Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

A grinding head and impeller technology, applied in the field of CNC machining, can solve the problems of reducing the precision of the machined surface, burning the machined surface, and aggravating tool wear, so as to reduce adhesion and wear, improve the quality of the machined surface, and reduce the amount of machining wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

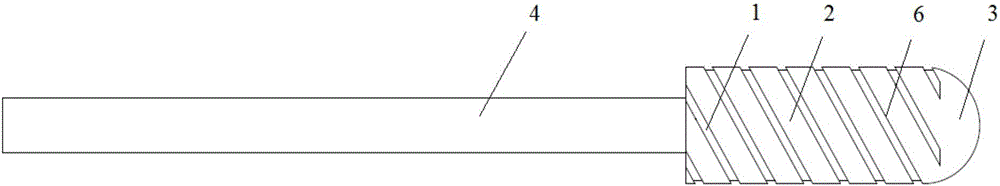

[0051] One embodiment of the present invention provides a grinding head for processing narrow grooved impellers, such as figure 1 As shown, the grinding head 2 is a cylinder, the top 3 of the grinding head 1 is spherical, and the side wall of the grinding head 2 is provided with a spiral groove 1 . The grinding head 2 is bonded on the handle 4, and the grooved part has a groove edge 6.

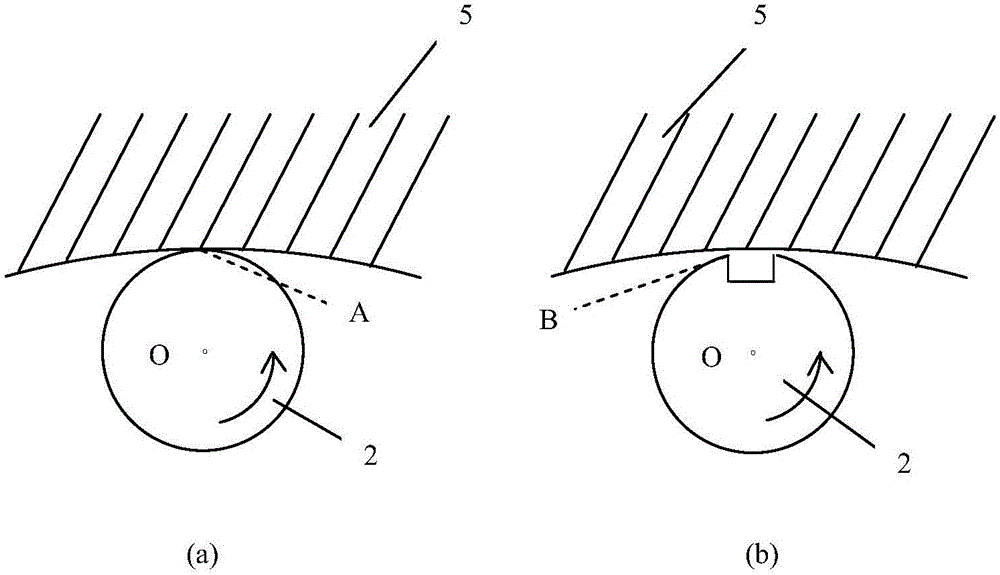

[0052] Schematic diagram of grinding head processing figure 2 As shown, the surface of the grinding head 2 is a cylindrical surface, and the section perpendicular to the axis is a circle, and the distance from the center of the circle to the processed surface is OA. After slotting at point A, the distance from the center of the circle to the machined surface is still OA. When the grinding head 2 rotates to the figure 2 (a) When the angles o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com