Speed-position dual close-loop control scheme for ultrasonic motor

An ultrasonic motor and speed closed-loop technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems that the stability of the robot cannot be guaranteed, and the accuracy of the joint position is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

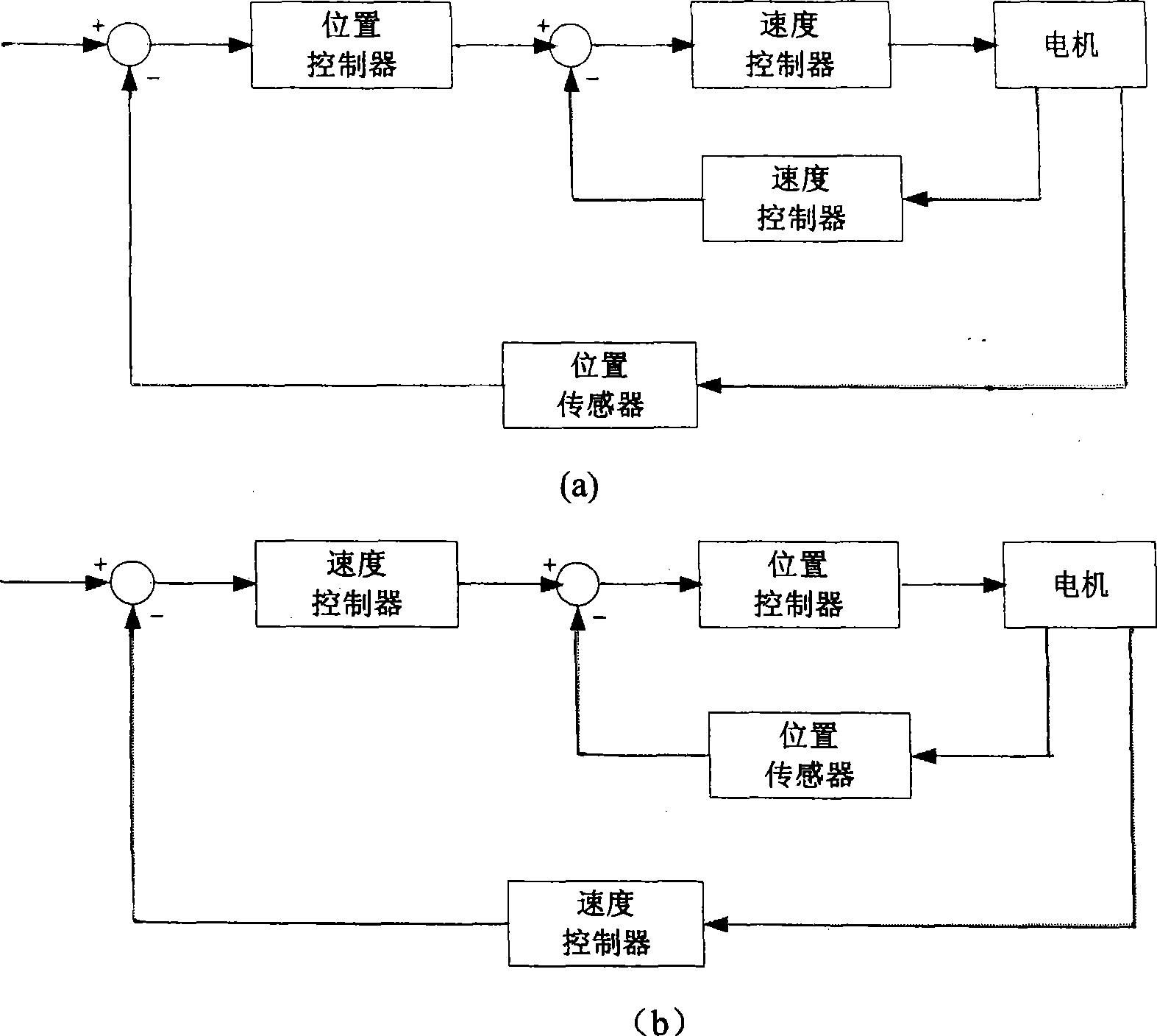

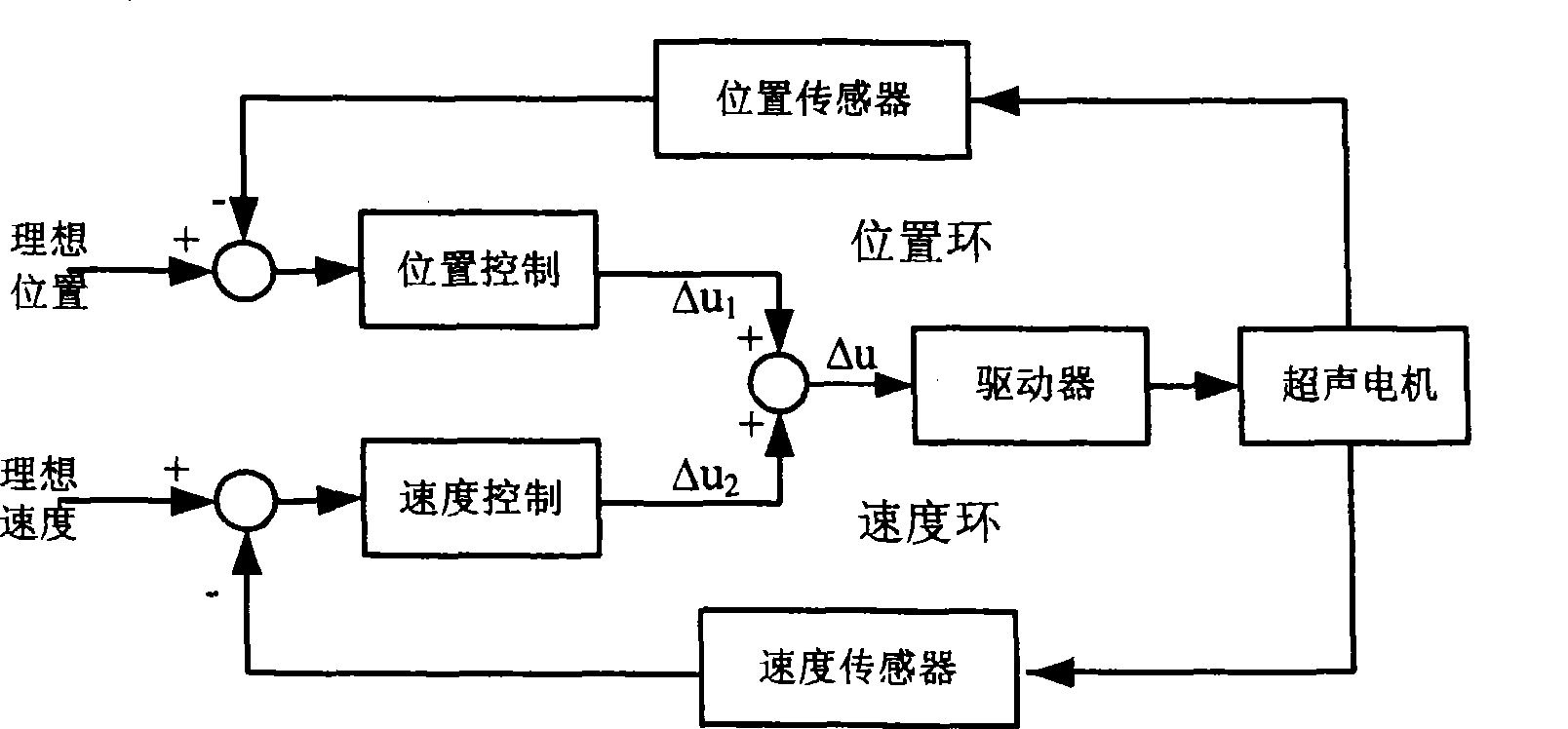

[0018] The existing double closed-loop control mode of electromagnetic motor is as follows: figure 1 as shown, figure 2 It is a double-closed-loop control mode proposed by the present invention aimed at the operating characteristics of the ultrasonic motor.

[0019] figure 1 Formally, the two closed-loop controls in are in the relationship of containment and contained. figure 1 (a) is that the position closed loop includes the speed closed loop, figure 1 (b) is that the speed closed loop includes the position closed loop. In the control of ultrasonic motors, if the figure 1 In the mode (a), the position accuracy can be ensured by comparing the position feedback first, but at this time, the actual instantaneous speed of the ultrasonic motor will have a large error from the ideal speed, and the motor is prone to chatter, and then the speed feedback comparison will be lost. Meaning; if adopted figure 1 In the mode (b), the speed feedback comparison is performed first, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com