Patents

Literature

180results about How to "Reduce flutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

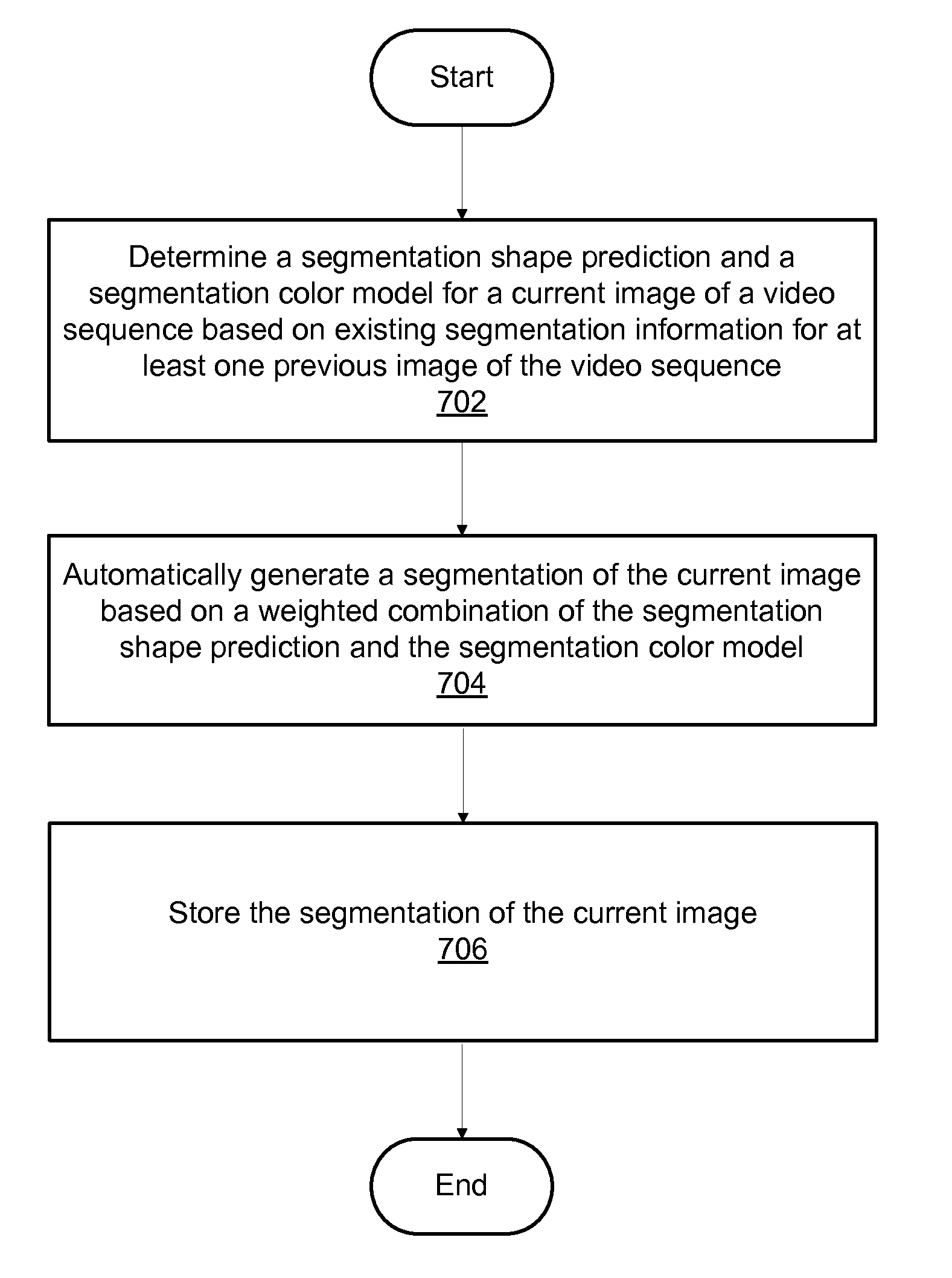

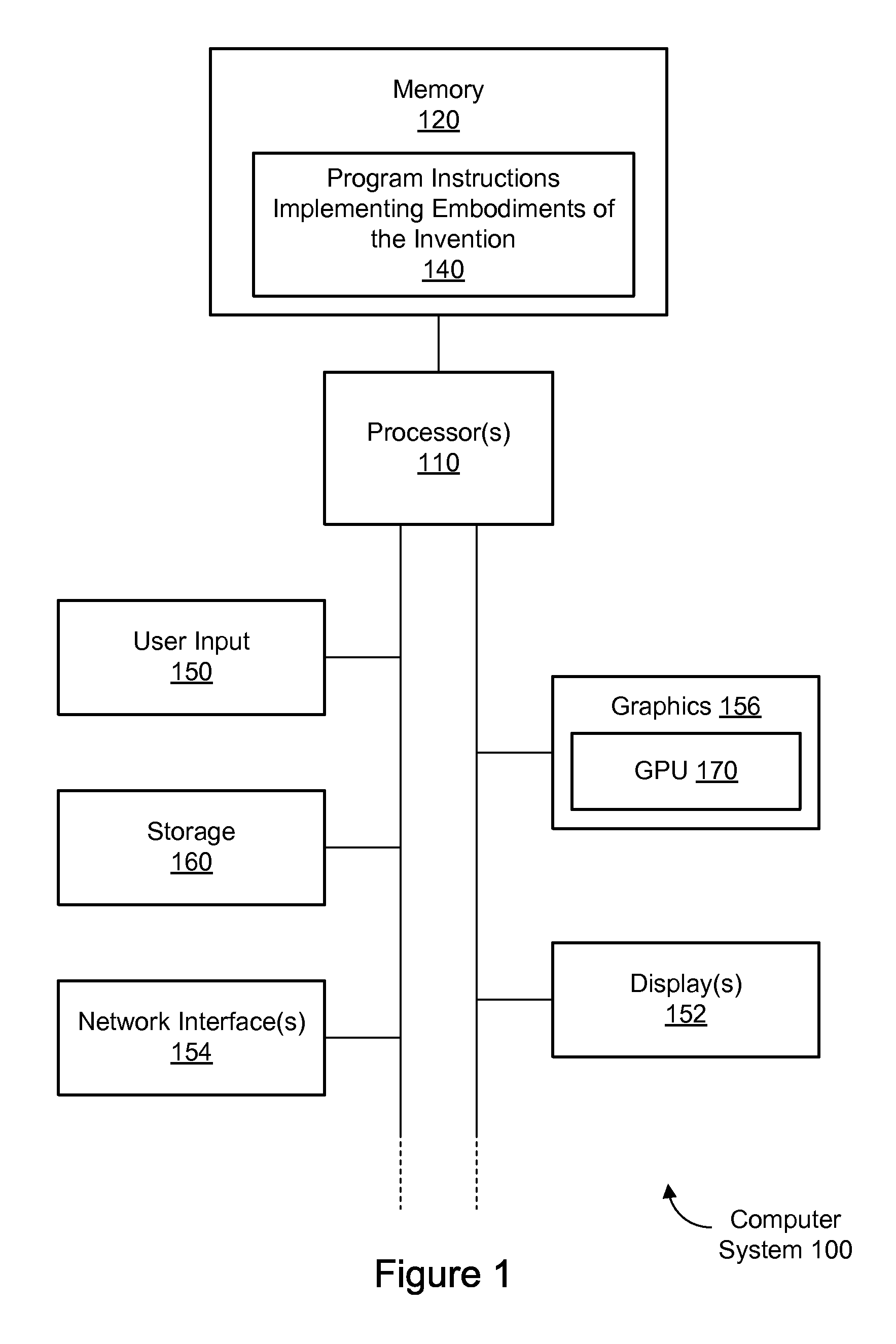

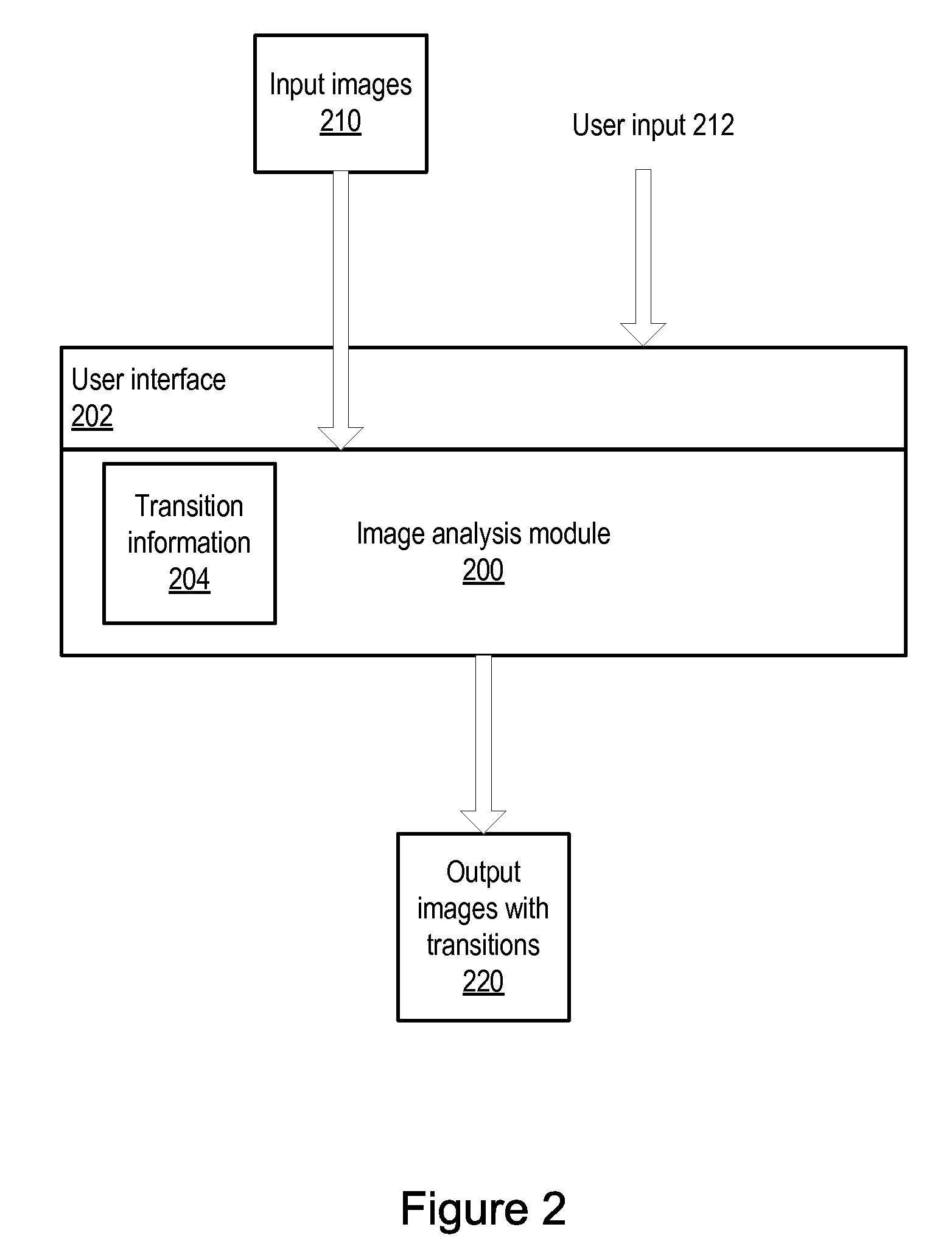

Methods and apparatus for chatter reduction in video object segmentation using a variable bandwidth search region

Systems, methods, and computer-readable storage media for chatter reduction in video object segmentation using a variable bandwidth search region. A variable bandwidth search region generation method may be applied to a uniform search region to generate a variable bandwidth search region that reduces the search range for segmentation methods such as a graph cut method. The method may identify parts of the contour that are moving slowly, and reduce the search region bandwidth in those places to stabilize the segmentation. This method may determine a bandwidth for each of a plurality of local windows of an image according to an estimate of how much an object in the image has moved from a previous image. The method may blend the bandwidths for the plurality of local windows to generate a blended map. The method may then generate a variable bandwidth search region for an object according to the blended map.

Owner:ADOBE SYST INC

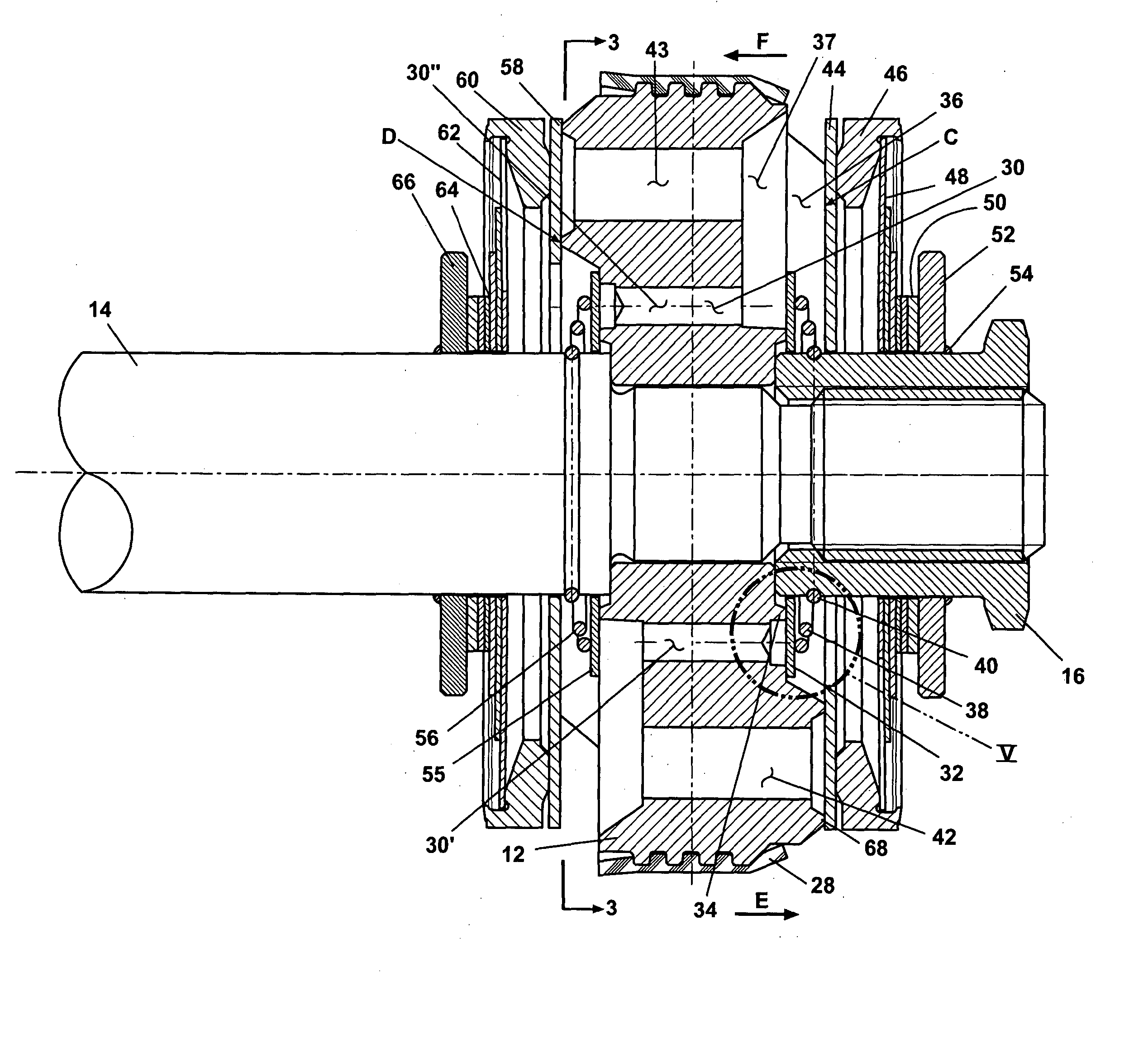

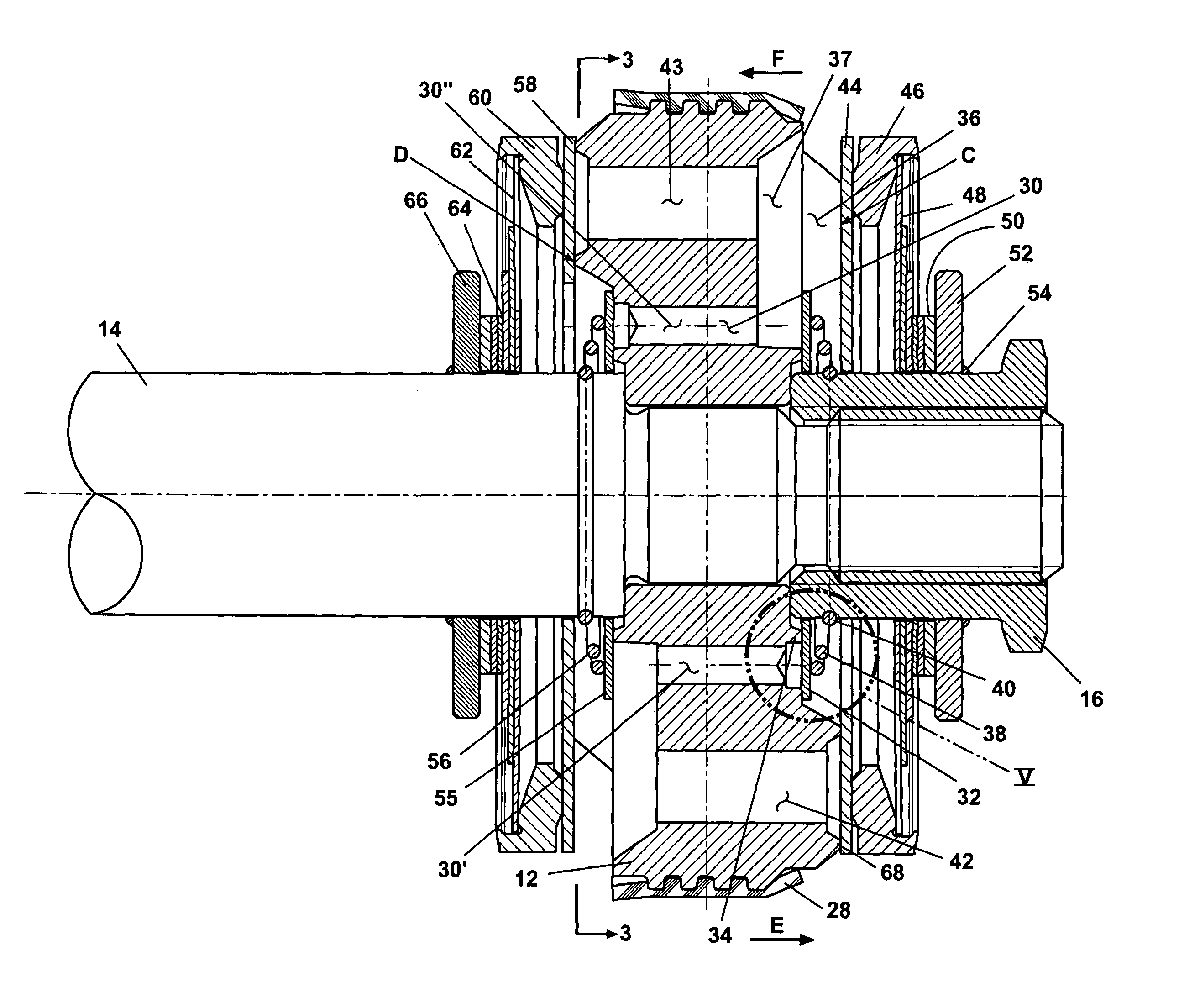

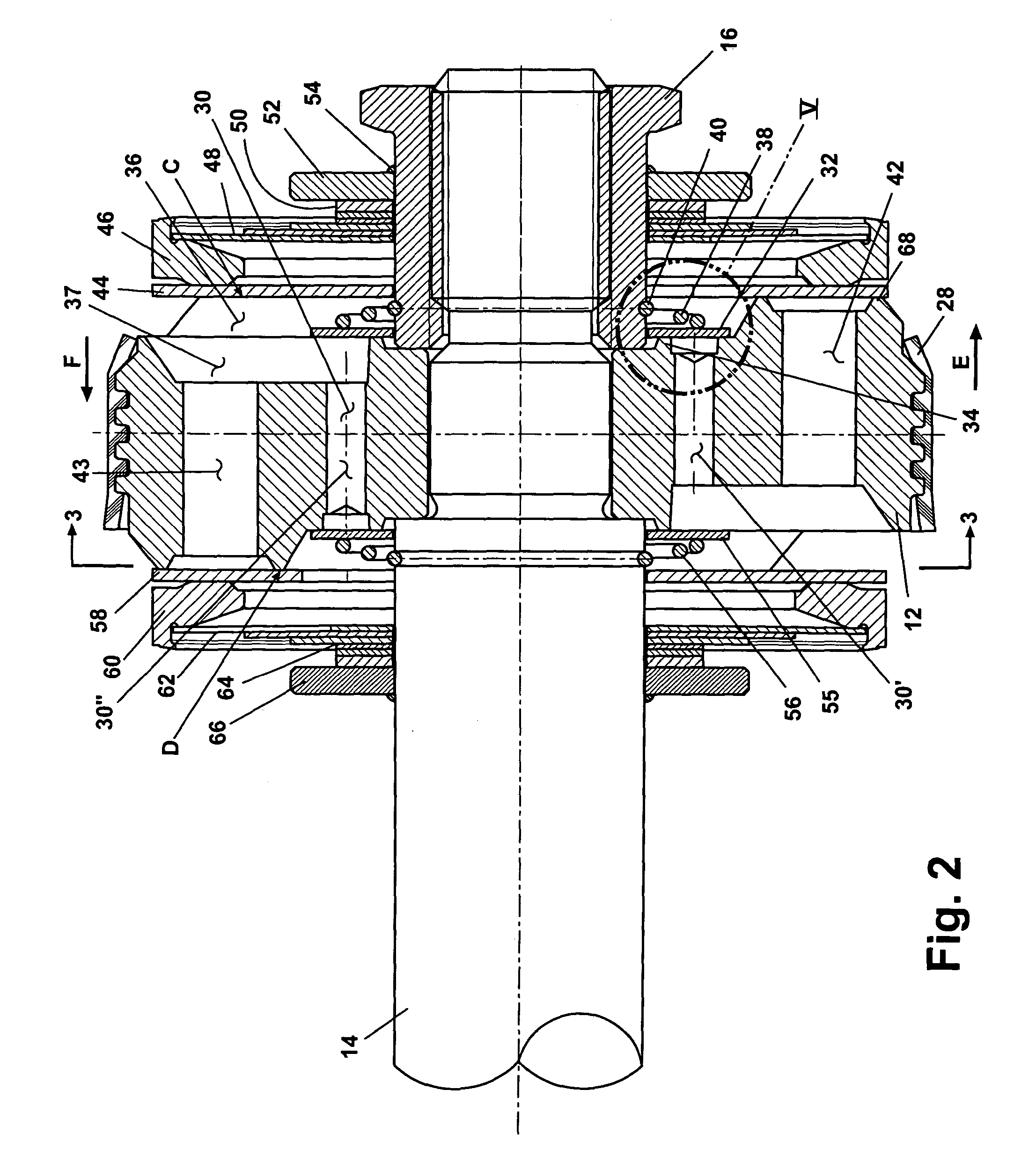

Monotube piston valving system with selective bleed

InactiveUS20050056505A1Accurate initial adjustmentReduces manufacturing and storage costSpringsShock absorbersEngineeringPiston

A shock absorber piston assembly includes a piston having a first face, a second face and a plurality of fluid passages. Preloaded flow control devices each seal at least one of the fluid passages, including: a first bleed plate contacting the first face and a second bleed plate contacting the second face; and a pair of blow-off discs, with a first blow-off disc contacting the first face and a second blow-off disc contacting the second face. Each of the flow control devices opens at an individually adjustable device opening pressure. Each of the multiple passages in contact with the blow-off discs can also differ in flow area to permit the blow-off discs to angularly lift to limit disc chatter.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

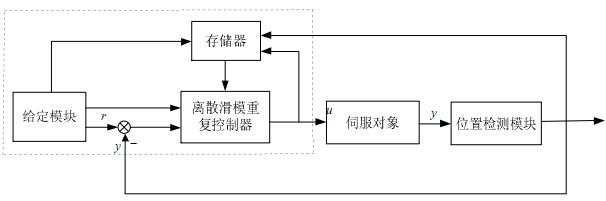

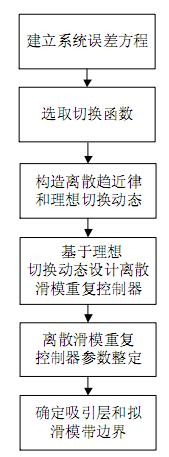

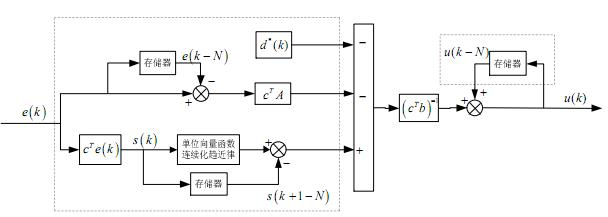

Discrete sliding mode repetitive control method for periodic servo system

ActiveCN101976042AEliminate the effects ofServo PreciseControllers with discontinuous output signalState spaceControl quality

The invention relates to a discrete sliding mode repetitive control method for a periodic servo system, which comprises the following steps: identifying a difference equation model of the current servo system, and converting the difference equation model into a state space model; selecting a linear switching function; forming a discrete reaching law, and constructing an ideal switching dynamic state according to the formed discrete reaching law; constructing a discrete sliding mode repetitive controller model according to the ideal switching dynamic state; and using current control variables as the control command for a controlled servo system to enable the servo system to change with reference signals. The invention can weaken the system chattering, and simultaneously inhibit the influence of periodic disturbance on the system, thereby improving the control quality and realizing the accurate control on periodic tracking tasks.

