Vortex tubular gas-liquid separator

A technology of gas-liquid separator and vortex tube, which is applied in the direction of separation method, dispersed particle separation, chemical instrument and method, etc., can solve the problems of reduced separation effect, small adjustment ratio, low energy consumption, etc., achieve simple structure, reduce chatter Vibration, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

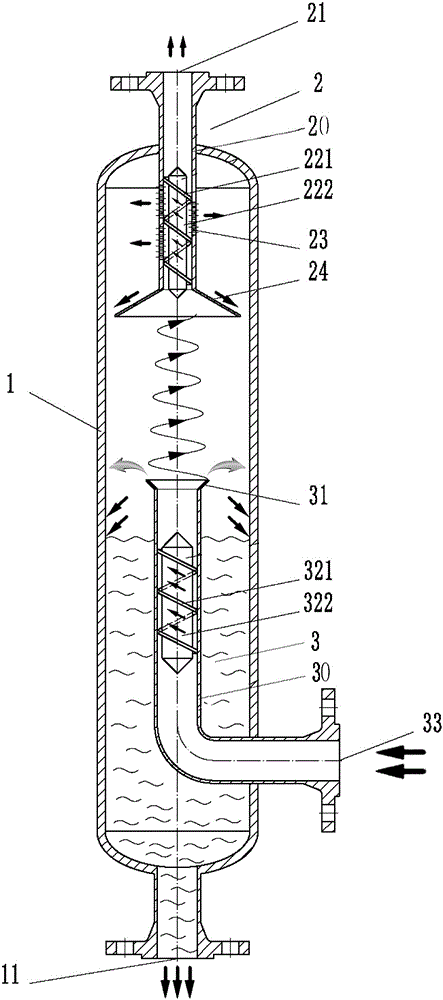

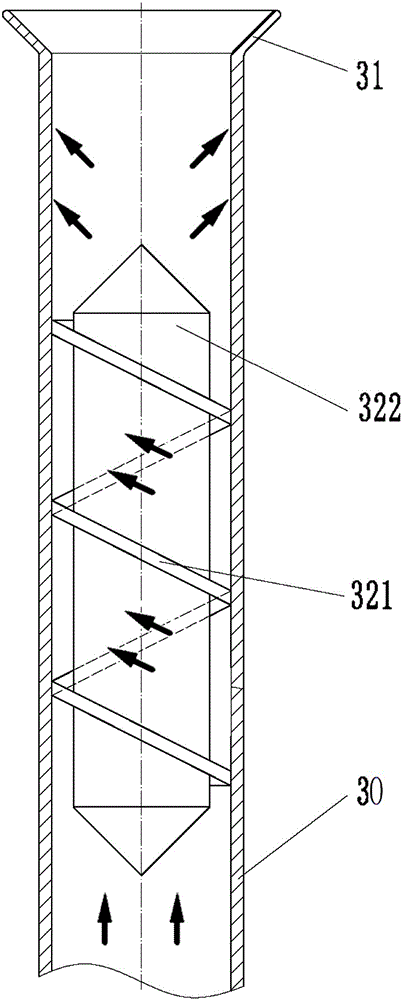

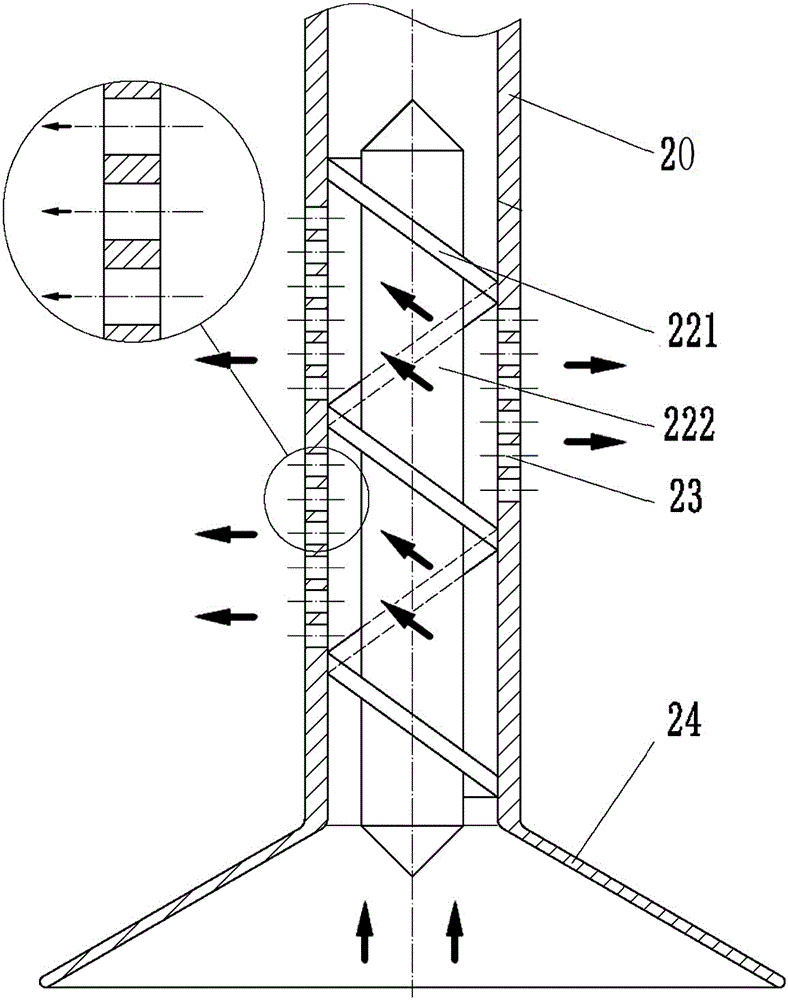

[0027] refer to Figure 1 to Figure 4 , a vortex tube type gas-liquid separator, including a vertical housing 1, a primary spiral separation device 3 and a secondary spiral separation device 2 are installed in the housing 1, and the secondary spiral separation device 2 is located in the Above the primary spiral separation device 3, the lower end of the secondary spiral separation device 2 and the upper end of the primary spiral separation device 3, and the outer wall of the secondary spiral separation device 2 and the outer wall of the primary spiral separation device 3 and the housing 1 There is a certain space between the inner walls. The lower end of the housing 1 is provided with a liquid phase outlet 11; the primary spiral separation device 3 includes a primary centrifugal shell 30, and a primary centrifugal shaft 322 is installed in the primary centrifugal shell 30, and the primary centrifugal shaft 322 is provided with a helical primary vortex blade 321, the lower end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com