The axis slide table 8 moves along the front and rear ends of the bed, and the X-axis slide table 4 in the vertical direction is arranged outside the Y-axis slide table 8, and the Z-axis guide rail is provided on the top surface of the X-axis slide table 4, and the cutter head or The grinding wheel 10 is installed on the end of the Z-axis slide table 6 close to the workpiece box 13 .

[0030] Other components of this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com