Owner:ZHEJIANG UNIV OF TECH

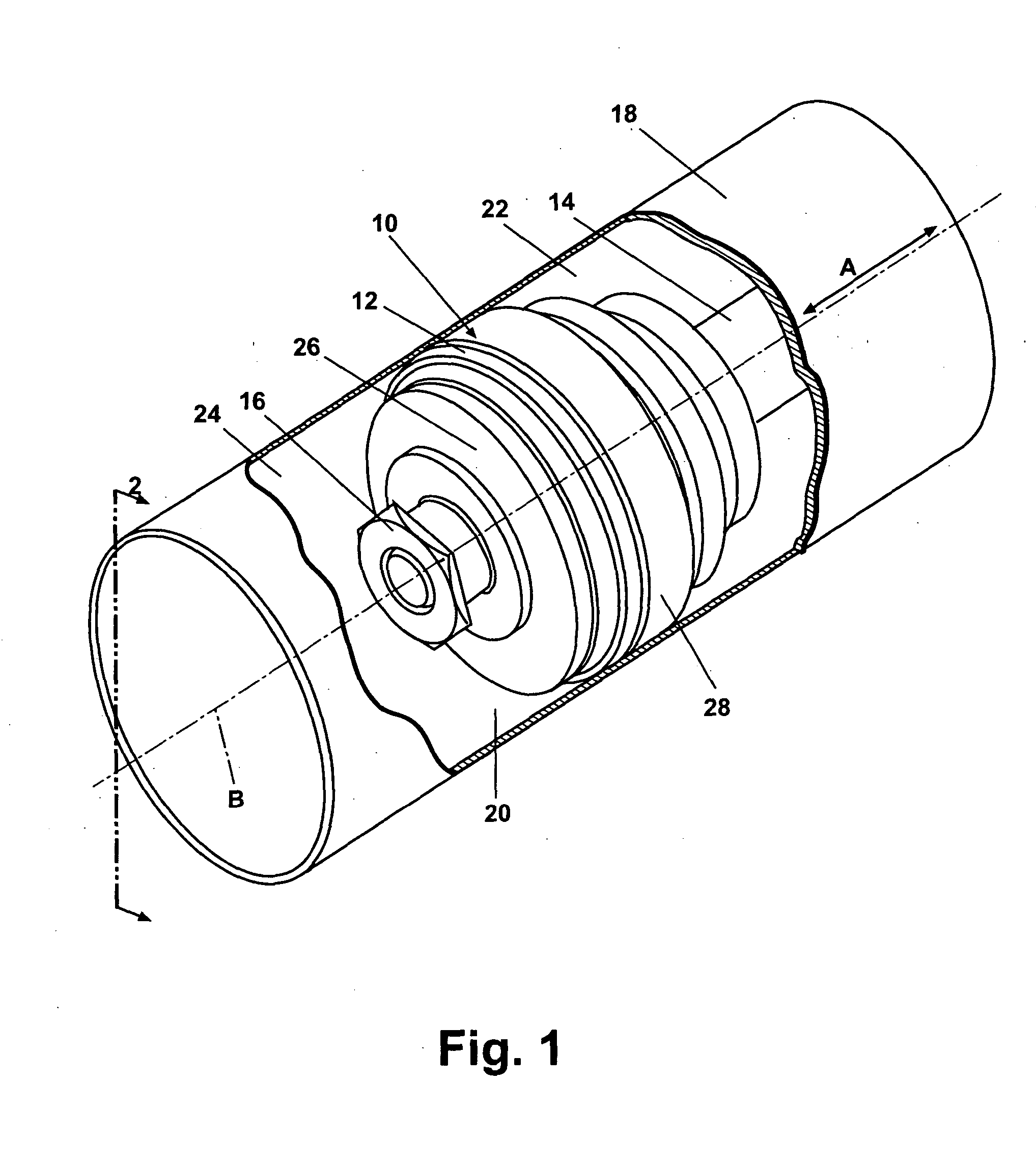

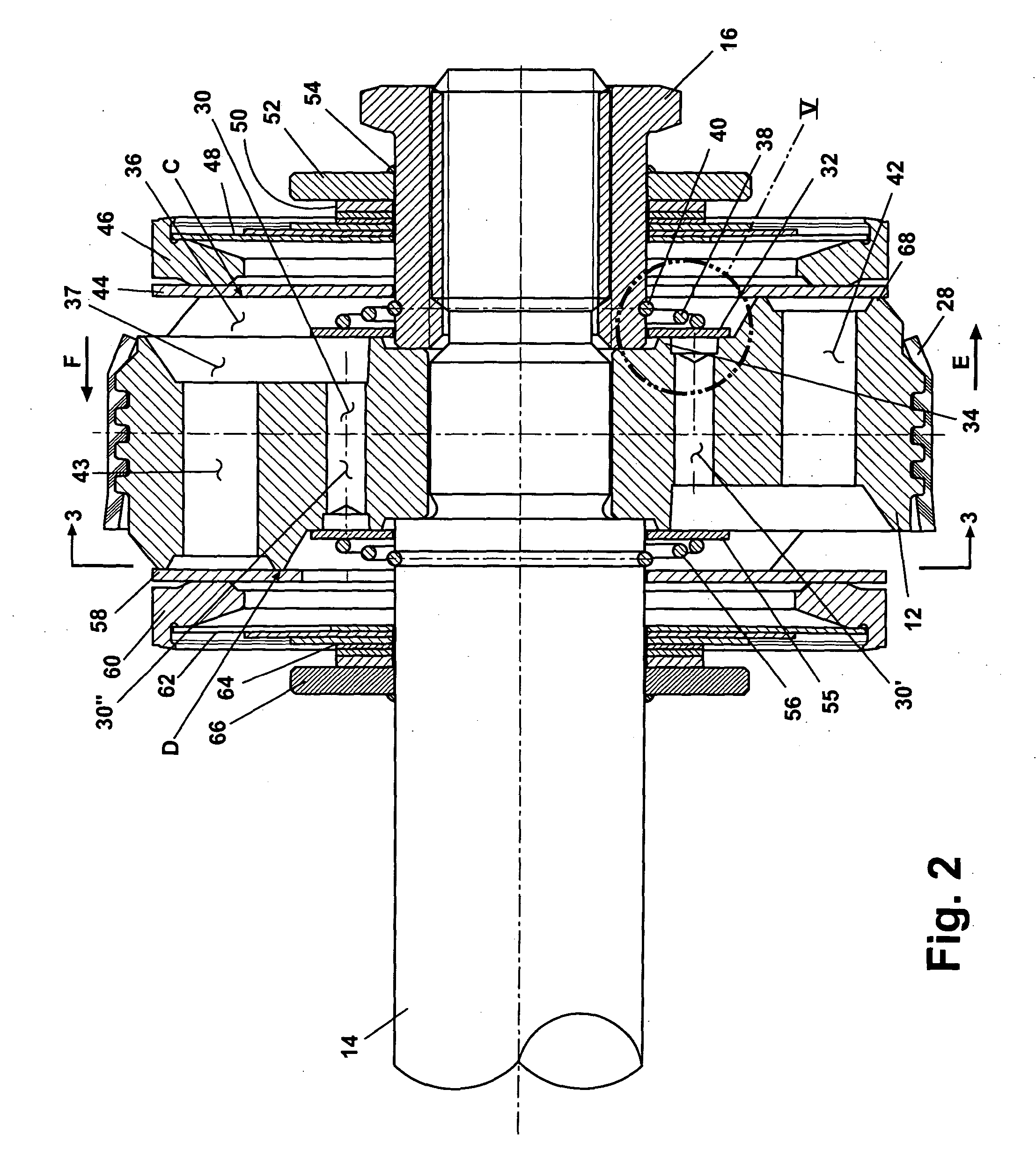

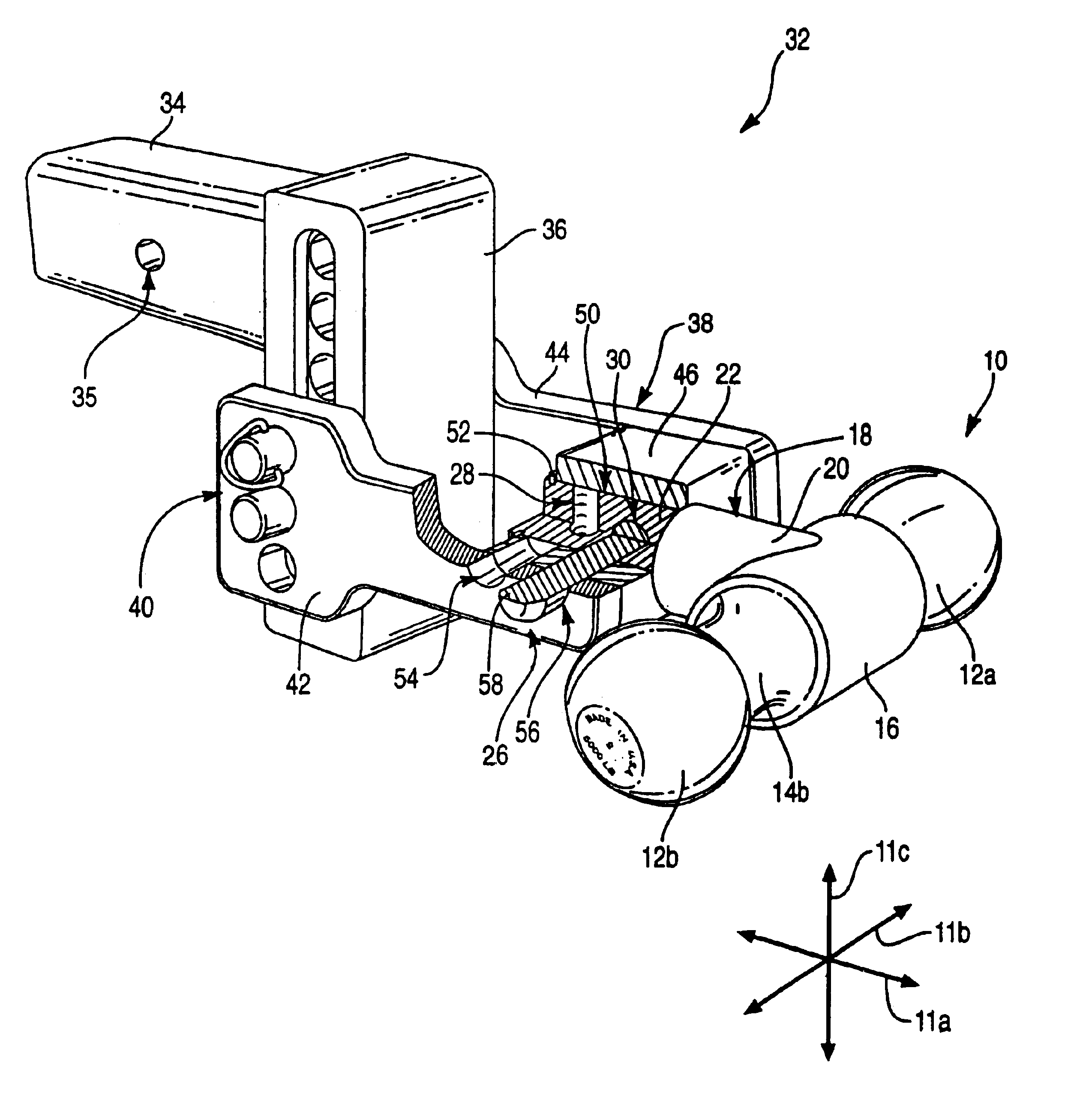

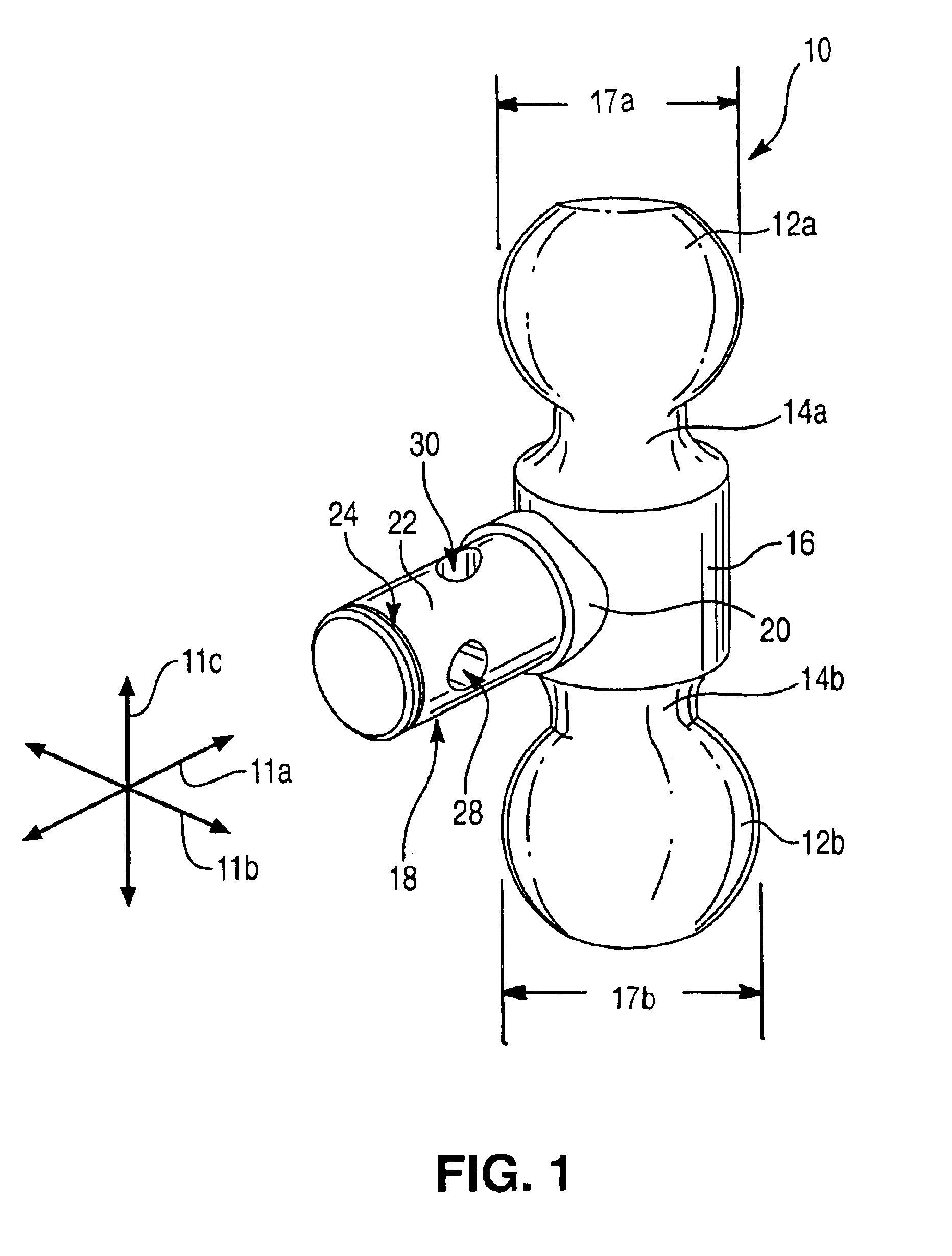

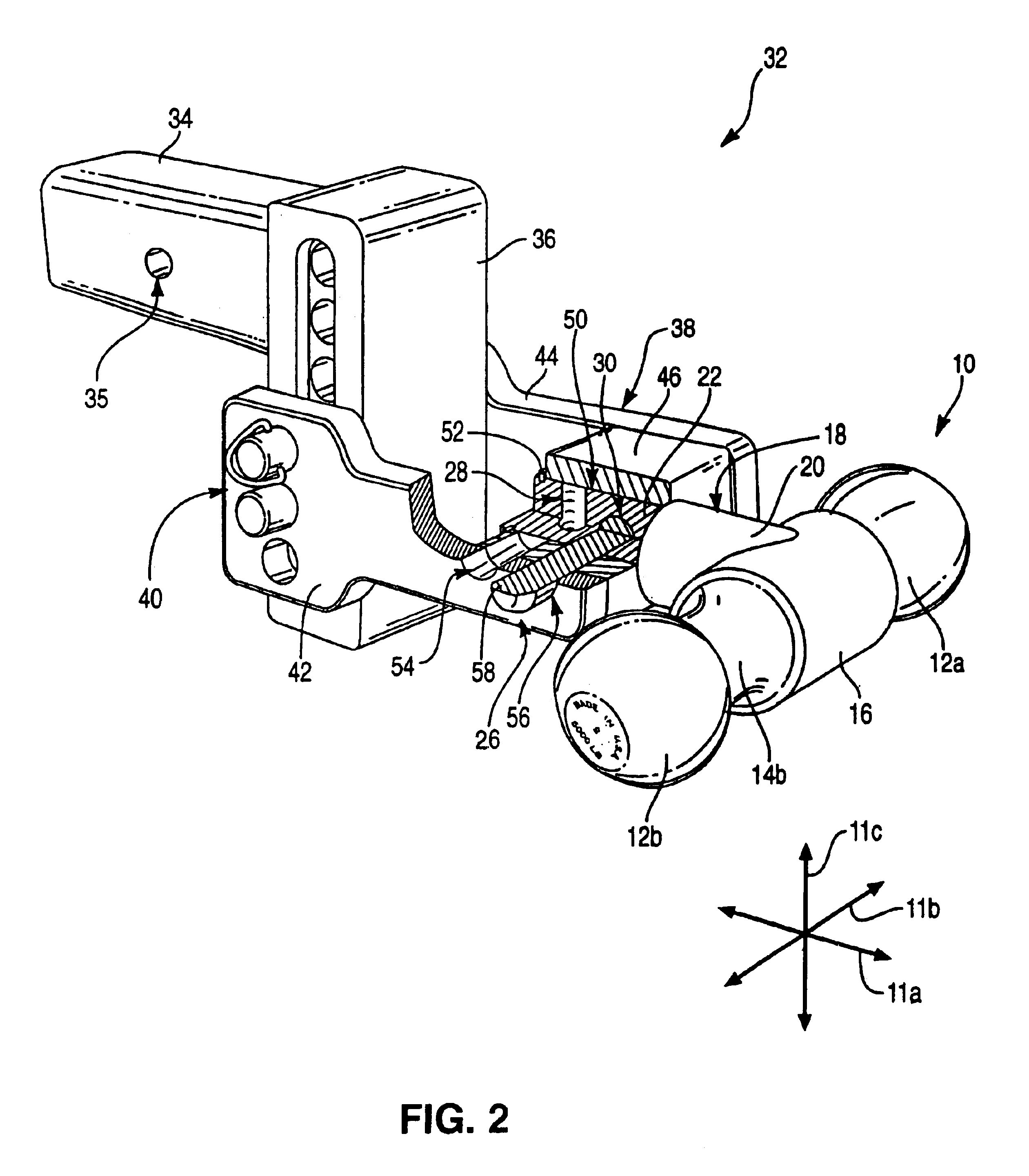

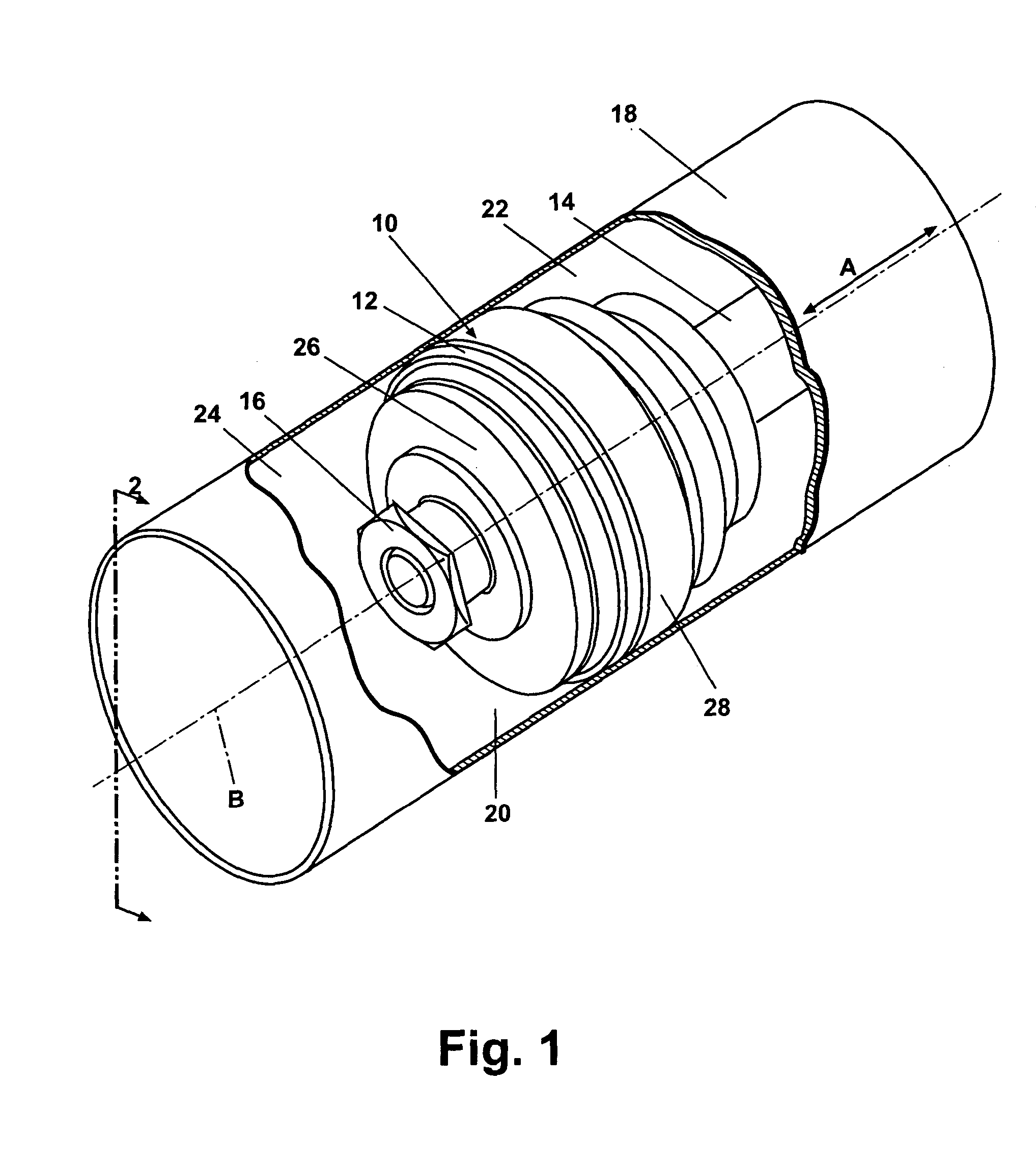

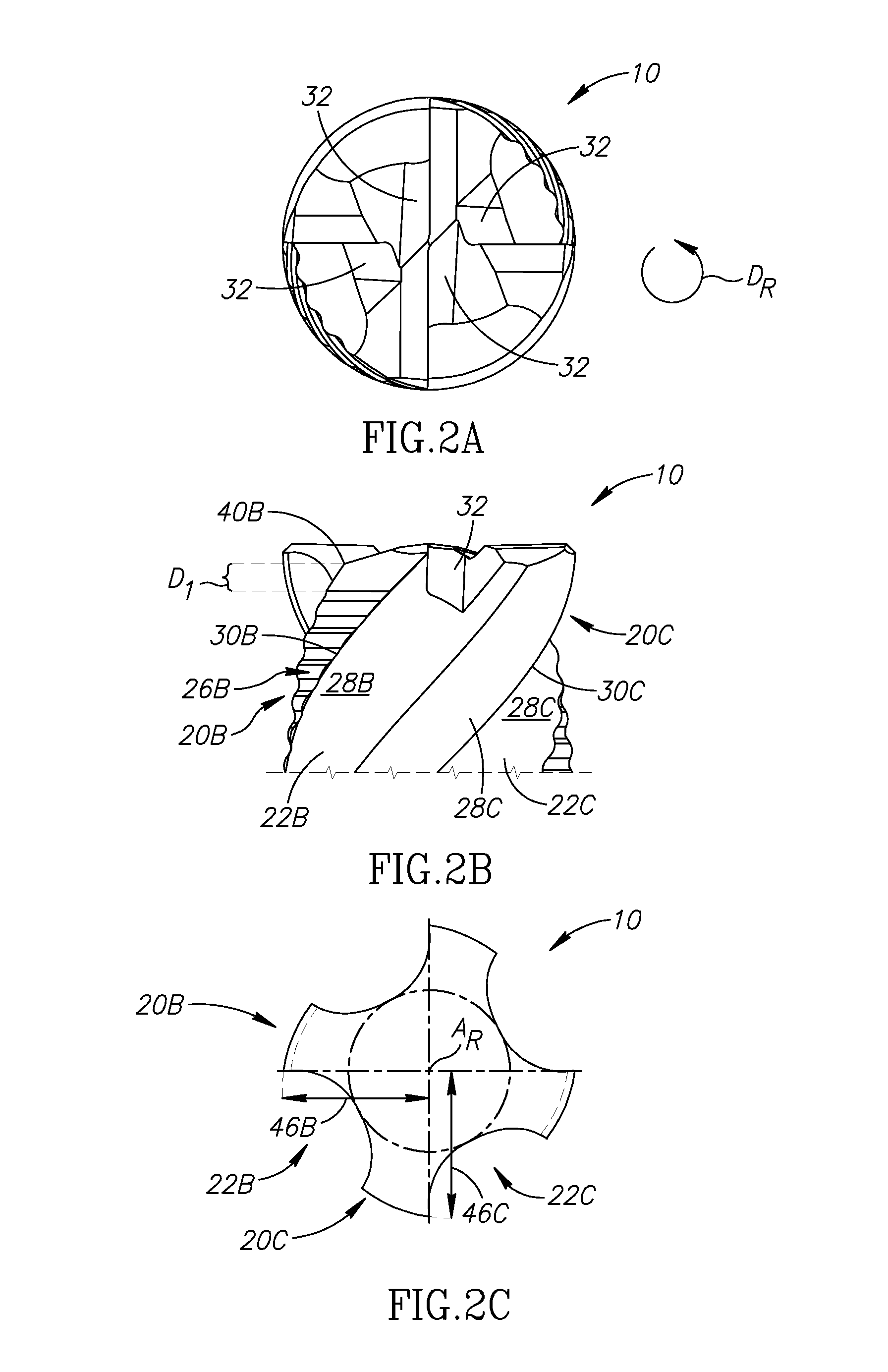

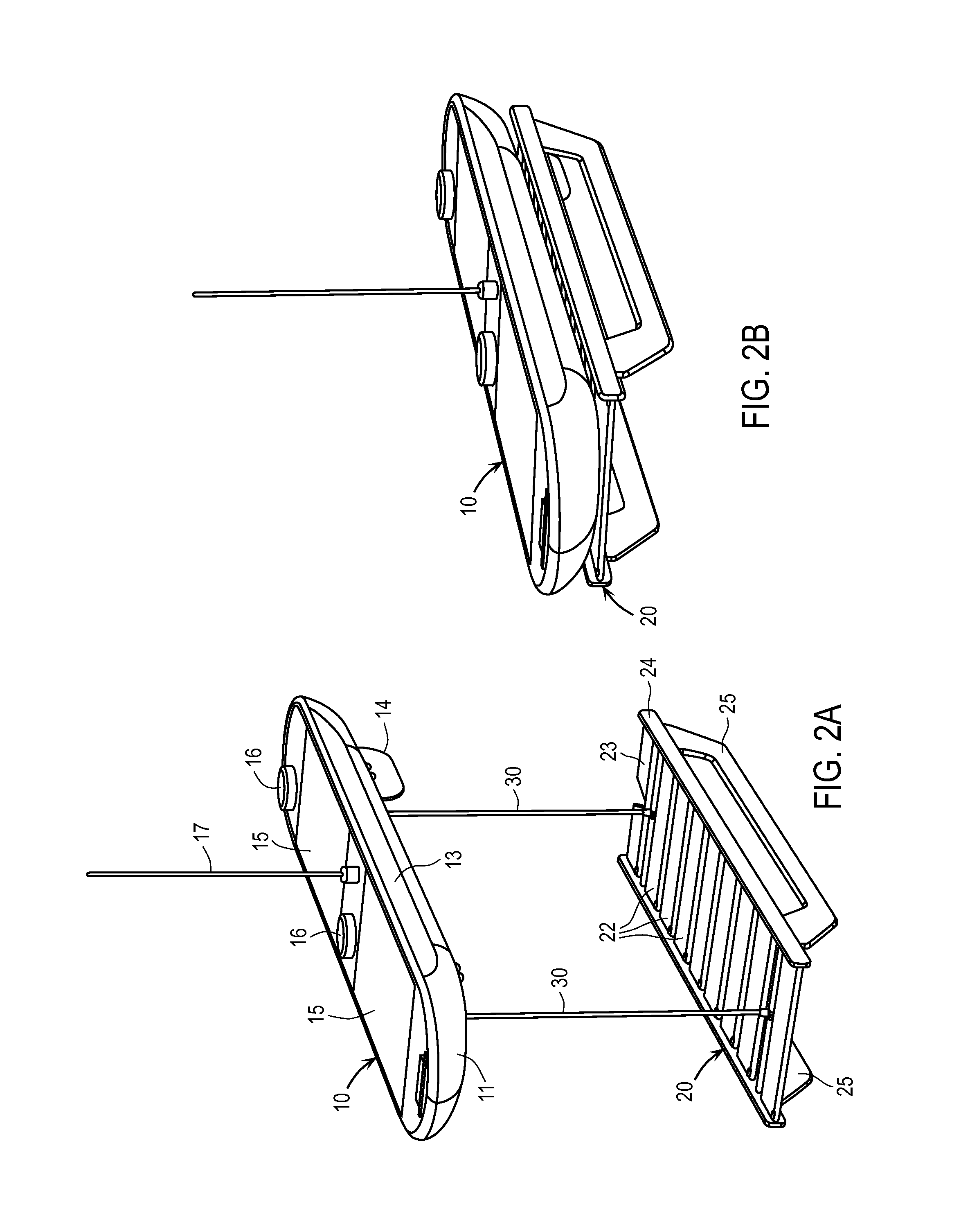

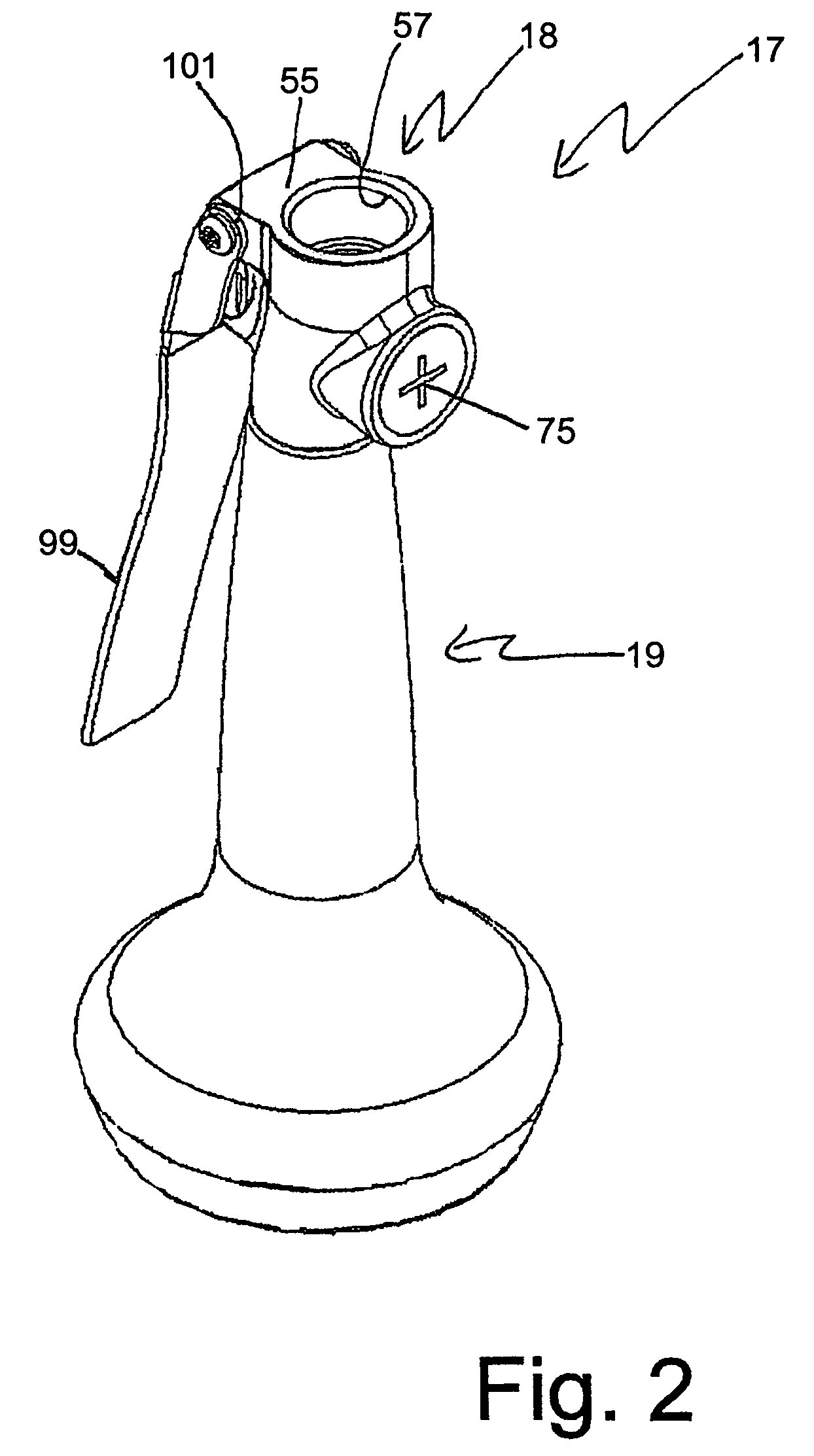

Monolithic, double-ball hitch

InactiveUS7004492B2Help positioningReduce flutterMechanical machines/dredgersTowing devicesMechanical engineeringSpherical form

A hitch for presenting different sized ball hitches for towing use. The hitch may include a first ball and pedestal extending in a first direction. A second ball and pedestal may extend in a second direction, distinct from the first direction. The first ball and pedestal and the second ball and pedestal may be homogenously formed of a single material to form a monolith. A stem may connect to the monolith to support and present the first ball and pedestal and the second ball and pedestal for towing use. The stem may extend away from the monolith in a third direction, distinct from both the first and second directions.

Owner:B & W CUSTOM TRUCK BEDS

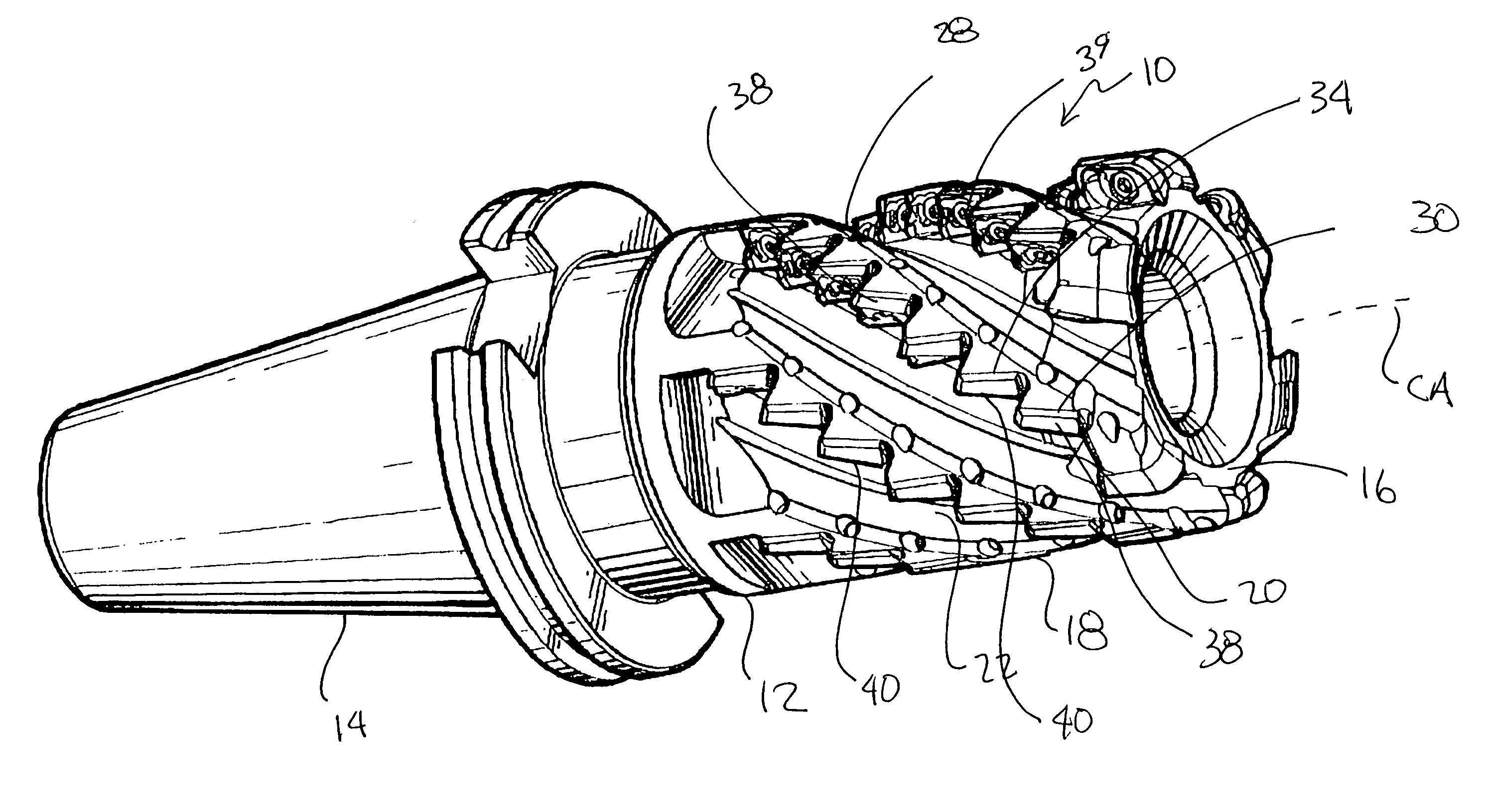

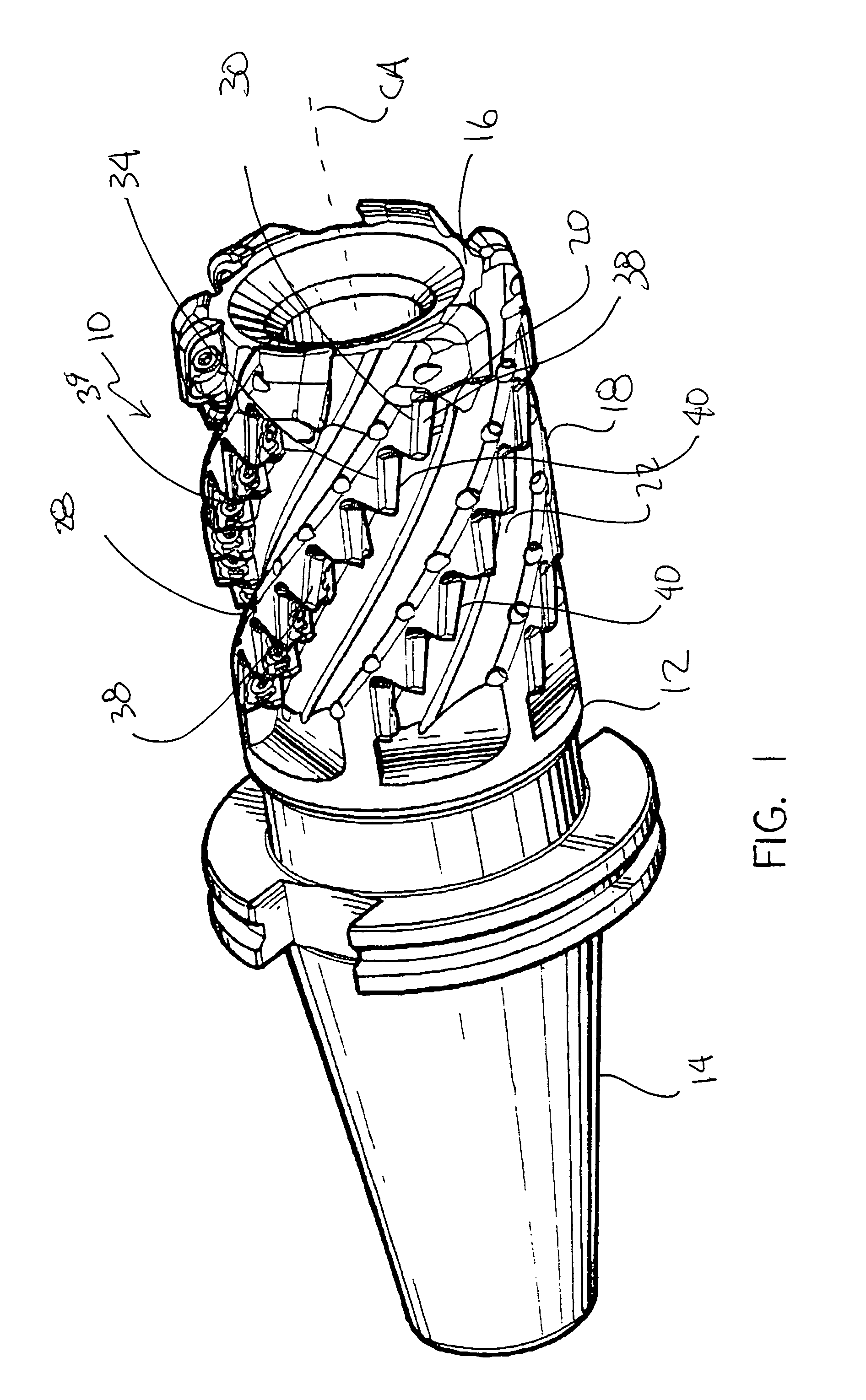

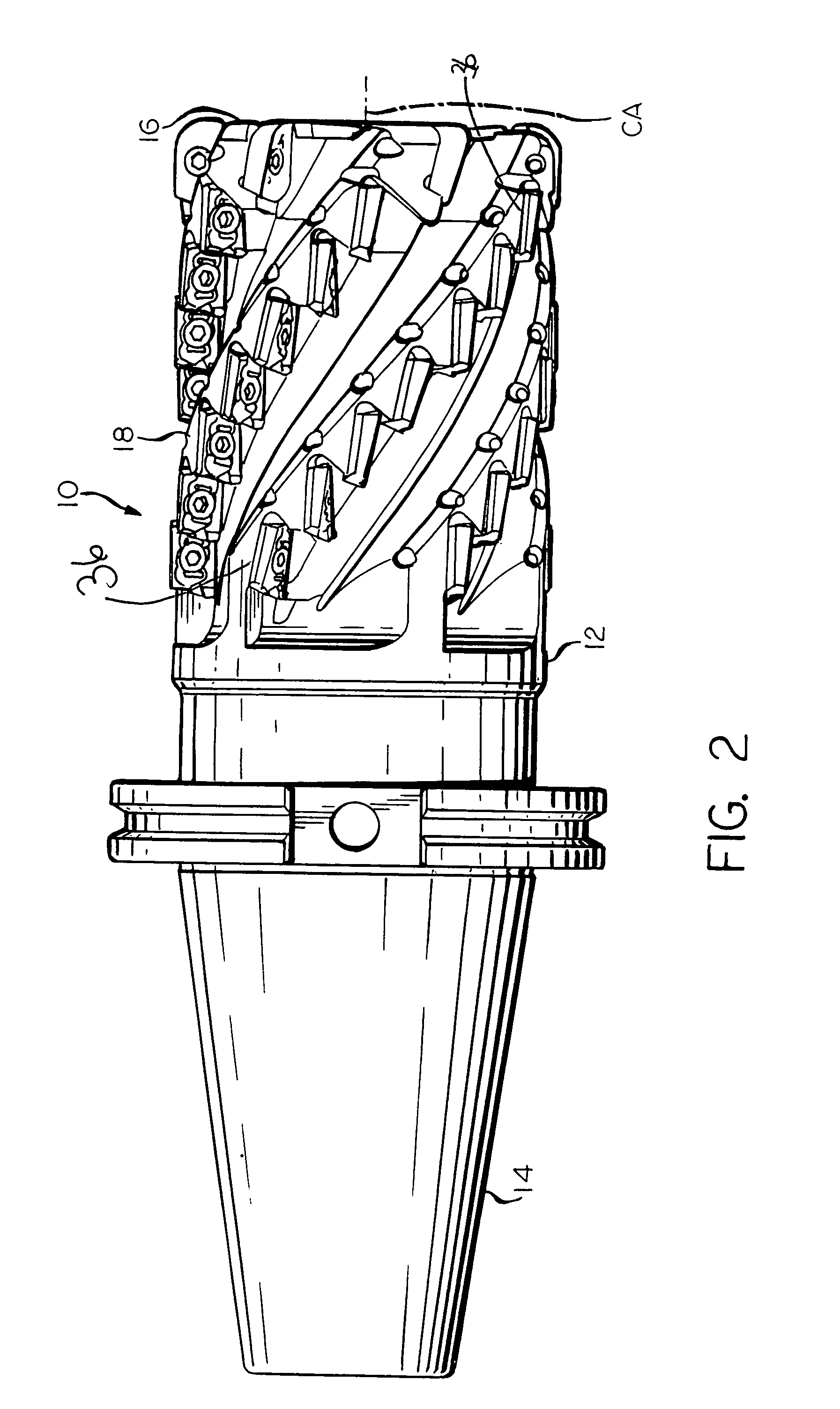

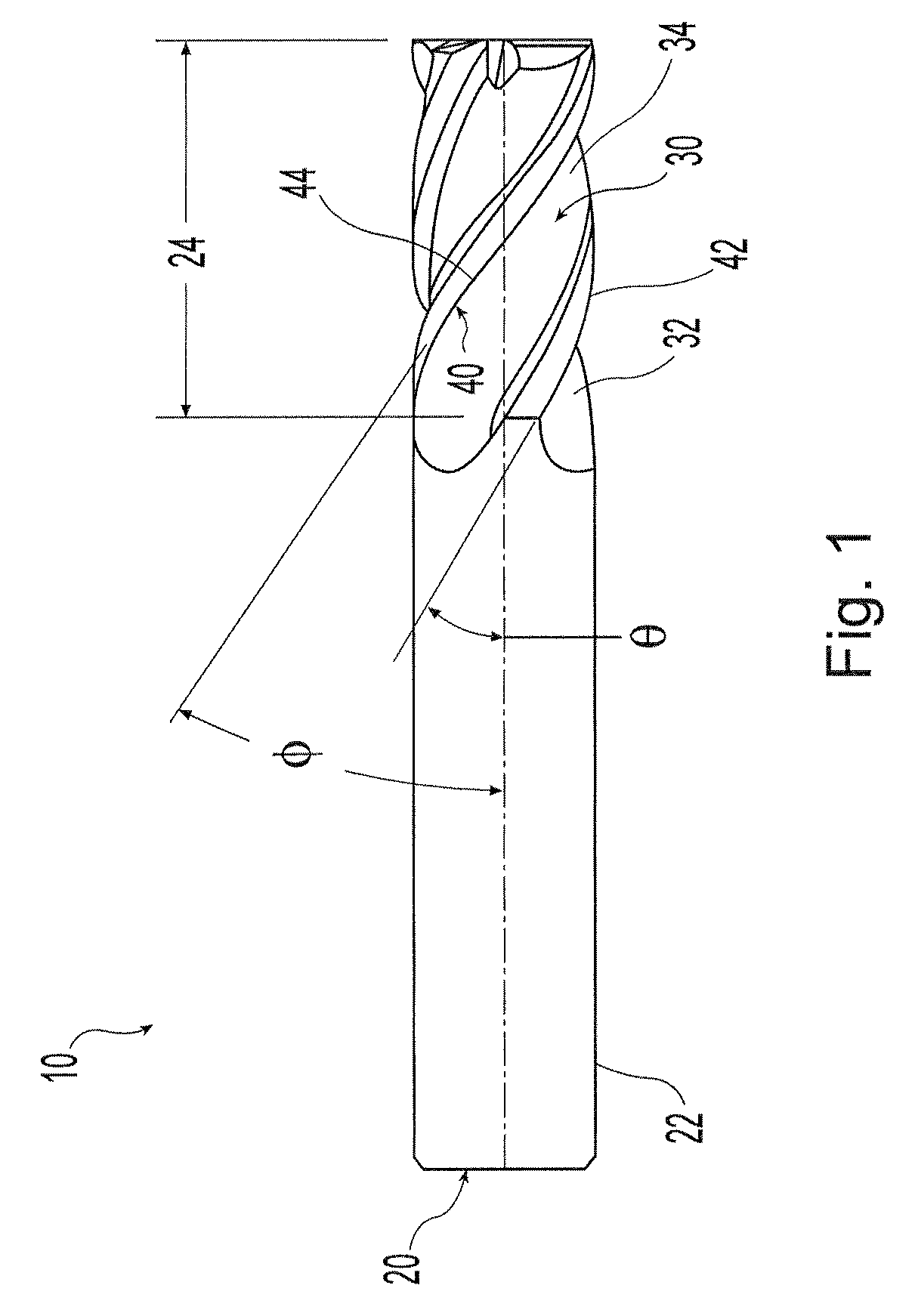

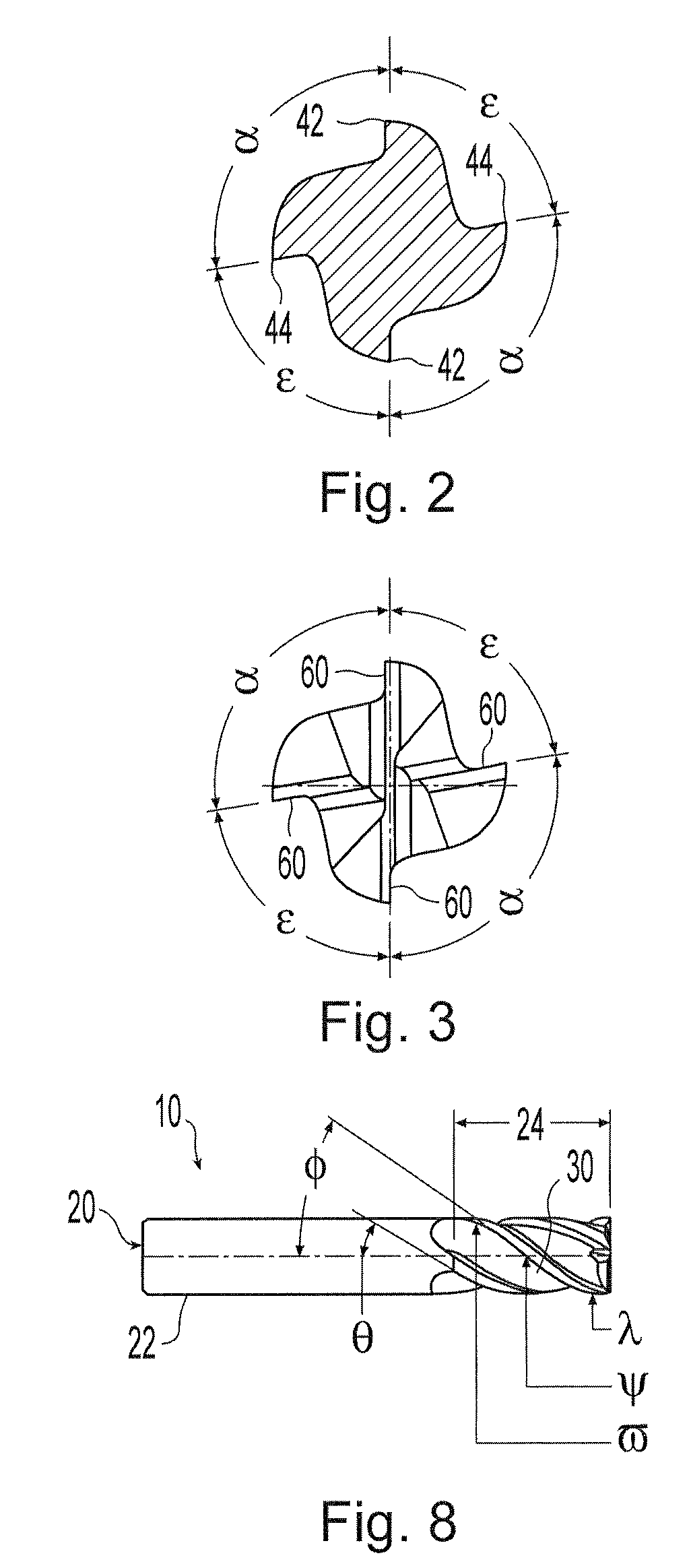

Milling cutter

InactiveUS6976811B1High surface finishSmooth cutting actionMilling cuttersShaping cuttersFluteMilling cutter

A cutting tool for cutting a workpiece comprising a tool body having an outer surface thereon and a central axis therein and including at least a first and second spiraling flute in the outer surface, each flute including a plurality of inserts secured therein to define an axial rake angle, wherein the axial rake angle of the inserts varies between flutes and within each flute.

Owner:KENNAMETAL INC

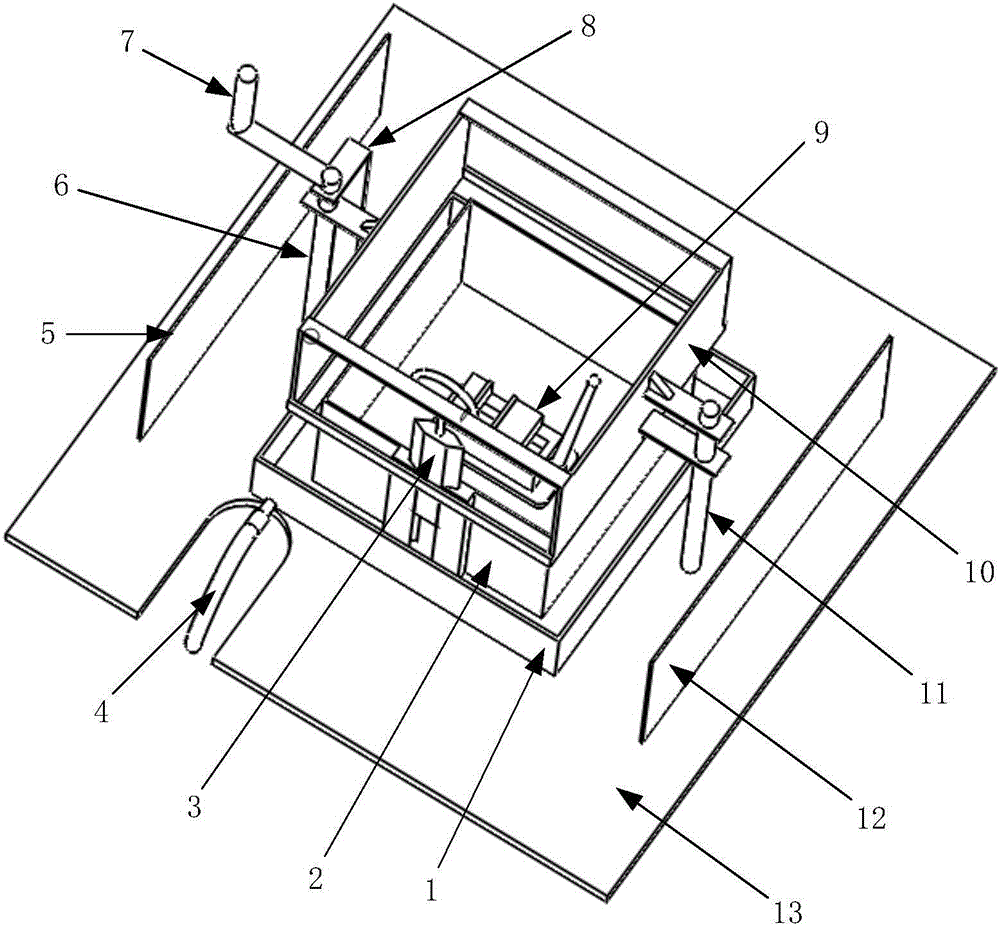

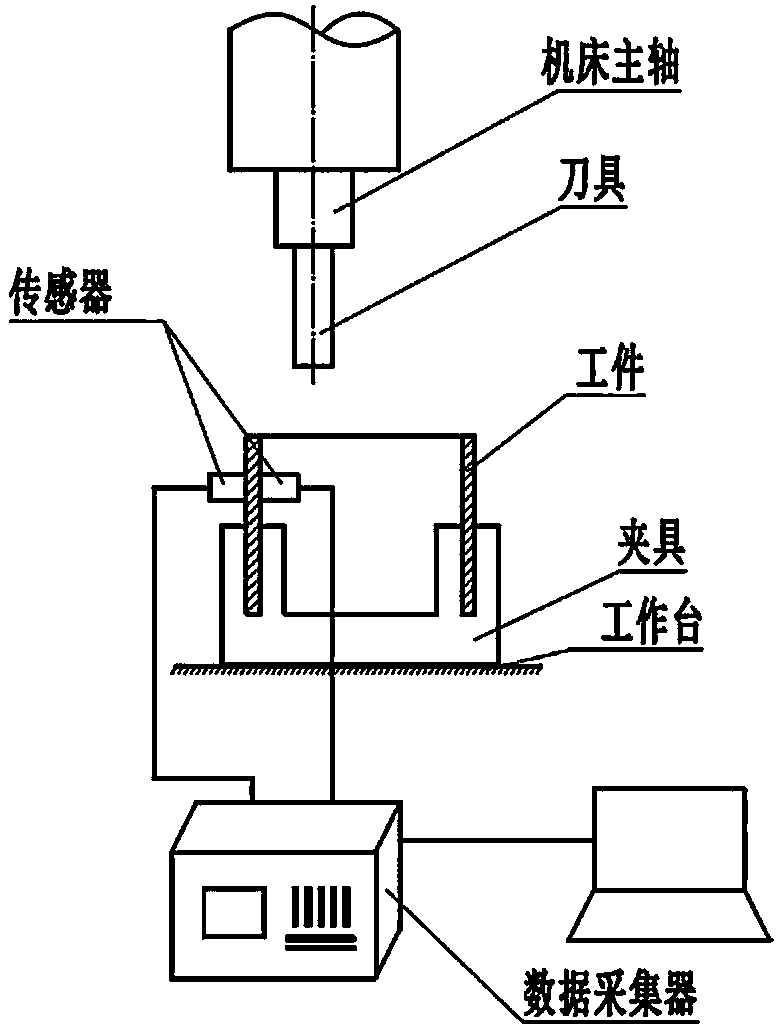

Flexible clamp for milling thin-walled workpiece with complex curved surface

ActiveCN106514369AEven by forceReduce processing deformationMilling equipment detailsPositioning apparatusMachining deformationMagnetorheological fluid

The invention discloses a flexible clamp for milling a thin-walled workpiece with a complex curved surface, and belongs to the field of machining. The flexible clamp comprises a vice clamp, a fluid carrying trough for accommodating a magnetorheological fluid, a magnetoresistive plate frame arranged at the upper part of the fluid carrying trough, and plate electrodes for providing a horizontal magnetic field, wherein the left side of the magnetoresistive plate frame is connected with a lead screw through threads; the right side of the magnetoresistive plate frame sleeves a supporting and positioning rod in a matching way; the upper end of the lead screw is connected with an operating crank; and the operating crank can drive the lead screw to rotate and drive the magnetoresistive plate frame to rise and fall. The flexible clamp provided by the invention can effectively reduce the machining deformation of the thin-walled workpiece with the curved surface, effectively restrains the vibration of the thin-walled workpiece with the curved surface during milling, lowers the machining noise, reduces the machining error, and guarantees high machining efficiency and high surface machining quality.

Owner:SHANDONG UNIV

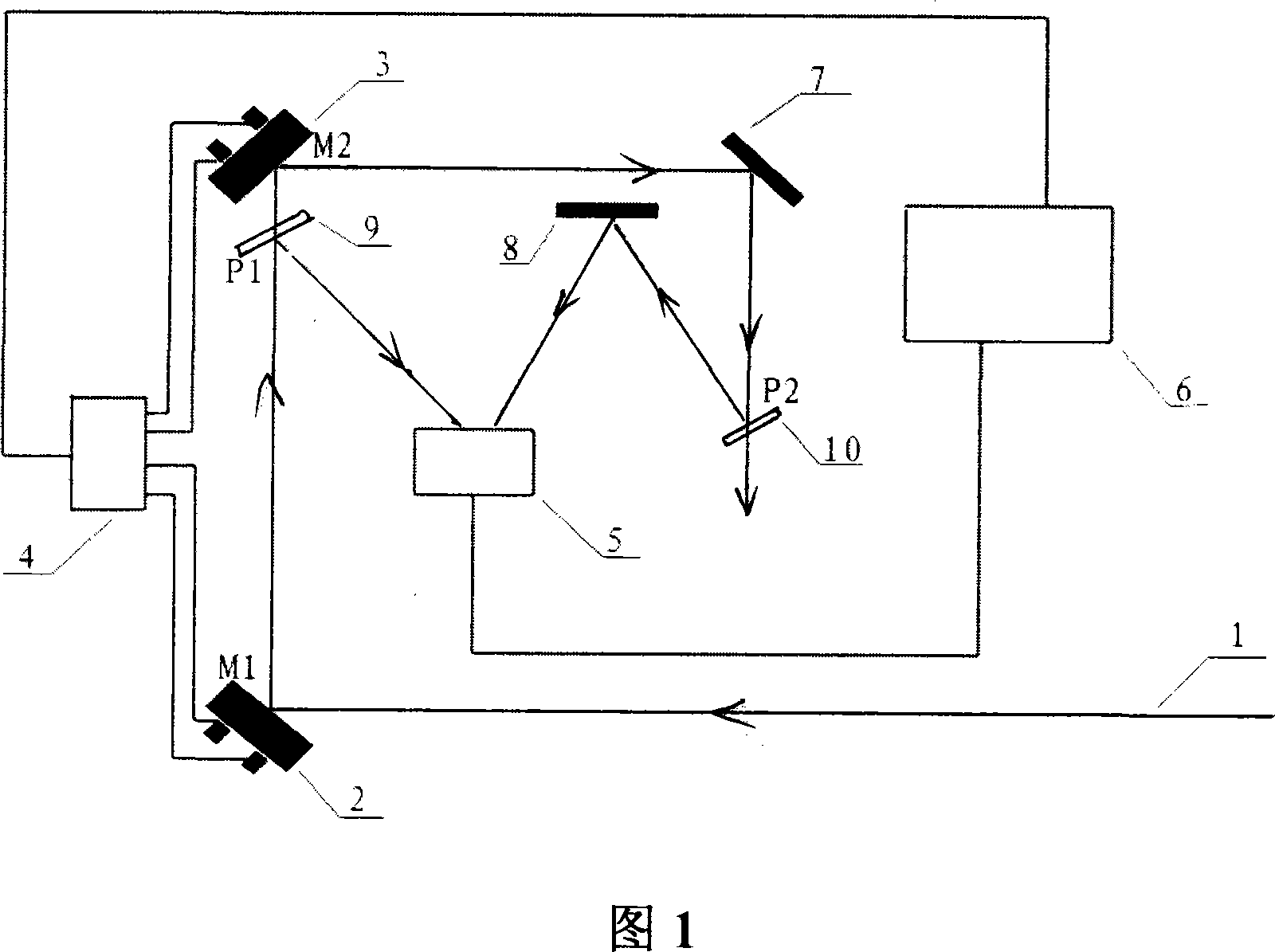

Method and arrangement for real time monitoring laser luminous spot and light path automatically collimating

InactiveCN101063751ASimple structureHigh precisionProgramme controlComputer controlElectricityDevice Monitor

This invention relates to one laser spot real time monitor and light path automatic calibration method and device, which uses single CCD camera head to collect laser spot, piezoelectricity electrical lens rack automatic calibration path by use of computer for spot process and real time monitor, wherein the device monitor spot frequency is about 10Hz and feedback control frequency is of 1Hz to eliminate and lower shake circle for float more than one second with stability less than 0. 5 micro arc degree in calibration laser space.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Monotube piston valving system with selective bleed

InactiveUS7070029B2Accurate initial adjustmentReduces manufacturing and storage costSpringsShock absorbersEngineeringPiston

A shock absorber piston assembly includes a piston having a first face, a second face and a plurality of fluid passages. Preloaded flow control devices each seal at least one of the fluid passages, including: a first bleed plate contacting the first face and a second bleed plate contacting the second face; and a pair of blow-off discs, with a first blow-off disc contacting the first face and a second blow-off disc contacting the second face. Each of the flow control devices opens at an individually adjustable device opening pressure. Each of the multiple passages in contact with the blow-off discs can also differ in flow area to permit the blow-off discs to angularly lift to limit disc chatter.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Compressor stator vane

A vane unit system having a plurality of vane units having at least one air foil projecting from a base. The base has a hole which receives a pin which extends between adjacent bases of vane units therein forming a rigid ring of vanes that are less susceptible to vane motion caused by pressure fluctuations within the compressor of a gas turbine. A blade assembly tool having a shape to fit within the slot in a casing that receives the vane units allows for the installation of vane units with interlocking pins without the necessity of having to remove the rotor from the casing.

Owner:DRS NAVAL POWER SYST INC

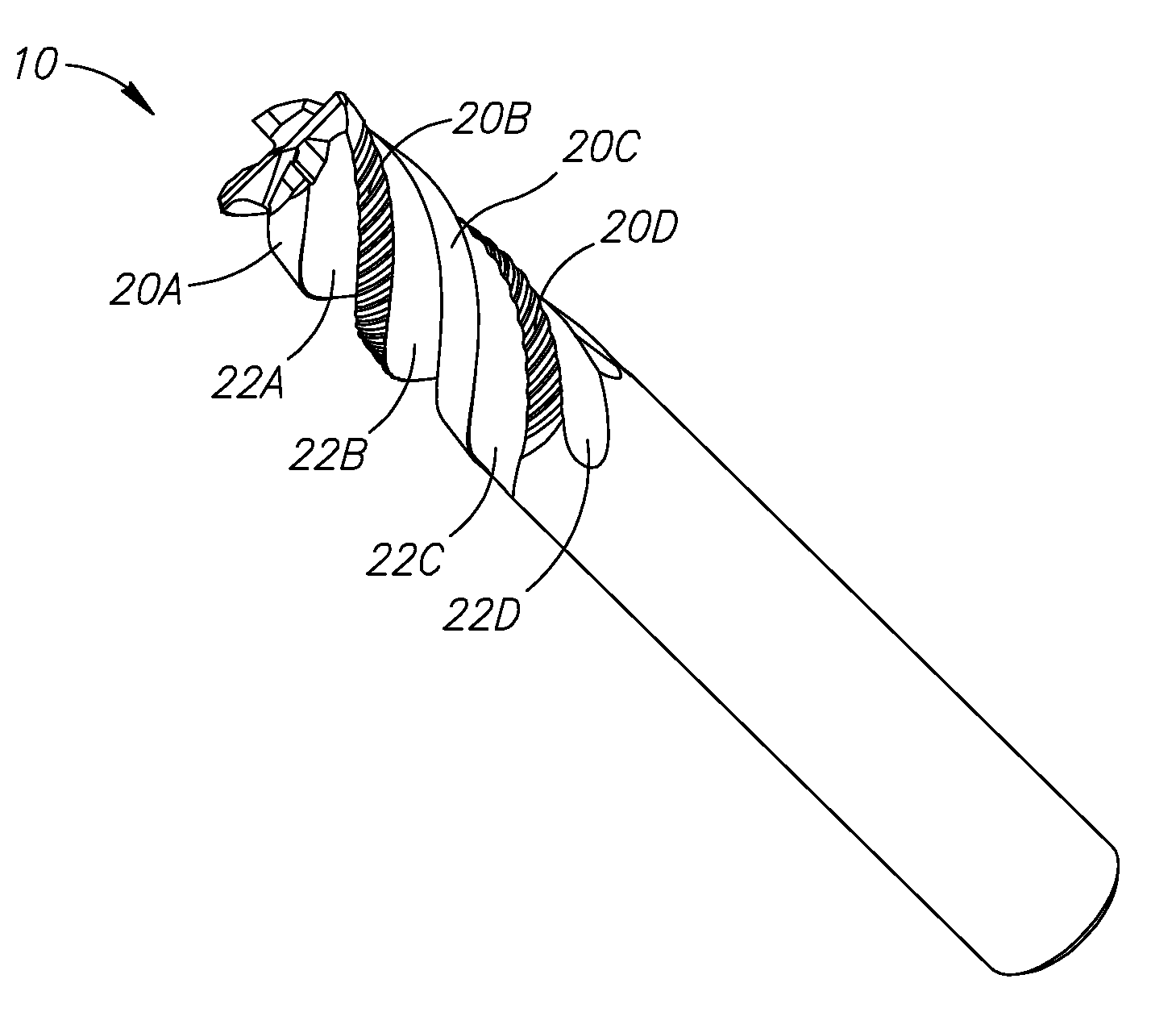

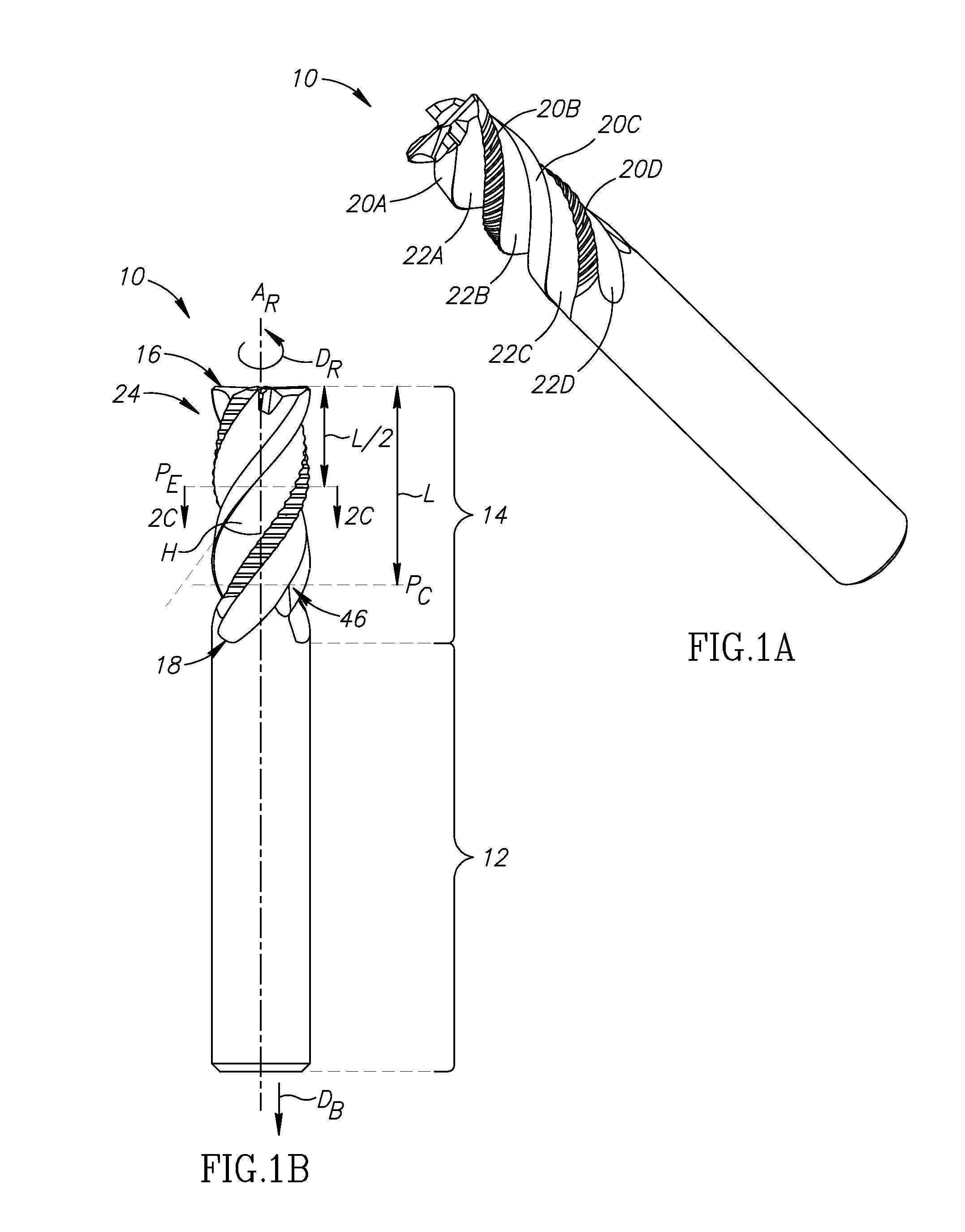

Rotary cutting tool

A rotary cutting tool or end mill is provided, the tool comprising a plurality of pairs of diametrically-opposed, symmetrical, helical flutes formed in a cutting portion of the tool body, wherein the pitch between at least one pair of adjacent helical flutes is less than or greater than the pitch of at least one other pair of adjacent helical flutes in at least one radial plane along the axial length of the flutes, a plurality of peripheral cutting edges, wherein at least one of the peripheral cutting edges has a radial rake angle different from radial rake angle of a peripheral cutting edge of a different helical flute.

Owner:KYOCERA SGS PRECISION TOOLS INC

Roughing and Semi-Finishing End Mill Having Serrated and Non-Serrated Cutting Teeth

An end mill having a plurality of teeth configured for both roughing and semi-finishing applications, the teeth being alternated with a plurality of flutes. At least one tooth of the plurality of cutting teeth is a serrated tooth formed with serrations along a relief surface thereof and at least one other tooth is free of serrations. Each tooth of the plurality of cutting teeth includes an actual internal cutting angle formed at an intersection of a rake cutting sub-surface and a relief surface. The actual internal cutting angle of each tooth has a greater value than an imaginary internal cutting angle formed at an intersection of imaginary extension lines of a rake recessed sub-surface and a relief surface of the same tooth.

Owner:ISCAR LTD

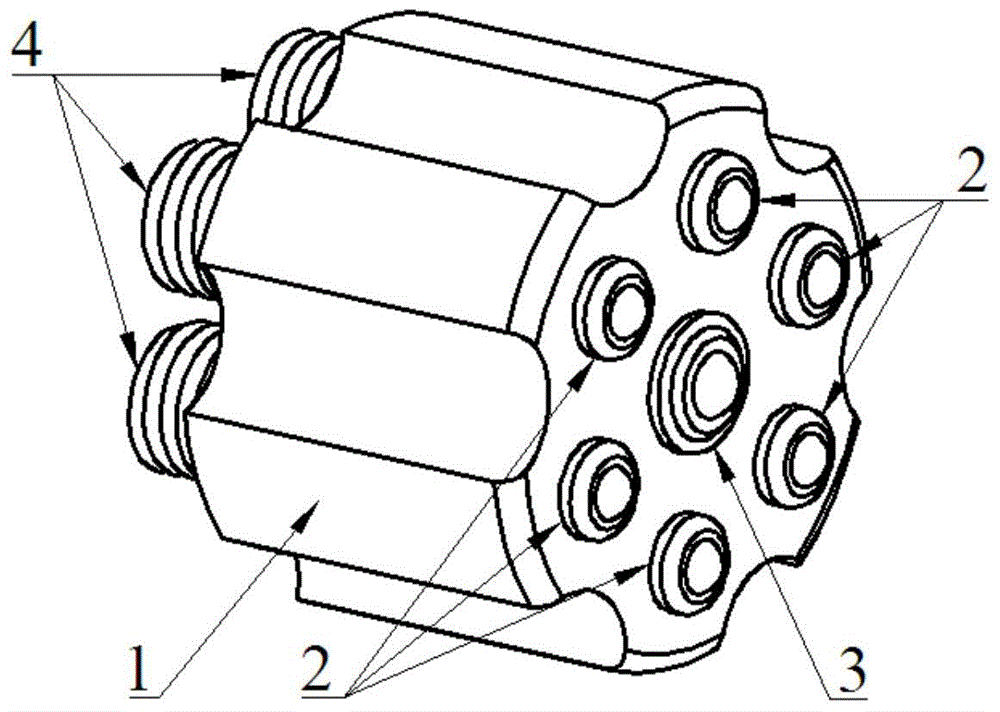

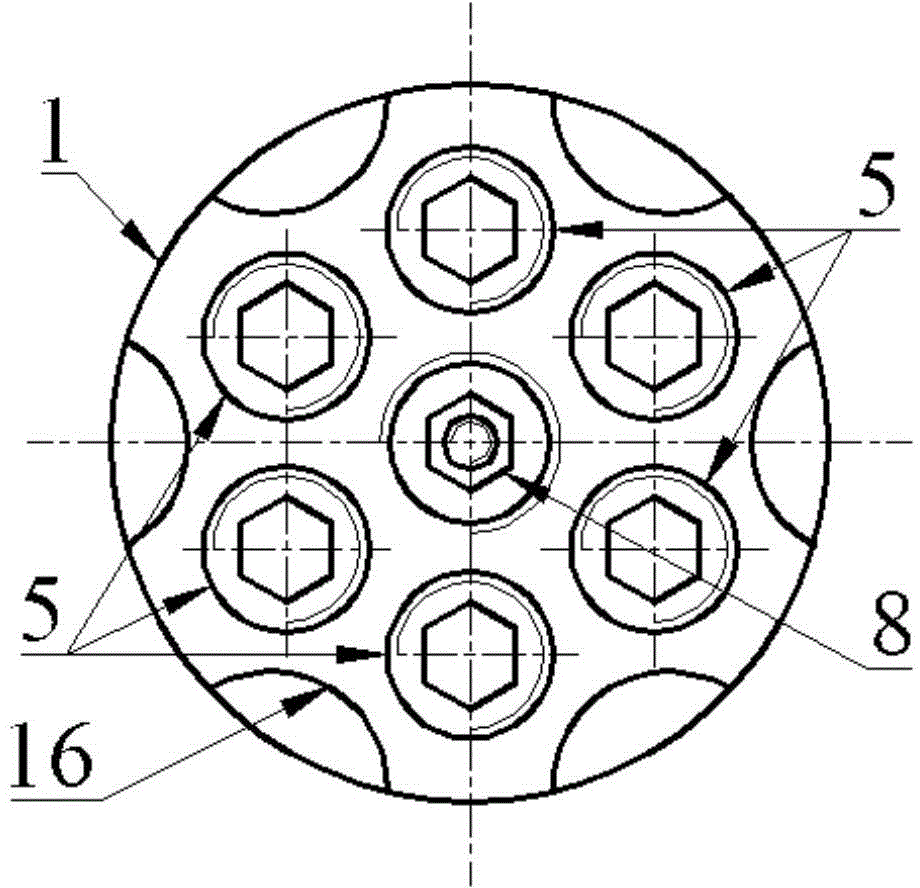

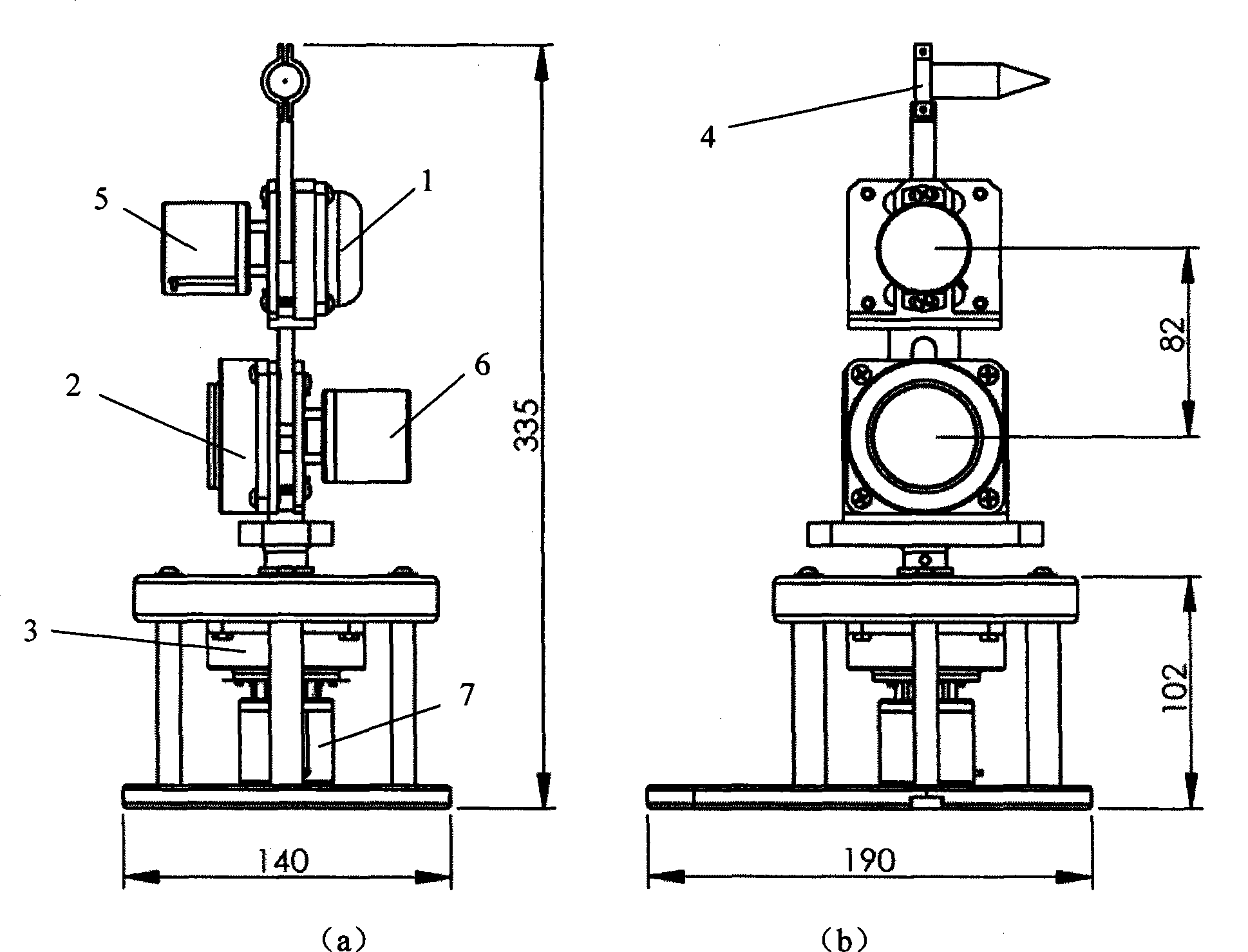

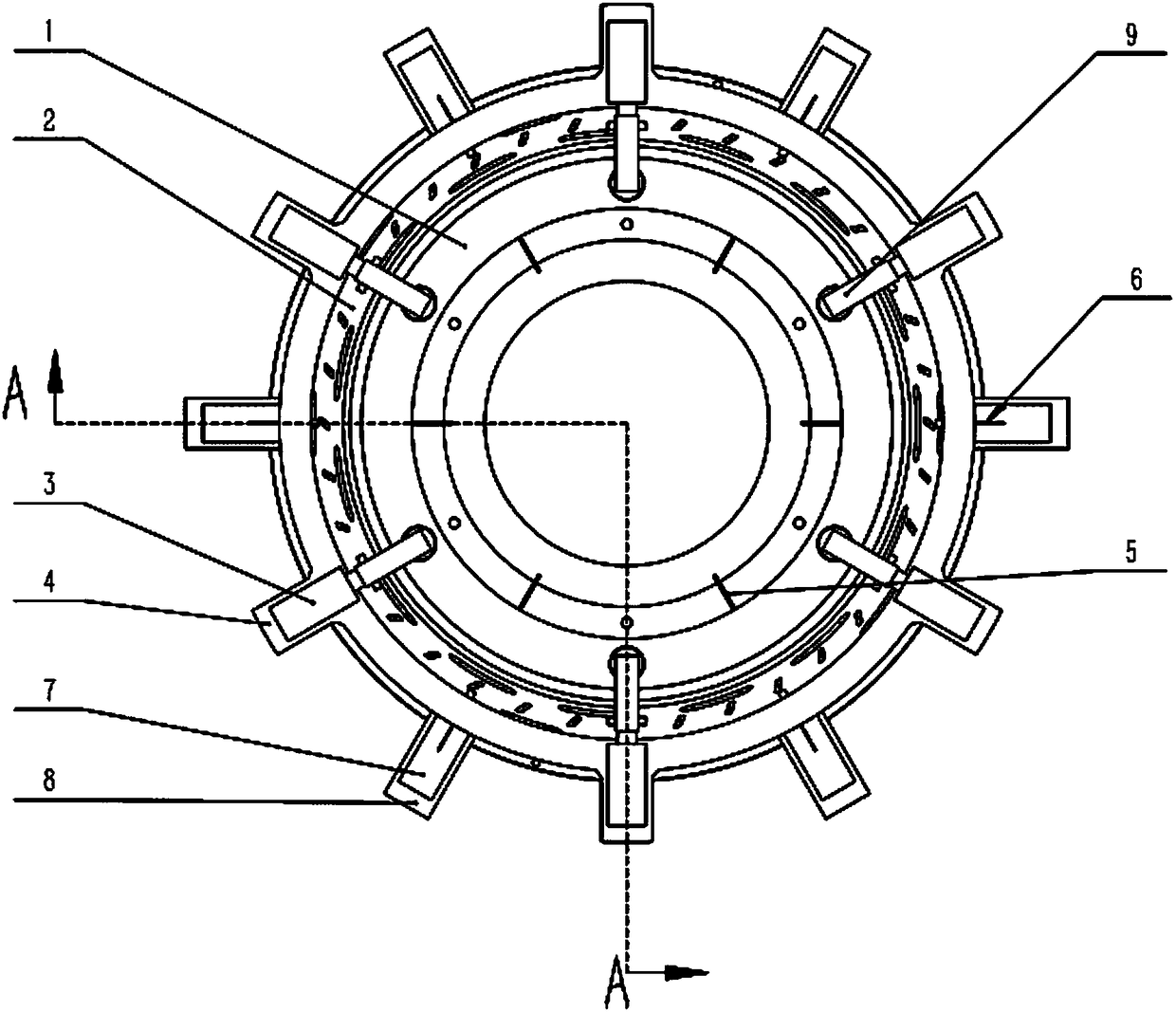

Hard-soft multipoint follow-up supporting head used for image processing

ActiveCN104668989AReduce flutterPrecise positioningPositioning apparatusMetal-working holdersImaging processingEngineering

The invention discloses a hard-soft multipoint follow-up supporting head used for image processing. The hard-soft multipoint follow-up supporting head comprises a base, multiple circumferential step through holes with axes parallel to one another are formed in the base uniformly along the circumferential direction, a central step through hole parallel to the axes of the circumferential step through holes is formed in the middle of the base, an internal thread is arranged on the left side of each of the circumferential step through hole and the central step through hole, a threaded connecting member, a left spring and a supporting rod where a right spring sleeves are sequentially mounted in each circumferential step through hole from left to right, the right end of each supporting rod is connected with an auxiliary universal ball, a left-side threaded end of a main supporting rod is fixedly connected at the right end of the central step through hole, the right end of the main supporting rod is connected with a main universal ball, and the auxiliary universal ball and the main universal ball are arranged outside the right end face of the base. According to the hard-soft multipoint follow-up supporting head, chattering of a thin-wall member is reduced due to flexible supporting, and the thin-wall member is positioned accurately due to rigid supporting; due to multipoint supporting, supporting area is increased, and controlling difficulty is lowered.

Owner:TIANJIN UNIV

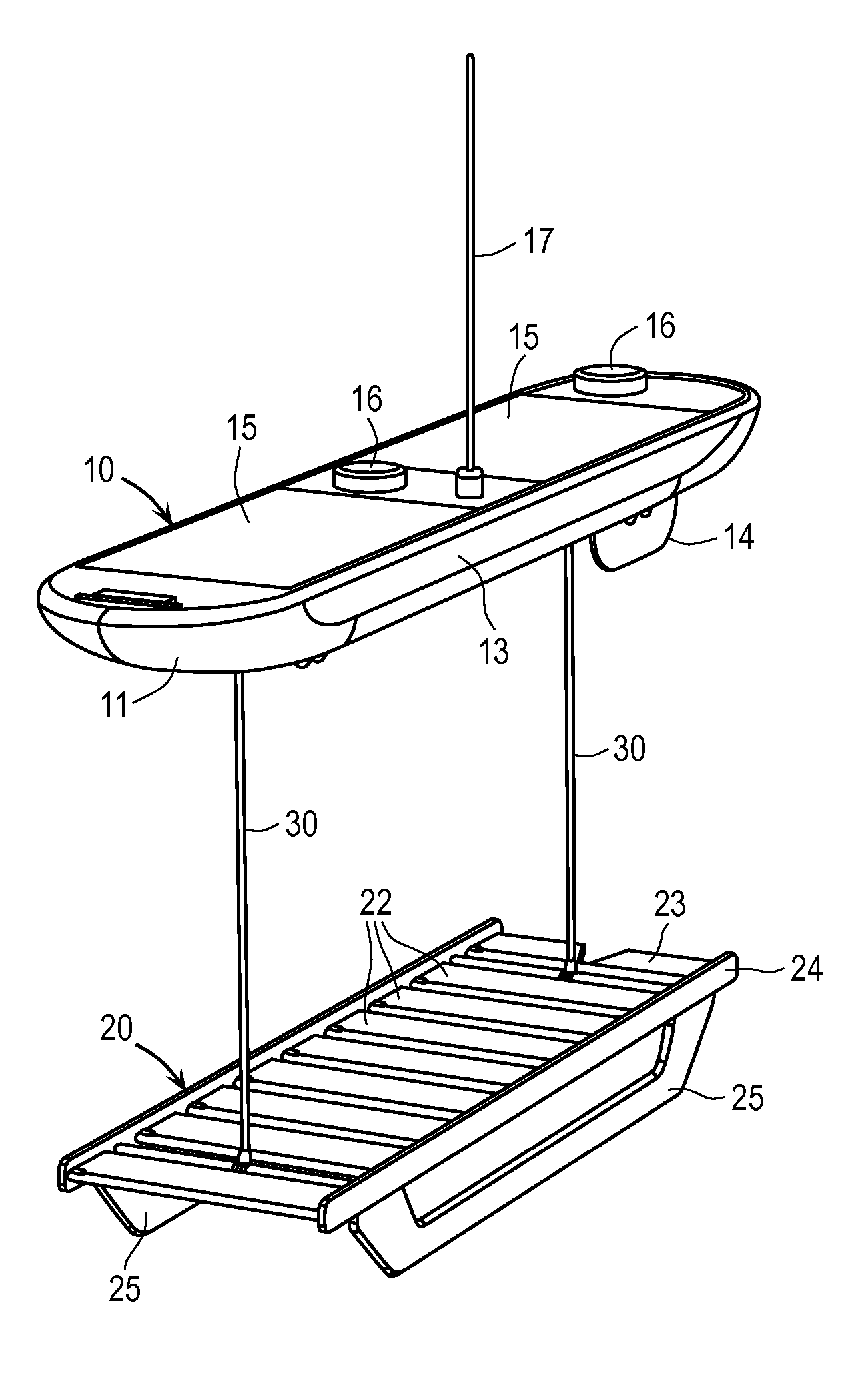

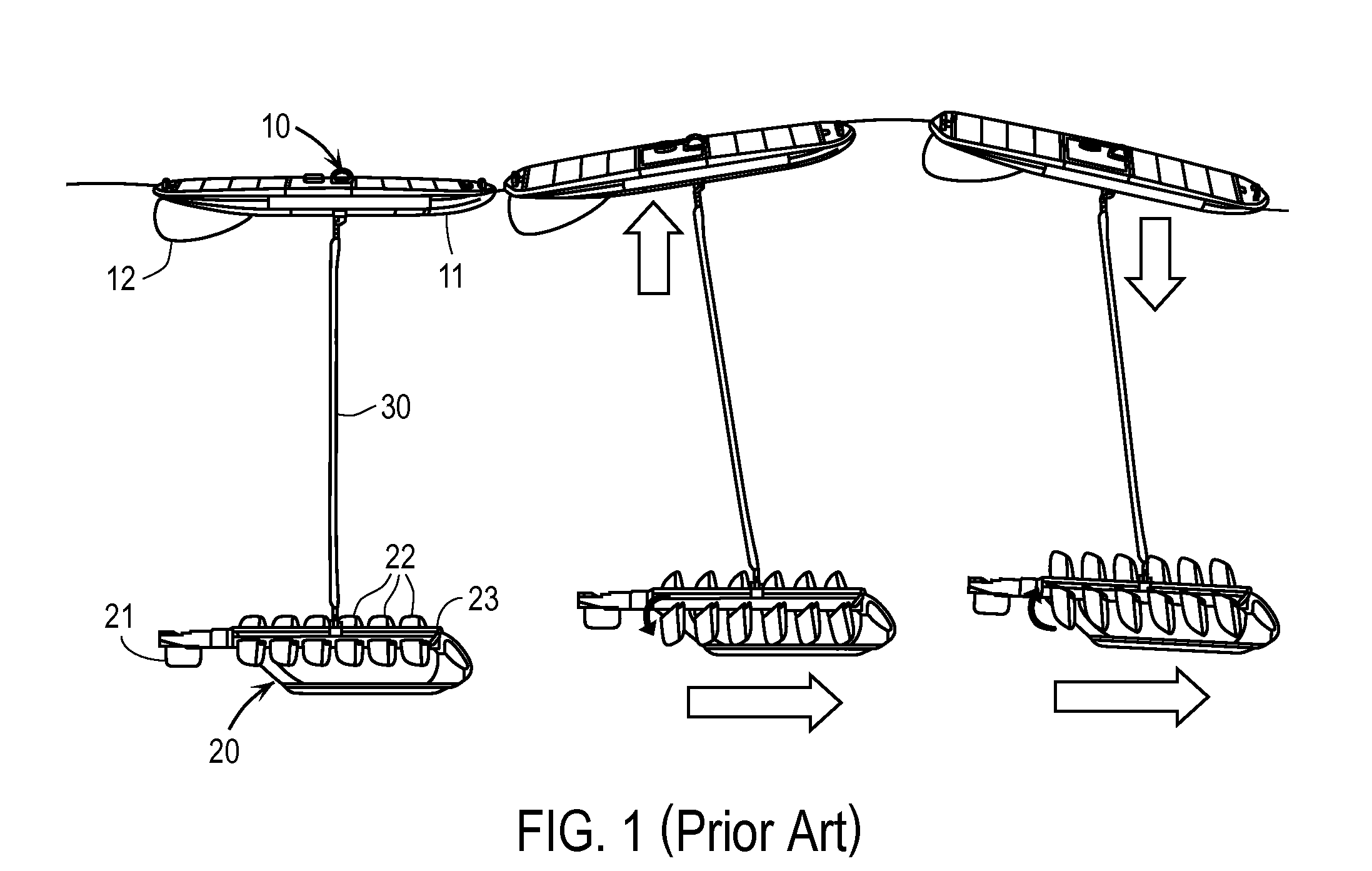

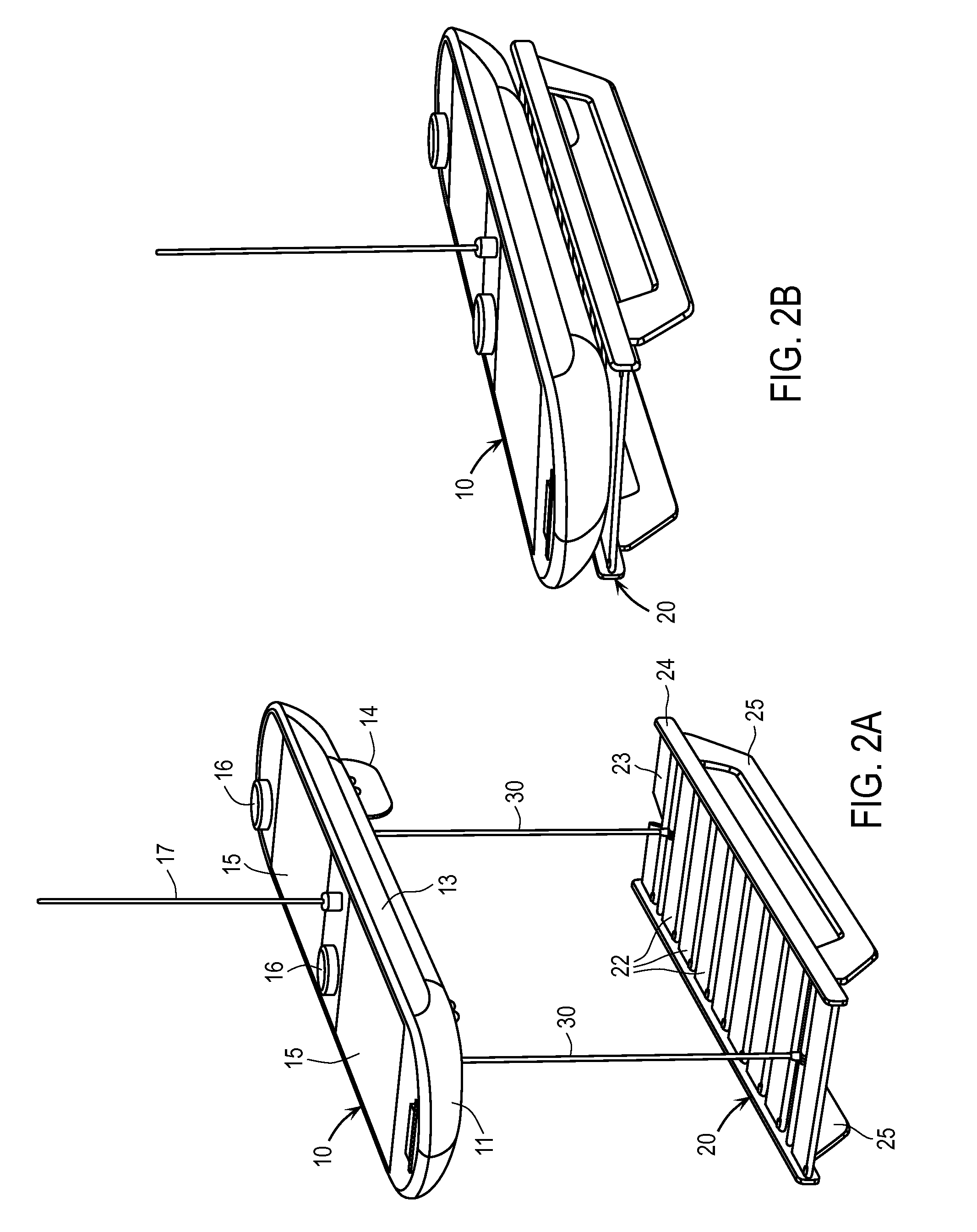

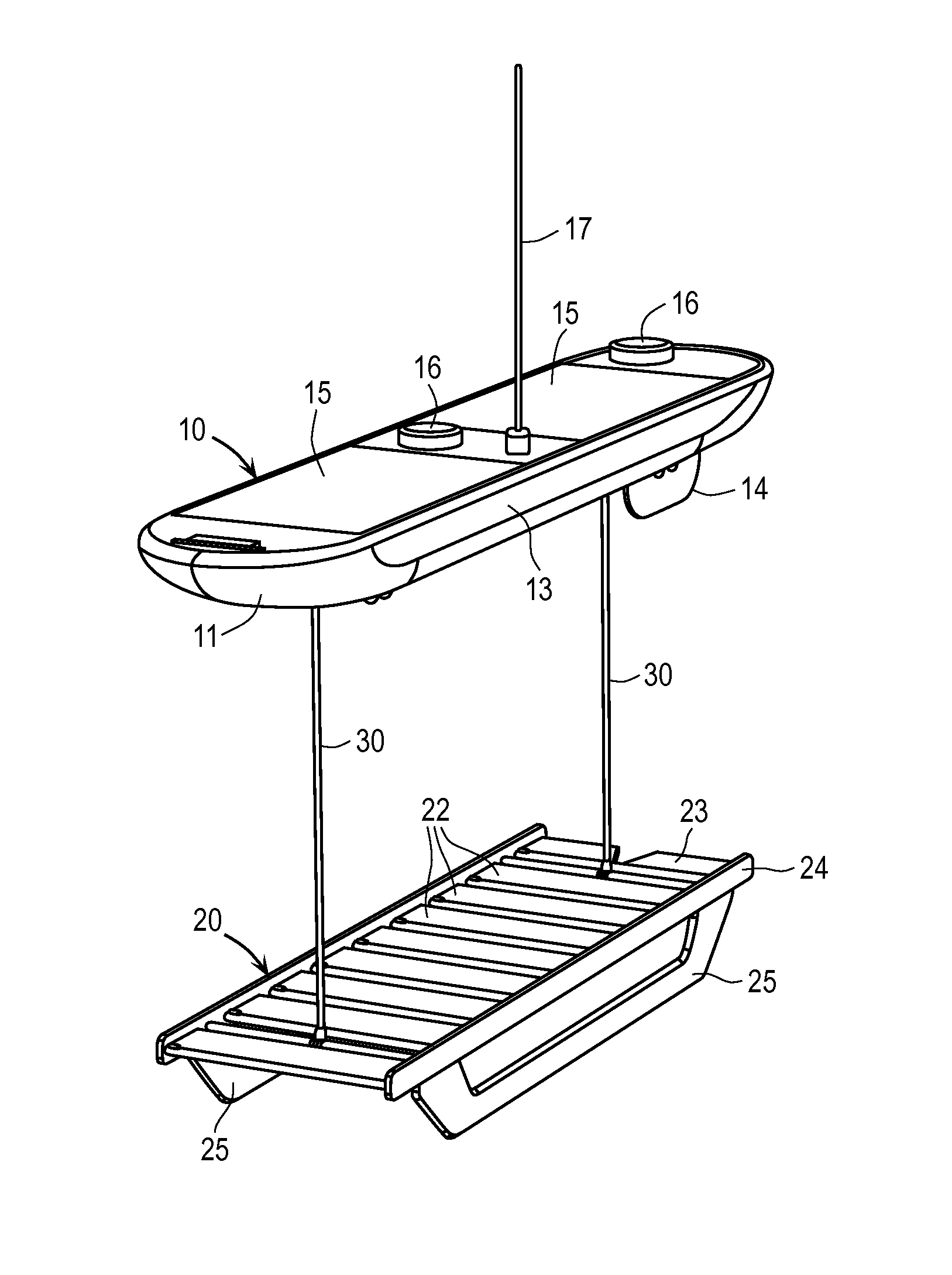

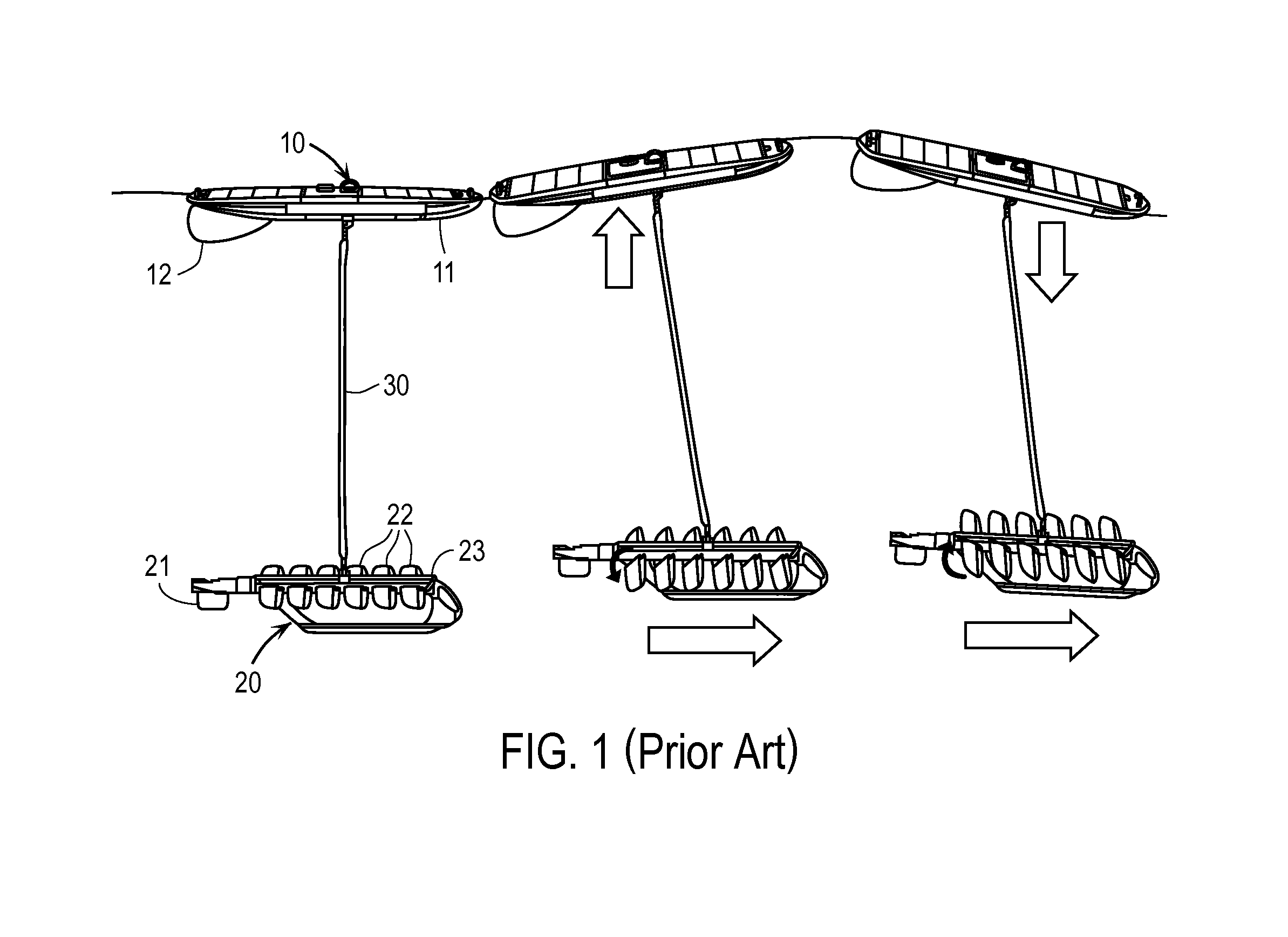

Wave-powered devices configured for nesting

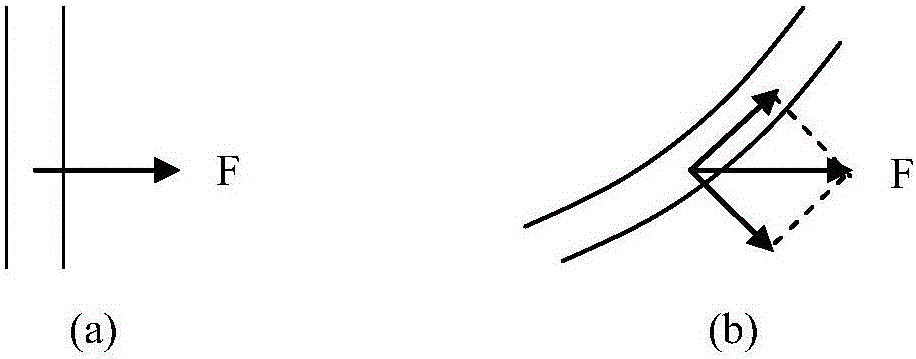

ActiveUS20120285160A1Reducing bowingReduce flutterTowing/pushing equipmentPropulsion based emission reductionClassical mechanicsMechanical engineering

A wave-powered water vehicle includes a) a first component which is a float that travels on or near the water surface; b) a second component which is wave actuated and travels below the first component; and c) a means whereby the first component engages the second component and / or the second component engages the first component; wherein the engagement means provides lateral support of one component for the other, and thereby minimizes lateral movement of one against the other when the components are fitted together.

Owner:LIQUID ROBOTICS

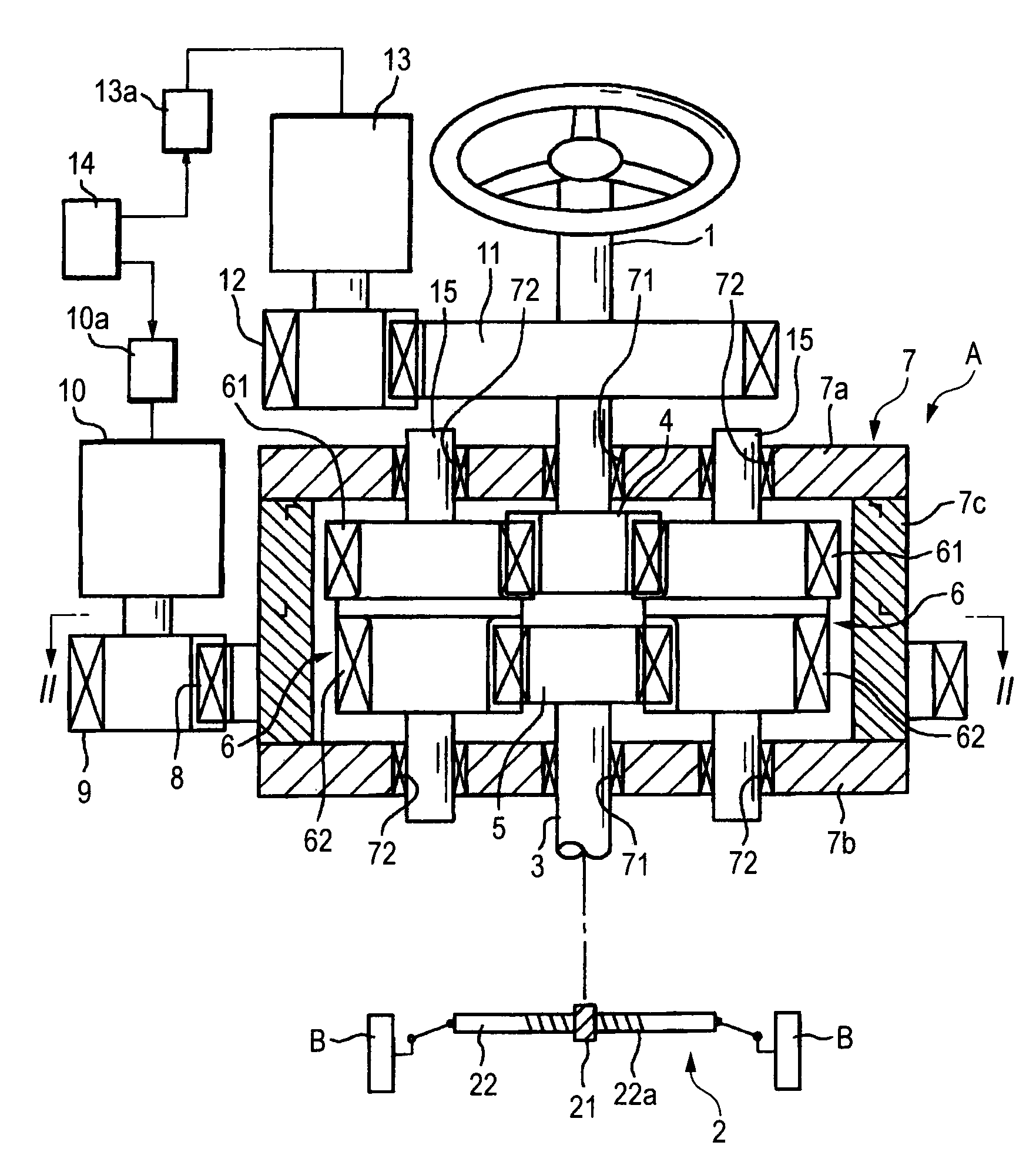

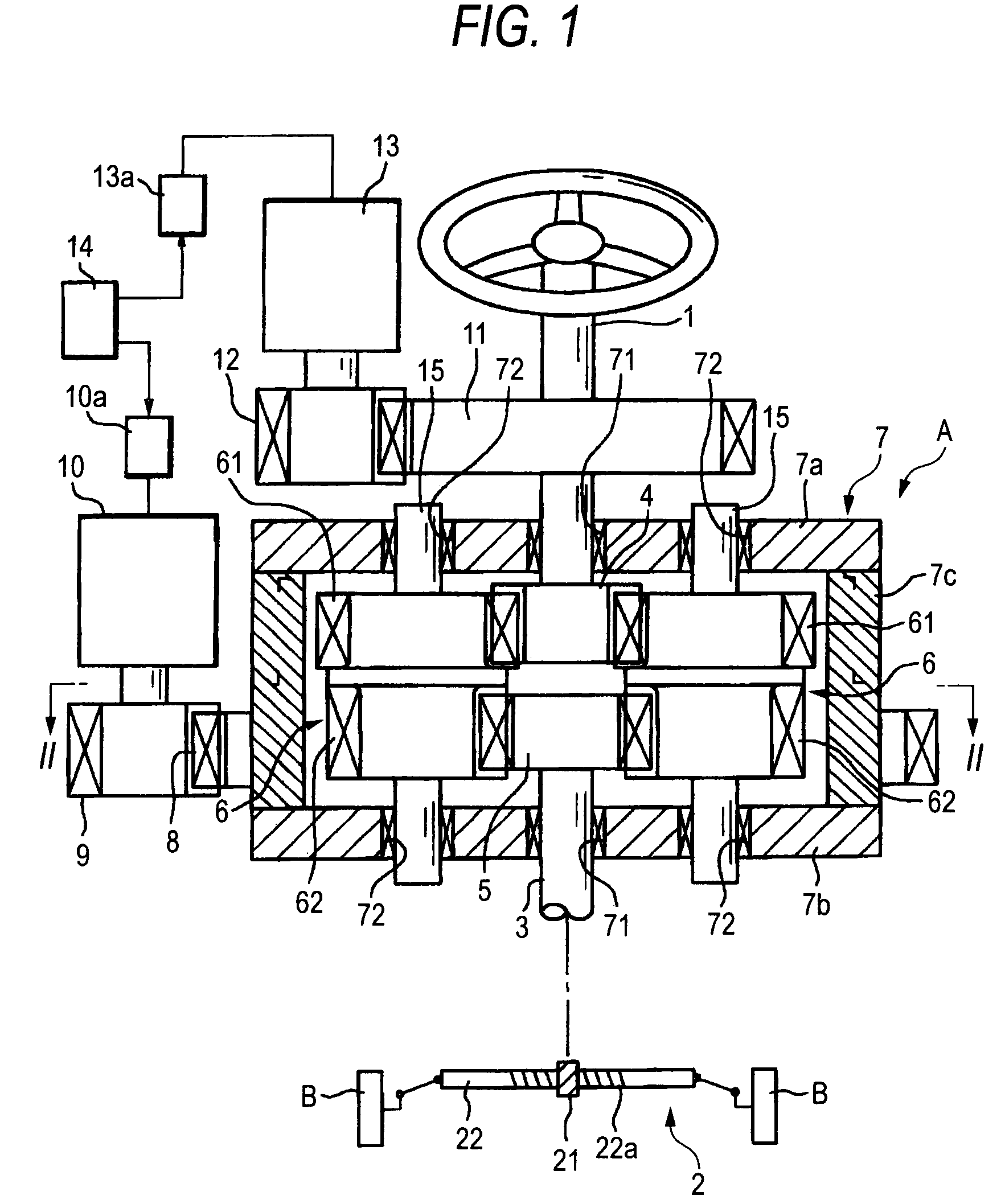

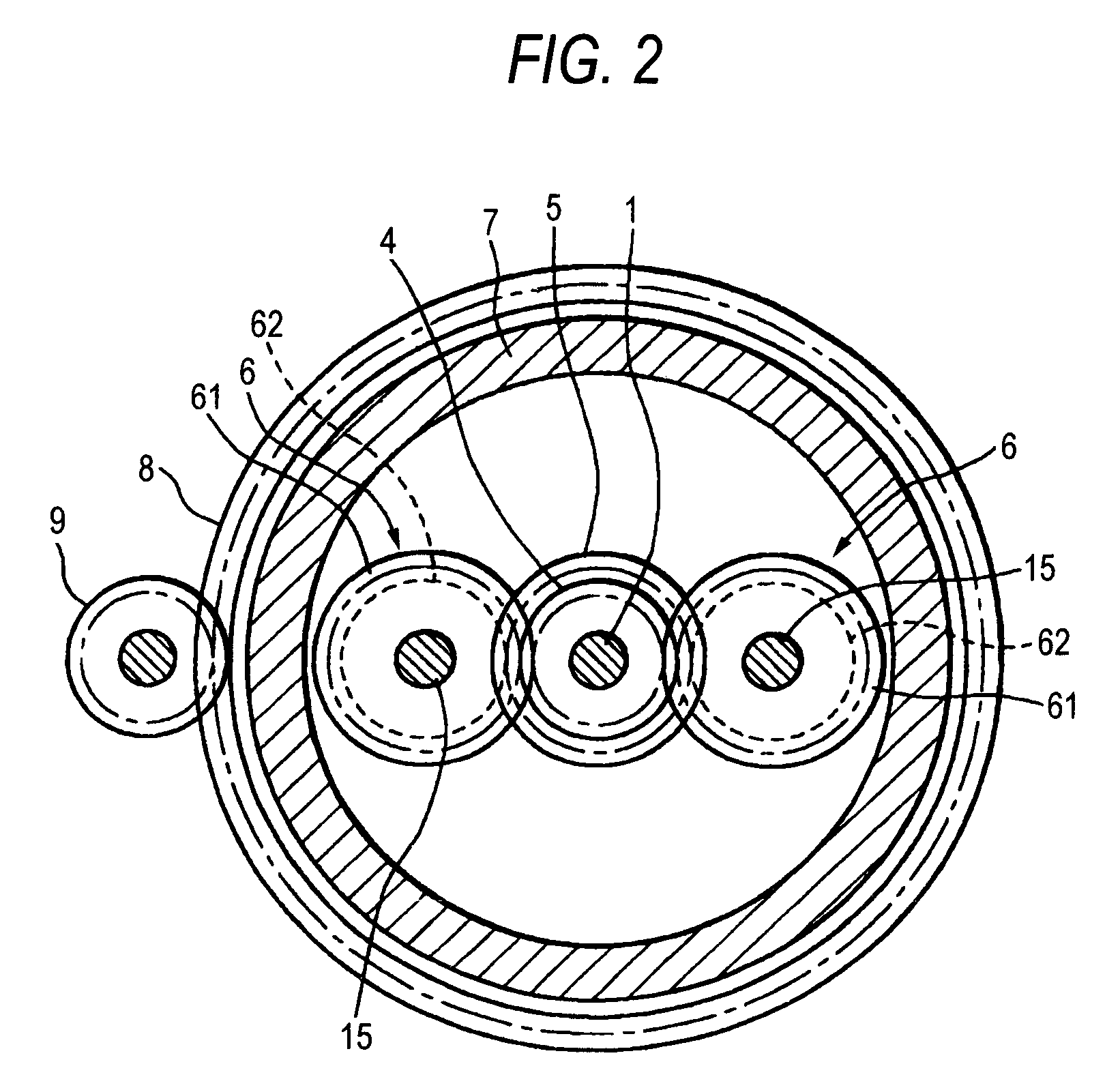

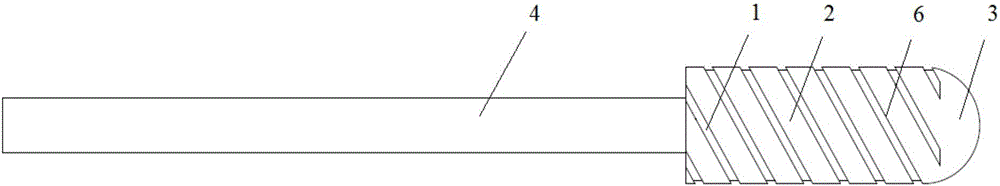

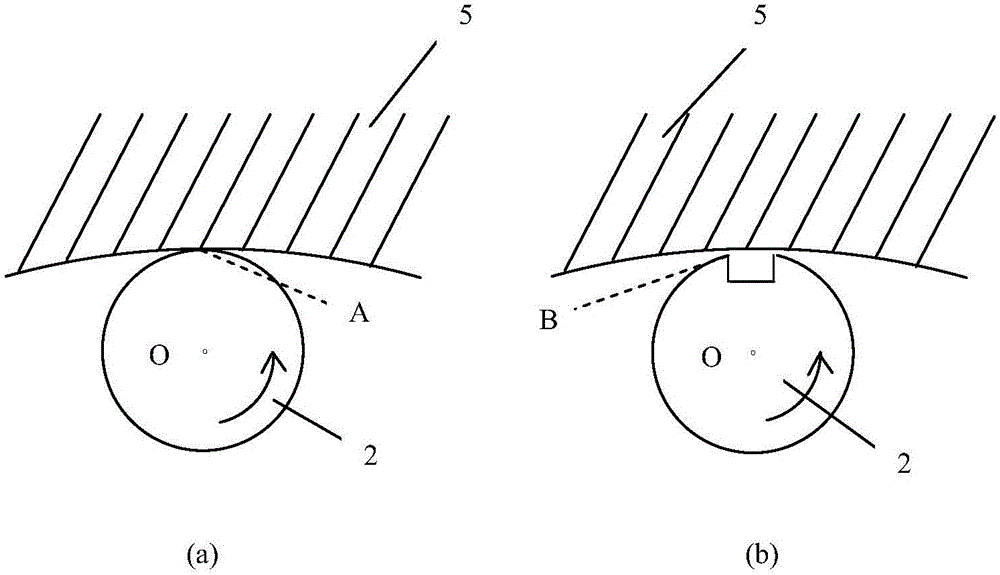

Vehicle steering system

InactiveUS7665572B2Reduce in quantityShorten the lengthFluid steeringElectrical steeringTurn angleSteering column

A vehicle steering system is provided which includes a variable angle ratio mechanism for changing an angle ratio of a steering angle of a steering member to a turning angle of a steering mechanism, the variable angle ratio mechanism including a first sun gear connected to a steering column, a second sun gear connected to the steering mechanism, and planetary gears each having a first toothed portion and a second toothed portion which are adapted to mesh with the first and second sun gears respectively, and are arranged to be spaced apart from each other in a tooth face width direction, the first toothed portion and the second toothed portion being formed integrally through forging.

Owner:JTEKT CORP

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

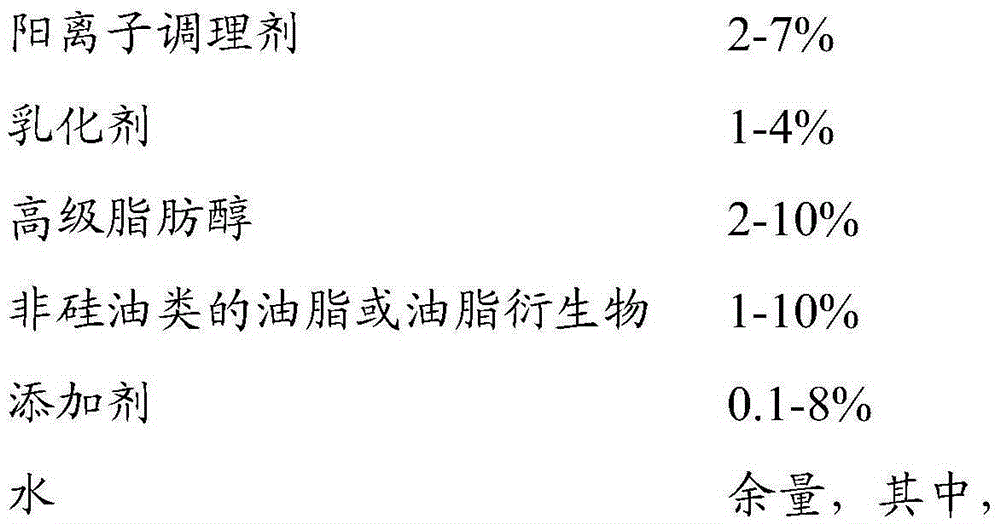

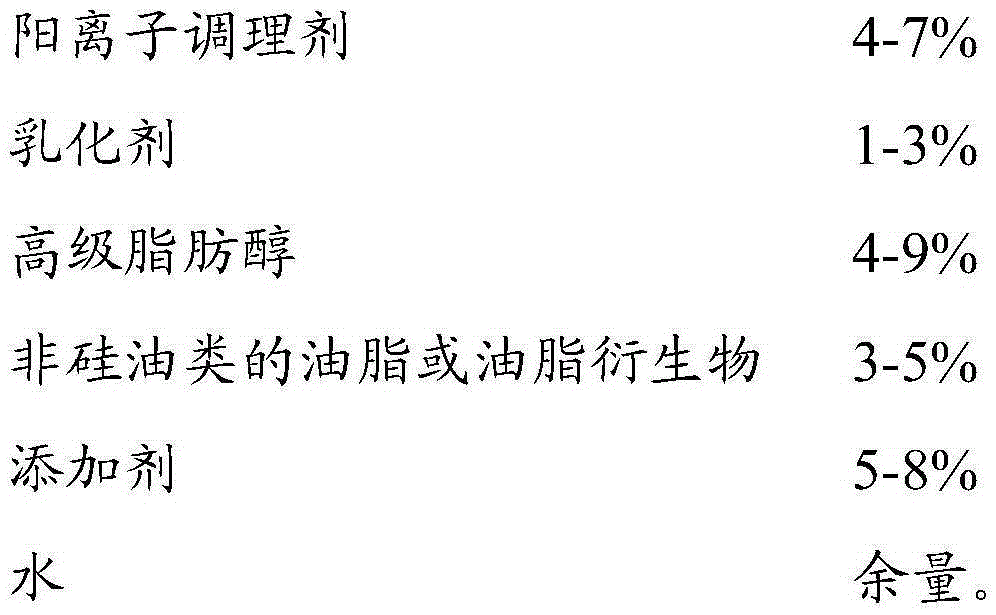

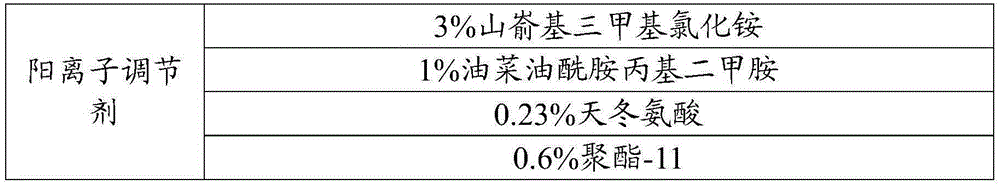

Mild nursing hair oil treatment and care composition containing no silicone oil and preparation method of mild nursing hair oil treatment and care composition

InactiveCN105380831AImprove toughnessIncrease elasticityCosmetic preparationsHair cosmeticsPolyesterMedicine

The invention relates to a mild nursing hair oil treatment and care composition containing no silicone oil and a preparation method of the mild nursing hair oil treatment and care composition. The hair care composition is prepared from the following components in percentage by weight: 2-7% of a cation conditioner, 1-4% of an emulsifier, 2-10% of higher aliphatic alcohol, 1-10% of non-silicone oil-type oil or a derivative thereof, 0.1-8% of an additive, and the balance of water, wherein the cation conditioner is composed of behentrimonium chloride, oilseed rape oleamidopropyl dimethylamine, aspartic acid and polyester-11. According to the hair care composition, no silicone oil is added, so that the defects that after silicone oil products are used for a long term, the conditioning property and the smoothness of hair are reduced, and the hair is dry, bifurcate, broken and free of luster are overcome, the hair care composition achieves the effects of moistening and caring hair in the real sense, preserves moisture and provides nutrition from the deep position of the hair, obviously improves the combing property of the wet hair, the combing property of the dry hair, the limpness of the wet hair, and the limpness of the dry hair, and obviously improves the tenacity, the elasticity and the luster of the hair.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

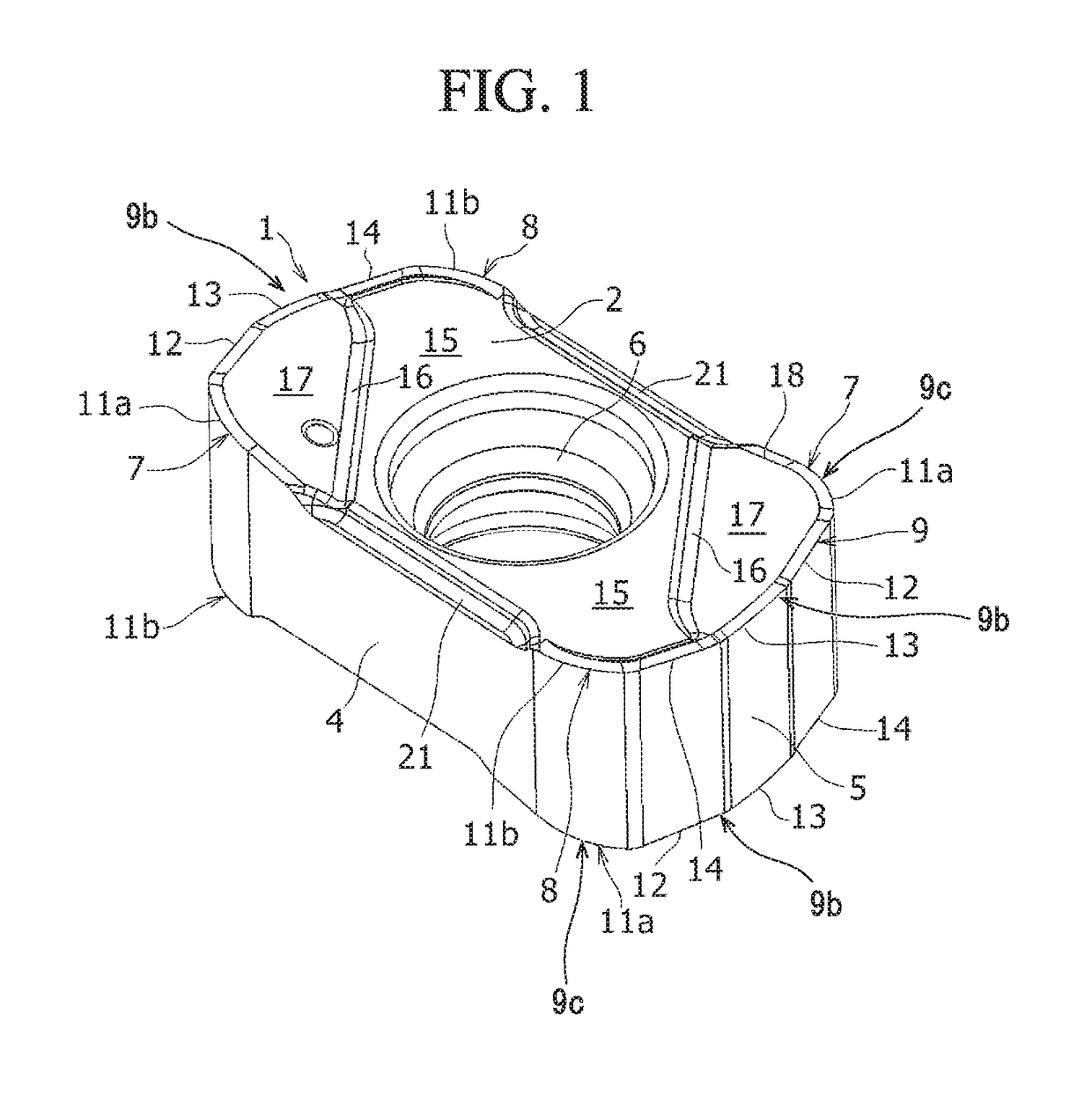

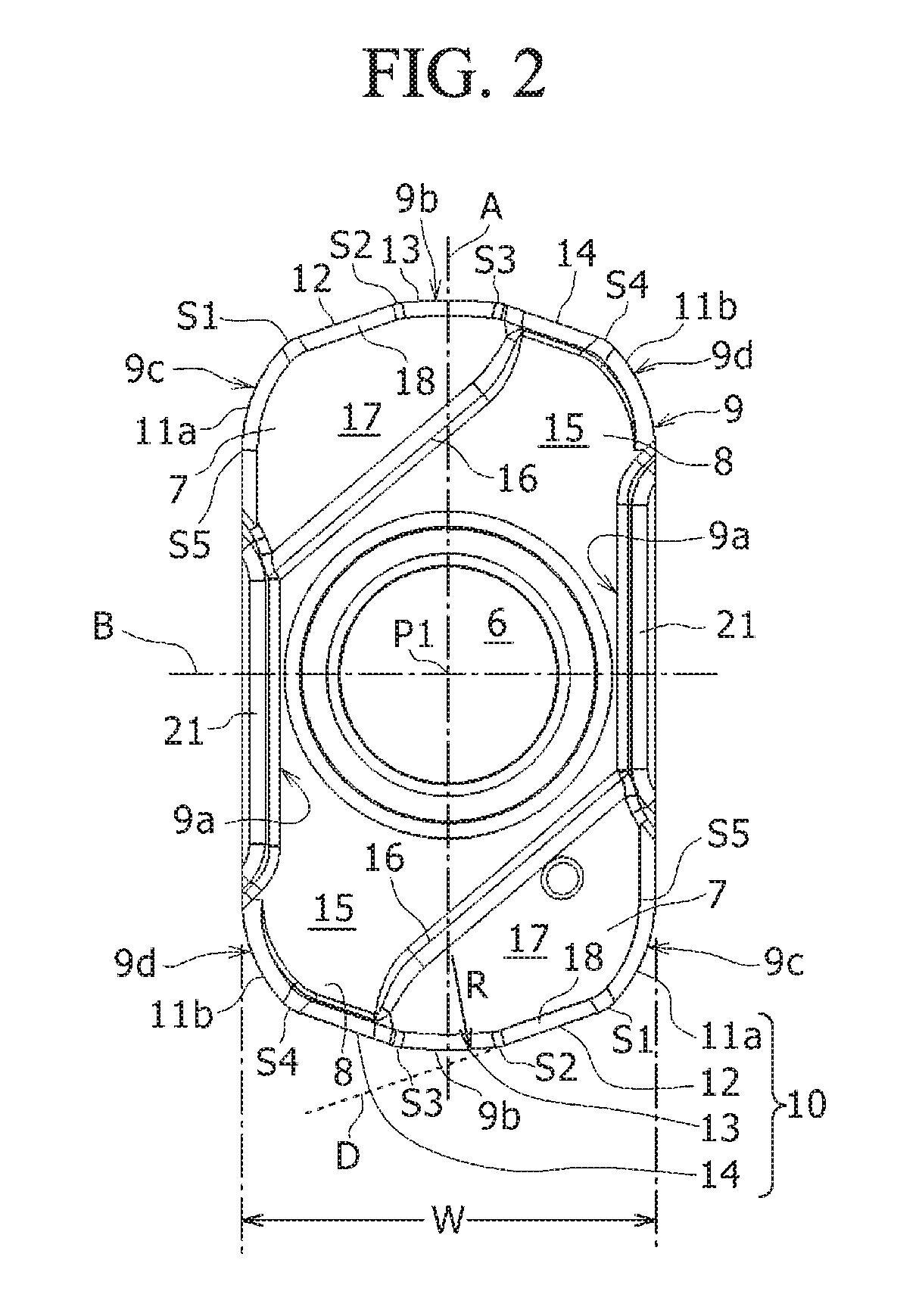

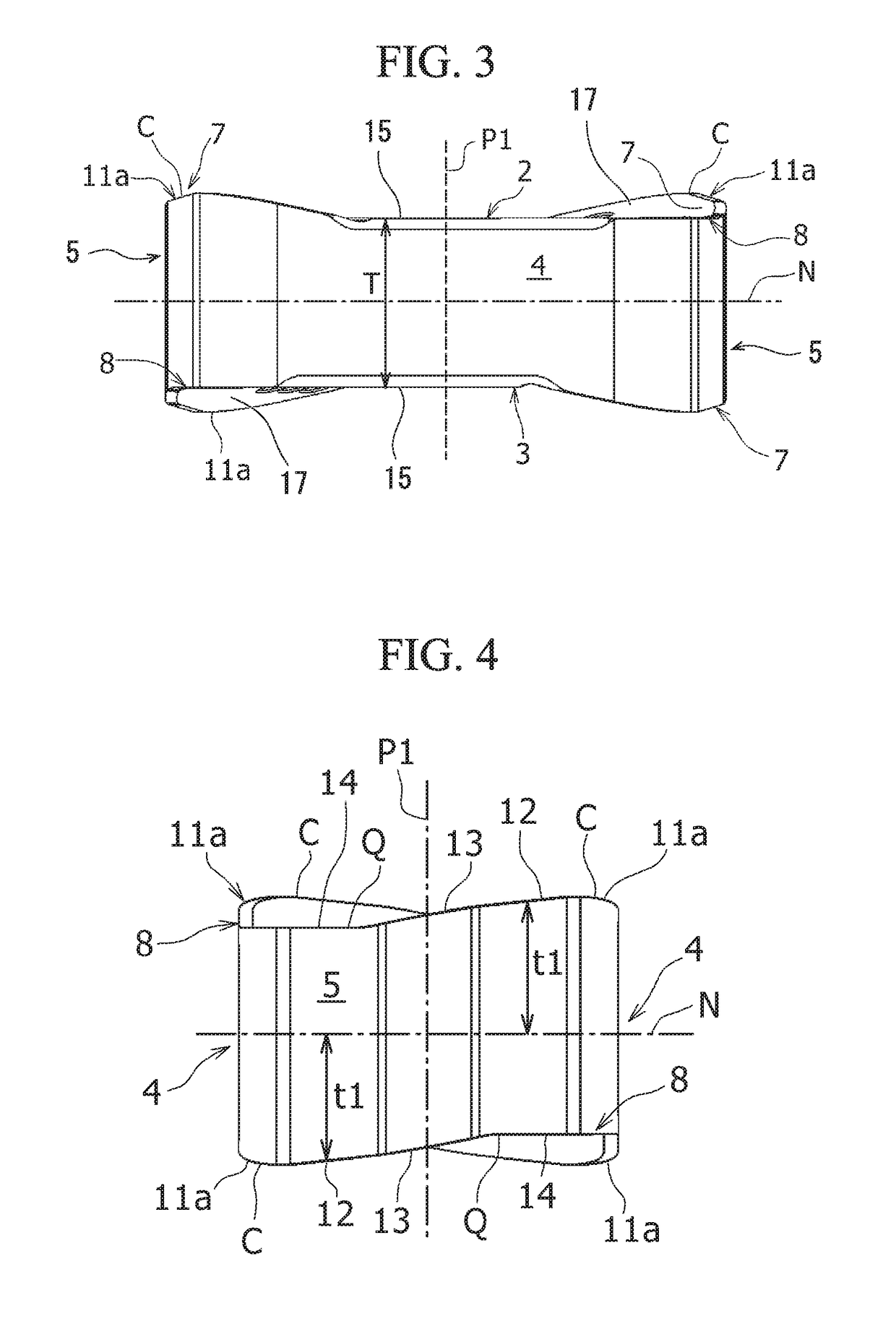

Cutting insert and indexable rotary cutting tool

ActiveUS20180339350A1Reduce flutterImprove surface roughnessTransportation and packagingMilling cuttersStructural engineeringKnife blades

In the cutting insert of the present invention, the cutting edge portion includes: a first corner edge; a major cutting edge continuous with a first end portion (S1) of the first corner edge near the short-side-direction side surface and formed into a straight line; a first minor cutting edge continuous with a second end portion (S2) of the major cutting edge and formed into a circular arc; and a second minor cutting edge continuous with a third end portion (S3) of the first minor cutting edge and formed into a straight line. In a cross-sectional view of a rake face of the second minor cutting edge perpendicular to the second minor cutting edge, a cross-sectional ridgeline of the rake face of the second minor cutting edge is formed into a convex shape protruding above a cross-sectional ridgeline of a reference plane.

Owner:HITACHI TOOL ENG LTD

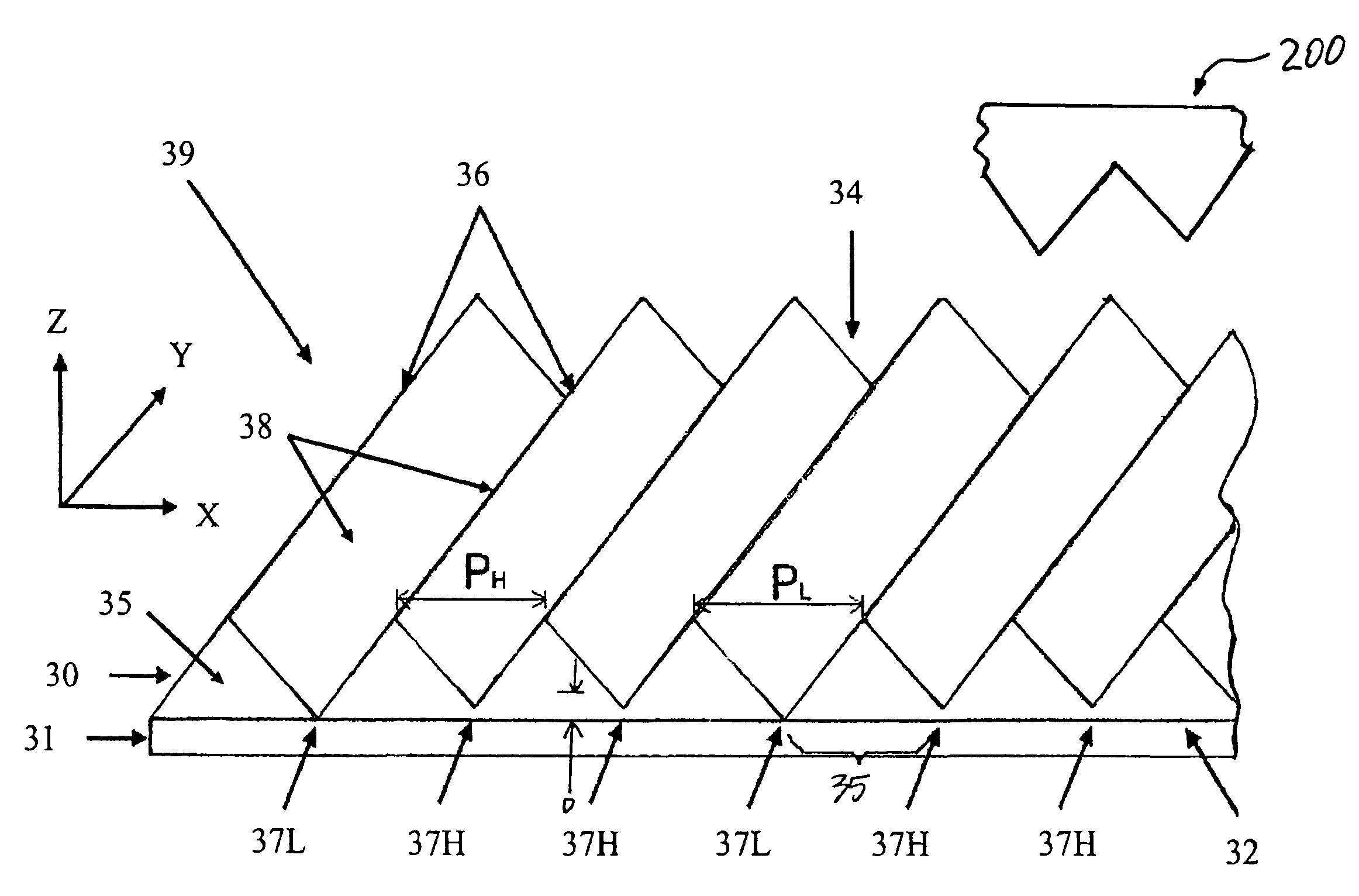

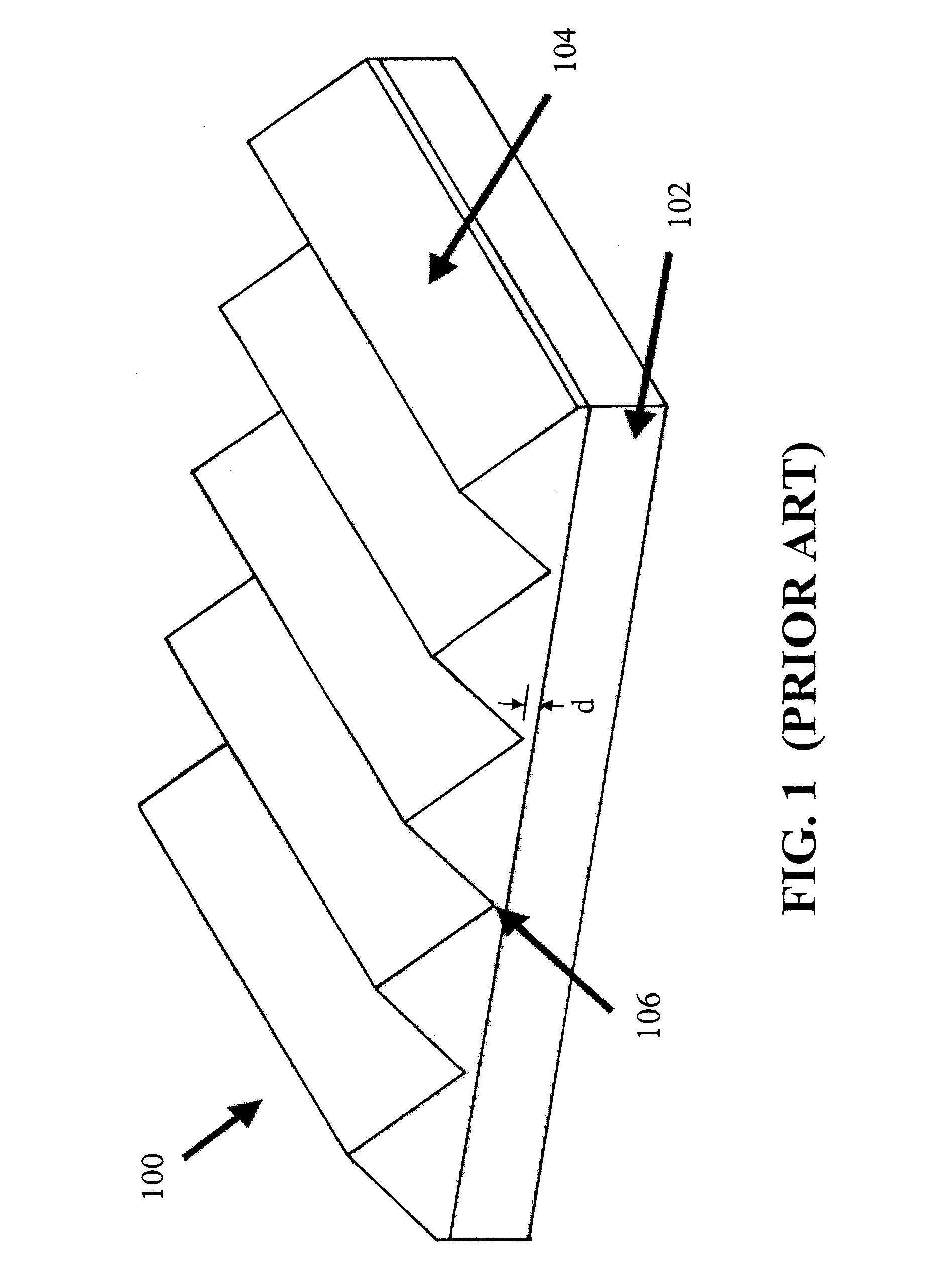

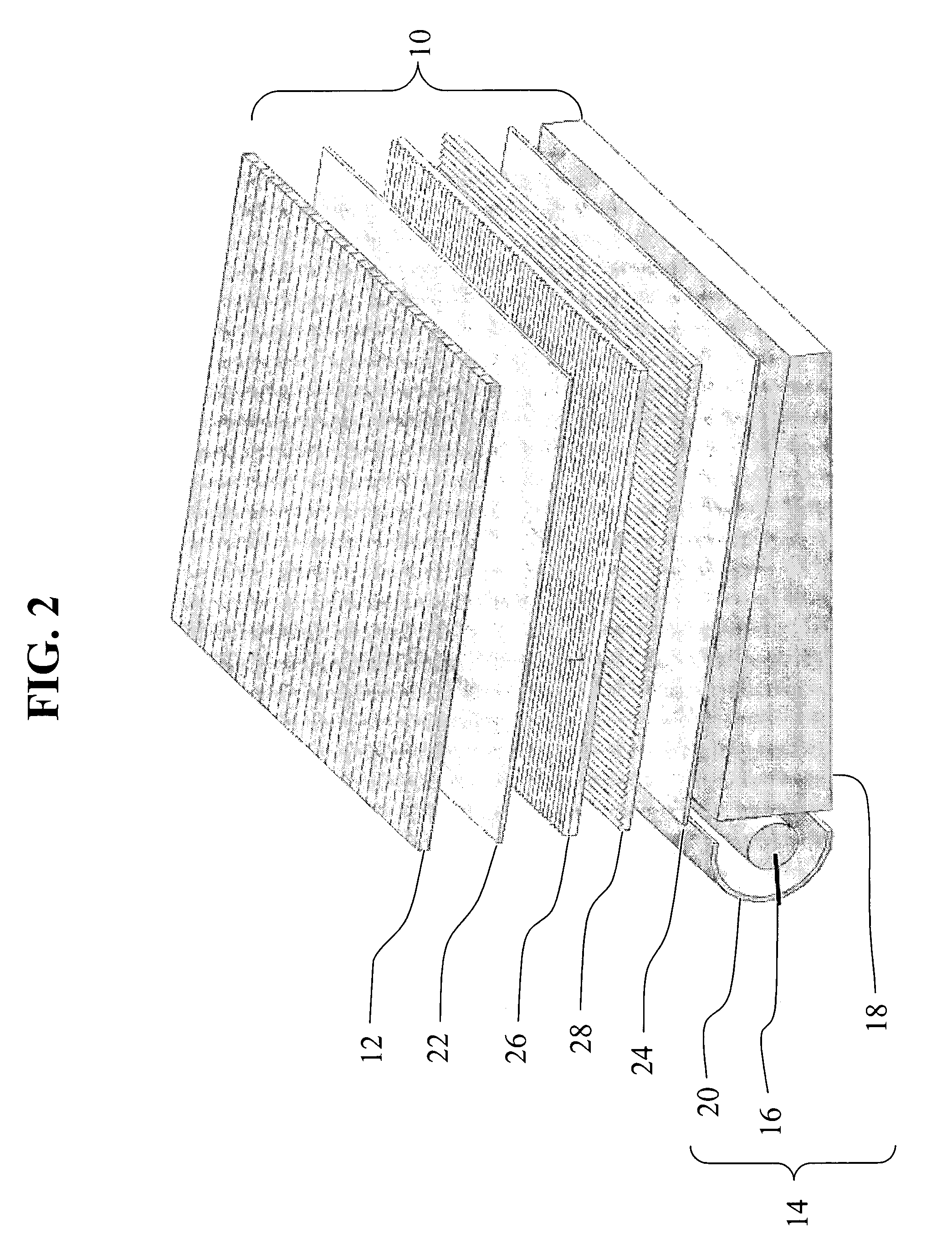

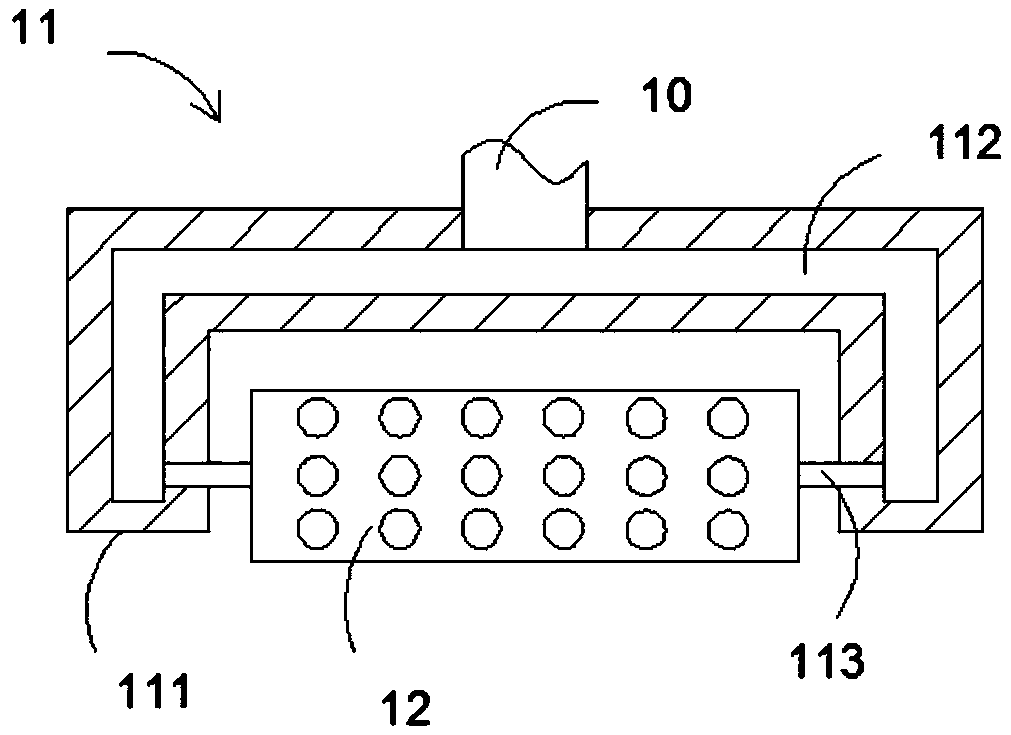

Luminance enhancement optical substrates with anti-chatter structures

ActiveUS7712944B2Increase brightnessImprove luminancePrismsMechanical apparatusOptoelectronicsBrightness perception

Owner:UBRIGHT OPTRONICS CORP

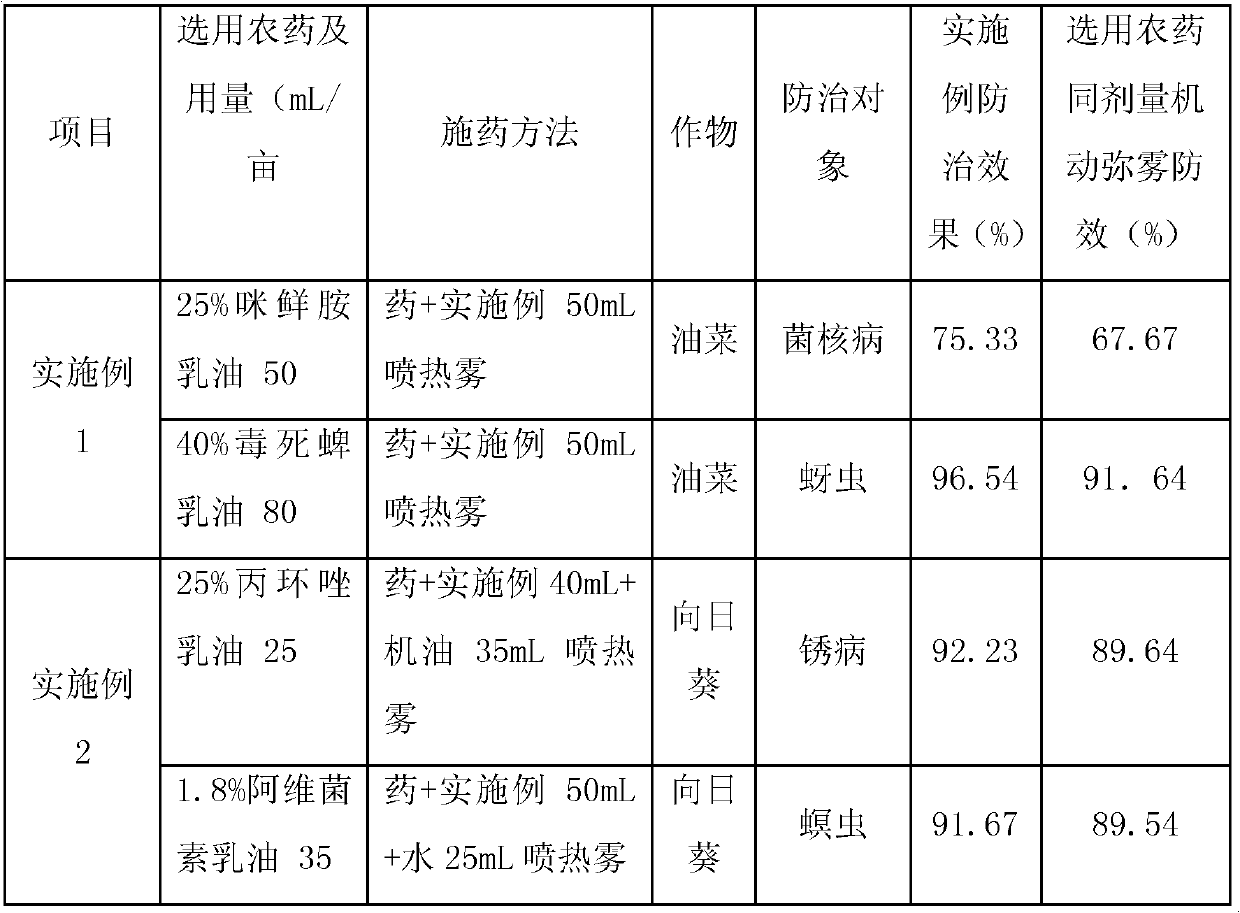

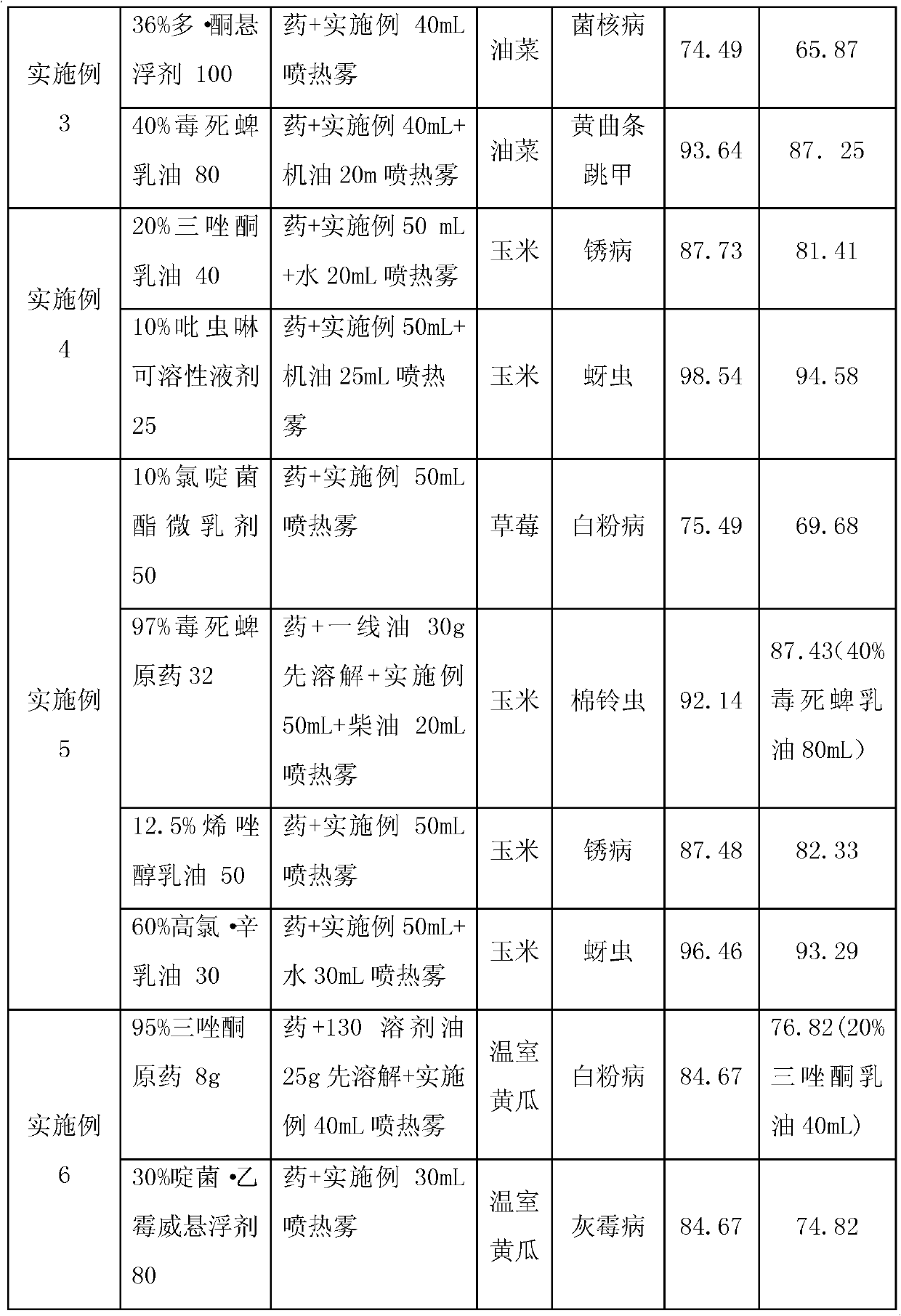

Dedicated additive for hot fog machine and preparation method thereof

ActiveCN102165949AReduce flutterHigh densityBiocideAnimal repellantsVolumetric Mass DensitySURFACTANT BLEND

The invention discloses a dedicated additive for a hot fog machine and a preparation method thereof. The dedicated additive for a hot fog machine comprises the following raw material components in percentage by mass: 5-20% of surfactant, 1-25% of hot fog density modifier, 1-10% of antifreeze agent, 0.1-6% of antifoaming agent and the balance of water. When the dedicated additive is prepared, all raw material components which can be dissolved into water are mixed to obtain an aqueous phase; then the insoluble hot fog density modifier is introduced into the aqueous phase; the hot fog density modifier and the aqueous phase are stirred; and residues are removed by filtering to obtain a finished product. According to the dedicated additive, the prevention and treatment safety and effect of thehot fog machine can be effectively improved, the type range of the hot fog machine on preventing and treating crop pests is expanded, the compatibility problem of pesticides, smoke agents and water can be solved, and the problem that the hot fog machine is applicable to middle-stalked crops and short-stalked crops, such as corn, wheat and the like is solved.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

Finish-milling feeding speed optimizing method based on integral impeller blade shape

ActiveCN103586738AImprove processing efficiencyGuarantee the quality of the machined surfaceAutomatic control devicesWorkpiecesImpellerProcess quality

The invention discloses a finish-milling feeding speed optimizing method based on integral impeller blade shape. The method comprises the steps of generating a finish-machining cutter track source file of a spherical head cutter blade with the radius as RT and based on a spherical head according to a geometrical shape of an integral impeller blade, introducing a single impeller blade model, judging the cross line between a runner and the blade according to the distance between a point on the blade and the center of an impeller, extracting the cross line, discreting the cross line into W points according to equal chord heights, composing a point set U through W points, setting the longitudinal depth acceleration proportion omega between the top end of the blade and the tail end of the blade, sequentially reading and analyzing the cutter track source file generated in the step 1 line by line, and extracting cutter point information of all cutting paths in the cutter track source file generated in the step 1. In addition, the cutter track source file records cutter point coordinates under a processing coordinate system and cutter axis vectors corresponding to the cutter point coordinates. The finish-milling feeding speed optimizing method solves the technical problems that an existing method is low in processing efficiency, poor in processing quality and serious in cutter abrasion.

Owner:HUAZHONG UNIV OF SCI & TECH

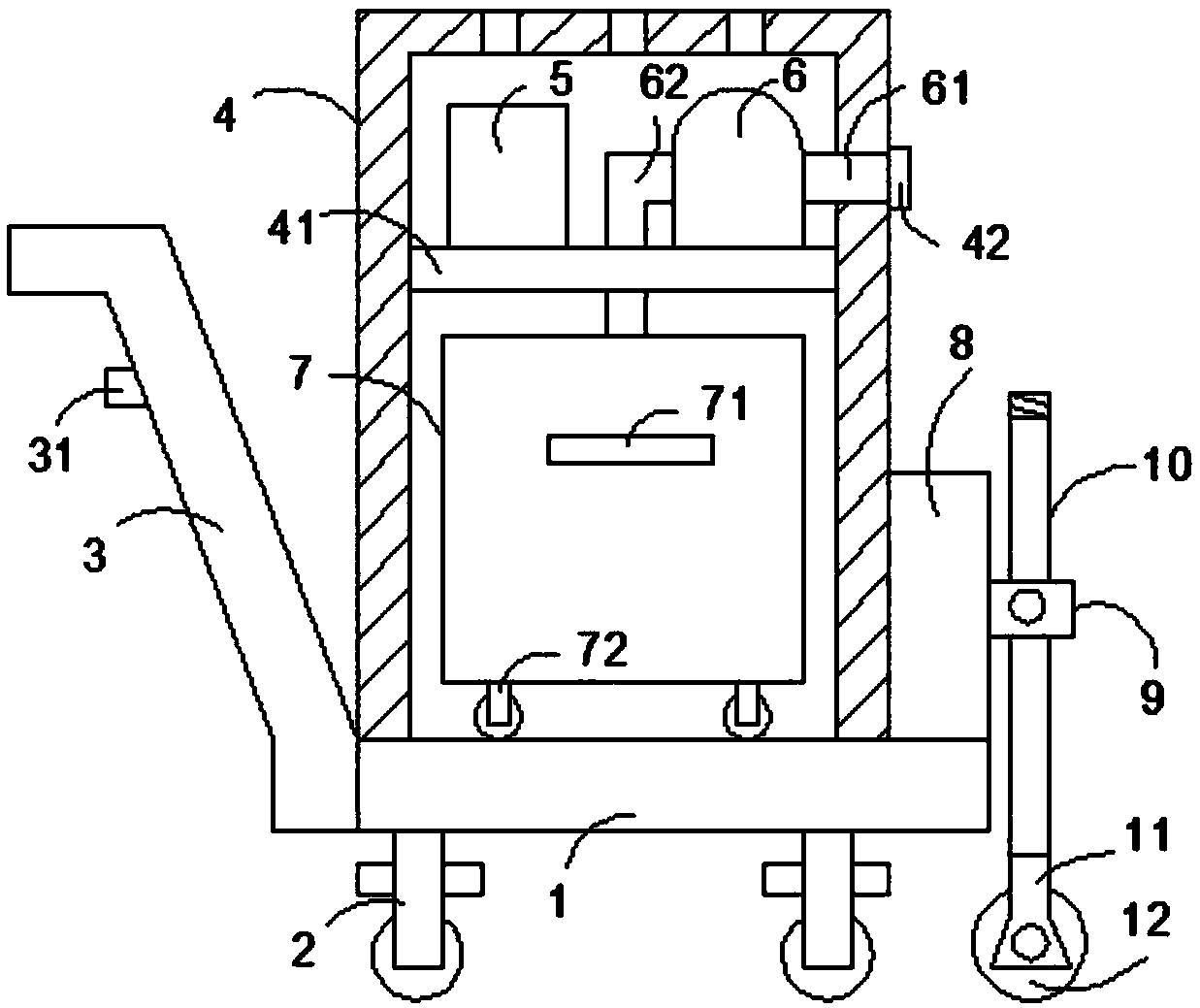

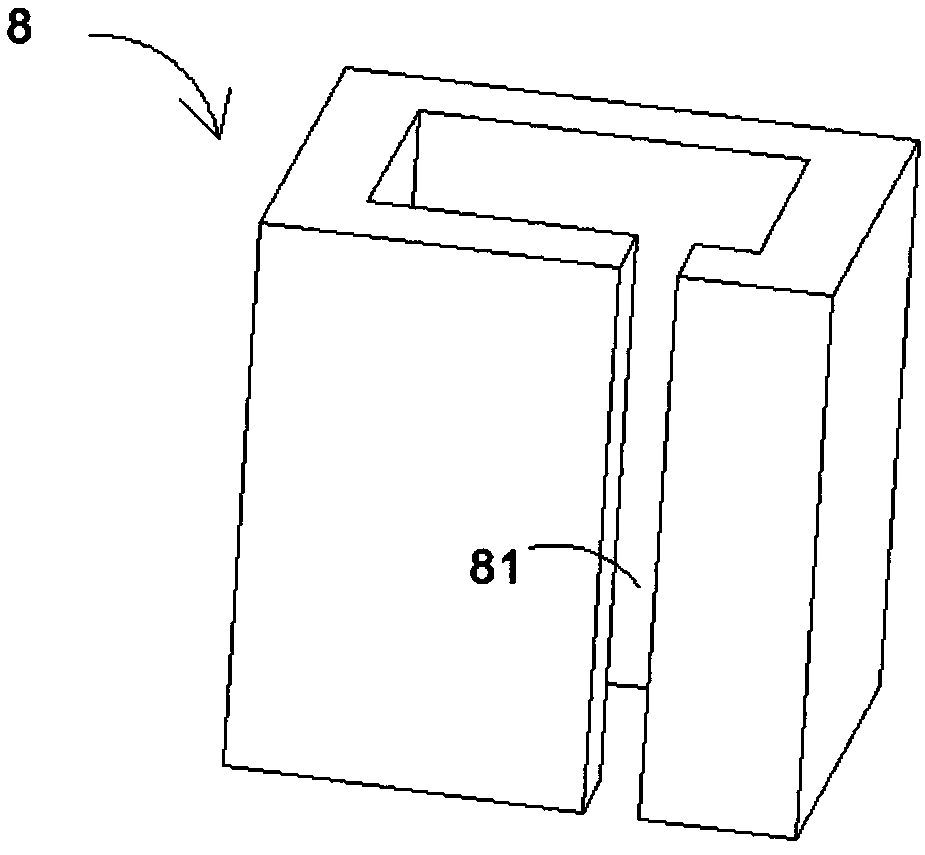

Dust collection device for textile workshop

InactiveCN108634865AEasy to operateEasy to use and cleanSuction filtersSuction nozzlesEngineeringControl switch

The invention discloses a dust collection device for a textile workshop, and belongs to the technical field of dust collection equipment for textile workshops. The dust collection device comprises a base, universal wheels are uniformly installed at the bottom of the base, a handheld push handle is connected to the left wall of the base, a control switch is arranged on the left side wall of the handheld push handle, and a shell and a storage box are installed on the top wall of the base; the storage box is connected with the right side wall of the shell, the shell is of a cavity structure, anda movable door is formed in the side wall of the shell. The dust collection device is easy to operate, convenient to use for cleaning, and capable of effectively reducing flying dust in the cleaning process, effectively reducing inhalation of the flying dust into the nasal cavity of a cleaner, and reducing the harm of the flying dust to the body of the cleaner; a dust collection box makes it convenient to collect and process the flying dust centralizedly and helps to improve the cleaning efficiency; a dust collection roller makes it convenient to clean some cleaning dead corners like wall corners, and helps to maintain hygiene of the environment of the workshop.

Owner:长兴明远布艺科技有限公司

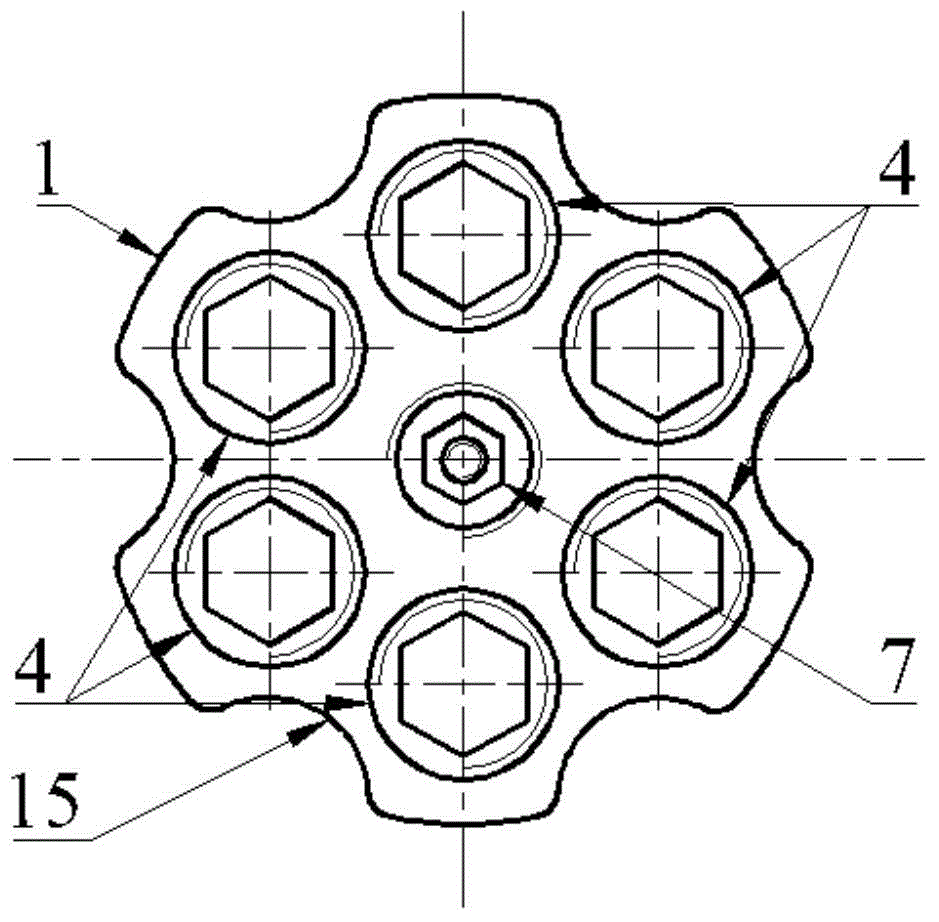

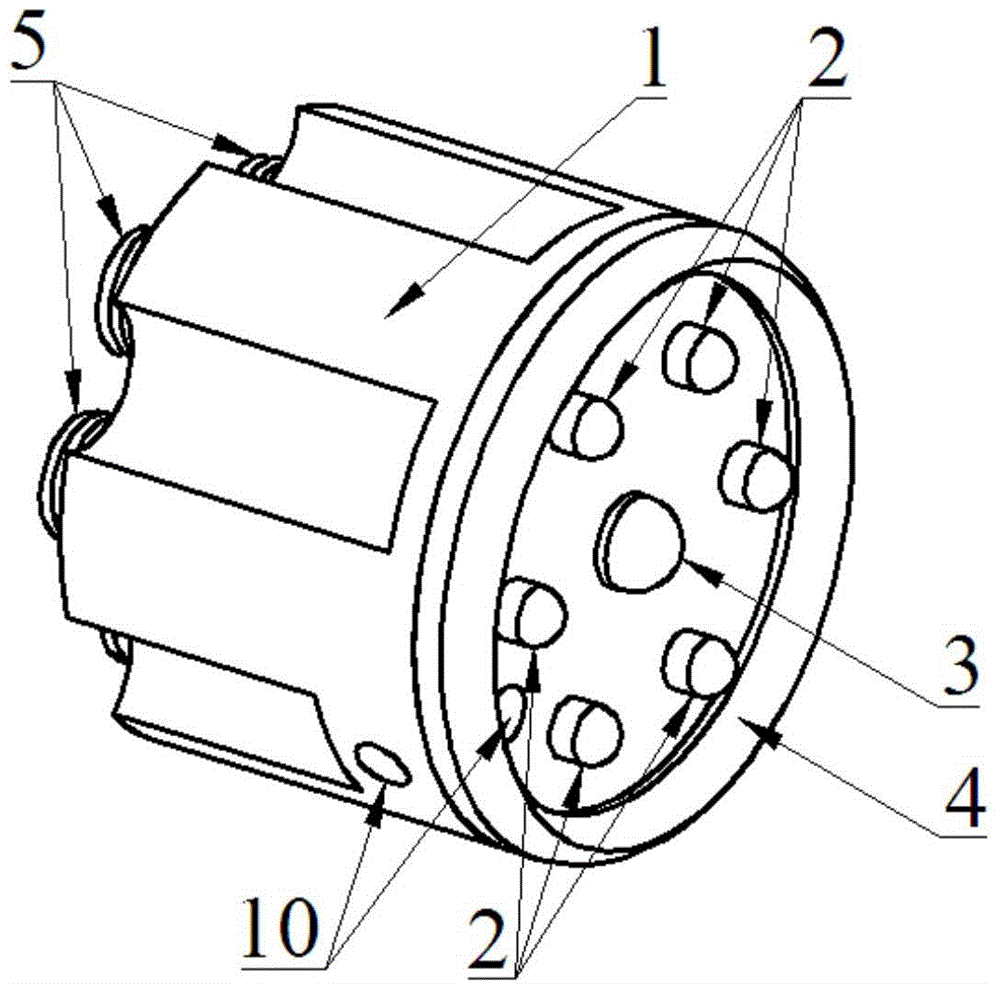

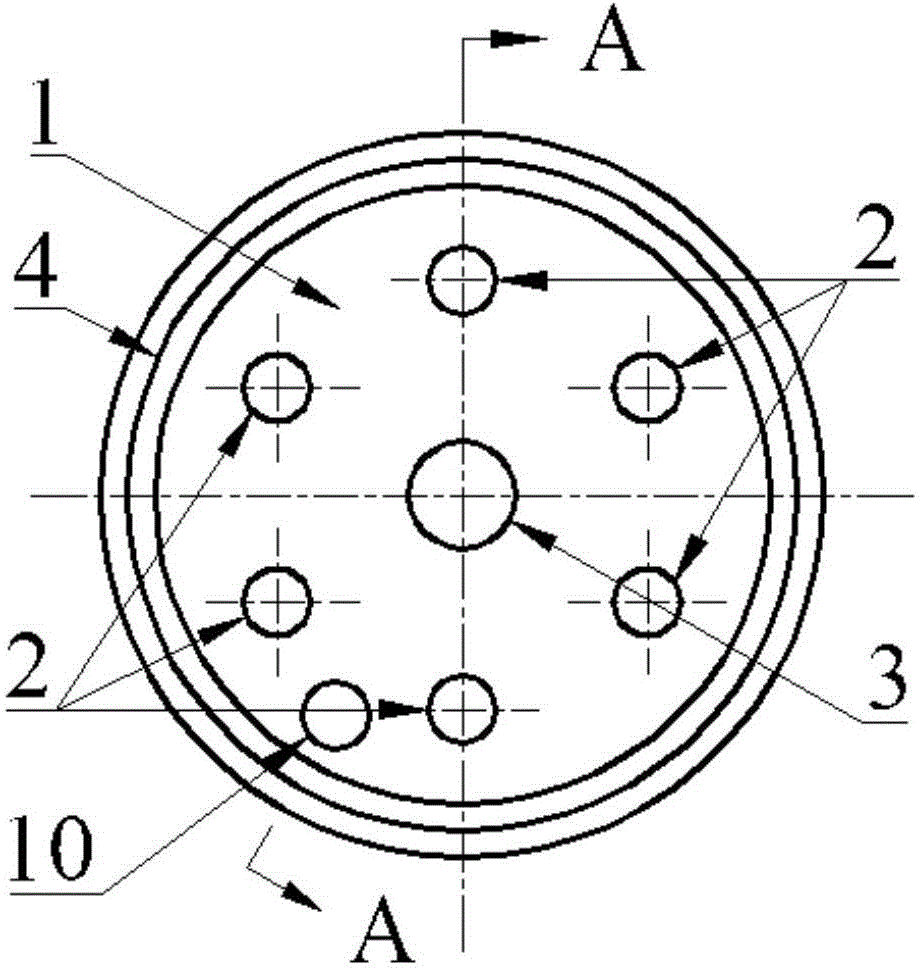

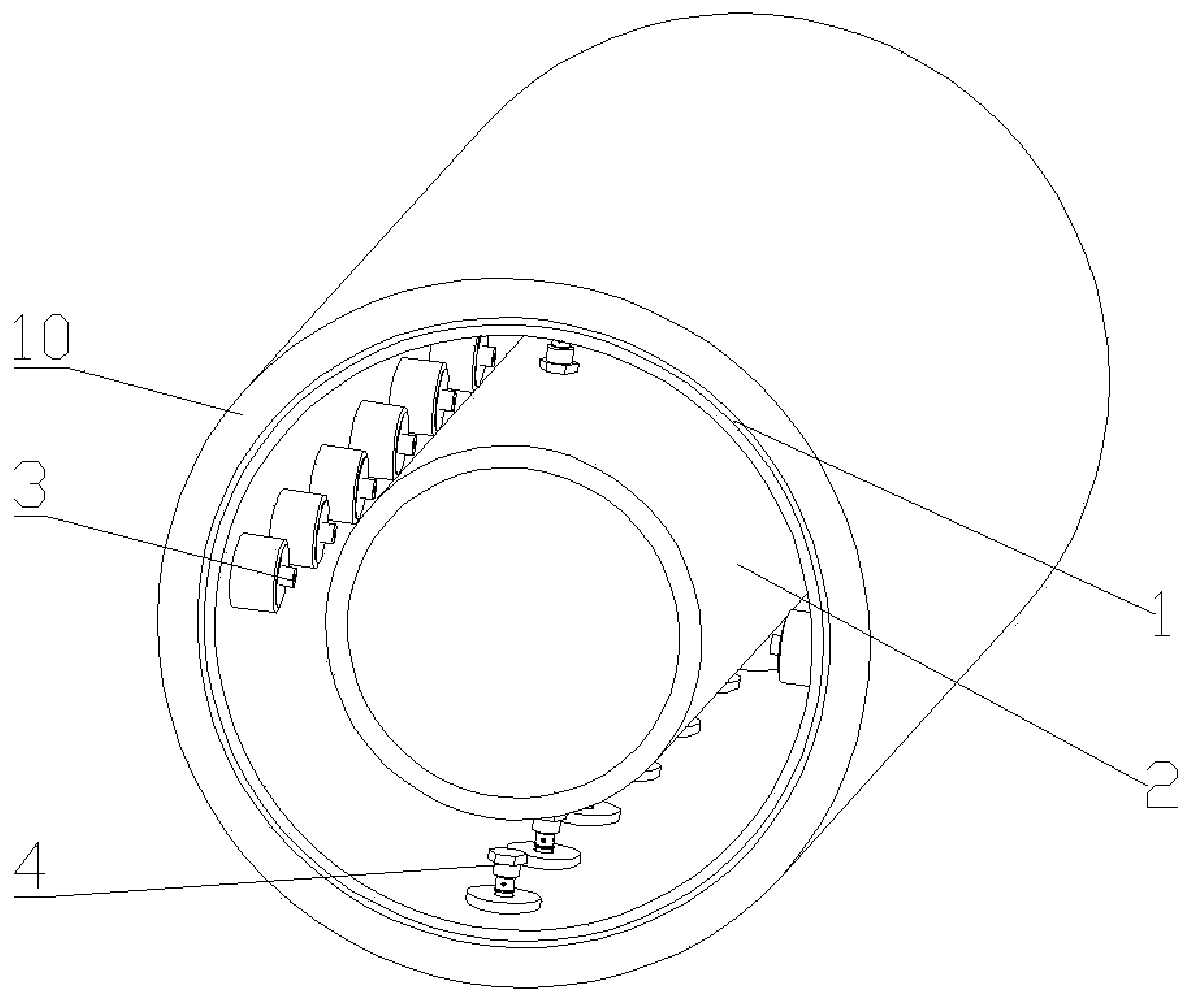

Sucking supporting head provided with rigid and flexible supports and used for machining grids of thin-walled workpiece

ActiveCN104690577AReduce flutterIncrease stiffnessPositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a sucking supporting head provided with rigid and flexible supports and used for machining grids of a thin-walled workpiece. The sucking supporting head comprises a base, wherein ventilation holes used for connection of a negative pressure pump are formed in the right end surface and the side surface of the base; multiple circumferential stepped through holes with parallel axes are uniformly formed in the base in the circumferential direction, a central stepped through hole parallel to the axes of the circumferential stepped through holes is formed in the center of the base, internal threads are arranged on left sides of the multiple circumferential stepped through holes and the left side of the central stepped through hole, a threaded connection part, a left spring and an auxiliary bulb supporting rod sleeved with a right spring are sequentially mounted in each circumferential stepped through hole from left to right, and a rubber suction cup is fixedly connected onto the outer circumference of the right end surface of the base. The sucking supporting head is provided with the flexible supports and the rubber suction cup to reduce vibration of the thin-walled workpiece and is also provided with the rigid supports to accurately position the thin-walled workpiece, meanwhile, the rigidity of the thin-walled workpiece is increased due to the multi-point supports, and the machining precision is improved.

Owner:TIANJIN UNIV

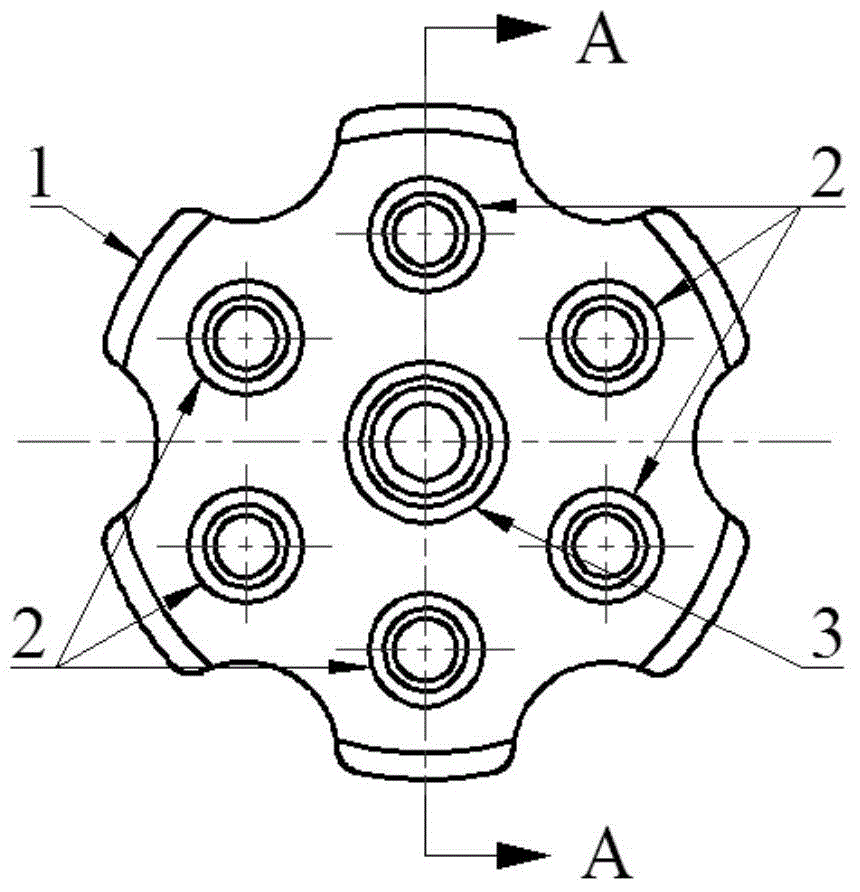

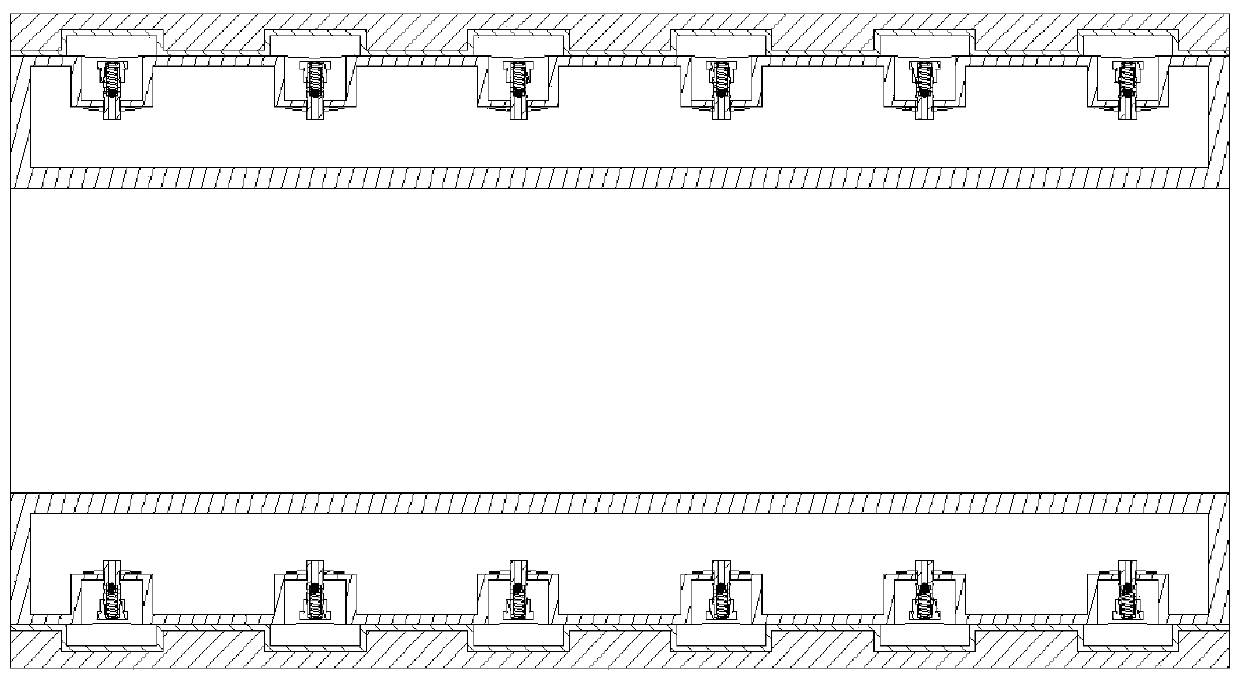

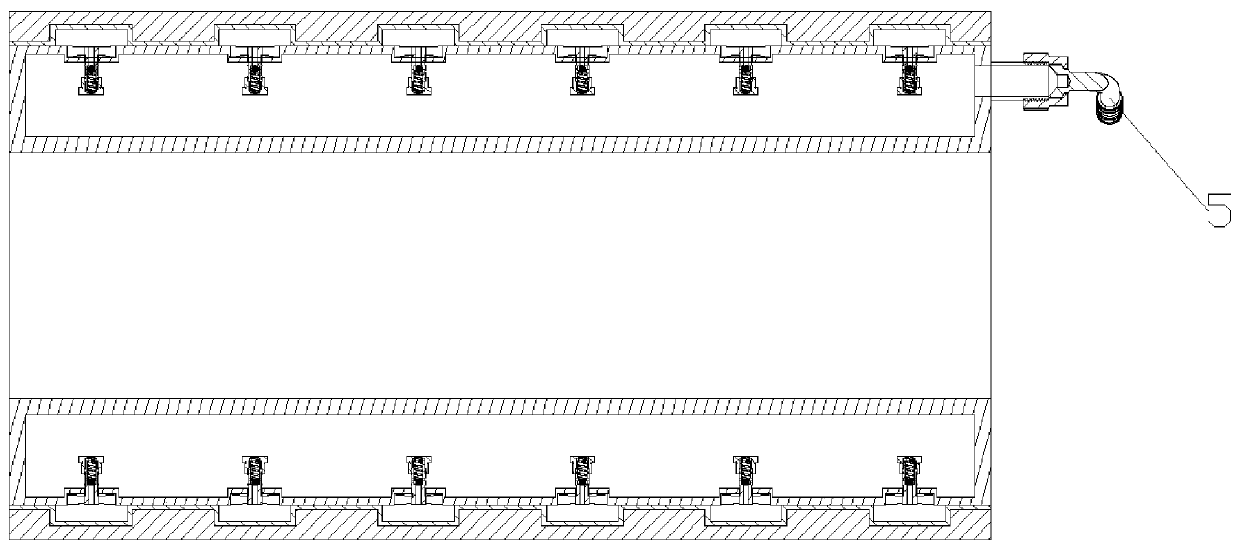

Auxiliary supporting device, system and method for thin-walled barrel piece machining

ActiveCN111230527APlay a supporting roleIncrease stiffnessWork clamping meansPositioning apparatusMachining deformationInlet valve

The invention discloses an auxiliary supporting device, system and method for thin-walled barrel piece machining. Machining deformation of a thin-walled barrel piece is reduced, vibration during machining is reduced, machining errors are decreased, and the machining precision is improved; and the problem that a common single-layer airbag is not suitable for supporting a thin-walled barrel piece ofwhich the surface is uneven is solved. The structure is simple, disassembling and assembling are convenient, and the auxiliary supporting device can be closely attached to the surface of the thin-walled barrel piece in a supporting mode. According to the technical scheme, an inner layer airbag and an outer layer airbag which are sleeved together are included, a plurality of air inlet valves and air outlet valves are installed between the inner layer airbag and the outer layer airbag, and under control of the air inlet valves, the inner layer airbag and the outer layer airbag expand in sequence so that the to-be-machined thin-walled barrel piece can be supported.

Owner:SHANDONG UNIV

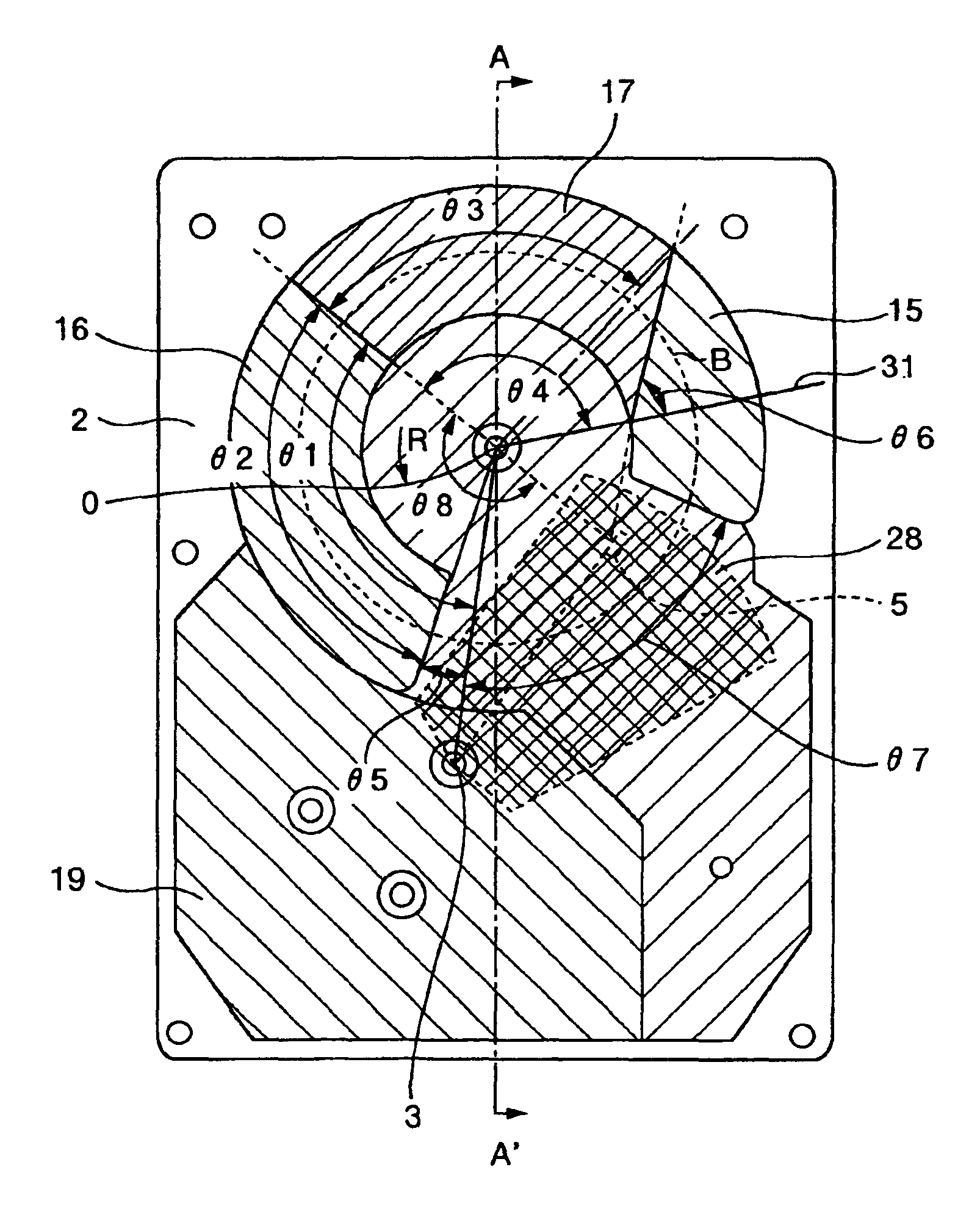

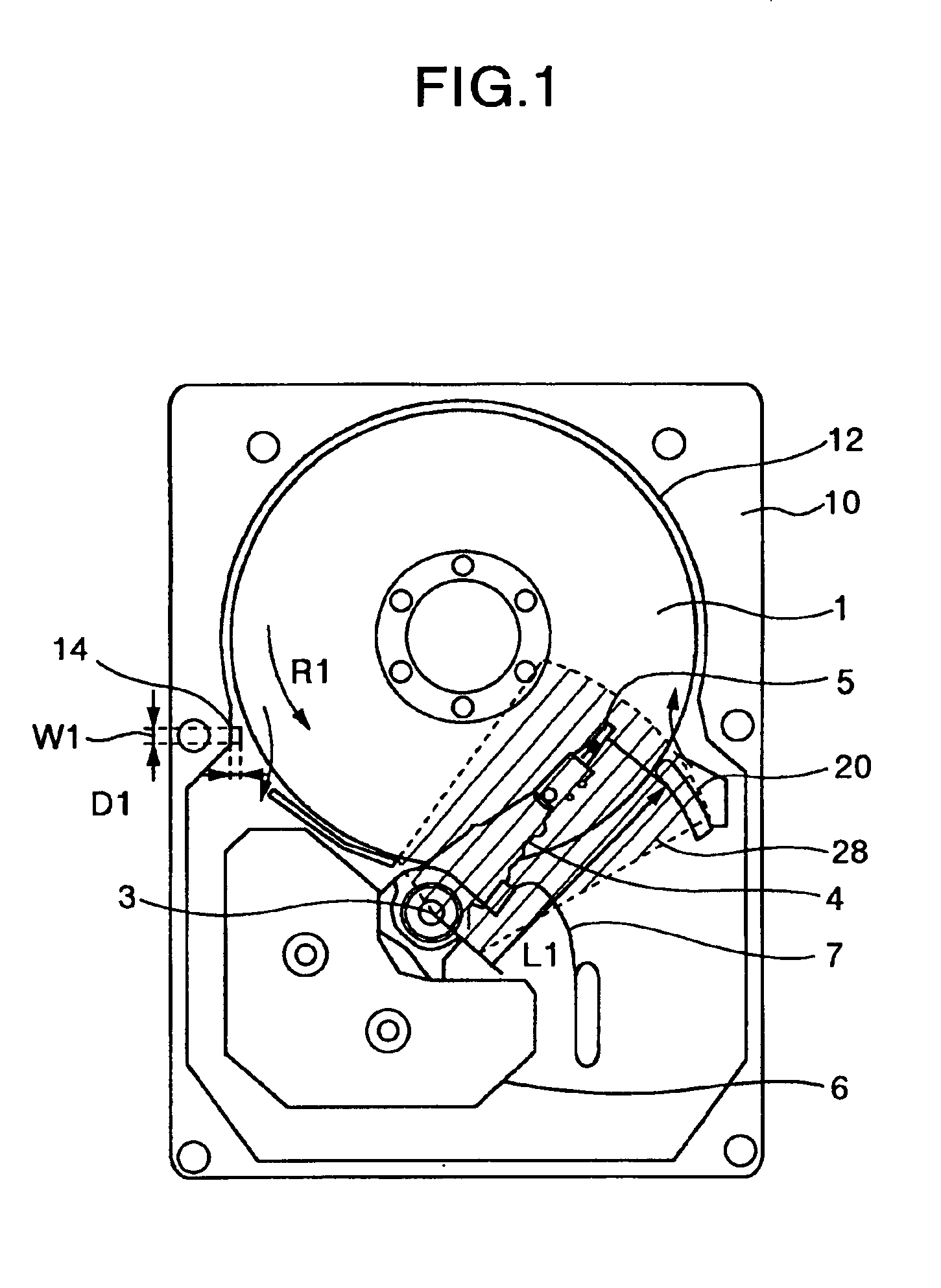

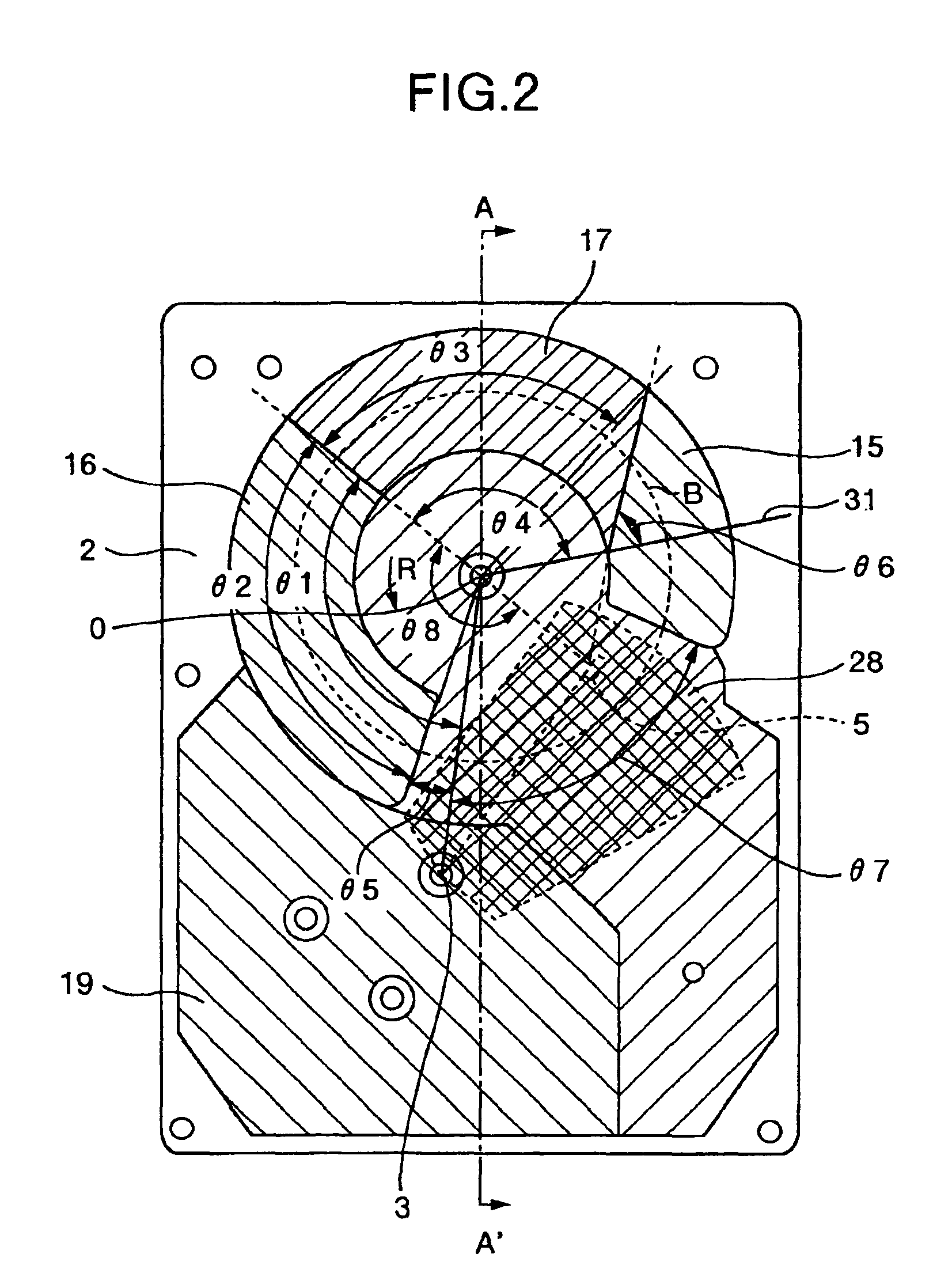

Recording apparatus having improved anti-vibration arrangements

InactiveUS6894866B2Reduce gap sizeReduce flutterReducing temperature influence on carrierApparatus for flat record carriersEngineeringCounter rotation

In a recording apparatus capable of reducing an airflow and disturbance of the air flow simultaneously, thereby reducing flutter vibration effectively, a cover includes first convex sections for reducing a size of a gap between a disk surface and a cover or between the disk surface arid a housing in an area outside of an area in which an arm traverses on a disk in comparison with the area in which the arm traverses, and a second convex section on a part of the first convex sections to further reduce the size of the gap, and the second convex section is provided in a range extending with a tan shape thereof in a reverse rotational direction of said disk from a position distant by 110-170° in the reverse rotational direction from a straight line connecting the rotational shaft of said disk and the rotational shaft of said arm.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Wave-powered devices configured for nesting

ActiveUS9151267B2Reducing bowingReduce flutterTowing/pushing equipmentPropulsion based emission reductionClassical mechanicsPower equipment

A wave-powered water vehicle includes a) a first component which is a float that travels on or near the water surface; b) a second component which is wave actuated and travels below the first component; and c) a means whereby the first component engages the second component and / or the second component engages the first component; wherein the engagement means provides lateral support of one component for the other, and thereby minimizes lateral movement of one against the other when the components are fitted together.

Owner:LIQUID ROBOTICS

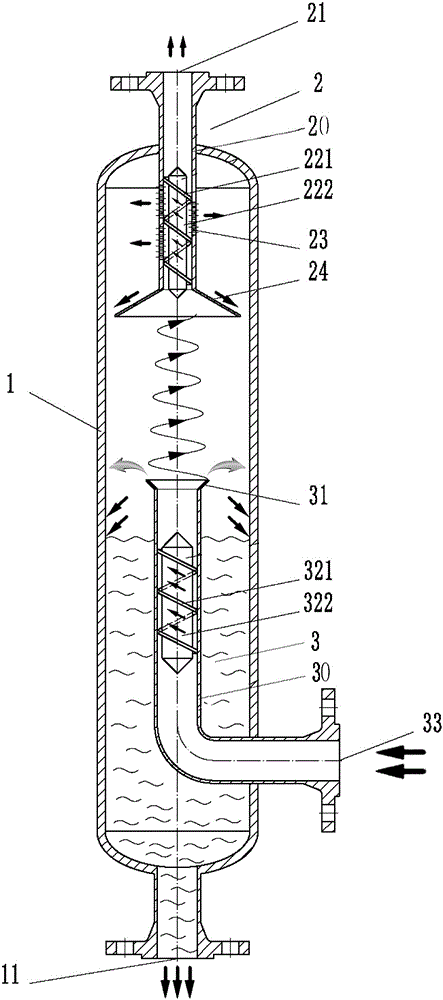

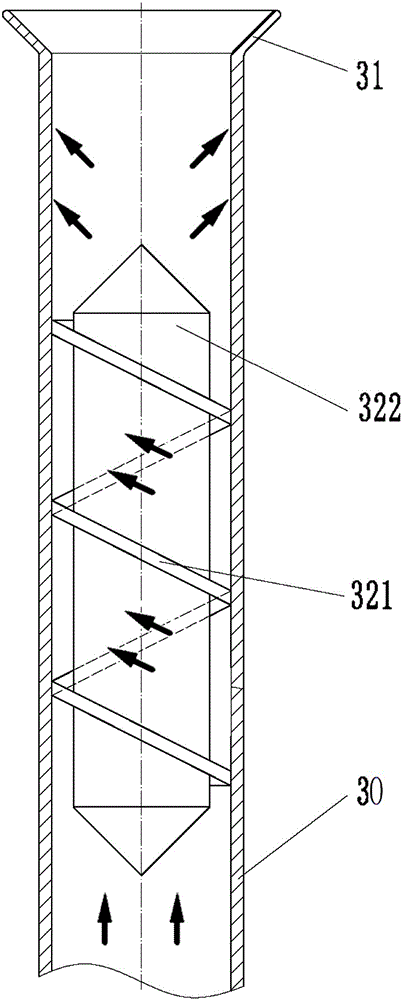

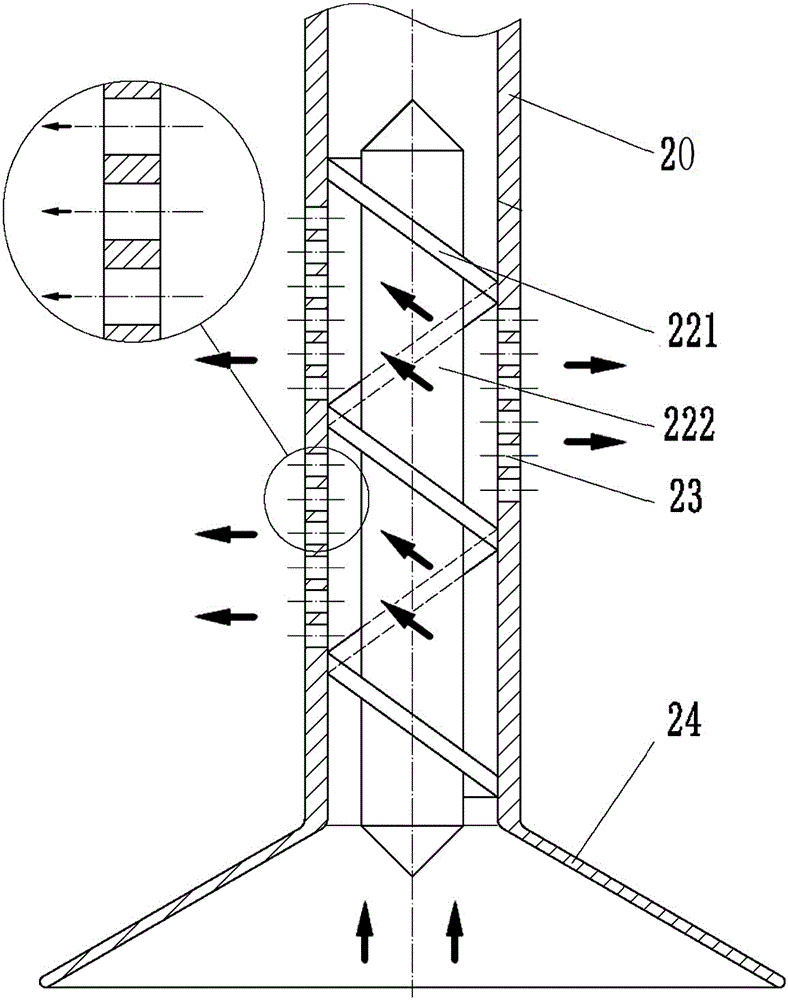

Vortex tubular gas-liquid separator

ActiveCN105148625AEliminate the effects ofEfficient separationDispersed particle separationVapor–liquid separatorLiquid ratio

The invention discloses a vortex tubular gas-liquid separator. The vortex tubular gas-liquid separator comprises a vertical shell, wherein a primary spiral separation device and a secondary spiral separation device are installed in the shell. A two-level centrifugal separation way is adopted, the liquid content of a separated gas phase is reduced to 3 percent or less, the gas content of a liquid phase is reduced to 1 percent or less, so that the metering, sampling and purifying of the gas phase and the liquid phase are guaranteed, the harms of gas-liquid mixed fluid, such as vibration, gas corrosion and corrosion on downstream equipment and pipelines are reduced, and the vortex tubular gas-liquid separator has the advantages of simplicity and compactness in structure, easiness in manufacturing and the like. Under the situations of large and frequent variation of flow and gas-liquid ratio as well as a slug flow, the vortex tubular gas-liquid separator can achieve good gas-liquid separation effects, is widely applicable to various gas-liquid separation fields and particularly suitable for the gas-liquid separation field having high requirements on the separation rate, can achieve a gas-liquid separation effect of a liquid-gas ratio of 1: 100 and can separate a liquid drop with a minimum diameter more than or equal to 5 micrometers.

Owner:山东华盛荣油气装备有限公司

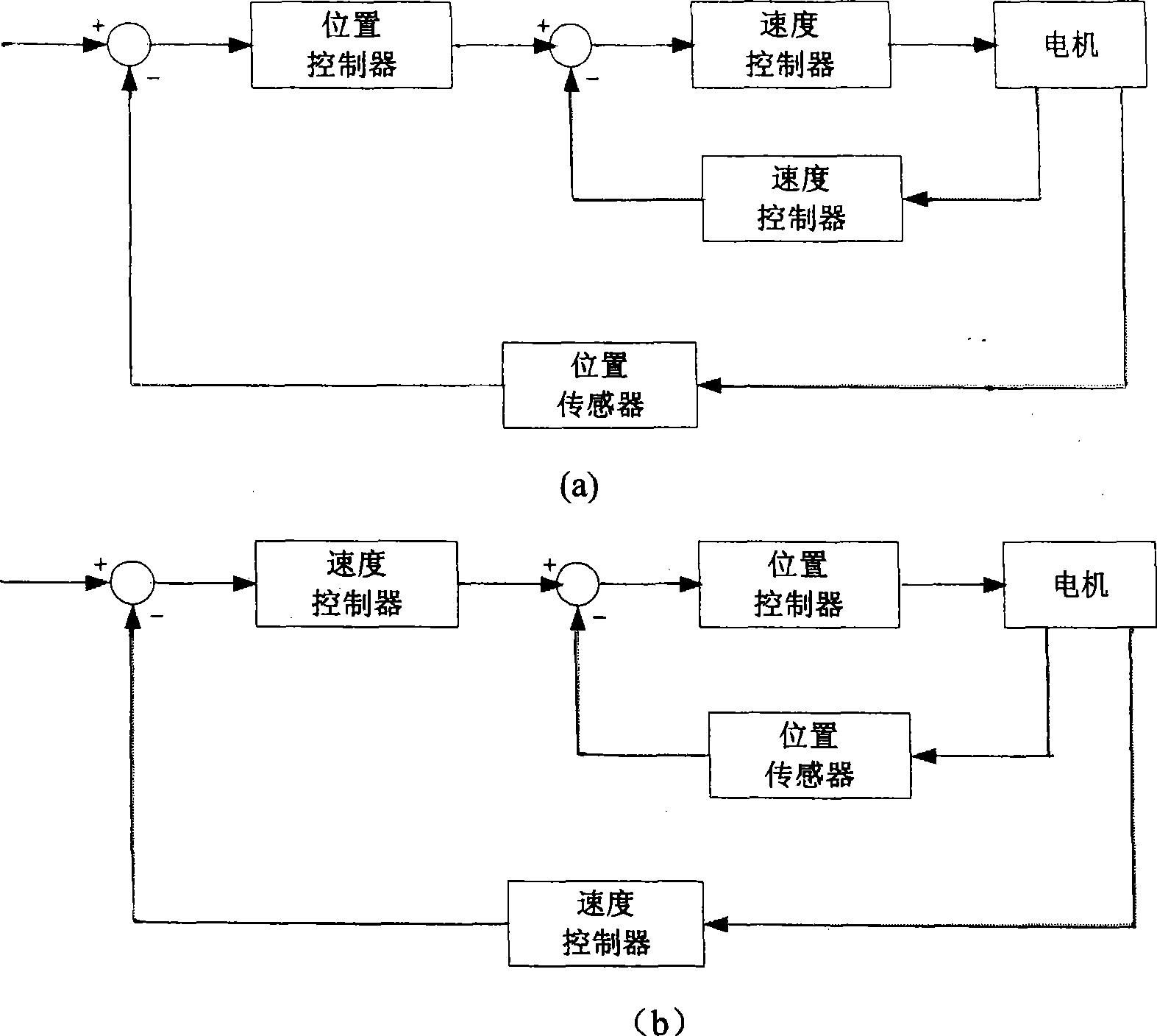

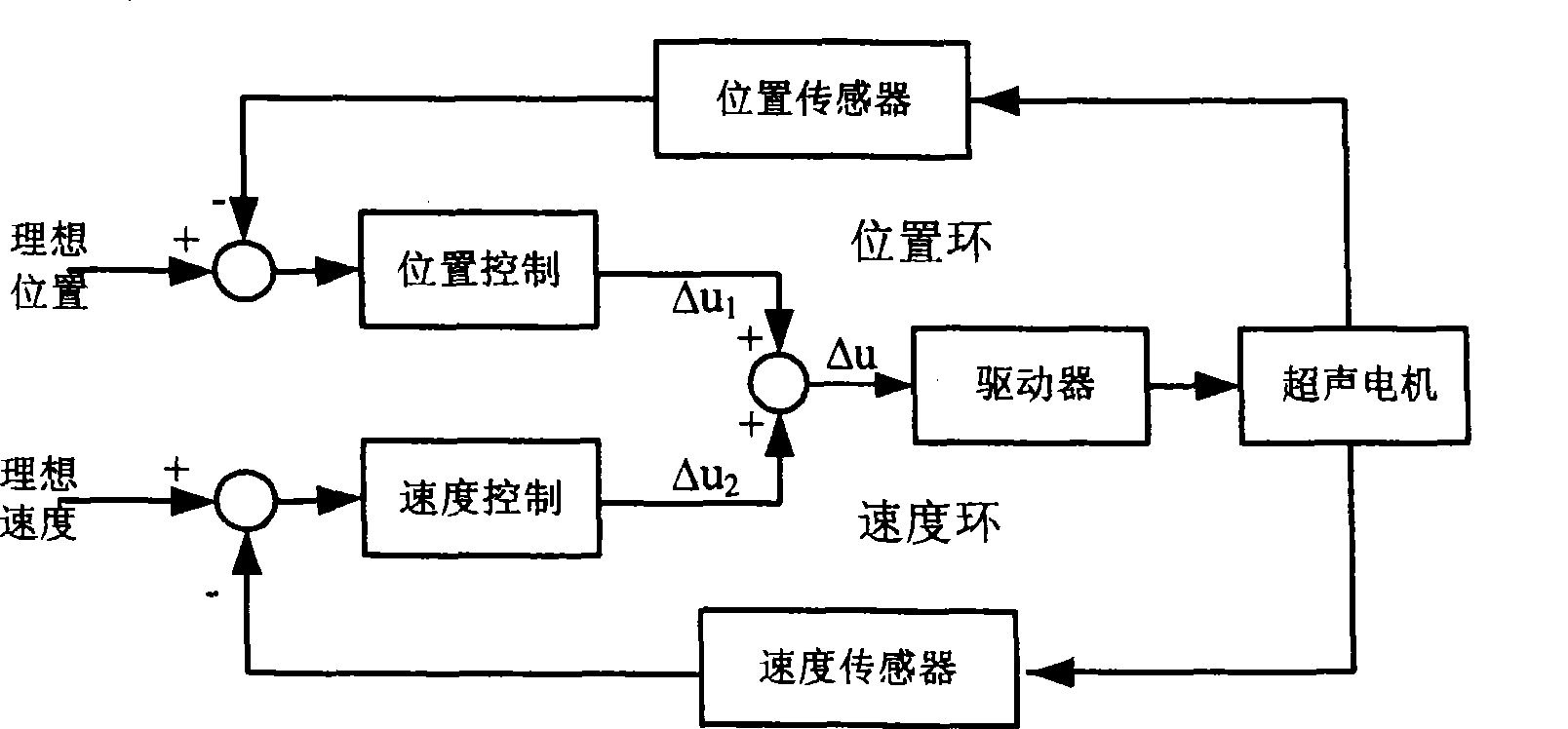

Speed-position dual close-loop control scheme for ultrasonic motor

InactiveCN101478262AReduce flutterReduce precisionPiezoelectric/electrostriction/magnetostriction machinesAdaptive controlLoop controlAutomatic control

The invention relates to a control method for increasing the operation performance of a plurality of ultrasonic motors running in equipment. The method belongs to the automatic control field. When a plurality of ultrasonic motors are needed to drive and control at the same time in a set of equipment, the position feedback control can obtain better position accuracy, and the speed of the ultrasonic motors changes more tempestuously because the response speed of the ultrasonic motors is very fast, so the running stability of the whole equipment cannot be ensured; and the speed feedback control can obtain well moving stability, but the position accuracy is worse. In order to resolve the contradiction, a novel speed-position double close loop control mode is designed, the speed close loop control voltage increment and the position close loop control voltage increment are added up, and the sum is taken as the total control voltage increment and acts on drivers of the ultrasonic motors so as to increase the integral operation performance of the ultrasonic motors and driving equipment thereof. The control method is applied to the equipment driven by the ultrasonic motors, and is especially suitable for occasions requiring a plurality of the ultrasonic motors to drive and control at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

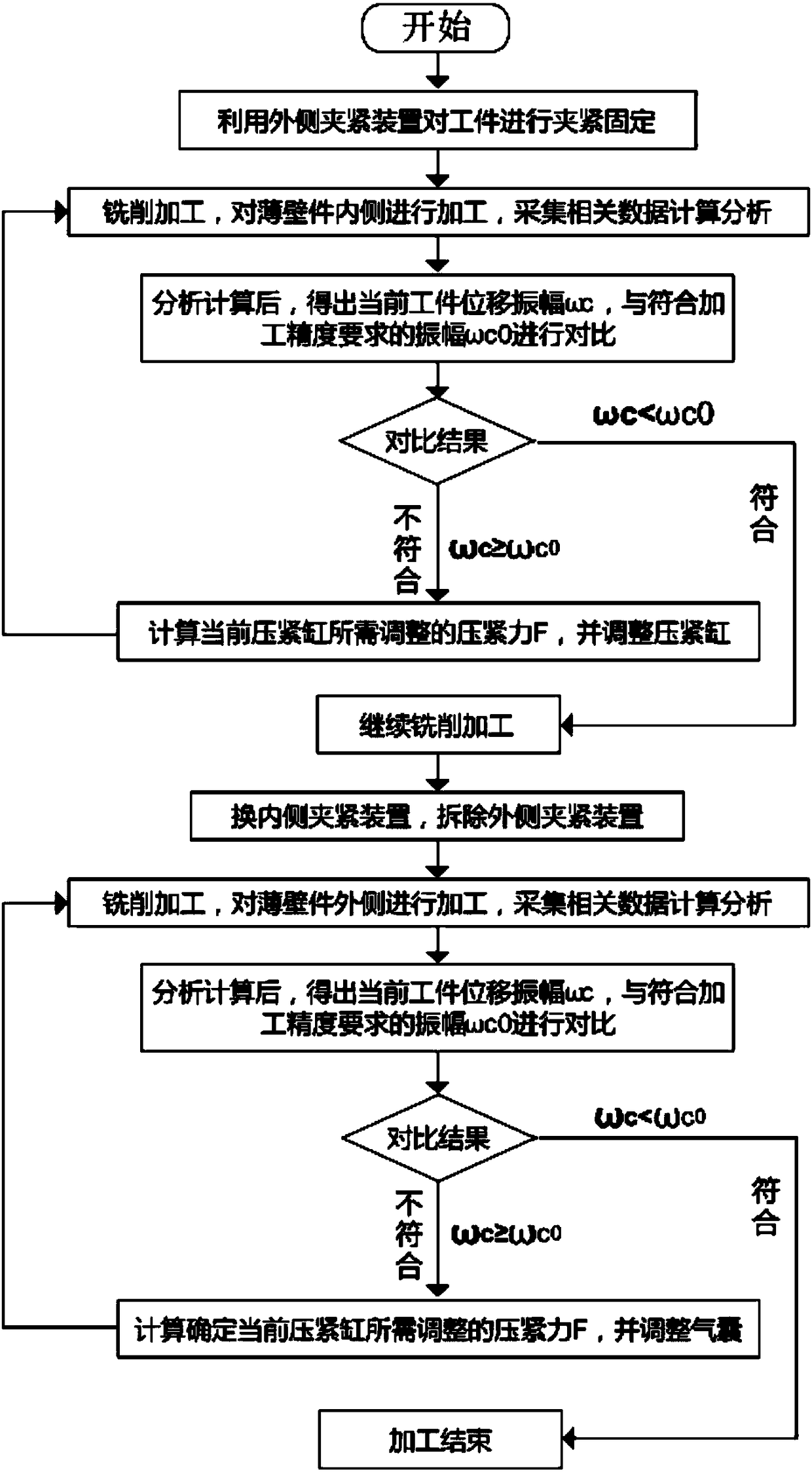

Thin-walled casing part non-chatter processing method and processing fixture thereof

InactiveCN108481052AImprove product qualityMeet the machining accuracy requirementsAutomatic control devicesMeasurement/indication equipmentsComputer control systemAirbag deployment

A thin-walled casing part non-chatter processing method and a processing fixture thereof, the processing method of the present invention includes the steps of monitoring the condition of a casing during processing by a sensor and determining whether the current processing state of the casing satisfies processing accuracy requirements, if the processing accuracy requirements are not satisfied in result of chatter, adjusting the pressing force of a pressing device in real time by a computer control system to increase the rigidity and dynamic damping of the thin-walled casing part. The fixture includes a work piece outboard clamping device and a work piece inboard clamping device mounted on a base, and the casing is arranged between the work piece outboard clamping device and the work piece inboard clamping device during processing. The work piece outboard clamping device includes an upper compression cylinder and a lower compression cylinder, the work piece inboard clamping device includes an airbag base having an upper airbag and a lower airbag mounted thereon. The top of the airbag base is also provided with an empty pressure corner cylinder. The processing method of the present invention is simple to operate and can ensure the processing accuracy.

Owner:XI AN JIAOTONG UNIV

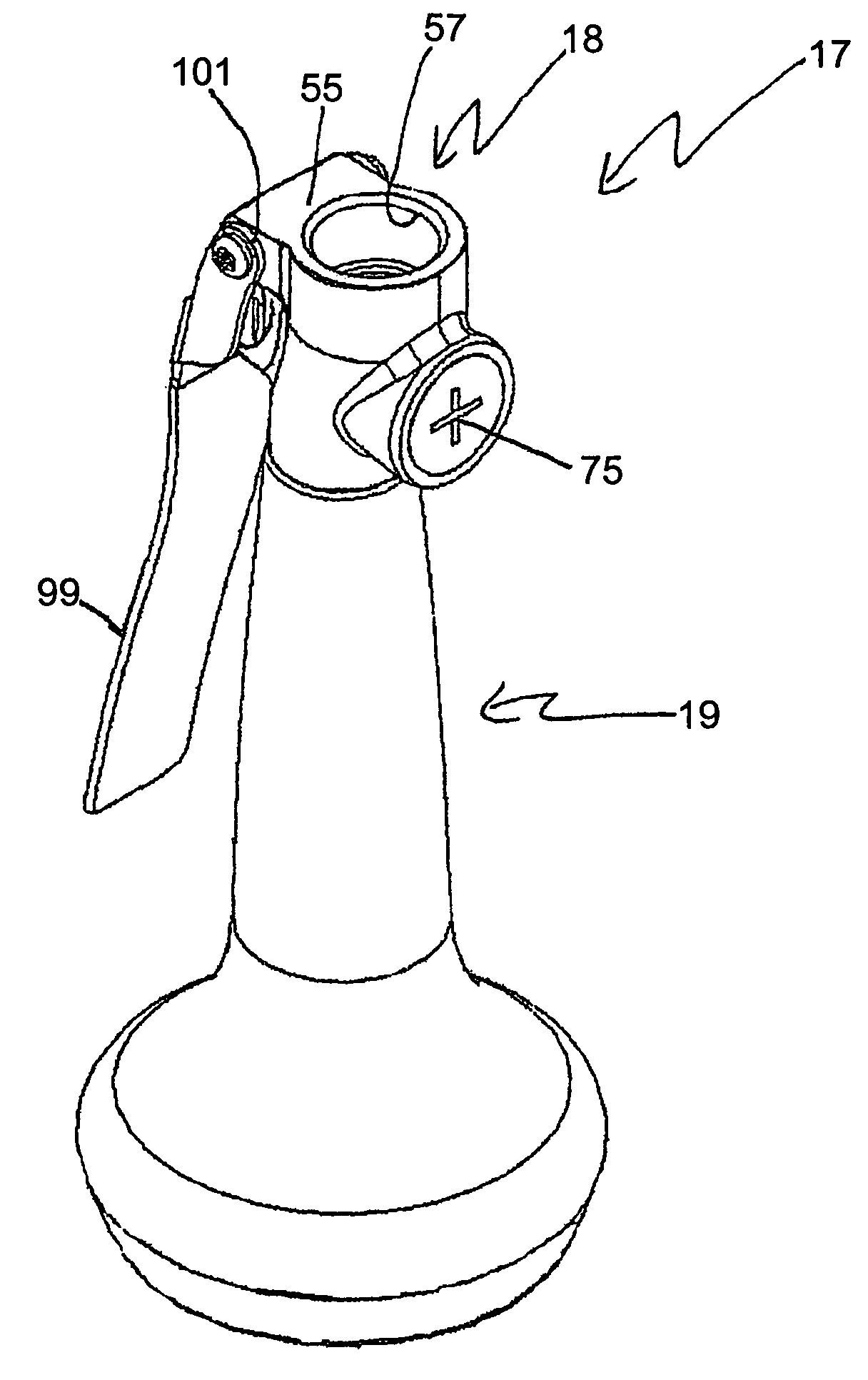

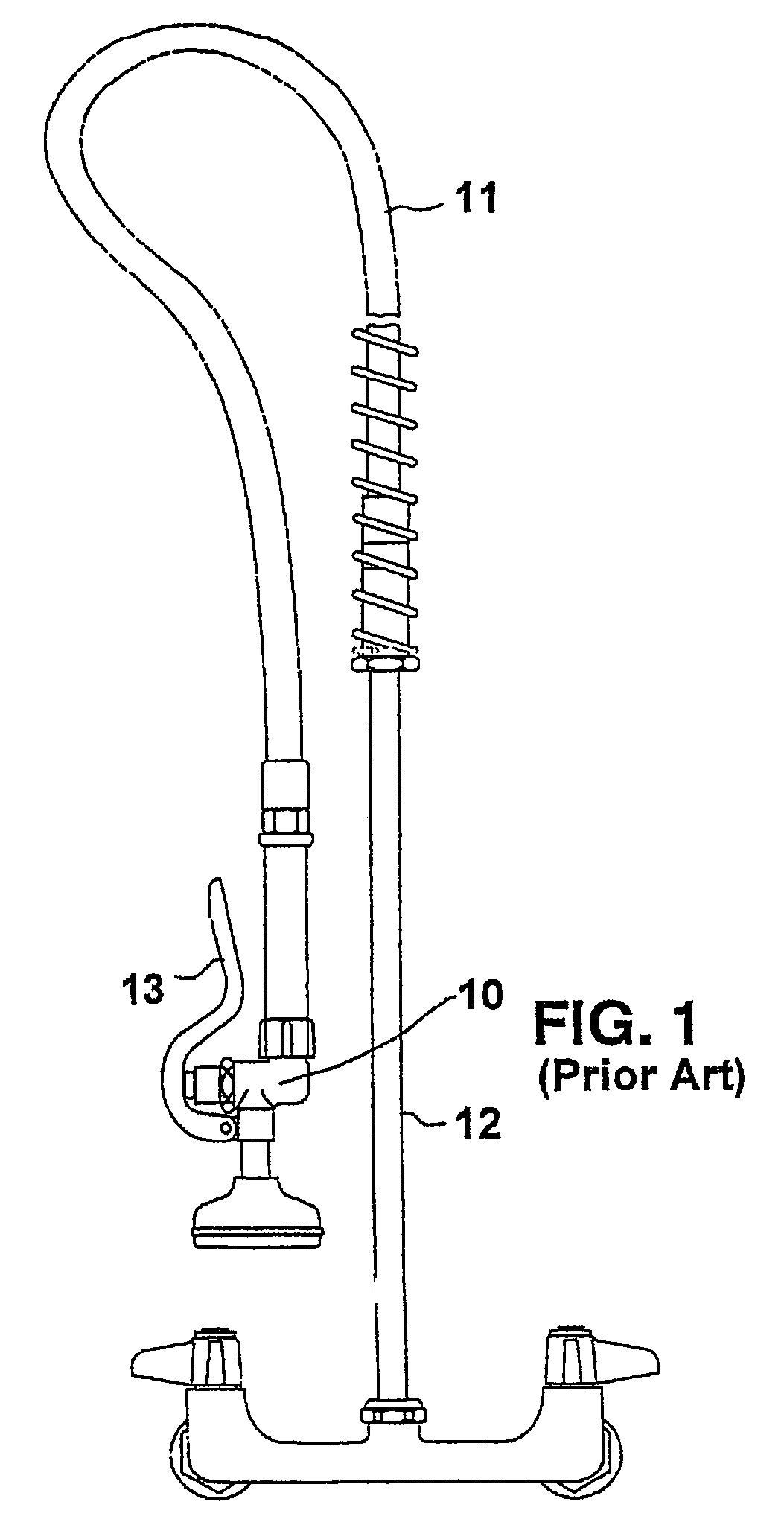

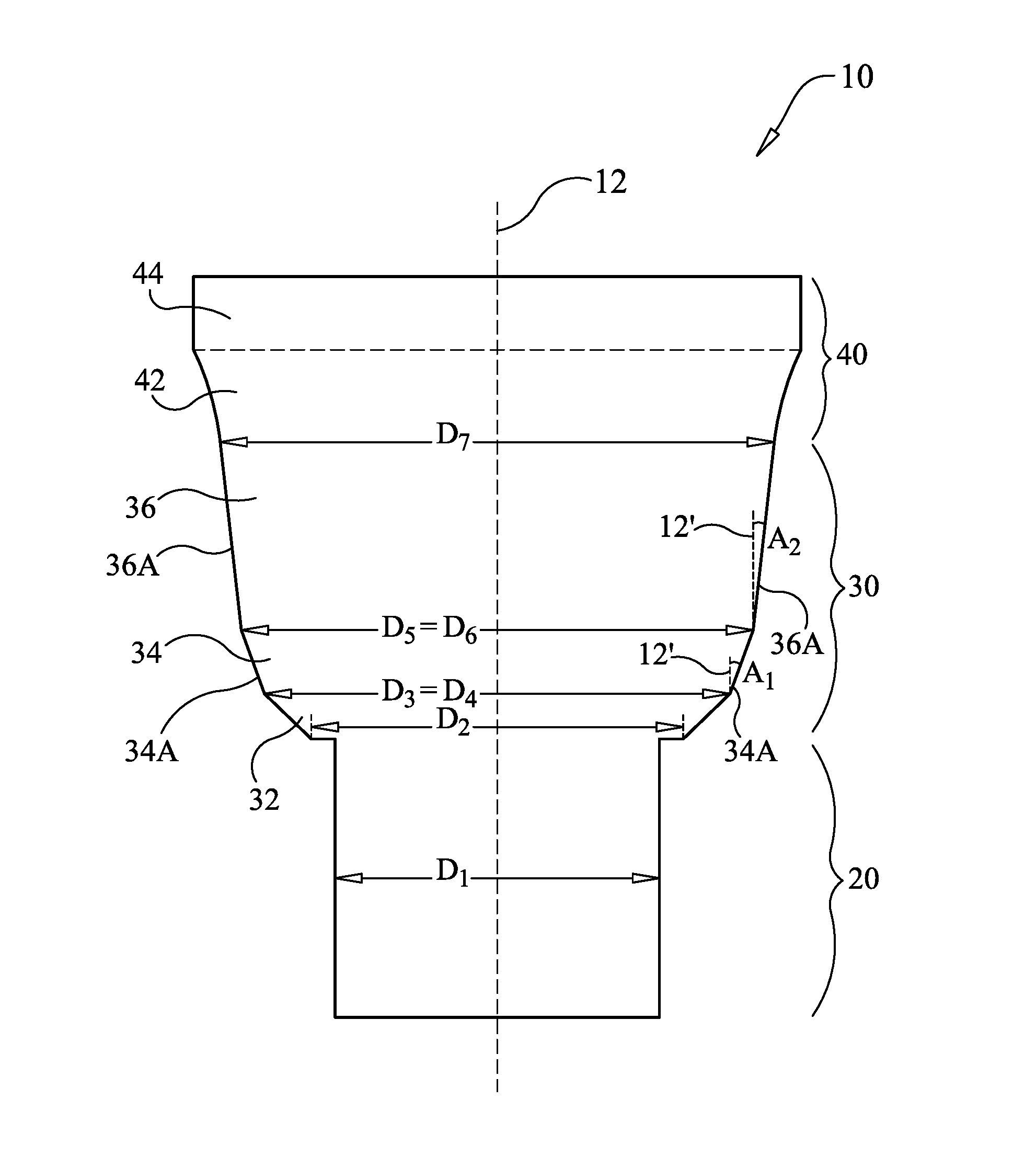

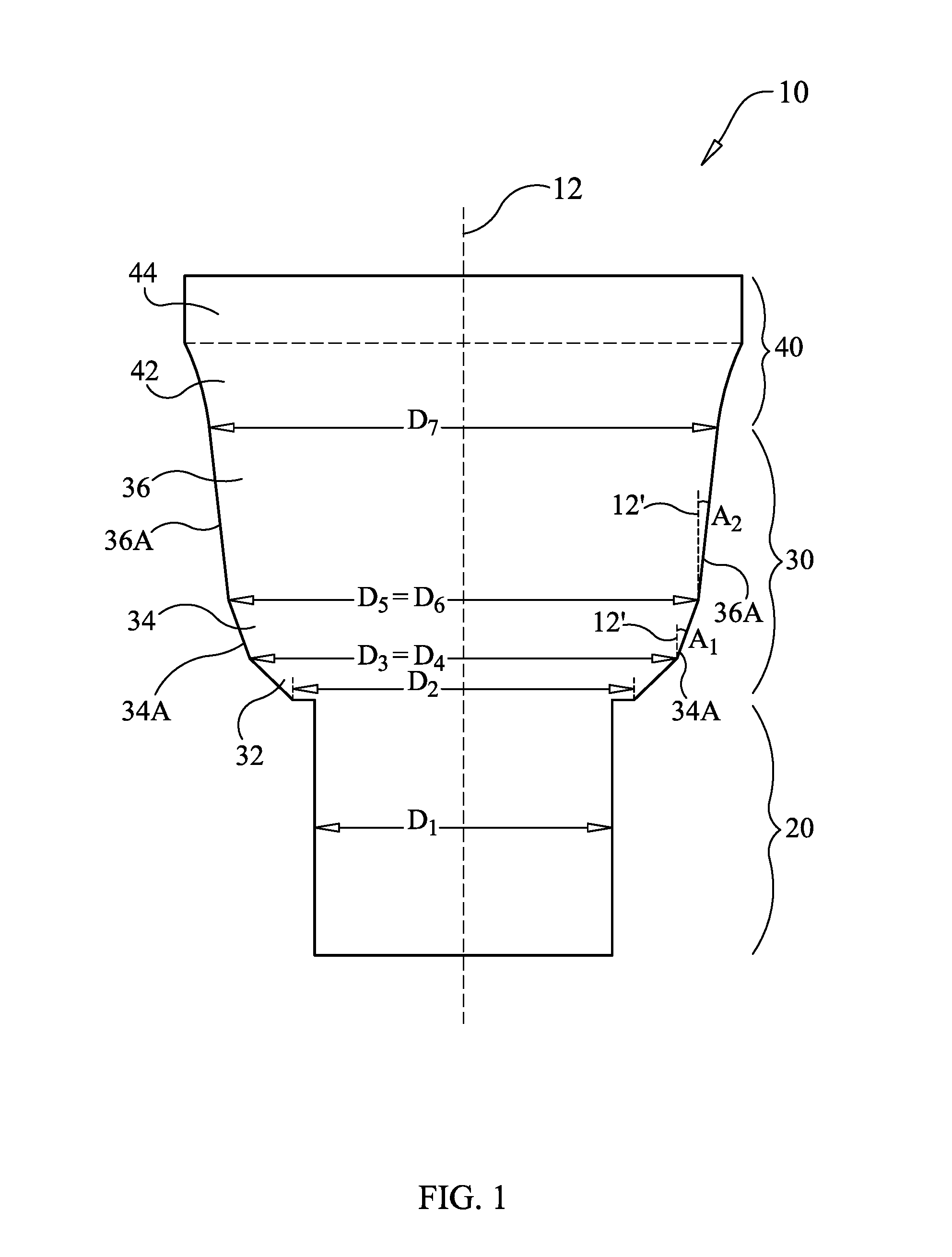

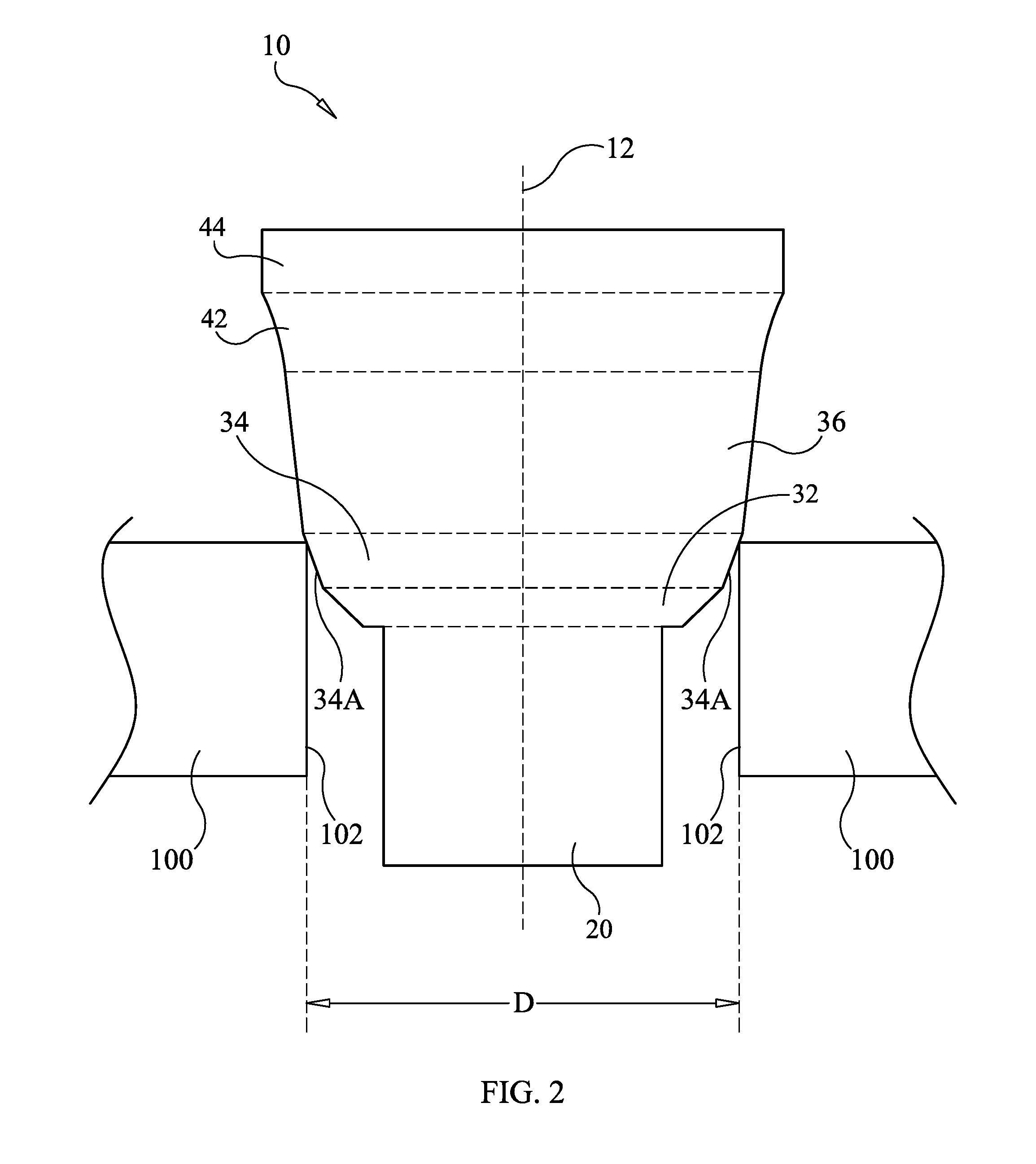

Pre-rinse unit spray valve mechanism

ActiveUS7150415B2Reduce flutterPrevent backflowServomotor componentsDomestic plumbingWater flowEngineering

A spray valve is configured with a fluid path that always provides dynamic water flow on both opposite surfaces of the seating flange of the valve stem when the valve is almost completely closed and when the valve is just beginning to be opened. This equalization of dynamic pressure from the incoming water flow tends to reduce the frequency of vibration that is imposed upon the valve stem and biasing member by the incoming water flow. A check valve is built into the spray valve, which has a trigger lock and a selectively removable spray disk. The valve has an outer sleeve that surrounds the valve's base member and defines a gap therebetween and is formed of mechanical shock-resilient, heat-insulating material.

Owner:T S BRASS & BRONZE WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com